Design of and Experimentation on an Intelligent Intra-Row Obstacle Avoidance and Weeding Machine for Orchards

Abstract

1. Introduction

2. Materials and Methods

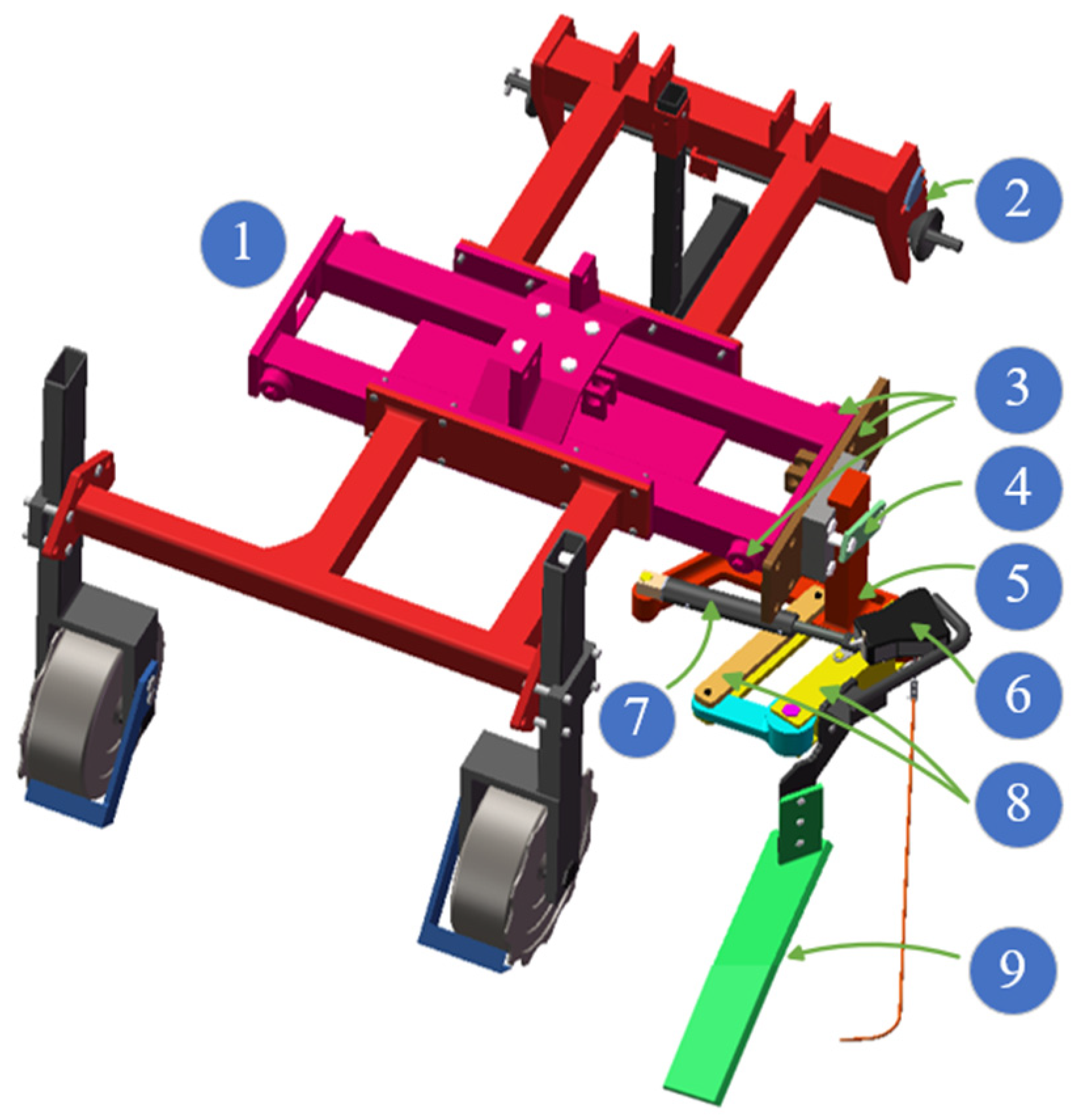

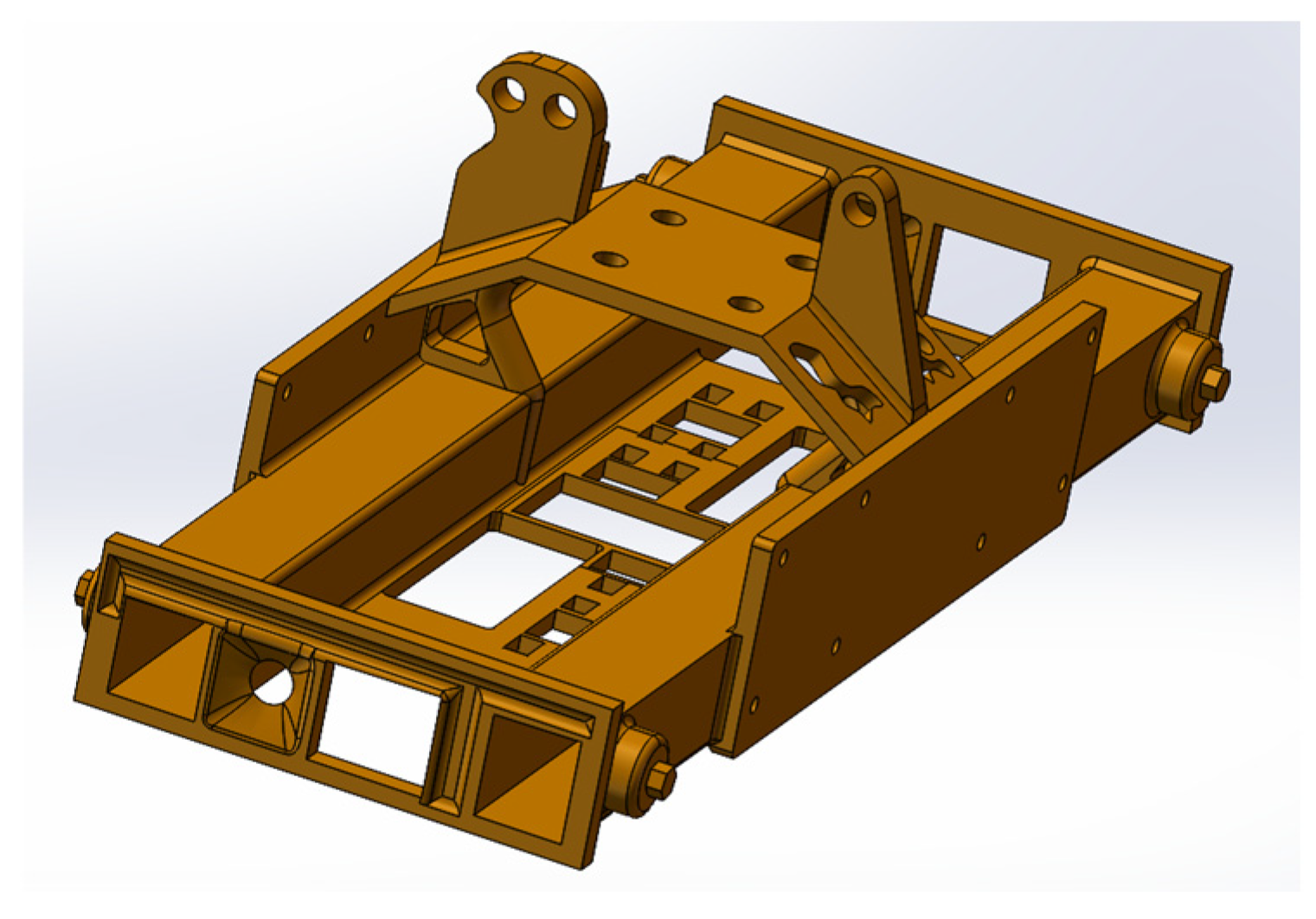

2.1. Design, Functions, and Working Principles

