Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions

Abstract

1. Introduction

2. Materials and Methods

2.1. Autonomous Mower Working Features

2.2. Cases of Study

2.3. Autonomous Mowers Involved in the Study

3. Results and Discussion

3.1. Interviews Results

3.2. Analysis of Criticisms

3.3. Description and Planning Improvements of the Selected Study Case

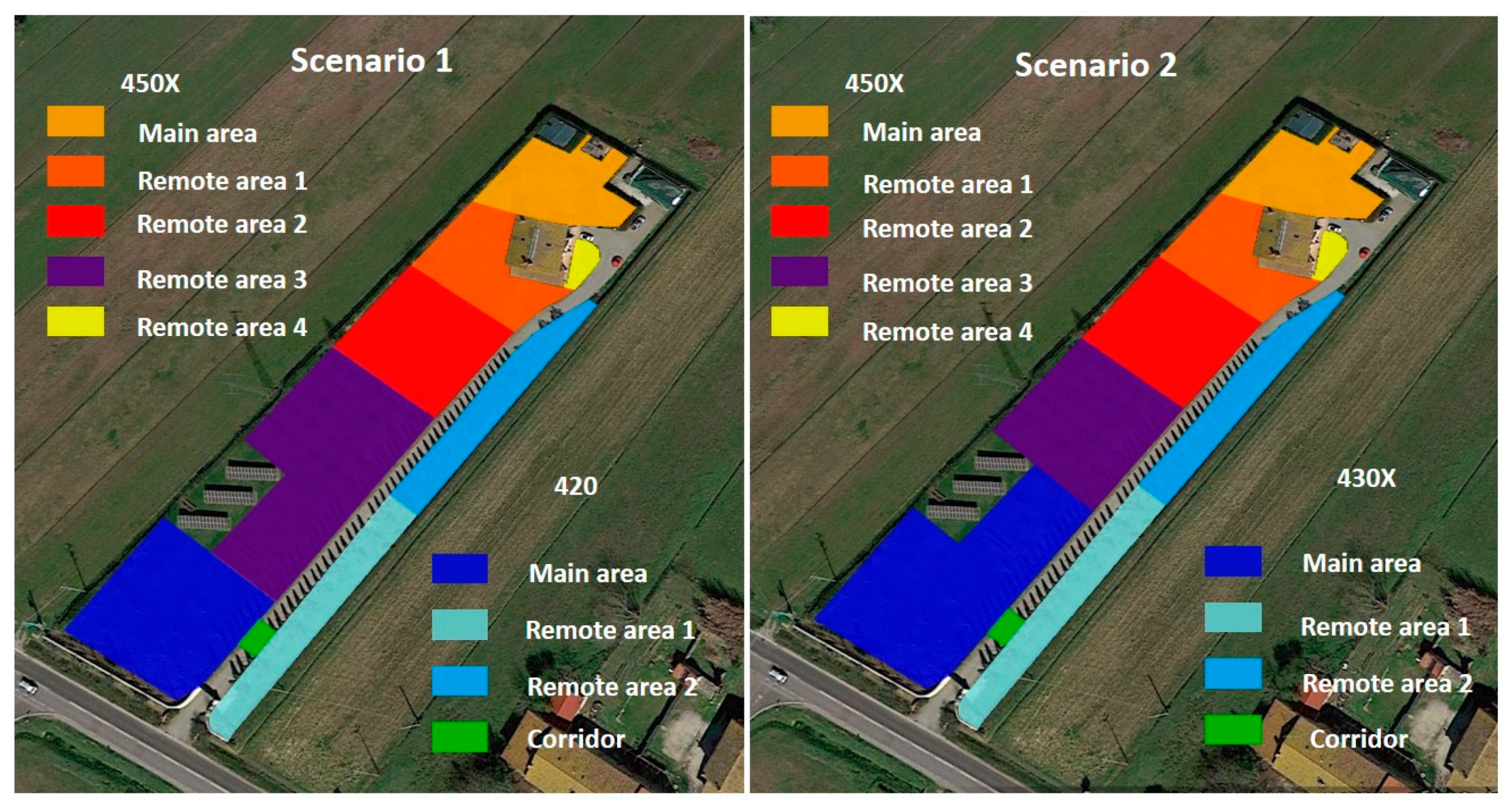

3.4. Autonomous Mowers Management Solutions Redesigning

3.5. Analysis of Costs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tzoulas, K.; Korpela, K.; Venn, S.; Yli-Pelkonen, V.; Kaźmierczak, A.; Niemela, J.; James, P. Promoting ecosystem and human health in urban areas using Green Infrastructure: A literature review. Landsc. Urban Plan. 2007, 81, 167–178. [Google Scholar] [CrossRef]

- Masoudi, M.; Puay, Y.T.; Liew, S.C. Multi-city comparison of the relationships between spatial pattern and cooling effect of urban green spaces in four major Asian cities. Ecol. Indic. 2019, 98, 200–213. [Google Scholar] [CrossRef]

- Keniger, L.E.; Gaston, K.J.; Irvine, K.N.; Fuller, R.A. What are the benefits of interaction with nature? Int. J. Environ. Res. Public Health 2013, 10, 913–935. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Yang, Q.; Duan, L. Adjusting the structure combinations of plant communities in urban greenspace reduced the maintenance energy consumption and GHG emissions. J. Environ. Eng. Landsc. Manag. 2018, 26, 261–274. [Google Scholar] [CrossRef]

- Jo, H.K.; McPherson, G.E. Carbon storage and flux in urban residential greenspace. J. Environ. Manag. 1995, 45, 109–133. [Google Scholar] [CrossRef]

- Beard, J.B.; Green, J.L. The role of turfgrasses in environmental protection and their benefits to humans. J. Environ. Qual. 1994, 23, 452–460. [Google Scholar] [CrossRef]

