The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid

Abstract

1. Introduction

2. Materials and Methods

2.1. Rehydration and Ensiling of Maize Grain

2.2. Analyses of Physical Properties of Maize Grain

2.3. Analysis of Chemical Properties of Ensiled Maize Grain

2.4. In Vitro Starch Digestion of Ensiled Maize Grain

2.5. In Vitro Starch Digestion Calculations

2.6. Statistical Analysis

3. Results and Discussion

3.1. Physical Properties of Tested Maize Hybrids

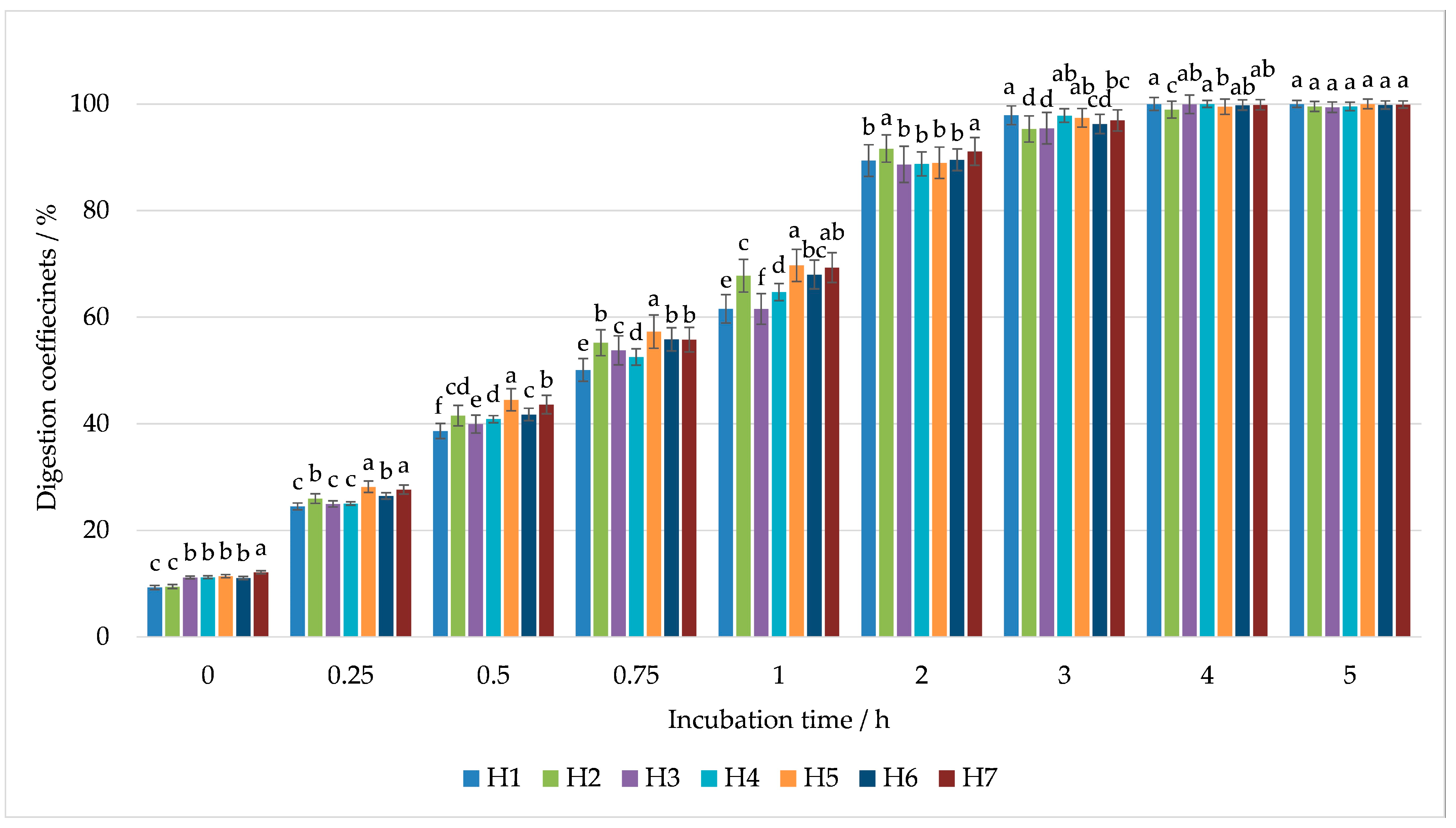

3.2. Starch Digestibility Kinetics of Tested Maize Hybrids

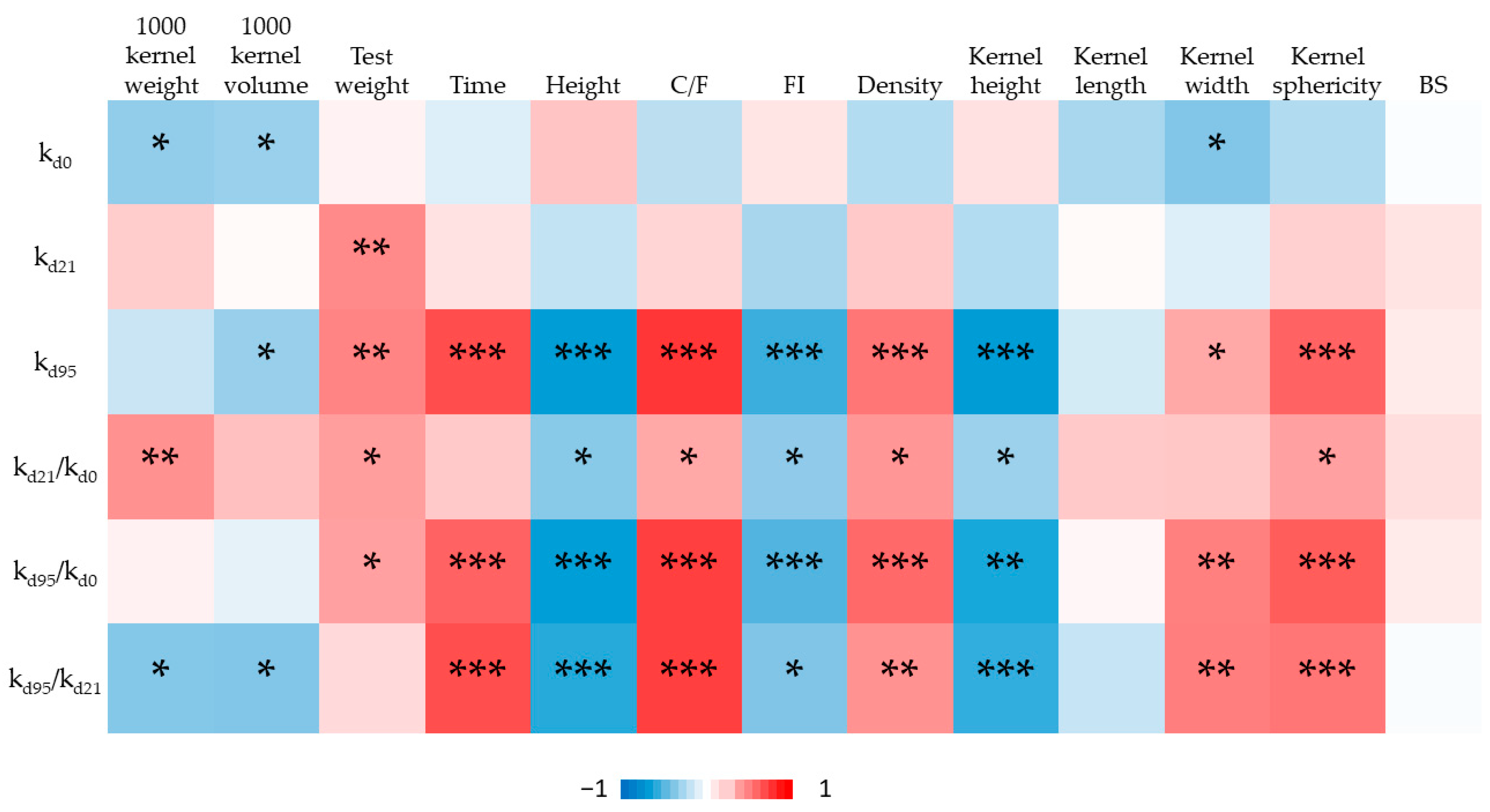

3.3. Relationship Between Physical Grain Properties and Starch Digestibility Rate

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, S.; Cho, J.H.; Kim, Y.; Kim, H.B.; Song, M. Effects of substitution of corn with ground brown rice on growth performance, nutrient digestibility, and gut microbiota of growing-finishing pigs. Animals 2021, 11, 375. [Google Scholar] [CrossRef] [PubMed]

- Płacheta, B.; Motyl, I.; Berłowska, J.; Mroczyńska-Florczak, M. The use of fermented plant biomass in pigs feeding. Sustainability 2022, 14, 14595. [Google Scholar] [CrossRef]

- Mihok, T.; Hreško Šamudovská, A.; Bujňák, L.; Timkovičová Lacková, P. Determination of buffering capacity of the selected feeds used in swine nutrition. J. Cent. Eur. Agric. 2022, 23, 732–738. [Google Scholar] [CrossRef]

