Tractor Power Take-Off and Drawbar Pull Performance and Efficiency Evolution Analysis Methodology and Model: A Case Study

Abstract

1. Introduction

1.1. Current Issues

1.1.1. Portfolio Complexity

1.1.2. Emission Regulations

1.2. Previous Studies

1.3. Hypothesis and Goals

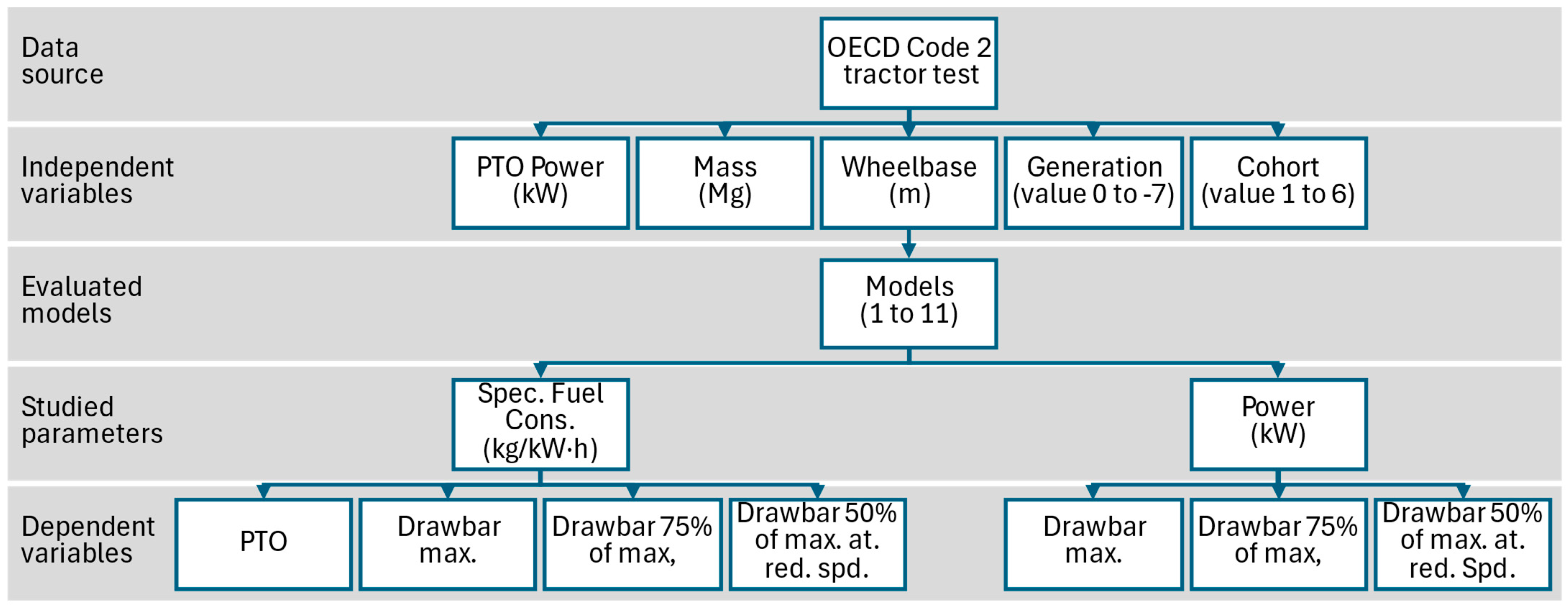

2. Materials and Methods

2.1. Dataset

2.2. Data Preparation

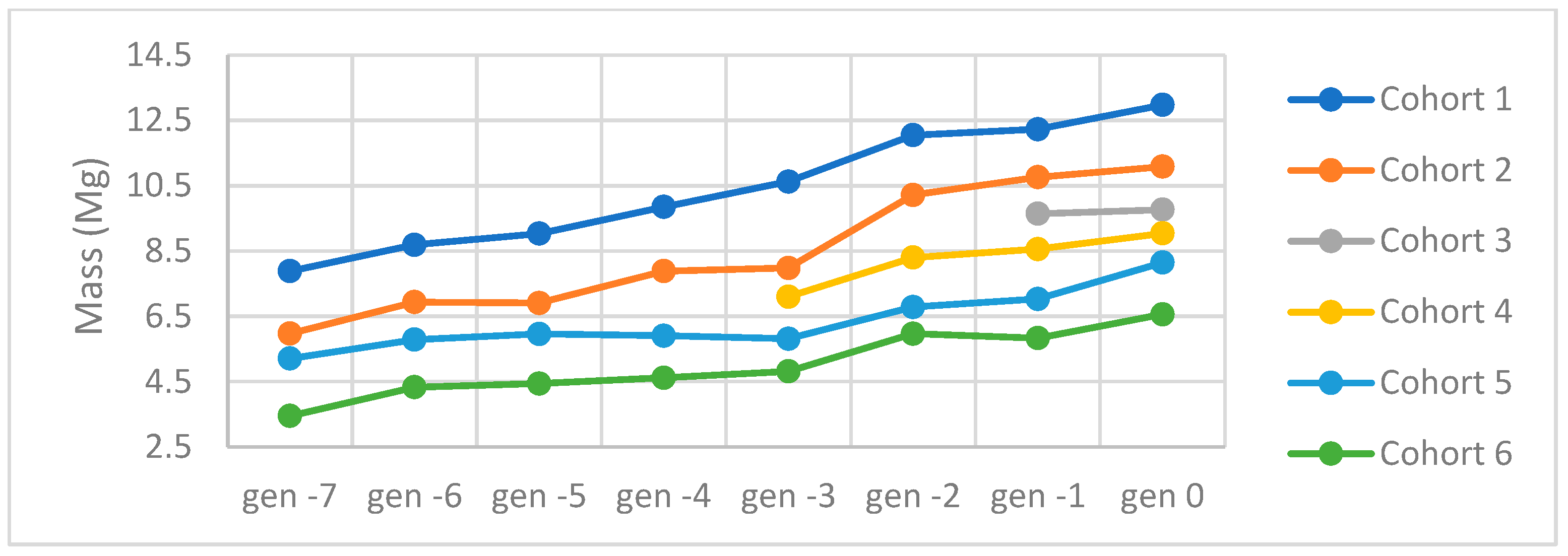

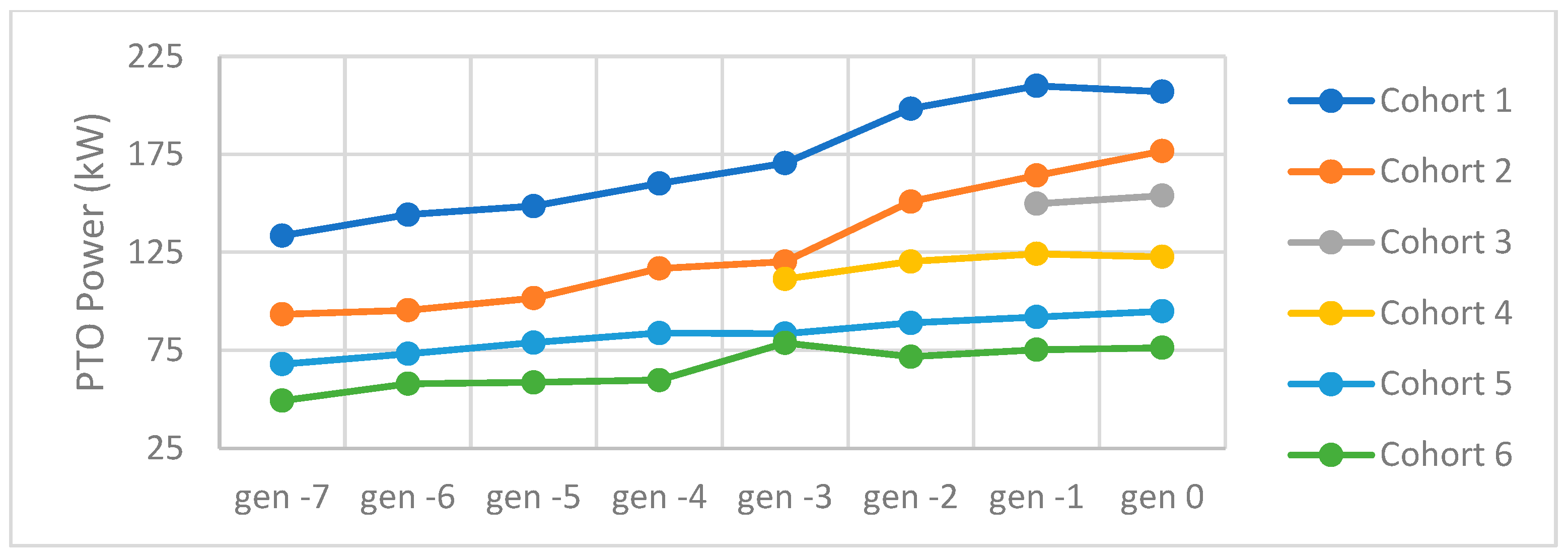