2.1.1. Technical Approach and Power Flow Analysis

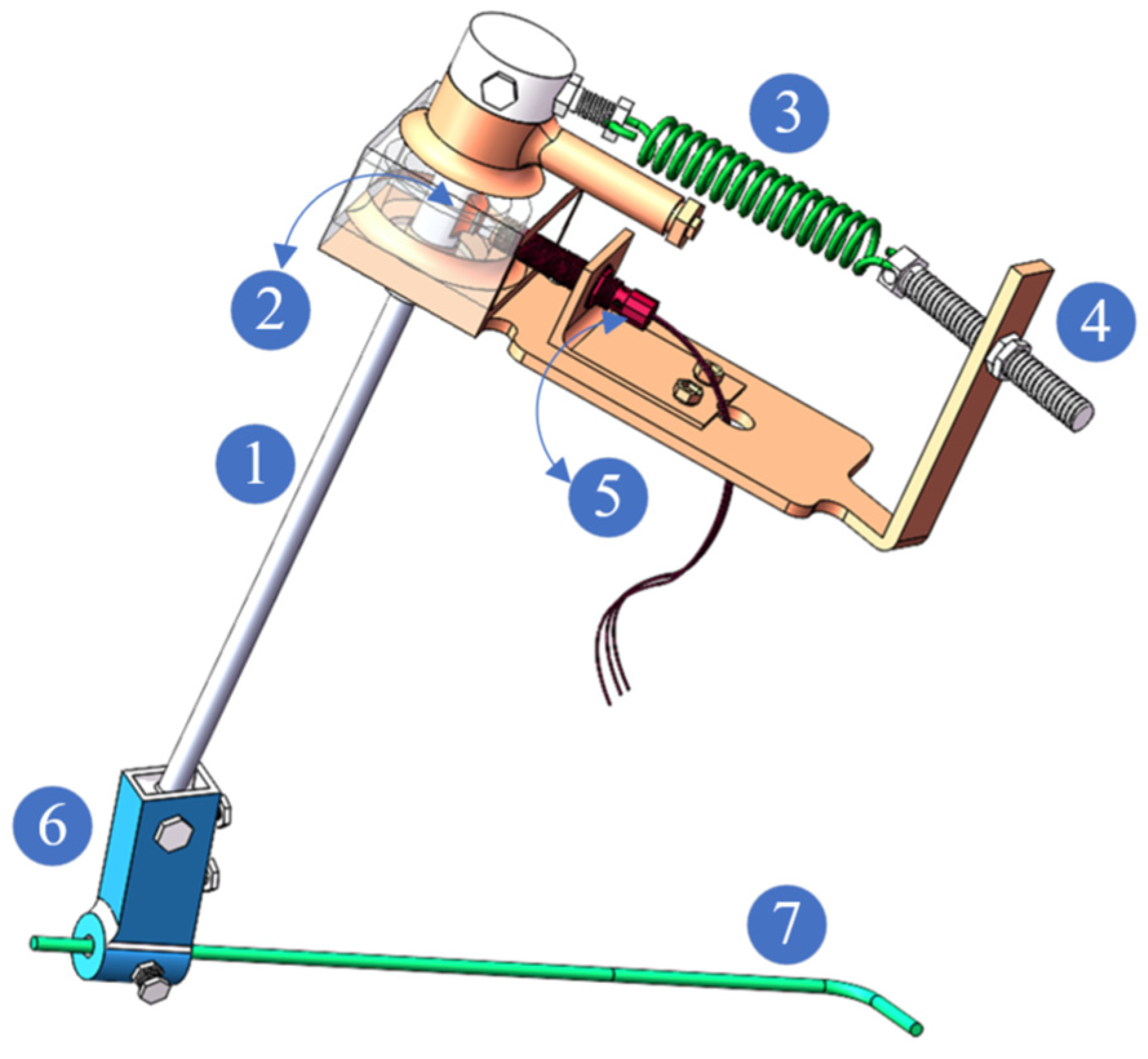

2.1.2. Sensor System

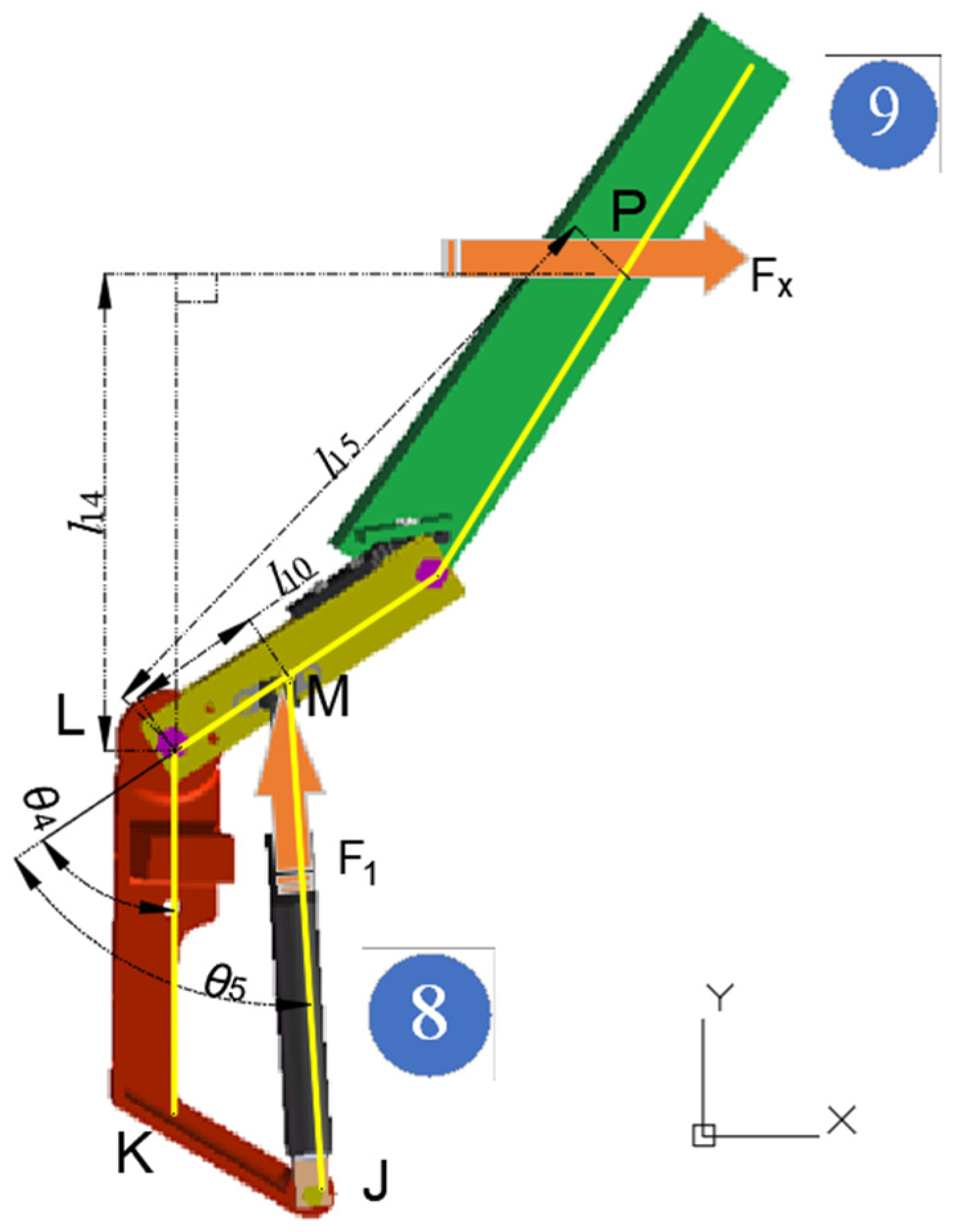

2.1.3. Functions and Working Principles of Key Components

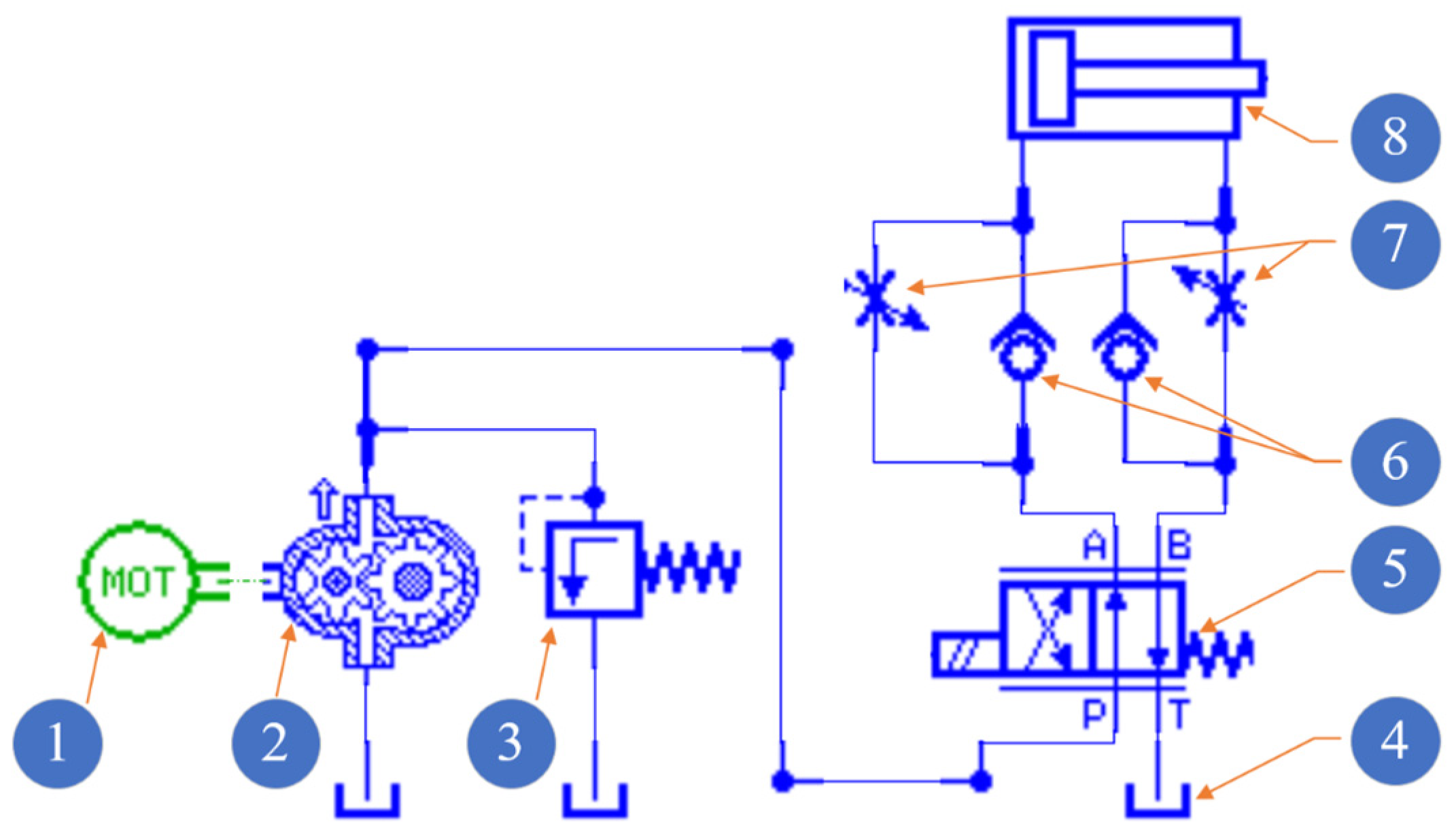

2.1.4. Hydraulic System

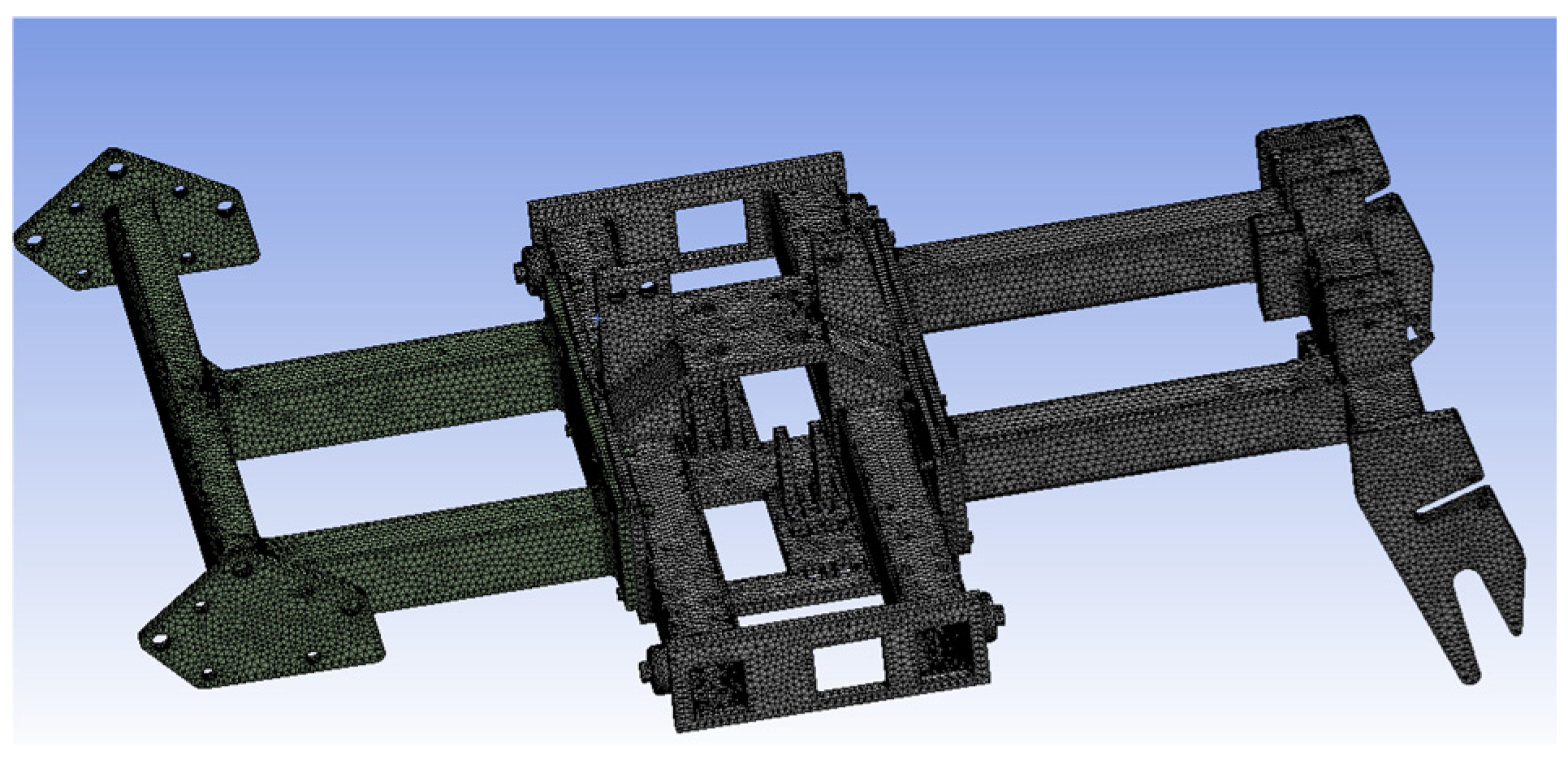

