2.2. Dual Closed-Loop Optimal Control Framework of Greenhouse Crop Production System

A greenhouse crop production system has two subsystems, including microclimate subsystem and crop growth subsystem, which can be expressed as follows:

where

,

are the indoor climate states and crop growth states, respectively;

and

are the weather and control inputs of the actuators respectively; and

and

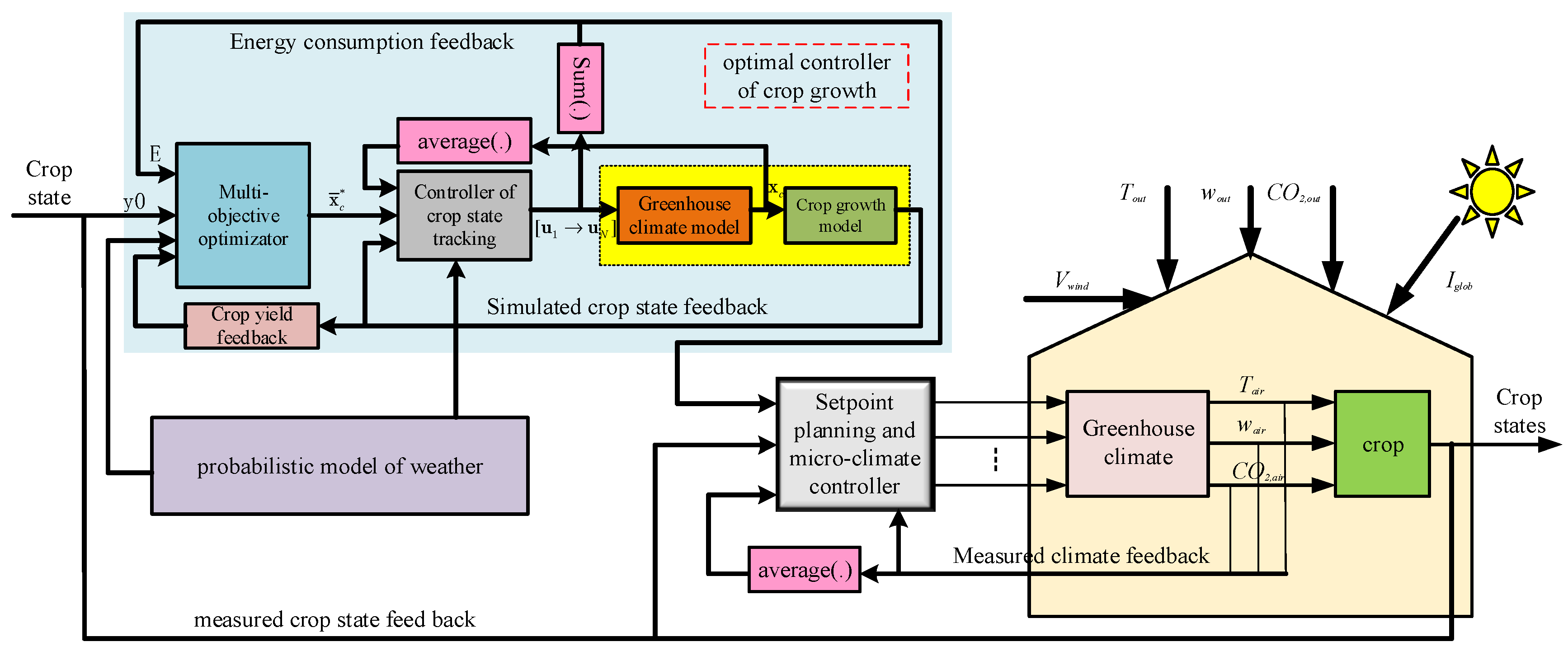

represent the environment subsystem and crop growth subsystem, respectively. The entire greenhouse crop production control system can be considered as a typical dual closed-loop control system, as shown in

Figure 1. The control system has two controllers, the outer loop controller is used to generate the daily setpoint of the greenhouse climate, and the inner loop controller is used to generate the control inputs of heating, fogging, ventilating, CO

2 enrichment and supplemental light to ensure the setpoint tracking control performance of the greenhouse climate.

Assuming that the crop-growth states and greenhouse climate can be accurately detected online, then the aim of greenhouse climate optimal control is to maximize the crop yield with the minimum energy input. However, due to both the great uncertainty of weather and to model error, the controllers must have the ability to correct the control error according to real-time feedback, which means a good control approach is important. In fact, in the dual closed-loop control system, the outer loop controller is a setpoint optimiser, and the daily setpoint can be obtained by maximizing crop yield and minimizing energy consumption.

From the dynamic characteristics of both subsystems, it can be known that the response speed of the crop growth subsystem is much slower than that of the greenhouse environment subsystem; thereby, the greenhouse crop production system behaves as a typical singular perturbation system with two time-scales [

29,

30,

31,

32]. In general, the greenhouse environment can be measured in real-time; for example, the microclimate can be detected every 5 min, but the sampling period of the crop growth states is set as 24 h. Therefore, the greenhouse climate setpoint generated by the outer controller is a daily average setpoint. Thus, a mechanism must be introduced to transform the daily average setpoint into the setpoint trajectory.

For some crops, such as tomato and cucumber, the crop yield can only be measured at harvest time, meaning that the overall crop growth and control process greenhouse climate must be simulated to estimate the crop yield and energy consumption. Then, by using the obtained control inputs and simulation climate, the energy consumption and crop yield can be calculated as follows:

where

,

are the transplant time and harvest time, respectively;

is the capacity of the actuator; and

denotes the number of actuators. If the greenhouse climate model and crop growth model have good simulation performance, then Equations (3) and (4) can accurately predict the total energy consumption and crop yield. Furthermore, the following important issues must be considered:

- (1)

Transforming the daily average setpoints of greenhouse climate into the setpoint trajectory.

- (2)

Studying an effective control strategy to ensure the desired control performance.

- (3)

Developing a surrogate-based optimisation method to optimise the setpoint of greenhouse climate.

