A Review of Spoon-Style Potato Seed-Metering Defects Monitoring and Inhibition

Abstract

1. Introduction

2. Research Status and Development Trends of Spoon-Type Potato Seed-Metering Defect Monitoring and Inhibition

3. Main Problems of Spoon-Type Potato Planters

4. Main Solutions to Existing Problems

4.1. Improve the Reliability of the Seed-Metering Monitoring System

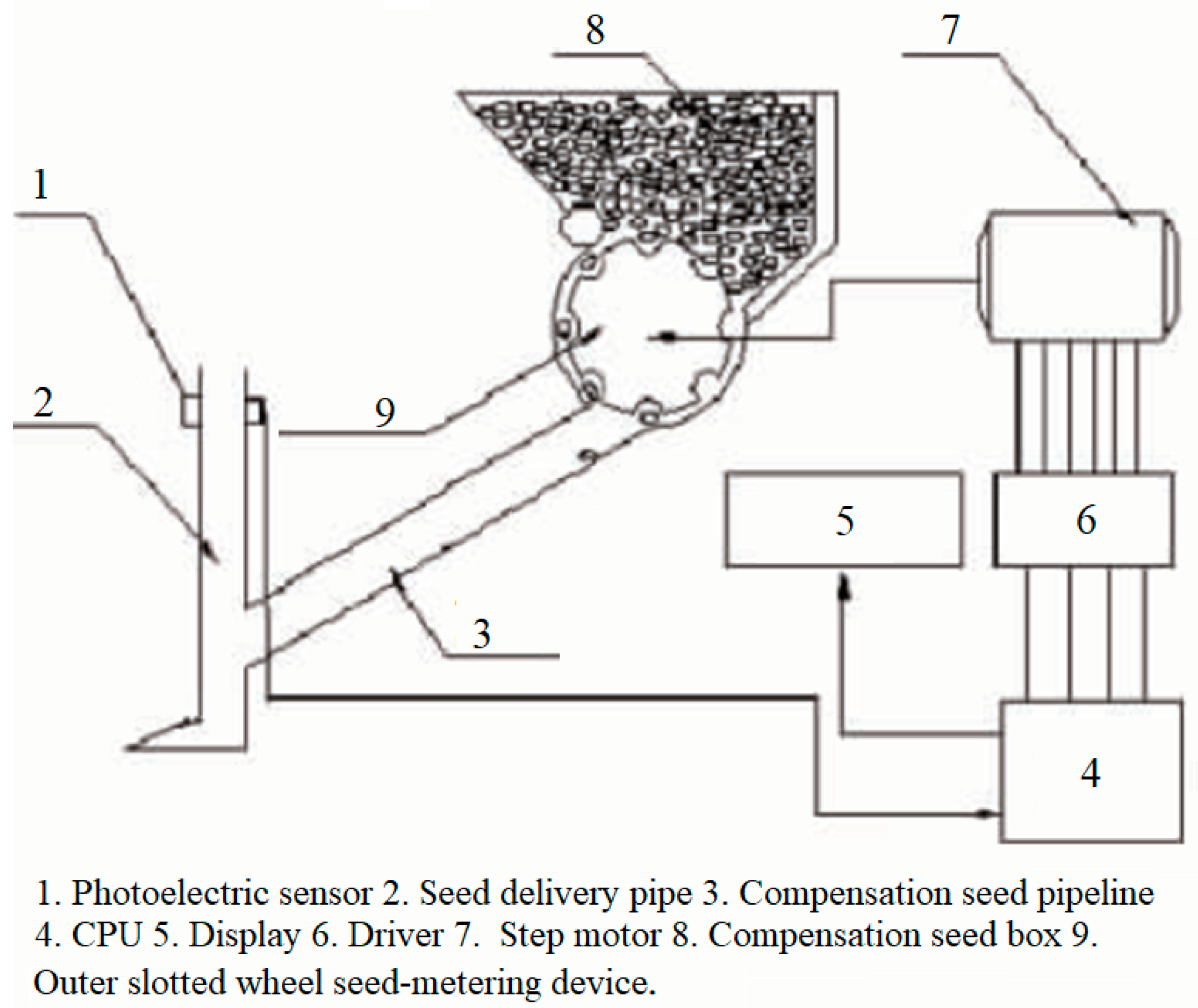

