Cumin-Harvesting Mechanization of the Xinjiang Cotton–Cumin Intercropping System: Review of the Problem Status and Solutions

Abstract

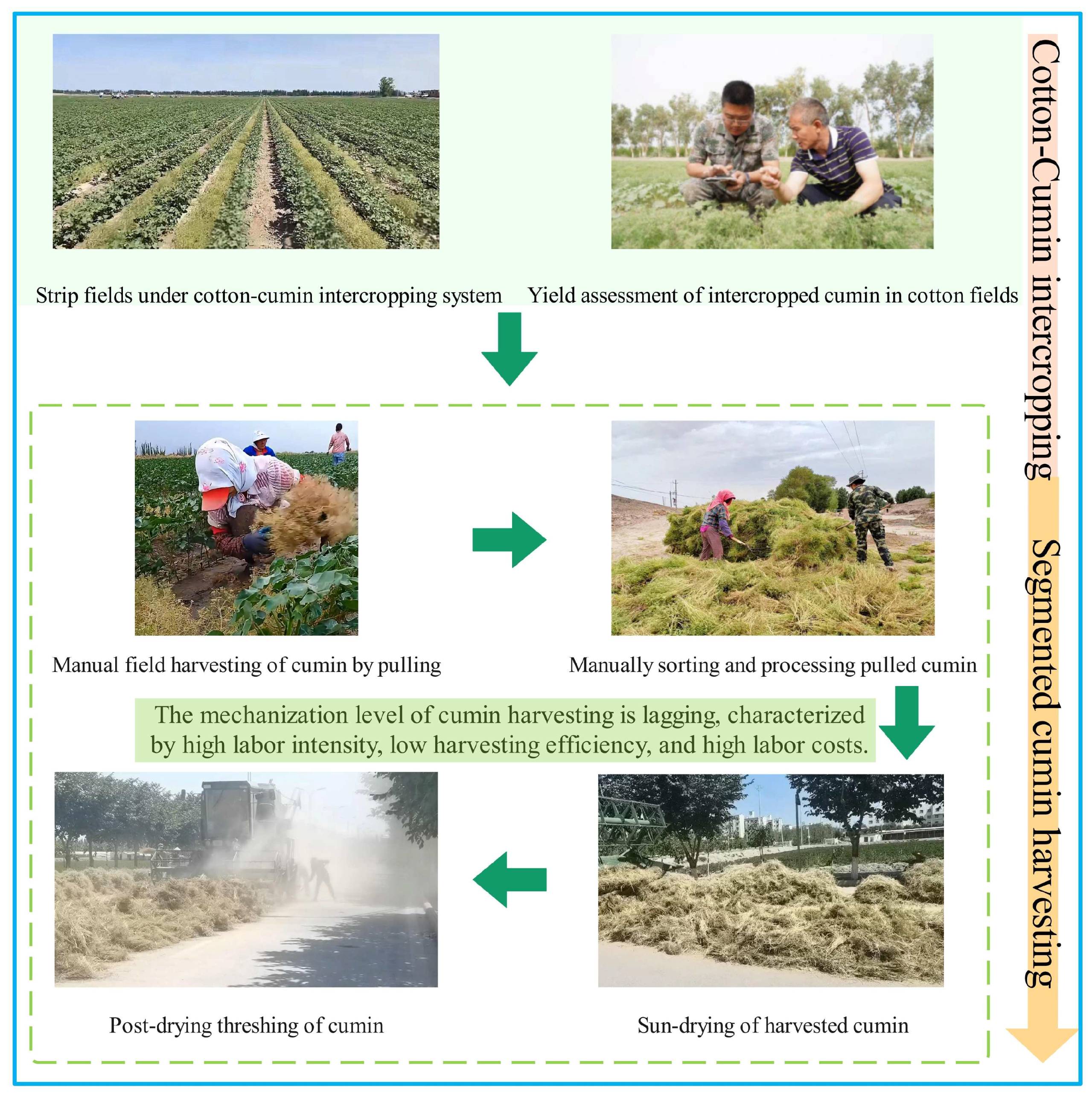

1. Introduction

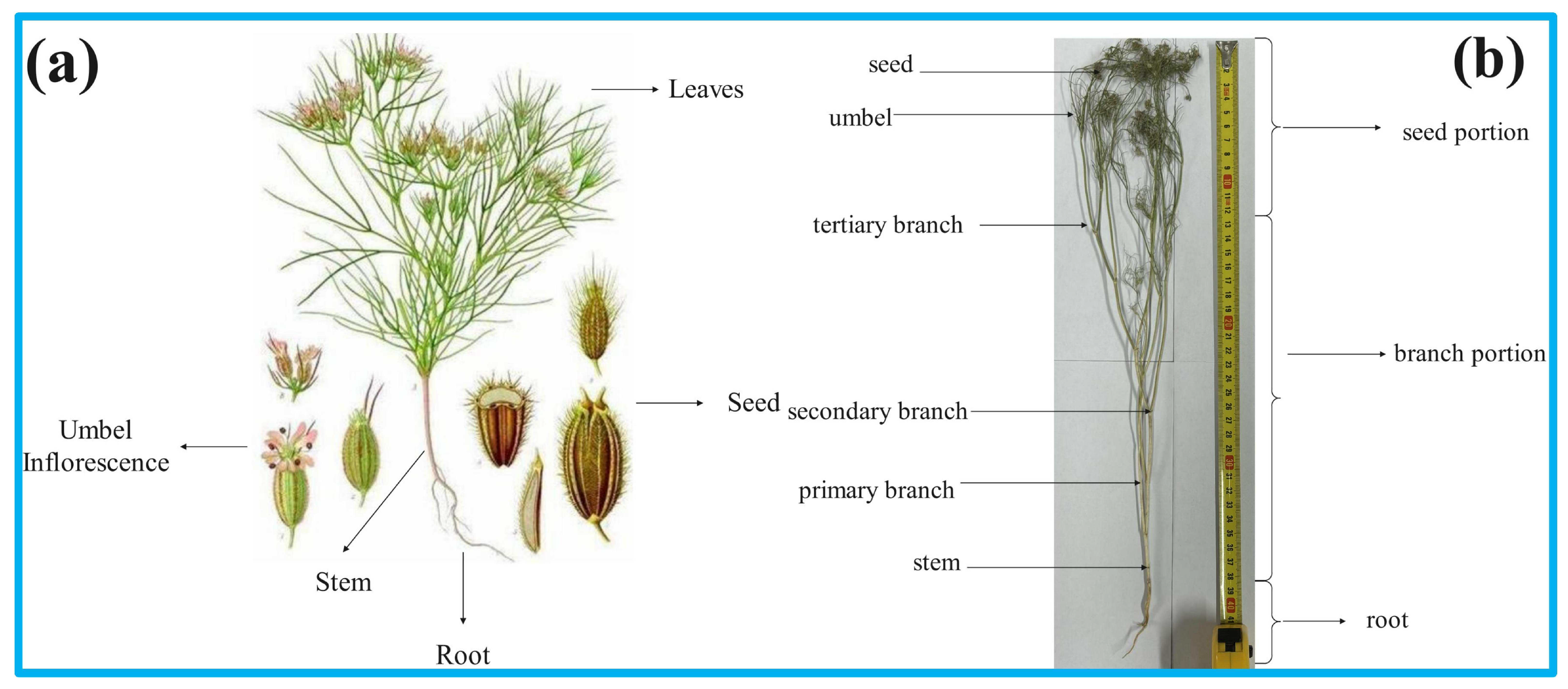

2. Current Research on Biological Traits of Cumin and Cultivation Models of Cumin Intercropping

2.1. Biological Traits of Cumin

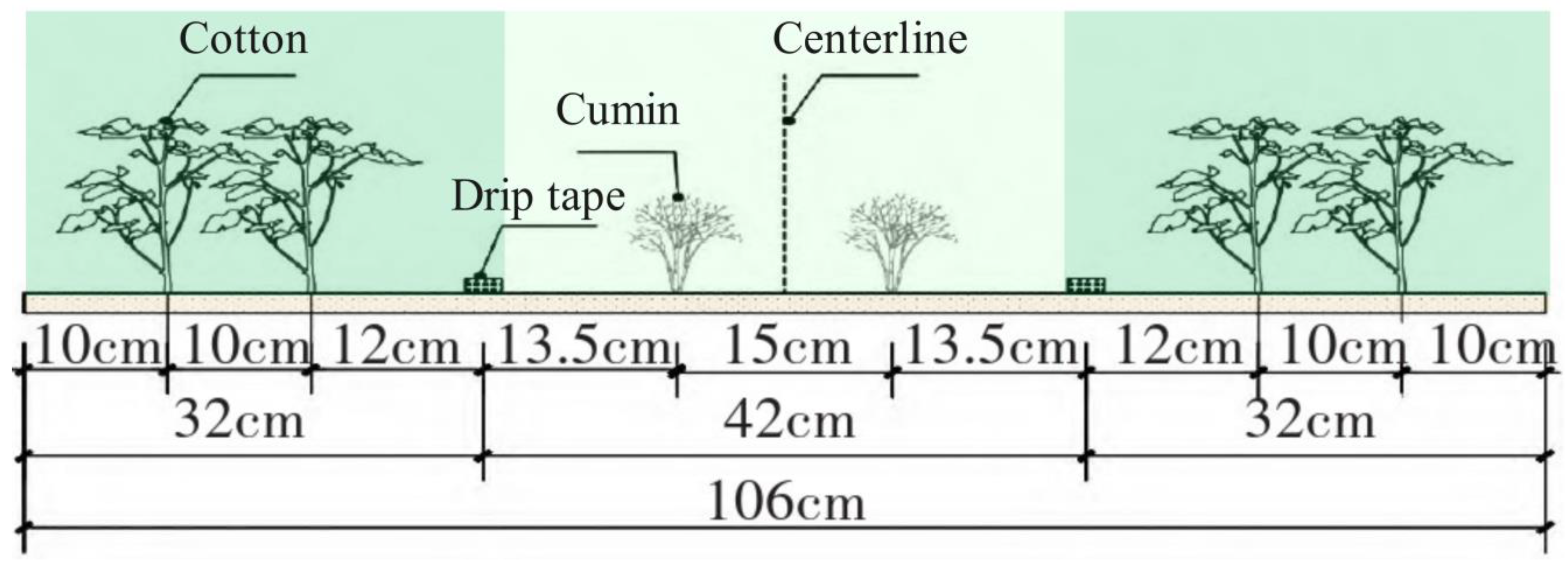

2.2. Cultivation Models of Cumin Intercropping

- (1)

- Enhanced Land Use Efficiency: Cotton cultivation under mechanized picking mode requires a larger row spacing, reaching up to 66 cm [11], as shown in Figure 3, which provides ample inter-row space for cumin growth. Cumin has a shorter growth cycle, allowing for sowing, growth, and harvesting to be completed early in the cotton growing season, thereby efficiently utilizing land, light, and heat resources [12].

- (2)

- Improved Soil Microenvironment: Cumin plants act as a ground cover, reducing soil moisture evaporation, lowering soil temperature, and improving the soil microclimate, consequently promoting cotton seedling growth.

- (3)

- Biological Pest Control: Cumin intercropping demonstrates effective biological pest control benefits. It enhances biodiversity in the field, attracts beneficial insects, and contributes to building a stable ecosystem. This facilitates biological control of cotton pests and diseases, reduces reliance on chemical pesticides, and promotes green production [12].

