Abstract

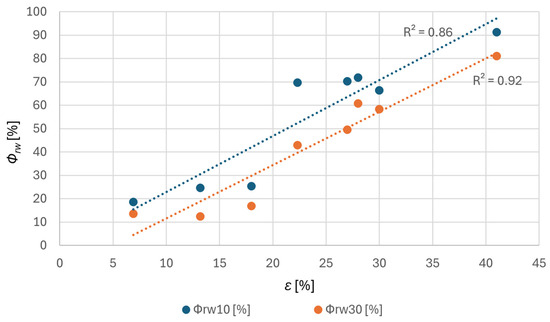

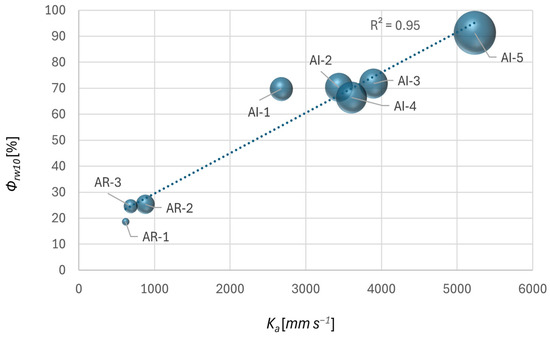

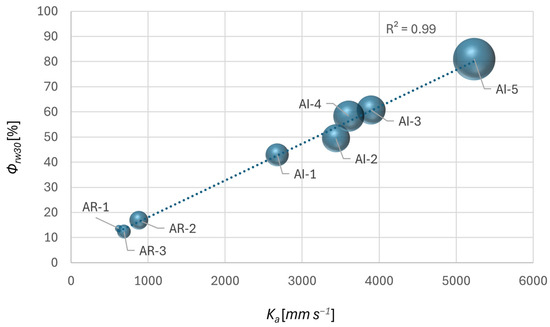

Plastic agrotextiles are increasingly used in modern agriculture to protect crops from adverse climatic events, such as excessive rainfall, wind, and solar radiation. Among these, anti-rain nets represent a promising solution to mitigate rain-induced disorders, such as fruit cracking, especially in crops sensitive to water excess. This study investigates the structural and functional properties of eight agrotextiles, including both anti-rain and anti-insect nets. The analysis focuses on geometric characteristics (porosity, thread diameter, mesh density) and on functional performance through experimental evaluation of air and rainwater permeability under different slope conditions. Air permeability was assessed using a wind tunnel, while rainwater permeability was tested via a rainfall simulation bench. The results demonstrate a stronger correlation between the air permeability index (Ka) and the rainwater permeability index Φrw (R2 = 0.95–0.99), across different net slopes (10° and 30°), than between the net porosity and Φrw (R2 = 0.86–0.92). These findings emphasize the greater explanatory power of the dynamic performance indicator Ka as a predictor of rainwater permeability, over purely geometric descriptors like porosity, since it inherently accounts for the dynamic performance of the air flow through the net. This contributes to the development of more effective and sustainable net-based crop protection systems tailored to specific environmental and agronomic needs.

1. Introduction

Modern agriculture must face increasingly complex challenges due to climate change and the growing need for sustainable production. In this context, the use of plastic nets for crop protection has emerged as an effective solution to improve both the quality and quantity of crop production by controlling and/or managing weather events that can negatively impact productivity [1,2,3,4]. The use of ‘Agrotextiles’ for crop protection is associated with the ability of the net, for example, to physically exclude highly harmful insects, vectors of serious diseases and yield losses. In addition to anti-insect function, nets are widely used for wind control, hail protection, and selective solar radiation management and filtering both in hot environments, such as those in the Mediterranean, and in cold environments, such as those in Northern Europe [1,5]. In recent years, research has focused on optimizing specific performances of nets and their use. Different strategies to further improve insect-proof nets have been explored such as the production of thinner fibers to facilitate air exchange without reducing insect exclusion efficiency, and the use of optical additives that, by absorbing specific spectra of ultraviolet radiation, disorient insects; however, fibers that are too thin may compromise the mechanical properties of the nets, while optical additives can increase the shading performance of the net [6]. Considerable research has investigated the application of shade nets to improve the crop microenvironment, enhance plant growth, reduce plant diseases and physiological disorders, and extend the harvesting season, thereby promoting their use as an adaptation strategy to climate change, especially in hot environments [7]. In this context, studies have also focused on the spatial distribution of air temperature and relative humidity in greenhouses influenced by external shading nets, as well as on evaluating their cooling potential in arid regions [8,9].

Climate change, through the increasing frequency and intensity of extreme weather events, has made horticultural crops particularly vulnerable to environmental stress. Among the most notable effects are disruptions in key plant physiological processes, such as nutrient uptake, photosynthesis, and stomatal conductance, which can negatively impact both fruit development and quality. Protecting orchard crops from rain is a major concern, as heavy rainfall can cause irreversible damage, making adequate protection essential. One of the most severe consequences is fruit cracking—a physiological disorder commonly observed in many fleshy fruit species—that lowers commercial value, shortens shelf life, and increases susceptibility to fungal and bacterial infections [10]. Furthermore, in some cases, genetic selection aimed at boosting yield has inadvertently reduced the adaptive capacity of crops, making them more sensitive to stress conditions such as high temperatures and water scarcity [11].

To protect crops from high-intensity precipitation, treatments with plant protection products, customized fertilization plans, and impermeable covers, such as traditional plastic films, are commonly used. Chemical treatments combined with fertilization are employed to reduce the osmotic potential within the fruit, but their effectiveness varies [12], and in cases of heavy rainfall, the percentage reduction in fruit cracking remains very low. Moreover, such treatments can compromise the fruit’s healthiness by increasing the risk of chemical residues especially in years with limited rainfall [13]. Plastic films protect crops from rainfall while simultaneously retaining moisture and heat, which may lead to the creation of an overly humid and poorly ventilated environment. This condition favours the proliferation of fungal and bacterial diseases, the development of root rot, and a decline in fruit quality. These limitations have prompted scientific research to explore innovative strategies aimed at minimizing the impact of rainfall on agricultural crops. There is a clear need to develop more effective technical solutions that ensure improved protection against rainfall, while also addressing the shortcomings of current approaches, such as excessive air relative humidity and the potential for chemical residues.

Multifunctional agricultural nets are emerging as crucial tools for enhancing crop resilience, allowing for adequate ventilation rates compared to plastic films and enabling farmers to limit the use of phytosanitary products. In recent years, new products as anti-rain nets have been introduced to the market, stimulating scientific interest in evaluating their suitability as a rain mitigation strategy for agricultural crops. Anti-rain nets could be used in agriculture to protect crops from the negative effects of rainfall and could be mainly applied to fruit crops such as cherry, kiwi, grapevine and berries which are particularly susceptible to rain damage [14,15]. Some species of fruit trees, such as cherries, are prone to splitting when they absorb too much water, so the use of rain nets could help to keep fruit surfaces dry, preventing fruit splitting [16]. In general, anti-rain agrotextiles may be useful in regions with frequent or intense rainfall during critical crop maturation periods. The use of these agrotextiles can also generate positive effects on agricultural production through their biostimulating effects on agricultural crops, thanks to their ability to anticipate and/or postpone fundamental phenological phases such as flowering and fruit ripening, as they are able to regulate local environmental conditions and trigger physiological responses that enhance plant development and productivity [17,18].

