Precision Feeding Systems in Animal Husbandry: Guiding Rabbit Farming from Concept to Implementation

Abstract

1. Introduction

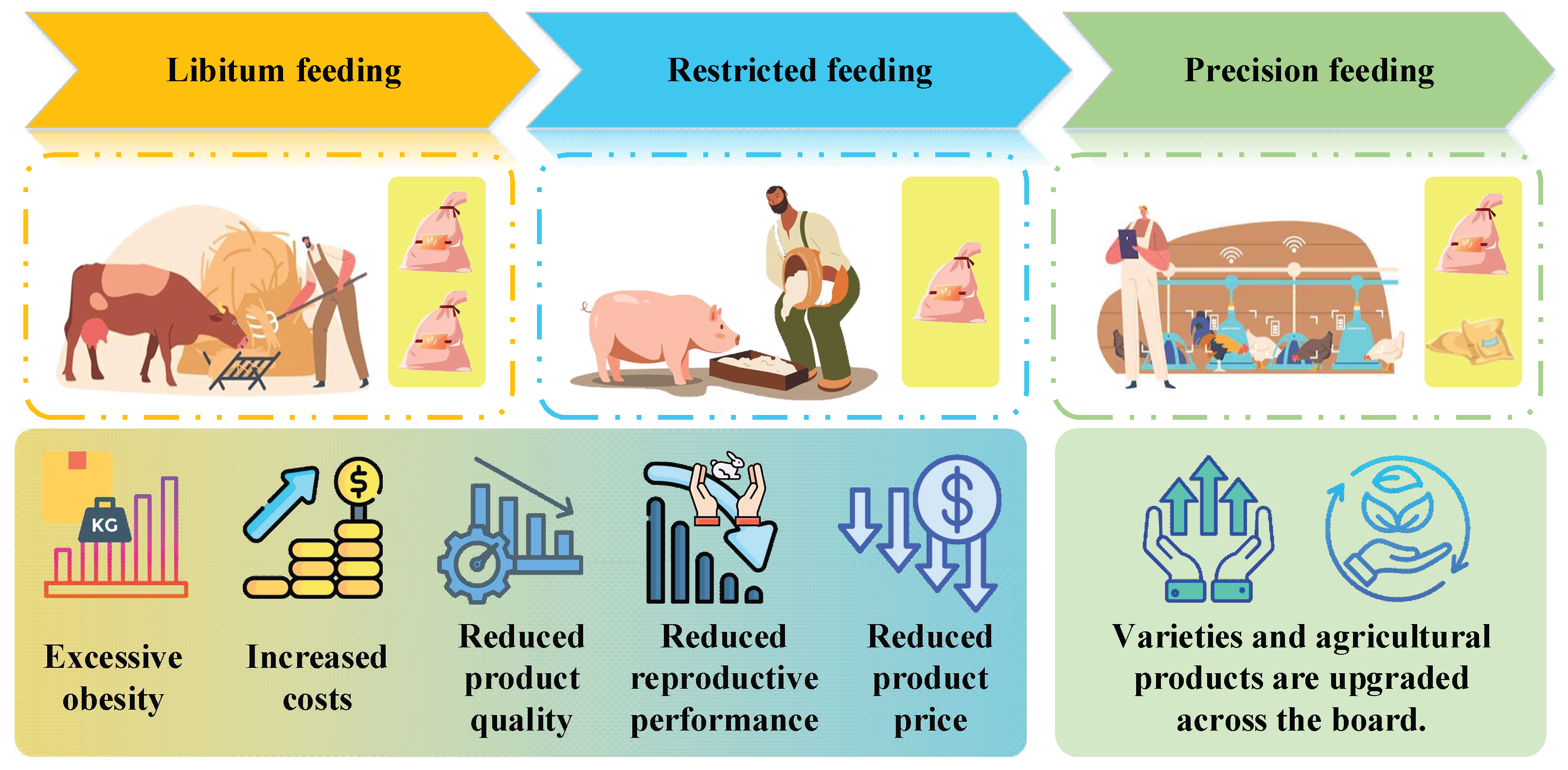

2. Precision Feeding Under Precision Livestock Farming

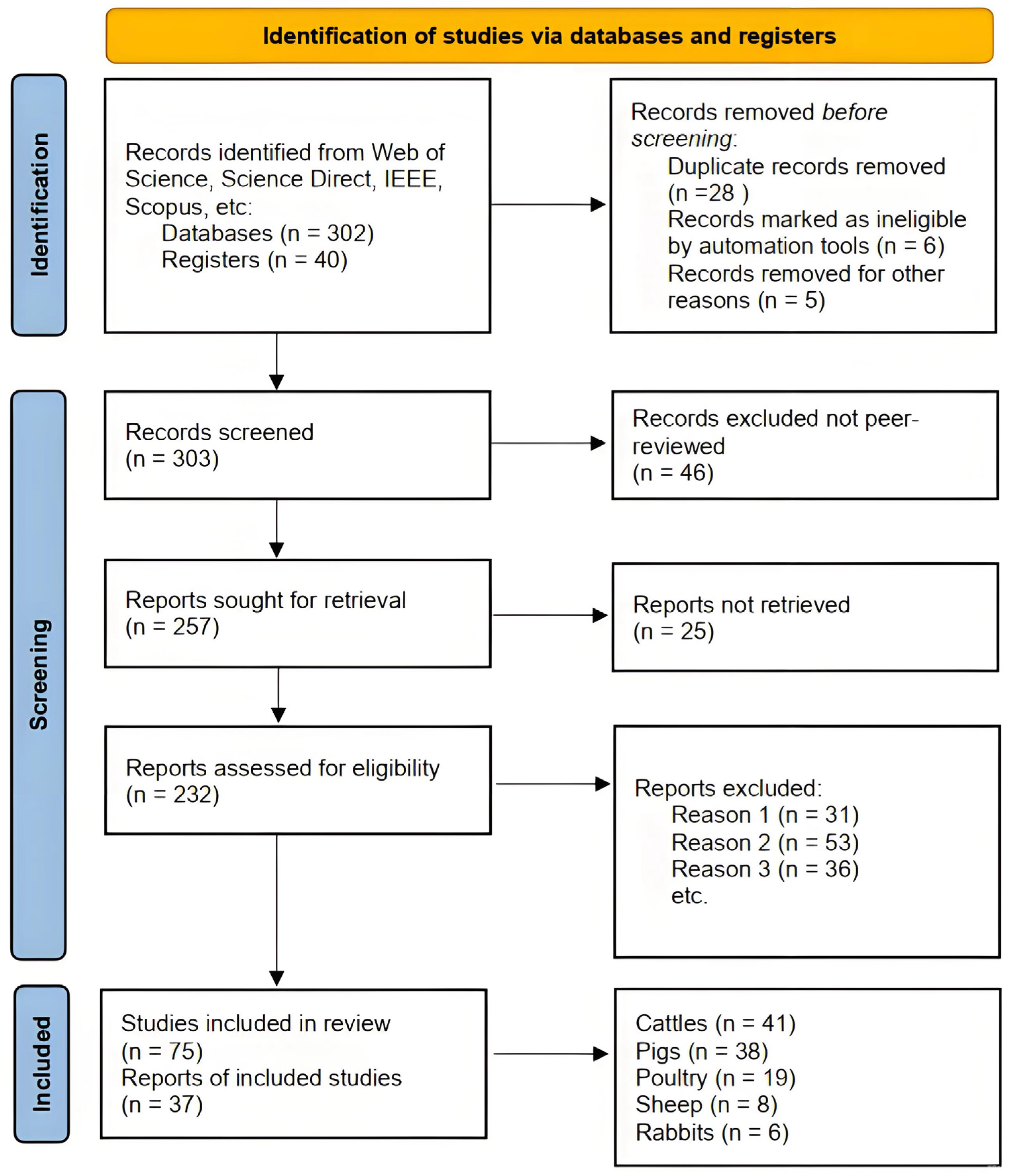

3. Research Methodology

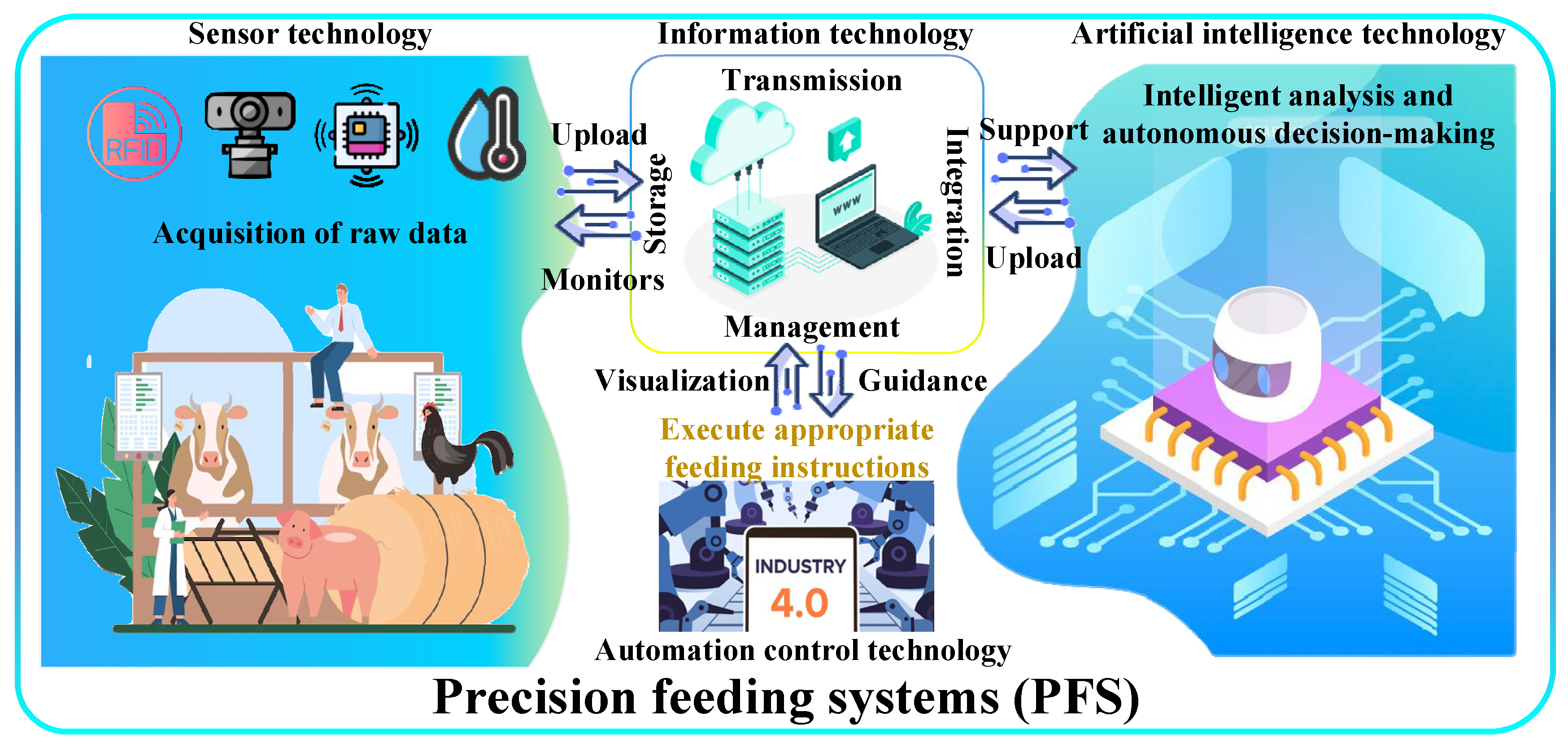

4. General Technologies in Precision Feeding Systems

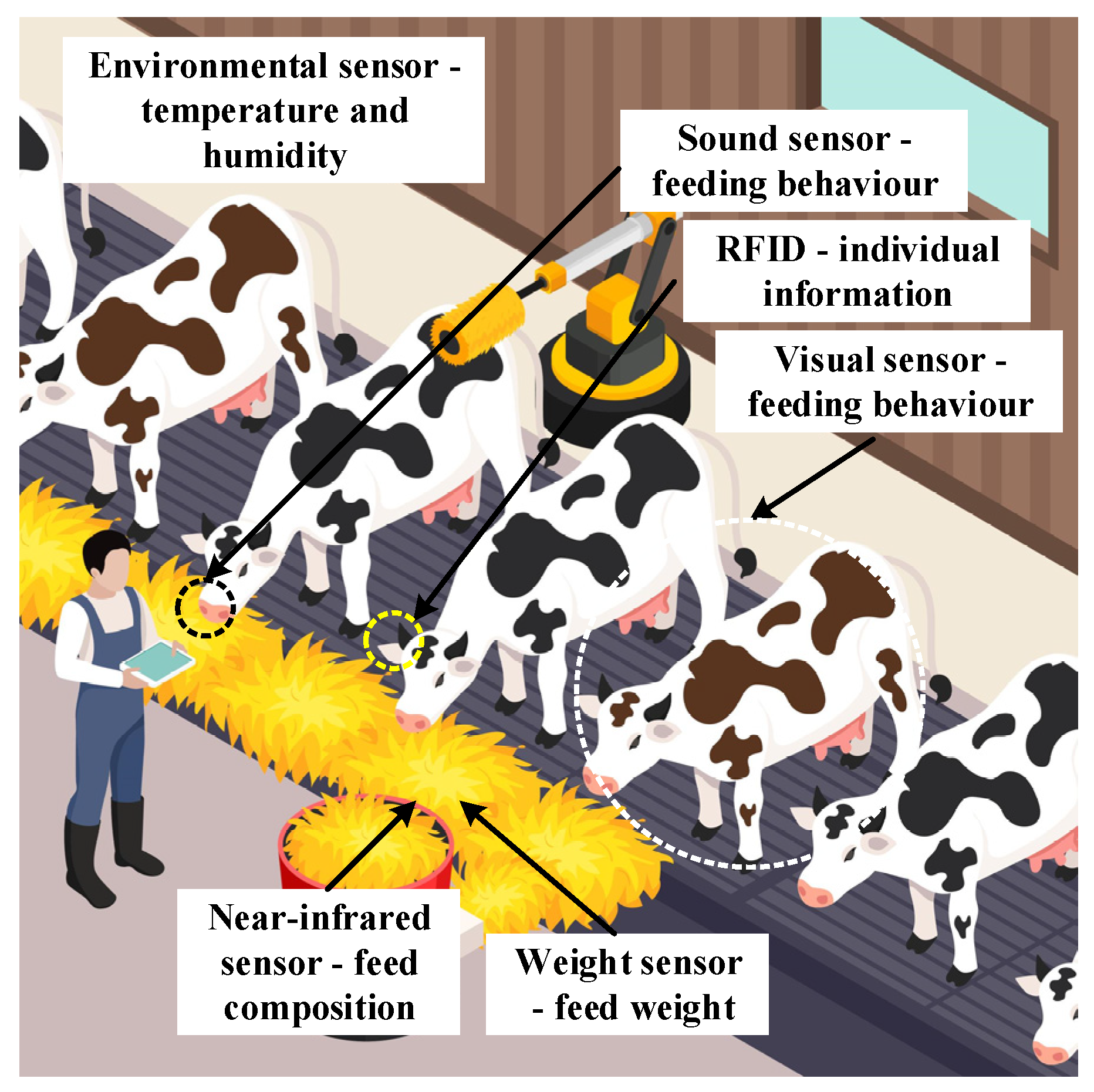

4.1. Sensor Technology

4.1.1. Sensor Technology for Non-Living Things

4.1.2. Sensor Technology for Livestock and Poultry

4.2. Information Technology

4.3. Artificial Intelligence Technology

4.4. Automated Control Technology

5. Commercial Precision Feeding Systems

6. Precision Feeding Systems in Rabbit Farming from Concept to Implementation

6.1. The Necessity of Precision Feeding in Rabbit Farming

6.2. Current Status of Precision Feeding Systems in Rabbit Farming

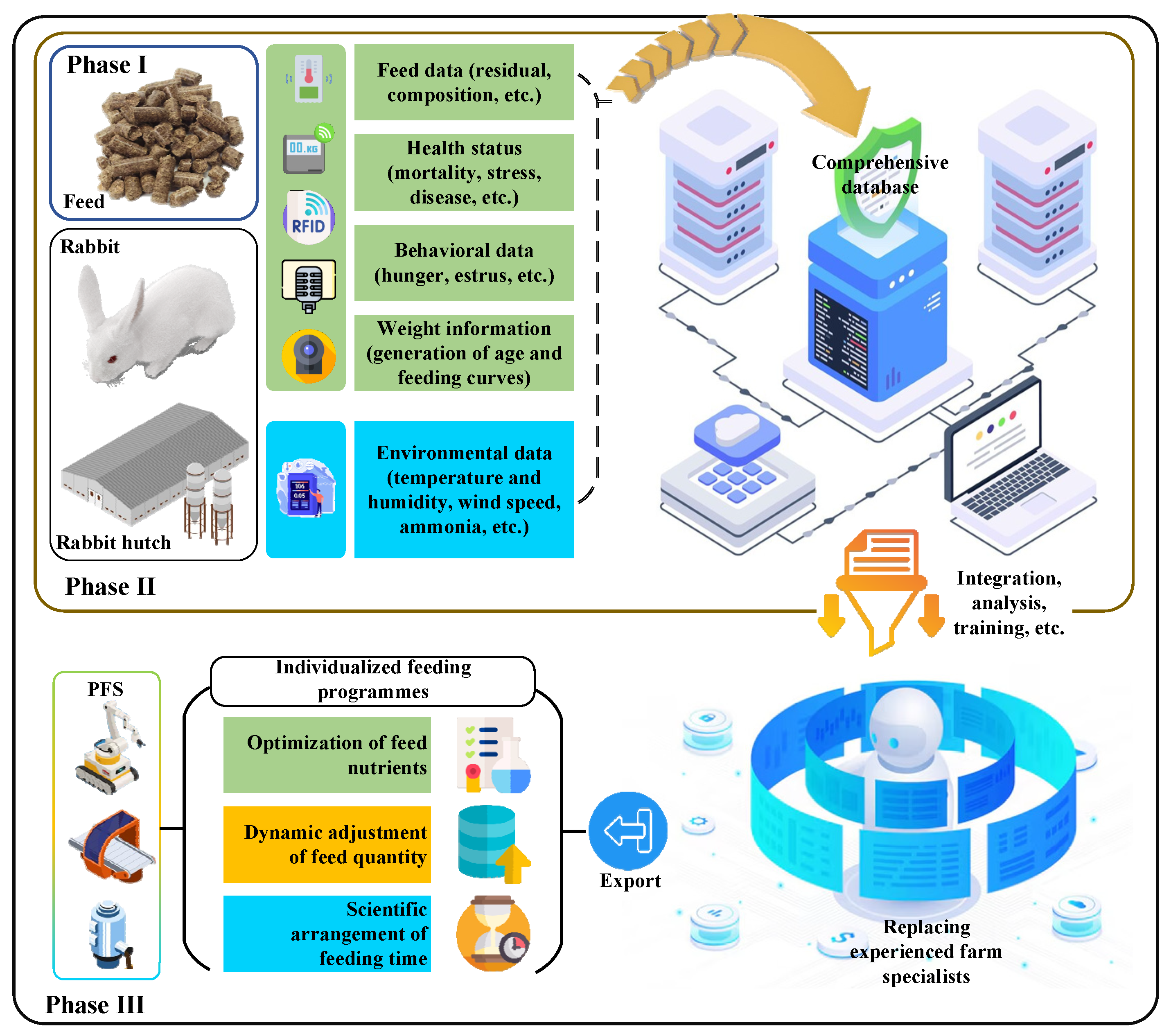

6.3. Precise Feeding Implementation Framework for Three Stages of Rabbit Farming

6.4. Feasibility Analysis of a Three-Stage Implementation Framework

6.5. Challenges Facing the Rabbit Farming Industry and Future Development Directions

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khaleel, S.; Osaili, T.; Abdelrahim, D.; Zeb, F.; Naja, F.; Radwan, H.; Faris, M.; Hasan, H.; Ismail, L.; Obaid, R.; et al. Attachment to Meat and Willingness Towards Cultured Alternatives Among Consumers: A Cross-Sectional Study in the UAE. Nutrients 2024, 17, 28. [Google Scholar] [CrossRef] [PubMed]

- Kweon, J.; Lee, H.; Kim, S.; Song, G. Environmental antibiotic emissions and their residual impact on livestock farming. Mol. Cell. Toxicol. 2025, 21, 351–362. [Google Scholar] [CrossRef]

- Kleyn, R.; Ciacciariello, M. Putting sustainable poultry production into perspective. Worlds Poult. Sci. J. 2025, 81, 343–357. [Google Scholar] [CrossRef]

- Pomar, C.; Remus, A. Review: Fundamentals, limitations and pitfalls on the development and application of precision nutrition techniques for precision livestock farming. Animal 2023, 17, 100763. [Google Scholar] [CrossRef]

- Rojo-Gimeno, C.; van der Voort, M.; Niemi, J.; Lauwers, L.; Kristensen, A.; Wauters, E. Assessment of the value of information of precision livestock farming: A conceptual framework. NJAS-Wagening. J. Life Sci. 2019, 90–91, 100311. [Google Scholar] [CrossRef]

