Prediction of Quality Attributes of the Ruaner Pear Using Dielectric Properties During Post-Ripening Variable Temperature Frozen Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Ruaner Pear Processing

2.3. Chemicals

2.4. Determination of Quality Attribute for Ruaner Pear

2.4.1. Determination of Peel and Flesh Color

2.4.2. Determination of Total Soluble Solids, Soluble Sugar, Titratable Acids

2.4.3. Determination of Water Content

2.4.4. Determination of Stone Cell Content

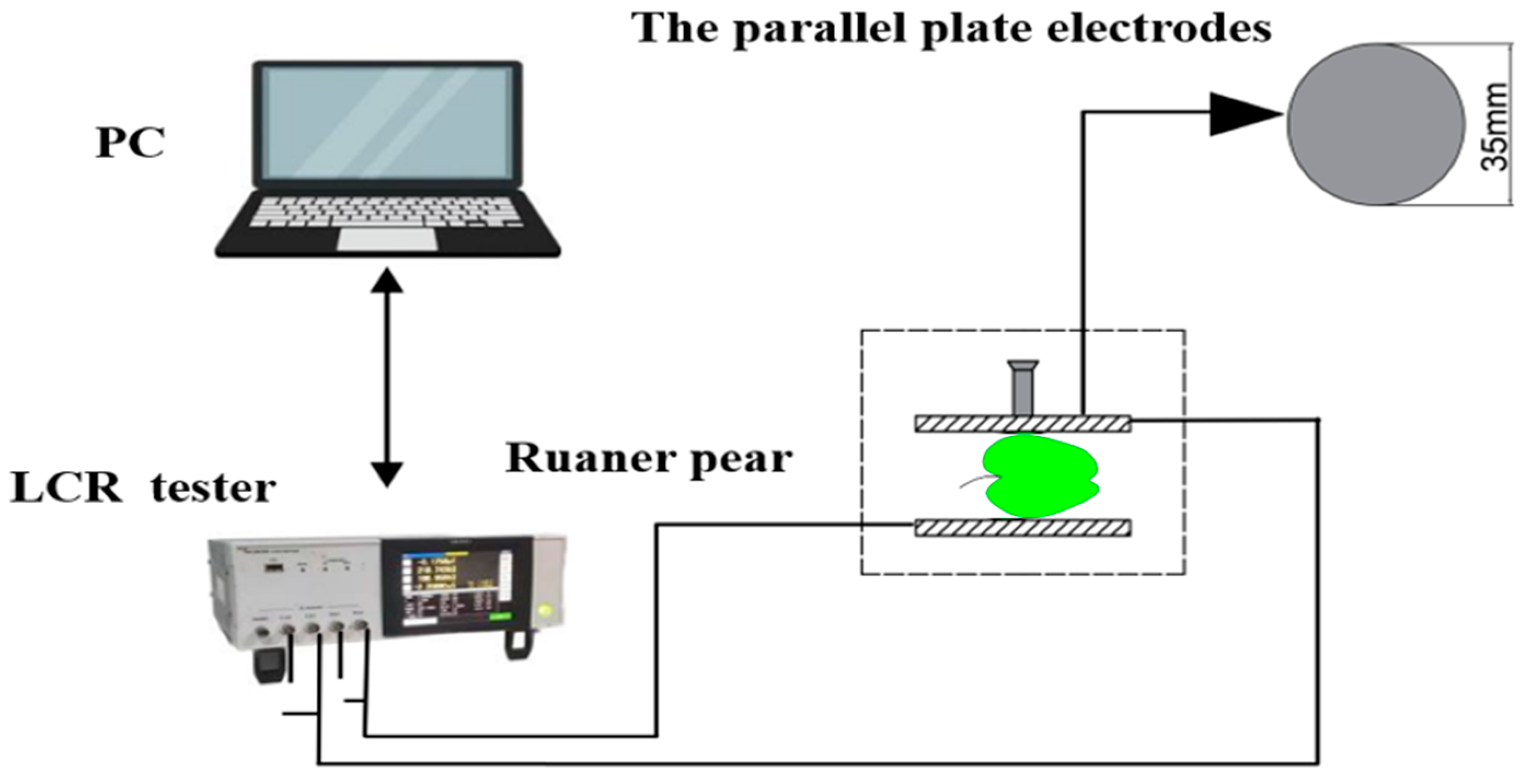

2.5. Dielectric Properties of Ruaner Pear During Post-Ripening Variable Temperature Frozen Storage

2.6. Principal Component Analysis (PCA)

2.7. Gray Relational Analysis

2.8. Data Statistics and Analysis

3. Results and Discussion