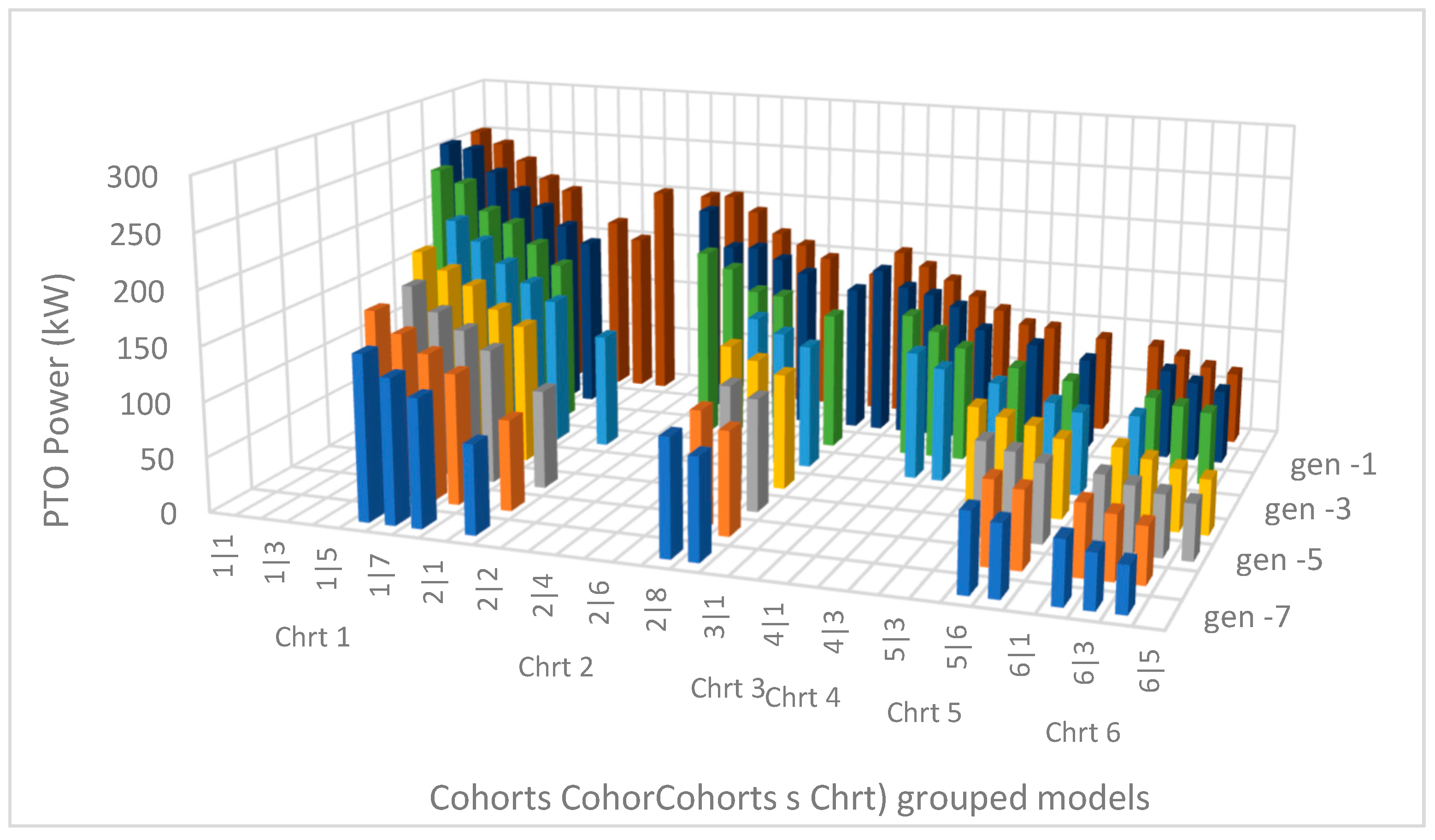

2.2.1. Tractor Cohorts (Chrt)

2.2.2. Tractor Generations

2.3. Data Regression

- pwr = tested PTO power (kW) at rated engine speed.

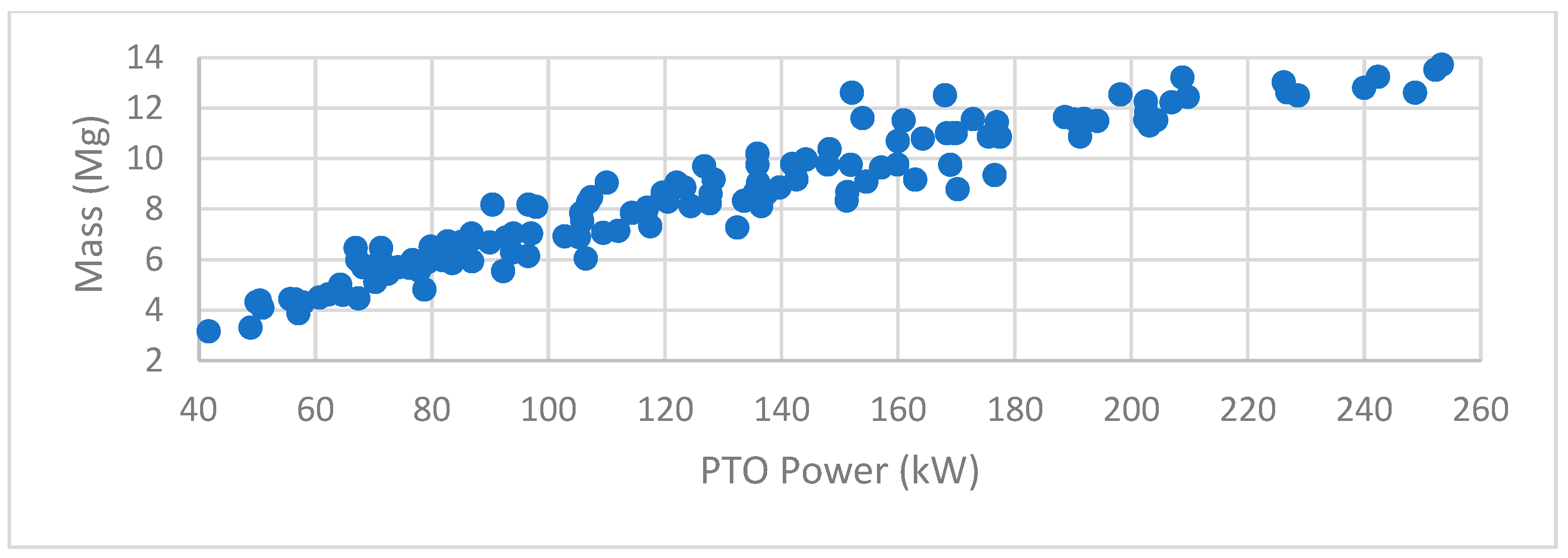

- mss = tested total tractor mass (Mg).