The full methodological diagram is shown in

Figure 2.

2.4. Setpoint Trajectory Programming

- (1)

Temperature setpoint programming

According to crop growth models such as TOMGRO [

37] and TOMSIM [

25], crop growth is mainly affected by the average daily temperature, and the fluctuation of transient temperature does not have a large impact on crop growth when the ambient temperature fluctuates within the safe growth temperature range, such as 10~40 °C for a specific tomato cultivar. Therefore, the regulation of the temperature should focus on the daily average temperature rather than the transient temperature. Generally, the higher temperature contributes to photosynthesis, while the lower temperature can save much heating energy. Therefore, when programming the setpoint, we must maximize the photosynthesis rate and minimize the difference between indoor and outdoor temperatures as much as possible.

To achieve a good energy-saving performance in the greenhouse climate regulation process, the setpoint optimisation of indoor temperature must consider the following situations:

- (1)

If the daily mean temperature setpoint is not higher than the daily average outdoor temperature, then the real-time setpoint of indoor temperature should not be higher than the outside temperature . In this case, the heater must be turned off, and ventilation windows should be opened to regulate the indoor temperature. When the indoor temperature is higher than the setpoint due to solar radiation, the pad-and-fan system must be turned on to cool the greenhouse. The control strategies of ventilation and cooling are generated by the controller. As the energy consumption of the roof ventilation can be almost neglected, the main energy consumption mainly comes from the pad-and-fan system.

- (2)

If the daily mean temperature is higher than the daily average outdoor temperature, and the average outdoor temperature during the night is higher than a given minimum temperature, then the temperature setpoint should be as close as possible to the outdoor temperature. In this case, the temperature inside the greenhouse can only be regulated by ventilation to avoid the activation of the heating system and the pad cooling system. During the day, the temperature setpoint may be set as a higher value due to the thermal effect of solar radiation. In this case, the higher temperature can enhance photosynthesis without consuming extra heating energy.

- (3)

If the daily average outdoor temperature is lower than the temperature setpoint, and the outside temperature is smaller than the lower bound , then the temperature setpoint during the night should not be less than the lower bound.

In any case, the indoor temperature should not be higher than the upper bound that the crop can tolerate. denotes the daily mean temperature of a day, which represents the daily accumulated temperature; denotes the average daily outdoor temperature; and denotes the average temperature during the night outside the greenhouse.

Then, according to the three cases above, we can form the following rules for the planning of the temperature setpoint:

- Rule 1:

if , then when , it can set , otherwise it has .

- Rule 2:

if , and , then the temperature setpoint can be programmed separately in different time period of a day, and there are two cases, as follows:

- (a)

During the night:

- (b)

During the day: assume that there is an optimal temperature

for photosynthesis, then, when programming the temperature setpoint of the day, for a given accumulated temperature, the temperature setpoint should be as close as possible to the optimal temperature, but if the outdoor temperature is lower than the optimal temperature, the optimal photosynthetic temperature compensation must be carried out when the outdoor temperature is high, as shown in

Figure 3. Thus, we can reduce the energy consumption of the heating. Generally, during such period, solar radiation is strong, and raising the temperature can improve photosynthesis. Therefore, it is reasonable to raise the temperature setpoint to the optimal photosynthetic temperature. If the outdoor temperature is higher than the upper bound

, the setpoint must be set as

.

- Rule 3:

If

, and

, i.e., the weather is cold, then the temperature setpoint should not be less than the lower bound

for the protection of the crop. However, from an energy-saving point of view, setting a lower temperature setpoint during the night can greatly reduce the energy of the heating when the temperature setpoint is not more than the upper bound

. However, according to the photosynthesis model [

38], if the light intensity is not sufficient, raising the temperature alone cannot significantly improve the photosynthesis rate, as shown in

Figure 4. Consequently, during the periods 6:00~7:30 and 16:30~18:00, in which the light intensity is weak, the temperature setpoint should be set as a small value. The temperature setpoint can change with linear law during both periods, i.e., we can construct a daily trapezium setpoint trajectory, as shown in

Figure 5.

During the period

, the difference of the maximal and minimal temperature setpoints can be calculated as follows:

where

is the average temperature during the day;

is the temperature setpoint during the night;

and

represent the times 6:00 and 7:30, respectively; and

and

are the initial time and terminal time of a day, respectively. Then, the temperature setpoint during

can be determined as follows:

Because the setpoint during the day depends on and , the setpoint during the night should be suitable, such that the setpoint during may be close to with the minimum energy consumption.

- (2)

