Design and Optimization of a Biomimetic Pineapple Harvester Device Based on the Mechanical Properties of the Stem-Fruit Junction

Abstract

1. Introduction

2. Pineapple Agronomic Parameters and Mechanical Properties

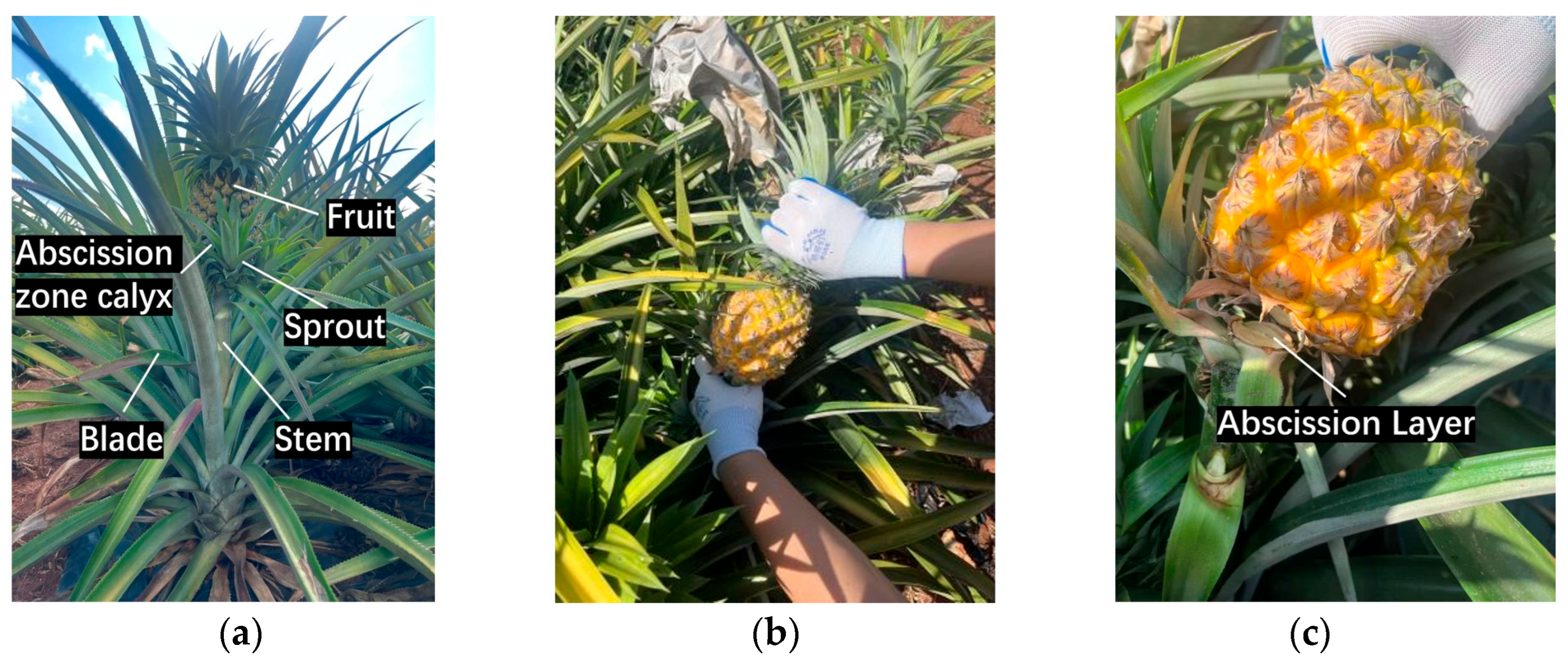

2.1. Agronomic Parameters and Physical Characteristics of Pineapple Cultivation

2.2. Analysis of Biomimetic Principles in Pineapple Harvesting Processes

2.3. Mechanical Properties of Pineapple Calyx

3. Structure and Working Principle of Pineapple Harvesting Device

3.1. Structure of Pineapple Harvesting Device

3.2. The Principle of Pineapple Harvesting

3.3. Force Analysis of Pineapple Harvesting

4. Key Component Design and Analysis

4.1. Motion Analysis of the Rotating Harvesting Unit

4.2. Rotation Radius of the Rotating Harvesting Unit

4.3. Feed Angle of the Rotating Harvesting Unit

4.4. Rotational Speed of the Rotating Harvesting Unit

5. Simulation Analysis

5.1. 3D Model Construction and Parameter Settings

5.2. Simulation Test

5.3. Simulation Test Results and Analysis

5.3.1. Tensile Force Analysis

5.3.2. Support Force Analysis

5.3.3. Comprehensive Analysis

6. Bench Test

6.1. Pineapple Harvesting Experiment

6.2. Evaluation Indicators

6.3. Bench Test Design and Results Analysis

7. Field Experiment

7.1. Experimental Site

7.2. Experimental Design and Results Analysis

7.3. Comparison with Manual Harvesting

8. Conclusions

- (1)