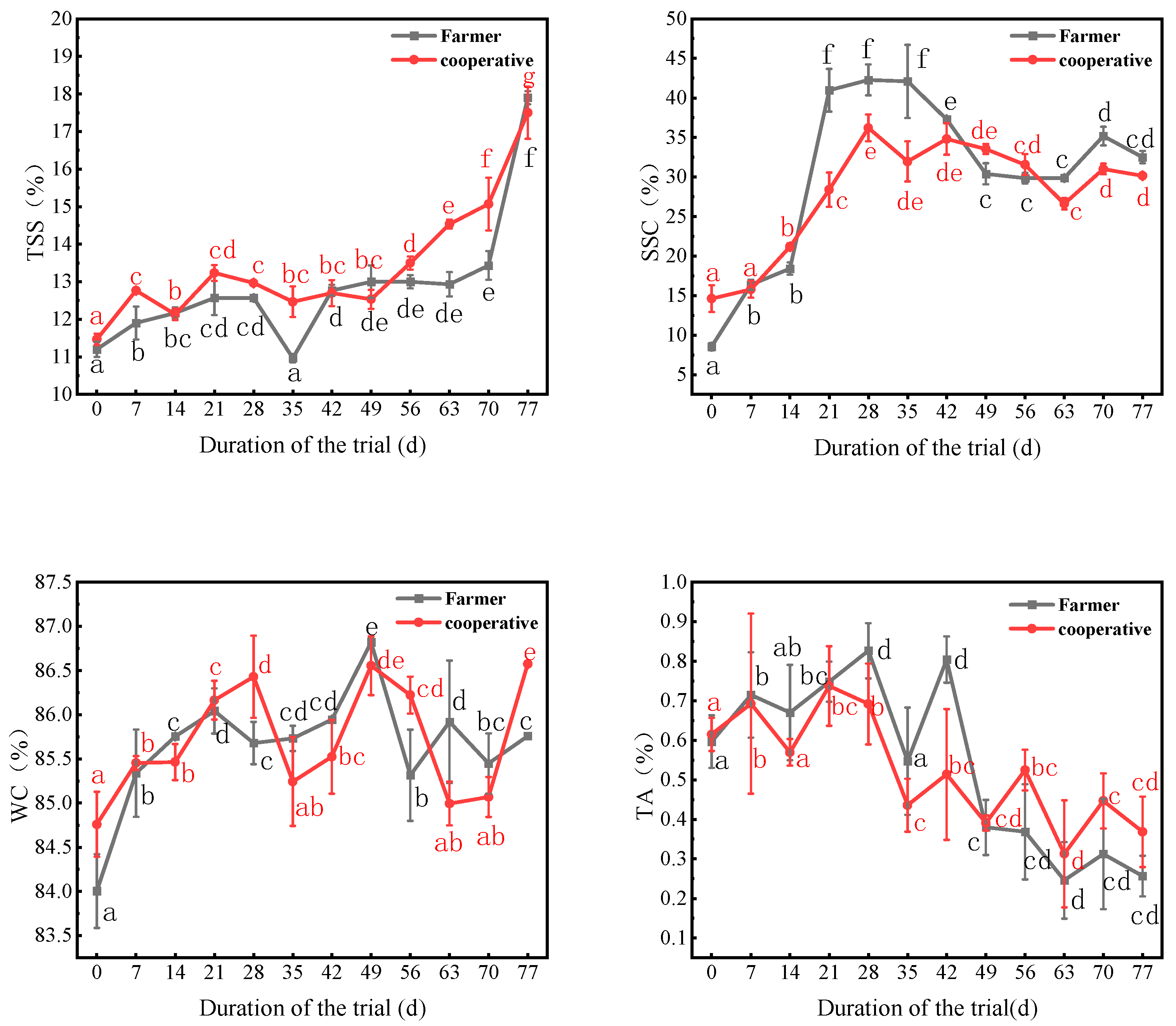

3.1. Changes in TSS, SSC, WC, TA, SCC, and TT During the Post-Ripening Variable-Temperature Frozen Period

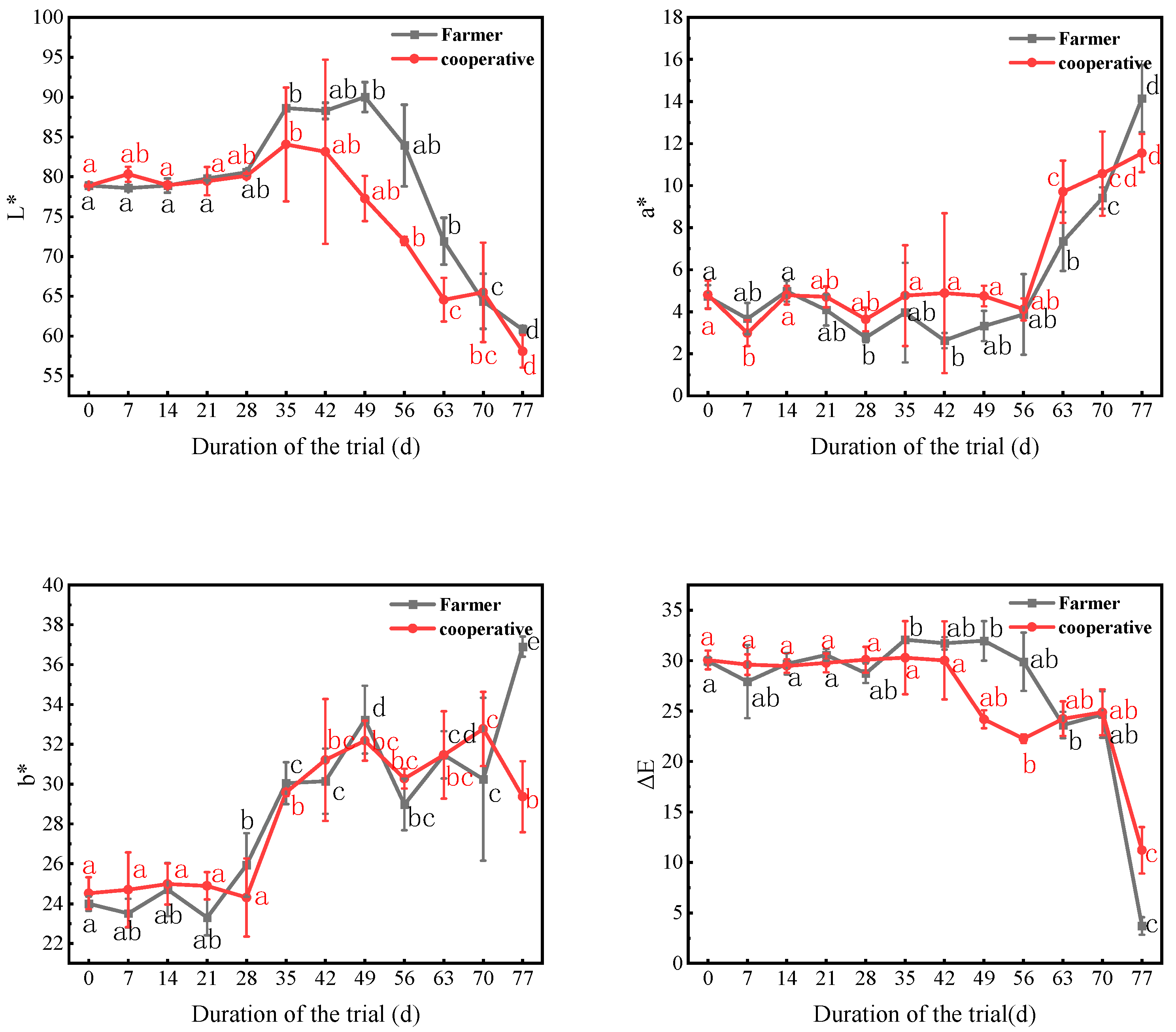

3.2. Changes in Peel Color of Ruaner Pear During Post-Ripening Variable Temperature Frozen Storage

3.3. Changes in Flesh Color of Ruaner Pear During Post-Ripening Variable Temperature Frozen Storage

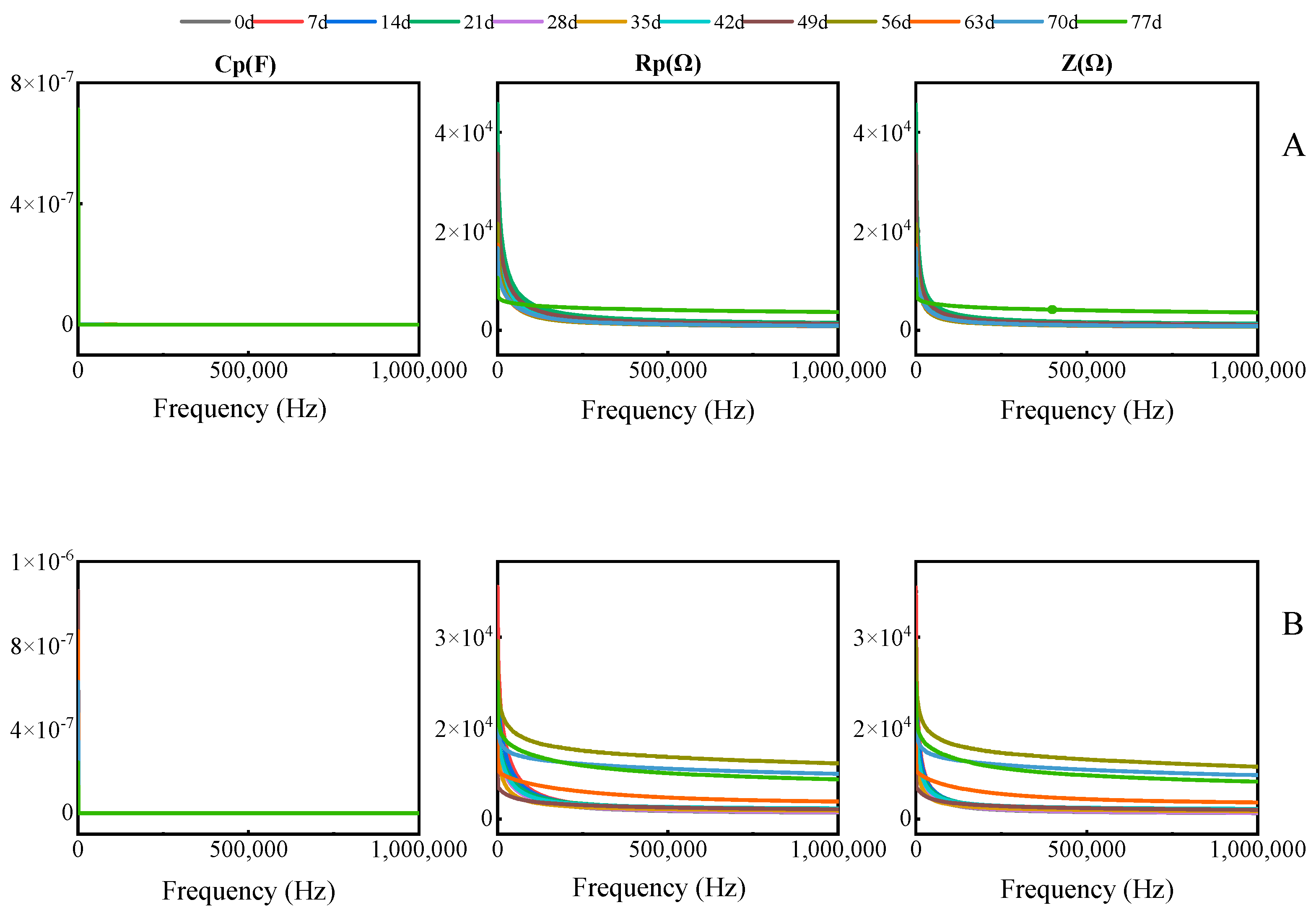

3.4. Changes in Cp, Rp, and Z Values of Ruaner Pear During Post-Ripening Variable-Temperature Frozen Storage

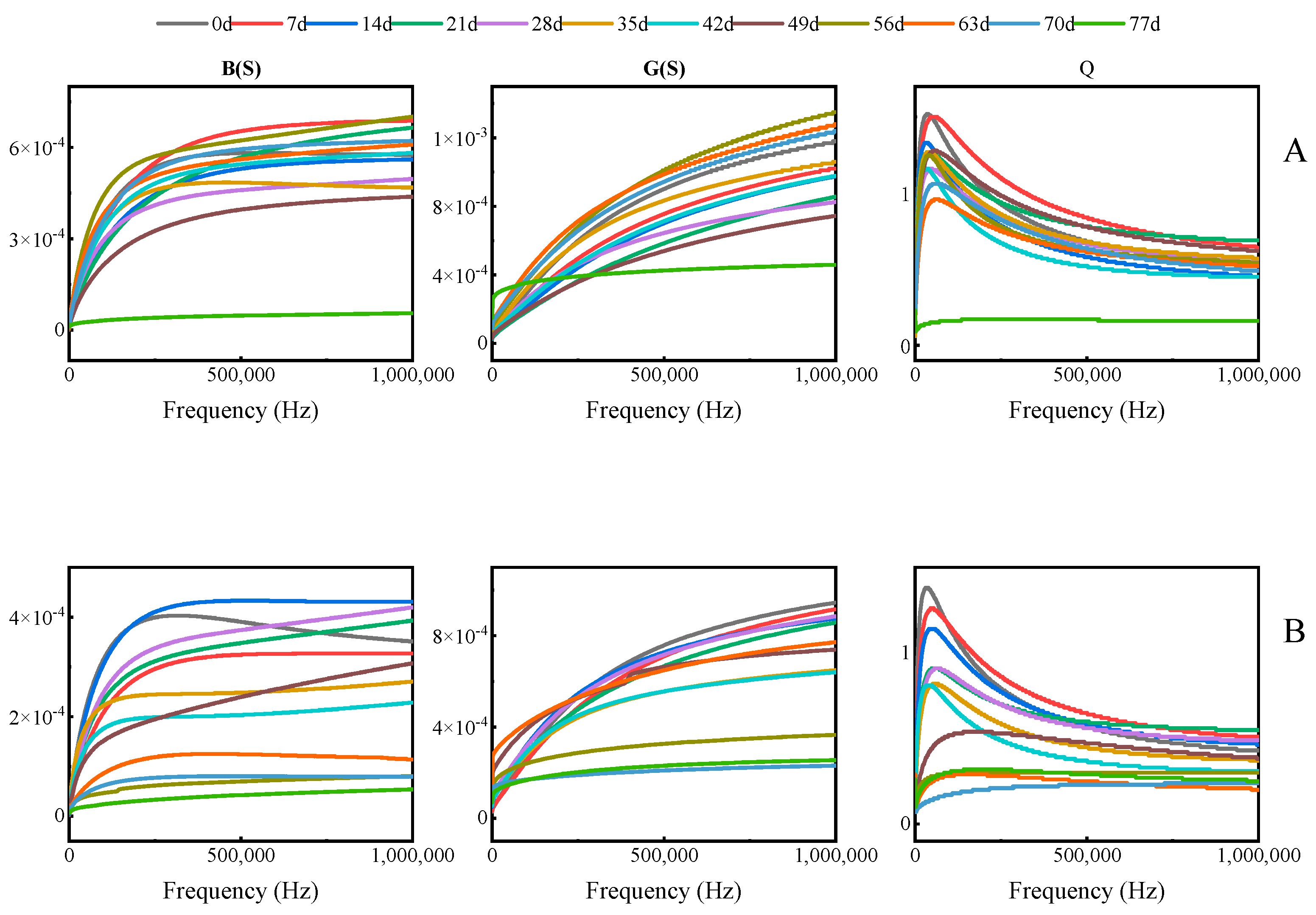

3.5. Changes in B, G, and Q Values of the Ruaner Pear During Post-Ripening Variable Temperature Frozen Storage

3.6. Changes in X and D Values of Ruaner Pear During Post-Ripening Variable Temperature Frozen Storage