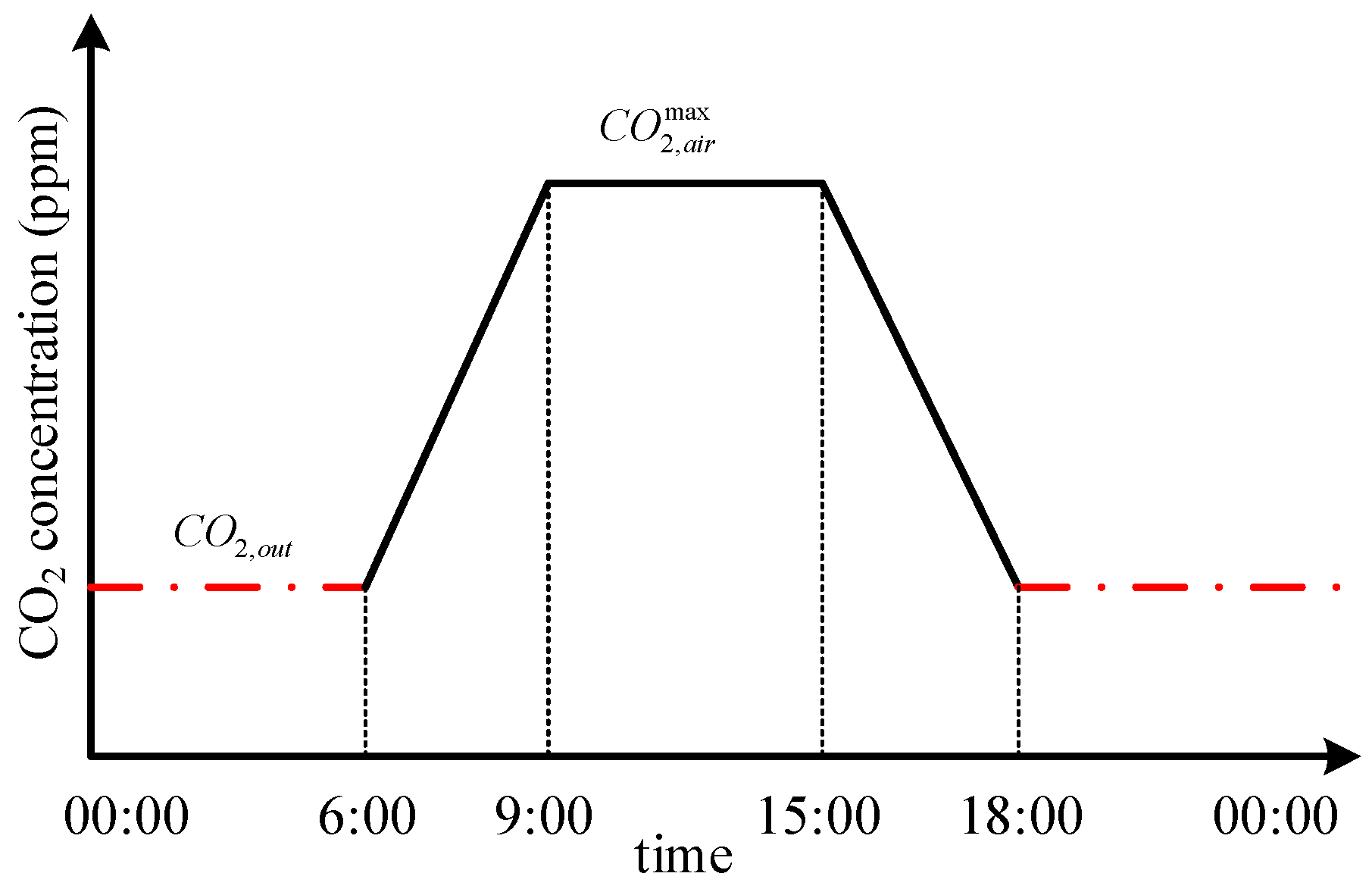

CO2 concentration setpoint programming

The CO

2 concentration can significantly impact crop growth. Generally, under favourable light conditions, high CO

2 concentrations can greatly promote crop growth. However, if the light is not sufficient, then only increasing indoor CO

2 concentration cannot significantly improve photosynthesis [

39,

40]. Therefore, it is not reasonable to set a fixed CO

2 concentration. The indoor CO

2 concentration must be adjusted according to the light conditions. During the day, CO

2 concentration setpoint should change with the solar radiation, and higher solar radiation requires a higher CO

2 concentration setpoint. If not considering the supplemental light at night, the CO

2 enrichment is not required to maintain the CO

2 concentration. As a result, we do not consider the nighttime setpoint trajectory programming. For a given maximum CO

2 concentration, the trajectory of the CO

2 concentration setpoint of a day can be constructed as a trapezoidal shape, as shown in

Figure 6.

For the Shanghai region in winter, generally, the solar radiation gradually increases from 6:00, but before 9:00 is not strong. In this case, it is not suitable to set a higher CO2 concentration. A reasonable method is to make the indoor CO2 concentrations gradually increase with solar radiation. Similarly, the indoor CO2 concentrations should be reduced between 15:00 and 18:00 due to the sunset. However, the setting should not be lower than the outdoor CO2 concentration, and the lower bound of the indoor CO2 concentration setpoint can be equal to the outdoor CO2 concentration.

2.5. Model-Based Interpolation Control Strategy

If the optimal setpoint of the greenhouse climate is obtained, then an effective control strategy must be introduced to ensure the tracking performance of the optimal setpoint. Many control methods have been proposed over the years to solve the greenhouse climate control problem. However, as the greenhouse climate is a strongly coupled nonlinear system, some traditional control methods, such as PID control, often have difficulty solving the multi-factor coordination control problem of greenhouse climate, while, though many Lyapunov-based control algorithms can achieve a good control performance in the simulation, they are usually complex, and require a small control step size. As a result, those control methods are difficult to be applied in the control engineering practices. In most cases, the threshold switch control is still the main control method in practice. As the response of crop growth to the environment is usually robust, a small control error may not significantly impact crop growth. Therefore, it is not necessary to drive the greenhouse climate to completely track the setpoint, i.e., a small tracking control error is acceptable.

To prevent the actuator from operating too frequently, the control step size should be reasonably set, such as at 15 min, or even 1 h, but must meanwhile ensure stability and control performance. In general, the control inputs can be expressed as a function with respect to the indoor and outdoor environmental factors, i.e., it can be described as follows:

where

represents a control law.

If using a greenhouse climate model to simulate the control under various conditions, then we can obtain many control rules. Based on the control rule samples, a control rule library can be constructed. In the control process, a new control strategy can be derived from the control rule library according to a given control condition. The main idea is to first generate a number of samples of initial indoor climate and weather, as well as a set of setpoint samples. For each setpoint sample, different initial conditions result in different control strategies. Suppose that there are

L samples of initial states and weather, and

S setpoint samples, then, for a given initial condition and setpoint, a one-step forward control simulation is carried out to search for a control strategy in the decision space to ensure the tracking error below a given threshold, as shown in

Figure 7. The details of this implementation procedure are presented in the

supplementary materials. For each setpoint,

N initial conditions can result in

N control rules, thereby, for

S samples of the setpoint,

control rules can be obtained. We can use the control rules in a control rule library. If the number of the initial condition samples is large enough, the control rule library can cover most control strategies of the control process. Therefore, it can easily generate a real-time control strategy using the interpolation method.

