Study on the Effects of High-Voltage Discharge Plasma Drying on the Volatile Organic Compounds and Texture Characteristics of Oat Grass

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

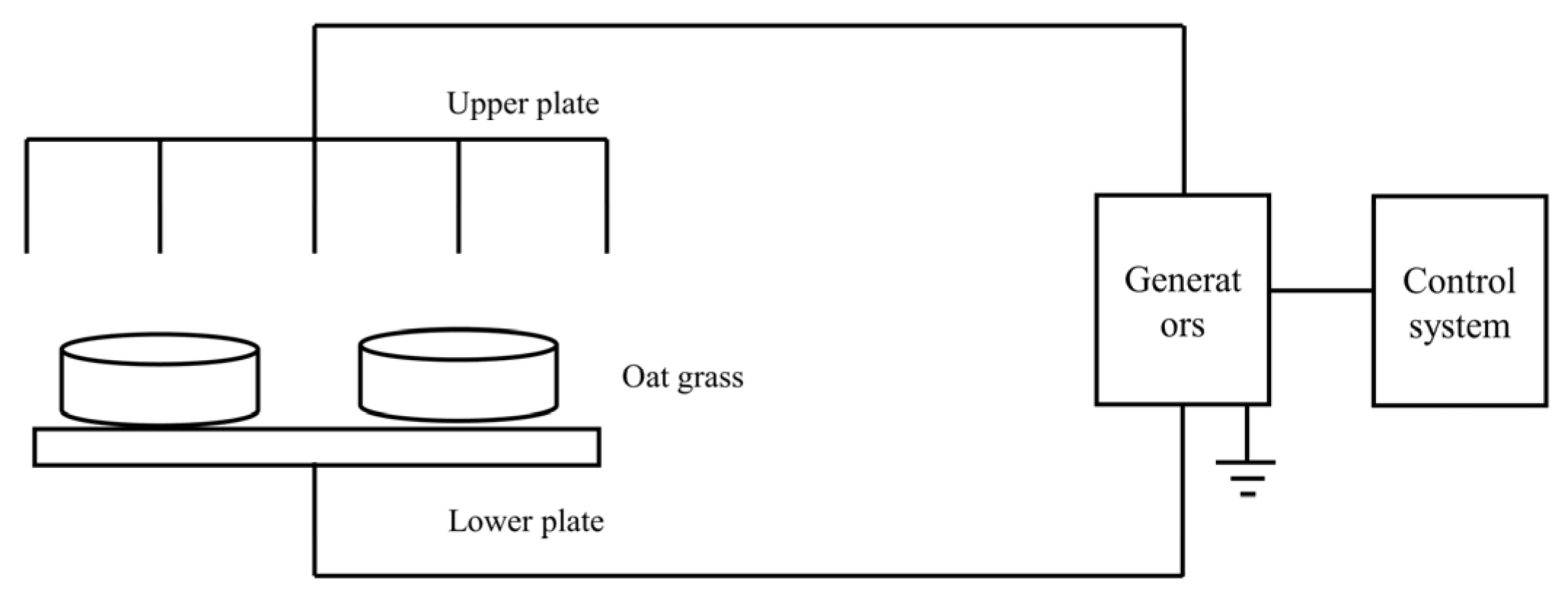

2.2. Experimental Equipment

2.3. Dry Preparation of Oat Grass

2.4. Extraction of Volatile Organic Compounds

2.5. Analytical Conditions for Gas Chromatography–Mass Spectrometry

2.6. Determination and Conditions of Texture Characteristics

- (1)

- Selection of Shear Testing Conditions

- (2)

