Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement

Abstract

1. Introduction

2. Material and Methods

2.1. General Experiment Information

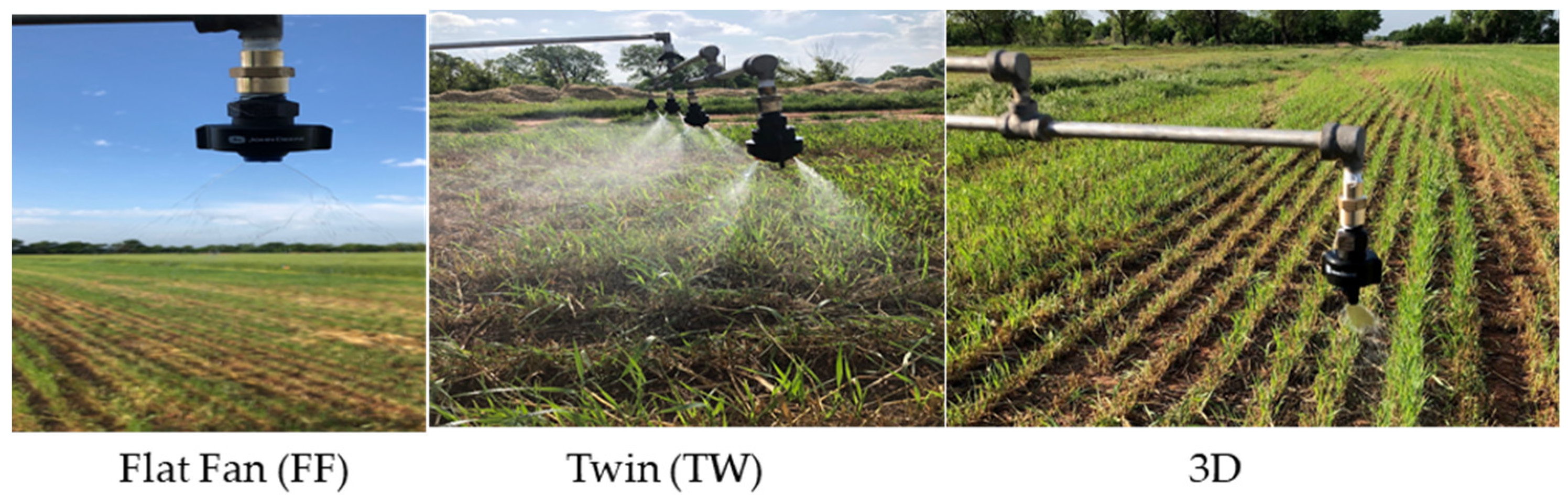

2.2. Experimental Design, Treatment Structure, and Harvest

2.3. Data Analysis

3. Results

3.1. Overview of Grain Yield and Grain Protein Concentration Responses

3.2. Grain Protein Concentration Response Patterns Across Locations

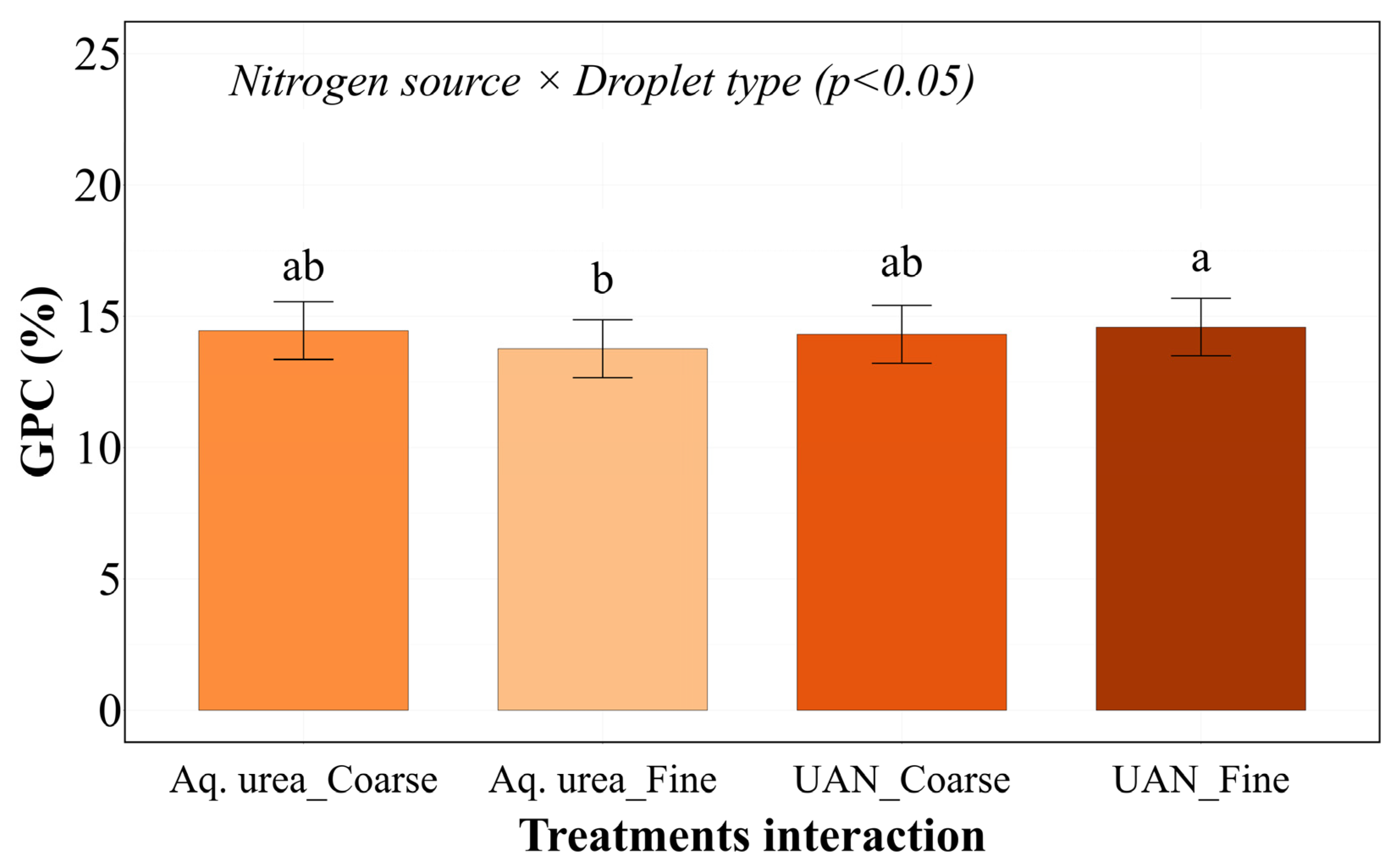

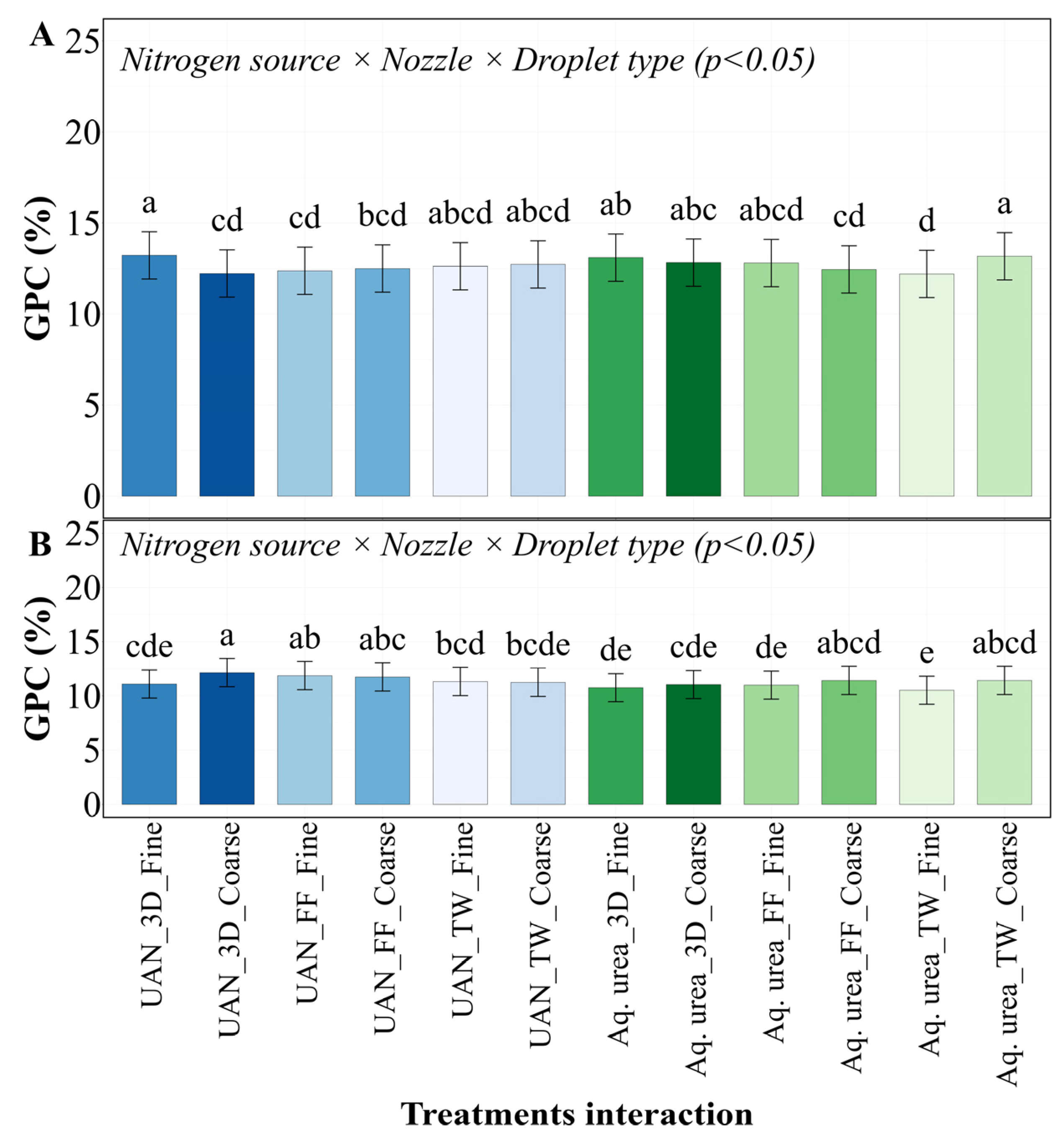

3.3. Interactive Effects of Foliar N Treatments on Grain Protein Concentration

4. Discussion

4.1. Foliar N Applications at Anthesis for Protein Enhancement

4.2. Nitrogen Source Dynamics: UAN Versus Aq. Urea Performance Across Environments