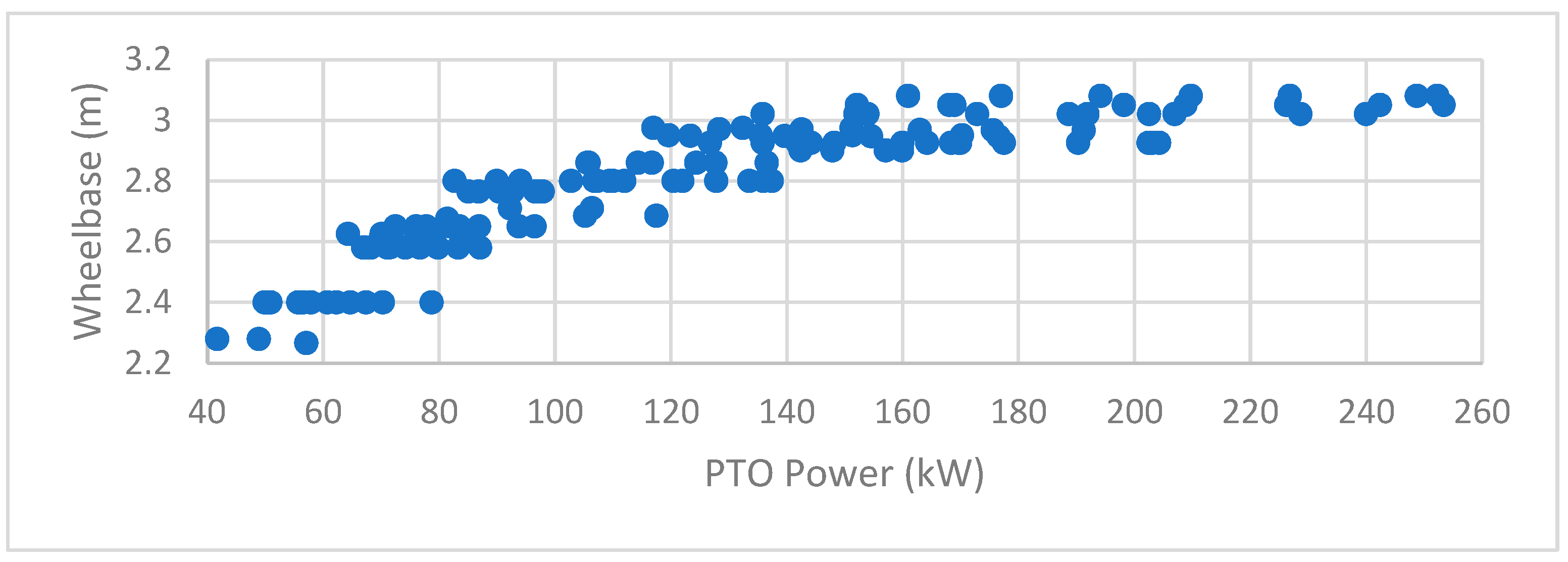

- wbs = tested tractor wheelbase (m).

- generationi = i tractor generations analyzed in this study (i from 0 to −7 and value 1 or 0).

- cohortj = j tractor cohorts in which the study tractor population has been grouped (j from 1 to 6 and value 1 or 0).

- coefpwr1 = coefficient that affects the power.

- coefpwr2 = coefficient that affects the power2.

- coefmss1 = coefficient that affects the mass.

- coefmss2 = coefficient that affects the mass2.

- coefwbs1 = coefficient that affects the wheelbase.

- coefwbs2 = coefficient that affects the wheelbase2.

- coefpwrmss = coefficient that affects the power and mass product.

- coefpwrwbs = coefficient that affects the power and wheelbase product.

- coefmsswbs = coefficient that affects the mass and wheelbase product.

- y = dependent variable:

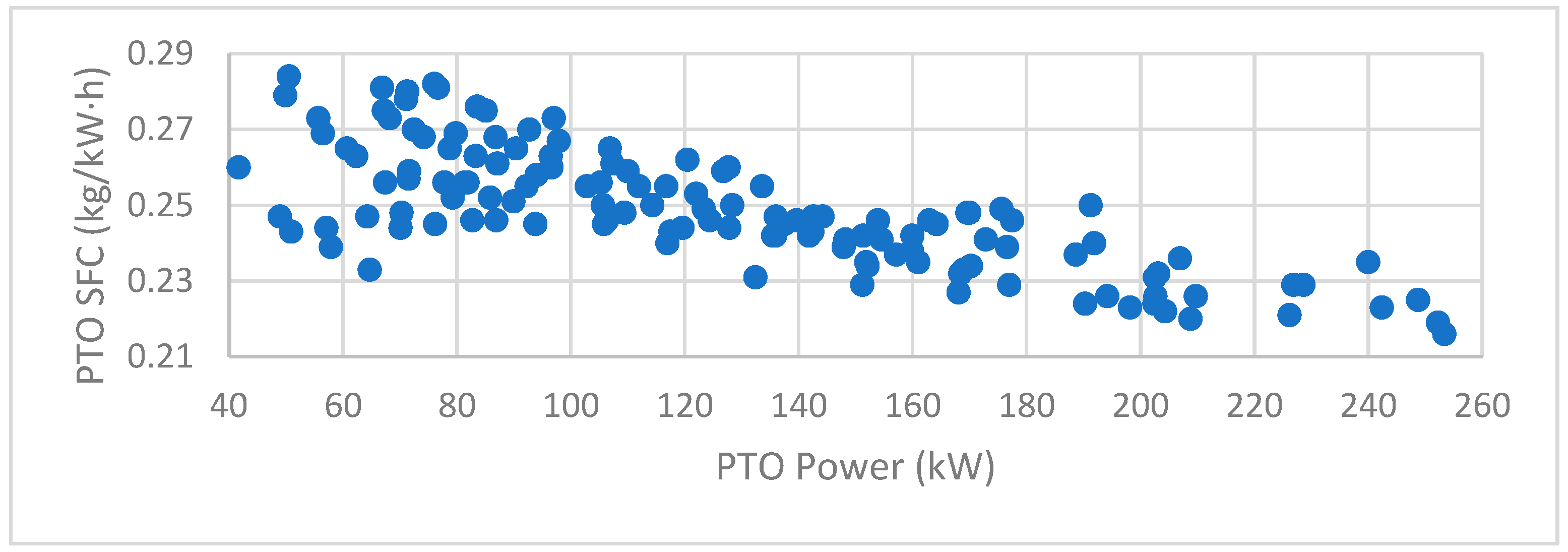

- Specific fuel consumption (SFC) in kg/kW·h;

- Drawbar (DB) power in kW.

3. Results

4. Discussion

Future Stydie Recommendations

5. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Coefficient | Specific Fuel Consumption (kg/kW·h) | Drawbar Power (kW) | |||||

|---|---|---|---|---|---|---|---|

| PTO Pwr. Test | BD Max. Pwr. | 75% Pull @ Max. Pwr | 50% Pull @ Red. Spd. | BD Max. Pwr. | 75% Pull @ Max. Pwr | 50% Pull @ Red. Spd. | |

| −2.48 × 10−6 | −1.67 × 10−6 | −3.50 × 10−6 | 3.44 × 10−7 | 7.63 × 10−4 | 6.44 × 10−4 | 4.19 × 10−4 | |

| 0.0013 | 0.0028 | 0.0036 | 0.0040 | −0.9069 | −0.7848 | −0.4940 | |

| −0.0011 | −0.0033 | −0.0036 | −0.0044 | 0.0768 | 0.2290 | 0.6186 | |

| 1.59 × 10−6 | −4.64 × 10−7 | −9.79 × 10−8 | −2.53 × 10−6 | 1.39 × 10−3 | 1.26 × 10−3 | 8.27 × 10−4 | |

| 0.0038 | 0.0108 | 0.0128 | 0.0144 | −0.3631 | −0.8879 | −2.3329 | |

| −0.1881 | −0.1699 | −0.3195 | −0.2675 | 90.5187 | 68.3840 | 13.1318 | |

| −0.0030 | −0.0157 | −0.0302 | −0.0328 | −0.4585 | 1.0243 | 8.9200 | |

| 0.8769 | 0.7111 | 1.5125 | 1.2376 | −389.5790 | −296.2519 | −50.5722 | |

| 0.0216 | 0.0190 | 0.0300 | 0.0350 | 2.3012 | 2.2435 | −4.7346 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| −0.0010 | 0.0007 | 0.0007 | 0.0028 | 1.5741 | 1.5623 | −3.5789 | |

| 0.0119 | 0.0132 | 0.0184 | 0.0241 | 1.7771 | 1.7593 | −3.8391 | |

| 0.0169 | 0.0225 | 0.0296 | 0.0302 | 1.4235 | 1.7915 | −4.4166 | |

| 0.0216 | 0.0190 | 0.0300 | 0.0350 | 2.3012 | 2.2435 | −4.7346 | |

| 0.0328 | 0.0235 | 0.0307 | 0.0248 | 3.9527 | 4.1087 | −5.0199 | |

| 0.0294 | 0.0141 | 0.0182 | 0.0155 | 8.7574 | 7.7383 | −3.3393 | |

| 0.0272 | 0.0147 | 0.0209 | 0.0200 | 6.0824 | 5.6664 | −5.2044 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 0.0093 | −0.0005 | −0.0129 | −0.0251 | 2.0093 | 2.7019 | 1.0747 | |

| 0.0123 | 0.0012 | −0.0101 | −0.0096 | 3.6275 | 4.8623 | 0.9628 | |

| 0.0192 | 0.0119 | −0.0035 | 0.0049 | 0.7371 | 2.5272 | −1.3172 | |

| 0.0262 | 0.0160 | 0.0033 | −0.0024 | 2.2380 | 3.9765 | −1.5888 | |

| 0.0471 | 0.0391 | 0.0285 | 0.0247 | −1.0538 | 2.0150 | −5.5286 | |

| −0.7150 | −0.3276 | −1.2889 | −0.9076 | 409.7138 | 311.4502 | 23.4191 | |

References

- Renius, K.T. Fundamentals of Tractor Design; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Zoz, F.M.; Grisso, R.D. Traction and Tractor Performance; American Society of Agricultural Engineers: St. Joseph, MI, USA, 2003; Volume 27. [Google Scholar]