Net types can be differentiated based on a range of structural parameters, such as the type of threads, fabric structure, fibre shape and mesh dimensions, as well as on their physical properties such as weight, colour, shading coefficient, durability, porosity, and air permeability. Generally, anti-rain nets are made of high-density polyethylene (HDPE), a non-toxic, recyclable, and waterproof material, which offers durability and strong resistance, especially to atmospheric agents. The meshes are made in such a way as to create a sufficiently dense weave that allows for optimal air passage while preventing raindrops from passing easily. The porosity and colour of nets regulate the intensity and quality of the transmitted radiation [1]. Mesh sizes vary according to the type of protection required. For rain protection nets, the mesh openings are very small, e.g., 0.03 × 0.94 mm, to effectively reduce the penetration of raindrops through the net without eliminating natural ventilation. The colour of agricultural nets plays a key role in the optical and thermal performance of the materials, influencing the balance between reflected and absorbed solar radiation. Light-coloured and transparent nets allow greater transmission of photosynthetically active radiation (PAR) and global solar radiation and produce a milder shading effect [19]. Anti-rain nets are commonly manufactured in neutral, white, or grey colours, to protect crops without significantly altering light conditions.

Anti-rain nets can limit water permeation, but their effectiveness depends on the material’s characteristics, such as the size and arrangement of the threads, which determine the shape and size of the pores. Similarly, these characteristics influence air permeability [20] and thus also air relative humidity [14]. Air permeability is a fundamental parameter for anti-rain nets, as it enables air exchange between the external environment and the protected area, contributing to the regulation of internal relative humidity. It represents the ability of the mesh material to allow air to pass through its structure and depends on multiple factors, including air flow velocity, the diameter and thickness of the threads, the mesh size, and the surface porosity of the fabric. In particular, it has been observed that an increase in porosity leads to a reduction in aerodynamic resistance and in the loss coefficient of the material, with reference to the pressure drop of the air flow through the net. However, the relationship between porosity and permeability is not linear and is also influenced by the air flow regime and the three-dimensional structure of the net [21]. Conventionally, porosity has been described as a two-dimensional (2D) parameter, calculated as the ratio of the open area to the total area of the fabric viewed in a plane. However, recent developments also highlight the importance of three-dimensional (3D) porosity, which considers the volumetric structure of the material and provides a more accurate representation than traditional 2D approaches, especially for woven fabrics such as nets [22,23]. Volumetric porosity has been estimated using mathematical and computational models that replicate the material’s geometry. Based on measurable parameters, such as thread diameter, the distance between them, and the overall thickness of the fabric, acquired through optical microscopy or 3D scanning, these models reconstruct the 3D fabric structure to calculate total and void volumes. This approach allows for accurate visual representation, volumetric porosity evaluation, and prediction of its effects on air permeability and mechanical strength. Despite these advances, a comprehensive understanding of how porosity influences the aerodynamic behavior of agrotextiles is still lacking. Models based on 2D porosity have shown good correlations only within a limited range of porosity values, making them less effective in representing structures characterized by very high or very low porosity [21]. At the same time, 3D models are still unable to describe the behavior of more complex structures (such as Leno or Raschel) or in cases where the structure is made up of polyethylene strips instead of conventional threads [21].

Only a few laboratory tests were carried out to assess the efficiency of anti-rain nets using a specific rainfall simulation device designed to test agrotextiles samples at different inclinations and with a predetermined rainfall intensity [14]. A rain permeability index was defined and calculated as the ratio between the water passing through the net sample and the water sprayed by the nozzles of the rain simulator. This method allows an experimental agrotextile performance to be verified before it can be tested in the open field and subsequently marketed.

Currently, there are no standardized procedures for testing and comparing the rainwater permeability of crop protection nets, nor is there an internationally accepted index for classifying these nets based on their effectiveness in shielding crops from rainfall. Moreover, given the limited availability of experimental studies on nets specifically designed for rain protection, the influence of net geometric properties on rain permeability remains unclear, in contrast to the well-documented effects on air permeability, radiometric behaviour, and mechanical performance.

The present study aims to deepen the knowledge of the structural and functional characteristics of agrotextiles, with particular reference to anti-rain capability, in order to support the adoption of more effective and sustainable agronomic strategies. The specific objectives are to evaluate the rain and air permeability properties of agrotextiles intended for rainwater and insect control, to investigate their performance under different operating conditions, and to analyse the influence of the geometric characteristics on their performance. The effect of inclination relative to the horizontal plane on the hydraulic behaviour of agrotextiles has been investigated, with the aim of laying the basis for guiding the development of new design solutions for better performing agricultural cover systems, depending on the agronomic and climatic context. This type of experimental activity offers relevant insights for developing technical and scientific guidelines aimed at adopting innovative and customized agrotextiles, supporting the evolution of agricultural practices in response to climate change. The results of this study may support the development of a standardized procedure for characterizing agrotextiles in terms of rain permeability, with the ultimate aim of providing farmers and agronomists with practical information to cope with climate change and heavy rainfall events, reduce water-related risks, and ensure greater production stability. The adoption of tested and certified agrotextiles represents an innovative strategy to strengthen the resilience and sustainability of agricultural systems in the face of rapid climate change.

2. Materials and Methods

Agrotextiles marketed by their producers as specific rain protection nets were selected. These nets are characterized by a particularly low porosity (almost 10%). To obtain a more significant variability in the results as a function of the net’s geometric characteristics, other nets with same kind of threads and woven, marketed as insect-proof (anti-insect), were also chosen. These nets are characterised by a higher porosity, which was, however, less than 50%. Specifically, eight different types of nets were selected. Three novel nets marketed as “anti-rain” nets were considered; they are designed with innovative features related to the protection of tree or herbaceous crops from the rain. Being semi-permeable covers, they offer a partial protection from rainwater. The other five are conventional anti-insect nets, having different levels of porosity. To identify the different nets, codes related to the main function of the net, whether anti-rain (AR) or anti-insect (AI), were used (Table 1).

Table 1.

Agrotextiles selected for experimental analysis.