- Yue, C.; Wang, J.; Watkins, E.; Bonos, S.A.; Nelson, K.C.; Murphy, J.A.; Meyer, W.A.; Horgan, B.P. Heterogeneous Consumer Preferences for Turfgrass Attributes in the United States and Canada. Can. J. Agric. Econ./Revue Can. D’agroecon. 2017, 65, 347–383. [Google Scholar] [CrossRef]

- Vitirover. Vitirover Solutions. Available online: https://www.vitirover.fr/en-robot (accessed on 3 April 2019).

- Franklin robotics. Franklin Robotics Tertill. Available online: https://www.franklinrobotics.com (accessed on 3 April 2019).

- Etesia. They Mow Every Day, without You. Available online: http://www.etesia.com/en/products/robot-etm105.html (accessed on 3 April 2019).

- Honda. Miimo at a Glance. Available online: http://www.honda.co.uk/lawnandgarden/products/miimo-2015/overview.html (accessed on 3 April 2019).

- Husqvarna. Husqvarna Automower 105/310/315/320/330X/420/430X/450X Operator’s Manual. Available online: http://www.husqvarna.com/uk/support/manuals-downloads/ (accessed on 3 April 2019).

- Robomow. Choose Your Best Team Player. Available online: http://robomow.com/en-GB/product-category/mowers/ (accessed on 3 April 2019).

- Zucchetti. Ambrogio Robot. Available online: http://www.ambrogiorobot.com/en/ambrogiorobot (accessed on 3 April 2019).

- Heckman, J.R.; Liu, H.; Hill, W.; DeMilia, M.; Anastasia, W.L. Kentucky Bluegrass Responses to Mowing Practice and Nitrogen Fertility Management. J. Sustain. Agric. 2000, 15, 25–33. [Google Scholar] [CrossRef]

- Hicks, R.W.; Hall, E.L. Survey of robot lawn mowers. In Proceedings SPIE 4197, Intelligent Robots and Computer Vision XIX: Algorithms, Techniques, and Active Vision; Society of Photo-Optical Instrumentation Engineers (SPIE): Boston, MA, USA, 2000; pp. 262–269. [Google Scholar]

- Nelson, R.G. Automated Lawn Mower. U.S. Patent 5 974 347, 26 October 1999. [Google Scholar]