- Brixius, W.W.; Zoz, F.M. Tires and Tracks in Agriculture; SAE Transactions: St. Joseph, MI, USA, 1976; pp. 2034–2044. [Google Scholar]

- Grisso, R.D.; Kocher, M.F.; Vaughan, D.H. Predicting Tractor Fuel Consumption. Appl. Eng. Agric. 2004, 20, 553–561. [Google Scholar] [CrossRef]

- Grisso, R.D.; Perumpral, J.V.; Vaughan, D.H.; Roberson, G.T.; Pitman, R.M. Predicting Tractor Diesel Fuel Consumption; Virginia Coopertive Extension: Blacksburg, VA, USA, 2010. [Google Scholar]

- Stephens, L.E.; Spencer, A.D.; Floyd, V.G.; Brixius, W.W. Energy Requirements for Tillage and Planting. ASAE Tech. Pap. 1981, 81, 1512. [Google Scholar]

- Kastens, T. Farm Machinery Operations Cost Calculations; Kansas State University: Manhattan, KS, USA, 1997. [Google Scholar]

- Herranz-Matey, I.; Ruiz-Garcia, L. New Agricultural Tractor Manufacturer’s Suggested Retail Price (MSRP) Model in Europe. Agriculture 2024, 14, 342. [Google Scholar] [CrossRef]

- Herranz-Matey, I.; Ruiz-Garcia, L. A New Method and Model for the Estimation of Residual Value of Agricultural Tractors. Agriculture 2023, 13, 409. [Google Scholar] [CrossRef]

- Dallmann, T.; Menon, A. Technology Pathways for Diesel Engines Used in Non-Road Vehicles and Equipment; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2016. [Google Scholar]

- EPA. Control of Emissions of Air Pollution From Nonroad Diesel Engines and Fuel; Final Rule. U.S. Environ. Prot. Agency (EPA) Fed. Regist. 2004, 69, 4213. [Google Scholar]

- EPA. Control of Emissions of Air Pollution From Nonroad Diesel Engines; Final Rule. U.S. Environ. Prot. Agency (EPA) Fed. Regist. 1998, 63, 56968–57023. [Google Scholar]

- EPA. Determination of Significance for Nonroad Sources and, Emission Standards for New Nonroad Compression-Ignition Engine At or Above 37 Kilowatts; Final Rule. U.S. Environ. Prot. Agency (EPA) Fed. Regist. 1994, 59. [Google Scholar]

- EC. Directive 97/68/EC of the European Parliament and of the Council of 16 December 1997; European Commission (EC): Brussels, Belgium, 1997. [Google Scholar]

- EC. Directive 2000/25/EC of the European Parliament; European Commission (EC): Brussels, Belgium, 2000. [Google Scholar]

- EC. Directive 2004/26/EC of the European Parliament and of the Council of 21 April 2004 Amending Directive 97/68/EC; European Commission (EC): Brussels, Belgium, 2004. [Google Scholar]

- EC. Directive 2009/30/EC of the European Parliament and of the Council of 23 April 2009 Amending Directive 98/70/EC; European Commission (EC): Brussels, Belgium, 2009. [Google Scholar]

- Janulevičius, A.; Juostas, A.; Čiplienė, A. Estimation of Carbon-Oxide Emissions of Tractors during Operation and Correlation with the Not-to-Exceed Zone. Biosyst. Eng. 2016, 147, 117–129. [Google Scholar] [CrossRef]

- Larsson, G.; Hansson, P.-A. Environmental Impact of Catalytic Converters and Particle Filters for Agricultural Tractors Determined by Life Cycle Assessment. Biosyst. Eng. 2011, 109, 15–21. [Google Scholar] [CrossRef]

- Janulevičius, A.; Juostas, A.; Pupinis, G. Engine Performance during Tractor Operational Period. Energy Convers. Manag. 2013, 68, 11–19. [Google Scholar] [CrossRef]

- Lovarelli, D.; Fiala, M.; Larsson, G. Fuel Consumption and Exhaust Emissions during On-Field Tractor Activity: A Possible Improving Strategy for the Environmental Load of Agricultural Mechanisation. Comput. Electron. Agric. 2018, 151, 238–248. [Google Scholar] [CrossRef]

- Bacenetti, J.; Lovarelli, D.; Facchinetti, D.; Pessina, D. An Environmental Comparison of Techniques to Reduce Pollutants Emissions Related to Agricultural Tractors. Biosyst. Eng. 2018, 171, 30–40. [Google Scholar] [CrossRef]

- Reckleben, Y.; Trefflich, S.; Thomsen, H. Impact of Emission Standards on Fuel Consumption of Tractors in Practical Use. Environ. Eng. 2014, 322–326. [Google Scholar]