- Pomar, C.; Hauschild, L.; Zhang, G.; Pomar, J.; Lovatto, P. Precision feeding can significantly reduce feeding cost and nutrient excretion in growing animals. In Modelling Nutrient Digestion and Utilization in Farm Animals; Brill: Leiden, The Netherlands, 2010; pp. 327–334. [Google Scholar]

- Akinyemi, B.E.; Vigors, B.; Turner, S.P.; Akaichi, F.; Benjamin, M.; Johnson, A.K.; Pairis-Garcia, M.D.; Rozeboom, D.W.; Steibel, J.P.; Thompson, D.P.; et al. Precision livestock farming: A qualitative exploration of swine industry stakeholders. Front. Anim. Sci. 2023, 4, 1150528. [Google Scholar] [CrossRef]

- Remus, A.; Pomar, C. Fundamentals, limitations and pitfalls on the development and application of sustainable pig precision nutrition. In Proceedings of the 21st Annual Midwest Swine Nutrition Conference Proceedings, Danville, IN, USA, 8 September 2022; pp. 25–33. [Google Scholar]

- Terré, M.; Morey, L.; Sabrià, D.; Bach, A. Effectiveness of precision feeding in reducing N excretion in dairy cattle. J. Dairy Sci. 2020, 103, 203. [Google Scholar]

- Jiang, B.; Tang, W.; Cui, L.; Deng, X. Precision Livestock Farming Research: A Global Scientometric Review. Animals 2023, 13, 2096. [Google Scholar] [CrossRef]

- Banhazi, T.; Banhazi, A.; Tikasz, I.E.; Palotay, S.; Mallimger, K.; Neubauer, T.; Corpaci, L.; Marchaim, U.; Kopler, I.; Opalinski, S.; et al. Facilitating PLF technology adoption in the pig and poultry industries. Stud. Agric. Econ. 2024, 126, 43–49. [Google Scholar] [CrossRef]

- Bailey, D.; Trotter, M.; Tobin, C.; Thomas, M. Opportunities to Apply Precision Livestock Management on Rangelands. Front. Sustain. Food Syst. 2021, 5, 611915. [Google Scholar] [CrossRef]

- Ebeid, T.; Al-Homidan, I.; Saleh, A.; Barakat, H. Physiological and immunological aspects of feed restriction and its beneficial impacts in fattening rabbits’ productivity-an updated review. Trop. Anim. Health Prod. 2024, 56, 33. [Google Scholar] [CrossRef]

- Madkour, M.; Aboelenin, M.; Shakweer, W.; Alfarraj, S.; Alharbi, S.; Abdel-Fattah, S.; Alagawany, M. Early life thermal stress modulates hepatic expression of thermotolerance related genes and physiological responses in two rabbit breeds. Ital. J. Anim. Sci. 2021, 20, 736–748. [Google Scholar] [CrossRef]