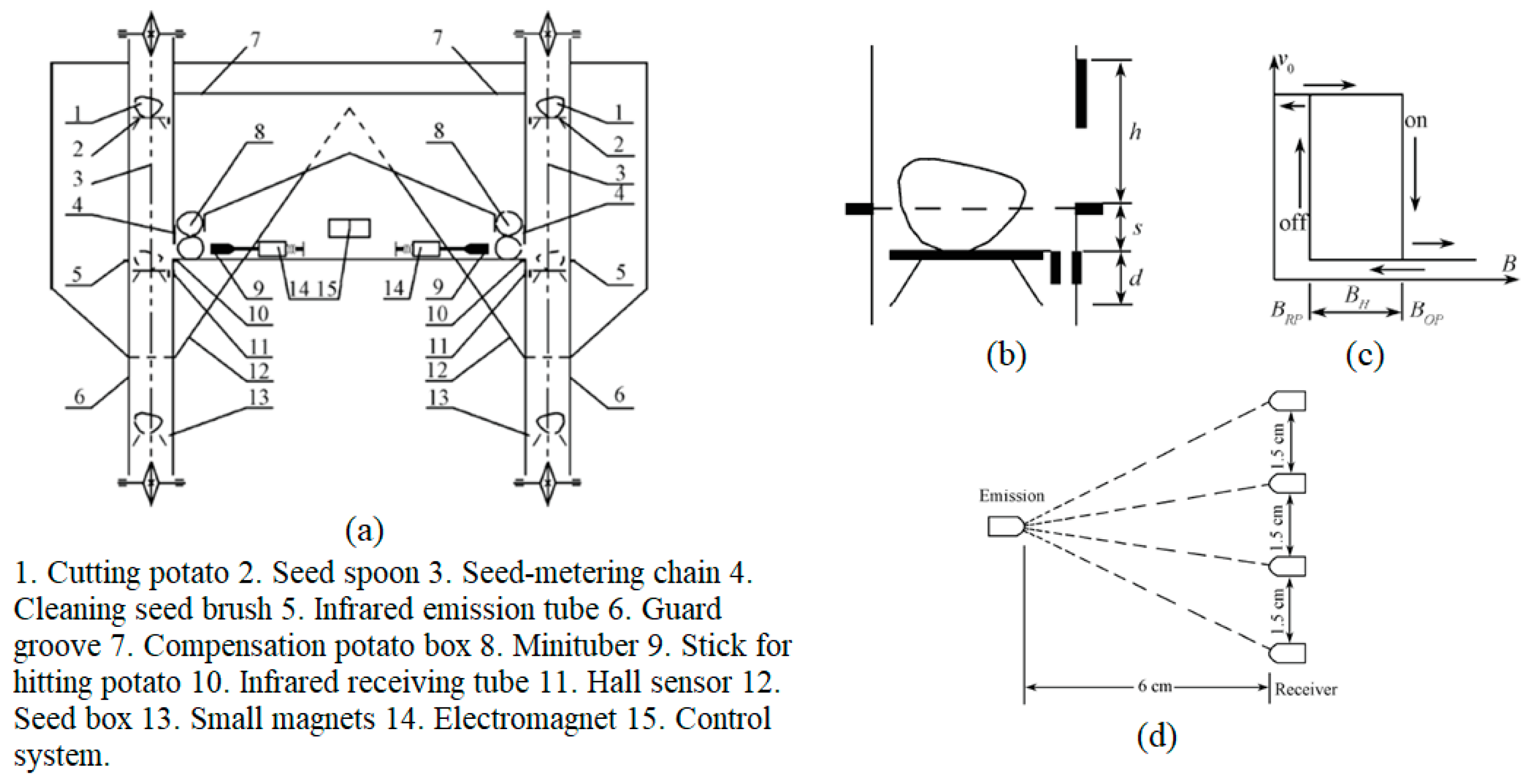

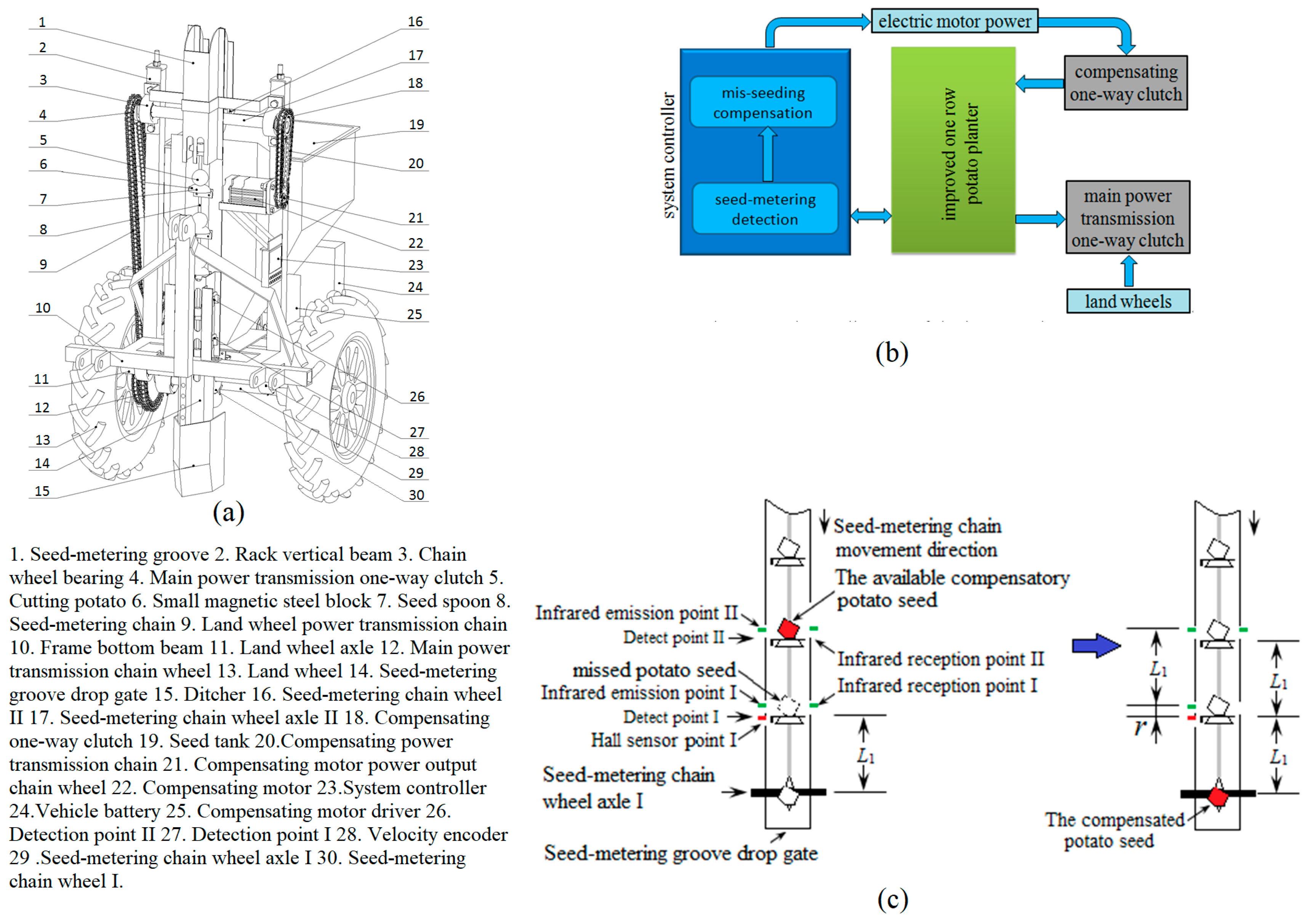

4.2. Simplification and Practicality of Miss-Picking Compensation System

4.3. Implementation of Multi-Picking Reduction Strategy Based on the Abrupt Trajectory Change in Potato Seeds

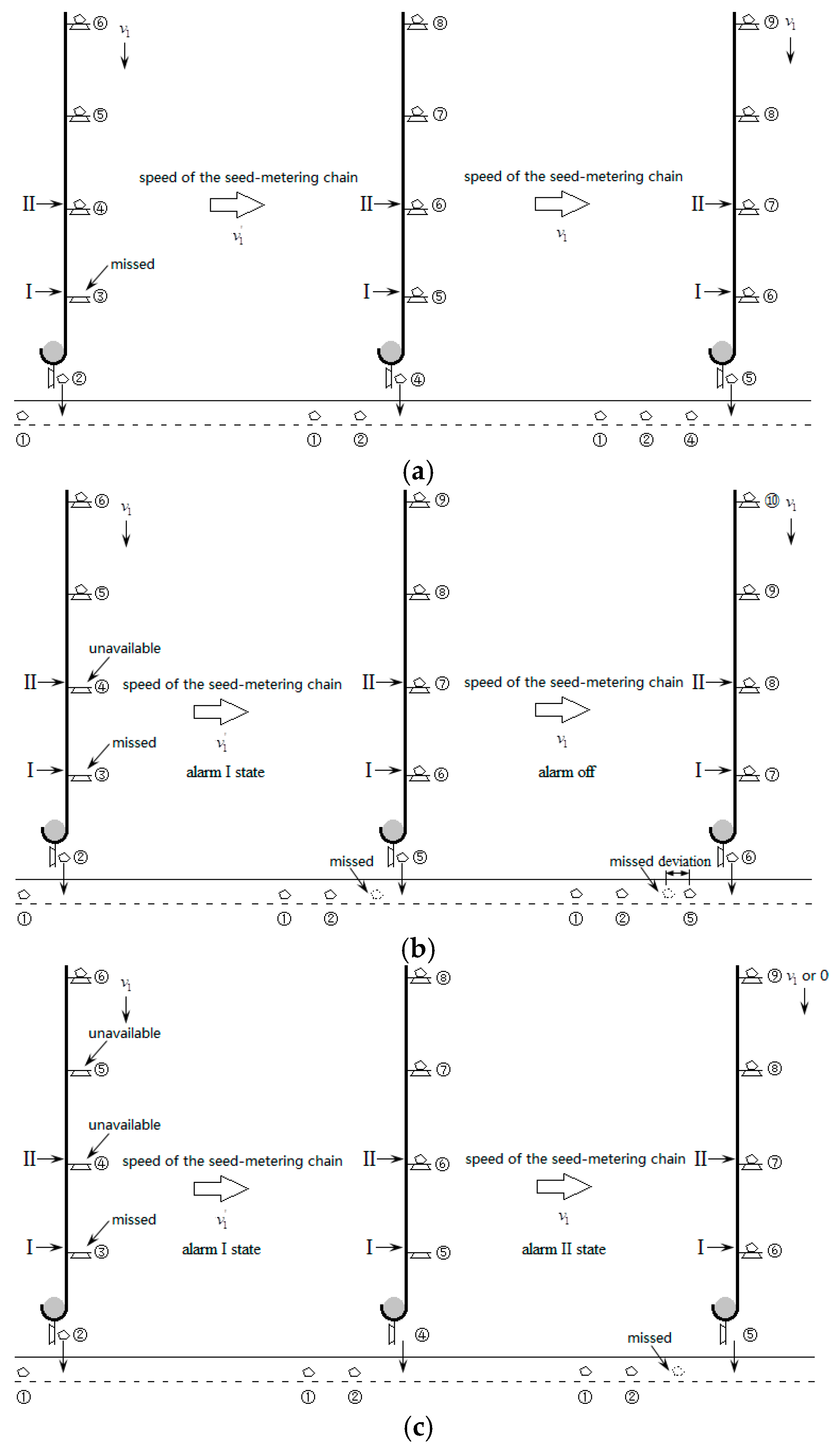

4.4. Research on the Deep Additional Effects of the ‘Catching-Up Compensation’ Strategy

4.5. Low-Cost Active Seed-Metering Defect Inhibition Based on Multi-Means Coupling Simulation Assistance

5. Conclusions and Prospects

5.1. Main Conclusions

5.2. Prospects

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lü, J.Q.; Zhao, Z.M.; Yang, D.Q.; Zhu, X.X.; Qi, Y. Research on Mechanized Sowing Technology and Application of Potatoes. In Proceedings of the 24th China Potato Conference, Qiqihar, China, 15–18 July 2023; pp. 224–229. (In Chinese). [Google Scholar]

- Pei, L.Q.; Sun, W.; Wang, J.L.; Simionescu, P.A. Design and experiment of a film-drilling potato seeder with eccentric coupling. Agriculture 2024, 14, 933. [Google Scholar] [CrossRef]

- Wang, J.R.; Liao, M.; Xia, H.L.; Chen, R.; Li, J.J.; Li, J.M.; Yang, J. Study on a novel reseeding device of a precision potato planter. Agriculture 2024, 14, 1824. [Google Scholar] [CrossRef]