- Lovarelli, D.; Bacenetti, J. Exhaust Gases Emissions from Agricultural Tractors: State of the Art and Future Perspectives for Machinery Operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Posada, F.; Isenstadt, A.; Badshah, H. Estimated Cost of a Diesel Emissions-Control Technology to Meet Future California Low NOx Standards in 2024 and 2027; The International Council of Clean Transportation: Washington, DC, USA, 2020. [Google Scholar]

- Posada, F.; Chambliss, S.; Blumberg, K. Cost of Emission Reduction Technologies for Heavy Duty Diesel Vehicles; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2016. [Google Scholar]

- Kienzle, J.; Ashburner, J.E.; Sims, B.G. Mechanization for Rural Development: A Review of Patterns and Progress from around the World. Integr. Crop Manag. 2013, 20. [Google Scholar]

- Fitzgerald, D. Beyond Tractors: The History of Technology in American Agriculture. Technol. Cult. 1991, 32, 114–126. [Google Scholar] [CrossRef]

- Olmstead, A.; Rhode, P. The Diffusion of the Tractor in American Agriculture: 1910-60; National Bureau of Economic Research: Cambridge, MA, USA, 2000. [Google Scholar]

- Gray, R.B. Development of the Agricultural Tractor in the United States; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1956. [Google Scholar]

- White, W.J. Economic History of Tractors in the United States; Whaples, R., Ed.; EH. Net. Encyclopedia: La Crosse, WI, USA, 2001. [Google Scholar]

- Leffingwell, R. John Deere: A History of the Tractor; Voyageur Press: Floodwood, MN, USA, 2006; ISBN 1610606515. [Google Scholar]

- Wik, R.M. Henry Ford’s Tractors and American Agriculture. Agric. Hist. 1964, 38, 79–86. [Google Scholar]

- Duarte, V.; Sarkar, S. A Cinderella Story: The Early Evolution of the American Tractor Industry; CEFAGE-UE Working Paper; University of Evora: Évora, Portugal, 2009. [Google Scholar]

- Dahlstrom, N. Tractor Wars: John Deere, Henry Ford, International Harvester, and the Birth of Modern Agriculture; BenBella Books: Dallas, TX, USA, 2022; ISBN 1953295746. [Google Scholar]

- Kim, K.U.; Bashford, L.L.; Sampson, B.T. Improvement of Tractor Performance. Appl. Eng. Agric. 2005, 21, 949–954. [Google Scholar] [CrossRef]

- Díaz Lankenau, G.F.; Winter, A.G. An Engineering Review of the Farm Tractor’s Evolution to a Dominant Design. J. Mech. Des. 2019, 141, 031107. [Google Scholar] [CrossRef]

- Bietresato, M.; Mazzetto, F. A Reasoned Evolutionary Study on the Actual Design of Farm Tractors. In Proceedings of the Creative Solutions for a Sustainable Development: 21st International TRIZ Future Conference, TFC 2021, Bolzano, Italy, 22–24 September 2021; Proceedings 21. Springer: Berlin/Heidelberg, Germany, 2021; pp. 256–275. [Google Scholar]

- Grisso, R.D. Gear up and Throttle Down. 2001. Available online: https://www.pubs.ext.vt.edu/442/442-450/442-450.html (accessed on 1 January 2025).

- Maulud, D.; Abdulazeez, A.M. A Review on Linear Regression Comprehensive in Machine Learning. J. Appl. Sci. Technol. Trends 2020, 1, 140–147. [Google Scholar] [CrossRef]

- Heiberger, R.M.; Neuwirth, E.; Heiberger, R.M.; Neuwirth, E. Polynomial Regression. R Through Excel. A Spreadsheet Interface Stat. Data Anal. Graph. 2009, 269–284. [Google Scholar]

- Ostertagová, E. Modelling Using Polynomial Regression. Procedia Eng. 2012, 48, 500–506. [Google Scholar] [CrossRef]

- Zuev, K. Statistical Inference. Political Methods: Quantitative Methods eJournal 2016. Available online: https://ssrn.com/abstract=3125891 (accessed on 18 February 2018).

- Lim, J.S.; Kim, Y.D.; Woo, J.-C. Approximated Uncertainty Propagation of Correlated Independent Variables Using the Ordinary Least Squares Estimator. Molecules 2024, 29, 1248. [Google Scholar] [CrossRef] [PubMed]

- Dette, H.; Pepelyshev, A.; Zhigljavsky, A.A. Best Linear Unbiased Estimators in Continuous Time Regression Models. arXiv 2016, arXiv:1611.09804. [Google Scholar]

- Lei, L.; Wooldridge, J. What Estimators Are Unbiased For Linear Models? arXiv 2022, arXiv:2212.14185. [Google Scholar]