- Chelotti, J.; Martinez-Rau, L.; Ferrero, M.; Vignolo, L.; Galli, J.; Planisich, A.; Rufiner, L.; Giovanini, L. Livestock feeding behaviour: A review on automated systems for ruminant monitoring. Biosyst. Eng. 2024, 246, 150–177. [Google Scholar] [CrossRef]

- Mcloughlin, M.; Stewart, R.; McElligott, A. Automated bioacoustics: Methods in ecology and conservation and their potential for animal welfare monitoring. J. R. Soc. Interface 2019, 16, 20190225. [Google Scholar] [CrossRef] [PubMed]

- Neethirajan, S. Affective State Recognition in Livestock-Artificial Intelligence Approaches. Animals 2022, 12, 759. [Google Scholar] [CrossRef] [PubMed]

- Prates, J. Heat Stress Effects on Animal Health and Performance in Monogastric Livestock: Physiological Responses, Molecular Mechanisms, and Management Interventions. Vet. Sci. 2025, 12, 429. [Google Scholar] [CrossRef]

- Ojo, R.; Ajayi, A.; Owolabi, H.; Oyedele, L.; Akanbi, L. Internet of Things and Machine Learning techniques in poultry health and welfare management: A literature literature review. Comput. Electron. Agric. 2022, 200, 107266. [Google Scholar] [CrossRef]

- Garrido, L.; Sato, S.; Costa, L.; Daros, R. Can We Reliably Detect Respiratory Diseases through Precision Farming? A Systematic Review. Animals 2023, 13, 1273. [Google Scholar] [CrossRef]

- Cai, Z.J.; Cui, J.L.; Yuan, H.B.; Cheng, M. Application and research progress of infrared thermography in temperature measurement of livestock and poultry animals: A review. Comput. Electron. Agric. 2023, 205, 107586. [Google Scholar] [CrossRef]

- Suminda, G.; Bhandari, S.; Won, Y.; Goutam, U.; Pulicherla, K.; Son, Y.; Ghosh, M. High-throughput sequencing technologies in the detection of livestock pathogens, diagnosis, and zoonotic surveillance. Comput. Struct. Biotechnol. J. 2022, 20, 5378–5392. [Google Scholar] [CrossRef]

- Umurungi, S.; Ufitikirezi, J.; Zoubek, T.; Bumbálek, R.; Kunes, R.; Sramhauser, K.; Stehlík, R.; Havelka, Z.; Olsan, P.; Bartos, P. Leveraging the potential of convolutional neural networks in poultry farming: A 5-year overview. Worlds Poult. Sci. J. 2025, 81, 3–34. [Google Scholar] [CrossRef]