- Gao, Y.; Huang, Y.X.; Li, P.; Zhang, S.L.; Zheng, Z.Q. Design and experiment of three-claw spoon type potato precise metering device. J. Agric. Mech. Res. 2023, 45, 191–197. (In Chinese) [Google Scholar]

- Zhang, W.Z.; Zhang, H.Y.; Liu, S.F.; Zeng, X.; Mu, G.Z.; Zhang, T.T. Detection of potato seed buds based on an improved YOLOv7 model. Trans. CSAE 2023, 39, 148–158. (In Chinese) [Google Scholar]

- Lü, J.Q.; Wen, X.Y.; Li, Z.H.; Li, J.C.; Liu, Z.Y. Design and experiment of the grading device for a potato seed cutting machine. Trans. CSAE 2020, 36, 76–83. [Google Scholar]

- Luo, Q.Y.; Lu, H.W.; Li, G.J.; Gao, M.J.; Lü, J.F. Analysis of the development situation of china’s potato industry in 2022. In Proceedings of the 24th China Potato Conference, Qiqihar, China, 16 July 2023. (In Chinese). [Google Scholar]

- Sun, W.; Liu, X.L.; Zhang, H.; Wang, H.C.; Tian, B. Design of potato casing soil planter in all-in-one machine combined with fertilizing, sowing, ridging, complete film mulching and planting line covering. Trans. CSAE 2017, 33, 14–22. (In Chinese) [Google Scholar]

- Yang, H.G.; Liu, Z.S.; Ni, Z.W.; Lin, L.C.; Yang, R.B. Design and test of 2CM-4 type potato planter. J. Qingdao Agric. Univ. (Nat. Sci.) 2017, 34, 137–140. (In Chinese) [Google Scholar]

- Aboegela, M.A.; El-Ghobashy, H.M.; Shaban, Y.A. Development a single row potato planter for small holdings. J. Soil Sci. Agric. Eng. 2021, 12, 137–143. [Google Scholar] [CrossRef]

- Rathore, F.; Chaturvedi, S. Development and performance evaluation of manually operated potato planter. Bhartiya Krishi Anusandhan Patrika 2018, 33, 215–217. [Google Scholar] [CrossRef]

- Shi, L.R.; Yang, X.P.; Zhao, W.Y.; Sun, W.; Li, R.B.; Sun, B.G. Design and test of potato combine seeder with throwing and covering soil on film edge. Trans. Chin. Soc. Agric. Mach. 2018, 49, 129–137. (In Chinese) [Google Scholar]

- Sun, C.Z.; Wang, F.M.; Li, X.Q.; Su, G.L.; Wang, X.Y.; Wei, Z.C.; Sun, J.B. Design of intelligent control system of potato precision planter. Trans. CSAE 2017, 33, 36–44. (In Chinese) [Google Scholar]

- Wang, G.P.; Sun, W.; Zhang, H.; Liu, X.L.; Yang, X.P.; Yang, H.; Li, Y.M.; Li, H.L.; Yang, W.X.; Gao, X.Y.; et al. A Planting and Compensating Integrated Potato Planter with Dual One-Way Clutch Cooperation. Chinese Patent ZL201910106116.6, 1 September 2023. [Google Scholar]

- Zhang, H.; Zhao, W.Y.; Sun, W.; Wang, G.P.; Liu, X.L.; Feng, B.; Shi, L.R.; Liu, Y.; Li, H.L. Potato planter test bed based on capacitive precision seed-monitoring and miss-seeding compensation system. Int. J. Agric. Biol. Eng. 2022, 15, 104–112. [Google Scholar] [CrossRef]

- Krestenitis, M.; Raptis, E.K.; Kapoutsis, A.C.; Ioannidis, K.; Kosmatopoulos, E.B.; Vrochidis, S. Overcome the Fear of Missing Out: Active Sensing UAV Scanning for Precision Agriculture. Robot. Auton. Syst. 2024, 172, 104581. [Google Scholar] [CrossRef]

- Nagesh, O.S.; Budaraju, R.R.; Kulkarni, S.S.; Vinay, M.; Ajibade, S.S.M.; Chopra, M.; Jawarneh, M.; Kaliyaperumal, K. Boosting enabled efficient machine learning technique for accurate prediction of crop yield towards precision agriculture. Discov. Sustain. 2024, 5, 78. [Google Scholar] [CrossRef]