4.3. Nozzle Design Influence on Foliar N Efficiency and GPC

4.4. Droplet Size Characteristics Influence on GPC

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. FAO Statistical Pocket Book; Food and Agricultural Organization: Rome, Italy, 2015; p. 28. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/9a8e88e3-5814-49c9-b350-1d68a745ca6a/content (accessed on 24 January 2025).

- Abiola, S.O.; Lacasa, J.; Carver, B.F.; Arnall, B.D.; Ciampitti, I.A.; de Oliveira Silva, A. Nitrogen uptake dynamics of high and low protein wheat genotypes. Front. Plant Sci. 2024, 15, 1493901. [Google Scholar] [CrossRef] [PubMed]

- Bogard, M.; Allard, V.; Brancourt-Hulmel, M.; Heumez, E.; Machet, J.M.; Jeuffroy, M.H.; Le Gouis, J. Deviation from the grain protein concentration–grain yield negative relationship is highly correlated to post-anthesis N uptake in winter wheat. J. Exp. Bot. 2010, 61, 4303–4312. [Google Scholar] [CrossRef]

- Lollato, R.P.; Figueiredo, B.M.; Dhillon, J.S.; Arnall, D.B.; Raun, W.R. Wheat grain yield and grain-nitrogen relationships as affected by N, P, and K fertilization: A synthesis of long-term experiments. Field Crops Res. 2019, 236, 42–57. [Google Scholar] [CrossRef]

- Karim, M.R.; Zhang, Y.Q.; Zhao, R.R.; Chen, X.P.; Zhang, F.S.; Zou, C.Q. Alleviation of drought stress in winter wheat by late foliar application of zinc, boron, and manganese. J. Plant Nutr. Soil Sci. 2012, 175, 142–151. [Google Scholar] [CrossRef]