On hot days, this often uses ventilation or a wet curtain to cool the greenhouse, while if the weather is cold, the heating operation must be performed to maintain the indoor temperature. Due to the different heat dissipation conditions of greenhouses during the day and at night, such as the influence of solar radiation during the day, different interpolation surfaces of control rules for both daytime and nighttime must be constructed. As this study focuses on the cultivation period from 1 September to 31 December, the weather changes from hot to cold. In the early stages of the cultivation period, the wet curtain was usually turned on to cool the greenhouse, while, in later stages, heating is required to raise the indoor temperature. During this period, several control operations, including wet curtain cooling, roof ventilation, thermal screen, shading and heating are considered in the overall control process of the greenhouse climate.

As the indoor temperature is the primary environmental factor that greatly influences the crop growth, the control performance of the indoor temperature must firstly be ensured. Under such prerequisites, the light and CO2 concentration can be regulated to further improve crop growth. When obtaining the control strategies of the ventilation and pad, the supply fluxes of the supplemental light and CO2 can be calculated by the air fluxes. According to the energy dissipation conditions inside the greenhouse, four control strategy libraries can be built for different cases.

- (1)

Outside temperature is lower than the indoor temperature setpoint, i.e.,

Such a case implies that, if we want to drive the indoor temperature to the setpoint, the heating system must be turned on to provide enough heat. However, during the day, if the difference between the outdoor temperature and the temperature setpoint is small, then the solar radiation can compensate for heat loss to maintain the indoor temperature, i.e., the heating operation may not be adopted. Therefore, the control rule libraries of the nighttime and daytime must be established separately, i.e., the following sub-cases can be considered:

The heating control input is mainly affected by the indoor temperature setpoint and outdoor temperature, thereby, if ignoring the indoor temperature control error, the heating control inputs at night can be expressed as

. The interpolation surfaces of both control operations can be obtained by simulating a one-step forward control under different indoor temperature setpoints and outdoor temperature conditions, and the construction process of the interpolation surfaces is demonstrated by

Algorithm S1 in the Supplementary Materials.

In this study, the maximal control error of the temperature is set as 0.5 °C, and, at night, the domain of the temperature setpoint is defined as

and the outside temperature changes within

. The initial values of the floor temperature, top temperature and cover temperature are set as

,

,

, respectively, meaning that we can then obtain the interpolation surfaces of the heating operation for two cases during the night, as shown in

Figure 8.

As depicted in

Figure 8, it is evident that the higher the temperature setpoint and the lower the outdoor temperature, the greater power of the heating is required to maintain the temperature setpoint. Consequently, this leads to an increase of energy consumption. However, under cold weather conditions, unfolding the thermal screen at night can reduce the energy consumption of the heating by approximately 10%. Moreover, when the temperature setpoint is close to the outdoor temperature, the energy consumption does not increase, as shown in

Figure 8, because the heat transferred from the ground to the indoor air can compensate for the heat loss caused by the low outdoor temperature.

Under the given initial condition of greenhouse climate, the heating control strategy derived from the interpolation surface can ensure a control error not exceeding 0.5 °C. However, since the initial conditions of the actual control process may be different from the conditions of the one-step forward control simulation, the control strategy derived from the interpolation surface may lead to a larger control error than 0.5 °C. Therefore, the control strategy derived from the interpolation surface must be corrected according to the actual initial condition and control error, i.e., the corrected control strategy can be expressed as follows:

where

,

,

are the correction parameters of the floor temperature, the temperature of the top temperature and cover temperature, respectively, and

is the correction parameter of control error.

Besides the outdoor temperature and indoor temperature setpoint, the control input of heating during the day is also influenced by solar radiation. Strong solar radiation can reduce heat loss, meaning that the heating operation may not be turned on for energy saving. In some cases, roof windows may be opened to cool the greenhouse. However, if solar radiation cannot compensate for the heat loss, then the heating system must be activated to maintain the temperature. Therefore, both heating and ventilation operations during the day can be described as follows:

Generally, one can assume that the outdoor temperature, the temperature setpoint and the solar radiation are bounded by

,

,

, respectively. In this study, the domains of these three parameters are respectively set to

,

, and

. The construction process of the daytime control rule libraries is similar. Due to the difference of the control conditions, the actual heating and ventilation control strategies must be corrected:

where

,

,

,

,

are the correction parameters.