- Hallin, M. Gauss–Markov Theorem in Statistics; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- McCarthy, R.V.; McCarthy, M.M.; Ceccucci, W.; Halawi, L. Applying Predictive Analytics; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-14037-3. [Google Scholar]

| Model | Power | Mass | Wheelbase | Binomial | Generation | Cohorts |

|---|---|---|---|---|---|---|

| 1 | linear | |||||

| 2 | linear | linear | linear | |||

| 3 | poly. 2nd | poly. 2nd | poly. 2nd | |||

| 4 | poly. 2nd | poly. 2nd | poly. 2nd | linear | ||

| 5 | poly. 2nd | poly. 2nd | poly. 2nd | linear (wbs2) | ||

| 6 | poly. 2nd | poly. 2nd | poly. 2nd | linear (mss2) | ||

| 7 | poly. 2nd | poly. 2nd | poly. 2nd | linear (pwr2) | ||

| 8 | linear | linear | linear | linear | linear | |

| 9 | linear | linear | linear | linear | linear | linear |

| 10 | poly. 2nd | poly. 2nd | poly. 2nd | linear | linear | linear |

| 11 | poly. 2nd | poly. 2nd | poly. 2nd | linear (mss2) | linear | linear |

| Model | PTO Pwr Test | DB Max. Pwr | 75% Pull @ Max. Pwr | 50% Pull @ Red. Spd. | ||||

|---|---|---|---|---|---|---|---|---|

| RSQ | RMSE | RSQ | RMSE | RSQ | RMSE | RSQ | RMSE | |

| 1 | 0.6091 | 0.0097 | 0.5998 | 0.0134 | 0.6545 | 0.0178 | 0.6123 | 0.0242 |

| 2 | 0.6216 | 0.0096 | 0.6318 | 0.0130 | 0.6681 | 0.0175 | 0.6383 | 0.0235 |

| 3 | 0.7120 | 0.0085 | 0.6591 | 0.0126 | 0.6923 | 0.0171 | 0.6592 | 0.0231 |

| 4 | 0.7321 | 0.0083 | 0.6814 | 0.0124 | 0.7167 | 0.0166 | 0.6829 | 0.0226 |

| 5 | 0.7296 | 0.0083 | 0.6783 | 0.0124 | 0.7133 | 0.0167 | 0.6784 | 0.0227 |

| 6 | 0.7305 | 0.0083 | 0.6810 | 0.0124 | 0.7130 | 0.0167 | 0.6741 | 0.0229 |

| 7 | 0.7286 | 0.0084 | 0.6693 | 0.0126 | 0.7026 | 0.0170 | 0.6662 | 0.0231 |

| 8 | 0.7767 | 0.0076 | 0.7223 | 0.0116 | 0.7507 | 0.0156 | 0.6866 | 0.0225 |

| 9 | 0.7836 | 0.0076 | 0.7580 | 0.0110 | 0.7910 | 0.0146 | 0.7405 | 0.0209 |

| 10 | 0.8372 | 0.0067 | 0.7810 | 0.0106 | 0.8127 | 0.0140 | 0.7533 | 0.0206 |

| 11 | 0.8519 | 0.0065 | 0.8123 | 0.0100 | 0.8373 | 0.0132 | 0.7691 | 0.0202 |

| Model | DB Max. Pwr | 75% Pull @ Max. Pwr | 50% Pull @ Red. Spd. | |||

|---|---|---|---|---|---|---|

| RSQ | RMSE | RSQ | RSQ | RMSE | RSQ | |

| 1 | 0.9899 | 4.8068 | 0.9900 | 3.7181 | 0.9809 | 3.4632 |

| 2 | 0.9902 | 4.7721 | 0.9901 | 3.7246 | 0.9810 | 3.4802 |

| 3 | 0.9914 | 4.5143 | 0.9914 | 3.5091 | 0.9829 | 3.3437 |

| 4 | 0.9921 | 4.3873 | 0.9923 | 3.3740 | 0.9837 | 3.2986 |

| 5 | 0.9921 | 4.3935 | 0.9922 | 3.3812 | 0.9837 | 3.2993 |

| 6 | 0.9920 | 4.4145 | 0.9921 | 3.4033 | 0.9834 | 3.3262 |

| 7 | 0.9921 | 4.3873 | 0.9923 | 3.3788 | 0.9837 | 3.3034 |

| 8 | 0.9925 | 4.2934 | 0.9923 | 3.3885 | 0.9831 | 3.3684 |

| 9 | 0.9934 | 4.1103 | 0.9932 | 3.2312 | 0.9854 | 3.1949 |

| 10 | 0.9937 | 4.0534 | 0.9938 | 3.1333 | 0.9860 | 3.1683 |

| 11 | 0.9943 | 3.9141 | 0.9945 | 3.0012 | 0.9868 | 3.1175 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herranz-Matey, I. Tractor Power Take-Off and Drawbar Pull Performance and Efficiency Evolution Analysis Methodology and Model: A Case Study. Agriculture 2025, 15, 354. https://doi.org/10.3390/agriculture15030354

Herranz-Matey I. Tractor Power Take-Off and Drawbar Pull Performance and Efficiency Evolution Analysis Methodology and Model: A Case Study. Agriculture. 2025; 15(3):354. https://doi.org/10.3390/agriculture15030354

Chicago/Turabian StyleHerranz-Matey, Ivan. 2025. "Tractor Power Take-Off and Drawbar Pull Performance and Efficiency Evolution Analysis Methodology and Model: A Case Study" Agriculture 15, no. 3: 354. https://doi.org/10.3390/agriculture15030354

APA StyleHerranz-Matey, I. (2025). Tractor Power Take-Off and Drawbar Pull Performance and Efficiency Evolution Analysis Methodology and Model: A Case Study. Agriculture, 15(3), 354. https://doi.org/10.3390/agriculture15030354