- Brown-Brandl, T.; Adrion, F.; Maselyne, J.; Kapun, A.; Hessel, E.; Saeys, W.; Van Nuffel, A.; Gallmann, E. A Review of Passive Radio Frequency Identification Systems for Animal Monitoring in Livestock Facilities. Appl. Eng. Agric. 2019, 35, 579–591. [Google Scholar] [CrossRef]

- Golinski, P.; Sobolewska, P.; Stefanska, B.; Golinska, B. Virtual Fencing Technology for Cattle Management in the Pasture Feeding System–A Review. Agriculture 2023, 13, 91. [Google Scholar] [CrossRef]

- Chapa, J.; Maschat, K.; Iwersen, M.; Baumgartner, J.; Drillich, M. Accelerometer systems as tools for health and welfare assessment in cattle and pigs—A review. Behav. Process. 2020, 181, 104262. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Zhu, W.X.; Norton, T. Behaviour recognition of pigs and cattle: Journey from computer vision to deep learning. Comput. Electron. Agric. 2021, 187, 106255. [Google Scholar] [CrossRef]

- Glencorse, D.; Grupen, C.; Bathgate, R. A Review of the Monitoring Techniques Used to Detect Oestrus in Sows. Animals 2025, 15, 331. [Google Scholar] [CrossRef]

- Yang, D.; Cui, D.; Ying, Y. Development and trends of chicken farming robots in chicken farming tasks: A review. Comput. Electron. Agric. 2024, 221, 108916. [Google Scholar] [CrossRef]

- Wu, D.; Cui, D.; Zhou, M.; Ying, Y. Information perception in modern poultry farming: A review. Comput. Electron. Agric. 2022, 199, 107131. [Google Scholar] [CrossRef]

- Das, S.; Shaji, A.; Nain, D.; Singha, S.; Karunakaran, M.; Baithalu, R. Precision technologies for the management of reproduction in dairy cows. Trop. Anim. Health Prod. 2023, 55, 286. [Google Scholar] [CrossRef]

- Özentürk, U.; Chen, Z.; Jamone, L.; Versace, E. Robotics for poultry farming: Challenges and opportunities. Comput. Electron. Agric. 2024, 226, 109411. [Google Scholar] [CrossRef]

- Ellis, J.L.; Jacobs, M.; Dijkstra, J.; van Laar, H.; Cant, J.P.; Tulpan, D.; Ferguson, N. Review: Synergy between mechanistic modelling and data-driven models for modern animal production systems in the era of big data. Animal 2020, 14, S223–S237. [Google Scholar] [CrossRef]

- Tadele, E.; Worku, D.; Yigzaw, D.; Muluneh, T.; Melese, A. Precision of dairy farming: Navigating challenges and seizing opportunities for sustainable dairy production in Africa. Front. Anim. Sci. 2025, 6, 1541838. [Google Scholar] [CrossRef]

- Leddin, C.; Morse-McNabb, E.; Smith, K.; Ho, C.; Jacobs, J. How can improv. farmer decis. farm syst. impacts resulting use digit. forage meas. technol. dairy farms be valued? Agric. Syst. 2023, 212, 103755. [Google Scholar] [CrossRef]

- Fels, M.; Benato, L.; Whittaker, A. Editorial: Health and welfare of rabbits (on a farm, in the laboratory or as a pet). Front. Vet. Sci. 2024, 11, 1522420. [Google Scholar] [CrossRef]

- Russkii, V.G.; Platonovskii, N.G. Economic efficiency of an industrial rabbit farm for small-size farming (project development). Ekon. Sel’skokhozyaĭstvennykh Pererabat. Predpriyatiĭ 2017, 37–42. Available online: https://www.cabidigitallibrary.org/doi/full/10.5555/20173254581 (accessed on 25 September 2025).

- Lamanna, M.; Bovo, M.; Cavallini, D. Wearable Collar Technologies for Dairy Cows: A Systematized Review of the Current Applications and Future Innovations in Precision Livestock Farming. Animals 2025, 15, 458. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Liu, K.; Cuan, K.; Hua, Z.; Li, K.; Wang, K. Non-invasive monitoring for precision sheep farming: Development, challenges, and future perspectives. Comput. Electron. Agric. 2025, 231, 110050. [Google Scholar] [CrossRef]

- Su, J.; Tan, B.; Jiang, Z.; Wu, D.; Nyachoti, C.; Kim, S.; Yin, Y.; Wang, J. Accelerating precision feeding with the internet of things for livestock: From concept to implementation. Sci. Bull. 2024, 69, 2156–2160. [Google Scholar] [CrossRef]

- Oliveira, D.; Pereira, L.; Bresolin, T.; Ferreira, R.; Dorea, J. A review of deep learning algorithms for computer vision systems in livestock. Livest. Sci. 2021, 253, 104700. [Google Scholar] [CrossRef]

- Gorr, S.; Leeb, C.; Zollitsch, W.; Winckler, C.; Parsons, T. Ad libitum feeding systems for lactating sows: Effects on productivity and welfare of sows and piglets. Animal 2024, 18, 101093. [Google Scholar] [CrossRef]

- Ebeid, T.; Tumova, E.; Al-Homidan, I.; Ketta, M.; Chodov, D. The potential role of feed restriction on productivity, carcass composition, meat quality, and muscle fibre properties of growing rabbits: A review. Meat Sci. 2022, 191, 108845. [Google Scholar] [CrossRef]

- Ait-Sidhoum, A.; Guesmi, B.; Cabas-Monje, J.; Gil, J. The impact of alternative feeding strategies on total factor productivity growth of pig farming: Empirical evidence from EU countries. Span. J. Agric. Res. 2021, 19, e0106. [Google Scholar] [CrossRef]

- Pizolotto, W.; Costa, M.M.; Gasperin, N.Z.; Rodrigues, L.B.; dos Santos, L.R.; Pilotto, F. Economic and productive performance of broilers subjected to quantitative feed restriction. Acta Vet. Bras. 2024, 18, 173–178. [Google Scholar] [CrossRef]

- Anane, I.O.; Adomako, K.; Hamidu, J.A.; Olympio, O.S. Effects of feed restriction and early age thermal conditioning on growth performance and carcass characteristics of meat-type chickens. Ghana J. Agric. Sci. 2022, 57, 50–61. [Google Scholar]

- Terre, M.; Prat, N.; Sabria, D. Precision Feed in Dairy Cattle. In Proceedings of the XX Jornadas Sobre Producción Animal, Zaragoza, Spain, 13–14 June 2023; p. 275. [Google Scholar]

- Koley, S.; Singh, S.; Ojha, B.K.; Kurechiya, N.; Singh, A. Precision feeding in pig production: A review. Indian J. Anim. Health 2023, 62, 21–34. [Google Scholar] [CrossRef]

- Chen, C.; Liu, X.; Liu, C.; Pan, Q. Development of the precision feeding system for sows via a rule-based expert system. Int. J. Agric. Biol. Eng. 2023, 16, 187–198. [Google Scholar] [CrossRef]

- Kamau, K.; Thorpe, B.; Meier, K.; Endres, M.; Salfer, I. Effects of automated feeding systems on milk components and ration consistency. J. Dairy Sci. 2022, 105, 27. [Google Scholar]

- Paul, J.; Lim, W.; O’Cass, A.; Hao, A.; Bresciani, S. Scientific procedures and rationales for systematic literature reviews (SPAR-4-SLR). Int. J. Consum. Stud. 2021, 45, O1–O16. [Google Scholar] [CrossRef]

- Xiao, Y.; Watson, M. Guidance on Conducting a Systematic Literature Review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Oleinik, S.; Skripkin, V.; Lesnyak, T.; Litvin, D. Application of remote monitoring and ground-based sensing in pastoralism. BIO Web Conf. 2023, 66, 09007. [Google Scholar] [CrossRef]

- Kleen, J.; Guatteo, R. Precision Livestock Farming: What Does It Contain and What Are the Perspectives? Animals 2023, 13, 779. [Google Scholar] [CrossRef]

- Stygar, A.; Gómez, Y.; Berteselli, G.; Dalla Costa, E.; Canali, E.; Niemi, J.; Llonch, P.; Pastell, M. A Systematic Review on Commercially Available and Validated Sensor Technologies for Welfare Assessment of Dairy Cattle. Front. Vet. Sci. 2021, 8, 634338. [Google Scholar] [CrossRef] [PubMed]

- Kaur, U.; Malacco, V.; Bai, H.; Price, T.; Datta, A.; Xin, L.; Sen, S.; Nawrocki, R.; Chiu, G.; Sundaram, S.; et al. Invited review: Integration of technologies and systems for precision animal agriculture-a case study on precision dairy farming. J. Anim. Sci. 2023, 101, skad206. [Google Scholar] [CrossRef] [PubMed]