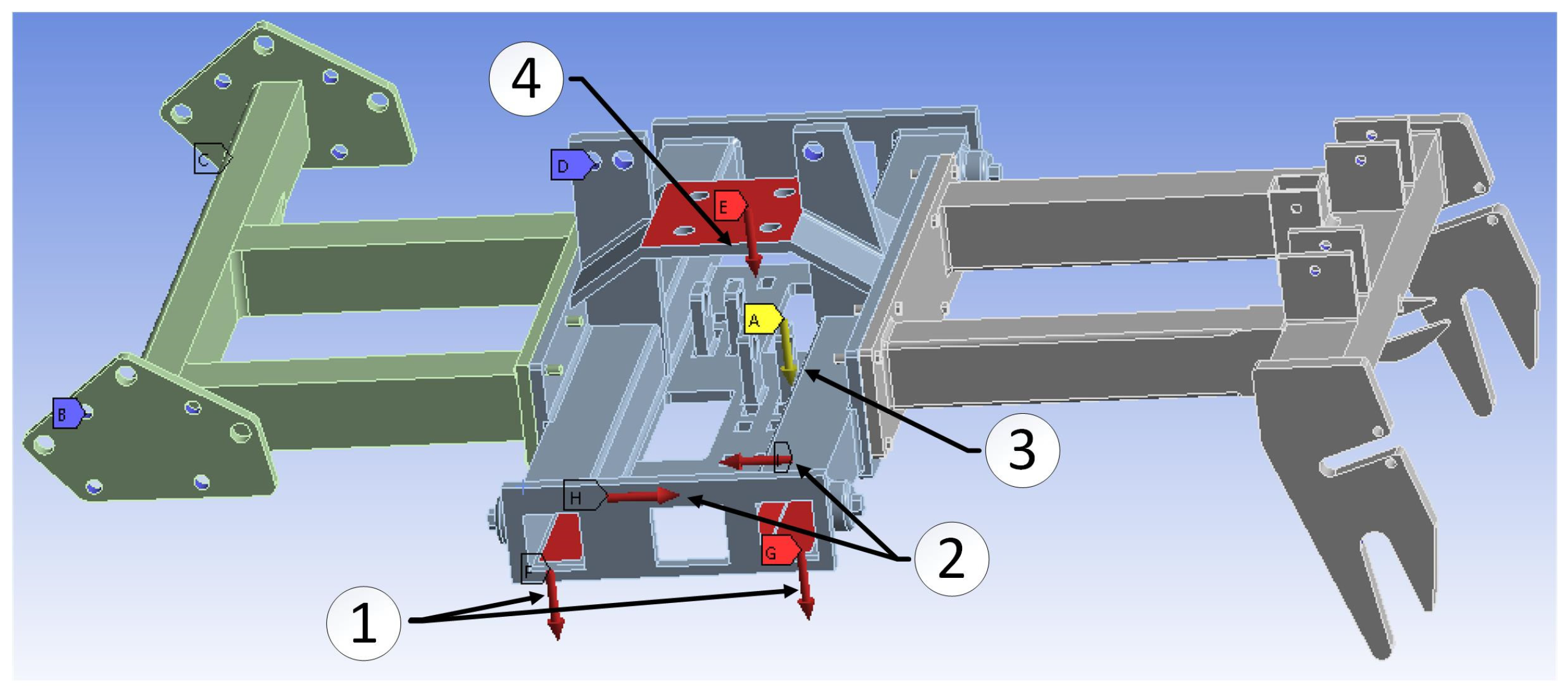

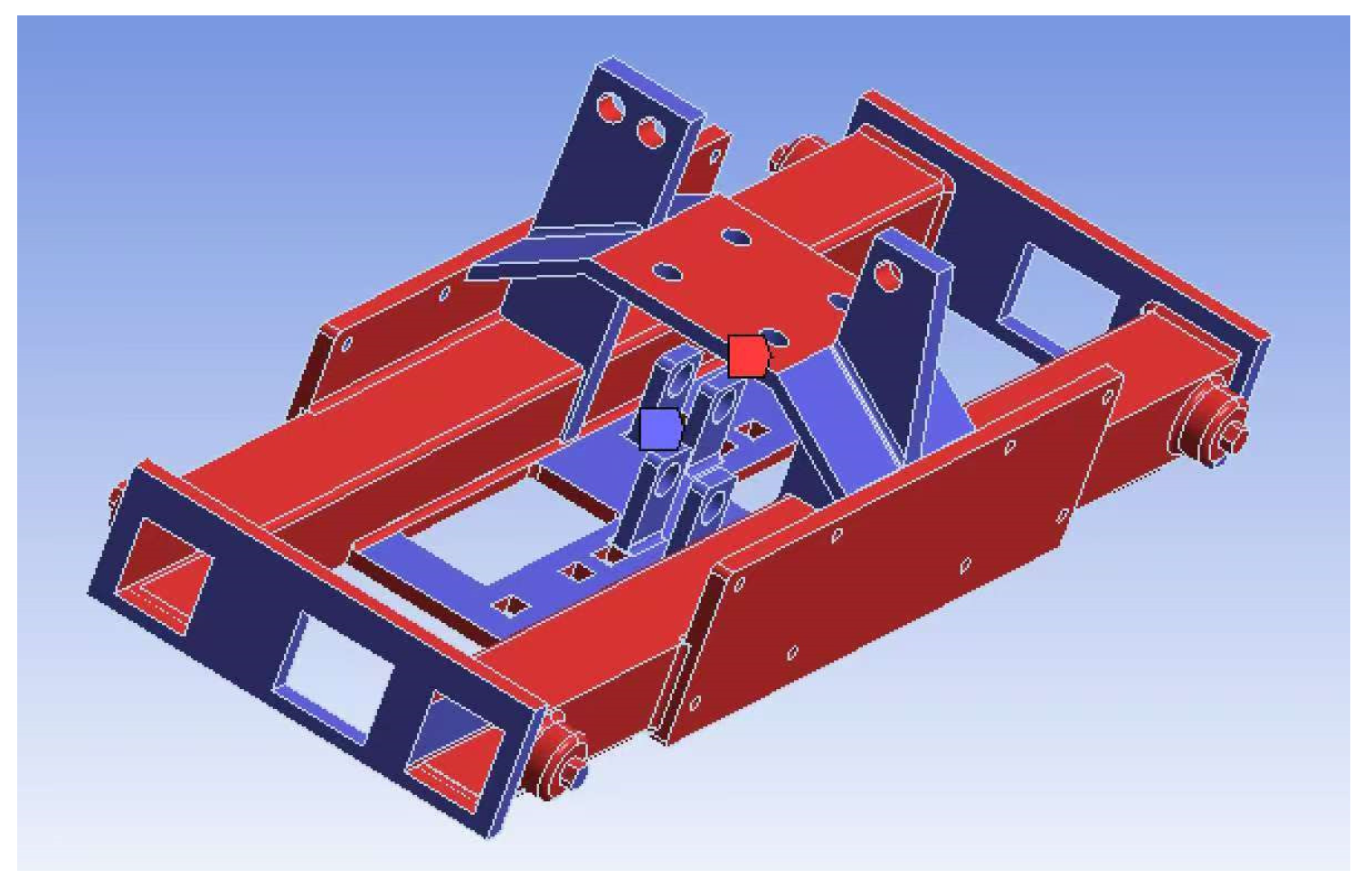

2.2. Finite Element Model of the Chassis

2.2.1. Ansys and SolidWorks

2.2.2. Simulation and Preprocessing

2.3. Field Experiment

2.3.1. Experimental Conditions

2.3.2. Experimental Scheme

3. Results

3.1. Results and Analysis of Finite Element Simulation