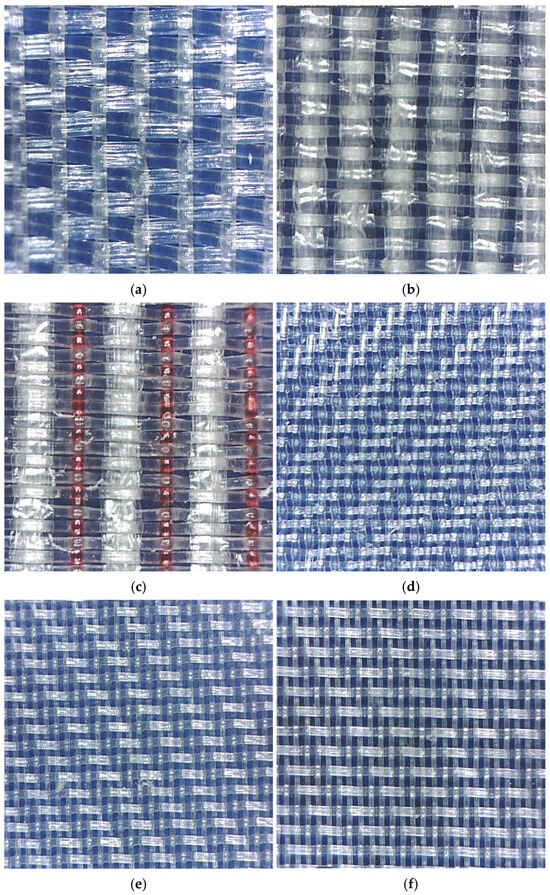

Figure 1 below shows some images of the eight examined nets.

Figure 1.

Samples of the nets selected for experimental research: (a) AR-1; (b) AR-2; (c) AR-3; (d) AI-1; (e) AI-2; (f) AI-3; (g) AI-4; (h) AI-5. Images are not in the same scale.

AR-1 net is designed to protect crops from rain, and also from hail, sun, wind and insects. This net is a flat woven one made with HDPE monofilament warp and weft, a very dense mesh, and hence a low porosity. This net has a weft thread type (rhomboid) with a major diagonal of 0.49 mm and a minor diagonal of 0.22 mm. The major diagonal lies in the net plane, while the minor diagonal is perpendicular to the net plane. For the purposes of the analytical calculation of the porosity, the major diagonal is considered.

AR-2 and AR-3 nets are novel flat woven anti-rain and anti-insect nets made with HDPE round monofilament warp and weft in fibrillated raffia tape. These nets are not completely waterproof but manage to block water droplets while providing air permeability. They are proposed by the manufacturer mainly to prevent or limit the wetting of fruits susceptible to the cracking phenomenon, as well as protecting from hail, frost, wind and excessive solar radiation. Both AR-2 and AR-3 are characterized by a dense mesh, with the AR-3 having a tighter mesh. They are neutral in colour. AR-3 has also the addition of 3.8 cm red and neutral bands (consisting of a total of 4.7 fibrillated bands/cm alternating with 4.7 red weft threads) every 24.2 cm.

AI-1 and AI-4 nets are flat woven anti-insect nets, in particular for the protection from thrips (Thripidae Stevens, 1829), made with HDPE round monofilament warp and weft. Their innovative design allows them for small hole sizes and high efficiency in excluding insects. By using a very thin and high tenacity yarn, nets were obtained with more holes per square metre with the same hole size as commonly used insect-nets, and consequently greater porosity and increased air passage through the nets. Additionally, using a greater number of yarns, more structured, stable and uniform nets were obtained. AI-1 has a tighter knit with a smaller mesh size and smaller holes, with respect to AI-4.

Also, AI-2 and AI-3 nets are flat woven anti-insect nets made with small-diameter fibres that exclude very small insects such as thrips while allowing good air flow, and thus a cooler and less humid climate in greenhouses. They are manufactured with round monofilament warp and weft.

AI-5 is a flat woven anti-insect net with round monofilament warp and weft, with 20 warps per centimetre, and 10 wefts per centimetre. AI-5 is a type of net very widely used in agriculture to protect crops from smaller insects such as aphids.

All these AR and AI nets are neutral in colour, which ensures good solar light transmission.

2.1. Geometrical Characteristics of the Nets

When using agrotextiles correctly, porosity is a key technical characteristic that must be taken into account. The porosity of a geometric structure represents the percentage of open area relative to the total area of the mesh. This parameter can be determined through a variety of methods including radiation balance, solar radiation interception and material image analysis [24]. The thickness of the net threads was measured using a micrometer with an accuracy of ±0.01 mm. Before taking measurements, the micrometer was calibrated using certified calibration blocks to ensure the accuracy of the readings. The size of the voids was measured through image analysis methods. A digital microscope (model Dino-Lite AM3013T, Dino-Lite Europe, IDCP B.V., Almere, The Netherlands) with an accuracy of ±0.04 mm at a magnification of 200× was used to capture the images and then Dino-Capture software (version 2.0, Dino-Lite Europe, IDCP B.V., Almere, The Netherlands) was used to measure the voids’ dimensions. The microscope was calibrated using the manufacturer’s calibration slide, and calibration was repeated at the start of each measurement session to minimise drift.

The porosity of the nets (ε [%]) was estimated by analysing images [25] which were acquired using a flatbed scanner at a resolution of 2400 dpi. The scanner was calibrated by comparing scanned images of a precision calibration grid (10 mm × 10 mm) with its known geometrical values to verify dimensional accuracy. The images were processed using Adobe Photoshop software (version 2021, Adobe, San Jose, CA, USA). Each image was binarised, with black being assigned to the net and white to the gaps. The gray threshold value was set to 128 (neutral gray threshold). On each image, a representative area (10 cm × 10 cm) was identified and the percentage of white pixels with respect to the entire selected portion of the image was calculated to estimate porosity. Measurements were taken on at least three different representative areas for each sample and the final value of ε was obtained as the average of the results. The measured pore size and fibre thickness closely matched the manufacturers’ specifications, and the resulting porosity values were consistent with the reference data.

For meshes with extremely narrow openings, determining porosity via image analysis is not feasible. In this case, an analytical calculation was performed according to the following Formula (1):

where the parameters dwarp [mm] and dweft [mm] represent the diameters of the monofilaments oriented along the warp and weft directions, respectively; similarly, lwarp [mm] and lweft [mm] refer to the lengths of the voids between filaments in the warp and weft directions, respectively. Analytical calculation was used to determine the porosity of the AR-1 net only, as the mesh density was so high that image analysis would have provided negligible or unreliable results.