- (4)

- Wind and Sand Fixation: In areas prone to wind and sandstorms, cumin plants exhibit sand fixation and windbreak effects, protecting young cotton seedlings from wind and sand damage [12].

- (1)

- Optimization of Planting Models: Research should be conducted to optimize planting models based on regional climate, soil, and cotton varieties, such as cumin-sowing time, planting density, row spacing, fertilization, and irrigation management. Reasonably adjusting cumin-sowing time and density is crucial for minimizing competition between cumin and cotton for nutrients and light, thereby promoting their co-growth and high yield.

- (2)

- Water Resource Management: In arid and semi-arid environments, water scarcity is a significant limiting factor for agricultural production. Research should prioritize exploring efficient under-film drip irrigation techniques to improve water use efficiency and provide adequate water supply for both cumin and cotton production.

3. Current Research Status on Grain Loss and Stalk Damage Patterns

3.1. Grain Loss in Stripper Harvesting

3.2. Stalk Damage Patterns

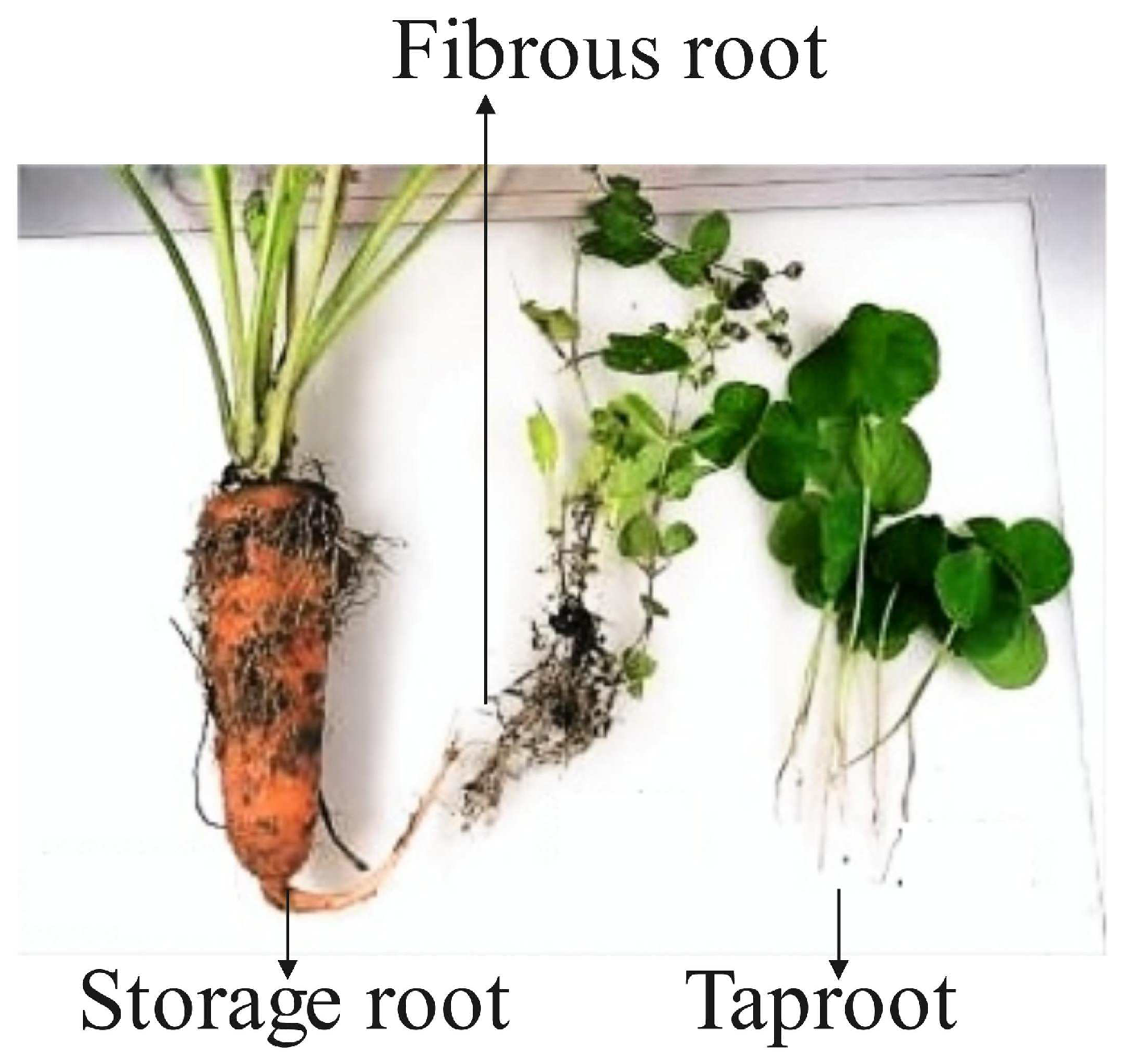

4. Current Research Status on Factors Influencing Root–Soil Interaction During Mechanical Extraction

- (1)