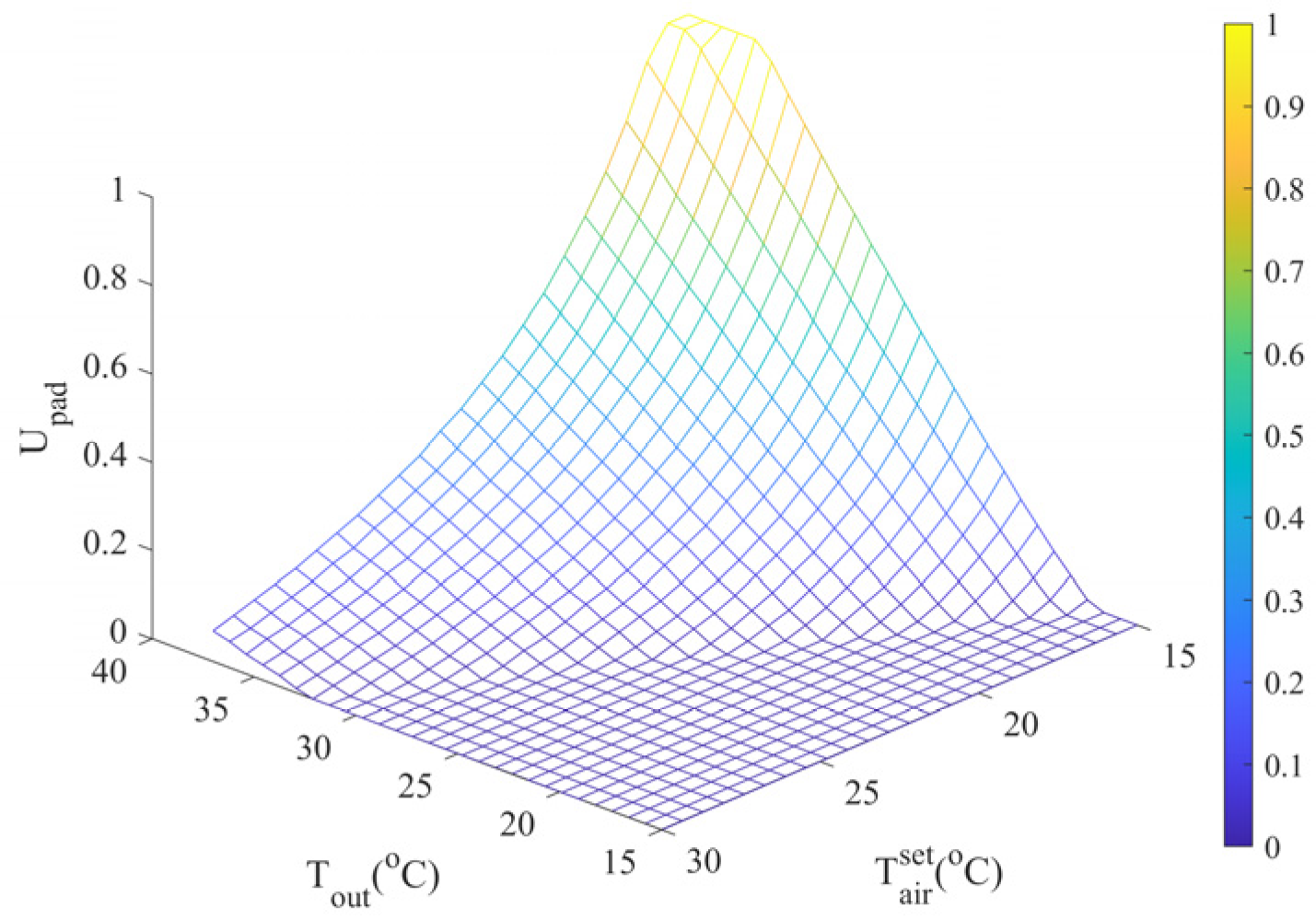

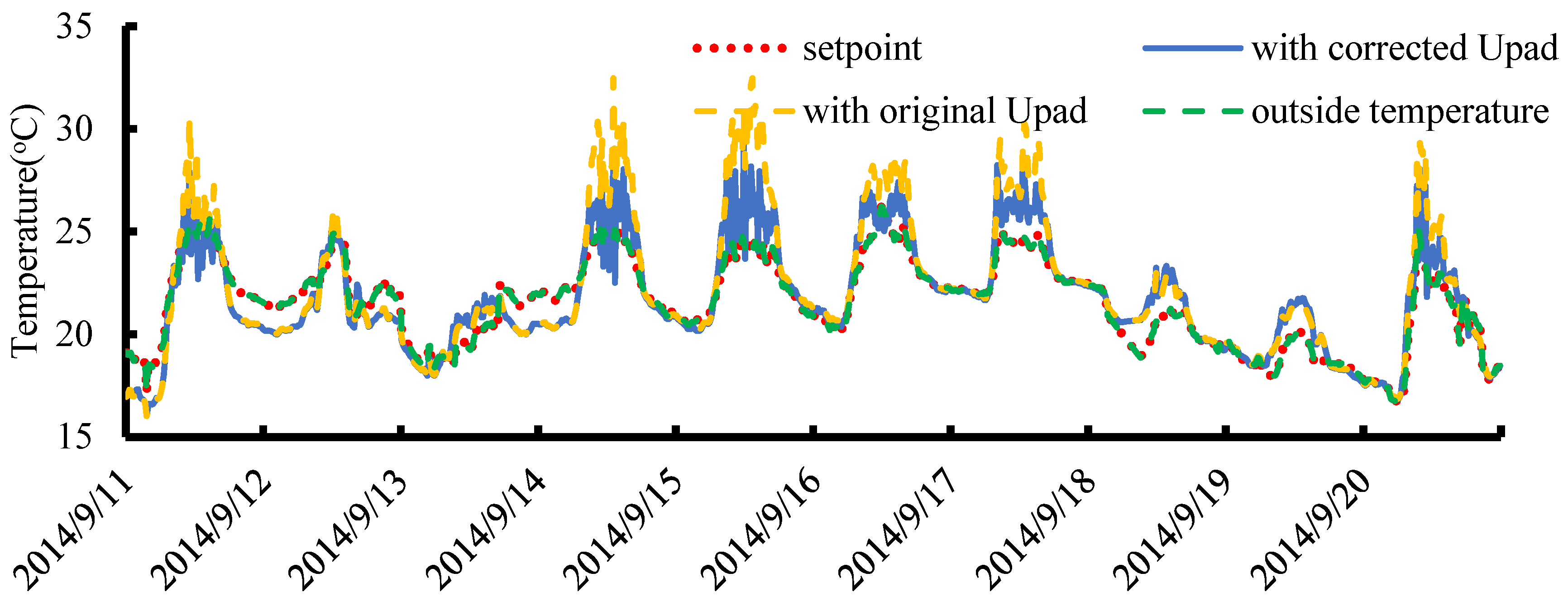

- (1)

Outside temperature is higher than the temperature, i.e.,

This case requires the activation of ventilation and pad cooling systems to decrease the temperature. If the pad cooling system has sufficient capacity, the indoor temperature can be adjusted to any reasonable setpoint. However, during nighttime and daytime, the factors that influence the control strategy of the pad are different. The control of the pad at night is primarily influenced by outdoor temperature and indoor temperature set value, whereas during the day it is affected by outdoor temperature, indoor temperature setpoint, and solar radiation. Therefore, the control input of the pad during nighttime and daytime can be respectively expressed as follows:

In the control process, one can use the measured greenhouse climate and the control error to correct the control inputs:

where

,

,

,

,

,

,

,

are the correction parameters.