2.2. Air Permeability Tests

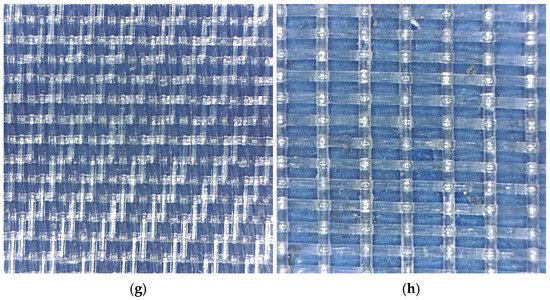

The overall characterization of the tested agrotextiles was conducted by measuring the air permeability Ka [mm s−1] index of the nets. The determination of Ka is done according to the UNI EN ISO 9237:1997 standard methodology [26]. Air permeability tests were carried out at the “Testing and Engineering Laboratory” of Arrigoni S.p.A. (Uggiate-Trevano, Italy), using a micro wind tunnel (Figure 2). The wind tunnel, in stainless steel, is equipped with a circular test cross-section of diameter 0.051 m, and incorporates test segments located upstream and downstream of the sample, each 0.989 m in length. An industrial blower model CIMME-Mediojet (2.2 kW, 300 rpm, pressure range −19.5/+18.5 kPa; manufactured by CIMME, Guardamiglio, Italy) was used for air flow generation. The system enables air flow velocity within the range 0–15 m s−1. The pressure differentials across the net sample have been monitored using a pressure gauge (model MM200600, Aerofiltri S.R.L., Milan, Italy), capable of detecting variations in the range of 0–200 ± 5 Pa. To minimise the influence of the net on the inlet and outlet air flow, the pressure measuring ports were placed at a distance exceeding five times the diameter of the test section. The air flow rate through the wind tunnel was quantified using a digital air flow sensor (model PF2A 721H, SMC ITALIA S.p.A., Brugherio, Italy) featuring a measurement range of 0.01–0.20 ± 1.7 10−4 m3 s−1, an accuracy ± 5% of full scale, and operating pressures between 0.1 and 1.5 MPa. The air flow sensor was installed in series with the net under investigation.

Figure 2.

Schematic representation of the testing system used for the air permeability tests.

The distributed pressure drop, which can be attributed to the internal roughness of the duct, was quantified by means of three measurements taken at different air velocities in the absence of the net sample. For each sample tested, the average value of the distributed pressure drop values, determined as a function of the air flow velocity, was subtracted from the collected experimental data. In the fluid dynamics calculations, the air velocity was determined with reference to the wind tunnel cross-section area.

During the tests, the ambient temperature was kept constant at 20 ± 1 °C in accordance with the sensor specifications. The air permeability test was conducted by applying a pressure difference of 50 Pa to the sample and adjusting the fan speed accordingly. After stabilising the system, the air flow rate through the net inside the wind tunnel was measured and used to calculate Ka. This study reports the results for the air flow perpendicular to the samples, with an air velocity varying from 5 to 15 m s−1. This range of air velocity values is commonly employed for investigating the nets’ aerodynamic characteristics and quantifying the wind loads on the structure. These high velocities are functional for achieving the 50 Pa pressure difference mandated by the UNI EN ISO 9237:1997 standard. While the system enables air flow velocity within the range 0–15 m s−1, calibration trials indicated high fluctuations in measured values within the 0–5 m s−1 range. Consequently, the results presented herein are restricted to the 5–15 m s−1 range.

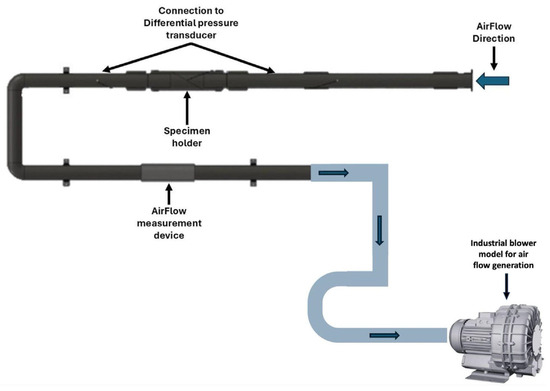

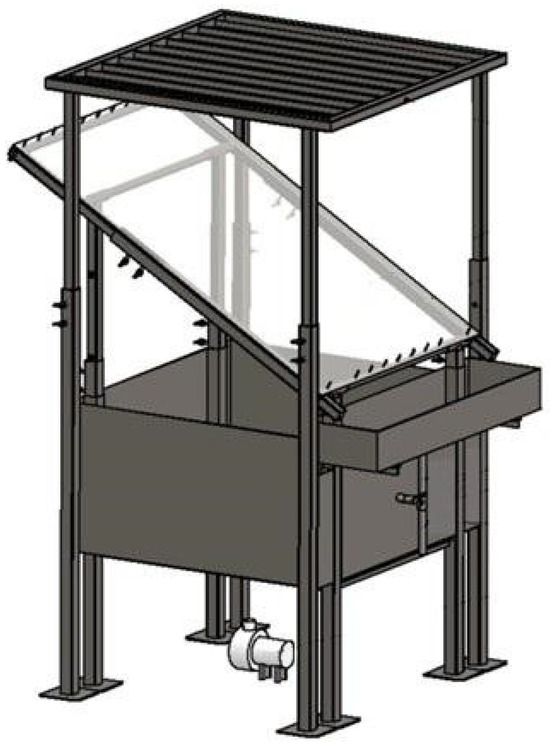

2.3. Rainwater Permeability Laboratory Tests

The experimental setup for rainwater permeability testing (Figure 3) evaluates the capacity of an agrotextile to allow rainwater to pass through to the crops and soil below using a rain simulator test bench. This apparatus comprises several water-spraying nozzles, a steel frame supporting net samples exposed to simulated rainfall at inclinations ranging from 0° to 45°, a container collecting water that passed through the nets, and a custom-designed measurement system [14]. The nozzles are spaced at an average distance of 130 cm from the fabric and distribute the water flow evenly over the fabric’s surface area (measuring 1 m2 on a horizontal projection) under test. A centrifugal pump at the bottom recirculates the water back to the nozzles for continuous operation. This system enables the calculation of the rainwater permeability index Φrw [%], which is defined as the ratio of the amount of water that penetrates through a net sample, to the amount of water that falls on the net sample. Using this system, the index Φrw can be calculated as the ratio between the water collected in the container beneath the net sample (V [dm3]) and the total water sprayed by the nozzles:

where Q [dm3 s−1] is the sprayed water flow rate, and t [s] is the duration of the simulated rainfall.

Figure 3.

Layout of the system for testing the permeability of HDPE nets to rain.

The tests were conducted for a duration of 10 min each, under a rainfall intensity equivalent to 60 mm h−1.

2.4. Statistical Analysis

Three repetitions of the air permeability test were performed for each net sample, and the Ka average values and corresponding standard deviations were calculated.

To determine the rainwater permeability indices at 10° and 30°, tests were repeated three times for each net sample and for each slope angle, and then the Φrw average values and standard deviation were calculated, under steady-state conditions.

To assess the relationship between rainwater permeability, air permeability, and geometrical porosity of the nets, a simple linear regression analysis was conducted as follows, using the mean values to reduce experimental variability. Rainwater permeability indices were considered at the two slope angles (10° and 30°), and regressed against Ka and ε. For each pair of variables, linear regression was applied, and the coefficient of determination (R2) and the p-value were used to evaluate model fit and statistical significance. All analyses were performed using Excel’s Analysis ToolPak (Microsoft® Excel® for Microsoft 365 MSO, Version 2509).