- Field-Experiment-Based Research on Influencing Factors of Uprooting Force: To explore suitable methods and key parameters for mechanized crop harvesting, numerous scholars have focused on directly measuring crop-uprooting force through field experiments and analyzing the primary factors influencing this force. Xin et al. investigated mature Zhongshu No. 8 potato plants as their research subject. They directly measured the uprooting force of potato plants in the field using a pointer-type push–pull dynamometer and simultaneously measured soil hardness and moisture content. Their findings revealed a significant positive linear correlation between potato plant quality, soil hardness, moisture content, and uprooting force [80]. Liu et al. concentrated on the mechanized harvesting of carrots. By statistically analyzing experimental data from a self-developed numerically controlled vegetable-uprooting force testing platform, they elucidated the influence patterns of key soil physical parameters, such as soil moisture content, hardness, and bulk density, on carrot-uprooting force [81].

- (2)

- Discrete Element Method (DEM)-Based Research on Soil–Root Interaction Mechanism: With the rapid development of computer technology, the Discrete Element Method (DEM) has gradually become a crucial approach for studying soil–root interaction mechanisms. The DEM can simulate the discrete characteristics of soil particles and the contact interaction between roots and soil, thereby revealing the mechanical behavior of soil–root interaction during mechanical uprooting at a microscopic level. Liu et al. employed discrete element theory to establish a soil–carrot model for the carrot-uprooting process. Through a simulation analysis, they deeply investigated the soil disturbance caused by mechanical uprooting and explored the influence of key mechanical uprooting operating parameters on the carrot mechanical uprooting force [84]. Yan et al., based on the field growth characteristics of white radish, developed a corresponding DEM model, calculated the pull-out force, and analyzed the effects of soil bed compactness, pulling speed, and angle on the pull-out force. They also conducted laboratory pull-out mechanical tests, and the results showed good agreement between simulation results and experimental results, validating the effectiveness of DEM in predicting root system pull-out force [85].

- (3)

- Root–Soil Friction Research Based on Root System Mechanical Properties: The friction between the roots and soil is a significant component of the soil–root interaction, directly affecting the magnitude of resistance during uprooting. To delve into the characteristics of root–soil friction, some scholars have conducted root–soil friction experiments from the perspective of the root system’s mechanical properties. Wu et al. used shrub Indigofera amblyantha and Senna biflora as research subjects and found that there are three failure modes in root and branch uprooting: pull-out failure, taproot fracture failure, and branch–root fracture failure, with pull-out failure being the primary mode [86]. Peng established a mechanical model for the uprooting force of long rhizome crops like scallions. His research indicated that scallions are not easily damaged during uprooting, and the uprooting resistance primarily originates from the tensile force of fibrous roots. The number of fibrous roots, scallion white diameter, fibrous root depth, and scallion quality are significant factors influencing uprooting force [87].

5. Current Research Status on Uprooting–Conveying Harvesting Techniques and Row Division and Plant Singulation for Root and Tuber Crop Harvesting

5.1. Uprooting–Conveying Harvesting of Root and Tuber Crops

| No. | Crop | Description | Author Name and Title |

|---|---|---|---|

| 1 |  Carrot | A multi-functional machine that integrates ridge-bottom tillage, extraction, haulm removal, conveying, and loading capabilities. | [88] Han Design and Research of Double-Row Pulling Carrot Harvester 2012 |

| 2 |  Cotton | It utilizes wavy-toothed clamping chains to grip and pull cotton stalks, supplemented by stalk diverting wheels and guide plates for stalk harvesting. | [90] Wang Design of a Gripping-Chain Type Uprooting Machine for Xinjiang Cotton Stalks 2023 |

| 3 |  Spinach | It employs an ordered root-cutting, clamping, conveying method, vibration-assisted root cutting and variable stiffness flexible clamping. | [92] Zou Research on the Key Technologies of Low Damage and Orderly Harvest for Spinach with Root 2022 |

| 4 |  Cabbage | It utilizes a double spiral picking structure and a double spiral rod with a top-pressing conveyor belt. | [94] Yang Design and experimental study of cabbage picking and conveying device 2023 |

| 5 |  Peanut | It features a self-propelled design, integrated digging and picking mechanisms, and advanced cleaning and separation systems. | [98] Hu Study on Key Technologies of Half-Feed Peanut Combine Harvester 2011 |

| 6 |  Garlic | It integrates digging, cleaning, conveying, and collecting into a single, simplified, smaller, and more cost-effective. | [99] Yang Research on the Key Components of Garlic Harvester Based on the Disruptive Innovation Theory 2017 |

| 7 |  Napa Cabbage | It utilizes a horizontal and vertical double-disk cutter and a conveying system. | [100] Zhang Research on physical and mechanical properties of headed Chinese cabbage and its crawler self-propelled harvesting equipment 2022 |

| 8 |  Broccoli | It features a bio-inspired cutter based on locust mandible morphology, a wavy conveying system, and a manual sorting station. | [101] Zhao Structural Design and Performance Experimental Research of Self-Propelled Harvester for Densely Planted Broccoli 2023 |

5.2. Techniques for Row Division and Plant Singulation

6. Research Status of Cumin-Threshing and -Cleaning Devices

6.1. Research Status of Cumin-Cleaning Devices

6.2. Research Status of Vibrating Screening Devices

6.3. Research Status of Air Separation Devices

7. Prospects

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El-Ghorab, A.H.; Nauman, M.; Anjum, F.M.; Hussain, S.; Nadeem, M. A Comparative Study on Chemical Composition and Antioxidant Activity of Ginger (Zingiber officinale) and Cumin (Cuminum cyminum). J. Agric. Food Chem. 2010, 58, 8231–8237. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.-m.; Mu, T.-h. Effects of extraction methods and particle size distribution on the structural, physicochemical, and functional properties of dietary fiber from deoiled cumin. Food Chem. 2016, 194, 237–246. [Google Scholar] [CrossRef] [PubMed]

- Vallverdu-Queralt, A.; Regueiro, J.; Martinez-Huelamo, M.; Rinaldi Alvarenga, J.F.; Leal, L.N.; Lamuela-Raventos, R.M. A comprehensive study on the phenolic profile of widely used culinary herbs and spices: Rosemary, thyme, oregano, cinnamon, cumin and bay. Food Chem. 2014, 154, 299–307. [Google Scholar] [CrossRef]

- Ancuceanu, R.; Dinu, M.; Hovaneţ, M.V.; Anghel, A.I.; Popescu, C.V.; Negreş, S. A survey of plant iron content—A semi-systematic review. Nutrients 2015, 7, 10320–10351. [Google Scholar] [CrossRef] [PubMed]

- Levi, M.; Rosselli, M.; Simonetti, M.; Brignoli, O.; Cancian, M.; Masotti, A.; Pegoraro, V.; Cataldo, N.; Heiman, F.; Chelo, M. Epidemiology of iron deficiency anaemia in four European countries: A population-based study in primary care. Eur. J. Haematol. 2016, 97, 583–593. [Google Scholar]