- Field measurements and mechanical characterization tests quantified the tensile force required for the detachment of Tainung 16 pineapple fruit from the stem at the calyx abscission zone as 100.42–165.38 N. This foundational mechanical dataset enabled the rational design of the harvesting device, ensuring sufficient force for effective fruit-stem separation while mitigating excessive mechanical damage to the fruit.

- (2)

- Dynamic simulation via Adams 18.0 software identified the optimal operational parameters: a travelling speed of 1.5 m/s, a rotational speed of 37 r/min for the rotary harvesting unit, and a motion trajectory characteristic parameter (λ) of 1.3. Subsequent field validation demonstrated that the device achieved an average harvesting rate of 81.23% and a fruit damage rate of 9.35%, effectively addressing the core technical bottlenecks of low efficiency and high fruit damage in mechanized pineapple harvesting.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ikram, M.M.M.; Mizuno, R.; Putri, S.P.; Fukusaki, E. Comparative metabolomics and sensory evaluation of pineapple (Ananas comosus) reveal the importance of ripening stage compared to cultivar. J. Biosci. Bioeng. 2021, 132, 592–598. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, F.; Cabral, J. Pineapple germplasm in Brazil. Int. Pineapple Symp. 1992, 334, 23–26. [Google Scholar] [CrossRef]

- Horry, J.; Lenoir, H.; Perrier, X.; Teisson, C. The CIRAD pineapple germplasm database. IV Int. Pineapple Symp. 2002, 666, 73–76. [Google Scholar] [CrossRef]

- Liu, T.H.; Ehsani, R.; Toudeshki, A.; Zou, X.J.; Wang, H.J. Experimental study of vibrational acceleration spread and comparison using three citrus canopy shaker shaking tines. Shock Vib. 2017, 1, 9827926. [Google Scholar] [CrossRef]

- He, F.G.; Zhang, Q.; Deng, G.R.; Li, G.J.; Yan, B.; Pan, D.X.; Luo, X.W.; Li, J.H. Research status and development trend of key technologies for pineapple harvesting equipment: A review. Agriculture 2024, 14, 975. [Google Scholar] [CrossRef]

- Liu, T.H.; Zheng, Y.; Lai, J.S.; Cheng, Y.F.; Chen, S.Y.; Mai, B.F.; Liu, Y.; Li, J.Y.; Xue, Z. Extracting visual navigation line between pineapple field rows based on an enhanced YOLOv5. Comput. Electron. Agric. 2024, 217, 108574. [Google Scholar] [CrossRef]

- Sarkar, P. Use of shaking mechanism and robotic arm in fruit harvesting: A comprehensive review. J. Crop Weed 2021, 17, 1–9. [Google Scholar] [CrossRef]

- O’Brien, M.; Cargill, B.F.; Fridley, R.B. Economic aspects related to the fruit industry. In Principles and Practices for Harvesting and Handling Fruits and Nuts; AVI Press: Westport, CT, USA, 1983; pp. 47–70. [Google Scholar]

- Wang, H.X.; Li, H.L.; Zhang, X.M.; Sun, W.S.; Sun, H.T.; Zou, H.F.; Yu, Z.Z.; Wang, C. Research progress of mechanization technology and equipment for the whole pineapple production process. J. Agric. Mech. Res. 2025, 47, 283–292. [Google Scholar] [CrossRef]

- Liu, W.; Liu, T.H.; Zeng, T.Y.; Ma, R.J.; Cheng, Y.F.; Yan, Z.; Qiu, J.; Long, Q. Prediction of internal mechanical damage in pineapple compression using finite element method based on Hooke’s and Hertz’s laws. Sci. Hortic. 2023, 308, 111592. [Google Scholar] [CrossRef]

- Liu, T.H.; Liu, W.; Zeng, Y.T.; Cheng, Y.F.; Yan, Z.; Qiu, J. A multi-flexible-fingered roller pineapple harvesting mechanism. Agriculture 2022, 12, 1175. [Google Scholar] [CrossRef]