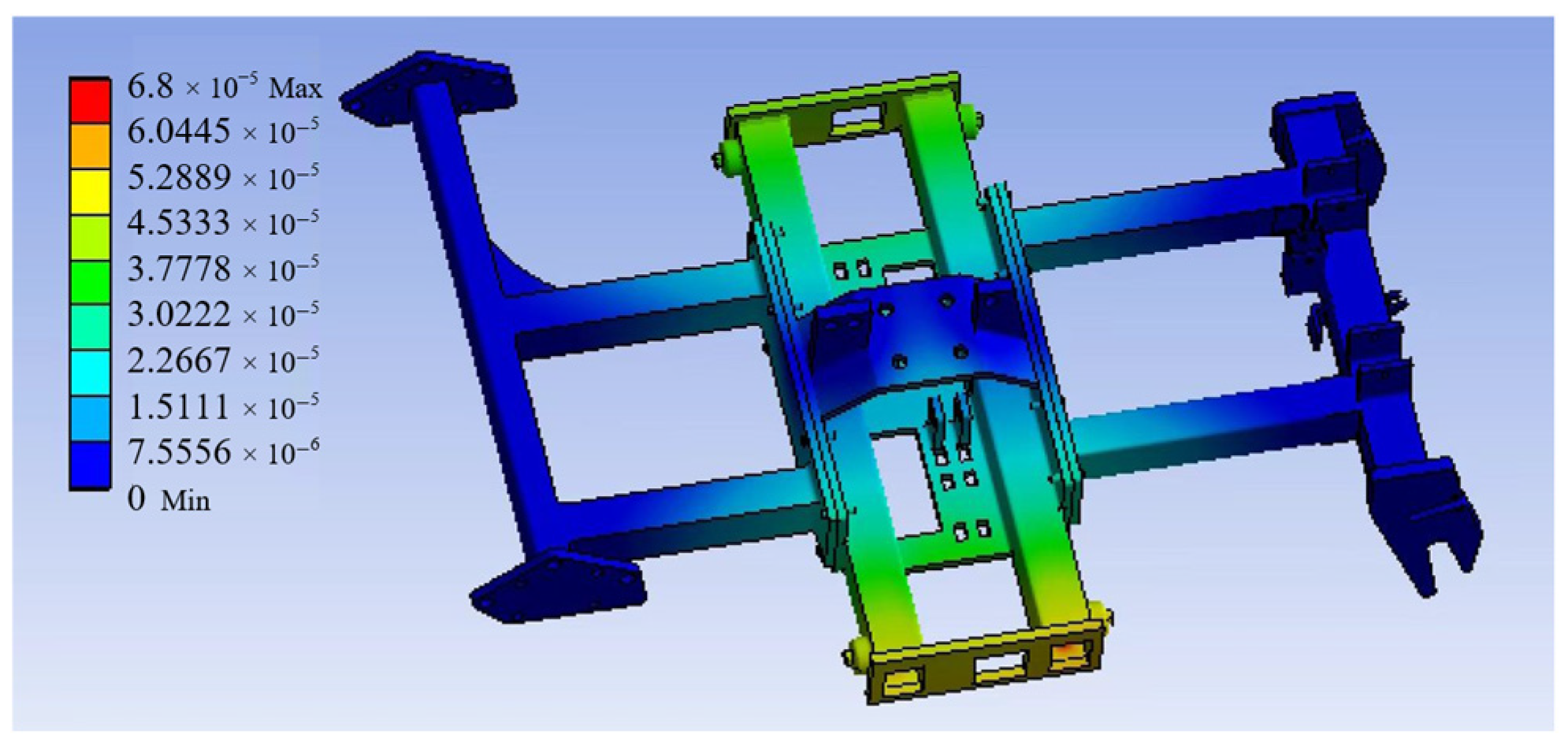

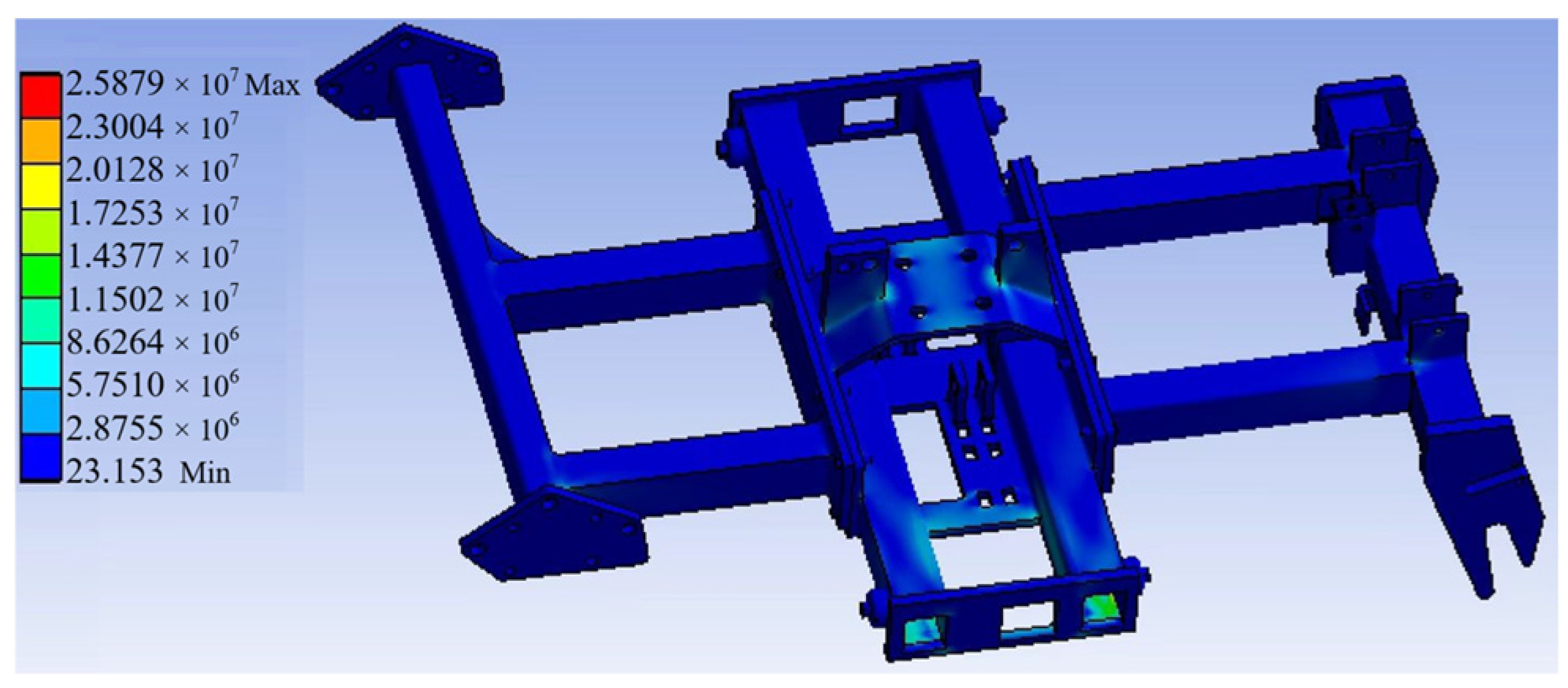

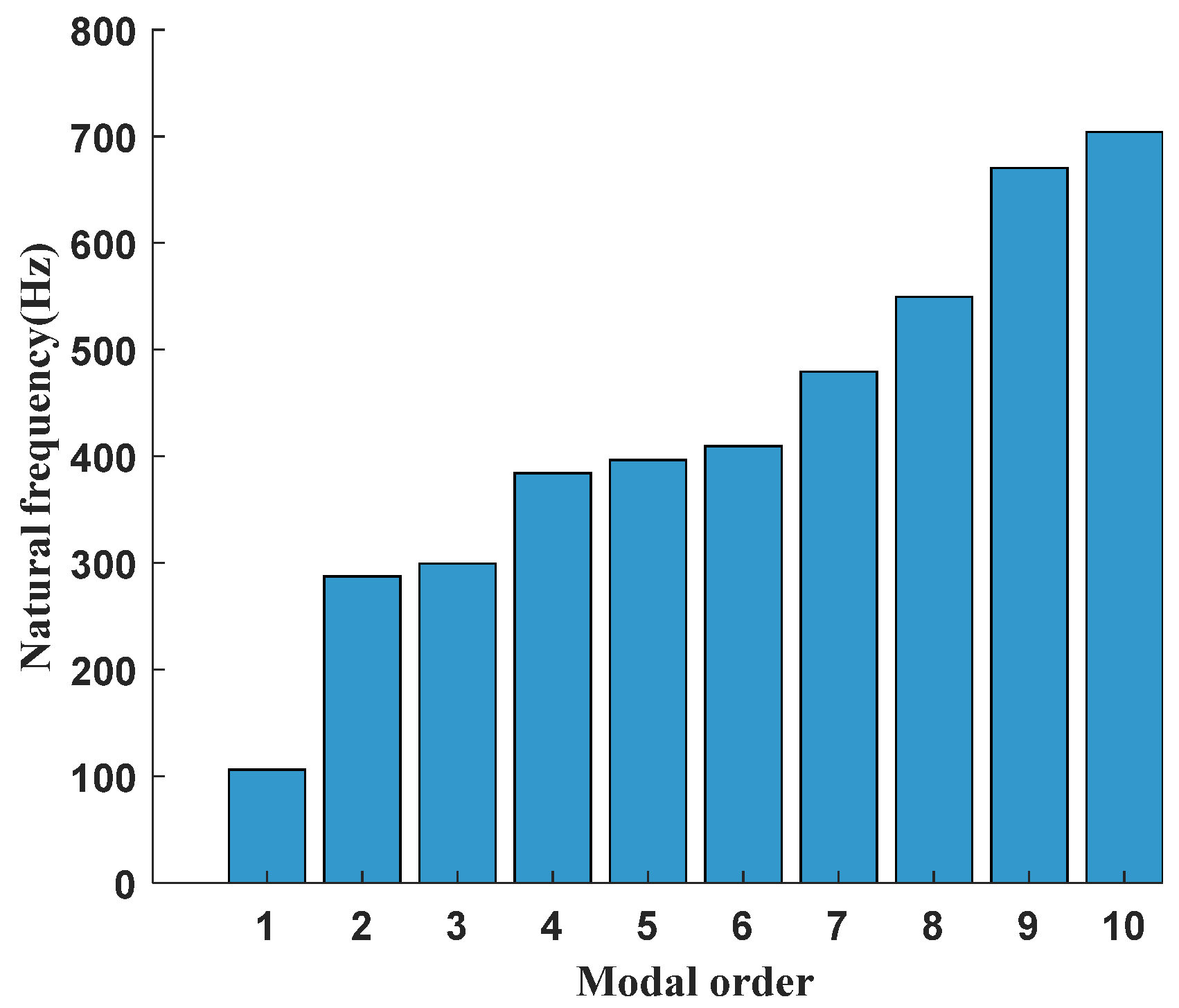

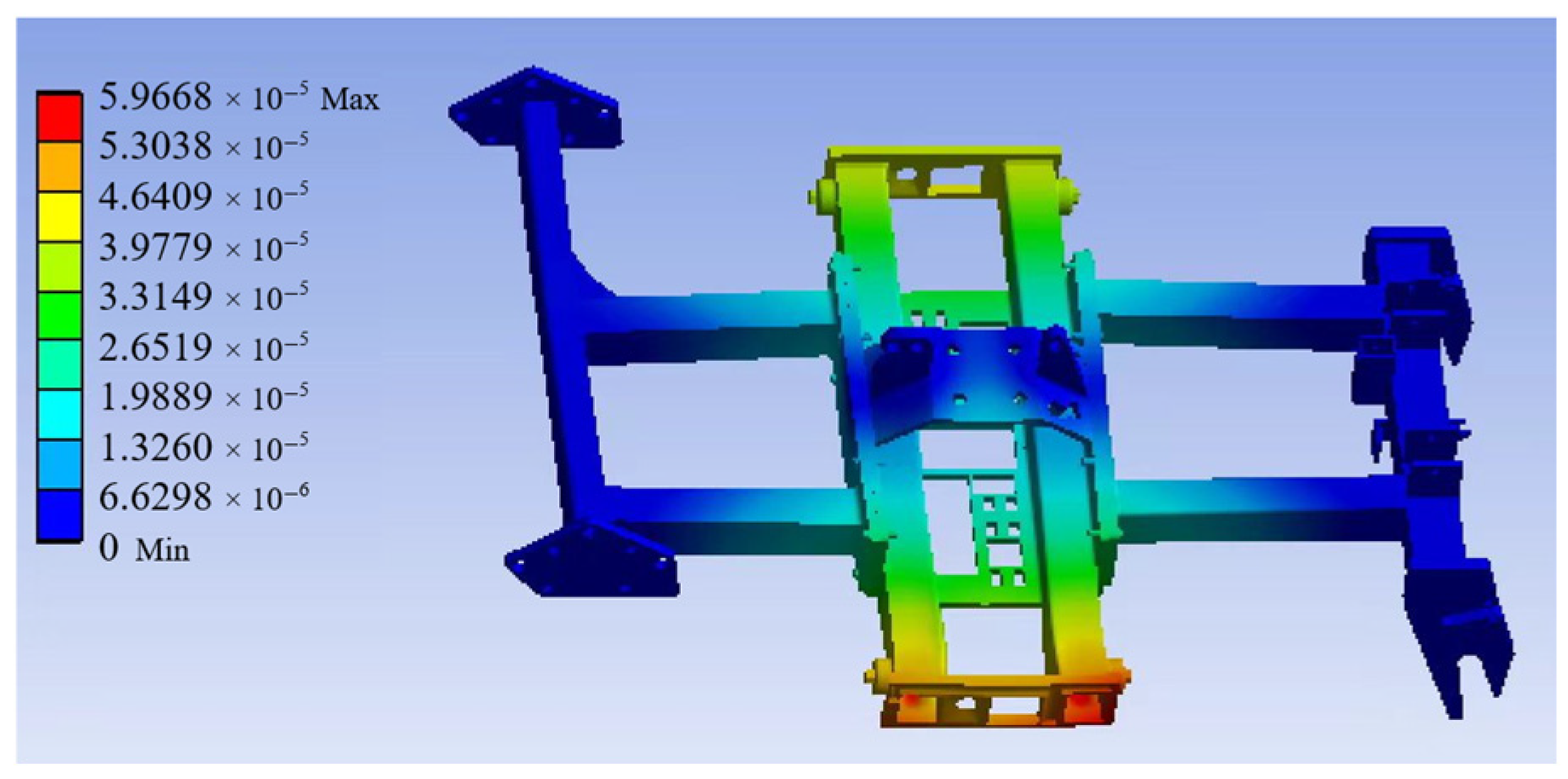

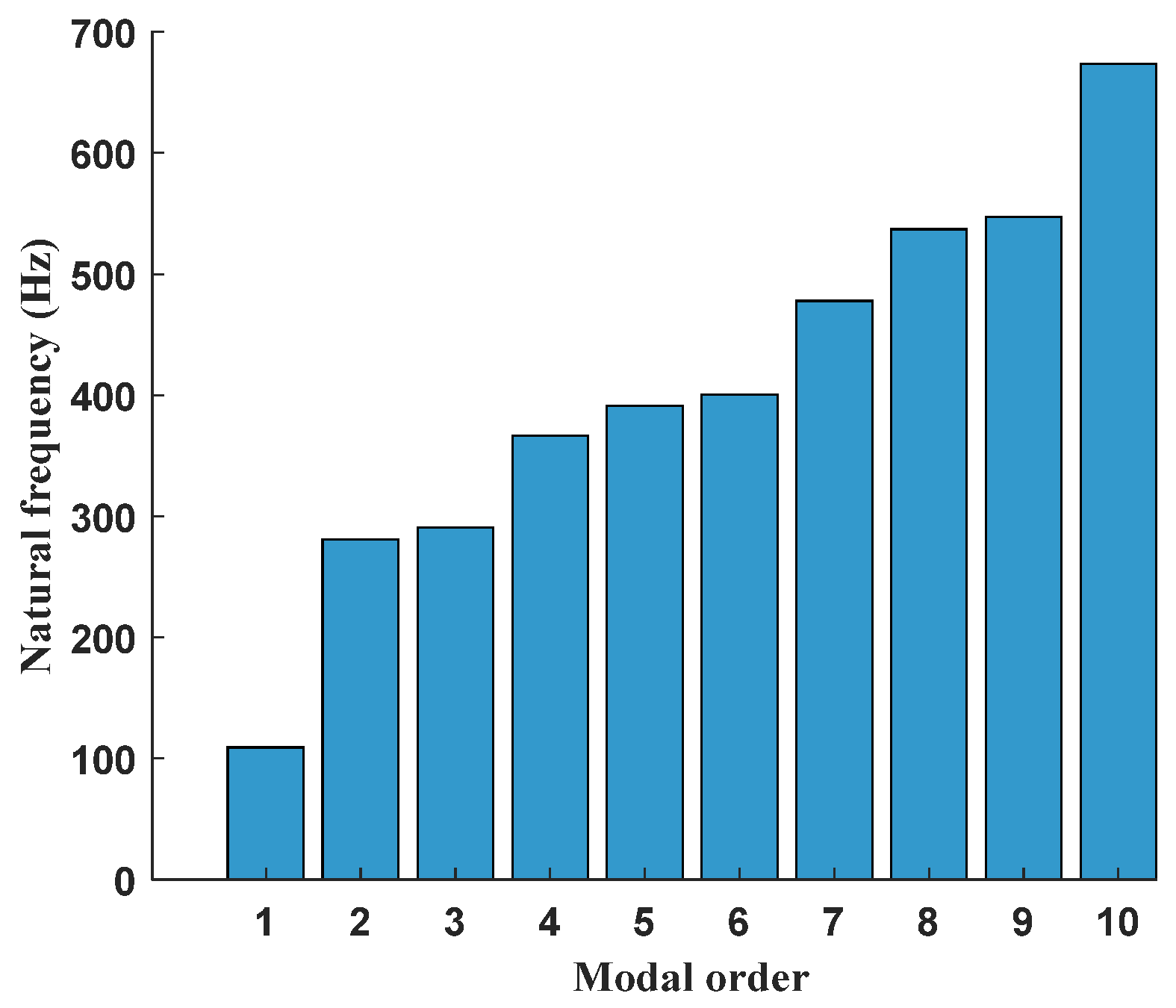

3.1.1. Static and Modal Analysis of the Chassis