- Man, Y.; Xu, T.; Adhikari, B.; Zhou, C.; Wang, Y.; Wang, B. Iron supplementation and iron-fortified foods: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 4504–4525. [Google Scholar] [CrossRef]

- Tao, S. A Survey on the Current Status of Improved Cumin Cultivar Breeding in Bazhou Prefecture. Agric. Technol. China 2021, 41, 117–119. [Google Scholar] [CrossRef]

- Xu, N.; Qiao, Y.; Zhao, S.; Yang, X.; Li, J.; Fok, M. Optimizing the test locations and replicates in multi-environmental cotton registration trials in southern Xinjiang, China. Crop Sci. 2022, 62, 1866–1879. [Google Scholar] [CrossRef]

- Wang, X.; Hong, T.; Fang, W.; Chen, X. Optimized Design for Vibration Reduction in a Residual Film Recovery Machine Frame Based on Modal Analysis. Agriculture 2024, 14, 543. [Google Scholar] [CrossRef]

- Wang, J.; Tian, Z.; Yang, T.; Li, X.; He, Q.; Wang, D.; Chen, R. Characteristics of limited flow and soil water infiltration boundary of a subsurface drip irrigation emitter in silty loam soil. Agric. Water Manag. 2024, 291, 108636. [Google Scholar] [CrossRef]

- Feng, N.; Yi, G.; Pengxiang, C.; Lixia, L.; Qianwen, C. A Comparative Study on Different Planting Patterns in Cotton-Cumin Intercropping Systems. Xinjiang Farm Res. Sci. Technol. China 2024, 47, 6–9. [Google Scholar] [CrossRef]

- Guojun, W. Three Highly Efficient Intercropping Modes and Cultivation Essentials for Cumin. Gansu Agric. Sci. Technol. China 2010, 6, 50–51. [Google Scholar] [CrossRef]

- Jiang, N.; Zhu, C.; Hu, Z.-Z.; McPhaden, M.J.; Lian, T.; Zhou, C.; Qian, W.; Chen, D. El Niño and Sea Surface Temperature Pattern Effects Lead to Historically High Global Mean Surface Temperatures in 2023. Geophys. Res. Lett. 2025, 52, e2024GL113733. [Google Scholar] [CrossRef]

- Kasera, R.; Minocha, V.K. Impact of El Nino onset timing on Indian Monsoon Rainfall patterns. Glob. Planet. Chang. 2025, 245, 104689. [Google Scholar] [CrossRef]

- Velivelli, S.; Satyanarayana, G.C.; Chowdary, J.S.; Srinivas, G.; Darshana, P.; Konda, G.; Attada, R.; Parekh, A.; Gnanaseelan, C. Surface air temperature variability over India in CMIP6 models during spring and early summer: After effect of El Niño. Clim. Dyn. 2025, 63, 164. [Google Scholar] [CrossRef]

- Yen, N.T.H.; Nguyet, L.T. Climate variability induced the impact of El-Niño Southern Oscillation events on rice-growing areas in the Mekong Delta region1. Rev. Bras. Eng. Agric. Ambient. 2025, 29, e288921. [Google Scholar] [CrossRef]

- Kumar, M.; Sahoo, P.K.; Kushwaha, D.K.; Mani, I.; Pradhan, N.C.; Patel, A.; Tariq, A.; Ullah, S.; Soufan, W. Force and power requirement for development of cumin harvester: A dynamic approach. Sci. Rep. 2024, 14, 13666. [Google Scholar] [CrossRef]

- Wang, J.; Luo, X.; Yan, X.; Ni, Z.; Ma, J.; Ayixiamuguli. Breeding of a New Cumin Variety: “New Cumin No. 3”. Rural. Sci. Technol. China 2010, 6, 15–16. [Google Scholar] [CrossRef]

- Dar, E.A.; Mehdi, M.; Ahmad, M.; Bhat, F.; Hussain, N.; Hussain, M. Cumin: The flavour of Indian cuisines-history, cultivation and uses. Chem. Sci. Rev. Lett 2019, 8, 129–135. [Google Scholar]

- Guan, C.; Fu, J.; Cui, Z.; Wang, S.; Gao, Q.; Yang, Y. Evaluation of the tribological and anti-adhesive properties of different materials coated rotary tillage blades. Soil Tillage Res. 2021, 209, 104933. [Google Scholar] [CrossRef]

- Jin, Y.; Liu, J.; Xu, Z.; Yuan, S.; Li, P.; Wang, J. Development status and trend of agricultural robot technology. Int. J. Agric. Biol. Eng. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, E.; Mao, H.; Zuo, Z.; Peng, H.; Zhao, M.; Yu, Y.; Li, Z. Design and Testing of an Electric Side-Mounted Cabbage Harvester. Agriculture 2024, 14, 1741. [Google Scholar] [CrossRef]

- Ma, Z.; Wu, Z.; Li, Y.; Song, Z.; Yu, J.; Li, Y.; Xu, L. Study of the grain particle-conveying performance of a bionic non-smooth-structure screw conveyor. Biosyst. Eng. 2024, 238, 94–104. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, Y.; Wu, Z.; Traore, S.N.; Chen, D.; Xing, L. BP neural network model for material distribution prediction based on variable amplitude anti-blocking screening DEM simulations. Int. J. Agric. Biol. Eng. 2023, 16, 190–199. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Xu, L.; Ma, Z. Screen oilseed rape (Brassica napus) suitable for low-loss mechanized harvesting. Agriculture 2021, 11, 504. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Yang, Y.; Xu, L.; Ma, Z. Development and experiments on reel with improved tine trajectory for harvesting oilseed rape. Biosyst. Eng. 2021, 206, 19–31. [Google Scholar] [CrossRef]

- Wang, F.; Liu, Y.; Li, Y.; Ji, K. Research and experiment on variable-diameter threshing drum with movable radial plates for combine harvester. Agriculture 2023, 13, 1487. [Google Scholar] [CrossRef]

- Yang, Q.; Shi, L.; Shi, A.; He, M.; Zhao, X.; Zhang, L.; Addy, M. Determination of key soil characteristic parameters using angle of repose and direct shear stress test. Int. J. Agric. Biol. Eng. 2023, 16, 143–150. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, J.; Xu, L.; Cai, Q.; Yu, X.; Liu, P. Impurity/breakage assessment of vehicle-mounted dynamic rice grain flow on combine harvester based on improved Deeplabv3+ and YOLOv4. IEEE Access 2023, 11, 49273–49288. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, Z.; Li, X.; Xue, Z.; Jin, M.; Deng, B. Near-Infrared-Based Measurement Method of Mass Flow Rate in Grain Vibration Feeding System. Agriculture 2024, 14, 1476. [Google Scholar] [CrossRef]

- Zhu, Z.; Chai, X.; Xu, L.; Quan, L.; Yuan, C.; Tian, S. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Moghaddam, M.; Pirbalouti, A.G. Agro-morphological and phytochemical diversity of Iranian Cuminum cyminum accessions. Ind. Crops Prod. 2017, 99, 205–213. [Google Scholar] [CrossRef]

- Mohit, K. Design and Development of Cumin Harvester for Small Farmers; Division of Agricultural Engineering Icar-Indian Agricultural Research Institute: New Delhi, India, 2022. [Google Scholar]

- Li, Y. Effect of Replacing Wheat Straw with Cumin Straw on Performance, Rumenmicrobial Composition and Gastrointestinal Tract Morphology in Lambs. Master’s Thesis, Tarim University, Alar, China, 2023. [Google Scholar]

- Zhang, F.; Wu, S.; Zhang, W.; Sun, X. Cumin Planting Modes Survey and Quality Evaluation of China. Food Ind. China 2015, 36, 171–173. [Google Scholar]

- Tian, X. The Study and Evaluation on Ecological Adaptability of Cumin Germplasm Resources in Southern Xinjiang. Master’s Thesis, Tarim University, Alar, China, 2017. [Google Scholar]