- Bhat, K.; Chayalakshmi, C. Microcontroller-based semiautomated pineapple harvesting system. Int. Conf. Mob. Comput. Sustain. Inform. 2021, 12, 383–392. [Google Scholar] [CrossRef]

- O’Brien, M.; Kahl, W.H.; Moffett, L. Is mechanically harvesting pineapple practical? Agric. Eng. 1970, 51, 564–565. [Google Scholar]

- Plebe, A.; Grasso, G. Localization of spherical fruits for robotic harvesting. Mach. Vis. Appl. 2001, 13, 70–79. [Google Scholar] [CrossRef]

- Van Henten, E.J.; Hemming, J.; Van Tuijl, B.; Kornet, J.; Meuleman, J.; Bontsema, J.; Van Os, E.A. An autonomous robot for harvesting cucumbers in greenhouses. Auton. Robot. 2002, 13, 241–258. [Google Scholar] [CrossRef]

- Du, X.; Yang, X.; Ji, J.; Jin, X.; Chen, L. Design and test of a pineapple picking end-effector. Appl. Eng. Agric. 2019, 35, 1045–1055. [Google Scholar] [CrossRef]

- Ma, X.Z.; Lian, H.S.; Gong, M.F.; Chen, H.L.; Liao, G.X.; Deng, Z.X. Structural design and experiment of pineapple picking manipulator. J. Shandong Agric. Univ. (Nat. Sci. Ed.) 2020, 51, 727–732. [Google Scholar]

- Zhang, X.; Zhang, Y. Design of the pineapple picking manipulator. J. Agric. Mech. Res. 2014, 12, 130–132. [Google Scholar]

- Wang, H.F.; Li, B.; Liu, G.Y.; Xu, L.M. Design and experiment of pineapple picking manipulator. Trans. Chin. Soc. Agric. Eng. 2012, 28, 42–46. [Google Scholar] [CrossRef]

- Liu, T.H.; Nie, X.N.; Wu, J.M.; Zhang, D.; Liu, W.; Cheng, Y.F.; Yan, Z.; Qiu, J.; Long, Q. Pineapple (Ananas comosus) fruit detection and localization in natural environment based on binocular stereo vision and improved YOLOv3 model. Precis. Agric. 2023, 24, 139–160. [Google Scholar] [CrossRef]

- Li, B.; Wang, M.H.; Li, L. Identification of pineapple fruits in the field based on monocular vision. Trans. Chin. Soc. Agric. Eng. 2010, 26, 345–349. [Google Scholar] [CrossRef]

- Li, B.; Wang, H.F.; Huang, W.Q.; Zhang, C. Construction and field trial of low-cost binocular vision platform for pineapple harvesting machinery. Trans. Chin. Soc. Agric. Eng. 2012, 28, 188–192. [Google Scholar] [CrossRef]

- Li, B.; Wang, M. In-field recognition and navigation path extraction for pineapple harvesting robots. Intell. Autom. Soft Comput. 2013, 19, 99–107. [Google Scholar] [CrossRef]

- Lin, G.H.; Wu, Z.M.; Yan, M.S.; Liang, R.J.; Wu, Y.Y.; Yan, F.W.; Wu, T.J.; Deng, G.K.; Yao, J.Y.; Zhang, Y.L. Design and experiment of multi-arm pineapple picking robot based on machine vision. Mech. Electr. Eng. Technol. 2023, 52, 141–144+154. [Google Scholar] [CrossRef]

- Jiao, R.; Ma, R.J.; Chen, Y.; Wu, E.H.; Yang, J.P.; Wen, G.Z.; Pan, X. Detection method of cutting point of pineapple stem based on multi-sensor information fusion. J. Huazhong Agric. Univ. 2024, 43, 21–30. [Google Scholar] [CrossRef]

- Xue, Z.; Chen, R.Y.; Zhang, X.M. Research status of mechanized planting and harvesting of pineapple. J. Shanxi Agric. Univ. (Nat. Sci. Ed.) 2021, 41, 110–120. [Google Scholar] [CrossRef]

- Sirisomboon, P.; Tanaka, M.; Kojima, T. Evaluation of tomato textural mechanical properties. J. Food Eng. 2012, 111, 618–624. [Google Scholar] [CrossRef]

- Cui, Z.D.; Chen, M.W.; Xie, J.Q.; Deng, G.R.; Zhou, W.; Zheng, S. Preliminary study on the cultivation mode of mechanized pineapple and its mechanization in Zhanjiang. Mod. Agric. Equip 2022, 43, 2–9. [Google Scholar]