- Wu, W.; Wang, Y.; Wang, L.; Xu, H.; Zörb, C.; Geilfus, C.M.; Ma, W. Booting stage is the key timing for split nitrogen application in improving grain yield and quality of wheat–A global meta-analysis. Field Crops Res. 2022, 287, 108665. [Google Scholar] [CrossRef]

- Niu, J.; Liu, C.; Huang, M.; Liu, K.; Yan, D. Effects of foliar fertilization: A review of current status and future perspectives. J. Soil Sci. Plant Nutr. 2021, 21, 104–118. [Google Scholar] [CrossRef]

- Ishfaq, M.; Kiran, A.; ur Rehman, H.; Farooq, M.; Ijaz, N.H.; Nadeem, F.; Wakeel, A. Foliar nutrition: Potential and challenges under multifaceted agriculture. Environ. Exp. Bot. 2022, 200, 104909. [Google Scholar] [CrossRef]

- Bi, G.; Scagel, C. Nitrogen foliar feeding has advantages. Nurs. Manag. Prod. 2007, 23, 43–46. Available online: https://scholar.google.com/scholar?hl=en&as_sdt=0%2C37&q=14.%09Bi%2C+G.%3B+Scagel%2C+C.+%282007%29.+Nitrogen+foliar+feeding+has+advantages.+Nurs+Manage+Prod%2C+23%283%29%2C+43-46.&btnG= (accessed on 24 January 2025).

- Lyu, X.; Liu, Y.; Li, N.; Ku, L.; Hou, Y.; Wen, X. Foliar applications of various nitrogen (N) forms to winter wheat affect grain protein accumulation and quality via N metabolism and remobilization. Crop J. 2022, 10, 1165–1177. [Google Scholar] [CrossRef]

- Sotiropoulos, S.; Chatzissavvidis, C.; Papadakis, I.; Kavvadias, V.; Paschalidis, C.; Antonopoulou, C.; Koriki, A. Inorganic and organic foliar fertilization in olives. Hortic. Sci. 2023, 50, 1–11. [Google Scholar] [CrossRef]

- Woodard, H.J.; Bly, A. Relationship of nitrogen management to winter wheat yield and grain protein in South Dakota. J. Plant Nutr. 1998, 21, 217–233. [Google Scholar] [CrossRef]

- Dick, C.D.; Thompson, N.M.; Epplin, F.M.; Arnall, D.B. Managing late season foliar nitrogen fertilization to increase grain protein for winter wheat. Agron. J. 2016, 108, 2329–2338. [Google Scholar] [CrossRef]

- Walsh, O.S.; Shafian, S.; Christiaens, R.J. Nitrogen fertilizer management in dryland wheat cropping systems. Plants 2018, 7, 9. [Google Scholar] [CrossRef]

- Fernández, V.; Eichert, T. Uptake of hydrophilic solutes through plant leaves: Current state of knowledge and perspectives of foliar fertilization. Crit. Rev. Plant Sci. 2009, 28, 36–68. [Google Scholar] [CrossRef]

- Massinon, M.; Lebeau, F. Review of physicochemical processes involved in agrochemical spray retention. Biotechnol. Agron. Soc. Environ. 2013, 17, 494–504. Available online: https://hdl.handle.net/2268/148678 (accessed on 25 March 2025).

- Wang, S.; Li, X.; Nuyttens, D.; Zhang, L.; Liu, Y.; Li, X. Evaluation of compact air-induction flat fan nozzles for herbicide applications: Spray drift and biological efficacy. Front. Plant Sci. 2023, 14, 1018626. [Google Scholar] [CrossRef]

- Michielsen, J.M.G.P.; van de Zande, J.C.; Wenneker, M. Nozzle classification for drift reduction in orchard spraying; effect of nozzle type on a dormant stage orchard. In Proceedings of the SuproFruit 2009 10th Workshop on Spray Application Techniques in Fruit Growing, Wageningen, The Netherlands, 30 September–2 October 2009; pp. 36–37. [Google Scholar]

- Blomendahl, S. Understanding Droplet Sizes Produced by Agricultural Sprayer Nozzles. Available online: https://www.dultmeier.com/understanding-droplet-sizes-produced-by-agricultural-sprayer-nozzles (accessed on 21 January 2025).

