Towards Fuel Consumption Reduction Based on the Optimum Contra-Rotating Propeller

Abstract

1. Introduction

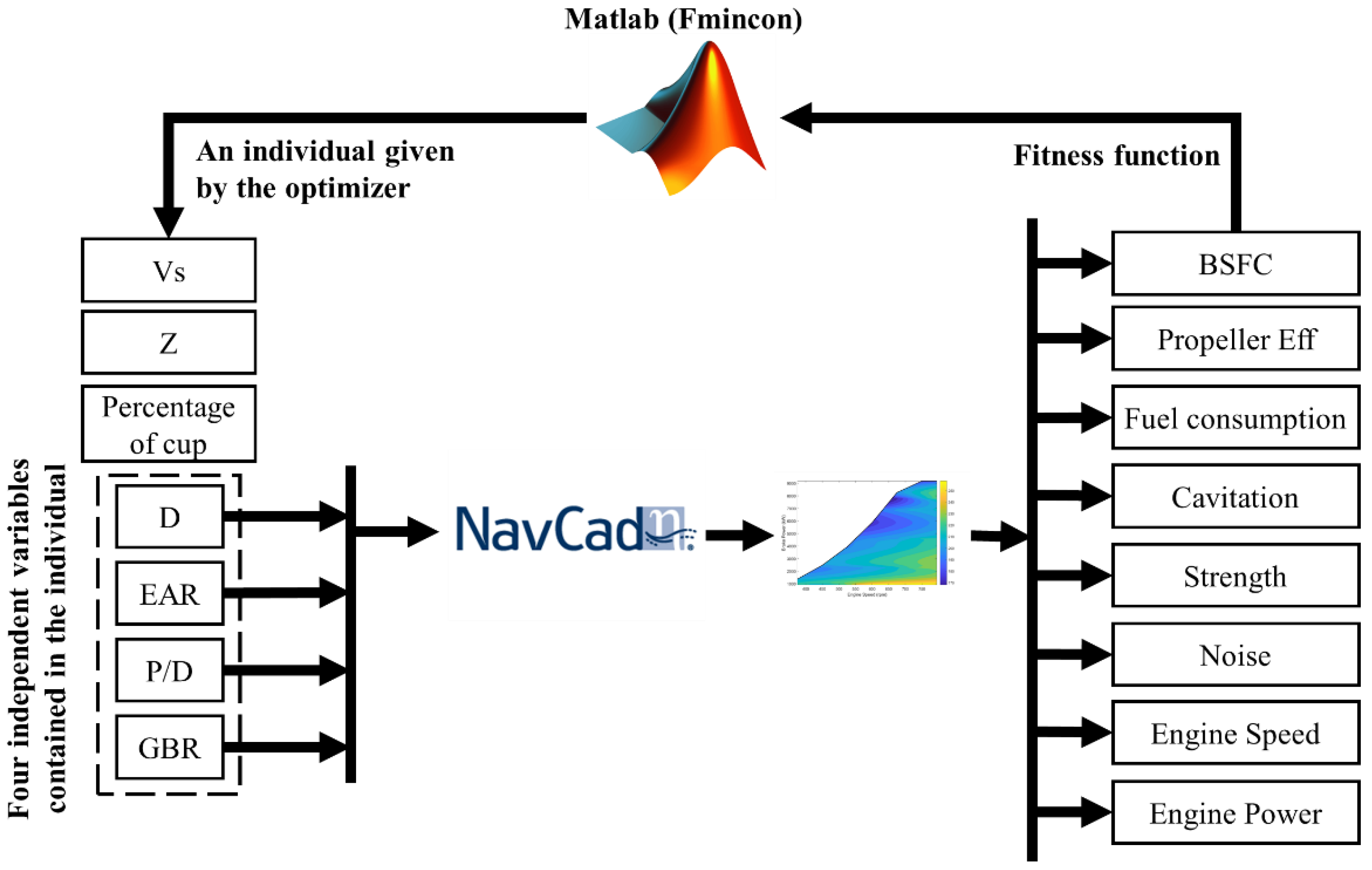

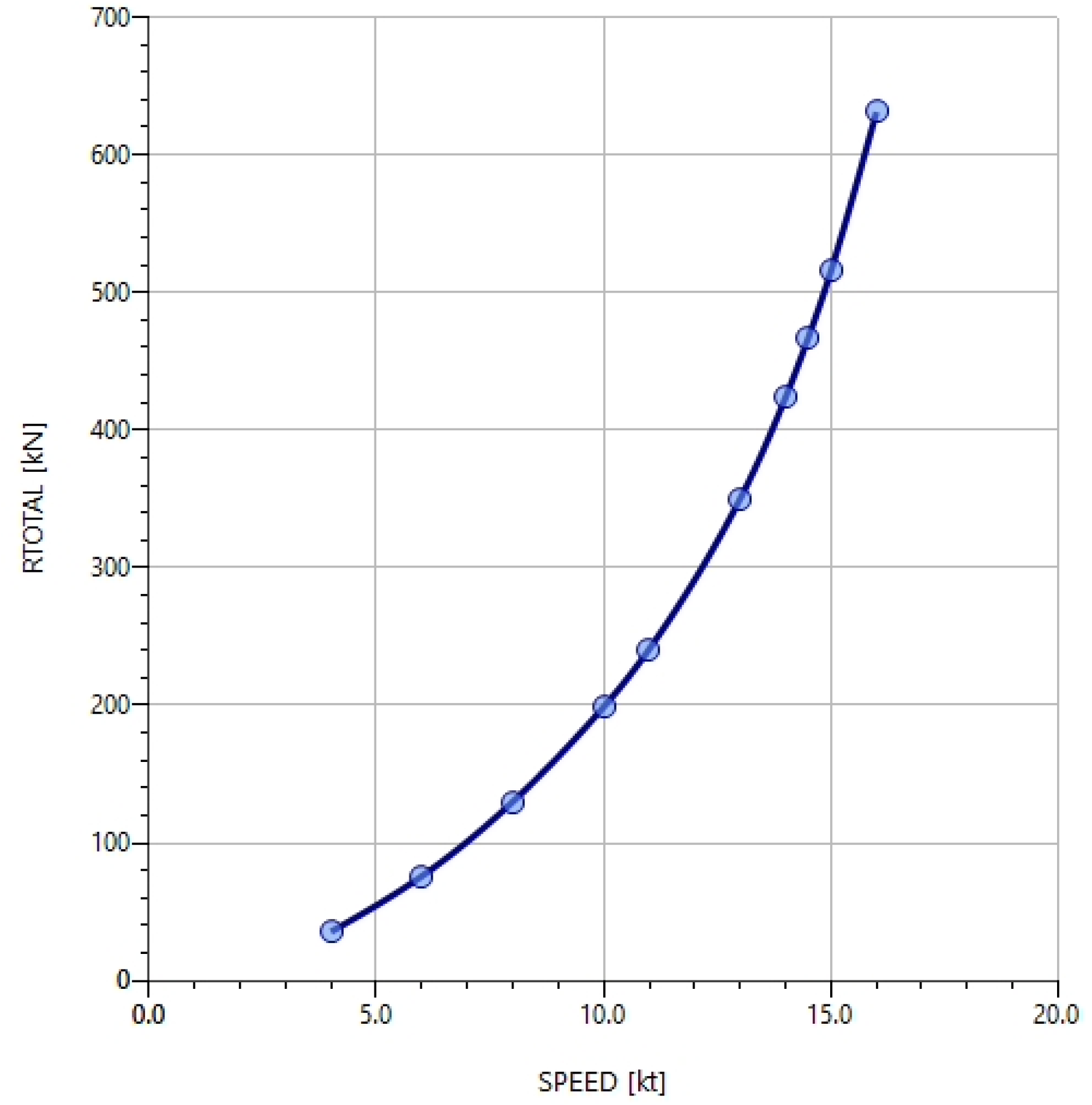

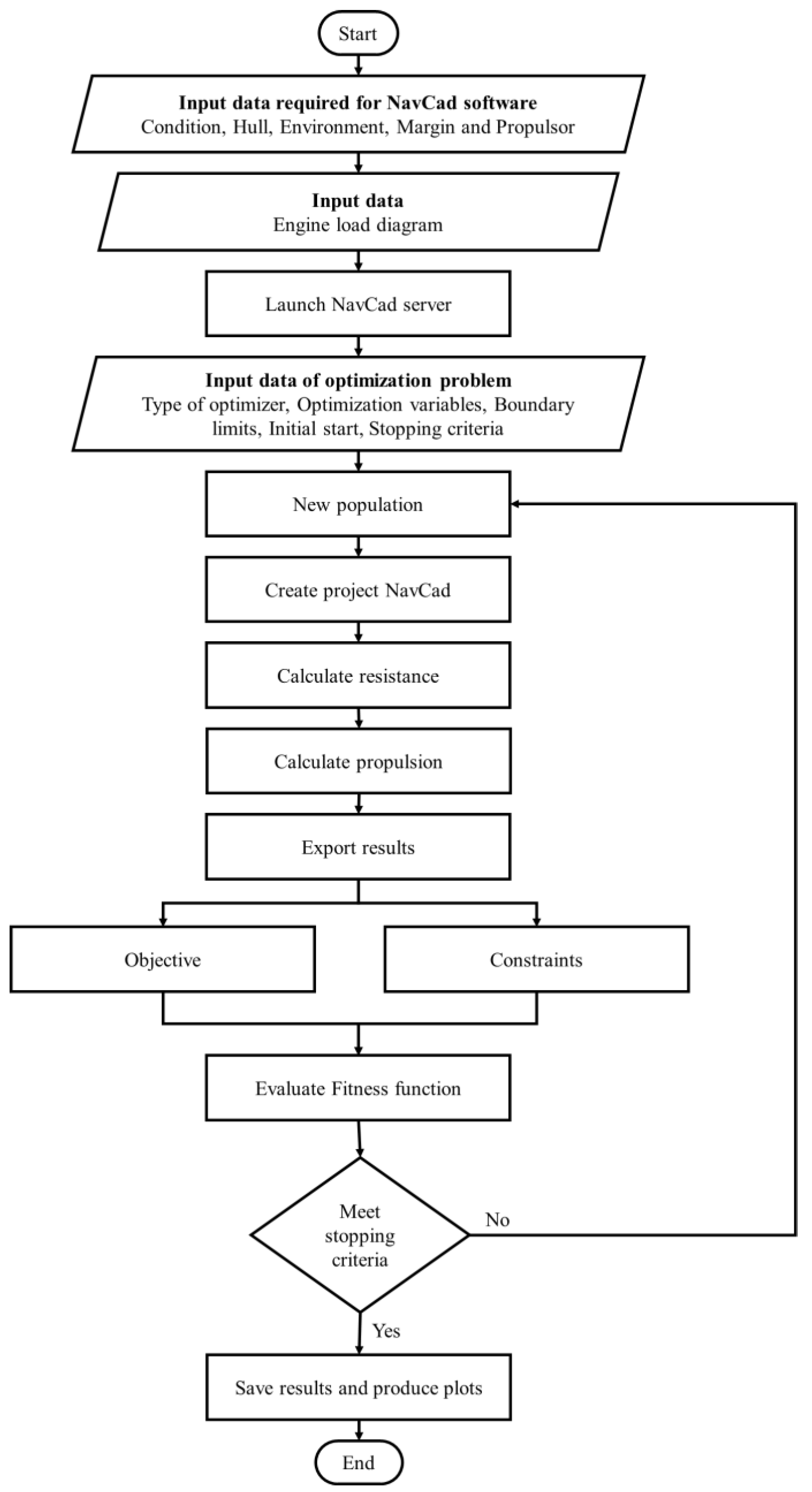

2. Numerical Model

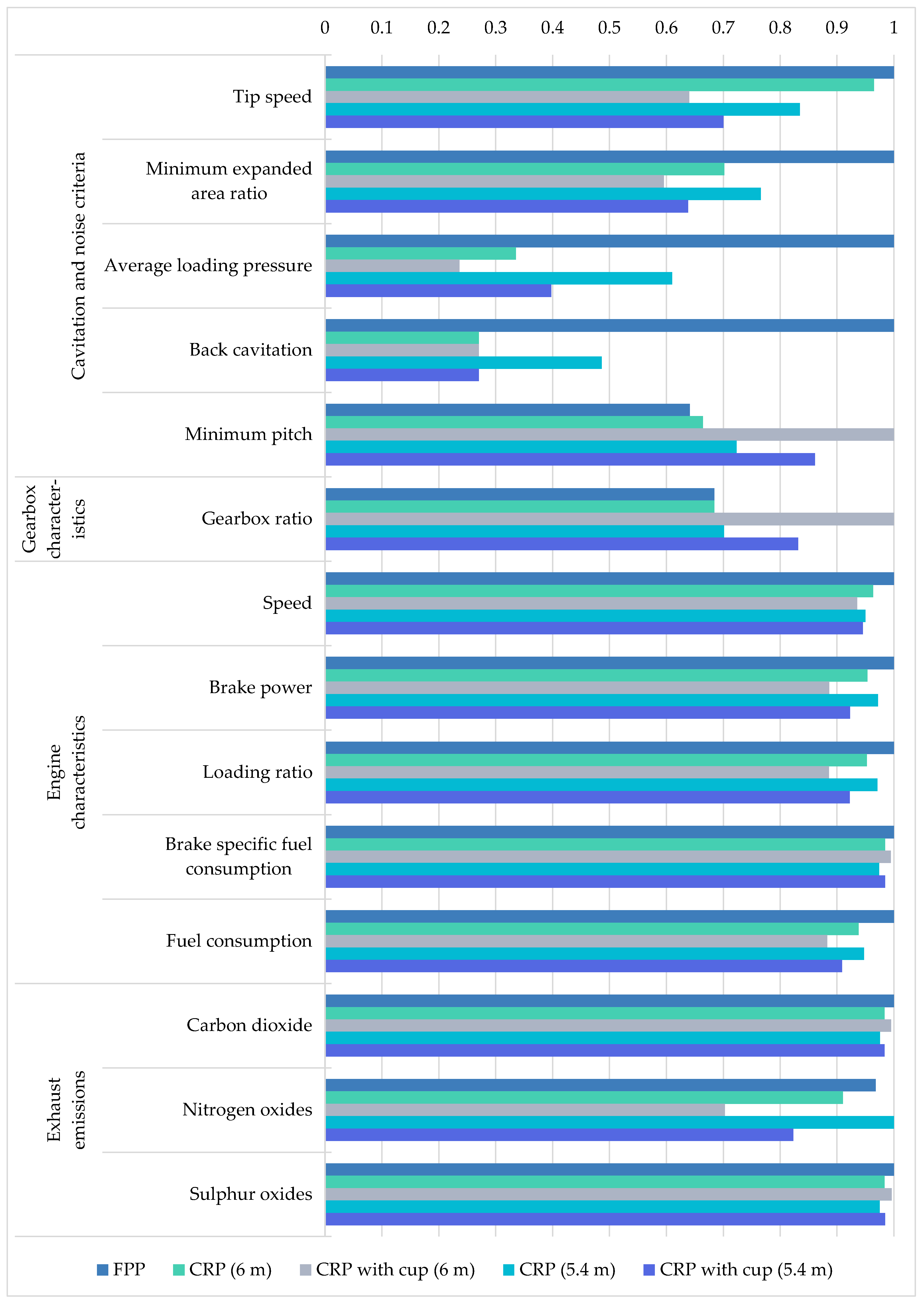

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ηH | Hull efficiency |

| ηo | Open-water propeller efficiency |

| ηRR | Relative-rotative efficiency |

| 3D | Three dimensional |

| API | Application programming interface |

| BSFC | Brake-specific fuel consumption |