- Stein, H.; De Lange, K. Alternative feed ingredients for pigs. In Proceedings of the 2007 London Swine Conference—Todays Challenges Tomorrow’s Opportunities, London, ON, Canada, 3–4 April 2007; Murphy, J.M., Ed.; London Swine Conference: London, ON, Canada, 2007; pp. 109–117. [Google Scholar]

- Chaves, A.A.M.; Martins, C.F.; Vasconcels, M.; Almeida, A.M.; Freire, J.P.B. In vitro digestibility of four high moisture grains used in liquid pig feeding. Trop. Anim. Health. Prod. 2022, 54, 136. [Google Scholar] [CrossRef]

- Silva, M.A.A.; Carvalho, P.L.O.; Paiano, D.; Silva, M.A.; Genova, J.L.; Grando, M.A.; Carvalho, S.T. Statistical assessment of feeding corn with higher oil content to piglets in the starter phase. S. Afr. J. Anim. Sci. 2021, 51, 460–468. [Google Scholar] [CrossRef]

- Zanin, E.; Horst, E.H.; Dario, J.G.N.; Krzezanovski, C.K.B.; Ruiz, G.; Fregonesi, J.A.; Silva, C.A.; Bumbieris, V.H. Performance and feed preference of weaned piglets fed with corn grain silage subjected to different rehydration sources. Arq. Bras. Med. Vet. Zootec. 2023, 75, 485–499. [Google Scholar] [CrossRef]

- Cruz-Polycarpo, V.C.; Sartori, J.R.; Gonçalves, J.C.; Pinheiro, D.F.; Madeira, L.A.; Polycarpo, G.V.; Zanetti, L.H.; Santos, T.S.; Pezzato, A.C. Feeding high-moisture corn grain silage to broilers fed alternative diets and maintained at different environmental temperatures. Braz. J. Poult. Sci. 2014, 16, 448–457. [Google Scholar] [CrossRef]

- de Castro Lopes, A.B.R.; Berto, D.A.; Costa, C.; Muniz, M.H.B.; de Magalhães Rosa, G.J. Silagem de grãos úmidos de milho para suínos nas fases de crescimento e terminação. B. Ind. Anim. 2001, 58, 191–200. [Google Scholar]

- Tse, M.L.P.; Berto, D.A.; Tofoli, C.A.; Wechsler, F.S.; Trindade Neto, M.A. Nutritional value of high moisture corn silage with different particle sizes for piglets in nursery phase. Arq. Bras. Med. Vet. Zootec. 2006, 58, 1214–1221. [Google Scholar] [CrossRef]

- Bassi, L.S.; Hejdysz, M.; Pruszyńska-Oszmałek, E.; Kołodziejski, P.A.; Cowieson, A.J.; Kaczmarek, S.A.; Svihus, B. Nutrient digestion efficiency: A comparison between broiler chickens and growing pigs fed maize, barley and oats-based diets with an emphasis on starch. Br. J. Nutr. 2025, 133, 182–193. [Google Scholar] [CrossRef] [PubMed]

- Kljak, K.; Duvnjak, M.; Grbeša, D. Contribution of zein content and starch characteristics to vitreousness of commercial maize hybrids. J. Cereal Sci. 2018, 80, 57–62. [Google Scholar] [CrossRef]

- Gayral, M.; Gaillard, C.; Bakan, B.; Dalgalarrondo, M.; Elmorjani, K.; Delluc, C.; Brunet, S.; Linossier, L.; Morel, M.-H.; Marion, D. Transition from vitreous to floury endosperm in maize (Zea mays L.) kernels is related to protein and starch gradients. J. Cereal Sci. 2016, 68, 148–154. [Google Scholar] [CrossRef]

- Xu, A.; Lin, L.; Guo, K.; Liu, T.; Yin, Z.; Wei, C. Physicochemical properties of starches from vitreous and floury endosperms from the same maize kernels. Food Chem. 2019, 291, 149–156. [Google Scholar] [CrossRef]

- García-Lara, S.; Chuck-Hernandez, C.; Serna-Saldivar, S.O. Development and structure of the corn kernel. In Corn: Chemistry and Technology, 3rd ed.; Serna-Saldivar, S.O., Ed.; AACC International Press: St. Paul, MN, USA, 2019; pp. 147–163. [Google Scholar] [CrossRef]

- Hamaker, B.R.; Mohamed, A.A.; Habben, J.E.; Huang, C.P.; Larkins, B.A. Efficient procedure for extracting maize and sorghum kernel proteins reveals higher prolamin contents than the conventional method. Cereal Chem. 1995, 72, 583–588. [Google Scholar]