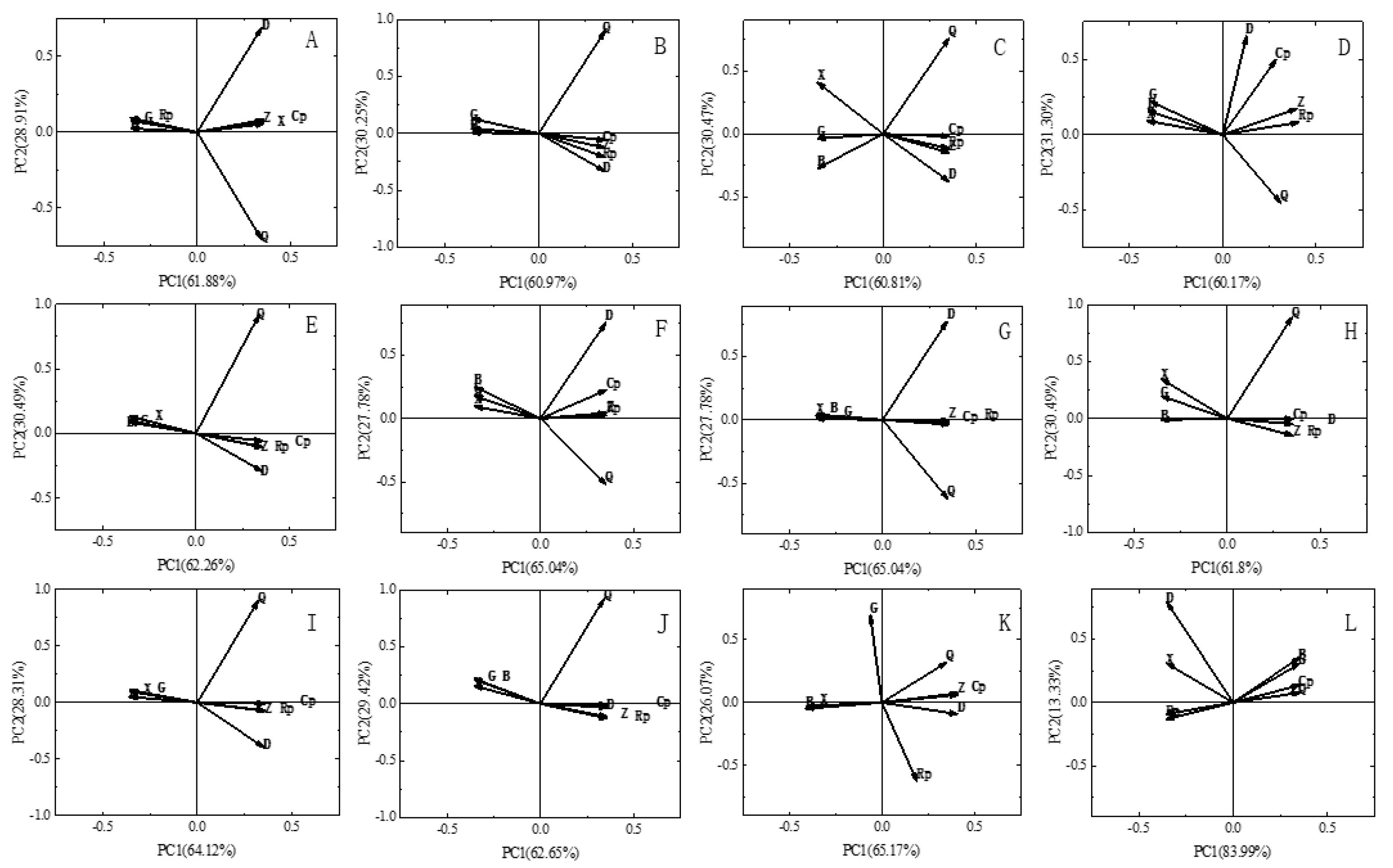

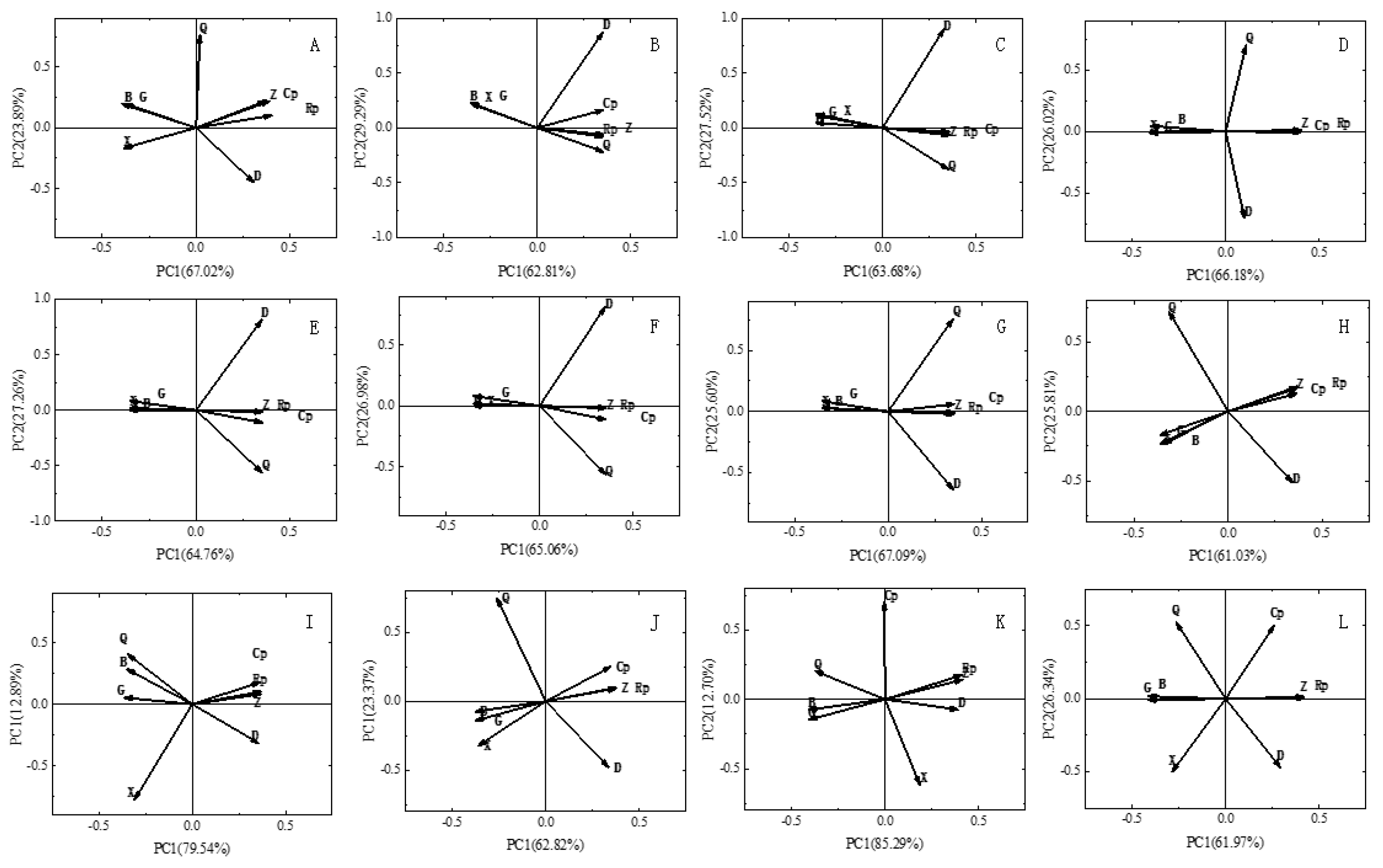

3.7. Selection of Principal Components for Dielectric Parameters

3.8. Selection of Characteristic Frequency Points for Dielectric Parameter Principal Components

3.9. Quality Attribute Prediction Models of Ruaner Pear

3.10. Validation of Quality Attribute Evaluation Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shyamali, G.; Dhillon, W. Fruit development studies in Asian soft pear. Indian J. Hortic. 2009, 66, 43–47. [Google Scholar]

- Bauchot, A.D.; Harker, F.R.; Arnold, W.M. The use of electrical impedance spectroscopy to assess the physiological condition of kiwifruit. J. Postharvest Biol. Technol. 2000, 18, 9–18. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Y.; Che, F.; Zhang, Z.; Chen, B. Physical-Chemical Composition and Quality Related Changes in “Ruaner” Pear (Pyrus ussuriensis) During Freezing-Thawing Period. Molecules 2019, 24, 2611. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.; Chaoling, M.; Ruojun, D.; Yang, B.; Yi, W.; Yongbo, W. Effect of Postharvest Ethephon Treatment on Physiological and Quality Attributes of Ripening Ruan’er Pear Fruits. Food Sci. 2017, 38, 252–258. [Google Scholar]

- Li, G.; Jia, H.; Li, J.; Li, H.; Teng, Y. Effects of 1-MCP on volatile production and transcription of ester biosynthesis related genes under cold storage in ‘Ruanerli’ pear fruit (Pyrus ussuriensis Maxim). Postharvest Biol. Technol. 2016, 111, 168–174. [Google Scholar] [CrossRef]

- Zhang, P.; Tian, R.; Hu, H.U.; Zhao, T.L.; Lei, J.; Wang, H.L. Effects of warming and precipitation changes on soil organic carbon and enzyme activities in semi-arid wheatland fields on the Loess Plateau of central Gansu Province, China. Ying Yong Sheng Tai Xue Bao = J. Appl. Ecol. 2024, 35, 3031–3042. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Qi, L.; Yang, F.; Han, M.; Yao, S. Subsurface irrigation with ceramic emitters: Optimal working water head improves yield, fruit quality and water productivity of greenhouse tomato. Sci. Hortic. 2023, 310, 111712. [Google Scholar] [CrossRef]

- Mitropoulos, D.; Lambrinos, G. “Delicious Pilafa” apple density changes as a quality index of mass loss degradation during storage. J. Food Qual. 2007, 30, 527–537. [Google Scholar] [CrossRef]

- Du, W.; Tian, S.; Zhao, J.; Deng, B. Drunken jujube: Ancient preservation unveils enhanced flavor and bioactives. LWT 2025, 233, 118507. [Google Scholar] [CrossRef]

- Bian, H.; Shi, P.; Tu, P. Determination of physicochemical quality of bruised apple using dielectric properties. J. Food Meas. Charact. 2020, 14, 2590–2599. [Google Scholar] [CrossRef]

- Bian, H.; Tu, P.; Li, X.; Shi, P. Quality predictions for bruised apples based on dielectric properties. J. Food Process. Preserv. 2019, 43, e14006. [Google Scholar] [CrossRef]

- Fazayeli, A.; Kamgar, S.; Nassiri, S.M.; Fazayeli, H.; de la Guardia, M. Dielectric spectroscopy as a potential technique for prediction of kiwifruit quality indices during storage. Inf. Process. Agric. 2019, 6, 479–486. [Google Scholar] [CrossRef]