- Lu, J.Z.; Liu, S.P.; Wang, Q.; Liao, M. Research on device and sensing technology for precision seeding of potato. Agriculture 2024, 14, 2146. [Google Scholar] [CrossRef]

- Lü, J.Q.; Zhang, H.; Li, J.C.; Liu, Z.Y.; Su, W.H.; Zhu, X.Y. Design and experiment of sorting device of potato seed cutting machine. J. Northeast Agric. Univ. 2022, 53, 47–59. (In Chinese) [Google Scholar]

- Yang, S.; Zhai, C.Y.; Gao, Y.Y.; Dou, H.J.; Zhao, X.G.; He, Y.K.; Wang, X. Planting uniformity performance of motor-driven maize precision seeding systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Wang, S.; Sun, Y.H.; Yang, C.; Yu, Y.C. Advanced design and tests of a new electrical control seeding system with genetic algorithm fuzzy control strategy. J. Comput. Methods Sci. Eng. 2021, 21, 703–712. [Google Scholar] [CrossRef]

- Mhango, J.K.; Harris, E.W.; Green, R.; Monaghan, J.M. Mapping potato plant density variation using aerial imagery and deep learning techniques for precision agriculture. Remote Sens. 2021, 13, 2705. [Google Scholar] [CrossRef]

- Bai, J.Q.; Hao, F.Q.; Cheng, G.H.; Li, C.G. Machine vision-based supplemental seeding device for plug seedling of sweet corn. Comput. Electron. Agric. 2021, 188, 106345. [Google Scholar] [CrossRef]

- Liu, H.X.; Yin, L.W.; Xie, Y.T.; Zhao, Y.J.; Fang, L. Development of the transfer platform with ground wheel in front for the medium-sized no-tillage stalk mulching ridge corn planter. Trans. CSAE 2022, 38, 10–18. (In Chinese) [Google Scholar]

- He, X.; Wang, M.S.; Zhang, R.; Zhu, Y.H.; Chen, Y.; Shao, F.L.; Chen, Y.; Chen, X.C.; Lü, Z.J. Design and experiment of wheat multi-level ballast control sowing monomer. J. Henan Agric. Univ. 2024, 58, 1002–1011. (In Chinese) [Google Scholar]

- Ding, Y.Q.; Chen, C.; Yu, H.F.; Zhang, H.D.; Dou, X.L.; Liu, Z. Self-correcting method for application rate control parameters of wheat seed drill machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 31–37+275. (In Chinese) [Google Scholar]

- Ding, Y.C.; Chen, L.Y.; Wang, D.H.; Liu, X.D.; Xu, C.B.; Wang, K.Y. Design and test of monitoring system for rapeseed sowing quality. J. South China Agric. Univ. 2021, 42, 43–51. (In Chinese) [Google Scholar]

- Liao, Y.T.; Sun, M.; Liao, Q.X.; Wang, C.Q.; Zheng, J.; Wu, A.Y. Ordering of seed flow in seed guiding of precision sowing for rapeseed. Trans. CSAE 2023, 39, 23–35. (In Chinese) [Google Scholar]

- Zhang, X.D.; Wu, J.M.; Sun, W.; Wang, D. Design of automatic compensation system for potato planter. J. Gansu Agric. Univ. 2013, 48, 145–149. (In Chinese) [Google Scholar]

- Liu, Q.W.; Wu, J.M.; Wang, D.; Sun, W.; Wang, G.P.; Shi, L.R.; Wu, J. Design and test of a microcomputer-controlled loss sowing compensation system for 2CM-2 potato seeder. Agric. Res. Arid Areas 2013, 31, 260–266. (In Chinese) [Google Scholar]

- Sun, W.; Wang, G.P.; Wu, J.M. Design and experiment on loss sowing testing and compensation system of spoon-chain potato metering device. Trans. CSAE 2016, 32, 8–15. (In Chinese) [Google Scholar]

- Wang, G.P.; Sun, W. Development of a kind of potato loss sowing detection and compensation device. Res. Agric. Mod. 2016, 37, 1008–1014. (In Chinese) [Google Scholar]

- Wang, G.P.; Sun, W.; Zhang, H.; Liu, X.L.; Li, H.L.; Yang, X.P.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electron. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Wang, G.P.; Sun, W.; Chen, L.D.; Zhang, H.; Liu, X.L.; Li, H.L.; Yang, X.P.; Yang, H. Realization of an integrated seeding and compensating potato planter based on one-way clutch. Int. J. Agric. Biol. Eng. 2020, 13, 79–87. [Google Scholar] [CrossRef]