- McCormick, A.N.; Smith, L.G.; Dillon, T.W.; Collie, L.M.; Davis, B.M.; Butts, T.R. Nozzle type and arrangement effect on spray coverage. Res. Ser. Ark. Agric. Exp. Stn. 2020, 670, 135–139. [Google Scholar]

- Parkin, C.S. Methods for measuring spray droplet sizes. In Application Technology for Crop Protection; CAB International: Wallingford, UK, 1993; pp. 57–84. [Google Scholar]

- Tishkoff, J.M.; Ingebo, R.D.; Kennedy, J.B. (Eds.) Liquid Particle Size Measurement Techniques: A Symposium; ASTM International: West Conshohocken, PA, USA, 1983; Volume 848. [Google Scholar]

- Piggott, S.; Matthews, G.A. Air induction nozzles: A solution to spray drift? Int. Pest Control 1999, 41, 24–28. [Google Scholar]

- Al-Juthery, H.W.; Habeeb, K.H.; Altaee, F.J.K.; AL-Taey, D.K.; Al-Tawaha, A.R.M. Effect of foliar application of different sources of nano-fertilizers on growth and yield of wheat. Biosci. Res. 2018, 15, 3976–3985. [Google Scholar]

- Barneix, A.J. Physiology and biochemistry of source-regulated protein accumulation in the wheat grain. J. Plant Physiol. 2007, 164, 581–590. [Google Scholar] [CrossRef]

- McDonald, G.K. Effects of nitrogenous fertilizer on the growth, grain yield and grain protein concentration of wheat. Aust. J. Agric. Res. 1992, 43, 949–967. [Google Scholar] [CrossRef]

- Woolfolk, C.W.; Raun, W.R.; Johnson, G.V.; Thomason, W.E.; Mullen, R.W.; Wynn, K.J.; Freeman, K.W. Influence of late-season foliar nitrogen applications on yield and grain nitrogen in winter wheat. Agron. J. 2002, 94, 429–434. [Google Scholar] [CrossRef]

- Bly, A.G.; Woodard, H.J. Foliar nitrogen application timing influence on grain yield and protein concentration of hard red winter and spring wheat. Agron. J. 2003, 95, 335–338. [Google Scholar] [CrossRef]

- Delfine, S.; Tognetti, R.; Desiderio, E.; Alvino, A. Effect of foliar application of N and humic acids on growth and yield of durum wheat. Agron. Sustain. Dev. 2005, 25, 183–191. [Google Scholar] [CrossRef]

- Warren, J.; Zhang, H.; Arnall, B.; Bushong, J.; Raun, B.; Penn, C.; Abit, J. Oklahoma Soil Fertility Handbook; Oklahoma Cooperative Extension Service: Stillwater, OK, USA, 2017; id. E-1039; Available online: https://extension.okstate.edu/fact-sheets/oklahoma-soil-fertility-handbook-full.html (accessed on 25 March 2025).

- Fox, J.; Weisberg, S.; Adler, D.; Bates, D.; Baud-Bovy, G.; Ellison, S.; Firth, D.; Friendly, M.; Gorjanc, G.; Graves, S.; et al. Package ‘car’. R Found. Stat. Comput. 2012, 16, 333. [Google Scholar]

- Kuznetsova, A.; Brockhoff, P.B.; Christensen, R.H.B. Package ‘lmertest’. R Package Version 2015, 2, 734. [Google Scholar] [CrossRef]

- de Mendiburu, F.; de Mendiburu, M.F. Package ‘agricolae’. R Package Version 2019, 1, 1143–1149. [Google Scholar] [CrossRef]

- Fortunato, S.; Nigro, D.; Lasorella, C.; Marcotuli, I.; Gadaleta, A.; de Pinto, M.C. The role of glutamine synthetase (GS) and glutamate synthase (GOGAT) in the improvement of nitrogen use efficiency in cereals. Biomolecules 2023, 13, 1771. [Google Scholar] [CrossRef]

- Turley, D.B.; Sylvester-Bradley, R.; Dampney, P.M. Foliar-applied nitrogen for grain protein and canopy management of wheat. HGCA Res. Rev. 2001, 47, 32. [Google Scholar]