- Li, M.; Hu, J.; Yang, M.; Yang, J.; Zhang, Q.; Zubarev, Y.A.; Zhao, W.; Bi, Y. Quality Attributes and Dielectric Properties of Sea Buckthorn Berries under Differing Freezing Regimes and Their Interrelationships. Foods 2022, 11, 3825. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Use of material dielectric properties in agricultural applications. J. Microw. Power Electromagn. Energy 2016, 50, 237–268. [Google Scholar] [CrossRef]

- Cao, M.; Zeng, S.; Wang, J.; Guo, W. Dielectric properties of peaches with and without skin during storage and their relationship to internal quality. Postharvest Biol. Technol. 2023, 204, 112433. [Google Scholar] [CrossRef]

- Kaur, K.; Dhillon, W.S. Influence of maturity and storage period on physical and biochemical characteristics of pear during post cold storage at ambient conditions. J. Food Sci. Technol. Mysore 2015, 52, 5352–5356. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, H.; Liang, Q.; Xia, Y.; Che, J.; Liu, Y. Non-Destructive Testing of the Internal Quality of Korla Fragrant Pears Based on Dielectric Properties. Horticulturae 2024, 10, 572. [Google Scholar] [CrossRef]

- Zheng, J.; Kallio, H.; Linderborg, K.; Yang, B. Sugars, sugar alcohols, fruit acids, and ascorbic acid in wild Chinese sea buckthorn (Hippophaë rhamnoides ssp. sinensis) with special reference to influence of latitude and altitude. Food Res. Int. 2011, 44, 2018–2026. [Google Scholar]

- Zhang, X.; Gao, Z.; Shu, X. Theory of Fruit Chroma Research and the Application on Fuji Apple. Tianjin Agric. Sci. 2005, 22–24. [Google Scholar]

- Cao, J.K.; Zhao, Y.M.; Jiang, W.B. Postharvest Physiological and Biochemical Experiment Technology of Fruits and Vegetables. In Experimental Guidance of Postharvest Physiology and Biochemistry Experiment of Fruits and Vegetables; China Light Industry Press: Beijing, China, 2007; pp. 24–54. [Google Scholar]

- Huang, X.; Li, W.; Wang, Y.; Wan, F. Drying characteristics and quality of Stevia rebaudiana leaves by far-infrared radiation. J. LWT 2021, 140, 110638. [Google Scholar] [CrossRef]

- Nie, J.; Li, J.; Yang, Z.; Zhang, H.; Li, M. Study on the conditions for measur ing stone cell content in pear flesh by freezing method. J. Fruit. Sci. 2006, 39, 133–135. [Google Scholar]

- Serrano-Pallicer, E.; Muñoz-Albero, M.; Pérez-Fuster, C.; Masot Peris, R.; Laguarda-Miró, N. Early detection of freeze damage in navelate oranges with electrochemical impedance spectroscopy. J. Sens. 2018, 18, 4503. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.; Ali, B.; Habib, M.; Frnda, J.; Ullah, I.; Anwar, M.S. An ensemble face recognition mechanism based on three-way decisions. J. King Saud. Univ. Comput. Inf. Sci. 2023, 35, 196–208. [Google Scholar] [CrossRef]

- Wen, J.; Mao, S.; Wu, C.; Xiao, X. The Grey Information Measurement in Grey Information Treated Space. J. Grey Syst. 2015, 27, 104–113. [Google Scholar]

- Fernandez-Novales, J.; Garde-Cerdan, T.; Tardaguila, J.; Gutierrez-Gamboa, G.; Pilar Perez-Alvarez, E.; Paz Diago, M. Assessment of amino acids and total soluble solids in intact grape berries using contactless Vis and NIR spectroscopy during ripening. Talanta 2019, 199, 244–253. [Google Scholar] [CrossRef]

- Jha, P.K.; Xanthakis, E.; Chevallier, S.; Jury, V.; Le-Bail, A. Assessment of freeze damage in fruits and vegetables. J. Food Res. Int. 2019, 121, 479–496. [Google Scholar] [CrossRef]

- Kami, D.; Muro, T.; Sugiyama, K. Changes in starch and soluble sugar concentrations in winter squash mesocarp during storage at different temperatures. Sci. Hortic. 2010, 127, 444–446. [Google Scholar] [CrossRef]

- Wang, K.; Xu, Z.; Liao, X. Bioactive compounds, health benefits and functional food products of sea buckthorn: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 6761–6782. [Google Scholar] [CrossRef]

- Dhillon, W.; Mahajan, B. Ethylene and ethephon induced fruit ripening in pear. J. Stored Prod. Postharvest Res. 2011, 2, 45–51. [Google Scholar]

- Jin, Q.; Yan, C.; Qiu, J.; Zhang, N.; Lin, Y.; Cai, Y. Structural characterization and deposition of stone cell lignin in Dangshan Su pear. Sci. Hortic. 2013, 155, 123–130. [Google Scholar] [CrossRef]

- Liang, Z. Review on Quality and Processing of Ruaner Pear Fruit. North. Hortic. 2018, 180–184. [Google Scholar]

- Guo, W.-C.; Nelson, S.O.; Trabelsi, S.; Kays, S.J. Dielectric properties of honeydew melons and correlation with quality. J. Microw. Power 2007, 41, 48–58. [Google Scholar] [CrossRef]