The setting up process of the control rule libraries of the pad cooling and roof ventilation at night is demonstrated by

Algorithm S2 in the Supplementary Material, and the setting up process of the control rule library during the day is similar.

When the outdoor temperature is not less than the indoor temperature setpoint, we can obtain the interpolation surface of the pad control rule at night, as shown in

Figure 9.

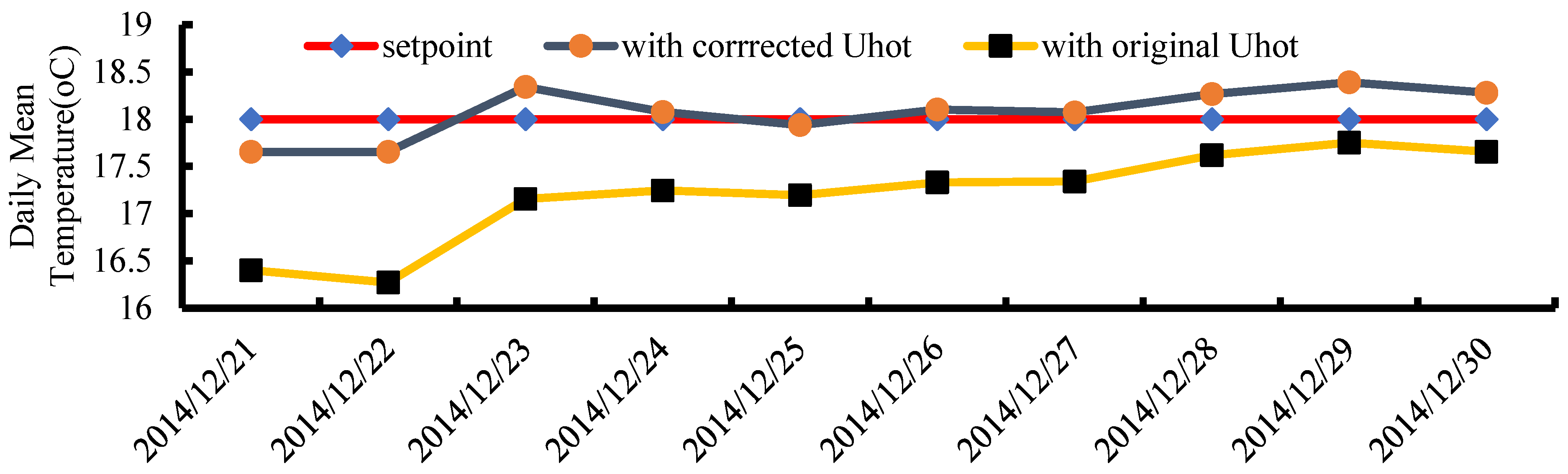

Although the corrected control strategy can achieve better control performance, it significantly depends on the correction coefficients. Therefore, the correction coefficients must be optimized to ensure the control performance. There are 17 parameters, and the parameter optimisation can be performed by two steps:

Step 1: By selecting a certain cold period of a year, such as 10–20 December 2014 in the Shanghai area, then the heating and ventilation control inputs can be corrected by minimizing the root mean square error:

where

is the number of the samples.

Step 2: By selecting a certain warm period of a year, the pad control input can be corrected by solving the following optimisation problems:

In this study, the particle swarm optimisation method was used to solve both optimisation problems, so that the best correction coefficient could then be obtained, as shown in

Table 1.

Indoor CO

2 concentration is an important factor that can affect crop growth, and high-tech agricultural greenhouses are usually equipped with CO

2 enrichment systems. CO

2 enrichment is usually carried out during the day, and, generally, the more active the photosynthesis is, the more CO

2 is consumed. Therefore, the CO

2 enrichment system is required to provide a significant amount of CO

2. Additionally, the ventilation and pad cooling can also affect indoor CO

2 concentration. As the appropriate temperature is the basic condition for crop growth, the control index of the indoor temperature must be ensured as a priority. Some regulation operations, such as ventilation and pad cooling, are always used to ensure the control performance of the temperature. Under such a premise, if the CO

2 concentration dynamics can be ignored, then the control input of the CO

2 enrichment can be derived based on the steady-state equation, which can be expressed as follows:

where

is the capacity of the CO

2 enrichment system (mg/(s·m

2)) and was set to 6 mg·s

−1·m

−2 in this study. Considering that the CO

2 concentration may not always be maintained at its setpoint and that different initial CO

2 concentrations may require different CO

2 supplies, then, to reduce the control error of the CO

2 concentration, a control error correction term and a compensation term for the ventilation control can be introduced to the steady-state control law of Equation (24). The steady-state control law can then be rewritten as follows:

where

, and the correction parameters

,

,

,

reflect the effect of the ventilation and photosynthesis on the indoor CO

2 concentration, and

is the correction parameter of the control error. To maintain the desired temperature, the heating and ventilation may be active at the same time, which implies that the ventilation results in additional CO

2 loss. Therefore, a ventilation correction term is introduced to the CO

2 control law to compensate for the CO

2 loss, and

is the correction parameter.

The correction factors can be obtained by solving the following minimization problem:

Under warm weather conditions, the ventilation should be used to cool the greenhouse as a priority, and we should avoid using the pad to cool the greenhouse as much as possible for energy saving. In this case, the indoor CO

2 concentration is usually close to the outdoor CO

2 concentration. Even if the CO

2 enrichment system is turned on, it is difficult to raise the indoor CO

2 concentration due to the ventilation. Consequently, the CO

2 enrichment system is generally not activated in warm weather conditions. To determine correction coefficients of the CO

2 control law, this study utilized outdoor climate data measured from 10 to 20 December 2014 to train the control process, the obtained optimal correction coefficients are presented in

Table 2.

Considering that the outdoor temperature is not less than the indoor temperature setpoint under warm weather conditions, the ventilation can be used to adjust the indoor temperature, such that the CO

2 enrichment may not be activated. The control strategy of the CO

2 enrichment can be generated according to

Algorithm S3, which is presented in the

Supplementary Material.