- Selection of TPA Measurement Conditions

2.7. Statistical Analysis

3. Results and Discussion

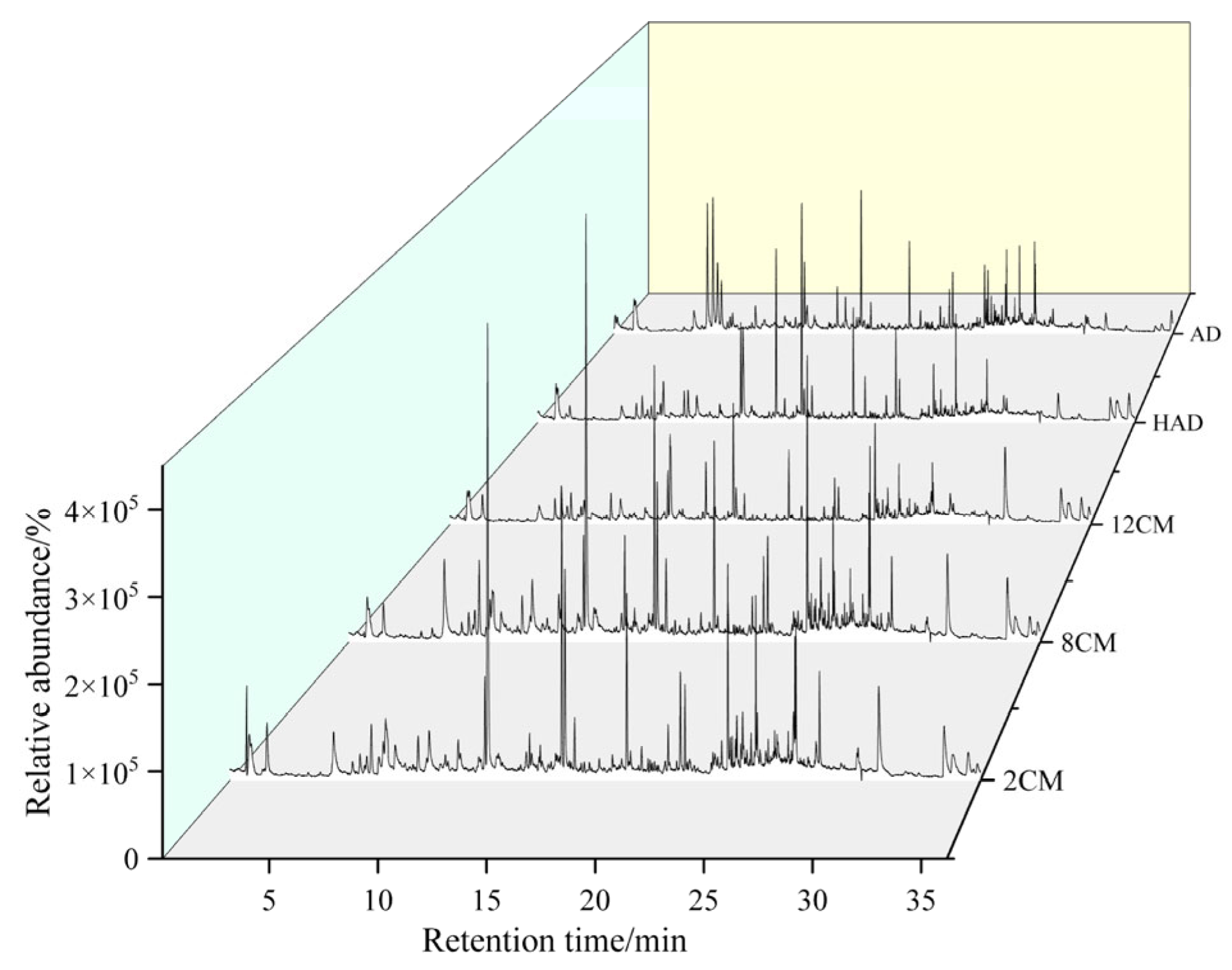

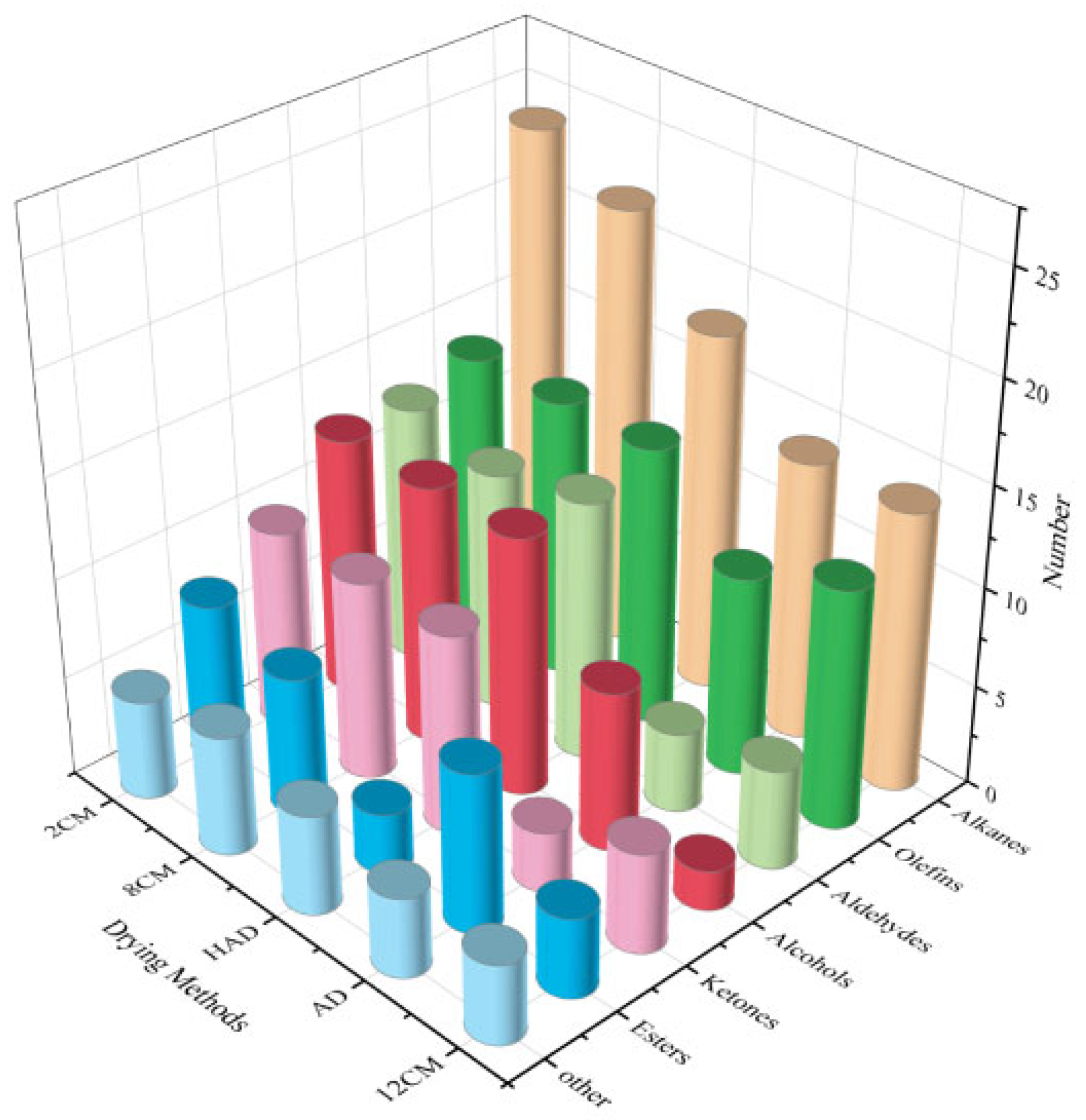

3.1. Analysis of the Types and Quantities of Volatile Components of Oat Grass After Different Drying Methods

3.2. Analysis of Volatile Components of Oat Grass After Treatment with Different Drying Methods

3.3. Specific Analysis of Volatile Components of Oat Grass Under Different Drying Methods

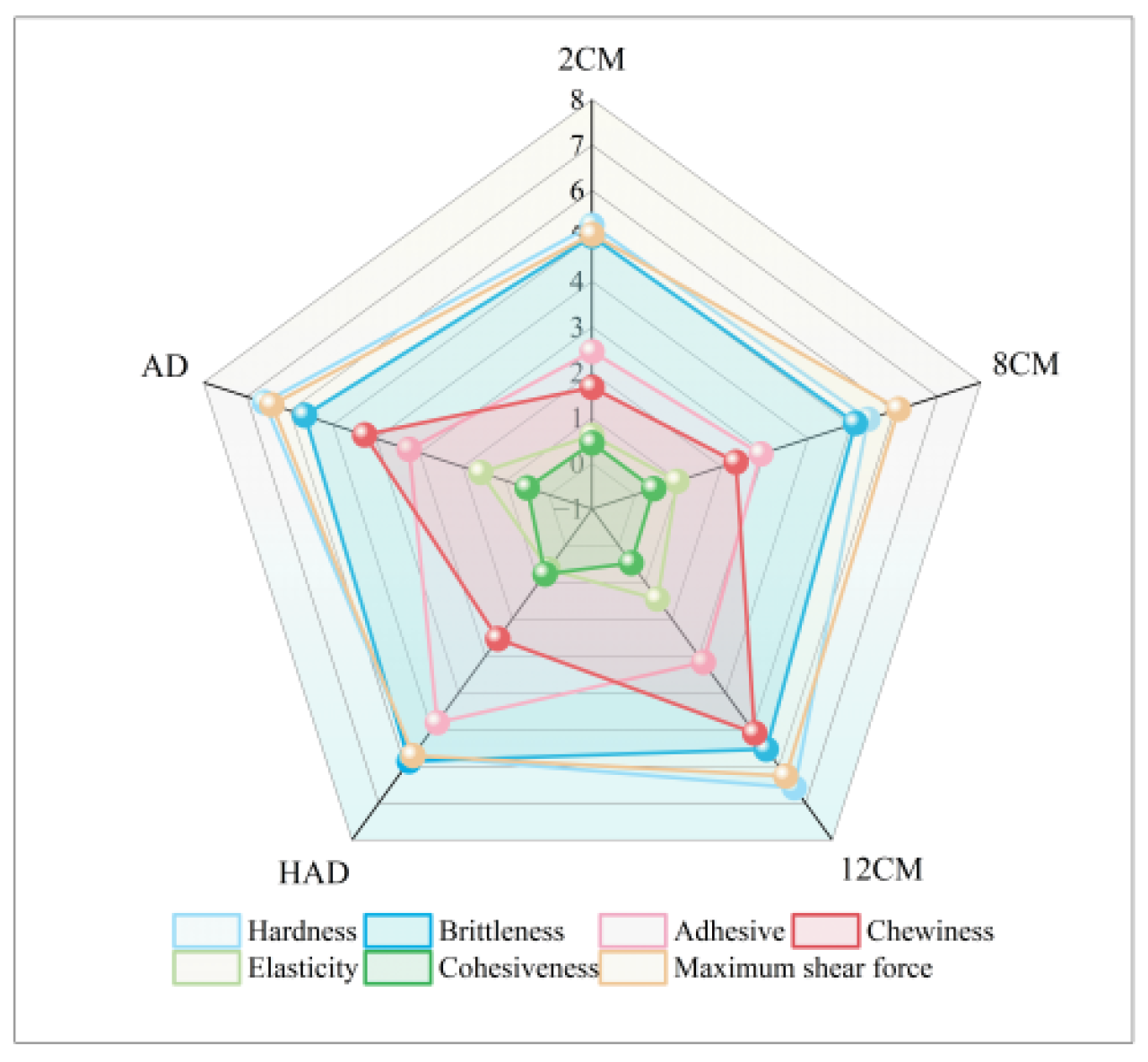

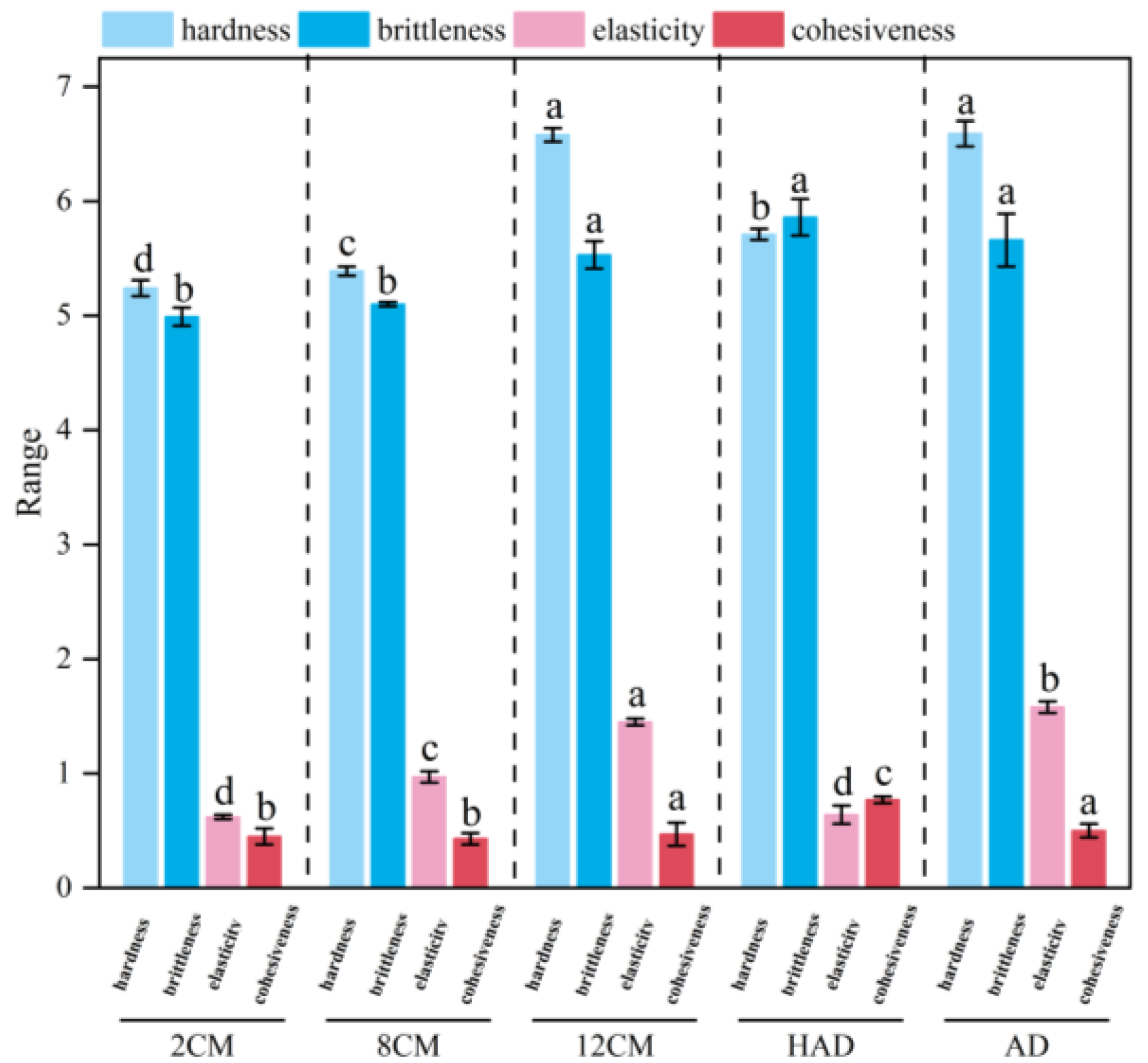

3.4. Analysis of the Effects of Different Drying Methods on the Texture Characteristics of Oat Grass

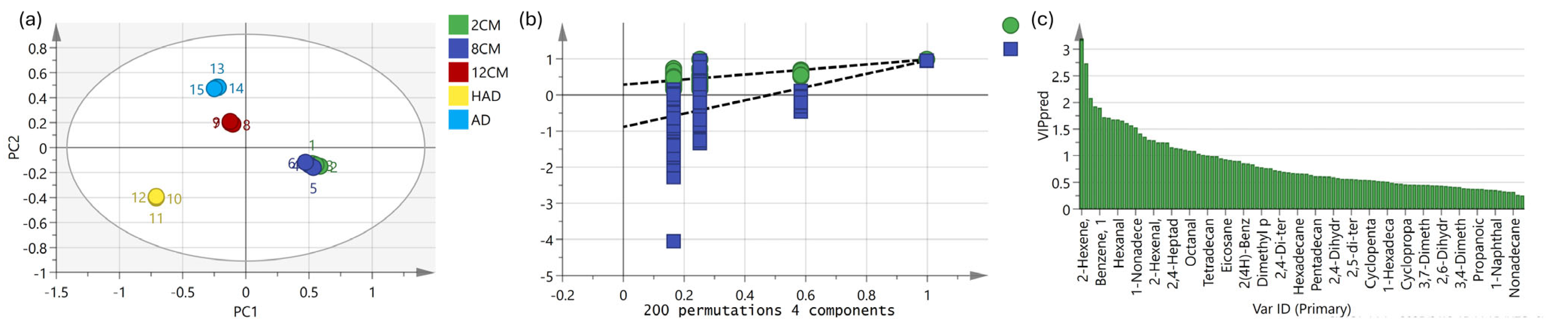

3.5. Principal Component Analysis

3.6. Correlation Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, D.; Zhang, Y.; Pan, X.; Yuan, L.; Cai, Y.; Lao, F.; Wu, J. Effect of extrusion on the structural and flavor properties of oat flours. J. Cereal Sci. 2023, 113, 103742. [Google Scholar] [CrossRef]