| CA | Correlation allowance |

| CAVAVG | Back cavitation |

| CF | Frictional coefficient |

| CFD | Computational fluid dynamics |

| CO2 | Carbon dioxide |

| CPP | Controllable pitch propeller |

| CR | Residuary coefficient |

| CRP | Contra-rotating propeller |

| CT | Total resistance coefficient |

| D | Propeller diameter |

| DHP | Delivered horsepower |

| EAR | Expanded area ratio |

| EARmin | Minimum expanded area ratio |

| FC | Fuel consumption |

| FPP | Fixed pitch propeller |

| g | Penalty function |

| GBR | Gearbox ratio |

| ITTC | International Towing Tank Conference |

| j | Number of constraints |

| JA | Advance coefficient |

| k | Form factor |

| KQ | Torque coefficient |

| KT | Thrust coefficient |

| LR | Loading ratio |

| N | Propeller speed |

| NOx | Nitrogen oxides |

| P/D | Pitch diameter ratio |

| PB | Brake power |

| PFC | Minimum pitch |

| PRESS | Average loading pressure |

| Q | Propeller torque |

| R | Constant |

| RPM | Engine speed |

| SMGT | Super marine gas turbine |

| SOx | Sulphur oxides |

| t | Thrust deduction factor |

| T | Propeller thrust |

| VGFs | Vortex generator fins |

| Vs | Ship design speed |

| Vtip | Tip speed |

| w | Wake fraction |

| WFSV | Wind farm support vessel |

| Z | Number of propeller blades |

| ρfuel | Fuel density |

Appendix A

| Main Characteristics | Parameters | Symbol | Unit | |||||

|---|---|---|---|---|---|---|---|---|

| Propeller type | [-] | FPP | CRP (6 m) | CRP with cup (6 m) | CRP (5.4 m) | CRP with cup (5.4 m) | ||

| Ship characteristics | Ship speed | Vs | [kn] | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 |