- Chandio, F.A.; Li, Y.; Ma, Z.; Ahmad, F.; Syed, T.N.; Shaikh, S.A.; Tunio, M.H. Influences of moisture content and compressive loading speed on the mechanical properties of maize grain orientations. Int. J. Agric. Biol. Eng. 2021, 14, 41–49. [Google Scholar]

- Jin, M.; Zhao, Z.; Chen, S.; Chen, J. Improved piezoelectric grain cleaning loss sensor based on adaptive neuro-fuzzy inference system. Precis. Agric. 2022, 23, 1174–1188. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Gao, Z.; Lu, E.; Li, Y. Effect of vibration on rapeseed header loss and optimization of header frame. Trans. Asabe 2021, 64, 1247–1258. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, J.; Guan, Z.; Song, J. Development of a monitoring system for grain loss of paddy rice based on a decision tree algorithm. Int. J. Agric. Biol. Eng. 2021, 14, 224–229. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Chen, L.; Zhang, T.; Liang, Z.; Huang, M.; Su, Z. Study on Performance of Concentric Threshing Device with Multi-Threshing Gaps for Rice Combines. Agriculture 2021, 11, 1000. [Google Scholar] [CrossRef]

- Qian, P.; Lu, T.; Shen, C.; Chen, S. Influence of vibration on the grain flow sensor during the harvest and the difference elimination method. Int. J. Agric. Biol. Eng. 2021, 14, 149–162. [Google Scholar] [CrossRef]

- Qing, Y.; Li, Y.; Xu, L.; Ma, Z.; Tan, X.; Wang, Z. Oilseed rape (Brassica napus L.) pod shatter resistance and its relationship with whole plant and pod characteristics. Ind. Crops Prod. 2021, 166, 113459. [Google Scholar] [CrossRef]

- Liang, Z. Selecting the proper material for a grain loss sensor based on DEM simulation and structure optimization to improve monitoring ability. Precis. Agric. 2021, 22, 1120–1133. [Google Scholar] [CrossRef]

- Xing, D.; Chen, X.; Wu, Y.; Li, Z.; Khan, S. Changes in elastic modulus, leaf tensity and leaf density during dehydration of detached leaves in two plant species of Moraceae. Chil. J. Agric. Res. 2021, 81, 434–447. [Google Scholar] [CrossRef]

- Li, J.; Liang, Z.; Zhu, F.; Liu, C. Optimum of Grain Loss Sensors by Analyzing Effects of Grain Collision Attitude on Signal Characteristics. Electronics 2022, 11, 3187. [Google Scholar] [CrossRef]

- Juan, D.; Bin, J.; Haifeng, Y.; Longmei, Z.; Chengqian, J.; Xiang, Y. Development of automatic control system for the rotation speed of combine harvester reel. J. Chin. Agric. Mech. China 2020, 41, 1–5. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Y.; Qing, Y. Adaptability Analysis of Mechanized Transplanting of Pepper in Hilly Mountainous Area. J. Agric. Mech. Res. China 2020, 42, 189–194. [Google Scholar] [CrossRef]

- Huang, X.; Fu, J.; Ma, L.; Zong, W.; Liu, W.; Liu, Y. Design and bench test of the dividing and supporting collecting tank on oil sunflower header. J. Anhui Agric. Univ. China 2020, 47, 664–673. [Google Scholar] [CrossRef]

- Jin, W.; Ding, Y.; Bai, S.; Zhang, X.; Yan, J.; Zhou, X. Design and experiments of the reel board header device for an oil sunflower harvester. Trans. Chin. Soc. Agric. Eng. China 2021, 37, 27–36. [Google Scholar] [CrossRef]

- Gang, L. Key Technology Research and Mechanism Optimisation for Plucking and Damage Reduction During Oilseed Rape Harvest. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2023. [Google Scholar] [CrossRef]

- Jin, C.; Qi, Y.; Liu, G.; Yang, T.; Ni, Y. Mechanism Analysis and Parameter Optimization of Soybean Combine Harvester Reel. Trans. Chin. Soc. Agric. Mach. China 2023, 54, 104–113. [Google Scholar] [CrossRef]

- Neenan, M.; Spencer-Smith, J. An analysis of the problem of lodging with particular reference to wheat and barley. J. Agric. Sci. 1975, 85, 495–507. [Google Scholar] [CrossRef]

- Prasad, J.; Gupta, C. Mechanical properties of maize stalk as related to harvesting. J. Agric. Eng. Res. 1975, 20, 79–87. [Google Scholar] [CrossRef]

- Iwaasa, A.; Beauchemin, K.; Buchanan-Smith, J.; Acharya, S. A shearing technique measuring resistance properties of plant stems. Anim. Feed Sci. Technol. 1996, 57, 225–237. [Google Scholar] [CrossRef]

- İnce, A.; Uğurluay, S.; Güzel, E.; Özcan, M. Bending and shearing characteristics of sunflower stalk residue. Biosyst. Eng. 2005, 92, 175–181. [Google Scholar] [CrossRef]

- Igathinathane, C.; Womac, A.; Sokhansanj, S.; Narayan, S. Size reduction of high-and low-moisture corn stalks by linear knife grid system. Biomass Bioenergy 2009, 33, 547–557. [Google Scholar] [CrossRef]

- Özbek, O.; Seflek, A.; Carman, K. Some mechanical properties of safflower stalk. Appl. Eng. Agric. 2009, 25, 619–625. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.; Schilling, M.; Columbus, E. Fast and simple measurement of cutting energy requirement of plant stalk and prediction model development. Ind. Crops Prod. 2011, 33, 518–523. [Google Scholar] [CrossRef]

- Gedam, K.V.; Deshmukh, M.; Thakare, S. Effect of blade parameters on force for cutting sugarcane stalk. BIOINFOLET-A Q. J. Life Sci. 2015, 12, 994–997. [Google Scholar]

- Liu, Q.; Qu, Y.; Qing, S.; Cheng, H. Failure tests of sugarcane stalks under torsion, compression and tension load. Trans. CSAE China 2006, 22, 201–204. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, J.; Zhang, Y.; Zhou, D. Effect of harvest date on shearing force of maize stems. Livest. Sci. 2007, 111, 33–44. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, F.; Cao, Z. Experiment on stalk mechanical properties of legume forage and grasses. Trans. CSA China 2009, 25, 122–126. [Google Scholar] [CrossRef]

- He, X.; Wu, X.; Zhang, L.; Chen, L. Research of Mechanics Characteristics for Soybean Stalks Compression. J. Agric. Mech. Res. China 2010, 32, 164–169. [Google Scholar] [CrossRef]

- Yan, Y.; Zhao, S.; Yang, Y.; Tian, B. Study on mechanics properties of soybean stems in mature stage. J. Northeast. Agric. Univ. China 2012, 43, 46–49. [Google Scholar] [CrossRef]

- Men, H.; Zhang, R.; Yuan, Y.; Zhu, C.; Yang, Q. Multiple Regression Analysis of Seedling Characters and Transplanting Modes on Yield of Welsh Onion. Shandong Agric. Sci. China 2014, 46, 23–25+32. [Google Scholar] [CrossRef]

- Chen, S. Finite Element Modeling and Analysis of Cassava Stalk Statics Simulation Based on ANSYS. Master’s Thesis, Hainan University, Hainan, China, 2015. [Google Scholar]

- Xiao, L. The Experiment Study on Mechanic Characteristic of Puelia Stalks and Single Disc Cutting Experiment Simulation. Master’s Thesis, Fujian Agriculture and Forestry University, Fuzhou, China, 2015. [Google Scholar] [CrossRef]

- Li, C. Experimental Study of the Mechanical Properties of Cassava Stalk. Master’s Thesis, Hainan University, Hainan, China, 2015. [Google Scholar]