- Mu-Forster, C.; Wasserman, B.P. Surface localization of zein storage proteins in starch granules from maize endosperm: Proteolytic removal by thermolysin and in vitro cross-linking of granule-associated polypeptides. Plant Physiol. 1998, 116, 1563–1571. [Google Scholar] [CrossRef]

- Zurak, D.; Kljak, K.; Grbeša, D. The composition of floury and vitreous endosperm affects starch digestibility kinetics of the whole maize kernel. J. Cereal Sci. 2020, 95, 103079. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, G. Physicochemical properties of vitreous and floury endosperm flours in maize. Food Sci. Nutr. 2019, 7, 2605–2612. [Google Scholar] [CrossRef]

- Kljak, K.; Grbeša, D.; Aleuš, D. Relationships between kernel physical properties and zein content in corn hybrids. Bull. UASVM Agric. 2011, 68, 188–194. [Google Scholar] [CrossRef]

- Fox, G.; Manley, M. Hardness methods for testing maize kernels. J. Agric. Food Chem. 2009, 57, 5647–5657. [Google Scholar] [CrossRef]

- Giuberti, G.; Gallo, A.; Moschini, M.; Cerioli, C.; Masoero, F. Evaluation of the impact of maize endosperm vitreousness on in vitro starch digestion, dry matter digestibility and fermentation characteristics for pigs. Anim. Feed Sci. Technol. 2013, 186, 71–80. [Google Scholar] [CrossRef]

- Correa, C.E.S.; Shaver, R.D.; Pereira, M.N.; Lauer, J.G.; Kohn, K. Relationship between corn vitreousness and ruminal in situ starch degradability. J. Dairy Sci. 2002, 85, 3008–3012. [Google Scholar] [CrossRef] [PubMed]

- Bello-Perez, L.A.; Flores-Silva, P.C.; Agama-Acevedo, E.; Tovar, J. Starch digestibility: Past, present, and future. J. Sci. Food Agric. 2020, 100, 5009–5016. [Google Scholar] [CrossRef]

- Wang, Y.; Ral, J.P.; Saulnier, L.; Kansou, K. How does starch structure impact amylolysis? Review of current strategies for starch digestibility study. Foods 2022, 11, 1223. [Google Scholar] [CrossRef]

- Singh, J.; Dartois, A.; Kaur, L. Starch digestibility in food matrix: A review. Trends Food Sci. Technol. 2010, 21, 168–180. [Google Scholar] [CrossRef]

- Dhital, S.; Shrestha, A.K.; Gidley, M.J. Relationship between granule size and in vitro digestibility of maize and potato starches. Carbohydr. Polym. 2010, 82, 480–488. [Google Scholar] [CrossRef]

- Zurak, D.; Vlajsović, D.; Duvnjak, M.; Salajpal, K.; Kljak, K. Factors affecting starch digestibility rate of maize grain in poultry. World’s Poult. Sci. J. 2023, 79, 43–68. [Google Scholar] [CrossRef]

- Xia, J.; Zhu, D.; Wang, R.; Cui, Y.; Yan, Y. Crop resistant starch and genetic improvement: A review of recent advances. Theor. Appl. Genet. 2018, 131, 2495–2511. [Google Scholar] [CrossRef]

- Giuberti, G.; Gallo, A.; Cerioli, C.; Masoero, F. In vitro starch digestion and predicted glycemic index of cereal grains commonly utilized in pig nutrition. Anim. Feed Sci. Techol. 2012, 174, 163–173. [Google Scholar] [CrossRef]

- Khatun, A.; Waters, D.L.; Liu, L. The impact of rice protein on in vitro rice starch digestibility. Food Hydrocoll. 2020, 109, 106072. [Google Scholar] [CrossRef]

- Junges, D.; Morais, G.; Spoto, M.H.F.; Santos, P.S.; Adesogan, A.T.; Nussio, L.G.; Daniel, J.L.P. Influence of various proteolytic sources during fermentation of reconstituted corn grain silages. J. Dairy Sci. 2017, 100, 9048–9051. [Google Scholar] [CrossRef]

- Hoffman, P.C.; Esser, N.M.; Shaver, R.D.; Coblentz, W.K.; Scott, M.P.; Bodnar, A.L.; Schmidt, R.J.; Charley, R.C. Influence of ensiling time and inoculation on alteration of the starch-protein matrix in high-moisture corn. J. Dairy Sci. 2011, 94, 2465–2474. [Google Scholar] [CrossRef]

- Varela, J.; Ferraretto, L.F.; Kaeppler, S.M.; de León, N. Effects of endosperm type and storage length of whole-plant corn silage on nitrogen fraction, fermentation products, zein profile, and starch digestibility. J. Dairy Sci. 2023, 106, 8710–8722. [Google Scholar] [CrossRef]

- Svečnjak, Z.; Varga, B.; Pospišil, A.; Jukić, Ž.; Leto, J. Maize hybrid performance as affected by production systems in Croatia. Bodenkultur 2004, 55, 37–44. [Google Scholar]

- Agri4Cast Resources Portal. Available online: https://agri4cast.jrc.ec.europa.eu/DataPortal/Index.aspx (accessed on 20 March 2025).