| Propeller characteristics | Series | [-] | [-] | Wageningen B-series | ||||

| Cup | [-] | [%] | 0.00 | 0.00 | 1.50 | 0.00 | 1.50 | |

| Diameter | D | [m] | 6.00 | 6.00 | 6.00 | 5.40 | 5.40 | |

| Expanded area ratio | EAR | [-] | 0.47 | 0.70 | 0.59 | 0.47 | 0.45 | |

| Pitch | P | [m] | 6.58 | 5.55 | 8.08 | 6.76 | 7.06 | |

| Speed | N | [RPM] | 75 | 73 | 48 | 70 | 58 | |

| Thrust | T | [kN] | 576.49 | 576.49 | 576.49 | 576.49 | 576.49 | |

| Torque | Q | [kN·m] | 573.30 | 559.20 | 788.50 | 600.90 | 680.70 | |

| Open water efficiency | ηo | [%] | 59 | 63 | 67 | 61 | 64 | |

| Advance coefficient | JA | [-] | 0.62 | 0.64 | 0.96 | 0.74 | 0.88 | |

| Thrust coefficient | KT | [-] | 0.28 | 0.30 | 0.67 | 0.49 | 0.70 | |

| Torque coefficient | KQ | [-] | 0.05 | 0.05 | 0.15 | 0.09 | 0.15 | |

| Wake fraction | w | [-] | 0.38 | 0.38 | 0.38 | 0.38 | 0.38 | |

| Thrust deduction factor | t | [-] | 0.19 | 0.19 | 0.19 | 0.19 | 0.19 | |

| Cavitation and noise criteria | Tip Speed | Vtip | [m/s] | 23.61 | 22.78 | 15.12 | 19.70 | 16.53 |

| Minimum expanded area ratio | EARmin | [-] | 0.47 | 0.33 | 0.28 | 0.36 | 0.30 | |

| Average loading pressure | PRESS | [kPa] | 43.56 | 14.62 | 10.30 | 26.57 | 17.32 | |

| Back cavitation | CAVAVG | [%] | 7.40 | 2.00 | 2.00 | 3.60 | 2.00 | |

| Minimum pitch | PFC | [m] | 4.98 | 5.16 | 7.77 | 5.62 | 6.69 | |

| Gearbox characteristics | Gearbox ratio | GBR | [-] | 9.50 | 9.50 | 13.88 | 9.73 | 11.54 |

| Engine characteristics | Speed | RPM | [RPM] | 714 | 688 | 668 | 678 | 675 |

| Brake power | PB | [kW] | 4682 | 4465 | 4151 | 4551 | 4321 | |

| Loading ratio | LR | [%] | 65.6 | 62.5 | 58.1 | 63.7 | 60.5 | |

| BSFC | BSFC | [g/kW·h] | 192 | 189 | 191 | 187 | 189 | |

| Fuel consumption | FC | [l/nm] | 74.17 | 69.56 | 65.48 | 70.28 | 67.38 | |

| Exhaust emissions | Carbon dioxide | CO2 | [g/kW·h] | 608 | 598 | 605 | 593 | 598 |

| Nitrogen oxides | NOx | [g/kW·h] | 6.68 | 6.28 | 4.85 | 6.90 | 5.68 | |

| Sulphur oxides | SOx | [g/kW·h] | 9.59 | 9.43 | 9.55 | 9.35 | 9.44 | |

References

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transp. Res. D Transp. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Green Ship of the Future. 2019 Retrofit Project. Available online: https://greenship.org/project/2019-retrofit-series/ (accessed on 8 December 2021).

- Karatuğ, Ç.; Arslanoğlu, Y.; Guedes Soares, C. Evaluation of decarbonization strategies for existing ships. In Trends in Maritime Technology and Engineering; Guedes Soares, C., Santos, T.A., Eds.; Taylor & Francis Group: London, UK, 2022; pp. 45–54. [Google Scholar]

- DNV. Maritime Forecast to 2050: Energy Transition Outlook 2020; DNV: Bærum, Norway, 2020. [Google Scholar]

- Tadros, M.; Vettor, R.; Ventura, M.; Guedes Soares, C. Effect of different speed reduction strategies on ship fuel consumption in realistic weather conditions. In Trends in Maritime Technology and Engineering; Guedes Soares, C., Santos, T.A., Eds.; Taylor & Francis Group: London, UK, 2022; pp. 553–561. [Google Scholar]

- Vettor, R.; Tadros, M.; Ventura, M.; Guedes Soares, C. Route planning of a fishing vessel in coastal waters with fuel consumption restraint. In Maritime Technology and Engineering 3; Guedes Soares, C., Santos, T.A., Eds.; Taylor & Francis Group: London, UK, 2016; pp. 167–173. [Google Scholar]

- Ventura, M. Ship dimensioning in the initial design. In Developments in Maritime Transportation and Exploitation of Sea Resources; Guedes Soares, C., López Peña, F., Eds.; Taylor & Francis Group: London, UK, 2014; pp. 531–539. [Google Scholar]