3.1.2. Topological Optimization and Validation of the Chassis Structure

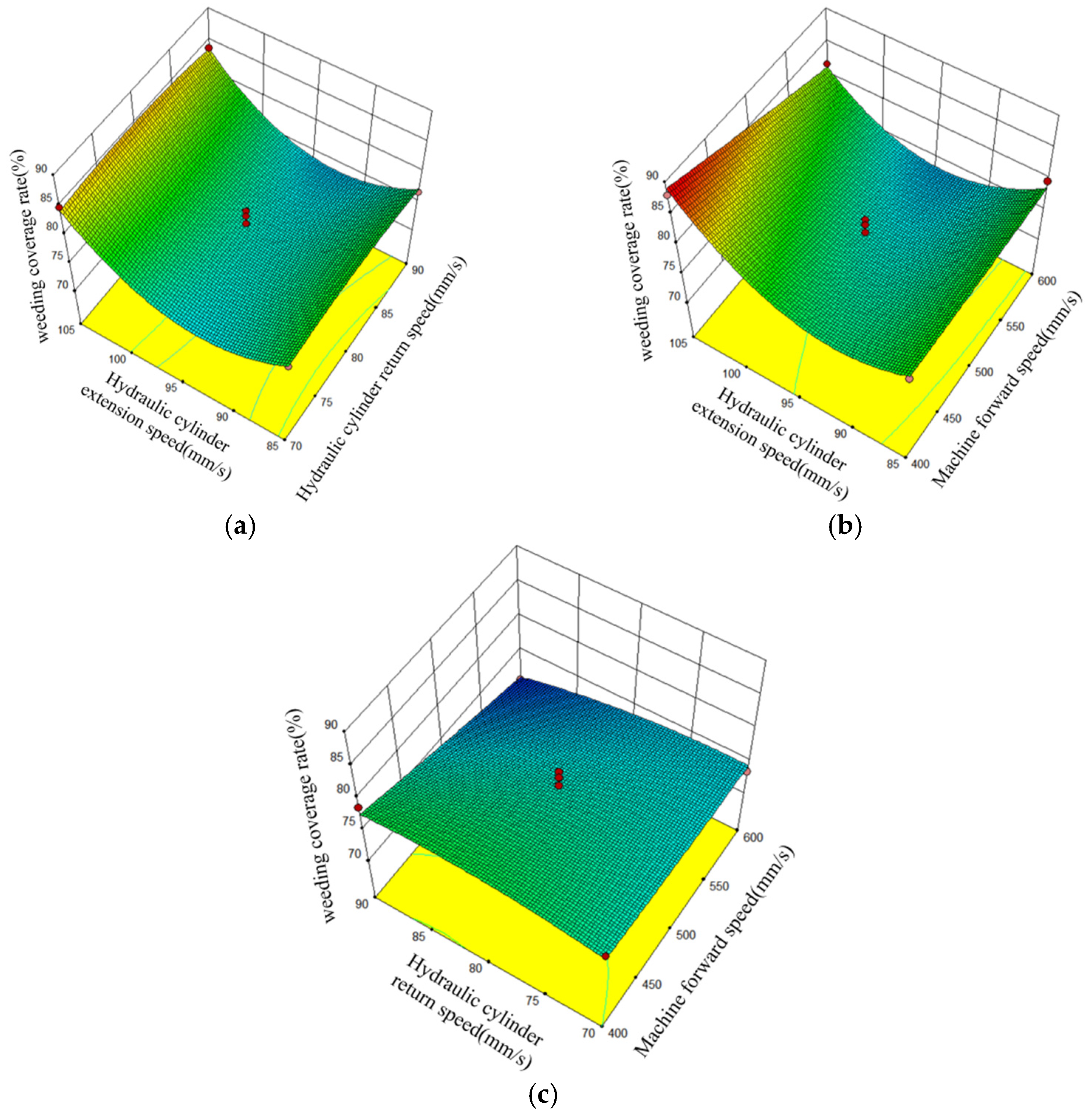

3.2. Field Experiments Results and Analysis

4. Discussion

5. Conclusions

- (1)

- In this study, an orchard intra-plant weeder was designed and theoretically analyzed and calculated. The machine is suitable for orchard environments with sandy soil, with row spacing greater than 3 m and plant spacing greater than 40 cm. The weeding machine integrates sensor technology, row width adjustment devices, depth-limiting devices, inter-row weeding components, and hydraulic systems, providing an intelligent solution for orchard intra-row weeding.