2.6. Global Optimisation of Setpoint

The setpoint of greenhouse climate has a significant impact on crop yields and energy consumption. In a broad sense, greenhouse climate setpoints can be understood in four ways. The first is the average of environmental variables of the entire crop growth period; the second is the average of environmental variables of a growth stage; the third is the daily average of the greenhouse climate; and the fourth is the real-time setpoints of each control step, which represent the desired trajectory of the indoor environment. If we want to achieve globally optimal results in terms of energy consumption and crop yield, the best way is to directly optimize the real-time setpoints. However, there are several challenges. Firstly, the setpoint of each control step must be considered a decision variable of the nonlinear optimisation problem; however, as the growth period usually spans several months, the number of decision variables is very large. In this case, the optimisation algorithms have great difficulty finding the optimal solutions. Secondly, the objective functions are very expensive, and a single optimisation process may take several dozen days, thereby it is difficult to ensure the real-time performance of the optimisation results.

In contrast to the global optimisation of the real-time setpoints, the optimisations of the former three setpoints are much simpler due to the smaller number of decision variables. As the average of the climate variables of the overall growth period can reflect the total energy consumption and the final crop yield, this study focuses on the optimisation of the global average of the greenhouse climate. As the setpoints on the different senses have different timescales, an allocation strategy must be introduced to transform the setpoint with large timescales into the setpoint with small timescales. For making a trade-off between reducing energy-saving and promoting photosynthesis, the principle of such an allocation strategy is that, if a day is cold, then a small average temperature setpoint should be set, while, when the solar radiation is strong, a high setpoint can be defined for the CO2 concentration. According to such a principle, an allocation strategy for the accumulated temperature and the average CO2 concentration is proposed in this study.

- (1)

Allocation strategy for temperature setpoint

Assuming that the daily average of the outdoor temperature of the overall growth period is known, where represents the number of days of the entire growth period and the average temperature is given as , then the daily mean temperature can be determined by two cases:

Case1: if , then

Case2:

In case 2, denotes

as the outdoor temperature, then the total cumulative temperature compensation can be calculated as follows:

where

is the number of days in which the average daily outdoor temperature is below

.

In general, if the light is sufficient, then the photosynthesis is active when the climate is warm. For instance, when the ambient temperature is close to 25 °C, the tomato crop has optimal photosynthesis. To improve the crop growth, the indoor temperature should be adjusted to the optimal temperature . When the weather is cold, if the temperature setpoint at night is set as , then, according to Equations (10) and (11), the temperature setpoint during the day may be set to the optimal ambient temperature , and the corresponding average daily temperature is .

The aim of accumulated temperature compensation is to compensate the average temperature of each day to the optimal average temperature according to the total accumulated temperature and the change in the outdoor temperature.

If the average outside temperature of a day is high, then the temperature setpoint of this day should be compensated to the optimal average temperature

as a priority. Conversely, if a day is cold, then it should be allocated less accumulated temperature for reducing energy consumption. In any case, the temperature setpoint must be no less than the lower bound

. Therefore, before performing the accumulation temperature compensation, we must determine a reference temperature, as follows:

The remaining accumulated temperature can be calculated as follows:

From the perspective of reducing energy consumption and promoting crop growth, a day with the highest reference temperature has the priority to compensate the accumulation temperature, and the amount of the compensation temperature is defined as follows:

If the amount of the accumulated temperature compensation

is greater than the total residual accumulated temperature

, then

must be reduced, and the updated law is as follows:

where

is the correction parameter. When

, then the updating process is terminated and the reference temperature can be updated as follows:

If

, then

can be set as 0, otherwise, it can be set as 1, i.e., if the reference temperature is close to the average optimal temperature, then the temperature compensation is not performed. Until

becomes zero, the whole accumulated temperature compensation and average temperature allocation process is terminated, as shown in

Figure 10.

- (2)

Allocation strategy for CO2 concentration setpoint

When optimizing the CO2 concentration setpoint, we must consider two boundary problems. Firstly, the setpoint cannot be lower than the outdoor CO2 concentration. Secondly, we should not exceed the CO2 saturation point of photosynthesis. Typically, if the indoor CO2 concentration is lower than the outdoor CO2 concentration, then we can use the ventilation operation to promote indoor CO2 concentration at a low cost. Therefore, the indoor CO2 concentration setpoint should not be lower than the outdoor CO2 concentration. According to the photosynthesis theory, if the CO2 concentration exceeds the saturation point, it cannot greatly enhance the photosynthetic rate, resulting in the wastage of CO2 and the increase of the regulation costs.

Let

,

be the maximum and minimum setpoint of the CO

2 concentration, respectively, and

is the average CO

2 concentration of the overall growth period. Then, referring to the lower bound of the CO

2 concentration setpoint, the total compensated amount of CO

2 can be calculated as follows:

where

denotes the average daily solar radiation of the overall growth period. If the initial value of the CO

2 concentration setpoint is set as

, then the daily CO

2 concentration setpoint can be iteratively calculated, and the update equation can be described as follows:

where

However, if the amount of the CO

2 mass is proportionally allocated with the solar radiation, this may lead the CO

2 concentration setpoint to exceed the preset maximum value

, meaning that the updated setpoint must be corrected, i.e., if

, then

, and the solar radiation of the

i-th day is removed from the set

, i.e.,

. Consequently, the CO

2 concentration setpoint that does not reach the maximum value will be re-allocated according to the residual compensation

, and the update equation can be described as follows:

where

The updating process will not stop until .