- Räisänen, S.E.; Sigurðardóttir, P.H.; Halmemies-Beauchet-Filleau, A.; Pitkänen, O.; Vanhatalo, A.; Sairanen, A.; Kokkonen, T. Ruminal methane emission and lactational performance of cows fed rapeseed cake and oats on a grass silage–based diet. J. Dairy Sci. 2024, 107, 6732–6741. [Google Scholar] [CrossRef] [PubMed]

- Vanhatalo, A.; Gäddnäs, T.; Heikkilä, T. Microbial protein synthesis, digestion and lactation responses of cows to grass or grass-red clover silage diet supplemented with barley or oats. Agric. Food Sci. 2006, 15, 252–267. [Google Scholar] [CrossRef]

- Kethireddipalli, P.; Hung, Y.C.; McWatters, K.H.; Phillips, R.D. Effect of milling method (wet and dry) on the functional properties of cowpea (Vigna unguiculata) pastes and end product (akara) quality. J. Food Sci. 2002, 67, 48–52. [Google Scholar] [CrossRef]

- Lin, W.L.; Yang, X.Q.; Li, L.H.; Hao, S.X.; Wang, J.X.; Huang, H.; Wei, Y.; Wu, Y.Y. Effect of Ultrastructure on Changes of Textural Characteristics between Crisp Grass Carp (Ctenopharyngodon Idellus C.Et V) and Grass Carp (Ctenopharyngodon Idellus) Inducing Heating Treatment. J. Food Sci. 2016, 81, E404–E411. [Google Scholar] [CrossRef]