- Nelson, S.O.; Bartley, P. Measuring frequency-and temperature-dependent permittivities of food materials. IEEE Trans. Instrum. Meas. 2002, 51, 589–592. [Google Scholar] [CrossRef]

- Jha, S.N.; Narsaiah, K.; Basediya, A.L.; Sharma, R.; Jaiswal, P.; Kumar, R.; Bhardwaj, R. Measurement techniques and application of electrical properties for nondestructive quality evaluation of foods-a review. J. Food Sci. Technol. Mysore 2011, 48, 387–411. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S. Factors Influencing the Dielectric Properties of Agricultural and Food Products. J. Microw. Power Electromagn. Energy 2012, 46, 93–107. [Google Scholar] [CrossRef] [PubMed]

| Quality Attribute | PCA1 Maximum Relevance R2 | PCA1 Eigenfrequency (Hz) | PCA2 Maximum Relevance R2 | PCA2 Eigenfrequency (Hz) |

|---|---|---|---|---|

| WC | 0.791 | 849,770 | −0.623 | 132,830 |

| TSS | 0.953 | 872,180 | −0.956 | 155,230 |

| TA | −0.742 | 513,710 | 0.642 | 401,680 |

| SSC | 0.637 | 894,580 | 0.511 | 356,880 |

| SCC | 0.550 | 782,560 | −0.550 | 132,830 |

| Quality Attribute | PCA1 Maximum Relevance R2 | PCA1 Eigenfrequency (Hz) | PCA2 Maximum Relevance R2 | PCA2 Eigenfrequency (Hz) |

|---|---|---|---|---|

| WC | 0.813 | 872,180 | −0.757 | 424,090 |

| TSS | 0.923 | 782,560 | −0.944 | 558,520 |

| TA | 0.595 | 760,160 | 0.704 | 648,130 |

| SSC | −0.648 | 916,990 | −0.635 | 334,470 |

| SCC | 0.508 | 894,580 | −0.570 | 132,830 |

| Quality Attribute | Evaluation Model | Coefficient of Determination R2 |

|---|---|---|

| WC | y = 84.33123 + 0.34892x1 + 3.41158x2 | 0.633 |

| TSS | y = 17.57086 + 2.76228x1 + 16.3003x2 | 0.628 |

| TA | y = 0.59776 − 0.50784x1 + 1.10645x2 | 0.649 |

| SSC | y = 117.20713 − 98.3175x1 − 253.57965x2 | 0.833 |

| SCC | y = 28.94763 + 0.35066x1 − 24.71632x2 | 0.581 |

| Quality Attribute | Evaluation Model | Coefficient of Determination R2 |

|---|---|---|

| WC | y = 76.62068 + 10.39529x1 + 2.02451x2 | 0.785 |

| TSS | y = 16.59898 − 2.09523x1 − 5.88408x2 | 0.535 |

| TA | y = −0.04275 − 0.53353x1 + 0.63141x2 | 0.625 |

| SSC | y = −258.4419 + 292.3474x1 + 69.85337x2 | 0.671 |

| SCC | y = 5.73439 − 1.20767x1 − 0.96853x2 | 0.795 |

| Quality Attribute | Farmers | Cooperative | ||

|---|---|---|---|---|

| Measured Values | Predicted Value | Measured Values | Predicted Value | |

| WC | 85.76 ± 0.13 | 85.06 | 86.58 ± 0.01 | 86.67 |

| TSS | 17.90 ± 0.17 | 17.63 | 17.50 ± 0.69 | 16.15 |

| TA | 0.26 ± 0.05 | 0.35 | 0.37 ± 0.09 | 0.40 |

| SSC | 32.51 ± 0.78 | 31.11 | 30.14 ± 0.32 | 40.78 |

| SCC | 4.21 ± 0.13 | 5.24 | 3.99 ± 0.11 | 4.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Yan, H.; Qiao, W.; Hu, J.; Guo, Y.; Zhang, F.; Zhang, Z.; Zhang, P. Prediction of Quality Attributes of the Ruaner Pear Using Dielectric Properties During Post-Ripening Variable Temperature Frozen Storage. Agriculture 2025, 15, 2254. https://doi.org/10.3390/agriculture15212254

Yang M, Yan H, Qiao W, Hu J, Guo Y, Zhang F, Zhang Z, Zhang P. Prediction of Quality Attributes of the Ruaner Pear Using Dielectric Properties During Post-Ripening Variable Temperature Frozen Storage. Agriculture. 2025; 15(21):2254. https://doi.org/10.3390/agriculture15212254

Chicago/Turabian StyleYang, Mei, Huili Yan, Weihao Qiao, Jingming Hu, Yeming Guo, Fang Zhang, Zhong Zhang, and Peiyu Zhang. 2025. "Prediction of Quality Attributes of the Ruaner Pear Using Dielectric Properties During Post-Ripening Variable Temperature Frozen Storage" Agriculture 15, no. 21: 2254. https://doi.org/10.3390/agriculture15212254

APA StyleYang, M., Yan, H., Qiao, W., Hu, J., Guo, Y., Zhang, F., Zhang, Z., & Zhang, P. (2025). Prediction of Quality Attributes of the Ruaner Pear Using Dielectric Properties During Post-Ripening Variable Temperature Frozen Storage. Agriculture, 15(21), 2254. https://doi.org/10.3390/agriculture15212254