- Min, W.; Hongyu, P.; Donglin, Z.; Dong, L. Analysis of Physicochemical Composition and Dynamic Mechanical Properties of Avena sativa Stalk. Trans. Chin. Soc. Agric. Mach. China 2018, 49, 447–455. [Google Scholar] [CrossRef]

- Liu, X.; Liang, Y.; Zhang, Y.; Cao, J. Impact of Planting Density on the Agronomic Traits and Yield of Chinese Onion. Inn. Mong. Agric. Sci. Technol. China 2019, 47, 86–89. [Google Scholar]

- Du, Z.; Hu, Y.; Buttar, N.A. Analysis of mechanical properties for tea stem using grey relational analysis coupled with multiple linear regression. Sci. Hortic. 2020, 260, 108886. [Google Scholar] [CrossRef]

- Yang, L.; Min, W.; Baoqin, W.; Jingbin, L.; Liqiao, L.; Za, K. Experimental study on the mechanical properties of Glycyrrhiza glabra stem on the grey correlation theory. J. Chin. Agric. Mech. China 2021, 42, 72–78. [Google Scholar] [CrossRef]

- Wang, F.; Ma, S.; Xing, H.; Bai, J.; Ma, J.; Yang, Y.; Hu, J. Base cutting energy consumption for sugarcane stools using contra-rotating basecutters. Trans. ASABE 2021, 64, 221–230. [Google Scholar] [CrossRef]

- Sun, G.; Pan, Y.; Wang, F. Study on Physical and Mechanical Properties of Green Onion. J. Agric. Mech. Res. China 2022, 44, 159–165+172. [Google Scholar] [CrossRef]

- Yu, Q.; Qiao, N.; Lu, H.; Hu, X.; Li, G.; Zhu, H. Effect Study of Plant Roots Reinforcement on Soil. Chin. J. Rock Mech. Eng. China 2012, 31, 3216–3223. [Google Scholar]

- Zhou, Y.; Chen, J.; Wang, X. Progress of study on soil reinforcement mechanisms by root and its expectation. Ecol. Environ. Sci. China 2012, 21, 1171–1177. [Google Scholar] [CrossRef]

- Liu, X. Study on Friction and Anchorage Characteristics Between Root System and Soil. Master’s Thesis, Beijing Forestry University, Beijing, China, 2013. [Google Scholar]

- Yun, S. The Research on the Mechanism of Vegetation for Slope Stabilization and the Design and Management of the Vegetation. Master’s Thesis, Central South University of Forestry and Technology, Changsha, China, 2005. [Google Scholar]

- Xin, Q.; Lv, Z.; Zhang, W.; Liu, L.; Cheng, X. Study on Pulling Force and Influencing Factors of Potato Seedling in Mature Period. J. Agric. Mech. Res. China 2020, 42, 173–176. [Google Scholar] [CrossRef]

- Liu, Q.; Tian, C.; Xu, L.; Lv, Z.; Liu, X.; Song, Y.; Yun, Y. Effect of Soil Physical Properties on Mechanical Pulling Process of Carrot. Agric. Eng. China 2019, 9, 63–66. [Google Scholar] [CrossRef]

- Xue, D.; Zhang, L.; Zhang, J.; Liu, X. Design and experimental research of mobile cotton stalk pulling resistance test device based on response surface method. J. Chin. Agric. Mech. China 2021, 42, 6–12. [Google Scholar] [CrossRef]

- Wang, C.; Hu, X.; Liu, C.; Li, X.; Fu, J.; Lu, H.; Zhao, J.; Xing, G.; He, W.; Yang, F.; et al. Study on the Characteristics and Influence Factors of Root Pull-out Resistance of Six Grasses in the Source Region of the Yellow River. Acta Agrestia Sin. China 2023, 31, 157–165. [Google Scholar] [CrossRef]

- Liu, Q.; Xu, L.; Liu, X.; Lv, Z.; Song, Y.; Li, C. Research on dynamic behavior during mechanical pulling of carrot based on distinct element method. J. Chin. Agric. Mech. China 2018, 39, 61–65. [Google Scholar] [CrossRef]

- Yan, K.; Yao, S.; Huang, Y.; Zhao, Z. Study on pulling dynamic characteristics of white radish and the optimal design of a harvesting device. Agriculture 2023, 13, 942. [Google Scholar] [CrossRef]

- Wu, W.; Pan, L.; Tang, L.; Liao, L.; Ruan, S. Friction characteristics of root-soil interface during branches root pull-out of Indigofera amblyantha and Cassia bicapsulafis. Trans. Chin. Soc. Agric. Eng. China 2023, 39, 57–65. [Google Scholar] [CrossRef]

- Peng, S. Design and Research on Key Technology of Double-Row Self-Propelled Welsh Onion Combine Harvester. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2018. [Google Scholar]

- Feng, H. Design and Research of Double-Row Pulling Carrot Harvester. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2012. [Google Scholar]

- Liu, Y.; Guo, H.; Li, L.; Sun, Y.; Simayi, A.; Li, Q. Developing of Gripping Chain Cotton Straw pulling up Machine. Xinjiang Agric. Mech. China 2017, 10–11+15. [Google Scholar] [CrossRef]

- Wang, Z.; Baikeli, Y.; Song, L. Design of a Gripping-Chain Type Uprooting Machine for Xinjiang Cotton Stalks. Jiangsu Agric. Mech. China 2023, 4, 11–15. [Google Scholar] [CrossRef]

- Song, Y. Low Damage Optimization and Test of the Pulling and Conveying Device of Spinach Whole Plant Orderly Harvester. Master’s Thesis, Shandong Agricultural University, Jinan, China, 2019. [Google Scholar]

- Zou, L. Research on the Key Technologies of Low Damage and Orderly Harvest for Spinach with Root. Doctoral Thesis, Shandong Agricultural University, Jinan, China, 2022. [Google Scholar] [CrossRef]

- Yao, S. Optimal Design and Experimental Research on Key Components of Cabbage Harvester. Master’s Thesis, Chinese Academy of Agricultural Sciences, Beijing, China, 2020. [Google Scholar]

- Yang, J. Design and Experimental Study of Cabbage Picking and Conveying Device. Master’s Thesis, Jiamusi University, Jiamusi, China, 2023. [Google Scholar] [CrossRef]

- Ma, M. Design and Optimization of Harvesting Components of Self-Propelled Cabbage Harvester. Master’s Thesis, Jiamusi University, Jiamusi, China, 2023. [Google Scholar]

- Wang, S. Design and Experimental Research of Self-Propelled Cabbage Harvesting Test Platform. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2023. [Google Scholar]

- Yang, R. Study on Design Principle and Tests for Main Parts of 4HQL-2 Peanut Combine. Doctoral Thesis, Shenyang Agricultural University, Shenyang, China, 2009. [Google Scholar]

- Hu, Z. Study on Key Technologies of Half-Feed Peanut Combine Harvester. Doctoral Thesis, Nanjing Agricultural University, Nanjing, China, 2011. [Google Scholar]

- Yang, J. Research on the Key Components of Garlic Harvester Based on the Disruptive Innovation Theory. Master’s Thesis, University of Jinan, Jinan, China, 2017. [Google Scholar] [CrossRef]

- Zhang, J. Research on Physical and Mechanical Properties of Headed Chinese Cabbage and Its Crawler Self-Propelled Harvesting Equipment. Doctoral Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar] [CrossRef]

- Zhao, Y. Structural Design and Performance Experimental Research of Self-Propelled Harvester for Densely Planted Broccoli. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2023. [Google Scholar]

- Guo, X. Study on Gripping Delivery Mechanism For Vertical-roller Corn Harvester. Master’s Thesis, Shandong University of Technology, Zibo, China, 2014. [Google Scholar]

- Hu, S. The current research status and prospective development directions of corn harvesting machinery. Mod. Agric. China 2013, 3, 59–61. [Google Scholar] [CrossRef]