- (2)

- After performing static and modal analyses on the machine chassis of the inter-row weeding machine, the results show that the chassis has good stiffness and safety under static loads. The maximum deformation is 0.068 mm, and the maximum equivalent stress is 25.88 MPa, which is below the designed allowable stress. In the modal analysis, the natural frequency range of the chassis is 106.43 to 703.82 Hz, and the excitation frequencies are not within this range, ensuring that resonance will not occur during actual operations. Furthermore, through topology optimization using the variable density method, the chassis structure was optimized. The optimized bracket weight was reduced by 8%, while meeting the strength and stiffness requirements.

- (3)

- Based on the field experiments and regression analysis results, the extension speed of the hydraulic cylinder has a significant impact on the weeding coverage rate, while the forward speed of the machine and the return speed of the hydraulic cylinder have no significant effect. Overall, this experiment indicates that the inter-row weeding machine effectively meets the weeding requirements. By selecting optimal parameters, a high weeding coverage rate can be achieved, while also demonstrating excellent obstacle avoidance stability.

6. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Sebastian, S.; Kalita, K. Theoretical analysis and design of inter cum intra-row wetland paddy field weeder. Crop. Prot. 2024, 181, 106696. [Google Scholar] [CrossRef]

- Jiao, J.K.; Hu, L.; Chen, G.L.; Chen, C.W.; Zang, Y. Development and experimentation of intra-row weeding device for organic rice. Agriculture 2024, 14, 146. [Google Scholar] [CrossRef]

- Cabrera-Pérez, C.; Llorens, J.; Escolà, A.; Royo-Esnal, A.; Recasens, J. Organic mulches as an alternative for under-vine weed management in Mediterranean irrigated vineyards: Impact on agronomic performance. Eur. J. Agron. 2023, 145, 126798. [Google Scholar] [CrossRef]

- Roberts, J.; Florentine, S. A review of the biology, distribution patterns and management of the invasive species Amaranthus palmeri S. Watson (Palmer amaranth): Current and future management challenges. Weed. Res. 2022, 62, 113–122. [Google Scholar] [CrossRef]

- Ren, J.; Li, F.D.; Yin, C.B. Orchard grass safeguards sustainable development of fruit industry in China. J. Clean. Prod. 2023, 382, 135291. [Google Scholar] [CrossRef]

- Cordill, C.; Grift, T.E. Design and testing of an intra-row mechanical weeding machine for corn. Biosyst. Eng. 2011, 110, 247–252. [Google Scholar] [CrossRef]

- Pradel, M.; de Fays, M.; Seguineau, C. Comparative life cycle assessment of intra-row and inter-row weeding practices using autonomous robot systems in French vineyards. Sci. Total. Environ. 2022, 838, 156441. [Google Scholar] [CrossRef]

- Palma-Guillén, A.; Salicrú, M.; Nadal, A.; Serrat, X.; Nogués, S. Non-chemical weed management for sustainable rice production in the Ebro Delta. Weed. Res. 2024, 64, 227–236. [Google Scholar] [CrossRef]

- Andreasen, C.; Vlassi, E.; Salehan, N. Laser weeding of common weed species. Front. Plant. Sci. 2024, 15, 1375164. [Google Scholar] [CrossRef]

- Weisberger, D.; Ray, M.A.; Basinger, N.T.; Thompson, J.J. Chemical, ecological, other? Identifying weed management typologies within industrialized cropping systems in Georgia (US). Agric. Hum. Values 2024, 41, 935–953. [Google Scholar] [CrossRef]

- Cabrera-Pérez, C.; Royo-Esnal, A.; Recasens, J. Herbicidal effect of different alternative compounds to control Conyza bonariensis in vineyards. Agronomy 2022, 12, 960. [Google Scholar] [CrossRef]

- Fan, Q.Q.; Shen, Y.; Yang, Y.; Zhang, Q.M. A review of remediation strategies for diphenyl ether herbicide contamination. Toxics 2024, 12, 397. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Guo, R.Y.; Liang, X.G.; Yao, B.; Yan, S.W.; Guo, Y.A.; Han, Y.H.; Cui, J.S. Pollution characteristics, ecological and health risks of herbicides in a drinking water source and its inflowing rivers in North China. Environ. Pollut. 2023, 334, 122130. [Google Scholar] [CrossRef]

- Mattiello, A.; Novello, N.; Cornu, J.Y.; Babst-Kostecka, A.; Poscic, F. Copper accumulation in five weed species commonly found in the understory vegetation of Mediterranean vineyards. Environ. Pollut. 2023, 329, 121675. [Google Scholar] [CrossRef] [PubMed]

- Melander, B.; Lattanzi, B.; Pannacci, E. Intelligent versus non-intelligent mechanical intra-row weed control in transplanted onion and cabbage. Crop. Prot. 2015, 72, 1–8. [Google Scholar] [CrossRef]

- Zawada, M.; Legutko, S.; Gościańska-Łowińska, J.; Szymczyk, S.; Nijak, M.; Wojciechowski, J.; Zwierzyński, M. Mechanical Weed Control Systems: Methods and Effectiveness. Sustainability 2023, 15, 15206. [Google Scholar] [CrossRef]

- Gagliardi, L.; Fontanelli, M.; Luglio, S.M.; Frasconi, C.; Peruzzi, A.; Raffaelli, M. Evaluation of sustainable strategies for mechanical under-row weed control in the vineyard. Agronomy 2023, 13, 3005. [Google Scholar] [CrossRef]

- McCollough, M.R.; Poulsen, F.; Melander, B. Informing the operation of intelligent automated intra-row weeding machines in direct-sown sugar beet (Beta vulgaris L.): Crop effects of hoeing and flaming across early growth stages, tool working distances, and intensities. Crop. Prot. 2024, 177, 106562. [Google Scholar] [CrossRef]

- Machleb, J.; Peteinatos, G.G.; Kollenda, B.L.; Andújar, D.; Gerhards, R. Sensor-based mechanical weed control: Present state and prospects. Comput. Electron. Agric. 2020, 176, 105638. [Google Scholar] [CrossRef]

- Sozzi, M.; Pasquetti, E.; De Ros, A.; Ferro, F. Performance evaluation of automated implement for vineyard mechanical weed control. In Proceedings of the 20th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 26–28 May 2021. [Google Scholar]

- Reiser, D.; Sehsah, E.; Bumann, O.; Morhard, J.; Griepentrog, H.W. Development of an autonomous electric robot implement for intra-row weeding in vineyards. Agriculture 2019, 9, 18. [Google Scholar] [CrossRef]

- Lei, X.H.; Qi, Y.N.; Zeng, J.; Yuan, Q.C.; Chang, Y.H.; Lyu, X.L. Development of unilateral obstacle-avoiding mower for Y-trellis pear orchard. Int. J. Agric. Biol. Eng. 2022, 15, 71–78. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, J.L.; Su, W.H.; Hu, R. A SPH-YOLOv5x-based automatic system for intra-row weed control in lettuce. Agronomy 2023, 13, 2915. [Google Scholar] [CrossRef]

- Assirelli, A.; Liberati, P.; Santangelo, E.; Del Giudice, A.; Civitarese, V.; Pari, L. Evaluation of sensors for poplar cutting detection to be used in intra-row weed control machine. Comput. Electron. Agric. 2015, 115, 161–170. [Google Scholar] [CrossRef]

- Mao, J.; Zhao, Z.; Li, X.Y.; Zhao, H.G.; Lin, C.Y. Comprehensive benefit of crop straw return volume under sustainable development management concept in Heilongjiang, China. Sustainability 2023, 15, 4129. [Google Scholar] [CrossRef]

- Pan, H.Y.; Zheng, X.Y.; Tian, X.; Geng, Y.; Zhang, X.H.; Xiao, S.J.; Gao, Z.Y.; Yang, Y.X.; Liu, X.C.; Li, L.; et al. Toward sustainable crop production in China: A co-benefits evaluation. J. Clean. Prod. 2022, 361, 132285. [Google Scholar] [CrossRef]

- Zhao, S.; Lu, C.; Li, S.; Xu, L.; Ma, S.; Niu, C.; Yan, C.; Tan, H. Optimization and experiment on the performance of kiwi inter-plant mechanical obstacle avoidance weeding machine. Agric. Mech. Res. 2023, 45, 134–142. [Google Scholar]

- Xie, K.T.; Zhang, Z.G.; Wang, Y.C.; Tang, J.X.; Yu, X.L. Simulation analysis and test of Panax notoginseng excavating shovel based on LS-DYNA. J. Northeast. Agric. Univ. 2021, 52, 79–88. [Google Scholar]

- Liu, W.K.; Li, S.F.; Park, H.S. Eighty years of the finite element method: Birth, evolution, and future. Arch. Comput. Method. Eng. 2022, 29, 4431–4453. [Google Scholar] [CrossRef]

- Ji, W.; Qian, Z.J.; Xu, B.; Tang, W.; Li, J.L.; Zhao, D.A. Grasping damage analysis of apple by end-effector in harvesting robot. J. Food. Process. Eng. 2017, 40, 8. [Google Scholar] [CrossRef]