- Deng, L.Z.; Mujumdar, A.S.; Yang, X.H.; Wang, J.; Zhang, Q.; Zheng, Z.A.; Gao, Z.J.; Xiao, H.W. High humidity hot air impingement blanching (HHAIB) enhances drying rate and softens texture of apricot via cell wall pectin polysaccharides degradation and ultrastructure modification. Food Chem. 2018, 261, 292–300. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, C.; Lu, J.; Zhu, J.; Bai, W.; Guan, P.; Song, Z.; Chen, H. Effect of electrohydrodynamic (EHD) drying on active ingredients, textural properties and moisture distribution of yam (Dioscorea opposita). Food Chem. X 2024, 23, 101622. [Google Scholar] [CrossRef]

- Adhikari, B.; Howes, T.; Bhandari, B.R.; Truong, V. Stickiness in foods: A review of mechanisms and test methods. Int. J. Food Prop. 2001, 4, 1–33. [Google Scholar] [CrossRef]

- Huang, T.; Sun, Y.; Guo, Y.; Wang, W.; He, T.; Cao, J. Application of HS-SPME-GC-MS combined with electronic nose technology in the odor recognition of pseudostellariae radix. Nat. Prod. Res. 2023, 37, 2457–2460. [Google Scholar] [CrossRef]