- Fan, G.; Yang, Q.; Zhang, X.; Wang, J.; Chen, R.; Ge, Y. Design and Test of Intelligent Tobacco Topping Machine with Clamping Belt. Trans. Chin. Soc. Agric. Mach. China 2017, 48, 121–126. [Google Scholar] [CrossRef]

- Zhu, G. Study on the Mechanism and Device of Biomimetic Ear Picking for Fresh Corn. Doctoral Thesis, Northeast Agricultural University, Harbin, China, 2023. [Google Scholar]

- Tong, W. Structural Design and Test Optimization of Key Components of Hand-Held Cabbage Harvester. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2023. [Google Scholar] [CrossRef]

- Chen, J.; Song, J.; Guan, Z.; Lian, Y. Measurement of the distance from grain divider to harvesting boundary based on dynamic regions of interest. Int. J. Agric. Biol. Eng. 2021, 14, 226–232. [Google Scholar] [CrossRef]

- Ji, K.; Li, Y.; Liang, Z.; Liu, Y.; Cheng, J.; Wang, H.; Zhu, R.; Xia, S.; Zheng, G. Device and Method Suitable for Matching and Adjusting Reel Speed and Forward Speed of Multi-Crop Harvesting. Agriculture 2022, 12, 213. [Google Scholar] [CrossRef]

- Zhuang, X.; Li, Y. Segmentation and Angle Calculation of Rice Lodging during Harvesting by a Combine Harvester. Agriculture 2023, 13, 1425. [Google Scholar] [CrossRef]

- Xin, S. Study on the Mechanism and Key Technology of Corn Ear Picking with Vertical Roller. Doctoral Thesis, Gansu Agricultural University, Lanzhou, China, 2020. [Google Scholar] [CrossRef]

- Li, Y.; Wan, X.; Liao, Q.; Liu, Y.; Zhang, Q.; Liao, Y. Design and experiment of wide folding rape windrower based on crawler type power chassis. J. Jilin Univ. (Eng. Technol. Ed.) China 2023, 54, 1–13. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, X.; Guo, H.; Sun, R.; Huo, Y.; He, Q. Design and experiment of track–type and self–propelledchive harvester. Agric. Equip. Veh. Eng. China 2024, 62, 1–6+13. [Google Scholar]

- Yan, D. Design and Test of Brush Roller Safflower Harvesting Device. Master’s Thesis, Shandong Agricultural University, Jinan, China, 2024. [Google Scholar] [CrossRef]

- Wei, W. Design and Experimental Study on Key Components of Brassica Chinensis Orderly Harvester. Doctoral Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar] [CrossRef]

- Chao, L. Design and Test of Walking Garlic Combine Harvester. Master’s Thesis, Shandong Agricultural University, Jinan, China, 2022. [Google Scholar] [CrossRef]

- Wei, L. Research on Key Technologies and Equipment For Reducing Losses in Cutting and Threshing of Oil Sunflower Combine Harvester. Doctoral Thesis, Huazhong Agricultural University, Wuhan, China, 2023. [Google Scholar]

- Kachru, R.; Sahay, K. Developing and testing of pedal-cum-power operated air screen grain cleaner. Agric. Mech. Asia Afr. Lat. Am. 1990, 21, 29–32. [Google Scholar]

- Srivastav, S.; Joshi, D. Mathematical model for design and development of double drum rotary screen cleaner-cum-grader for cumin seed. Agric. Mech. Asia Afr. Lat. Am. 2013, 44, 70–74. [Google Scholar]

- Jethva, K.; Varshney, A. Design and development of reciprocating type cumin cleaner cum grader. Agric. Mech. Asia Afr. Lat. Am. 2016, 47, 8. [Google Scholar]

- Aradwad, P.P.; TV, A.K.; Mani, I.; Sahoo, P. Design and Development of Cumin Destalker Machine. J. Sci. Ind. Res. 2022, 81, 705–711. [Google Scholar] [CrossRef]

- Alkhaldi, H.; Eberhard, P. Particle screening phenomena in an oblique multi-level tumbling reservoir: A numerical study using discrete element simulation. Granul. Matter 2007, 9, 415–429. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, C.; Yan, J. A virtual experiment showing single particle motion on a linearly vibrating screen-deck. Min. Sci. Technol. China 2010, 20, 276–280. [Google Scholar] [CrossRef]

- Li, J.; Webb, C.; Pandiella, S.; Campbell, G.M. A numerical simulation of separation of crop seeds by screening—Effect of particle bed depth. Food Bioprod. Process. 2002, 80, 109–117. [Google Scholar] [CrossRef]

- Myhan, R.; Jachimczyk, E. Grain separation in a straw walker unit of a combine harvester: Process model. Biosyst. Eng. 2016, 145, 93–107. [Google Scholar] [CrossRef]

- Lawinska, K.; Modrzewski, R. Analysis of sieve holes blocking in a vibrating screen and a rotary and drum screen. Physicochem. Probl. Miner. Process. 2017, 53, 812–828. [Google Scholar] [CrossRef]

- Ma, X.; Guo, B.; Li, L. Simulation and experiment study on segregation mechanism of rice from straws under horizontal vibration. Biosyst. Eng. 2019, 186, 1–13. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Zhou, Y.; Li, B.; Liang, Z.; Li, Y. Effects of throughput and operating parameters on cleaning performance in air-and-screen cleaning unit: A computational and experimental study. Comput. Electron. Agric. 2018, 152, 141–148. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; De Baerdemaeker, J.; Baelmans, M. Effect of a cross-flow opening on the performance of a centrifugal fan in a combine harvester: Computational and experimental study. Biosyst. Eng. 2010, 105, 247–256. [Google Scholar] [CrossRef]

- Gebrehiwot, M.G.; De Baerdemaeker, J.; Baelmans, M. Numerical and experimental study of a cross-flow fan for combine cleaning shoes. Biosyst. Eng. 2010, 106, 448–457. [Google Scholar] [CrossRef]

- Panasiewicz, M.; Sobczak, P.; Mazur, J.; Zawiślak, K.; Andrejko, D. The technique and analysis of the process of separation and cleaning grain materials. J. Food Eng. 2012, 109, 603–608. [Google Scholar] [CrossRef]

- Chen, X.; Bai, J.; Wang, X.; Fang, W.; Hong, T.; Zang, N.; Fang, L.; Wang, G. Calibration and Testing of Discrete Elemental Simulation Parameters for Pod Pepper Seeds. Agriculture 2024, 14, 831. [Google Scholar] [CrossRef]

- Chen, X.; Wang, X.; Bai, J.; Fang, W.; Hong, T.; Zang, N.; Wang, G. Virtual parameter calibration of pod pepper seeds based on discrete element simulation. Heliyon 2024, 10, e31686. [Google Scholar] [CrossRef] [PubMed]

- Du, C.; Han, D.; Song, Z.; Chen, Y.; Chen, X.; Wang, X. Calibration of contact parameters for complex shaped fruits based on discrete element method: The case of pod pepper (Capsicum annuum). Biosyst. Eng. 2023, 226, 43–54. [Google Scholar] [CrossRef]

- Fang, W.; Wang, X.; Han, D.; Chen, X. Review of material parameter calibration method. Agriculture 2022, 12, 706. [Google Scholar] [CrossRef]

- Liang, Z.; Li, J.; Liang, J.; Shao, Y.; Zhou, T.; Si, Z.; Li, Y. Investigation into experimental and DEM simulation of guide blade optimum arrangement in multi-rotor combine harvesters. Agriculture 2022, 12, 435. [Google Scholar] [CrossRef]

- Wang, L.; Chai, X.; Huang, J.; Hu, J.; Cui, Z. Efficient and Low-Loss Cleaning Method for Non-Uniform Distribution of Threshed Materials Based on Multi-Wing Curved Combination Air Screen in Computational Fluid Dynamics/Discrete Element Method Simulations. Agriculture 2024, 14, 895. [Google Scholar] [CrossRef]