3. Results

3.1. Results of the Geometrical Analysis

Table 2 summarises the main technical and structural parameters of the eight different types of agrotextiles analysed, highlighting differences in their physical and functional characteristics. The number of warps per centimeter (nwarp), the number of wefts per centimeter (nweft), the diameter of the warp (dwarp), the diameter of the thread (dweft), the porosity of the net and the weight of the test sample are shown.

Table 2.

Technical and structural characteristics results of the tested agrotextiles.

The anti-rain nets (AR) show a variable warp density (nwarp) and weft (nweft). For example, AR-1 has a high number of warp threads (32.00/cm) but a low weft density (7.00/cm), whereas AR-2 has a less dense warp (20.80/cm) and a higher weft density (9.44/cm). These differences indicate that, within the AR group, the mesh configuration varies considerably, affecting the overall compactness of the net. In the anti-insect nets (AI) group, nets such as AI-1 and AI-2 show a very uniform structure, with values of nwarp and nweft of approximately 31 threads per centimetre, while AI-5 is characterised by a lower density (20.40 and 9.80, respectively), resulting in increased porosity. Group (AR) nets generally employ thicker threads in the warp (e.g., AR-1 has a dwarp of 0.490 mm) and dweft (AR-1: 0.280 mm) than some AI-nets, which use thinner threads (0.150–0.170 mm). This aspect suggests that AR-nets may offer greater mechanical strength, whereas AI-nets, with their finer threads, are lighter and more flexible.

Porosity values vary widely. The selected AR-nets are characterised by a very tight mesh, with percentages of open area ranging from 6.90% (AR-1) to 18.00% (AR-2), suggesting greater protection from rainwater, hail and solar radiation, but limited air permeability. In contrast, the analysed AI-nets offer higher porosity, with values rising to 41.00% in AI-5. This high void area of the net meshes indicates a better capacity to allow ventilation.

The weight of the samples is significantly higher for the nets in the (AR) group, with AR-1 reaching approximately 250 g/m2, while the nets in the (AI) group are significantly lighter, with values ranging from 120 to 136 g/m2. The greater weight, together with the higher density and diameter of the threads in the AR-nets, gives them greater strength, while the lightness of the AI-nets may favour their application in contexts where greater breathability and ease of installation is required.

The data show a clear distinction between the two categories: AR-nets, with a more compact mesh and thicker threads, are designed to offer protection and durability against meteoric events, while AI-nets, characterised by greater porosity and lightness, are more suitable for applications that require good ventilation, light transmission, and lower handling costs. The choice between the two types should be guided by the specific agronomic needs and operating conditions in which they will be used.

3.2. Air Permeability Results

Table 3 summarises the results of the air permeability tests conducted on the eight types of nets, highlighting the air permeability Ka values.

Table 3.

Air permeability index of the tested agrotextiles. Average values and corresponding standard deviations are reported.

The Ka parameter is a key indicator for evaluating the suitability of nets in agronomic applications such as climate regulation and crop ventilation. Ka values vary widely among the tested agrotextiles, ranging from 620.12 mm s−1 (AR-1) to 5233.86 mm s−1 (AI-5). Low permeability agrotextiles (Ka ≤ 900 mm s−1), such as AR-1 (620.12 mm s−1), AR-3 (686.62 mm s−1), and AR-2 (879.66 mm s−1), provide a substantial barrier to air flow, making them suitable for scenarios where reducing wind ingress or heat loss is a priority. However, their limited air permeability may also increase the risk of moisture accumulation. Medium permeability agrotextiles (900 < Ka ≤ 3000 mm s−1), such as AI-1 (2676.80 mm s−1), offer a balanced solution providing adequate ventilation without significantly compromising protective functions. Finally, high-permeability agrotextiles (Ka > 3000 mm s−1), such as AI-2 (3438.54 mm s−1), AI-4 (3604.45 mm s−1), AI-3 (3895.60 mm s−1) and AI-5 (5233.86 mm s−1) allow a good passage of air, making them ideal for hot climates or crops that need ventilation to avoid heat and moisture stagnation.

Low permeability nets applications (AR-2, AR-3, AR-1) could be an ideal choice for high wind environments or for protection from dust and pesticides. They might allow tighter control of microclimatic conditions. Medium permeability agrotextile applications (AI-1) could be suitable for crops requiring moderate protection, such as sensitive orchards or vegetables. They might balance weather protection and sufficient ventilation. Finally, high-permeability agrotextiles (AI-5) could be used in hot, humid climates where good ventilation is essential for reducing the risk of fungal diseases. They could also be used to cultivate crops that are less susceptible to wind and dust, such as certain fast-growing fruit and vegetable varieties.

3.3. Laboratory Results on Rainwater Permeability

Table 4 summarises the results of the rainwater permeability tests, highlighting two main parameters, namely the rainwater permeability at a slope angle of 10° (Φrw10 [%]) and of 30° (Φrw30 [%]).

Table 4.

Results of rainwater permeability test of the tested agrotextiles. Average values and corresponding standard deviations are reported.

For all samples, a decrease in the percentage of water permeability is observed as the slope increases. This is consistent with the expected behaviour, i.e., at greater inclinations, the component of gravitational force acting along the surface increases, facilitating water runoff and reducing the amount of water that can infiltrate through the net. The agrotextiles in the AR group (AR-1, AR-2, AR-3) being anti-rain nets, present lower Φrw values than the other agrotextiles tested. For example, AR-1 shows Φrw10 values of 18.60% and Φrw30 of 13.60%. Among the AR nets, AR-2 records a higher Φrw10 (25.30%) and, as the slope angle increases up to 30°, maintains the highest permeability, compared to AR-1 and AR-3. AR-3, while having a Φrw10 (24.60%) only slightly lower than AR-2, records the lowest Φrw30 value (12.40%), indicating a greater sensitivity to increasing slope. AI-nets (AI) show significantly higher Φrw values than AR-nets, indicating a structure that allows more water to pass through. For example, AI-5 achieves the highest value of rainwater passage, with Φrw10 and Φrw30 of 91.30% and 81.00%, respectively.

With a significantly higher rainwater permeability index, AI-nets moderately allow water to pass through. This can be advantageous in tropical contexts, characterised by particularly violent rainfall events, by reducing stresses on the supporting structure of the nets. AR nets, on the other hand, with lower Φrw values, can offer greater control over the passage of rainwater, protecting crops with fruits particularly sensitive to the cracking phenomenon, from overwatering or heavy rainfall. If, on the other hand, more protection against excess water is required, for example, in regions subject to heavy rainfall or in crops requiring controlled irrigation, AR-nets could offer an advantage, due to their lower permeability.