- Zhou, L.M.; Zhang, X.C.; Yuan, Y.W. Design of capacitance seed rate sensor of wheat planter. Trans. CSAE 2010, 26, 99–103. (In Chinese) [Google Scholar]

- Zhou, L.M.; Wang, S.M.; Zhang, X.C.; Yuan, Y.W.; Zhang, J.N. Seed monitoring system for corn planter based on capacitance signal. Trans. CSAE 2012, 28, 16–21. (In Chinese) [Google Scholar]

- Niu, K.; Zhou, L.; Yuan, Y.W.; Liu, Y.C.; Fang, X.F. Design and experiment on automatic compensation system of spoon-chain potato metering device. Trans. Chin. Soc. Agric. Mach. 2016, 47 (Suppl. S1), 76–83. (In Chinese) [Google Scholar]

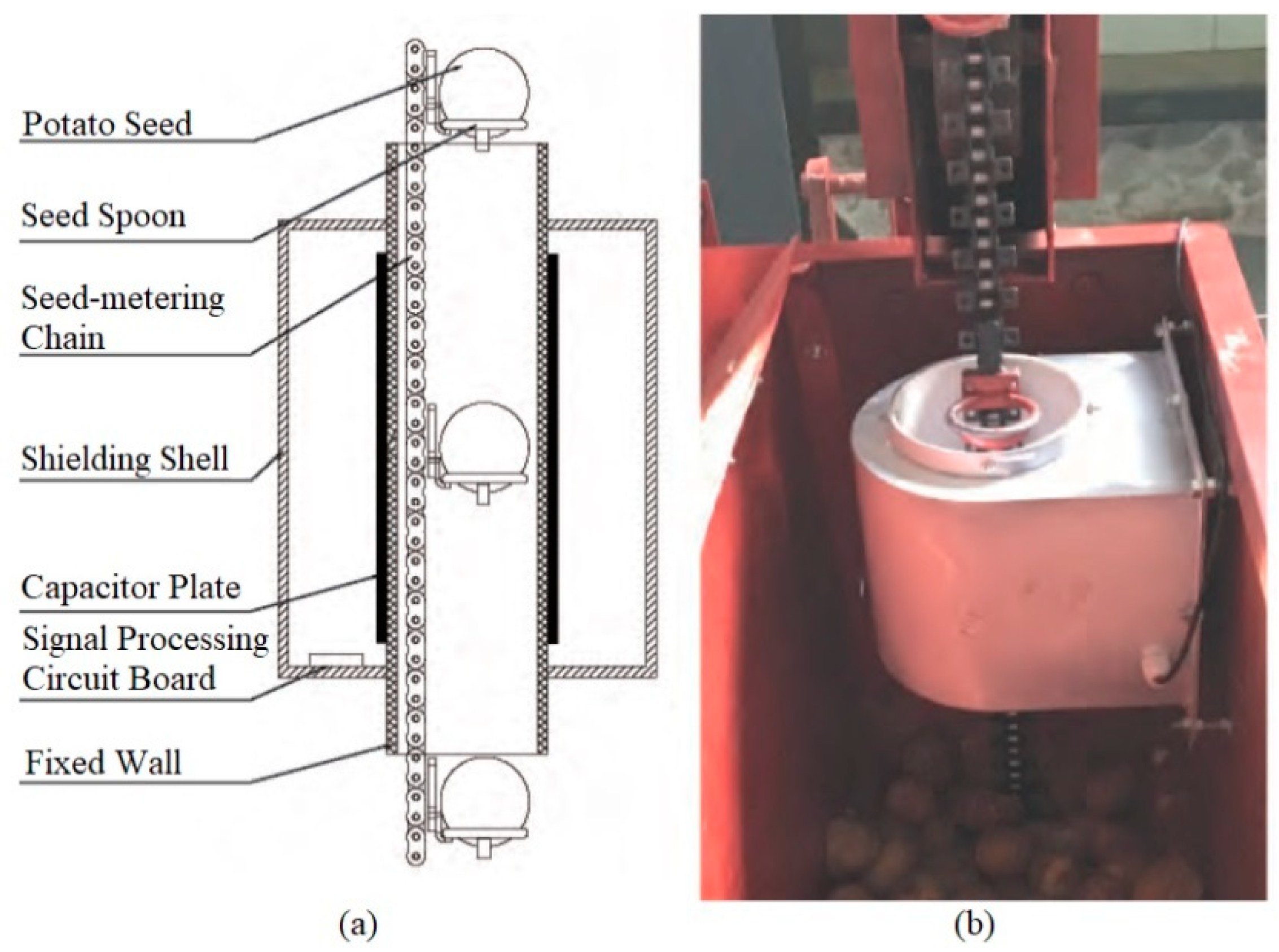

- Wang, G.P.; Yang, X.P.; Sun, W.; Liu, Y.; Wang, C.J.; Zhang, H.; Liu, X.L.; Feng, B.; Li, H.L. Potato seed-metering monitoring and improved miss-seeding catching-up compensation control system using spatial capacitance sensor. Int. J. Agric. Biol. Eng. 2024, 17, 255–264. [Google Scholar]

- Wen, B.Q.; Song, P.X.; Li, J.B.; Huang, Y.; Cen, H.L. Design and test of seeding monitoring and compensating system for belt-spoon type potato seed metering device. Trans. Chin. Soc. Agric. Mach. 2022, 53, 36–46. (In Chinese) [Google Scholar]

- Hu, T. Seed spacing recognition based on machine vision and its application. In Proceedings of the International Conference on Cognitive Based Information Processing and Applications, Changzhou, China, 22 November 2024. [Google Scholar]

- Bai, H.J.; Wang, N.; Long, J. Image-based corn seed embryo orientation detection and adjustment for precision planting. Comput. Electron. Agric. 2024, 224, 109139. [Google Scholar] [CrossRef]

- Li, H.L.; Liu, X.L.; Zhang, H.; Li, H.; Jia, S.Y.; Sun, W.; Wang, G.P.; Feng, Q.; Yang, S.; Xing, W. Research and experiment on miss-seeding detection of potato planter based on improved YOLOv5s. Agriculture 2024, 14, 1905. [Google Scholar] [CrossRef]

| Technology | Hardware | Software | Effect |

|---|---|---|---|

| Infrared photoelectric system | Simple | Simple | Good, not suitable for multi-picking detection, low price |