- Heinicke, R.; Gortner, W. Stem bromelain—A new protease preparation from pineapple plants. Econ. Bot. 1957, 11, 225–234. [Google Scholar] [CrossRef]

- Li, M.; He, L.; Yue, D.; Wang, B.; Li, J. Fracture mechanism and separation conditions of pineapple fruit-stem and calibration of physical characteristic parameters. Int. J. Agric. Biol. Eng. 2023, 16, 248–259. [Google Scholar] [CrossRef]

- Goren, R. Anatomical, physiological, and hormonal aspects of abscission in citrus. Hortic. Rev. 1993, 15, 145–182. [Google Scholar] [CrossRef]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-de-Santos, P. Soft grippers for automatic crop harvesting: A review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef] [PubMed]

- Jalali, A.; Abdi, R. The effect of ground speed, reel rotational speed and reel height in harvester losses. J. Agric. Sustain. 2014, 5, 221–231. [Google Scholar]

- Zhang, M.; Li, G.; Yang, Y.; Jin, M.; Jiang, T. Design and parameter optimization of variable speed reel for oilseed rape combine harvester. Agriculture 2023, 13, 1521. [Google Scholar] [CrossRef]

- Chen, Z.X.; Zhang, H.J.; Yang, H.W.; Yan, Y.F.; Sun, J.W.; Zhao, G.Z.; Wang, J.X.; Fan, G.Q. Optimization and experimental study of structural parameters for a low-damage packing device on an apple harvesting platform. Agriculture 2023, 13, 1653. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, H.; Zhang, Z.; Wei, X.; Zheng, W.; Wu, Y. Structure design and analysis of pineapple picking mechanism based on the principle of shutter mechanism. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 042049. [Google Scholar] [CrossRef]

- Fu, M.; Li, C.; Zheng, Z. Design and analysis of semi-automatic screw type pineapple picking-collecting machine. Chin. J. Chem. Eng. 2020, 27, 487–497. [Google Scholar]

- Zhang, R.; Shi, J.; Zhang, R. Structure design of automatic pineapple picking machine. J. Anhui Agric. Sci. 2011, 39, 9861–9863. [Google Scholar] [CrossRef]

| Parameters | Pineapple Pulp | Pineapple Rind | Pineapple Core |

|---|---|---|---|

| Modulus of elasticity/Mpa | 3.29 | 2.66 | 3.96 |

| Density/g·cm−3 | 0.92 | 1.02 | 1.05 |

| Poisson’s ratio | 0.33 | 0.23 | 0.20 |

| No. | Forward Speed | Rotational Speed | Characteristic | Tensile Force | Support Force |

|---|---|---|---|---|---|

| 1 | 0.3 | 6.5 | 1.1 | 102.33 | 29.32 |

| 0.3 | 7.5 | 1.3 | 104.94 | 30.05 | |

| 0.3 | 8.5 | 1.5 | 107.60 | 31.39 | |

| 0.3 | 9.5 | 1.7 | 109.99 | 32.24 | |

| 2 | 0.5 | 10.5 | 1.1 | 130.89 | 30.98 |

| 0.5 | 12.5 | 1.3 | 136.25 | 31.76 | |

| 0.5 | 14.5 | 1.5 | 142.25 | 32.75 | |

| 0.5 | 16 | 1.7 | 146.82 | 34.13 | |

| 3 | 1 | 21 | 1.1 | 159.55 | 36.26 |

| 1 | 25 | 1.3 | 166.76 | 37.02 | |

| 1 | 28.5 | 1.5 | 172.91 | 38.12 | |

| 1 | 32.5 | 1.7 | 180.43 | 38.78 | |

| 4 | 1.5 | 31.5 | 1.1 | 214.18 | 45.79 |

| 1.5 | 37 | 1.3 | 225.45 | 47.39 | |

| 1.5 | 43 | 1.5 | 236.02 | 48.78 | |

| 1.5 | 48.5 | 1.7 | 246.06 | 50.22 | |

| 5 | 2 | 42 | 1.1 | 249.75 | 52.24 |

| 2 | 49.5 | 1.3 | 262.84 | 53.25 | |

| 2 | 57.5 | 1.5 | 275.46 | 54.74 | |

| 2 | 65 | 1.7 | 288.30 | 56.59 | |

| 6 | 2.5 | 52.5 | 1.1 | 469.16 | 96.40 |

| 2.5 | 62 | 1.3 | 494.58 | 98.17 | |

| 2.5 | 71.5 | 1.5 | 519.29 | 100.91 | |

| 2.5 | 81 | 1.7 | 544.74 | 103.44 | |

| 7 | 3 | 63 | 1.1 | 538.28 | 108.62 |

| 3 | 74.5 | 1.3 | 566.71 | 110.81 | |

| 3 | 86 | 1.5 | 595.51 | 113.42 | |

| 3 | 97.5 | 1.7 | 624.55 | 116.30 |

| No. | Characteristic Parameter | Forward Speed | Rotational Speed | Harvesting Rate/% | Damage Rate/% |

