Laboratory Characterization and Discrete Element Modeling of Shrinkage and Cracking Behavior of Soil in Farmland

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory Experiments

2.1.1. Soil Shrinkage Experiment

2.1.2. Soil Cracking Experiment

2.1.3. Parameters of Soil Shrinkage and Crack

- (1)

- Equivalent diameter

- (2)

- Shrinkage characteristic curve

- (3)

- Anisotropy of soil shrinkage

- (4)

- Crack ratio

- (5)

- Crack length density

- (6)

- Contribution ratio of crack length (width)

- (7)

- Box-counting fractal dimension of crack network

2.1.4. Data Processing

2.2. Model Construction

2.2.1. Model Assumptions

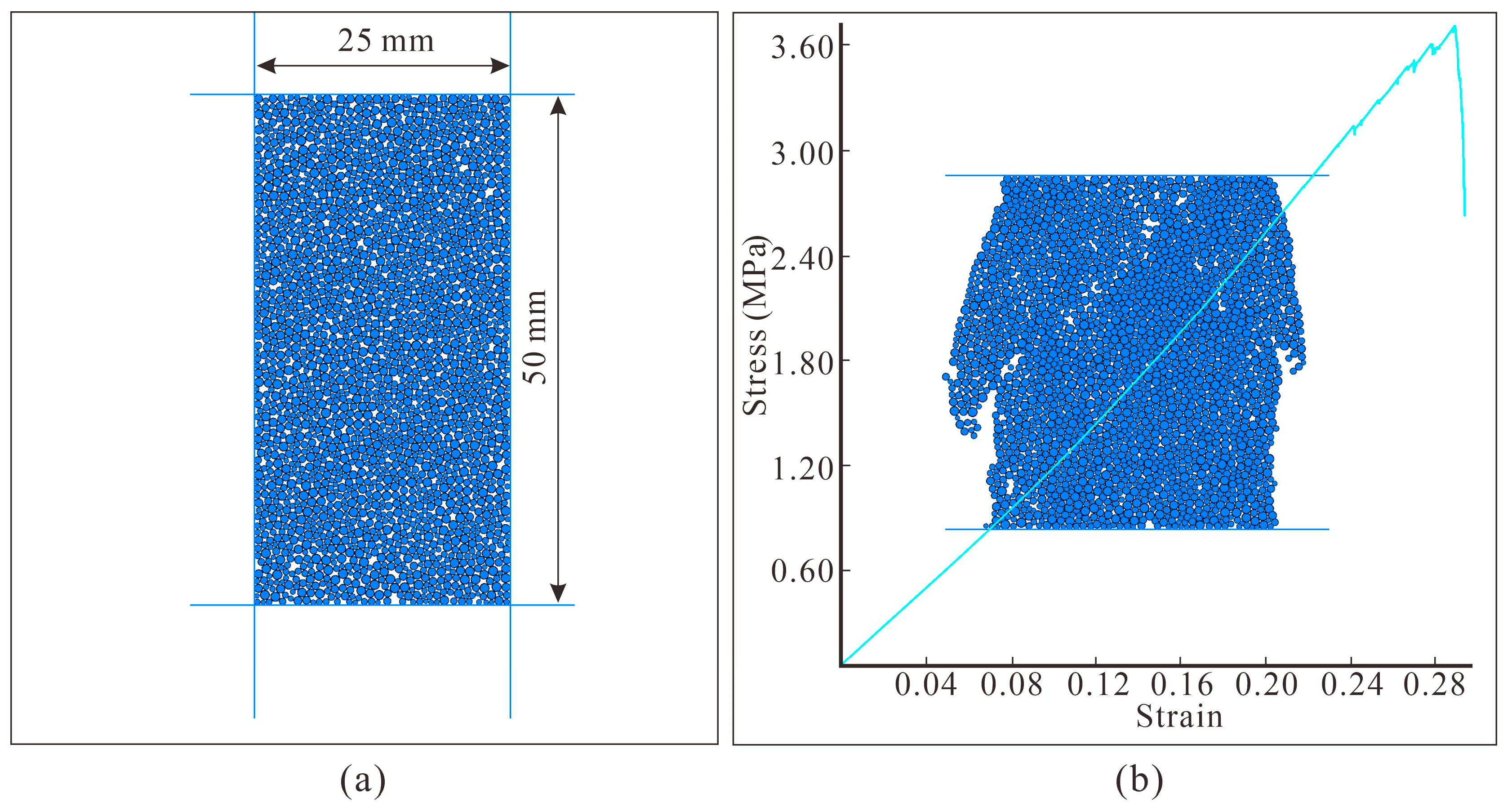

2.2.2. Sample Preparation

2.2.3. Contact Model