- Feng, Y.; el Moctar, O.; Schellin, T.E. Parametric Hull Form Optimization of Containerships for Minimum Resistance in Calm Water and in Waves. J. Mar. Sci. Appl. 2021, 20, 670–693. [Google Scholar] [CrossRef]

- Stark, C.; Xu, Y.; Zhang, M.; Yuan, Z.; Tao, L.; Shi, W. Study on Applicability of Energy-Saving Devices to Hydrogen Fuel Cell-Powered Ships. J. Mar. Sci. Eng. 2022, 10, 388. [Google Scholar] [CrossRef]

- Andersson, J.; Shiri, A.A.; Bensow, R.E.; Yixing, J.; Chengsheng, W.; Gengyao, Q.; Deng, G.; Queutey, P.; Xing-Kaeding, Y.; Horn, P.; et al. Ship-scale CFD benchmark study of a pre-swirl duct on KVLCC2. Appl. Ocean Res. 2022, 123, 103134. [Google Scholar] [CrossRef]

- Gaggero, S.; Martinelli, M. Pre-swirl fins design for improved propulsive performances: Application to fast twin-screw passenger ships. J. Ocean Eng. Mar. Energy 2022. [Google Scholar] [CrossRef]

- Seol, H. Virtue and Function. The Naval Architect. Available online: https://www.rina.org.uk/Virtue_and_function.html (accessed on 8 September 2022).

- Tadros, M.; Ventura, M.; Guedes Soares, C. Design of Propeller Series Optimizing Fuel Consumption and Propeller Efficiency. J. Mar. Sci. Eng. 2021, 9, 1226. [Google Scholar] [CrossRef]

- Nelson, M.; Temple, D.W.; Hwang, J.T.; Young, Y.L.; Martins, J.R.R.A.; Collette, M. Simultaneous optimization of propeller–hull systems to minimize lifetime fuel consumption. Appl. Ocean Res. 2013, 43, 46–52. [Google Scholar] [CrossRef]

- Tadros, M.; Ventura, M.; Guedes Soares, C. Optimum design of a container ship’s propeller from Wageningen B-series at the minimum BSFC. In Sustainable Development and Innovations in Marine Technologies; Georgiev, P., Guedes Soares, C., Eds.; Taylor & Francis Group: London, UK, 2020; pp. 269–274. [Google Scholar]

- Tadros, M.; Vettor, R.; Ventura, M.; Guedes Soares, C. Coupled Engine-Propeller Selection Procedure to Minimize Fuel Consumption at a Specified Speed. J. Mar. Sci. Eng. 2021, 9, 59. [Google Scholar] [CrossRef]

- Jaurola, M.; Hedin, A.; Tikkanen, S.; Huhtala, K. A TOpti simulation for finding fuel saving by optimising propulsion control and power management. J. Mar. Sci. Technol. 2020, 25, 411–425. [Google Scholar] [CrossRef]

- Tadros, M.; Ventura, M.; Guedes Soares, C. Optimization procedures for a twin controllable pitch propeller of a ROPAX ship at minimum fuel consumption. J. Mar. Eng. Technol. 2022. [Google Scholar] [CrossRef]

- Makino, H.; Umeda, N.; Ohtsuka, T.; Ikejima, S.; Sekiguchi, H.; Tanizawa, K.; Suzuki, J.; Fukazawa, M. Energy savings for ship propulsion in waves based on real-time optimal control of propeller pitch and electric propulsion. J. Mar. Sci. Technol. 2017, 22, 546–558. [Google Scholar] [CrossRef]

- Tadros, M.; Vettor, R.; Ventura, M.; Guedes Soares, C. Effect of propeller cup on the reduction of fuel consumption in realistic weather conditions. J. Mar. Sci. Eng. 2022, 10, 1039. [Google Scholar] [CrossRef]

- Wagner, R. Rückblick und Ausblick auf die Entwicklung des Contrapropellers. In Jahrbuch der Schiffbautechnischen Gesellschaft: 30. Band; Springer: Berlin/Heidelberg, Germany, 1929; pp. 195–256. [Google Scholar]

- Min, K.-S.; Chang, B.-J.; Seo, H.-W. Study on the Contra-Rotating Propeller system design and full-scale performance prediction method. Int. J. Nav. Arch. Ocean Eng. 2009, 1, 29–38. [Google Scholar] [CrossRef]

- van Manen, J.D.; Oosterveld, M.W.C. Model Tests on Contra-Rotating Propellers. Int. Shipbuild. Prog. 1969, 15, 401–417. [Google Scholar] [CrossRef]