- (3)

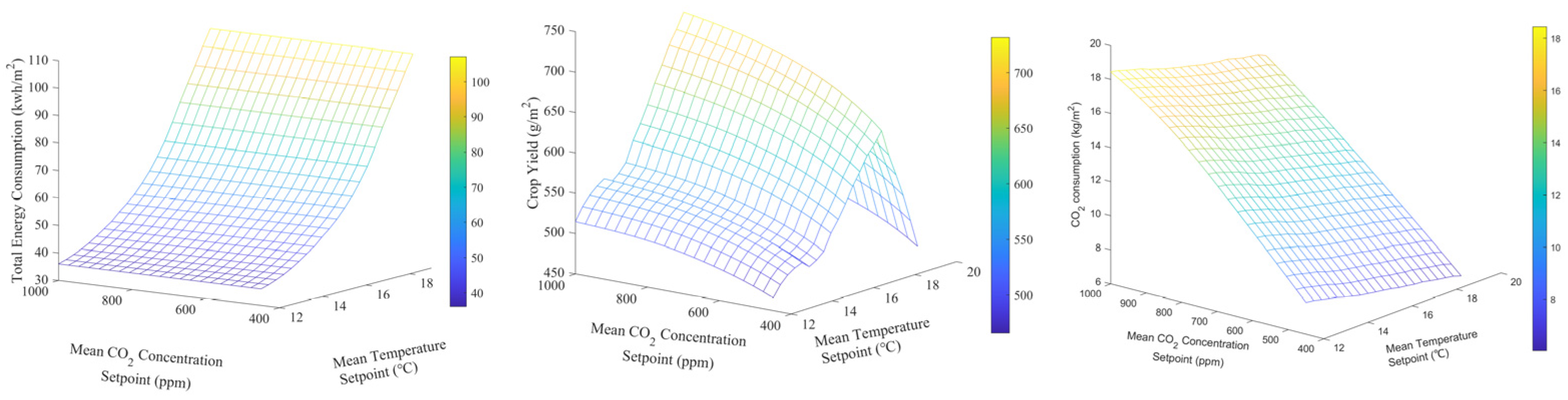

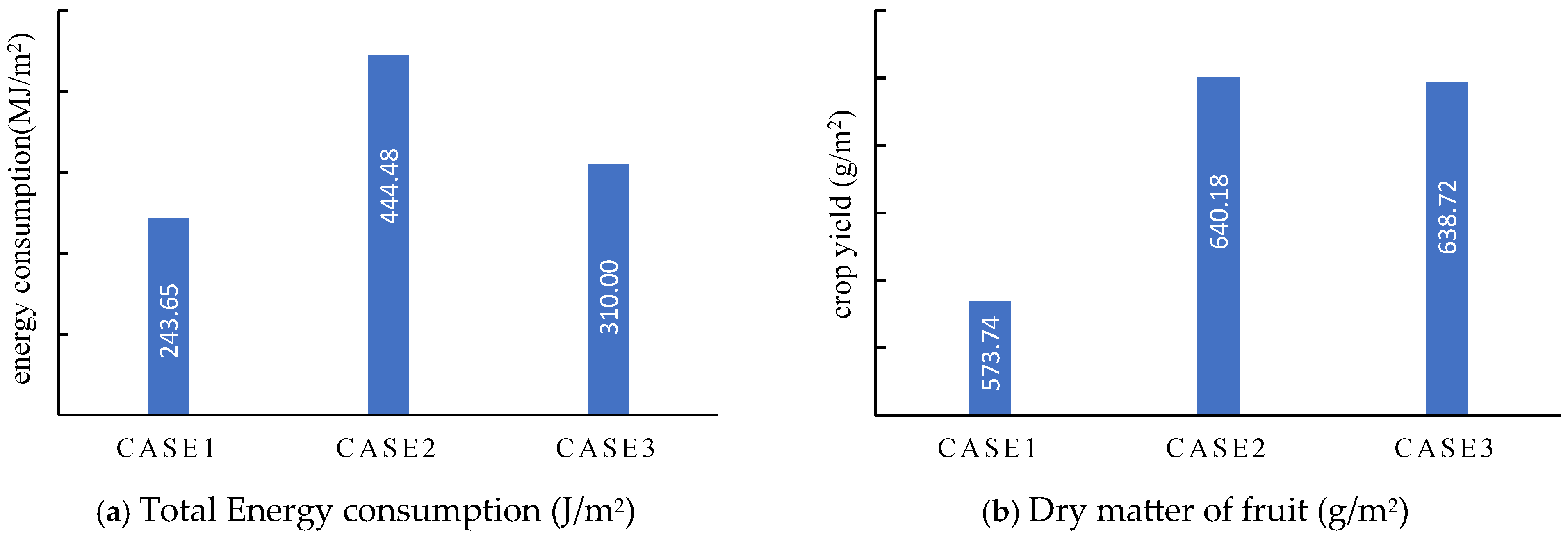

Total energy consumption and crop yield distribution for different setpoints

The optimisation of the greenhouse climate setpoint includes several steps. In this optimisation process, the overall average setpoint is gradually transformed into the daily average setpoint, and then into the real-time trajectory. The optimal setpoint can be obtained by maximizing the financial return, which can be expressed as follows:

where

and

represent the prices of the agricultural product and energy, respectively.

represents a generalized energy consumption which includes the energy of heating and the supply of the CO

2.

If the decision space of the optimisation problem is defined as

, then a 20 × 20 grid division of the decision space yields a grid surface with respect to the total energy consumption of the heating, the total CO

2 increase, and the crop yield, as depicted in

Figure 11.

The grid surface with respect to the crop yield and energy consumption accurately reflects the effects of the different matchings of the different setpoints on crop yield and energy consumption and can be regarded as a surrogate model of the crop yield and energy consumption. Therefore, the optimal solution can be directly searched on the grid surface, which can avoid the need to simulate the overall control process of the greenhouse climate for each candidate solution. Thus, the computation of the objective functions can be greatly reduced. In this study, the proposed global optimisation of the greenhouse climate setpoint can be considered a special surrogate-based optimisation. Additionally, as the energy consumption is estimated by directly integrating the control inputs, and any solution of the optimisation problem represents a full greenhouse climate control process, the optimisation process considers the effect of the control performance on the optimal solutions, which makes it more reliable in practice.