- Pirchio, M.; Fontanelli, M.; Frasconi, C.; Martelloni, L.; Raffaelli, M.; Peruzzi, A.; Gaetani, M.; Magni, S.; Caturegli, L.; Volterrani, M.; et al. Autonomous Mower vs. Rotary Mower: Effects on Turf Quality and Weed Control in Tall Fescue Lawn. Agronomy 2018, 8, 15. [Google Scholar] [CrossRef]

- Grossi, N.; Fontanelli, M.; Garramone, E.; Peruzzi, A.; Raffaelli, M.; Pirchio, M.; Martelloni, L.; Frasconi, C.; Caturegli, L.; Gaetani, M.; et al. Autonomous Mower Saves Energy and Improves Quality of Tall Fescue Lawn. HortTechnology 2016, 26, 825–830. [Google Scholar] [CrossRef]

- Peless, E.; Even, Y.; Shai, A.; Ramat, G.; Gideon, D. Navigation Method and System for Autonomous Machines with Markers Defining the Working Area. U.S. Patent 6 417 641, 9 July 2002. [Google Scholar]

| Features | Automower® 420 | Automower® 430X | Automower® 450X |

|---|---|---|---|

| Working capacity | 2200 m2 ± 20% | 3200 m2 ± 20% | 5000 m2 ± 20% |

| Mean energy consumption at maximum use | 19 kWh/month in a 2200 m2 working area | 20 kWh/month in a 3200 m2 working area | 24 kWh/month in a 5000 m2 working area |

| Battery | Special Li-ion battery 18 V/3.2 Ah, Part no. 580 68 33-01 | Special Li-ion battery 18 V/5.2 Ah, art no. 588 14 64-01 | Special Li-ion battery 18 V/10.4 Ah, Part no. 588 14 64-01 (2 pack) |

| Average mowing time | 105 min | 135 min | 260 min |

| Average charging time | 55 min | 65 min | 75 min |

| Blade motor speed | 2300 rpm | 2300 rpm | 2300 rpm |

| Power consumption during cutting | 30 W ± 20% | 30 W ± 20% | 30 W ± 20% |

| Cutting width | 24 cm | 24 cm | 24 cm |

| Maximum length of the boundary wire | 800 m | 800 m | 800 m |

| Maximum length of the guide loop | 400 m | 400 m | 400 m |

| Maximum number of remote areas | Three | Five | Five |

| Maximum number of guide wires | One | Two | Three |

| GPS assisted navigation | No | Yes | Yes |

| Study Case | Typology | Area [m2] | Number of Autonomous Mowers | Working Settings [h day-1] | Secondary Areas | Manual Positioning | Slopes | Narrow Passages | Walls | Curbs | Wire around Objects | Finishing Works | Owner Interventions |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Private | 200 | 1 | 8 | Yes | No | Yes | Yes | Yes | No | Yes | Yes | Yes |

| 2 | Private | 850 | 1 | 8 | Yes | No | No | Yes | No | Yes | Yes | Yes | Yes |

| 3 | Private | 1000 | 1 | 8 | Yes | Yes | Yes | Yes | No | Yes | Yes | Yes | Yes |

| 4 | Industrial | 3000 | 1 | 21 | No | No | No | No | Yes | No | Yes | Yes | No |

| 5 | Private | 9000 | 3 | 14 | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes |

| 6 | Industrial | 2500 | 2 | 12 | No | Yes | No | No | Yes | No | No | Yes | Yes |

| 7 | Private | 1400 | 1 | 12 | Yes | Yes | Yes | Yes | Yes | No | Yes | Yes | Yes |