- Koronowicz, T.; Krzemianowski, Z.; Tuszkowska, T.; Szantyr, J. A complete design of contra-rotating propellers using the new computer system. Pol. Marit. Res. 2010, 17, 14–24. [Google Scholar] [CrossRef]

- Ghassemi, H.; Taherinasab, M. Numerical calculations of the hydrodynamic performance of the contra-rotating propeller (CRP) for high speed vehicle. Pol. Marit. Res. 2013, 20, 13–20. [Google Scholar] [CrossRef][Green Version]

- Nouri, N.M.; Mohammadi, S.; Zarezadeh, M. Optimization of a marine contra-rotating propellers set. Ocean Eng. 2018, 167, 397–404. [Google Scholar] [CrossRef]

- Kayano, J.; Haraguchi, T.; Tsukada, Y.; Kano, T. On the ship maneuverability of tandem arrangement CRP pod propulsion system. In Maritime Transportation and Exploitation of Ocean and Coastal Resources; Guedes Soares, C., Garbatov, Y., Fonseca, N., Eds.; Taylor and Fransis: London, UK, 2005; pp. 189–193. [Google Scholar]

- Torneman, G. Multiple pod units for efficient vessel handling in wind farm operations. In Design & Operation of Offshore Wind Farm Support Vessels; Royal Institution of Naval Architects: London, UK, 2015. [Google Scholar]

- Hou, L.; Yin, L.; Hu, A.; Chang, X.; Lin, Y.; Wang, S. Optimal matching investigation of marine contra-rotating propellers for energy consumption minimization. J. Mar. Sci. Technol. 2021, 26, 1184–1197. [Google Scholar] [CrossRef]

- Minami, Y.; Kano, T. Evaluation of the emissions from the super eco-ship and the corresponding conventional ship. In Maritime Transportation and Exploitation of Ocean and Coastal Resources; Guedes Soares, C., Garbatov, Y., Fonseca, N., Eds.; Taylor and Fransis: London, UK, 2005; pp. 1721–1727. [Google Scholar]

- MAN Diesel & Turbo. 32/44CR Project Guide—Marine Four-Stroke Diesel Engines Compliant with IMO Tier II; MAN Diesel & Turbo: Augsburg, Germany, 2017. [Google Scholar]

- HydroComp. NavCad: Reliable and Confident Performance Prediction. HydroComp Inc. Available online: https://www.hydrocompinc.com/solutions/navcad/ (accessed on 30 January 2019).

- Tadros, M.; Ventura, M.; Guedes Soares, C. Surrogate models of the performance and exhaust emissions of marine diesel engines for ship conceptual design. In Maritime Transportation and Harvesting of Sea Resources; Guedes Soares, C., Teixeira, A.P., Eds.; Taylor & Francis Group: London, UK, 2018; pp. 105–112. [Google Scholar]

- Tadros, M.; Ventura, M.; Guedes Soares, C. Optimization procedure to minimize fuel consumption of a four-stroke marine turbocharged diesel engine. Energy 2019, 168, 897–908. [Google Scholar] [CrossRef]

- Tadros, M.; Ventura, M.; Guedes Soares, C. Simulation of the performance of marine Genset based on double-Wiebe function. In Sustainable Development and Innovations in Marine Technologies; Georgiev, P., Guedes Soares, C., Eds.; Taylor & Francis Group: London, UK, 2020; pp. 292–299. [Google Scholar]

- The MathWorks Inc. Fmincon. Available online: https://www.mathworks.com/help/optim/ug/fmincon.html (accessed on 2 June 2017).

- Holtrop, J. A statistical re-analysis of resistance and propulsion data. Int. Shipbuild. Prog. 1984, 31, 272–276. [Google Scholar]

- Holtrop, J. A Statistical Resistance Prediction Method With a Speed Dependent Form Factor. In Proceedings of Scientific and Methodological Seminar on Ship Hydrodynamics (SMSSH’88); Bulgarian Ship Hydrodynamics Centre: Varna, Bulgaria, 1988; pp. 1–7. [Google Scholar]

- ITTC. Skin Friction and Turbulence Stimulation. In Proceedings of the 8th ITTC, Madrid, Spain, 15–23 September 1957. [Google Scholar]

- ITTC. 1978 ITTC Performance Prediction Method. In Proceedings of the 28th ITTC, Wuxi, China, 27 November–2 December 2017. [Google Scholar]

- Islam, H.; Ventura, M.; Guedes Soares, C.; Tadros, M.; Abdelwahab, H.S. Comparison between empirical and CFD based methods for ship resistance and power prediction. In Trends in Maritime Technology and Engineering; Guedes Soares, C., Santos, T.A., Eds.; Taylor & Francis Group: London, UK, 2022; pp. 347–357. [Google Scholar]