- Griffiths, M.W.; Kettlewell, P.S.; Hocking, T.J. Effects of foliar-applied sulphur and nitrogen on grain growth, grain sulphur and nitrogen concentrations and yield of winter wheat. J. Agric. Sci. 1995, 125, 331–339. [Google Scholar] [CrossRef]

- Souza, J.L.B.; Antonangelo, J.A.; de Oliveira Silva, A.; Reed, V.; Arnall, B. Recovery of grain yield and protein with fertilizer application post nitrogen stress in winter wheat (Triticum aestivum L.). Agronomy 2022, 12, 2024. [Google Scholar] [CrossRef]

- Ren, B.; Guo, Y.; Liu, P.; Zhao, B.; Zhang, J. Effects of urea-ammonium nitrate solution on yield, N2O emission, and nitrogen efficiency of summer maize under integration of water and fertilizer. Front. Plant Sci. 2021, 12, 700331. [Google Scholar] [CrossRef] [PubMed]

- Gagnon, B.; Ziadi, N. Grain corn and soil nitrogen responses to sidedress nitrogen sources and applications. Agron. J. 2010, 102, 1014–1022. [Google Scholar] [CrossRef]

- Sundaram, P.K.; Mani, I.; Lande, S.D.; Parray, R.A. Evaluation of urea ammonium nitrate application on the performance of wheat. Int. J. Curr. Microbiol. App. Sci. 2019, 8, 1956–1963. [Google Scholar] [CrossRef]

- Kong, L.; Xie, Y.; Hu, L.; Si, J.; Wang, Z. Excessive nitrogen application dampens antioxidant capacity and grain filling in wheat as revealed by metabolic and physiological analyses. Sci. Rep. 2017, 7, 43363. [Google Scholar] [CrossRef] [PubMed]

- Arnall, D.B.; Mallarino, A.P.; Ruark, M.D.; Varsa, G.O.; Solie, J.B.; Raun, W.R. Relationship between grain crop yield potential and nitrogen response. Agron. J. 2013, 105, 1335–1344. [Google Scholar] [CrossRef]

- Mengel, D.B. Types and Uses of Nitrogen Fertilizers for Crop Production. Available online: https://www.extension.purdue.edu/extmedia/ay/ay-204.html (accessed on 4 April 2025).

- Castro, S.A.Q.D.; Kichey, T.; Persson, D.P.; Schjoerring, J.K. Leaf Scorching following Foliar Fertilization of Wheat with Urea or Urea–Ammonium Nitrate Is Caused by Ammonium Toxicity. Agronomy 2022, 12, 1405. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Li, B.N.; Gao, Q.; Feng, G.Z.; Li, C.L.; Li, Y.; ShaoJie, W. Effects of urea ammonium nitrate solution on grain yield and nitrogen uptake of spring maize in black soil region. Sci. Agric. Sin. 2018, 51, 718–727. [Google Scholar] [CrossRef]

- Millar, N.; Robertson, G.P.; Grace, P.R.; Gehl, R.J.; Hoben, J.P. Nitrogen fertilizer management for nitrous oxide (N2O) mitigation in intensive corn (Maize) production: An emissions reduction protocol for US Midwest agriculture. Mitig. Adapt. Strateg. Glob. Change 2010, 15, 185–204. [Google Scholar] [CrossRef]

- Hall, A.J.; Savin, R.; Slafer, G.A. Is time to flowering in wheat and barley influenced by nitrogen?: A critical appraisal of recent published reports. Eur. J. Agron. 2014, 54, 40–46. [Google Scholar] [CrossRef]

- Lake, J.R. The effect of drop size and velocity on the performance of agricultural sprays. Pestic. Sci. 1977, 8, 515–520. [Google Scholar] [CrossRef]

- Miller, P.C.H.; Ellis, M.B. Effects of formulation on spray nozzle performance for applications from ground-based boom sprayers. Crop Prot. 2000, 19, 609–615. [Google Scholar] [CrossRef]

- Hong, J.; Wang, C.; Wagner, D.C.; Gardea-Torresdey, J.L.; He, F.; Rico, C.M. Foliar application of nanoparticles: Mechanisms of absorption, transfer, and multiple impacts. Environ. Sci. Nano 2021, 8, 1196–1210. [Google Scholar] [CrossRef]