- ISO 6498:2012; Animal Feeding Stuffs—Guidelines for Sample Preparation. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 6496:1999; Animal Feeding Stuffs—Determination of Moisture and other Volatile Matter Content. International Organization for Standardization: Geneva, Switzerland, 1999.

- Matin, A.; Krička, T.; Voća, N.; Jukić, Ž.; Janušić, V. Impact of drying on dimensions of corn kernel grown at different agrotechnological levels. Agric. Conspec. Sci. 2007, 72, 205–209. [Google Scholar]

- Pomeranz, Y.; Czuchajowska, Z.; Martin, C.R.; Lai, F.S. Determination of corn hardness by the Stenvert hardness tester. Cereal Chem. 1985, 62, 108–112. [Google Scholar]

- Kim, T.H.; Opara, L.U.; Hampton, J.G.; Hardacre, A.K.; MacKay, B.R. PH-postharvest technology: The effects of grain temperature on breakage susceptibility in maize. Biosyst. Eng. 2002, 82, 415–421. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Starch (total) in cereal products, amyloglucosidase-α-amylase method—AOAC Official Method 996.11. In Official Methods of Analysis of Official Analytical Chemists International, 16th ed.; Association of Official Analytical Chemists: Washington DC, USA, 1995; pp. 55–58. [Google Scholar]

- Schoorl, N. Suiker titraties. Chem. Weekbl. 1929, 26, 130–134. [Google Scholar]

- Somogy, M. A new reagent for the determination of sugars. J. Biol. Chem. 1945, 160, 61–68. [Google Scholar]

- Córdova-Noboa, H.A.; Oviedo-Rondón, E.O.; Matta, Y.; Ortiz, A.; Buitrago, G.D.; Martinez, J.D.; Yanquen, Y.; Hoyos, S.; Castellanos, A.G.; Sorbara, J.O. Corn kernel hardness, drying temperature and amylase supplementation affect live performance and nutrient utilization of broilers. Poult. Sci. 2021, 100, 101395. [Google Scholar] [CrossRef]

- Caballero-Rothar, N.N.; Borrás, L.; Gerde, J.A. Physical and chemical kernel traits affect starch digestibility and glycemic index of cooked maize flours. Food Chem. 2022, 369, 130953. [Google Scholar] [CrossRef]

- Kljak, K.; Novaković, K.; Zurak, D.; Jareš, M.; Pamić, S.; Duvnjak, M.; Grbeša, D. Physical properties of kernels from modern maize hybrids used in Croatia. J. Cent. Eur. Agric. 2020, 21, 543–553. [Google Scholar] [CrossRef]

- Zurak, D.; Gunjević, V.; Grbeša, D.; Svečnjak, Z.; Kralik, Z.; Košević, M.; Džidić, A.; Pirgozliev, V.; Kljak, K. Kernel properties related to carotenoid release during in vitro gastrointestinal digestion in commercial dent maize hybrids. Food Chem. 2024, 435, 137535. [Google Scholar] [CrossRef] [PubMed]

- Jareš, M.; Zurak, D.; Novaković, K.; Pamić, S.; Kljak, K.; Grbeša, D. Prediction of maize vitreousness from kernel physical traits. In Book of Abstracts, Proceedings of the 25th International Conference “Krmiva 2018”, Opatija, Croatia, 6–8 June 2018; Modrić, M., Matin, A., Eds.; Krmiva D.O.O. Zagreb: Zagreb, Croatia, 2018; pp. 52–53. [Google Scholar]

- Tamagno, S.; Greco, I.A.; Almeida, H.; Borrás, L. Physiological differences in yield related traits between flint and dent Argentinean commercial maize genotypes. Eur. J. Agron. 2015, 68, 50–56. [Google Scholar] [CrossRef]

- Mun, S.H.; Shin, M. Mild hydrolysis of resistant starch from maize. Food Chem. 2006, 96, 115–121. [Google Scholar] [CrossRef]