- Villière, A.; Symoneaux, R.; Roche, A.; Eslami, A.; Perrot, N.; Le Fur, Y.; Prost, C.; Courcoux, P.; Vigneau, E.; Thomas-Danguin, T.; et al. Comprehensive sensory and chemical data on the flavor of 16 red wines from two varieties: Sensory descriptive analysis, HS-SPME-GC-MS volatile compounds quantitative analysis, and odor-active compounds identification by HS-SPME-GC-MS-O. Data Brief 2019, 24, 103725. [Google Scholar] [CrossRef]

- Hu, W.; Song, Z.; Ma, Q.; Li, B.; Zhang, M.; Ding, C.; Chen, H.; Zhao, S. Study on the Drying Characteristics and Physicochemical Properties of Alfalfa under High-Voltage Discharge Plasma. Agriculture 2024, 14, 1134. [Google Scholar] [CrossRef]

- Ouédraogo, A.; Zampaligré, N.; Mulubrhan, B.; Adesogan, A.T. Assessment of peri-urban livestock producers’ willingness to pay for improved forages as cash crops. Agron. J. 2022, 114, 63–74. [Google Scholar] [CrossRef] [PubMed]

- Vidinamo, F.; Fawzia, S.; Karim, M.A. Effect of drying methods and storage with agro-ecological conditions on phytochemicals and antioxidant activity of fruits: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 353–361. [Google Scholar] [CrossRef] [PubMed]