- Lv, X.; Ding, Y.; Long, M.; Liang, W.; Gu, X.; Liu, Y.; Wen, X. Effect of foliar application of various nitrogen forms on starch accumulation and grain filling of wheat (Triticum aestivum L.) under drought stress. Front. Plant Sci. 2021, 12, 645379. [Google Scholar] [CrossRef]

- Butler Ellis, M.C.; Tuck, C.R. How adjuvants influence spray formation with different hydraulic nozzles. Crop Prot. 1999, 18, 101–109. [Google Scholar] [CrossRef]

- Dombrowski, N.; Fraser, R.P. A photographic investigation into the disintegration of liquid sheets. Philos. Trans. R. Soc. Lond. A Math. Phys. Sci. 1954, 247, 101–130. [Google Scholar] [CrossRef]

- Dombrowski, N.; Hasson, D.; Ward, D.E. Some aspects of liquid flow through fan spray nozzles. Chem. Eng. Sci. 1960, 12, 35–50. [Google Scholar] [CrossRef]

- Ford, R.E.; Furmidge, C.G.L. The formation of drops from viscous Newtonian liquids sprayed through fan-jet nozzles. Br. J. Appl. Phys. 1967, 18, 335. [Google Scholar] [CrossRef]

- Syngenta. New Defy 3D Nozzles Improve Coverage and Reduce Drift. Available online: https://syngenta-au.my.salesforce.com/sfc/p/#90000atoO/a/900008gxf/SFdik58N0BmDc92cetlLFeJV1QV8AB3dFUo6pAi0t1M (accessed on 4 March 2025).

- Deere, J. John Deere Sprayer Parts Guide. Available online: https://jdparts.deere.com/partsmkt/unsecured/document/english/featbene/SPRAYER_PARTS_GUIDE_UPDATE.pdf (accessed on 22 January 2025).

- Hilz, E.; Vermeer, A.W. Spray drift review: The extent to which a formulation can contribute to spray drift reduction. Crop Prot. 2013, 44, 75–83. [Google Scholar] [CrossRef]

- Sun, T.; Zhang, S.; Xue, X.; Jiao, Y. Comparison of droplet distribution and control effect of wheat aphids under different operation parameters of the crop protection UAV in the wheat flowering stage. Agronomy 2022, 12, 3175. [Google Scholar] [CrossRef]

- Chen, H.; Weng, H.; Zhu, H.; Shen, S.; Li, W. Insights on droplet drift and effective utilization of pesticide in “Third Pole”: Qinghai-Tibet Plateau of China. Heliyon 2024, 10, e30935. [Google Scholar] [CrossRef] [PubMed]