- Neethirajan, S.; Kemp, B. Digital livestock farming. Sens. Bio-Sens. Res. 2021, 32, 100408. [Google Scholar] [CrossRef]

- Peng, Y.; Zeng, Z.; Lv, E.; He, X.; Zeng, B.; Wu, F.; Guo, J.; Li, Z. A Real-Time Automated System for Monitoring Individual Feed Intake and Body Weight of Group-Housed Young Chickens. Appl. Sci. 2022, 12, 12339. [Google Scholar] [CrossRef]

- Moffet, C.; Gunter, S.; Beck, P.; Vining, P. Evaluation of an in-pasture weighing system to measure body weight change of growing cattle grazing wheat pasture. J. Anim. Sci. 2024, 102, 615–616. [Google Scholar] [CrossRef]

- Blagov, D.A.; Mitrofanov, S.V.; Panfyorov, N.S.; Mel’nichuk, D.S. Technical features of feed mixers for the preparation of a fully mixed diet. Agrar. Nauchnyy Zhurnal 2021, 12, 107–111. [Google Scholar] [CrossRef]

- Rasmussen, D.; Weber, R.; Wechsler, B. Effects of animal/feeding-place ratio on the behaviour and performance of fattening pigs fed via sensor-controlled liquid feeding. Appl. Anim. Behav. Sci. 2006, 98, 45–53. [Google Scholar] [CrossRef]

- Bolaño, B.; Casuco, L.; Fesariton, J.; Romasanta, J. chickIT: A Smart Poultry Feeding System through the Internet of Things. In Proceedings of the 14th Symposium on Computer Applications & Industrial Electronics (ISCAIE), Penang, Malaysia, 24–25 May 2024; IEEE: New York, NY, USA, 2024; pp. 531–534. [Google Scholar]

- Mosquera, I.; Fierro, J.; Zacarias, J.; Montero, J.; Quijano, S.; Huamanchahua, D. Design of an Automated System for Cattle-Feed Dispensing in Cattle-Cows. In Proceedings of the 2021 IEEE 12th Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), New York, NY, USA, 1–4 December 2021; pp. 671–675. [Google Scholar]

- Bloch, V.; Levit, H.; Halachmi, I. Design a system for measuring individual cow feed intake in commercial dairies. Animal 2021, 15, 100277. [Google Scholar] [CrossRef]

- Rajakumar, G.; Narayanan, K.; Krishnan, R.; Robinson, Y.; Subramanian, M.; Asirvatham, M. Design of an Efficient IoT System for Poultry Farm Management. In Proceedings of the Distributed Computing and Optimization Techniques (ICDCOT), Bengaluru, India, 25–26 June 2021; pp. 325–335. [Google Scholar]

- Huang, J.; Luo, B.; Cao, Y.; Li, B.; Qian, M.; Jia, N.; Zhao, W. Fusion of THz-TDS and NIRS Based Detection of Moisture Content for Cattle Feed. Front. Phys. 2022, 10, 833278. [Google Scholar] [CrossRef]

- Shaoxiong, J.; Biao, X.; Kai, R.; Jianmin, X.; Wen, D.; Wei, W.; Shengli, L. Research Progress of the Detection Technology for Starch Content in Feed. Chin. J. Anim. Sci. 2024, 60, 5–11. [Google Scholar]

- Xiang, N.N.; Zhao, J.T.; Chen, L.; Xia, C.D.; Wang, X.Q.; Chen, L.; Ji, C.Z. Research on evaluation of fiber content in soybean hulls based on near-infrared spectroscopy technique. Chin. J. Anim. Nutr. 2021, 33, 1792–1800. [Google Scholar] [CrossRef]

- Yabuta, T.; Oviedo-Rondón, E. The value of near-infrared spectroscopy: Using nutritional information of soybean meals by country of origin in feed formulation. J. Appl. Poult. Res. 2024, 33, 100443. [Google Scholar] [CrossRef]

- Wang, P.-L.; Tang, Z.-Y.; Wang, P.L.; Tang, Z.Y. Application analysis and prospect of nanosensor in the quality and safety of agricultural products. Smart Agric. 2021, 2, 1–10. [Google Scholar] [CrossRef]

- Wyffels, S.A.; Parsons, C.T.; Dafoe, J.M.; Boss, D.L.; Carter, B.H.; Delcurto, T. The influence of age and winter environment on protein block intake behavior of beef cattle winter grazing mixed-grass rangelands. Ruminants 2021, 1, 191–201. [Google Scholar] [CrossRef]

- Tzanidakis, C.; Simitzis, P.; Arvanitis, K.; Panagakis, P. An overview of the current trends in precision pig farming technologies. Livest. Sci. 2021, 249, 104530. [Google Scholar] [CrossRef]

- Durand, M.; Largouët, C.; de Beaufort, L.; Dourmad, J.; Gaillard, C. Prediction of the daily nutrient requirements of gestating sows based on sensor data and machine-learning algorithms. J. Anim. Sci. 2023, 101, skad337. [Google Scholar] [CrossRef]

- Cruz, V.; Rico, J.; Coelho, D.; Baptista, F. Innovative PLF Tool to Assess Growing-Finishing Pigs’ Welfare. Agronomy 2022, 12, 2159. [Google Scholar] [CrossRef]

- Chapagaee, P.; Nainabasti, A.; Kunwar, A.; Bist, D.R.; Khatri, L.; Mandal, A. Precision livestock farming in the 21st century: Challenges and opportunities for sustainable agriculture. CABI Rev. 2024, 19, 1–8. [Google Scholar] [CrossRef]

- Chang, J.-W.; Kwak, H.Y. Cow Residual Feed Intake (RFI) monitoring and metabolic abnormality prediction system using wearable device for Milk cow and Beef. J. Korea Soc. Comput. Inf. 2021, 26, 139–145. [Google Scholar] [CrossRef]

- Muir, S.K.; Linden, N.P.; Kennedy, A.; Calder, G.; Kearney, G.; Roberts, R.; Knight, M.I.; Behrendt, R. Technical note: Validation of an automated feeding system for measuring individual animal feed intake in sheep housed in groups. Transl. Anim. Sci. 2020, 4, txaa007. [Google Scholar] [CrossRef]

- Gómez, Y.; Stygar, A.; Boumans, I.; Bokkers, E.; Pedersen, L.; Niemi, J.; Pastell, M.; Manteca, X.; Llonch, P. A Systematic Review on Validated Precision Livestock Farming Technologies for Pig Production and Its Potential to Assess Animal Welfare. Front. Vet. Sci. 2021, 8, 660565. [Google Scholar] [CrossRef]

- Campos, D.; Abatti, P.; Bertotti, F.; Hill, J.; da Silveira, A. Surface electromyography segmentation and feature extraction for ingestive behavior recognition in ruminants. Comput. Electron. Agric. 2018, 153, 325–333. [Google Scholar] [CrossRef]

- Nie, L.; Berckmans, D.; Wang, C.; Li, B. Is Continuous Heart Rate Monitoring of Livestock a Dream or Is It Realistic? A Review. Sensors 2020, 20, 2291. [Google Scholar] [CrossRef]

- Campos, D.; Abatti, P.; Bertotti, F.; Vieira, A.; Hill, J.; da Silveira, A. Short-term fibre intake estimation in goats using surface electromyography of the masseter muscle. Biosyst. Eng. 2019, 183, 209–220. [Google Scholar] [CrossRef]

- Yu, H.; Lee, K.; Morota, G. Forecasting dynamic body weight of nonrestrained pigs from images using an RGB-D sensor camera. Transl. Anim. Sci. 2021, 5, txab006. [Google Scholar] [CrossRef]

- Franchi, G.A.; Bus, J.D.; Boumans, I.J.M.M.; Bokkers, E.A.M.; Jensen, M.B.; Pedersen, L.J. Estimating body weight in conventional growing pigs using a depth camera. Smart Agric. Technol. 2023, 3, 100117. [Google Scholar] [CrossRef]

- Na, M.; Cho, W.; Kim, S.; Na, I. The Development of a Weight Prediction System for Pigs Using Raspberry Pi. Agriculture 2023, 13, 2027. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, M.; Peng, Z.; Deng, Y.; Gu, L.; Peng, Y. A real-time feeding behavior monitoring system for individual yak based on facial recognition model. PeerJ Comput. Sci. 2024, 10, e2427. [Google Scholar] [CrossRef]

- Arulmozhi, E.; Bhujel, A.; Moon, B.; Kim, H. The Application of Cameras in Precision Pig Farming: An Overview for Swine-Keeping Professionals. Animals 2021, 11, 2343. [Google Scholar] [CrossRef]

- Kostomakhin, N.; Tseiko, L.; Kostomakhin, M. Experience and prospects of the use of precision livestock farming in the Russian Federation. BIO Web Conf. 2024, 113, 02001. [Google Scholar] [CrossRef]

- Tekin, K.; Yurdakök Dikmen, B.; Kanca, H.; Guatteo, R. Precision livestock farming technologies: Novel direction of information flow. Ank. Univ. Vet. Fak. Derg. 2021, 68, 193–212. [Google Scholar] [CrossRef]