Evaluating the values of Φrw allows understanding how each net manages the balance between the passage of water and the protection of cultivated material. An appropriate choice of net must consider not only absolute rainwater permeability, but also its variation as a function of slope, a critical element in many agricultural contexts.

3.4. Relationships Between Rainwater Permeability, Air Permeability, and Geometrical Porosity

The relationship between the rainwater permeability index (Φrw10 and Φrw30) and porosity ε [%] was analysed using a scatter plot (Figure 4) as well as the relationship between the rainwater permeability index the air permeability index (Φrw10 and Φrw30) and the air permeability index (Ka) was analysed using a bubble chart (Figure 5 and Figure 6), where the size of each bubble represents the geometric porosity ε [%] of the nets. The data in Figure 5 show the differences between the two categories under investigation. The anti-rain nets (AR), characterised by a tight and compact mesh, are located in the low-permeability area (Φrw10 < 30%, Ka < 1000 mm s−1), while anti-insect nets (AI), with a less dense textile configuration, display considerably higher values for both indices, reaching Φrw10 > 90% and Ka > 5000 mm s−1% in the case of the AI-5 net. The distribution of points in the chart confirms a positive correlation between the two indices and highlights the discriminating role of geometric porosity: nets with higher ε values (e.g., AI-5, ε = 41%) tend to show higher permeability to both air and water, while those with lower porosity (e.g., AR-1, ε = 6.9%) show lower permeability levels.

Figure 4.

Relationship between porosity ε [%] and the rainwater permeability index Φrw [%] (at 10° and 30° inclination), with linear regression lines and corresponding coefficients of determination (R2).

Figure 5.

Bubble chart of Φrw10 versus Ka. The size of each bubble represents the porosity (ε) of the nets. A linear regression line is included with the corresponding coefficient of determination (R2).

Figure 6.

Bubble chart of Φrw30 versus Ka. The size of each bubble represents the porosity (ε) of the nets. A linear regression line is included with the corresponding coefficient of determination (R2).

As expected, Φrw30 (Figure 6) is generally lower than Φrw10, mainly due to the different angle of impact of the water flow. However, compared to the 10° slope case, the distribution of points appears more linear, especially with regard to the anti-insect nets: the increase in Φrw30 follows a more regular trend as Ka increases. The comparison between the two charts highlights how the slope angle can influence the hydraulic behaviour of the nets.

The results of the regression analysis emphasize that Ka is a significantly more reliable predictor of rainwater permeability than porosity. Specifically, the coefficient of determination (R2) between Φrw and Ka reached 0.95 (p < 0.0001) at a 10° inclination and 0.99 (p < 0.0001) at 30°, indicating an almost perfect linear relationship. In contrast, the R2 values for the relationship between Φrw and ε ranged from 0.86 (p = 0.0010) to 0.92 (p = 0.0002), suggesting that, although porosity plays a role, it does not fully account for the fluid–structure interaction involved in rainwater infiltration. The geometric analysis, although informative, does not account for three-dimensional effects such as filament overlap, tortuosity, and partial obstructions.

4. Discussion

The outcomes of this study directly address the research objectives by demonstrating how structural and functional features of agrotextiles strongly influence their capacity to provide rain protection when tested under controlled simulated scenarios. The results obtained provide important evidence of the effectiveness of the tested anti-rain nets in improving rainwater permeability management.

The performance of the different materials evaluated was analysed considering key parameters such as water permeability, air permeability, porosity, and other geometric characteristics. The morphological and structural analysis of the nets highlighted a clear distinction between AR and AI nets in terms of weaving density, filament thickness, and geometric porosity. The AR nets, designed to limit rainwater penetration, have more compact meshes, thicker threads, and lower porosity (e.g., AR-1 with ε = 6.90%). In contrast, AI nets, aimed at insect exclusion while maintaining good ventilation, show a higher porosity (up to 41% in AI-5). These structural differences translate into significantly different aero-dynamic and hydraulic behaviours, with relevant agronomic implications. The air permeability index (Ka) values proved to be consistent with the geometric properties of the nets. AI nets recorded significantly higher values than AR nets, with AI-5 reaching a Ka of 5233.86 mm s−1. AR nets, with Ka ≤ 900 mm s−1, are confirmed suitable for scenarios where reducing ventilation and air currents is necessary, such as in the case of crops sensitive to wind or to the dispersion of chemical treatments. This dichotomy suggests that AI nets are more suitable for hot and humid climates, where ventilation is crucial to avoid thermal stagnation and the proliferation of fungal pathogens. AR nets, on the other hand, in addition to rain control, are effective for passive protection against abiotic stresses such as strong winds or excessive temperature variations. Rainwater permeability tests confirmed the high capacity of AI nets to let water pass (Φrw10 up to 91.30% for AI-5), while AR nets showed lower values, consistent with their protective purpose. The inclination of the sample also had a significant influence: all samples showed a reduction in Φrw from 10° to 30°, due to the increase in the tangential component of the gravitational force, which favours surface flow. The consistent reduction in water permeability with increasing slope inclination highlights the critical role of installation geometry in orchards applications, thereby fulfilling the aim of assessing operational conditions.

It is important to emphasize the discriminating role of Ka, as the regression analysis demonstrated that air permeability (Ka) is a more reliable predictor of rainwater permeability than geometric porosity (ε). This evidence underlines the importance of dynamic experimental measurements over geometric characterisation alone, thus addressing the objective of identifying meaningful performance indicators especially for applications where the management of air and water flows is critical. Selecting the most suitable net solutions requires evaluating not only parameters such as porosity and weight, but also dynamic variables such as Ka, and Φrw, as well as the spatial configuration of the system, particularly slope.

The results of this study represent an advancement compared to previous research, both in terms of the number of nets tested and the methodological approach adopted. Castellano et al. [14], analysed rainwater permeability on a limited set of nets, focusing on two-dimensional porosity, slope, and double-layer configurations. Geometric porosity was found to have little influence, whereas mesh size, inclination, and the presence of a double layer significantly affected the rainwater permeability behaviour of the nets. Our study expanded both the number and types of nets examined, including those specifically designed for rain protection as well as insect-proof nets, thereby providing a more comprehensive overview of the relationships between structural parameters, air permeability, and rainwater permeability.