- da Silva, N.C.; Nascimento, C.F.; Campos, V.M.; Alves, M.A.; Resende, F.D.; Daniel, J.L.; Siqueira, G.R. Influence of storage length and inoculation with Lactobacillus buchneri on the fermentation, aerobic stability, and ruminal degradability of high-moisture corn and rehydrated corn grain silage. Anim. Feed Sci. Technol. 2019, 251, 124–133. [Google Scholar] [CrossRef]

- Duvnjak, M.; Butorac, A.; Kljak, K.; Nišavić, M.; Cindrić, M.; Grbeša, D. The evaluation of γ-zein reduction using mass spectrometry—The influence of proteolysis type in relation to starch degradability in silages. Fermentation 2022, 8, 551. [Google Scholar] [CrossRef]

- Caballero-Rothar, N.N.; Abdala, L.J.; Borrás, L.; Gerde, J.A. Role of yield genetic progress on the biochemical determinants of maize kernel hardness. J. Cereal Sci. 2019, 87, 301–310. [Google Scholar] [CrossRef]

- Brambillasca, S.; Fernández–García, M.; Aguerre, M.; Repetto, J.L.; Cajarville, C. Characterization of the in vitro digestion of starch and fermentation kinetics of dry sorghum grains soaked or rehydrated and ensiled to be used in pig nutrition. J. Cereal Sci. 2019, 89, 102817. [Google Scholar] [CrossRef]

- Kung Jr, L.; Shaver, R.D.; Grant, R.J.; Schmidt, R.J. Silage review: Interpretation of chemical, microbial, and organoleptic components of silages. J. Dairy Sci. 2018, 101, 4020–4033. [Google Scholar] [CrossRef]

- Tan, F.P.; Beltranena, E.; Zijlstra, R.T. Resistant starch: Implications of dietary inclusion on gut health and growth in pigs: A review. J. Anim. Sci. Biotechnol. 2021, 12, 124. [Google Scholar] [CrossRef]

- Metzler-Zebeli, B.U.; Canibe, N.; Montagne, L.; Freire, J.; Bosi, P.; Prates, J.A.; Tanghe, S.; Trevisi, P. Resistant starch reduces large intestinal pH and promotes fecal lactobacilli and bifidobacteria in pigs. Animal 2019, 13, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Su, Y.; Zhu, W. Microbiome-metabolome responses in the cecum and colon of pig to a high resistant starch diet. Front. Microbiol. 2016, 7, 779. [Google Scholar] [CrossRef]

- Adom, F.; Maes, A.; Workman, C.; Clayton-Nierderman, Z.; Thoma, G.; Shonnard, D. Regional carbon footprint analysis of dairy feeds for milk production in the USA. Int. J. Life Cycle Assess. 2012, 17, 520–534. [Google Scholar] [CrossRef]

- Saylor, B.; Diepersloot, E.C.; Heinzen, C.; McCary, C.L.; Ferraretto, L. Effect of kernel breakage on the fermentation profile, nitrogen fractions, and in vitro starch digestibility of whole-plant corn silage and ensiled corn grain. JDS Commun. 2021, 2, 191–195. [Google Scholar] [CrossRef]

- ISO 5984:2022; Animal Feeding Stuffs—Determination of Crude Ash. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 5983-2:2009; Animal Feeding Stuffs—Determination of Nitrogen Content and Calculation of Crude Protein Content. Part 2: Block Digestion and Steam Distillation Method. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 16472:2006; Animal Feeding Stuffs—Determination of Amylase-Treated Neutral Detergent Fibre Content (aNDF). International Organization for Standardization: Geneva, Switzerland, 2006.