- Ham, J.C.A.; Alawi, A.; Rizki, Z.; Boom, R.M.; Garbin, V.; Padding, J.T.; Schutyser, M.A.I. A multi-scale analysis on electrohydrodynamic drying technology for bio-based & food products. Trends Food Sci. Technol. 2024, 151, 104634. [Google Scholar] [CrossRef]

- Dalvand, M.J.; Mohtasebi, S.S.; Rafiee, S. Optimization on drying conditions of a solar electrohydrodynamic drying system based on desirability concept. Food Sci. Nutr. 2014, 2, 758–767. [Google Scholar] [CrossRef]

- Arkar, K.; Vasiliev, M.M.; Petrov, O.F.; Kononov, E.A.; Trukhachev, F.M. Dynamics of Active Brownian Particles in Plasma. Molecules 2021, 26, 256. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Wang, H.; Sun, D.-W. Insight into the IgE-binding sites of allergenic peptides of tropomyosin in shrimp (Penaeus chinensis) induced by cold plasma active particles. Int. J. Biol. Macromol. 2023, 234, 123690. [Google Scholar] [CrossRef]

- Prasad, C.T.M.; Kodde, J.; Angenent, G.C.; de Vos, R.C.H.; Diez-Simon, C.; Mumm, R.; Hay, F.R.; Siricharoen, S.; Yadava, D.K.; Groot, S.P.C. Experimental rice seed aging under elevated oxygen pressure: Methodology and mechanism. Front. Plant Sci. 2022, 13, 1050411. [Google Scholar] [CrossRef]

- Xu, X.; Ma, C.; Yang, Y.; Bian, X.; Wang, B.; Zhang, G.; Zhang, N. Effects of phytic acid from soybean meal on Maillard reaction and antioxidant properties of products. Food Chem. 2025, 463, 141257. [Google Scholar] [CrossRef]

- Zhao, R.; Xiao, H.; Liu, C.; Wang, H.; Wu, Y.; Ben, A.; Wang, Y. Dynamic changes in volatile and non-volatile flavor compounds in lemon flavedo during freeze-drying and hot-air drying. LWT 2023, 175, 114510. [Google Scholar] [CrossRef]

- Gonsowski, C.T.; Laster, M.J.; Eger, E.I.; Ferrell, L.D.; Kerschmann, R.L. Toxicity of compound-a in rats—Effect of increasing duration of administration. Anesthesiology 1994, 80, 566–573. [Google Scholar] [CrossRef] [PubMed]

- Macnee, N.C.; Rebstock, R.; Hallett, I.C.; Schaffer, R.J.; Bulley, S.M. A review of current knowledge about the formation of native peridermal exocarp in fruit. Funct. Plant Biol. 2020, 47, 1019–1031. [Google Scholar] [CrossRef]

- Yan, L.; Zhang, A.; Qin, X.; Yu, H.; Ji, X.; He, S.; Zong, Y.; Gu, C.; Feng, Z.; Hu, L.; et al. Changes in key volatile components associated with leaf quality of Pandanus amaryllifolius Roxb. alongside growth duration. Food Chem. X 2025, 25, 102–126. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, H.; Wang, W.; Kong, G.; Li, Z.; Zhang, T.; Wang, M.; Yang, D.; Zhang, C.; Li, Y.; et al. Characterization of Volatile Organic Compounds and Aroma Sensory Properties in Yunnan Cigar. J. Anal. Methods Chem. 2024, 2024, 9583022. [Google Scholar] [CrossRef]

- Yang, H.; Li, W.; Lu, B.; Zi, L.; Xu, N.; Guo, L. Effect of different hot air drying process on flavor compounds and Maillard reaction products of Boletus edulis by HS-SPME/GC-MS coupled with multivariate analysis. LWT 2024, 198, 116055. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Lyu, Y.; Li, Y.; He, R.; Chen, H. Metabolomics analysis reveals the non-enzymatic browning mechanism of green peppers (Piper nigrum L.) during the hot-air drying process. Food Chem. 2025, 464, 141654. [Google Scholar] [CrossRef]

- Zamora, R.; Gallardo, E.; Hidalgo, F.J. Strecker Degradation of Phenylalanine Initiated by 2,4-Decadienal or Methyl 13-Oxooctadeca-9,11-dienoate in Model Systems. J. Agric. Food Chem. 2007, 55, 1308–1314. [Google Scholar] [CrossRef]

- Xu, M.; Liu, Q.; Ni, X.; Chen, C.; Deng, X.; Fang, Y.; Wang, X.; Shen, Q.; Yu, R. Lipidomics reveals the effect of hot-air drying on the quality characteristics and lipid oxidation of Tai Lake whitebait (Neosalanx taihuensis Chen). LWT 2024, 197, 115942. [Google Scholar] [CrossRef]

- Ni, J.-B.; Bi, Y.-X.; Vidyarthi, S.K.; Xiao, H.-W.; Han, L.-D.; Wang, J.; Fang, X.-M. Non-thermal electrohydrodynamic (EHD) drying improved the volatile organic compounds of lotus bee pollen via HS-GC-IMS and HS-SPME-GC-MS. LWT 2023, 176, 114480. [Google Scholar] [CrossRef]