| Features | Unit of Measure | Quantity | Unit Price | Total Price |

|---|---|---|---|---|

| Husqvarna Automower 430X. | pcs | 1 | €3343.00 | €3343.00 |

| Boundary wire + installation | m | 519.82 | €1.58 | €821.31 |

| Guide wire1 + installation | m | 100.56 | €1.58 | €158.88 |

| Guide wire 2 + installation | m | 54.15 | €1.58 | €85.55 |

| Husqvarna Automower 430X. | pcs | 1 | €3343.00 | €3343.00 |

| Boundary wire + installation | m | 284.11 | €1.58 | €448.89 |

| Guide wire + installation | m | 85.55 | €1.58 | €135.16 |

| Husqvarna Automower 420. | pcs | 1 | €2721.00 | €2721.00 |

| Boundary wire + installation | m | 388.56 | €1.58 | €613.92 |

| Guide wire + installation | m | 137.25 | €1.58 | €216.85 |

| Total: | €11,662.56 |

| Features | Unit of Measure | Quantity | Unit Price | Total Price |

|---|---|---|---|---|

| Husqvarna Automower 450X. | pcs | 1 | €4514.00 | €4514.00 |

| Boundary wire + installation | m | 644.53 | €1.58 | €1018.36 |

| Guide wire 1 + installation | m | 135.46 | €1.58 | €214.03 |

| Guide wire 2 + installation | m | 79.33 | €1.58 | €125.34 |

| Husqvarna Automower 420. | pcs | 1 | €2721.00 | €2721.00 |

| Boundary wire + installation | m | 452.15 | €1.58 | €714.40 |

| Guide wire + installation | m | 149.77 | €1.58 | €236.64 |

| Husqvarna Automower 450X. | pcs | 1 | €4514.00 | €4514.00 |

| Boundary wire + installation | m | 644.53 | €1.58 | €1018.36 |

| Guide wire 1 + installation | m | 135.46 | €1.58 | €214.03 |

| Total: | €9543.77 |

| Features | Unit of Measure | Quantity | Unit Price | Total Price |

|---|---|---|---|---|

| Husqvarna Automower 450X. | pcs | 1 | €4514.00 | €4514.00 |

| Boundary wire + installation | m | 573.46 | €1.58 | €906.07 |

| Guide wire 1 + installation | m | 135.46 | €1.58 | €214.03 |

| Guide wire 2 + installation | m | 79.33 | €1.58 | €125.34 |

| Husqvarna Automower 430X. | pcs | 1 | €3343.00 | €3343.00 |

| Boundary wire + installation | m | 510.84 | €1.58 | €807.13 |

| Guide wire + installation | m | 191.04 | €1.58 | €301.84 |

| Husqvarna Automower 450X. | pcs | 1 | €4514.00 | €4514.00 |

| Boundary wire + installation | m | 573.46 | €1.58 | €906.07 |

| Guide wire 1 + installation | m | 135.46 | €1.58 | €214.03 |

| Total: | €10,211.41 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sportelli, M.; Martelloni, L.; Orlandi, A.; Pirchio, M.; Fontanelli, M.; Frasconi, C.; Raffaelli, M.; Peruzzi, A.; Consorti, S.B.; Vernieri, P. Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions. Agriculture 2019, 9, 115. https://doi.org/10.3390/agriculture9060115

Sportelli M, Martelloni L, Orlandi A, Pirchio M, Fontanelli M, Frasconi C, Raffaelli M, Peruzzi A, Consorti SB, Vernieri P. Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions. Agriculture. 2019; 9(6):115. https://doi.org/10.3390/agriculture9060115

Chicago/Turabian StyleSportelli, Mino, Luisa Martelloni, Aura Orlandi, Michel Pirchio, Marco Fontanelli, Christian Frasconi, Michele Raffaelli, Andrea Peruzzi, Salvatore Brunello Consorti, and Paolo Vernieri. 2019. "Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions" Agriculture 9, no. 6: 115. https://doi.org/10.3390/agriculture9060115

APA StyleSportelli, M., Martelloni, L., Orlandi, A., Pirchio, M., Fontanelli, M., Frasconi, C., Raffaelli, M., Peruzzi, A., Consorti, S. B., & Vernieri, P. (2019). Autonomous Mower Management Systems Efficiency Improvement: Analysis of Greenspace Features and Planning Suggestions. Agriculture, 9(6), 115. https://doi.org/10.3390/agriculture9060115