In this study, laboratory tests on rainwater permeability were undertaken to ensure standardized and highly reproducible conditions, which would not be achievable under natural rainfall events due to their intrinsic variability, thus allowing for a high number of experimental replications. On the other hand, the applied methodology has certain limitations, in the determination of the Φrw index, linked to the geometry of the laboratory rain simulator. In this regard, simulated rainfall cannot accurately represent open field conditions, due to the fixed distance between the nozzles and the tested net. In open-field conditions, the rainfall height is significantly greater than in the laboratory setup employed, which inevitably influences droplet size and distribution, as well as impact velocity. Under field conditions, factors such as wind dynamics, varying rainfall intensity, and increased drop fall distances may lead to permeability performance that differ from those observed in controlled laboratory tests. These differences highlight how laboratory conditions cannot fully replicate the complexity of natural rainfall; consequently, the results presented here should be regarded as preliminary and interpreted as comparative indications rather than absolute measures of the net performance. Future research could investigate, through open-field trials, the influence of additional descriptors, such as variable rainfall intensity and wind direction and speed in relation to the orientation of the nets, to obtain a more realistic and comprehensive assessment of the performance of the nets. These tests will be useful for calibrating the laboratory setup and for analysing how environmental conditions affect the rainwater permeability properties of the nets. The ultimate goal is to develop evaluation procedures that integrate parameters such as Ka and Φrw with other descriptors, thereby providing more effective tools for the design and selection of multifunctional nets adapted to different crop and climatic contexts. Moreover, the framework developed around Ka and Φrw represents a necessary preliminary step towards a broader performance assessment. Indeed, the results on rainwater and air permeability could be further related to complementary performance indicators, namely radiometric characteristics, and mechanical resistance, also after artificial aging of the nets. This approach will make it possible to identify a more complete range of descriptors that reflect multiple performance dimensions at the same time.

Boutry et al. [27] evaluated in the field an integrated system combining waterproof coverings and insect-proof netting, observing a reduction in fungal diseases and pests on apple trees. However, their study did not include an analysis of the physical–mechanical and functional properties of the materials used, nor a quantitative assessment of air and rainwater permeability. Our approach enabled the quantification of these parameters across different types of nets, providing technical guidance for the design of covering systems that effectively balance rain protection with adequate ventilation. This functional assessment can serve as an operational tool for selecting nets which, if appropriately combined in the field, can provide agronomic benefits like those observed by Boutry et al. [27], but with a deeper understanding of the intrinsic performance of the materials used.

Overall, the findings support the study’s initial aims of assessing the structural and functional properties of agrotextiles and advancing knowledge on their influence on rain permeability under different slope conditions, thereby providing a robust framework for the development of more effective agrotextile-based crop protection systems. Further optimisation of geometric, physical, and mechanical characteristics will be essential to improve overall efficiency and should represent a key direction for future research.

5. Conclusions

Plastic agrotextiles are becoming increasingly specific and customised, particularly for applications such as rain control, and are still under development. In this study, two types of agrotextiles were analysed: anti-rain agrotextiles and anti-insect agrotextiles with different structural characteristics. We examined nets with a narrow mesh configuration suitable for different types of control. The objective of this study was to evaluate the rainwater permeability properties of anti-rain and anti-insect agrotextiles. It has been demonstrated that the porosity of agrotextiles is a key parameter for rain control and for improving the air permeability of agrotextiles. However, this study supports the conclusion that functional measurements like air permeability—which intrinsically reflect the dynamic behaviour of the flow through the net—are better suited for estimating the net’s water permeability under rainfall conditions than static, image-based geometric descriptors. The analysed anti-rain nets can effectively control rain at a slope angle of 30° compared to the other nets studied, demonstrating greater effectiveness in reducing rainwater passage. Agrotextiles such as the analysed anti-insect nets are better suited to contexts where insect exclusion is more important than protection from rain, e.g., in the presence of crops particularly susceptible to virosis in hot, dry climates, such as tomatoes and peppers. The inclination with respect to the horizontal plane plays a fundamental role on water permeability, which could support the structural upgrading of crop protection systems for new production standards with new design features related precisely to anti-rain agrotextiles. These results provide a foundation for further testing on a larger number and variety of net, with the aim of improving their design to identify solutions that enhance not only rainwater permeability but also complementary properties such as ventilation performance, radiometric behaviour and mechanical strength, which are essential in specific application contexts.

In conclusion, our study contributes to strengthening knowledge on the use of agrotextiles in agriculture. Greater standardisation is needed in the way technical information on agrotextiles is provided. Product sheets for anti-rain nets should report the rainwater permeability index (Φrw), measured at different installation angles and determined according to a uniform procedure, in order to allow clear comparison of performance across products. Similarly, for anti-insect nets, the air permeability index (Ka) should be systematically reported. This would provide farmers and technicians with clear operational instructions for selecting the most appropriate net and installation method based on crop requirements and climatic conditions. Continued innovation in this area will be instrumental to addressing the challenges posed by climate change.

Author Contributions

Conceptualization, I.B., S.C., G.S.M., R.P., G.M. and P.P.; methodology, I.B., S.C., G.S.M., A.M.N.M. and P.P.; validation, G.S.M., and P.P.; formal analysis, A.M.N.M., R.P. and G.M.; investigation, A.M.N.M., S.C., R.P. and G.M.; resources, S.C., I.B. and G.S.M.; data curation, R.P., A.M.N.M. and G.M.; writing—original draft preparation, I.B., R.P. and G.M.; writing—review and editing, I.B., S.C., G.S.M., A.M.N.M. and P.P.; visualization, A.M.N.M., P.P., R.P. and G.M.; supervision, I.B., S.C. and P.P.; project administration, G.S.M.; funding acquisition, I.B., S.C., G.S.M. and P.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union—Next-GenerationEU—National Recovery and Resilience Plan (NRRP)—MISSION 4 COMPONENT 2, INVESTMENT N. 1.1, CALL PRIN 2022 PNRR D.D. 1409 14-09-2022—Project Title “RESCUE-NETS—RESilience to Climate change in agricultural production under multi-pUrposE NETS”—Cod. Prog. P2022YSF3K—CUP D53D23022120001.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Castellano, S.; Scarascia Mugnozza, G.; Russo, G.; Briassoulis, D.; Mistriotis, A.; Hemming, S.; Waaijenberg, D. Plastic Nets in Agriculture: A General Review of Types and Applications. Appl. Eng. Agric. 2008, 24, 799–808. [Google Scholar] [CrossRef]

- Manja, K.; Aoun, M. The Use of Nets for Tree Fruit Crops and Their Impact on the Production: A Review. Sci. Hortic. 2019, 246, 110–122. [Google Scholar] [CrossRef]

- Kalcsits, L.; Musacchi, S.; Layne, D.R.; Schmidt, T.; Mupambi, G.; Serra, S.; Mendoza, M.; Asteggiano, L.; Jarolmasjed, S.; Sankaran, S.; et al. Above and Below-Ground Environmental Changes Associated with the Use of Photoselective Protective Netting to Reduce Sunburn in Apple. Agric. For. Meteorol. 2017, 237–238, 9–17. [Google Scholar] [CrossRef]

- Mupambi, G.; Musacchi, S.; Serra, S.; Kalcsits, L.A.; Layne, D.R.; Schmidt, T. Protective Netting Improves Leaf-Level Photosynthetic Light Use Efficiency in ‘Honeycrisp’ Apple Under Heat Stress. HortScience 2018, 53, 1416–1422. [Google Scholar] [CrossRef]