- Cambra-Lopez, M.; Llonch, P.; Castillejos, L.; Pomar, J.; Maroto-Molina, F. Research in Precision Livestock Farming and Animal Digitalization: Evolution in Spain and Future Perspectives. In Proceedings of the XX Jornadas Sobre Producción Animal, Zaragoza, Spain, 13–14 June 2023; p. 269. [Google Scholar]

- Mateo-Fornés, J.; Pagès-Bernaus, A.; Plà-Aragonés, L.; Castells-Gasia, J.; Babot-Gaspa, D. An Internet of Things Platform Based on Microservices and Cloud Paradigms for Livestock. Sensors 2021, 21, 5949. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, I.; Prakash, N.; Jain, A. Integration of Blockchain& IoT in Precision Farming: Exploration, Scope and Security Challenges. In Proceedings of the IEEE 12th Annual Ubiquitous Computing, Electronics & Mobile Communication Conference (UEMCON), New York, NY, USA, 1–4 December 2021; pp. 854–859. [Google Scholar]

- Leishman, E.; You, J.; Ferreira, N.; Adams, S.; Tulpan, D.; Zuidhof, M.; Gous, R.; Jacobs, M.; Ellis, J. Review: When worlds collide—Poultry modeling in the ‘Big Data’ era. Animal 2023, 17, 100874. [Google Scholar] [CrossRef]

- Haldar, A.; Mandal, S.N.; Deb, S.; Roy, R.; Laishram, M. Application of Information and Electronic Technology for Best Practice Management in Livestock Production System; Springer: Berlin/Heidelberg, Germany, 2022; pp. 173–218. [Google Scholar]

- Eneh, A.H.; Udanor, C.N.; Ossai, N.I.; Aneke, S.O.; Ugwoke, P.O.; Obayi, A.A.; Ugwuishiwu, C.H.; Okereke, G.E. Towards an improved internet of things sensors data quality for a smart aquaponics system yield prediction. MethodsX 2023, 11, 102436. [Google Scholar] [CrossRef]

- Tangorra, F.; Buoio, E.; Calcante, A.; Bassi, A.; Costa, A. Internet of Things (IoT): Sensors Application in Dairy Cattle Farming. Animals 2024, 14, 3071. [Google Scholar] [CrossRef]

- Ubina, N.A.; Lan, H.-Y.; Cheng, S.-C.; Chang, C.-C.; Lin, S.-S.; Zhang, K.-X.; Lu, H.-Y.; Cheng, C.-Y.; Hsieh, Y.-Z. Digital twin-based intelligent fish farming with artificial intelligence internet of things (AIoT). Smart Agric. Technol. 2023, 5, 100285. [Google Scholar] [CrossRef]

- Chiu, C.; Liao, T.; Chen, C.; Kao, S. AIoT Precision Feeding Management System. Electronics 2022, 11, 3358. [Google Scholar] [CrossRef]

- Chen, Y.; Rustia, D.; Huang, S.; Hsu, J.; Lin, T. IoT-based system for individual dairy cow feeding behavior monitoring using cow face recognition and edge computing. Internet Things 2025, 33, 101674. [Google Scholar] [CrossRef]

- Shwetabhand, K.; Ambhaikar, A. Development of a low-cost livestock sorting information management system leveraging deep learning, AI, and IoT technologies. BIO Web Conf. 2024, 82, 05019. [Google Scholar] [CrossRef]

- Zhang, M.J.; Wang, X.P.; Feng, H.H.; Huang, Q.Y.; Xiao, X.Q.; Zhang, X.S. Wearable Internet of Things enabled precision livestock farming in smart farms: A review of technical solutions for precise perception, biocompatibility, and sustainability monitoring. J. Clean. Prod. 2021, 312, 127712. [Google Scholar] [CrossRef]

- Martinez-Rau, L.; Chelotti, J.; Giovanini, L.; Adin, V.; Oelmann, B.; Bader, S. On-Device Feeding Behavior Analysis of Grazing Cattle. IEEE Trans. Instrum. Meas. 2024, 73, 3376013. [Google Scholar] [CrossRef]

- Chen, C.; Zhu, W.X.; Steibel, J.; Siegford, J.; Han, J.J.; Norton, T. Recognition of feeding behaviour of pigs and determination of feeding time of each pig by a video-based deep learning method. Comput. Electron. Agric. 2020, 176, 105642. [Google Scholar] [CrossRef]

- Zom, R.; André, G.; van Vuuren, A. Development of a model for the prediction of feed intake by dairy cows 2. Evaluation of prediction accuracy. Livest. Sci. 2012, 143, 58–69. [Google Scholar] [CrossRef]

- Yin, M.; Ma, R.; Luo, H.; Li, J.; Zhao, Q.; Zhang, M. Non-contact sensing technology enables precision livestock farming in smart farms. Comput. Electron. Agric. 2023, 212, 108171. [Google Scholar] [CrossRef]

- Huang, Y.; Xiao, D.; Liu, J.; Liu, Y.; Tan, Z.; Hui, X.; Huang, S. Analysis of pig activity level and body temperature variation based on ear tag data. Comput. Electron. Agric. 2024, 219, 108768. [Google Scholar] [CrossRef]

- You, J.; Lou, E.; Afrouziyeh, M.; Zukiwsky, N.; Zuidhof, M. A supervised machine learning method to detect anomalous real-time broiler breeder body weight data recorded by a precision feeding system. Comput. Electron. Agric. 2021, 185, 106171. [Google Scholar] [CrossRef]

- Niloofar, P.; Lazarova-Molnar, S.; Francis, D.; Vulpe, A.; Suciu, G.; Balanescu, M. Modeling and Simulation for Decision Support in Precision Livestock Farming. In Proceedings of the 2020 Winter Simulation Conference (WSC), Virtual, 14–18 December 2020; IEEE: New York, NY, USA, 2020; pp. 2601–2612. [Google Scholar]

- Pomar, J.; López, V.; Pomar, C. Agent-based simulation framework for virtual prototyping of advanced livestock precision feeding systems. Comput. Electron. Agric. 2011, 78, 88–97. [Google Scholar] [CrossRef]

- Rongwei, D. Smart Precision Feeding System for Dairy Cows based on Amplitude Iterative Pruning Algorithm. In Proceedings of the 2024 5th International Conference on Mobile Computing and Sustainable Informatics (ICMCSI), Lalitpur, Nepal, 18–19 January 2024; pp. 415–420. [Google Scholar]

- Marcon, M.; Brossard, L.; Quiniou, N. Precision feeding based on individual daily body weight of group-housed pigs with an automatic feeder developed to allow for restricting feed allowance. Precis. Livest. Farming 2015, 15, e601. [Google Scholar]

- Chinaeke-Ogbuka, I.; Anoliefo, E.; Ajibo, A.; Ogbuka, C. Design and Implementation of an Automated Feeding System for Poultry Farms. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Singapore, 9–11 March 2021; pp. 532–540. [Google Scholar]

- Xiong, B.; Yang, L.; Zheng, S.; Cao, P.; Pan, X.; Wu, G. Design and test of precise blanking control system for lactating sows. Trans. Chin. Soc. Agric. Eng. 2017, 33, 177–182. [Google Scholar]

- Jiang, W.; Hao, H.; Fan, J.; Wang, L.; Wang, H. Rabbit feeding robot: Autonomous navigation and precision feeding. Biosyst. Eng. 2024, 239, 68–80. [Google Scholar] [CrossRef]

- Fu, Z.; Yafei, W.; Mei, L.; Jun, W.; Zihe, X.; Xinhui, C. Design and Experiment of Auto-precision Feeding System for Piglets. Trans. Chin. Soc. Agric. Mach. 2018, 49, 39–45. [Google Scholar]

- Bhoj, S.; Dhattarwal, P.; Harini, K.R.; Thakur, R.; Bhardwaj, S.; Tarafdar, A.; Pandey, H.O.; Gaur, G.K.; Singh, M. Mechanization of livestock farms. In Engineering Applications in Livestock Production; Elsevier: Amsterdam, The Netherlands, 2024; pp. 207–242. [Google Scholar]

- Uzedhe, G.O.; Akinloye, B.O.; Febaide, I.C. Development of an Animal Farm Robotic Feeding System. Trop. J. Sci. Technol. 2023, 4, 14–22. [Google Scholar] [CrossRef]

- Chiu, Y.; Tsai, W.; Wu, G. Developing an Automated Feeding System for Distributing Concentrated Goat Feed. Appl. Eng. Agric. 2020, 36, 125–140. [Google Scholar] [CrossRef]

- Sathyamohan, J.M.; Vaithilingam, C.A.; Sivasubramanian, R.; Prakash, O. Enhancing Efficiency in Broiler Chicken Farms: A Rail Systems-Based Approach Feeding Process. In Proceedings of the 2024 International Conference on Green Energy, Computing and Sustainable Technology (GECOST), Virtual, 12–14 November 2025; pp. 476–480. [Google Scholar]