- Ma, L.; Gao, M.; Zhang, L.; Qiao, Y.; Li, J.; Du, L.; Zhang, H.; Wang, H. Characterization of the key aroma-active compounds in high-grade Dianhong tea using GC-MS and GC-O combined with sensory-directed flavor analysis. Food Chem. 2022, 378, 132058. [Google Scholar] [CrossRef]

- Zamora, R.; Alcón, E.; Hidalgo, F.J. Strecker-Type Degradation of Phenylalanine Initiated by 4-Oxo-2-alkenals in Comparison to That Initiated by 2,4-Alkadienals, 4,5-Epoxy-2-alkenals, or 4-Hydroxy-2-nonenal. J. Agric. Food Chem. 2013, 61, 10231–10237. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Ding, C.; Lu, J.; Wang, H.; Bao, Y.; Han, B.; Zhu, J.; Duan, S.; Song, Z.; Chen, H. Effects of electrohydrodynamics on drying characteristics and volatile profiles of goji berry (Lycium barbarum L.). LWT 2024, 200, 116–149. [Google Scholar] [CrossRef]

- Yu, W.; Wei, Y.; Long, F.; Zhao, S.; Xiao, Y.; Gao, H. Insights into the dynamic evolution of quality and sensory attributes in red aril wine during fermentation. LWT 2024, 203, 116382. [Google Scholar] [CrossRef]

- Huang, Q.; Dong, K.; Wang, Q.; Huang, X.; Wang, G.; An, F.; Luo, Z.; Luo, P. Changes in volatile flavor of yak meat during oxidation based on multi-omics. Food Chem. 2022, 371, 103–131. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, D.; Dong, Y.; Ju, H.; Wu, C.; Lin, S. Characteristic volatiles fingerprints and changes of volatile compounds in fresh and dried Tricholoma matsutake Singer by HS-GC-IMS and HS-SPME-GC–MS. J. Chromatogr. B 2018, 1099, 46–55. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Q.; Liu, Q.; Xia, X.F.; Wang, Y.; Kong, B.H. Effect of different types of smoking materials on the flavor, heterocyclic aromatic amines, and sensory property of smoked chicken drumsticks. Food Chem. 2022, 367, 130680. [Google Scholar] [CrossRef]

- Wall, K.R.; Kerth, C.R.; Miller, R.K.; Alvarado, C. Grilling temperature effects on tenderness, juiciness, flavor and volatile aroma compounds of aged ribeye, strip loin, and top sirloin steaks. Meat Sci. 2019, 150, 141–148. [Google Scholar] [CrossRef]

- Zhao, F.; Wang, P.; Lucardi, R.D.; Su, Z.; Li, S. Natural Sources and Bioactivities of 2,4-Di-Tert-Butylphenol and Its Analogs. Toxins 2020, 12, 35. [Google Scholar] [CrossRef]

- Liu, M.; Yang, Y.; Zhao, X.; Wang, Y.; Li, M.; Wang, Y.; Tian, M.; Zhou, J. Classification and characterization on sorghums based on HS-GC-IMS combined with OPLS-DA and GA-PLS. Curr. Res. Food Sci. 2024, 8, 100692. [Google Scholar] [CrossRef]

- Chung, I.-M.; Kim, J.-K.; Han, J.-G.; Kong, W.-S.; Kim, S.-Y.; Yang, Y.-J.; An, Y.-J.; Kwon, C.; Chi, H.-Y.; Yhung Jung, M.; et al. Potential geo-discriminative tools to trace the origins of the dried slices of shiitake (Lentinula edodes) using stable isotope ratios and OPLS-DA. Food Chem. 2019, 295, 505–513. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, D.; Zhao, J.; Guo, Y.; Yan, W. Differentiation and characterization of volatile compounds in five common milk powders using HS-GC-IMS, HS-SPME-GC–MS, and multivariate statistical approaches. Food Chem. X 2025, 25, 102–179. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.I.; Kim, M.W.; Kim, Y.J.; Kim, M.J.; Choi, B.D.; Heu, M.S.; Kim, J.S. Processing optimization of restructured jerky from sea rainbow trout frame muscle. Food Sci. Biotechnol. 2016, 25, 707–712. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, Y.; Zhu, C.; Wei, M. Effects of different drying methods on the physical properties and sensory characteristics of apple chip snacks. LWT 2022, 154, 112829. [Google Scholar] [CrossRef]

- Elmas, F.; Bodruk, A.; Köprüalan, Ö.; Arıkaya, Ş.; Koca, N.; Serdaroğlu, F.M.; Kaymak-Ertekin, F.; Koç, M. The effect of pre-drying methods on physicochemical, textural and sensory characteristics on puff dried Turkey breast meat. LWT 2021, 145, 111350. [Google Scholar] [CrossRef]

- Qu, C.; Wang, X.; Wang, Z.; Yu, S.; Wang, D. Effect of Drying Temperatures on the Peanut Quality during Hot Air Drying. J. Oleo Sci. 2020, 69, 403–412. [Google Scholar] [CrossRef]

- Liu, C.; Zheng, X.; Jia, S.; Ding, N.; Gao, X. Comparative Experiment on Hot-Air and Microwave-Vacuum Drying and Puffing of Blue Honeysuckle Snack. Int. J. Food Eng. 2009, 5, 16–83. [Google Scholar] [CrossRef]