- Álvarez, A.J.; Oliva, R.M.; Martínez-Valderrama, J. The Efficacy of Protective Nets Against Drosophila suzukii: The Effect of Temperature, Airflow, and Pest Morphology. Insects 2025, 16, 253. [Google Scholar] [CrossRef] [PubMed]

- Giannoulis, A.; Briassoulis, D.; Papardaki, N.-G.; Mistriotis, A. Evaluation of Insect-Proof Agricultural Nets with Enhanced Functionality. Biosyst. Eng. 2021, 208, 98–112. [Google Scholar] [CrossRef]

- Kabir, M.Y.; Nambeesan, S.U.; Díaz-Pérez, J.C. Shade Nets Improve Vegetable Performance. Sci. Hortic. 2024, 334, 113326. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.; Al-Helal, I.; Alkoaik, F.; Alsadon, A.; Shady, M.; Ibrahim, A. Predicting the Cooling Potential of Different Shading Methods for Greenhouses in Arid Regions. Energies 2019, 12, 4716. [Google Scholar] [CrossRef]

- Ahmed, H.A.; Tong, Y.; Yang, Q.; Al-Faraj, A.A.; Abdel-Ghany, A.M. Spatial Distribution of Air Temperature and Relative Humidity in the Greenhouse as Affected by External Shading in Arid Climates. J. Integr. Agric. 2019, 18, 2869–2882. [Google Scholar] [CrossRef]

- Manzoor, A.M.; Xu, Y.; Lv, Z.; Xu, J.; Shah, I.H.; Sabir, I.A.; Wang, Y.; Sun, W.; Liu, X.; Wang, L.; et al. Horticulture Crop under Pressure: Unraveling the Impact of Climate Change on Nutrition and Fruit Cracking. J. Environ. Manag. 2024, 357, 120759. [Google Scholar] [CrossRef]

- Shelake, R.M.; Wagh, S.G.; Patil, A.M.; Červený, J.; Waghunde, R.R.; Kim, J. Heat Stress and Plant–Biotic Interactions: Advances and Perspectives. Plants 2024, 13, 2022. [Google Scholar] [CrossRef] [PubMed]

- Winkler, A.; Knoche, M. Penetration of Sweet Cherry Skin by 45Ca-Salts: Pathways and Factors. Sci. Rep. 2021, 11, 11142. [Google Scholar] [CrossRef]

- Wójcik, P.; Akgül, H.; Demirtaş, İ.; Sarısu, C.; Aksu, M.; Gubbuk, H. Effect of Preharvest Sprays of Calcium Chloride and Sucrose on Cracking and Quality of ‘Burlat’ Sweet Cherry Fruit. J. Plant Nutr. 2013, 36, 1453–1465. [Google Scholar] [CrossRef]

- Castellano, S.; Lippolis, M.; De Musso, M.; Starace, G. Evaluation of Rain Permeability of Agricultural Nets: First Experimental Results. In Proceedings of the 11th International AIIA Conference, Bari, Italy, 5–8 July 2017; Italian Association of Agricultural Engineering (AIIA): Rome, Italy, 2017. [Google Scholar]

- Țilincă, L.T.; Stănică, F. Influence of the Protective Nets on Fruit Production in Modern Orchards—A Review. Sci. Papers. Ser. B Hortic. 2024, LXVIII, 182–184. [Google Scholar]

- Correia, S.; Schouten, R.; Silva, A.P.; Gonçalves, B. Sweet Cherry Fruit Cracking Mechanisms and Prevention Strategies: A Review. Sci. Hortic. 2018, 240, 369–377. [Google Scholar] [CrossRef]

- Sharma, N.; Allardyce, B.; Rajkhowa, R.; Adholeya, A.; Agrawal, R. A Substantial Role of Agro-Textiles in Agricultural Applications. Front. Plant Sci. 2022, 13, 895740. [Google Scholar] [CrossRef]

- Pallotti, L.; Silvestroni, O.; Dottori, E.; Lattanzi, T.; Lanari, V. Effects of Shading Nets as a Form of Adaptation to Climate Change on Grapes Production: A Review. OENO One 2023, 57, 467–476. [Google Scholar] [CrossRef]

- Castellano, S.; Hemming, S.; Russo, G. The Influence of Colour on Radiometric Performances of Agricultural Nets. Acta Hortic. 2008, 801, 227–236. [Google Scholar] [CrossRef]

- Castellano, S.; Starace, G.; De Pascalis, L.; Lippolis, M.; Scarascia Mugnozza, G. Test Results and Empirical Correlations to Account for Air Permeability of Agricultural Nets. Biosyst. Eng. 2016, 150, 131–141. [Google Scholar] [CrossRef]

- Castellano, S.; Starace, G. Experimental Evaluation of the Loss Coefficient of Insect-Proof Agro-Textiles and Application to Wind Loads. AgriEngineering 2025, 7, 168. [Google Scholar] [CrossRef]

- Granados-Ortiz, F.-J.; López-Martínez, A.; Molina-Aiz, F.; Lai, C.; Peña-Fernández, A.; Martínez-Lao, J.; Valera-Martínez, D. Improvements in the Characterisation of Permeability and Inertial Factor of Insect-Proof Screens through Pressure Drop Coefficients. Agronomy 2023, 13, 602. [Google Scholar] [CrossRef]

- Granados-Ortiz, F.-J.; Arrabal-Campos, F.M.; López-Martínez, A.; Molina-Aiz, F.D.; Peña-Fernández, A.; Valera, D.L. On the Estimation of Three-Dimensional Porosity of Insect-Proof Screens. Comput. Electron. Agric. 2022, 193, 106639. [Google Scholar] [CrossRef]

- Cohen, S.; Fuchs, M. Measuring and Predicting Radiometric Properties of Reflective Shade Nets and Thermal Screens. J. Agric. Eng. Res. 1999, 73, 245–255. [Google Scholar] [CrossRef]

- López-Martínez, A.; Valera Martínez, D.L.; Molina-Aiz, F.; Peña-Fernández, A.; Marín-Membrive, P. Microclimate Evaluation of a New Design of Insect-Proof Screens in a Mediterranean Greenhouse. Span. J. Agric. Res. 2014, 12, 338–352. [Google Scholar] [CrossRef]

- UNI EN ISO 9237:1997; Tessili—Determinazione Della Permeabilità All’aria Dei Tessuti. UNI Ente Italiano di Unificazione: Milano, Italy, 1997.

- Boutry, C.; Kelderer, M.; Holtz, T.; Baumgartner, F.; Friedli, M. Testing the Effect of a Rainproof Protection Net on the Apple Production Regarding Disease and Pest Damages. In Proceedings of the 20th International Conference on Organic Fruit-Growing, Online, 21–23 February 2022; FÖKO e.V. (Fördergemeinschaft Ökologischer Obstbau e.V.): Weinsberg, Germany, 2022; pp. 101–106. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).