- Deqin, X.; Yigui, H.; Yuesong, X.; Junbin, L.; Zujie, T.; Siting, L. Research progress on robotic technology in the field of livestock and poultry farming. J. South China Agric. Univ. 2024, 45, 624–634. [Google Scholar]

- Isife, J.K.; Chijioke, U.; Godwin, S. Design and Simulation of an Automated Poultry Feed Mixing Machine Using Process Controller. Glob. Sci. J. 2019, 7, 537–602. [Google Scholar]

- Umogbai, V. Development of a Mechanical Family Poultry Feeder. Agric. Mech. Asia Afr. Lat. Am. 2015, 46, 72–79. [Google Scholar]

- Bae, J.; Park, S.; Jeon, K.; Choi, J.Y. Autonomous System of TMR (Total Mixed Ration) Feed Feeding Robot for Smart Cattle Farm. Int. J. Precis. Eng. Manuf. 2023, 24, 423–433. [Google Scholar] [CrossRef]

- Lv, Y.; Zheng, Z.; Zeng, J.; Chen, Y.; Abdeen, M.; Qiu, W.; Wu, W.; Luo, Y. Transportation Machinery and Feeding Systems for Pigs in Multi-Storey Buildings: A Review. Processes 2024, 12, 1427. [Google Scholar] [CrossRef]

- Shevchenko, I.A.; Aliev, E.B. Automated control systems for technical processes in dairy farming. Ann. Wars. Univ. Life Sci. SGGW Agric. (Agric. For. Eng.) 2013, 63, 41–49. [Google Scholar]

- Zhang DeMin, Z.D.; Li YouZhi, L.Y.; Zhang ShuEr, Z.S.; Zhang, D.M.; Li, Y.Z.; Zhang, S.E. Development and application of TMR intelligent surveillance system in dairy farm. China Herbiv. Sci. 2018, 38, 51–54. [Google Scholar]

- Fischer, B.; Engelhard, T.; Helm, L. TMR or feed dispensers? Optimal cow maintenance on small and medium farms using available methods. Mais 2000, 2000, 8–11. [Google Scholar]

- Angarita, B.; Han, J.; Cantet, R.; Chewning, S.; Wurtz, K.; Siegford, J.; Ernst, C.; Steibel, J. Estimation of direct and social effects of feeding duration in growing pigs using records from automatic feeding stations. J. Anim. Sci. 2021, 99, skab042. [Google Scholar] [CrossRef] [PubMed]

- Bruininx, E.; van der Peet-Schwering, C.; Schrama, J.; den Hartog, L.; Everts, H.; Beynen, A. The IVOG® feeding station:: A tool for monitoring the individual feed intake of group-housed weanling pigs. J. Anim. Physiol. Anim. Nutr. 2001, 85, 81–87. [Google Scholar] [CrossRef]

- Li, B.-m.; Wang, Y.; Zheng, W.-c.; Wang, C.-y.; Li, B.M.; Wang, Y.; Zheng, W.C.; Wang, C.Y. Research progress on intelligent equipment and information technology for livestock and poultry breeding. J. South China Agric. Univ. 2021, 42, 18–26. [Google Scholar] [CrossRef]

- Xiao, D.; Mao, Y.; Liu, Y.; Zhao, S.; Yan, Z.; Wang, W.; Xie, Q. Development and trend of industrialized poultry culture in China. J. South China Agric. Univ. 2023, 44, 1–12. [Google Scholar]

- Foreway. Foreway Shandong Livestock Technology [EB/OL]. Available online: https://www.foreway.cn/col.jsp?id=223 (accessed on 25 September 2025).

- IMETEC. Feeding robots [EB/OL]. Available online: https://www.chinayimeite.com/ (accessed on 25 September 2025).

- Honneur. ECO [EB/OL]. Available online: http://www.cnhonneur.net/product/14/ (accessed on 25 September 2025).

- Henty, S.; Ho, C.; Auldist, M.; Wales, W.; Malcolm, B. A whole-farm investment analysis of a partial mixed ration feeding system for dairy cows. Anim. Prod. Sci. 2020, 60, 444–453. [Google Scholar] [CrossRef]

- Wu, L. Worldwide Rabbit Meat Trade. In Veterinary Care of Farm Rabbits: A Complete Practice Guide to Rabbit Medicine and Production; Springer: Berlin/Heidelberg, Germany, 2024; pp. 67–92. [Google Scholar]

- Lukefahr, S.; McNitt, J.I.; Cheeke, P.R.; Patton, N.M. Rabbits for family and small farm development. In Rabbit Production; CABI: Los Angeles, CA, USA, 2022; pp. 270–280. [Google Scholar]

- World Rabbit Science (Ed.) Abstracts of 38th Symposium on Cuniculture, ASESCU. World Rabbit Sci. 2013, 21, 201–210. [Google Scholar] [CrossRef]

- Quaresma, M.; Roseiro, L.; Ferreira, T.; Nunes, M.; Pereira, G. Effect of Diet Supplementation with Oat Hay and Whole Carrot on Rabbit Growth and Productive Efficiency. Animals 2023, 13, 3138. [Google Scholar] [CrossRef]

- Dang, W.-Q.; He, M.; Cao, L.; Ren, K.-L.; Zhang, Y.-Q. Research progress on feed resources and nutritional requirements of rabbits in 2021 at home and abroad. J. Shanxi Agric. Sci. 2023, 51, 581–589. [Google Scholar] [CrossRef]

- le Normand, B. Welfare in rabbit fattening farms in France. Bull. G.T.V. 2015, 2015(Special Issue), 97–108. [Google Scholar]

- Garcia, R.P.A.; Vieira, M.d.M.; Soares, D.B. Animal performance, economic analysis and digestibility in rabbits in the growth phase supplemented with silage. Pubvet 2021, 15, 188. [Google Scholar] [CrossRef]

- Fengjie County People’s Government. High-Quality Development of the Meat Rabbit Industry in Fengjie [Policy Document]. 2025. Available online: https://cqfj.gov.cn/zwgk_168/zfxxgkmls/zcwj/qtwj/zhssf_495635/202506/t20250609_14695469.html (accessed on 25 September 2025).

- Xiangyang Municipal Bureau of Agriculture and Rural Affairs. Notice on Several Measures to Continue Promoting Stable Growth and Development in the Livestock Industry [Notice]. 2024. Available online: http://nyncj.xiangyang.gov.cn/zwgk/gkml/ggzypz/snbt/202410/t20241012_3687034.shtml (accessed on 25 September 2025).

- People’s Government of Ningxia Hui Autonomous Region. Assessment Report on the Circular Agriculture Innovation Pilot Project in Longde County, Ningxia [Government Report]. 2022. Available online: https://www.nx.gov.cn/ (accessed on 25 September 2025).

- Granaci, V. Seasonals particularity of the reproductive performances of domestic rabbits and opportunities of their recovery. Univ. Agric. Sci. Vet. Med. Iasi 2017, 67, 142–146. [Google Scholar]

- Huang, J.; Wang, Q.; Zhang, K.; He, S.; Liu, Z.; Li, M.; Liu, M.; Guo, Y.; Wu, Z. Optimizing Feeding Strategies for Growing Rabbits: Impact of Timing and Amount on Health and Circadian Rhythms. Animals 2023, 13, 2742. [Google Scholar] [CrossRef]

- Szendro, Z.; Papp, Z.; Kustos, K. Effect of ambient temperature and restricted feeding on the production of rabbit does and their kits. Acta Agrar. Kaposvariensis 2018, 22, 1–17. [Google Scholar] [CrossRef]

- Iyeghe-Erakpotobor, G.; Muhammad, I. Performance of rabbit breeding does feed concentrate and lablab combinations during pregnancy and lactation. J. Anim. Vet. Adv. 2007, 6, 358–363. [Google Scholar]

- Lazar, M.; Radu-Rusu, R.; Pavel, G.; Lazar, R. Biochemical and metabolic responses of rabbits (Oryctolagus cuniculus) to moderate and chronic stress. Repos. Iași Univ. Life Sci. 2024, 67, 15–22. [Google Scholar] [CrossRef]

- McIndoe, K.; Saunders, R.; Blackwell, E.; Rooney, N. The effect of blindfolding and swaddling on the stress response to handling in domestic rabbits. Anim. Welf. 2022, 31, 27–36. [Google Scholar] [CrossRef]

- Jaén-Téllez, J.; Sánchez-Guerrero, M.; Valera, M.; González-Redondo, P. Influence of Stress Assessed through Infrared Thermography and Environmental Parameters on the Performance of Fattening Rabbits. Animals 2021, 11, 1747. [Google Scholar] [CrossRef]

- Dutchman, B. Chain/Spiral Conveyance Systems. Available online: https://www.bigdutchman.com/en/homepage/ (accessed on 25 September 2025).

- FANCOM. Pipe Conveyance Synchronized. Available online: https://www.fancom.com/ (accessed on 25 September 2025).