- Terpstra, M.E.J.; Jellema, R.H.; Janssen, A.M.; de Wijk, R.A.; Prinz, J.F.; van der Linden, E. Prediction of texture perception of mayonnaises from rheological and novel instrumental measurements. J. Texture Stud. 2009, 40, 82–108. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, F.; Wang, J.; Ma, Q.; Sun, J.; Tang, Y.; Wang, J.; Wang, W. Real-Time Monitoring of the Quality Changes in Shrimp (Penaeus vannamei) with Hyperspectral Imaging Technology during Hot Air Drying. Foods 2022, 11, 3179. [Google Scholar] [CrossRef]

- Wang, H.; Liu, C.; Xue, Y.; Li, D. Correlation of mechanical properties of peach slices with cell wall polysaccharides and cell morphology during hot air predrying. J. Food Process. Preserv. 2019, 44, 14319. [Google Scholar] [CrossRef]

- Shrivastav, S.; Kumbhar, B.K. Textural profile analysis of paneer dried with low pressure superheated steam. J. Food Sci. Technol. 2010, 47, 10–59. [Google Scholar] [CrossRef]

- Ding, H.; Yang, C.; Cao, S.; Gu, J.; Li, Y.; Zang, Y.; Yao, X.; Zhu, R.; Wang, Q.; Dong, W.; et al. Prediction models of texture attributes for radiofrequency assisted hot air drying of jujube slices based on morphological parameters. LWT 2023, 190, 115527. [Google Scholar] [CrossRef]

- Wang, D.; Chen, X.; Pandiselvam, R.; Wang, Y.; Zhao, W.; Li, F.; Sun, X.; Guo, Y.; Su, D.; Xu, H. Effects of microwave power control on enzyme activity, drying kinetics, and typical nutrients of Pleurotus Eryngii: Exploring the blanching mechanism by microstructural and ultrastructural evaluation. J. Food Compos. Anal. 2024, 128, 106037. [Google Scholar] [CrossRef]

| Compound Category | Code Number | Compound Name | CAS | Chemical Formula | Molecule | Retention Time [min] | Incense Type |

|---|---|---|---|---|---|---|---|

| Alkanes | 1 | 3,5,5-trimethyl-2-Hexene | 26456-76-8 | C9H18 |  | 11.743 | Mint scent |

| 2 | Dodecane | 112-40-3 | C12H26 |  | 18.099 | Greasy odor | |

| 3 | 1-nonadecene | 18435-45-5 | C19H38 |  | 31.122 | Tobacco flavor | |

| 4 | Tridecane | 629-50-5 | C13H28 |  | 24.922 | / | |

| 5 | 3-methyl-Undecane | 1002-43-3 | C12H26 |  | 20.766 | Aromatic | |

| 6 | Tetradecane | 629-59-4 | C14H30 |  | 27.716 | / | |

| 7 | 1,2-Diphenoxyethane | 104-66-5 | C14H14O2 |  | 32.938 | / | |

| Aldehydes | 8 | Decanal | 112-31-2 | C10H2O |  | 21.944 | Citrus aroma |

| 9 | Hexanal | 66-25-1 | C6H12O |  | 0.900 | Grassy flavor | |

| 10 | 2-hexenal | 6728-26-3 | C6H10O |  | 4.044 | Leafy green aroma | |

| 11 | Phenylacetaldehyde | 122-78-1 | C8H8O |  | 15.418 | Fruity sweet aroma | |

| 12 | 2,4-Heptadienal | 4313-03-5 | C7H10O |  | 13.009 | Aromatic | |

| 13 | Octyl aldehyde | 124-13-0 | C8H16O |  | 13.325 | Fruity scent | |

| Ketones | 14 | -Ionone | 14901-07-6 | C13H20O |  | 29.779 | Violet scent |

| 15 | Hexahydrofarnesyl Acetone | 502-69-2 | C18H36O |  | 33.050 | Spicy notes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Song, Z.; Li, B.; Qin, C.; Ding, C.; Liu, L. Study on the Effects of High-Voltage Discharge Plasma Drying on the Volatile Organic Compounds and Texture Characteristics of Oat Grass. Agriculture 2025, 15, 468. https://doi.org/10.3390/agriculture15050468

Zhang M, Song Z, Li B, Qin C, Ding C, Liu L. Study on the Effects of High-Voltage Discharge Plasma Drying on the Volatile Organic Compounds and Texture Characteristics of Oat Grass. Agriculture. 2025; 15(5):468. https://doi.org/10.3390/agriculture15050468

Chicago/Turabian StyleZhang, Mingjie, Zhiqing Song, Bufan Li, Chunxu Qin, Changjiang Ding, and Liqiang Liu. 2025. "Study on the Effects of High-Voltage Discharge Plasma Drying on the Volatile Organic Compounds and Texture Characteristics of Oat Grass" Agriculture 15, no. 5: 468. https://doi.org/10.3390/agriculture15050468

APA StyleZhang, M., Song, Z., Li, B., Qin, C., Ding, C., & Liu, L. (2025). Study on the Effects of High-Voltage Discharge Plasma Drying on the Volatile Organic Compounds and Texture Characteristics of Oat Grass. Agriculture, 15(5), 468. https://doi.org/10.3390/agriculture15050468