| Abbreviation | Hybrid | Type | FAO Maturity Group |

|---|---|---|---|

| H1 | Bc 344 | hard dent | 300 |

| H2 | Bc 418b | hard dent | 460 |

| H3 | Bc 424 | dent | 460 |

| H4 | Bc 525 | dent | 510 |

| H5 | Bc 572 | hard dent | 500 |

| H6 | Kekec | semi-flint | 330 |

| H7 | Pajdaš | hard dent | 490 |

| Hybrid | 1000 Kernel Weight | 1000 Kernel Volume | Test Weight | Kernel | |||

|---|---|---|---|---|---|---|---|

| Height | Length | Width | Sphericity | ||||

| g | mL | kg/hL | mm | ||||

| H1 | 321.5 d | 434.4 b | 74.01 c | 11.30 c | 8.51 ab | 4.52 bc | 0.654 bc |

| H2 | 305.8 e | 422.8 b | 72.34 d | 11.37 c | 8.58 ab | 4.38 c | 0.662 b |

| H3 | 327.4 cd | 456.2 a | 71.77 d | 11.77 b | 8.61 ab | 4.83 a | 0.669 ab |

| H4 | 342.7 ab | 465.8 a | 73.57 c | 12.25 a | 8.48 b | 4.37 c | 0.629 c |

| H5 | 333.4 bc | 428.4 b | 77.83 a | 11.21 c | 8.39 b | 4.69 ab | 0.700 a |

| H6 | 263.7 f | 340.2 c | 77.49 a | 11.33 c | 7.76 c | 4.51 c | 0.665 b |

| H7 | 346.7 a | 452.6 a | 76.61 b | 11.75 b | 8.73 a | 4.69 ab | 0.667 b |

| SEM | 3.9 | 4.9 | 0.30 | 0.12 | 0.08 | 0.06 | 0.011 |

| p | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.0102 |

| Hybrid | Ensiling Period | Time of Incubation/h | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 0.25 | 0.50 | 0.75 | 1 | 2 | 3 | 4 | 5 | ||

| Ct/% | ||||||||||

| H1 | 0 | 7.50 dC | 21.36 cB | 31.49 dC | 39.15 eC | 48.45 dC | 74.35 cB | 94.44 aB | 100.00 a | 99.97 |

| 21 | 10.82 cdA | 26.07 cdA | 40.43 dB | 53.68 cB | 63.91 cB | 96.65 aA | 100.00 A | 100.00 | 100.00 | |

| 95 | 9.52 eB | 26.03 eA | 43.99 dA | 57.42 dA | 72.33 cA | 97.12 bA | 99.17A | 100.00 | 100.00 | |

| H2 | 0 | 7.44 dB | 21.60 cC | 31.70 dC | 42.71 bcC | 52.24 cC | 80.17 aC | 85.98 dB | 96.83 cB | 99.55 |

| 21 | 10.31 dA | 26.91 bcB | 44.09 bB | 58.69 bB | 73.25 aB | 94.70 aB | 99.94 A | 100.00 A | 99.46 | |

| 95 | 10.56 dA | 29.43 bcA | 48.73 bA | 64.18 bcA | 77.80 bA | 100.00 aA | 100.00 A | 100.00 A | 99.56 | |

| H3 | 0 | 10.29 bcB | 22.40 bcC | 31.89 dC | 40.73 deC | 47.24 dC | 73.49 cC | 86.33 dB | 99.97 a | 98.41 |

| 21 | 11.22 bcA | 25.24 dB | 40.91dB | 55.08 cB | 64.87 cB | 92.44 bB | 100.00 A | 99.79 | 99.74 | |

| 95 | 11.99 bcA | 27.21 dA | 47.05 c A | 65.53 bA | 72.49 cA | 100.00 aA | 100.00 A | 100.00 | 100.00 | |

| H4 | 0 | 12.02 aA | 23.87 aB | 38.83 aA | 44.79 aC | 56.82 aB | 77.46 bC | 94.35 aB | 100.00 a | 99.99 |

| 21 | 11.18 bcB | 26.55 cA | 43.69 bB | 57.61 bA | 68.28 bA | 96.56 aA | 99.82 A | 100.00 | 98.66 | |

| 95 | 10.38 dB | 24.72 fB | 40.09 eA | 55.15 eB | 69.02 dA | 92.24 cB | 99.24 A | 100.00 | 100.00 | |

| H5 | 0 | 10.19 cA | 23.52 abC | 34.10 cC | 41.68 cdC | 54.15 bcC | 73.50 cC | 92.20 bB | 98.46 bB | 100.00 |

| 21 | 11.39 bcB | 27.77 abB | 46.78 aB | 60.85 aB | 74.17 aB | 95.04 aB | 100.00 A | 100.00 A | 100.00 | |

| 95 | 12.65 aC | 33.23 aA | 52.62 aA | 69.31 aA | 80.80 aA | 98.27 abA | 100.00 A | 100.00 A | 100.00 | |

| H6 | 0 | 9.64 cB | 23.66 aC | 35.67 bB | 45.09 aC | 55.53 abC | 79.29 abC | 90.29 cB | 99.38 a | 100.00 |

| 21 | 11.78 bA | 27.07 bcB | 44.19 bA | 58.37 cB | 68.41 bB | 92.07 bB | 99.71 A | 100.00 | 100.00 | |

| 95 | 11.71 cA | 28.62 cA | 45.35 dA | 64.05 bcA | 80.03 abA | 97.15 bA | 98.68A | 100.00 | 99.45 | |

| H7 | 0 | 11.05 bB | 23.56 aC | 35.01 bcC | 43.83 abC | 55.51 abC | 78.70 abC | 91.17 bcB | 99.53 a | 100.00 |

| 21 | 12.82 aA | 28.87 aB | 45.71 aB | 60.61 aB | 71.88 aB | 95.46 aB | 99.55 A | 100.00 | 100.00 | |