- ROXELL. Feeding-Systems-for-Rabbits. Available online: https://www.roxell.com/ (accessed on 25 September 2025).

- Genetics, H. Hamel OptiBreeder. Available online: www.hamel-genetics.fr/en/livestock-solutions/rabbit (accessed on 25 September 2025).

- Kokko, E.; Kaukonen, E.; Norring, M. Housing and welfare of the farmed rabbits in Finland. Suom. Elainlaakaril. 2022, 128, 475–482. [Google Scholar]

- Trocino, A.; Tolini, C. measuring on-farm welfare in rabbits: A review with emphasis on animal-based indicators. WORLD Rabbit Sci. 2024, 32, 225–240. [Google Scholar] [CrossRef]

- Lefeng. Shaoxing Lefeng Cage Equipment Co. Available online: https://www.qianhongsong.cn/ (accessed on 25 September 2025).

- Jiang, W.; Hao, H.; Wang, H.; Wang, L. Possible application of agricultural robotics in rabbit farming under smart animal husbandry. J. Clean. Prod. 2025, 501, 145301. [Google Scholar] [CrossRef]

- Duan, E.; Wang, L.; Wang, H.; Hao, H.; Li, R. Feed weight estimation model for health monitoring of meat rabbits based on deep learning. Int. J. Agric. Biol. Eng. 2022, 15, 233–240. [Google Scholar] [CrossRef]

- Banhazi, T.; Halas, V.; Maroto-Molina, F. Practical Precision Livestock Farming: Hands-On Experiences with PLF Technologies in Commercial and R&D Settings; Brill: Leiden, The Netherlands, 2022. [Google Scholar]

- Gidenne, T.; Garreau, H.; Maertens, L.; Drouilhet, L. Feed efficiency in rabbit farming: Ways of improvement, technico-economical and environmental impacts. INRA Prod. Anim. 2019, 32, 431–444. [Google Scholar] [CrossRef]

- Trioliet. Triomatic HP Suspended Feeding Robot [EB/OL]. Available online: https://www.trioliet.com/products/automatic-feeding-systems/feeding-robot/suspended-feeding-robot (accessed on 25 September 2025).

- Trioliet. Triomatic WP Wheel-Driven Feeding Robot [EB/OL]. Available online: https://www.trioliet.com/products/automatic-feeding-systems/feeding-robot/wheel-driven-feeding-robot-triomatic (accessed on 25 September 2025).

- Rovibec. Rover MVR [EB/OL]. Available online: https://www.agriexpo.cn/prod/rovibec-agrisolusions/product-172425-9278.html (accessed on 25 September 2025).

- Rovibec. ROV [EB/OL]. Available online: https://www.agriexpo.cn/prod/rovibec-agrisolusions/product-172425-9285.html (accessed on 25 September 2025).

- Rovibec. DEC SR [EB/OL]. Available online: https://www.agriexpo.cn/prod/rovibec-agrisolusions/product-172425-9281.html (accessed on 25 September 2025).

- Rovibec. DEC HDR [EB/OL]. Available online: https://www.agriexpo.cn/zhizaoshang-agri/gui-dao-liao-ji-qi-ren-11030.html (accessed on 25 September 2025).

- Hetwin. ARAMISII [EB/OL]. Available online: https://www.agriexpo.cn/prod/hetwin-automation-systems-gmbh/product-171829-8972.html (accessed on 25 September 2025).

- Hetwin. ATHOS [EB/OL]. Available online: https://www.agriexpo.cn/prod/hetwin-automation-systems-gmbh/product-171829-63317.html (accessed on 25 September 2025).

- Lely. Vector [EB/OL]. Available online: https://www.lely.com/cn/solutions/feeding/ (accessed on 25 September 2025).

- Goke. TMR Feeding and Pushing Robots [EB/OL]. Available online: http://www.gokeagri.com/EquipmentandFacilities/462.html (accessed on 25 September 2025).

- BlueWay. TMR Precision Feeding System [EB/OL]. Available online: https://www.51blueway.com/?page_id=19657 (accessed on 25 September 2025).

- Hetwin. ARANOM [EB/OL]. Available online: https://www.agriexpo.cn/prod/hetwin-automation-systems-gmbh/product-171829-123029.html (accessed on 25 September 2025).

- Schauer. TRANSFEED ROVER [EB/OL]. Available online: https://www.schauer-agrotronic.com/rinderstall/ (accessed on 25 September 2025).

- DeLaval. OptiDuo [EB/OL]. Available online: https://www.delaval.com/zh-cn/mu-chang-jie-jue-fang-an/si-wei-chan-pin/li-la-fa-zi-dong-jiao-ban-tui-liao-ji-qi-ren-optiduo/ (accessed on 25 September 2025).

- KUHN. Aura [EB/OL]. Available online: https://www.kuhn.cn/guanyukuen/guanyuwomen/chuangxinyukeji (accessed on 25 September 2025).

- Goke. Intelligent Feeding Stations [EB/OL]. Available online: http://www.gokeagri.com/product/55.html (accessed on 25 September 2025).

- Osborne. Team [EB/OL]. Available online: https://www.agriexpo.cn/prod/osborne-industries-inc/product-172266-11520.html (accessed on 25 September 2025).

- JYGA. GESTAL 3G [EB/OL]. Available online: https://jygatech.com/products/gestation/gestal-3g/ (accessed on 25 September 2025).

- Schauer. Compident VII [EB/OL]. Available online: http://www.schauer.cn/contents/3/46.html (accessed on 25 September 2025).

- Nedap. Nedap Velos [EB/OL]. Available online: https://nedap.com/about-us/ (accessed on 25 September 2025).

- Muyuan. Intelligent Feeding System [EB/OL]. Available online: https://www.muyuanfoods.com/#/smartTechnology (accessed on 25 September 2025).

- BigHerdsman. Intelligent Feeding System for Sows at All Stages [EB/OL]. Available online: https://www.bigherdsmangroup.com/category/pig-3.html (accessed on 25 September 2025).

- Schauer. MIO [EB/OL]. Available online: http://www.schauer.cn/contents/5/62.html (accessed on 25 September 2025).

- JYGA. SOLO [EB/OL]. Available online: https://jygatech.com/products/farrowing/gestal-solo/ (accessed on 25 September 2025).

- BigDutchman. Callmatic 2 [EB/OL]. Available online: https://www.bigdutchmanchina.com/product/18 (accessed on 25 September 2025).

| Comparison Dimensions | Cattle | Pigs | Poultry | Rabbits (Traditional) | Rabbits (Three-Stage Framework) |

|---|---|---|---|---|---|

| Management unit | Individual (dairy cows)/Herd (beef cattle) | Group (pen system) | Group (cage/free-range) | Group (cage system) | Individual level (AI visual recognition replacing ear tags) |

| Farming method | Grazing/Confinement | Enclosed pens | Cage rearing/Floor rearing | Multi-tier cage rearing | Cage rearing + dynamic zone monitoring |

| Lifestyle habits | Gregarious but with high individual space requirements | Gregarious, highly competitive for food | Clear pecking order | Timid and easily stressed, feeds at night | AI identifies stress behavior and adjusts feeding schedule |

| Feeding habits | Slow eating, rumination | Rapid feeding | Intermittent pecking | Small meals, frequent meals | High-frequency, precise feeding (mimicking natural habits) |

| Feed differences | Coarse feed-based (TMR) | Pellet/powdered complete feed | Pellets/crushed feed | Pellets (fragile) | Pellet integrity monitoring + anti-waste design |

| Feeding method | TMR mixer truck/automatic feed hopper | Dry/wet feed hopper/automatic feed dispenser | Chain/disc feeder | Fixed feed hopper | Individual feed box (AI-controlled switch) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, W.; Li, G.; Xu, J.; Qin, Y.; Wang, L.; Wang, H. Precision Feeding Systems in Animal Husbandry: Guiding Rabbit Farming from Concept to Implementation. Agriculture 2025, 15, 2215. https://doi.org/10.3390/agriculture15212215

Jiang W, Li G, Xu J, Qin Y, Wang L, Wang H. Precision Feeding Systems in Animal Husbandry: Guiding Rabbit Farming from Concept to Implementation. Agriculture. 2025; 15(21):2215. https://doi.org/10.3390/agriculture15212215

Chicago/Turabian StyleJiang, Wei, Guohua Li, Jitong Xu, Yinghe Qin, Liangju Wang, and Hongying Wang. 2025. "Precision Feeding Systems in Animal Husbandry: Guiding Rabbit Farming from Concept to Implementation" Agriculture 15, no. 21: 2215. https://doi.org/10.3390/agriculture15212215

APA StyleJiang, W., Li, G., Xu, J., Qin, Y., Wang, L., & Wang, H. (2025). Precision Feeding Systems in Animal Husbandry: Guiding Rabbit Farming from Concept to Implementation. Agriculture, 15(21), 2215. https://doi.org/10.3390/agriculture15212215