- Guan, C.S.; Fu, J.J.; Xu, L.; Jiang, X.Z.; Wang, S.L.; Cui, Z.C. Study on the reduction of soil adhesion and tillage force of bionic cutter teeth in secondary soil crushing. Biosyst. Eng. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Ni, J.H.; Dong, J.T.; Ullah, I.; Mao, H.P. CFD simulation of sucrose flow field in the stem of greenhouse tomato seedling. Int. J. Agric. Biol. Eng. 2022, 15, 111–115. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Xu, W.; Li, R.R.; Zhou, J.C.; Luo, Z.Y. Study on sustainable lightweight design of airport waiting chair frame structure based on ANSYS Workbench. Sustainability 2024, 16, 5350. [Google Scholar] [CrossRef]

- Guo, M.X.; Fang, M.Z.; Wang, L.Y.; Hu, J.; Qi, J. Performance optimization design study of box-type substations subjected to the combined effects of wind, snow, and seismic loads. Appl. Sci. 2024, 14, 3958. [Google Scholar] [CrossRef]

- Yu, C.; Xu, L.; Wang, Q.; Yuan, Q.; Ma, S.; Niu, C.; Yuan, X.; Zeng, J.; Wang, S.; Chen, C. Design and experiment of bilateral operation intra-row auto obstacle avoidance weeder for trellis cultivated grape. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–9. [Google Scholar]

- Naseem, Z.; Iqbal, J.; Zahid, M.; Shaheen, A.; Hussain, S.; Yaseen, W. Use of hydrogen-bonded supramolecular eutectic solvents for eco-friendly extraction of bioactive molecules from Cymbopogon citratus using Box–Behnken design. J. Food. Meas. Charact. 2021, 15, 1487–1498. [Google Scholar] [CrossRef]

- Jia, W.D.; Tai, K.L.; Wang, X.W.; Dong, X.; Ou, M.X. Design and simulation of intra-row obstacle avoidance shovel-type weeding machine in orchard. Agriculture 2024, 14, 1124. [Google Scholar] [CrossRef]

- Wang, X.Z.; Hong, T.Y.; Fang, W.Q.; Chen, X.Y. Optimized design for vibration reduction in a residual film recovery machine frame based on modal analysis. Agriculture 2024, 14, 543. [Google Scholar] [CrossRef]

- Tyflopoulos, E.; Steinert, M. A comparative study of the application of different commercial software for topology optimization. Appl. Sci. 2022, 12, 611. [Google Scholar] [CrossRef]

- Najafi, M.; Rahimi, R.; Bräse, S. Synthesis of porphyrin-based MOF/Cloisite-30B nanocomposite for selective dye adsorption: Optimization by Design-Expert, adsorption, and kinetic study. J. Inorg. Organomet. Polym. Materi. 2024, 34, 3817–3830. [Google Scholar] [CrossRef]

- Qin, W.C.; Xue, X.Y.; Cui, L.F.; Zhou, Q.Q.; Xu, Z.F.; Chang, F.L. Optimization and test for spraying parameters of cotton defoliant sprayer. Int. J. Agric. Biol. Eng. 2016, 9, 63–72. [Google Scholar]

- Huang, J.C.; Tan, L.; Tian, K.P.; Zhang, B.; Ji, A.M.; Liu, H.L.; Shen, C. Formation mechanism for the laying angle of hemp harvester based on ANSYS-ADAMS. Int. J. Agric. Biol. Eng. 2023, 16, 109–115. [Google Scholar] [CrossRef]

- Lati, R.N.; Siemens, M.C.; Rachuy, J.S.; Fennimore, S.A. Intrarow weed removal in broccoli and transplanted lettuce with an intelligent cultivator. Weed. Technol. 2016, 30, 655–663. [Google Scholar] [CrossRef]

| Levels | Factors | ||

|---|---|---|---|

| Hydraulic Cylinder Return Speed (mm/s) | Machine Forward Speed (mm/s) | Hydraulic Cylinder Extension Speed (mm/s) | |

| −1 | 70 | 400 | 85 |

| 0 | 80 | 500 | 95 |

| 1 | 90 | 600 | 105 |

| Modal Order | Natural Frequency Before Optimization/Hz | Natural Frequency After Optimization/Hz |

|---|---|---|

| 1 | 109 | 106.43 |

| 2 | 280.54 | 287.46 |

| 3 | 290.82 | 299.5 |

| 4 | 366.7 | 384.34 |

| 5 | 391.32 | 396.62 |

| 6 | 400.15 | 409.63 |

| 7 | 477.8 | 479.53 |

| 8 | 536.99 | 549.55 |

| 9 | 547.09 | 670.15 |

| 10 | 673.49 | 703.82 |

| Test Number | Factors | Weeding Operation Coverage Rate (%) | ||

|---|---|---|---|---|

| Machine Forward Speed X1 (mm/s) | Hydraulic Cylinder Return Speed X2 (mm/s) | Hydraulic Cylinder Extension Speed X3 (mm/s) | ||

| 1 | −1 | −1 | 0 | 76.5 |

| 2 | 1 | −1 | 0 | 73.4 |

| 3 | −1 | 1 | 0 | 78.7 |

| 4 | 1 | 1 | 0 | 70.3 |

| 5 | −1 | 0 | −1 | 79.0 |

| 6 | 1 | 0 | −1 | 79.8 |

| 7 | −1 | 0 | 1 | 88.0 |

| 8 | 1 | 0 | 1 | 81.7 |

| 9 | 0 | −1 | −1 | 78.5 |

| 10 | 0 | 1 | −1 | 76.7 |

| 11 | 0 | −1 | 1 | 84.8 |

| 12 | 0 | 1 | 1 | 83.8 |

| 13 | 0 | 0 | 0 | 70.3 |

| 14 | 0 | 0 | 0 | 74.4 |

| 15 | 0 | 0 | 0 | 76.6 |

| 16 | 0 | 0 | 0 | 78.8 |

| 17 | 0 | 0 | 0 | 77.9 |

| Source | Sum of Squares | df | Mean Square | F Value | p Value |

|---|---|---|---|---|---|

| Model | 305.41 | 9 | 33.93 | 4.59 | 0.0286 |

| X1 | 36.13 | 1 | 36.13 | 4.88 | 0.0628 |

| X2 | 1.71 | 1 | 1.71 | 0.23 | 0.6452 |

| X3 | 73.81 | 1 | 73.81 | 9.98 | 0.0160 |

| X1 × X2 | 7.02 | 1 | 7.02 | 0.95 | 0.3624 |

| X1 × X3 | 12.60 | 1 | 12.60 | 1.70 | 0.2331 |

| X2 × X3 | 0.16 | 1 | 0.16 | 0.022 | 0.8872 |

| X12 | 0.095 | 1 | 0.095 | 0.013 | 0.9131 |

| X22 | 4.42 | 1 | 4.42 | 0.60 | 0.4647 |

| X32 | 171.12 | 1 | 171.12 | 23.13 | 0.0019 |

| Residual | 51.79 | 7 | 7.40 | ||

| Lack of Fit | 5.73 | 3 | 1.91 | 0.17 | 0.9141 |

| Pure Error | 46.06 | 4 | 11.52 | ||

| Cor Total | 357.20 | 16 |

| This Study | Ref [23] | Ref [43] | |

|---|---|---|---|

| Driving method for weeding parts | Hydraulic drive | Pneumatically driven | Hydraulic drive |

| Applicable scene | Fruit trees | Low-growing vegetables and bright scenes | Low-growing vegetables and bright scenes |

| Obstacle detection methods | Combined approach of non-contact sensors and mechanical haptic structures | Machine vision inspection | Machine vision inspection |

| Weeding tools | Weeding shovel | Two weeding blades | Two weeding poles per unit |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, W.; Tai, K.; Dong, X.; Ou, M.; Wang, X. Design of and Experimentation on an Intelligent Intra-Row Obstacle Avoidance and Weeding Machine for Orchards. Agriculture 2025, 15, 947. https://doi.org/10.3390/agriculture15090947

Jia W, Tai K, Dong X, Ou M, Wang X. Design of and Experimentation on an Intelligent Intra-Row Obstacle Avoidance and Weeding Machine for Orchards. Agriculture. 2025; 15(9):947. https://doi.org/10.3390/agriculture15090947

Chicago/Turabian StyleJia, Weidong, Kaile Tai, Xiang Dong, Mingxiong Ou, and Xiaowen Wang. 2025. "Design of and Experimentation on an Intelligent Intra-Row Obstacle Avoidance and Weeding Machine for Orchards" Agriculture 15, no. 9: 947. https://doi.org/10.3390/agriculture15090947

APA StyleJia, W., Tai, K., Dong, X., Ou, M., & Wang, X. (2025). Design of and Experimentation on an Intelligent Intra-Row Obstacle Avoidance and Weeding Machine for Orchards. Agriculture, 15(9), 947. https://doi.org/10.3390/agriculture15090947