- Yuan, H.; Cai, Y.; Liang, S.; Ku, J.; Qin, Y. Numerical simulation and analysis of feeding uniformity of viscous miscellaneous fish bait based on EDEM software. Agriculture 2023, 13, 356. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, S.; Wang, J.; Lu, Y. Numerical simulation and analysis of vibrating rice filling based on EDEM software. Agriculture 2022, 12, 2013. [Google Scholar] [CrossRef]

- Gierz, L.; Kruszelnicka, W.; Robakowska, M.; Przybl, K.; Koszela, K.; Marciniak, A.; Zwiachel, T. Optimization of the Sowing Unit of a Piezoelectrical Sensor Chamber with the Use of Grain Motion Modeling by Means of the Discrete Element Method. Case Study Rape Seed. Appl. Sci. 2022, 12, 1594. [Google Scholar] [CrossRef]

- Jawad, H.M.; Jawad, A.M.; Nordin, R.; Gharghan, S.K.; Abdullah, N.F.; Ismail, M.; Abu-AlShaeer, M.J. Accurate Empirical Path-Loss Model Based on Particle Swarm Optimization for Wireless Sensor Networks in Smart Agriculture. IEEE Sens. J. 2020, 20, 552–561. [Google Scholar] [CrossRef]

- Kumar, B.; Shaloo, H.; Bisht, H.; Meena, M.C.; Dey, A.; Dass, A.; Paramesh, V.; Babu, S.; Upadhyay, P.K.; Prajapati, V.K.; et al. Nitrogen management sensor optimization, yield, economics, and nitrogen use efficiency of different wheat cultivars under varying nitrogen levels. Front. Sustain. Food Syst. 2023, 7, 1228221. [Google Scholar] [CrossRef]

- Sharma, C.; Choudhury, R.; Sarma, U. Sensor Array Optimization to Design and Develop an Electronic Nose System for the Detection of Water Stress in Khasi Mandarin Orange. J. Circuits Syst. Comput. 2022, 31, 2250172. [Google Scholar] [CrossRef]

- Tang, R.; Yang, J.; Tang, J.; Aridas, N.K.; Abu Talip, M.S. Design of agricultural wireless sensor network node optimization method based on improved data fusion algorithm. PLoS ONE 2024, 19, e0308845. [Google Scholar] [CrossRef]

- Xu, S.; Xu, X.; Blacker, C.; Gaulton, R.; Zhu, Q.; Yang, M.; Yang, G.; Zhang, J.; Yang, Y.; Yang, M.; et al. Estimation of Leaf Nitrogen Content in Rice Using Vegetation Indices and Feature Variable Optimization with Information Fusion of Multiple-Sensor Images from UAV. Remote Sens. 2023, 15, 854. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter determination of a viscoelastic-plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Shi, M.; Liang, Z.; Zhang, J.; Xu, L.; Song, X. A robust prediction method based on Kriging method and fuzzy c-means algorithm with application to a combine harvester. Struct. Multidiscip. Optim. 2022, 65, 260. [Google Scholar] [CrossRef]

- Chen, H.; Dai, S.; Ou, M.; Li, S.; Wang, C.; Li, Z.; Wang, G.; Chen, Y.; Jia, W. Multibody Dynamics Simulation and Vibration Test for High Clearance Orchard Sprayer. Appl. Sci. 2022, 12, 8058. [Google Scholar] [CrossRef]

- Han, L.; Liu, Y.; Mo, M.; Ma, H.; Kumi, F.; Mao, H. Development and Evaluation of a Walking Type Two-row Semi-automatic Transplanter for Vegetable Plug Seedlings. Ama-Agric. Mech. Asia Afr. Lat. Am. 2023, 54. [Google Scholar]

- Huang, M.; Jiang, X.; He, L.; Choi, D.; Pecchia, J.; Li, Y. Development of a robotic harvesting mechanism for button mushrooms. Trans. Asabe 2021, 64, 565–575. [Google Scholar] [CrossRef]

- Ji, W.; He, G.; Xu, B.; Zhang, H.; Yu, X. A New Picking Pattern of a Flexible Three-Fingered End-Effector for Apple Harvesting Robot. Agriculture 2024, 14, 102. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.; Shen, Y.; Li, C.; Zhang, Y.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Liu, J.; Liang, J.; Zhao, S.; Jiang, Y.; Wang, J.; Jin, Y. Design of a Virtual Multi-Interaction Operation System for Hand-Eye Coordination of Grape Harvesting Robots. Agronomy 2023, 13, 829. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, J.; Wang, J.; Cai, L.; Jin, Y.; Zhao, S.; Xie, B. Realtime Picking Point Decision Algorithm of Trellis Grape for High-Speed Robotic Cut-and-Catch Harvesting. Agronomy 2023, 13, 1618. [Google Scholar] [CrossRef]

- Zhu, Q.; Zhang, H.; Zhu, Z.; Gao, Y.; Chen, L. Structural Design and Simulation of Pneumatic Conveying Line for a Paddy Side-Deep Fertilisation System. Agriculture 2022, 12, 867. [Google Scholar] [CrossRef]

- Lu, E.; Tian, Z.; Xu, L.; Ma, Z.; Luo, C. Observer-based robust cooperative formation tracking control for multiple combine harvesters. Nonlinear Dyn. 2023, 111, 15109–15125. [Google Scholar] [CrossRef]

- Xue, H.; Ding, D.; Zhang, Z.; Wu, M.; Wang, H. A Fuzzy System of Operation Safety Assessment Using Multimodel Linkage and Multistage Collaboration for In-Wheel Motor. IEEE Trans. Fuzzy Syst. 2022, 30, 999–1013. [Google Scholar] [CrossRef]

- Fue, K.; Porter, W.; Barnes, E.; Li, C.; Rains, G. Center-Articulated Hydrostatic Cotton Harvesting Rover Using Visual-Servoing Control and a Finite State Machine. Electronics 2020, 9, 1226. [Google Scholar] [CrossRef]

- Gu, S.; Sun, S.; Wang, X.; Wang, S.; Yang, M.; Li, J.; Maimaiti, P.; van der Werf, W.; Evers, J.B.; Zhang, L. Optimizing radiation capture in machine-harvested cotton: A functional-structural plant modelling approach to chemical vs. manual topping strategies. Field Crops Res. 2024, 317, 109553. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W.; Zhao, Z.; Wang, H.; Liu, X.; Zhang, H.; Li, H.; Simionescu, P.A. Development and Testing of a Self-Propelled Machine for Combined Potato Harvesting and Residual Plastic Film Retrieval. Machines 2023, 11, 432. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, S.; Tang, Z.; Li, B.; Wang, S.; Guo, X. Cumin-Harvesting Mechanization of the Xinjiang Cotton–Cumin Intercropping System: Review of the Problem Status and Solutions. Agriculture 2025, 15, 809. https://doi.org/10.3390/agriculture15080809

Tai S, Tang Z, Li B, Wang S, Guo X. Cumin-Harvesting Mechanization of the Xinjiang Cotton–Cumin Intercropping System: Review of the Problem Status and Solutions. Agriculture. 2025; 15(8):809. https://doi.org/10.3390/agriculture15080809

Chicago/Turabian StyleTai, Sheng, Zhong Tang, Bin Li, Shiguo Wang, and Xiaohu Guo. 2025. "Cumin-Harvesting Mechanization of the Xinjiang Cotton–Cumin Intercropping System: Review of the Problem Status and Solutions" Agriculture 15, no. 8: 809. https://doi.org/10.3390/agriculture15080809

APA StyleTai, S., Tang, Z., Li, B., Wang, S., & Guo, X. (2025). Cumin-Harvesting Mechanization of the Xinjiang Cotton–Cumin Intercropping System: Review of the Problem Status and Solutions. Agriculture, 15(8), 809. https://doi.org/10.3390/agriculture15080809