| Non-photoelectric system | Requires a spatial capacitance sensor | More complex | Good, suitable for both miss-picking and multi-picking, limited speed, moderate price |

| Machine vision | Complex | Complex | Very good, can provide a variety of information, high price |

| Technology | Additional Seed Box | Additional Special Channel for Compensating Potato Seeds | Effect |

|---|---|---|---|

| Stepper motor type | Yes | Yes | Poor performance, the compensated potato seed landing point deviation is uncontrollable, only suitable for miss-picking, complex, high price |

| Relay quick-impact type | Yes | No | Some are practical, simple system composition, low price; however, the preconditions for work are harsh |

| Catching-up compensation | No | No | Validated and practical, cooperation of one-way clutch and special compensation motor needed, only suitable for miss-picking compensation at present, system composition is slightly complex, moderate price |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, G.; Sun, W.; Li, G.; Zhang, J.; Li, Z.; Ding, L.; Li, H.; Wang, L. A Review of Spoon-Style Potato Seed-Metering Defects Monitoring and Inhibition. Agriculture 2025, 15, 720. https://doi.org/10.3390/agriculture15070720

Li X, Wang G, Sun W, Li G, Zhang J, Li Z, Ding L, Li H, Wang L. A Review of Spoon-Style Potato Seed-Metering Defects Monitoring and Inhibition. Agriculture. 2025; 15(7):720. https://doi.org/10.3390/agriculture15070720

Chicago/Turabian StyleLi, Xiaokang, Guanping Wang, Wei Sun, Guizi Li, Jiarui Zhang, Zhengsuo Li, Lili Ding, Hongling Li, and Lu Wang. 2025. "A Review of Spoon-Style Potato Seed-Metering Defects Monitoring and Inhibition" Agriculture 15, no. 7: 720. https://doi.org/10.3390/agriculture15070720

APA StyleLi, X., Wang, G., Sun, W., Li, G., Zhang, J., Li, Z., Ding, L., Li, H., & Wang, L. (2025). A Review of Spoon-Style Potato Seed-Metering Defects Monitoring and Inhibition. Agriculture, 15(7), 720. https://doi.org/10.3390/agriculture15070720