|---|---|---|---|---|---|

| 1 | 1.3 | 0.5 | 12.5 | 66.67 | 4.92 |

| 1.5 | 0.5 | 14.5 | 60.00 | 5.50 | |

| 1.7 | 0.5 | 16.0 | 69.33 | 8.94 | |

| 2 | 1.3 | 1 | 25.0 | 78.00 | 4.29 |

| 1.5 | 1 | 28.5 | 74.00 | 6.91 | |

| 1.7 | 1 | 32.5 | 74.67 | 5.64 | |

| 3 | 1.3 | 1.5 | 37.0 | 84.67 | 7.98 |

| 1.5 | 1.5 | 43.0 | 72.00 | 8.52 | |

| 1.7 | 1.5 | 48.5 | 67.33 | 6.63 | |

| 4 | 1.3 | 2 | 50.0 | 73.33 | 8.47 |

| 1.5 | 2 | 57.5 | 72.00 | 7.84 | |

| 1.7 | 2 | 65.0 | 63.33 | 9.60 | |

| 5 | 1.3 | 2.5 | 62.0 | 64.67 | 9.03 |

| 1.5 | 2.5 | 71.5 | 62.67 | 11.13 | |

| 1.7 | 2.5 | 81.0 | 52.67 | 16.50 | |

| 6 | 1.3 | 3 | 74.5 | 60.00 | 14.28 |

| 1.5 | 3 | 86.0 | 58.00 | 14.19 | |

| 1.7 | 3 | 97.5 | 56.67 | 18.80 |

| No. | Number of Successful Harvests | Number of Unsuccessful Harvests | Number of Undamaged Harvests | Number of Damaged Harvests | Harvesting Rate/% |

|---|---|---|---|---|---|

| 1 | 95 | 12 | 87 | 8 | 88.79 |

| 2 | 70 | 22 | 61 | 9 | 76.09 |

| 3 | 89 | 17 | 81 | 8 | 84.00 |

| 4 | 75 | 25 | 64 | 11 | 75.00 |

| 5 | 98 | 14 | 93 | 5 | 87.50 |

| 6 | 83 | 21 | 72 | 11 | 79.81 |

| 7 | 91 | 18 | 80 | 11 | 83.49 |

| 8 | 82 | 20 | 74 | 8 | 80.39 |

| 9 | 86 | 19 | 70 | 16 | 81.90 |

| 10 | 84 | 23 | 77 | 7 | 78.51 |

| Mean | - | - | - | - | 81.23 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Zhang, W.; Li, H.; Zou, H.; Sun, P.; Lu, M.; Xue, Z. Design and Optimization of a Biomimetic Pineapple Harvester Device Based on the Mechanical Properties of the Stem-Fruit Junction. Agriculture 2025, 15, 2562. https://doi.org/10.3390/agriculture15242562

Sun H, Zhang W, Li H, Zou H, Sun P, Lu M, Xue Z. Design and Optimization of a Biomimetic Pineapple Harvester Device Based on the Mechanical Properties of the Stem-Fruit Junction. Agriculture. 2025; 15(24):2562. https://doi.org/10.3390/agriculture15242562

Chicago/Turabian StyleSun, Haitian, Wei Zhang, Hailiang Li, Huafen Zou, Peng Sun, Meigu Lu, and Zhong Xue. 2025. "Design and Optimization of a Biomimetic Pineapple Harvester Device Based on the Mechanical Properties of the Stem-Fruit Junction" Agriculture 15, no. 24: 2562. https://doi.org/10.3390/agriculture15242562

APA StyleSun, H., Zhang, W., Li, H., Zou, H., Sun, P., Lu, M., & Xue, Z. (2025). Design and Optimization of a Biomimetic Pineapple Harvester Device Based on the Mechanical Properties of the Stem-Fruit Junction. Agriculture, 15(24), 2562. https://doi.org/10.3390/agriculture15242562