| Year | Site | Season | Cum PPT | T Max | T Min | T Avg | Cum GDD |

|---|---|---|---|---|---|---|---|

| MM | °C | ||||||

| 2019–20 | Lake Carl Blackwell | Fall | 134 | 33 | −11 | 8 | 364 |

| Winter | 219 | 34 | −11 | 7 | 1004 | ||

| Spring | 141 | 36 | −1 | 19 | 2814 | ||

| Perkins | Fall | 185 | 33 | −10 | 9 | 439 | |

| Winter | 267 | 33 | −9 | 8 | 1170 | ||

| Spring | 382 | 37 | −1 | 20 | 2784 | ||

| Chickasha | Fall | 204 | 20 | 5 | 12.5 | 600 | |

| Winter | 126 | 12 | −2 | 5 | 1200 | ||

| Spring | 318 | 20 | 10 | 17.5 | 2500 | ||

| 2020–21 | Lake Carl Blackwell | Fall | 220 | 18 | 3 | 10 | 586 |

| Winter | 137 | 12 | −2 | 5 | 1256 | ||

| Spring | 108 | 22 | 9 | 19 | 2560 | ||

| Perkins | Fall | 223 | 17 | 4 | 10 | 582 | |

| Winter | 133 | 11 | −1 | 5 | 1218 | ||

| Spring | 243 | 25 | 14 | 19 | 2363 | ||

| Fall | 174 | 20 | 5 | 12.5 | 600 | ||

| Chickasha | Winter | 126 | 10 | −2 | 4 | 1200 | |

| Spring | 364 | 25 | 10 | 17.5 | 2500 | ||

| 2021–22 | Lake Carl Blackwell | Fall | 127 | 20 | 6 | 13 | 829 |

| Winter | 117 | 20 | 10 | 5 | 1518 | ||

| Spring | 421 | 39 | 15 | 21 | 2666 | ||

| Chickasha | Fall | 144 | 20 | 5 | 12 | 908 | |

| Winter | 100 | 13 | −3 | 5 | 1609 | ||

| Spring | 409 | 28 | 15 | 21 | 2584 | ||

| Growing Season | Location | pH | BI | NO3 | M3P | K | SO4 | Ca | Mg | OM |

|---|---|---|---|---|---|---|---|---|---|---|

| mg kg−1 | % | |||||||||

| 2019–20 | Chickasha | 6 | 7 | 18.5 | 19.5 | 280 | 7.8 | 2515 | 1048 | 2.01 |

| LCB | 5.7 | 7.1 | 4.5 | 19.5 | 90 | 2.8 | 936.5 | 213.5 | 1.1 | |

| Perkins | 5.2 | 6.8 | 5 | 19 | 112 | 6 | 536.5 | 140.5 | 1.17 | |

| 2020–21 | Chickasha | 6.1 | 7.1 | 7 | 11 | 148 | 5.5 | 1519 | 537.5 | 1.7 |

| LCB | 6.1 | 7.1 | 9.5 | 24.5 | 125.5 | 5.52 | 1394 | 291.5 | 1.36 | |

| Perkins | 6.6 | 3 | 34 | 143.5 | 2.4 | 644 | 137.5 | 0.78 | ||

| 2021–22 | Chickasha | 6.1 | 7.1 | 8.5 | 18 | 133.5 | 3.2 | 1162.5 | 436.5 | 1.51 |

| LCB | 6.8 | 8.5 | 50.5 | 155 | 1.38 | 516.5 | 107 | 0.64 | ||

| Treatment Number | Nozzle Tech | Droplet Size | Nitrogen Source | Flow Rate (L ha−1) | kPa | Nozzle Used |

|---|---|---|---|---|---|---|

| 1 | Control | -- | -- | |||

| 2 | FF | Coarse | UAN | 187 | 138 | PSLDC 03 |

| 3 | FF | Coarse | Aq. Urea | 187 | 138 | PSLDC 02 |

| 4 | FF | Fine | UAN | 187 | 138 | PSERCQ 03 |

| 5 | FF | Fine | Aq. Urea | 187 | 138 | PSERCQ 02 |

| 6 | 3D | Coarse | UAN | 187 | 138 | PS3DQ0003 |

| 7 | 3D | Coarse | Aq. Urea | 187 | 138 | PS3DQ0003 |

| 8 | 3D | Fine | UAN | 187 | 276 | PS3DQ0002 |

| 9 | 3D | Fine | Aq. Urea | 187 | 276 | PS3DQ00015 |

| 10 | TW | Coarse | UAN | 187 | 207 | PSGAT1002 |

| 11 | TW | Coarse | Aq. Urea | 187 | 207 | PSGAT1002 |

| 12 | TW | Fine | UAN | 187 | 276 | PSERCQ02 Dual Fan |

| 13 | TW | Fine | Aq. Urea | 187 | 276 | PSERCQ02 Dual Fan |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abiola, S.O.; Sharry, R.; Bushong, J.; Arnall, D.B. Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement. Agriculture 2025, 15, 812. https://doi.org/10.3390/agriculture15080812

Abiola SO, Sharry R, Bushong J, Arnall DB. Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement. Agriculture. 2025; 15(8):812. https://doi.org/10.3390/agriculture15080812

Chicago/Turabian StyleAbiola, S. O., R. Sharry, J. Bushong, and D. B. Arnall. 2025. "Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement" Agriculture 15, no. 8: 812. https://doi.org/10.3390/agriculture15080812

APA StyleAbiola, S. O., Sharry, R., Bushong, J., & Arnall, D. B. (2025). Optimizing Spray Technology and Nitrogen Sources for Wheat Grain Protein Enhancement. Agriculture, 15(8), 812. https://doi.org/10.3390/agriculture15080812