| 95 | 12.52 bcA | 30.49 bA | 50.06 bA | 62.86 cA | 80.43 aA | 99.06 abA | 100.00 A | 100.00 | 99.70 | |

| SEM | 0.29 | 0.40 | 0.53 | 0.64 | 0.87 | 0.71 | 0.59 | 0.27 | 0.33 | |

| p | Hybrid (H) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.119 |

| Period (P) | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.740 | |

| H × P | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | 0.017 | |

| Hybrid | Density | Flotation Index | Stenvert | Breakage Susceptibility | ||

|---|---|---|---|---|---|---|

| Time | Height | C/F | ||||

| g/mL | % | mm | % | |||

| H1 | 1.249 bc | 40.90 c | 4.84 c | 8.15 c | 0.664 bc | 36.62 b |

| H2 | 1.230 d | 75.90 a | 4.45 d | 8.55 b | 0.620 d | 29.69 d |

| H3 | 1.232 cd | 64.00 b | 4.43 d | 8.64 b | 0.634 cd | 25.57 e |

| H4 | 1.223 d | 74.20 a | 3.42 e | 9.19 a | 0.462 e | 33.99 bc |

| H5 | 1.276 a | 6.60 d | 5.23 b | 7.97 d | 0.752 a | 37.27 ab |

| H6 | 1.261 ab | 9.06 d | 5.60 a | 8.10 cd | 0.726 a | 40.76 a |

| H7 | 1.253 b | 11.10 d | 5.00 bc | 8.08 cd | 0.672 b | 30.73 cd |

| SEM | 0.006 | 2.03 | 0.08 | 0.06 | 0.013 | 1.39 |

| p | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 | <0.001 |

| Hybrid | Ensiling Period | C0 | C∞ | kd |

|---|---|---|---|---|

| % | % | 1/h | ||

| H1 | 0 | 6.97 dAB | 103.22 aA | 0.537 bC |

| 21 | 7.63 cdA | 96.67 aB | 0.920 dB | |

| 95 | 6.28 eB | 96.54 aB | 1.075 dA | |

| H2 | 0 | 6.82 d | 96.70 cdA | 0.637 aC |

| 21 | 7.31 cd | 95.27 bB | 1.076 bB | |

| 95 | 7.48 d | 95.02 bcB | 1.243 bA | |

| H3 | 0 | 10.27 bA | 101.31 bA | 0.579 bC |

| 21 | 8.23 bcB | 95.55 bB | 0.910 dB | |

| 95 | 8.19 cB | 94.61 cB | 1.161 cA | |

| H4 | 0 | 11.32 aA | 94.88 e | 0.630 aC |

| 21 | 8.00 bcdB | 95.25 b | 1.016 cA | |

| 95 | 7.01 deC | 96.12 ab | 0.959 eB | |

| H5 | 0 | 10.15 bcA | 97.40 cA | 0.564 bC |

| 21 | 8.46 bB | 93.82 cB | 1.117 aB | |

| 95 | 10.17 aA | 91.46 eC | 1.356 aA | |

| H6 | 0 | 9.34 cA | 95.48 deA | 0.649 aC |

| 21 | 9.34 aA | 93.37 cdB | 0.989 cB | |

| 95 | 7.84 cdB | 94.12 cdB | 1.219 bA | |

| H7 | 0 | 10.07 bc | 95.97 deA | 0.619 aC |

| 21 | 10.02 a | 92.50 dB | 1.064 bB | |

| 95 | 9.31 b | 93.03 dB | 1.242 bA | |

| SEM | 0.29 | 0.45 | 0.012 | |

| p | Hybrid (H) | <0.001 | <0.001 | <0.001 |

| Period (P) | <0.001 | <0.001 | <0.001 | |

| H × P | <0.001 | <0.001 | <0.001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kljak, K.; Grbeša, D.; Duvnjak, M. The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid. Agriculture 2025, 15, 783. https://doi.org/10.3390/agriculture15070783

Kljak K, Grbeša D, Duvnjak M. The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid. Agriculture. 2025; 15(7):783. https://doi.org/10.3390/agriculture15070783

Chicago/Turabian StyleKljak, Kristina, Darko Grbeša, and Marija Duvnjak. 2025. "The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid" Agriculture 15, no. 7: 783. https://doi.org/10.3390/agriculture15070783

APA StyleKljak, K., Grbeša, D., & Duvnjak, M. (2025). The Effect of Ensiling on the Starch Digestibility Rate of Rehydrated Grain Silages in Pigs Depends on the Hardness of the Maize Hybrid. Agriculture, 15(7), 783. https://doi.org/10.3390/agriculture15070783