- Holtrop, J.; Mennen, G.G.J. An approximate power prediction method. Int. Shipbuild. Prog. 1982, 29, 166–170. [Google Scholar] [CrossRef]

- Oosterveld, M.; Van Oossanen, P. Further computer-analyzed data of the Wageningen B-screw series. Int. Shipbuild. Prog. 1975, 22, 251–262. [Google Scholar] [CrossRef]

- Lindgren, H.; Johnsson, C.-A.; Dyne, G. Studies of the Application of Ducted and Contrarotating Propellers on Merchant Ships. In Seventh ONR Symposium on Naval Hydrodynamics; Cooper, R.D., Doroff, S.W., Eds.; Office of Naval Research: Arlington, VA, USA, 1968. [Google Scholar]

- Bjarne, E. Systematic Studies of Contra-rotating Propellers for Merchant Ships. In Proceedings International Maritime and Shipping Conference (IMAS); Institute of Marine Engineers: London, UK, 1973. [Google Scholar]

- van Lammeren, W.P.A.; van Manen, J.D.; Oosterveld, M.W.C. The Wageningen B-screw series. Trans. SNAME 1969, 77, 269–317. [Google Scholar]

- Burrill, L.C.; Emerson, A. Propeller cavitation: Further tests on 16in. propeller models in the King’s College cavitation tunnel. Int. Shipbuild. Prog. 1963, 10, 119–131. [Google Scholar] [CrossRef]

- Blount, D.L.; Fox, D.L. Design Considerations for Propellers in a Cavitating Environment. Mar. Technol. 1978, 15, 144–178. [Google Scholar] [CrossRef]

- MacPherson, D.M. Reliable Propeller Selection for Work Boats and Pleasure Craft: Techniques Using a Personal Computer. In SNAME Fourth Biennial Power Boat Symposium; SNAME: Alexandria, VA, USA, 1991. [Google Scholar]

- Sasaki, N.; Kuroda, M.; Fujisawa, J.; Imoto, T.; Masaharu, S. On the Model Tests and Design Method of Hybrid CRP Podded Propulsion System of a Feeder Container Ship. In Proceedings of the First International Symposium on Marine Propulsors (SMP’09); Koushan, K., Steen, S., Eds.; Norwegian Marine Technology Research Institute (MARINTEK): Trondheim, Norway, 2009. [Google Scholar]

- Sasaki, N.; Murakami, M.; Nozawa, K.; Soejima, S.; Shikaki, A.; Aono, T. Design system for optimum contra-rotating propellers. J. Mar. Sci. Technol. 1998, 3, 3–21. [Google Scholar] [CrossRef]

| Characteristics | Unit | Value | |

|---|---|---|---|

| Ship characteristics | Length waterline | m | 154.00 |

| Breadth | m | 23.11 | |

| Draft | m | 10.00 | |

| Displacement | tonnes | 27,690 | |

| Service speed | knots | 14.5 | |

| Maximum speed | knots | 16.0 | |

| Number of propellers | - | 1 | |

| Type of propeller | - | FPP | |

| Rated power | kW | 7140 | |

| Engine characteristics | Engine builder | - | MAN Energy Solutions [31] |

| Brand name | - | MAN | |

| Bore | mm | 320 | |

| Stroke | mm | 440 | |

| Displacement | liters | 4954 | |

| Number of cylinders | - | 14 | |

| Rated speed | rpm | 750 | |

| Rated power | kW | 7140 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tadros, M.; Ventura, M.; Guedes Soares, C. Towards Fuel Consumption Reduction Based on the Optimum Contra-Rotating Propeller. J. Mar. Sci. Eng. 2022, 10, 1657. https://doi.org/10.3390/jmse10111657

Tadros M, Ventura M, Guedes Soares C. Towards Fuel Consumption Reduction Based on the Optimum Contra-Rotating Propeller. Journal of Marine Science and Engineering. 2022; 10(11):1657. https://doi.org/10.3390/jmse10111657

Chicago/Turabian StyleTadros, Mina, Manuel Ventura, and C. Guedes Soares. 2022. "Towards Fuel Consumption Reduction Based on the Optimum Contra-Rotating Propeller" Journal of Marine Science and Engineering 10, no. 11: 1657. https://doi.org/10.3390/jmse10111657

APA StyleTadros, M., Ventura, M., & Guedes Soares, C. (2022). Towards Fuel Consumption Reduction Based on the Optimum Contra-Rotating Propeller. Journal of Marine Science and Engineering, 10(11), 1657. https://doi.org/10.3390/jmse10111657