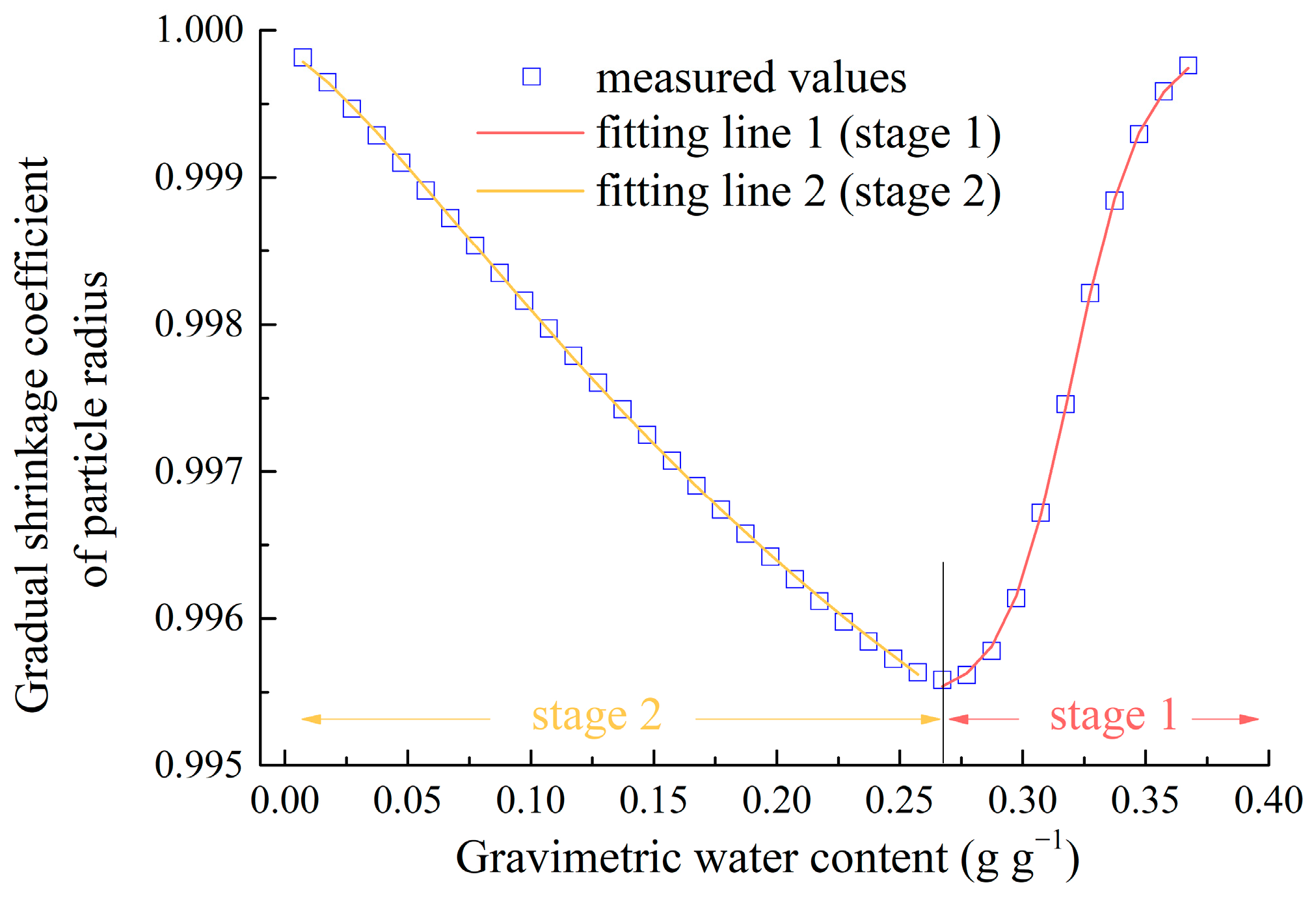

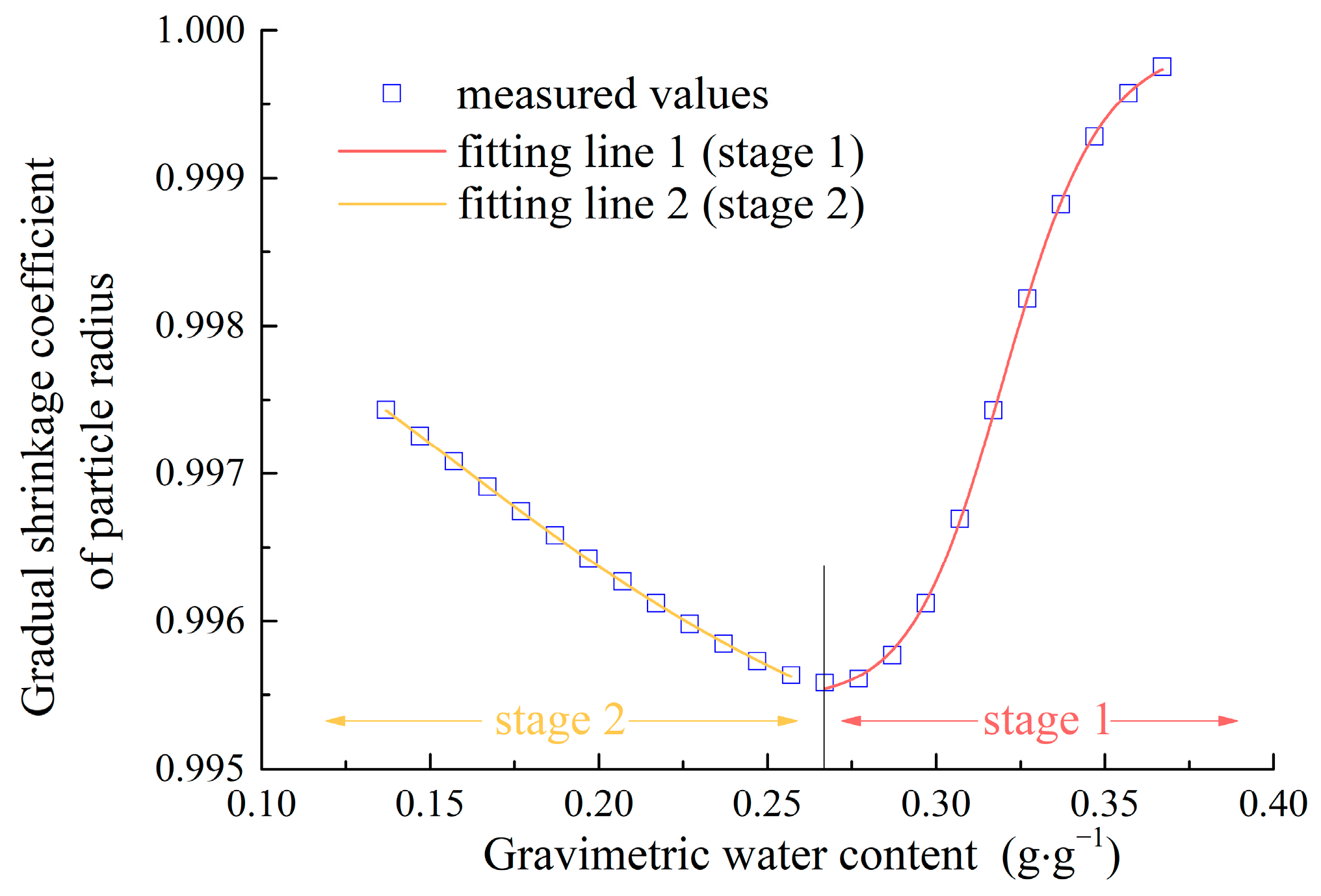

2.2.4. Shrinkage Pattern of Particles

2.2.5. Parameter Determination

Contact Model Parameters

- (1)

- Particle density

- (2)

- Particle normal and shear stiffness

- (3)

- Tensile strength and shear strength

Shrinkage Parameters

- (1)

- Shrinkage Model

- (2)

- Cracking Model

3. Results and Discussion

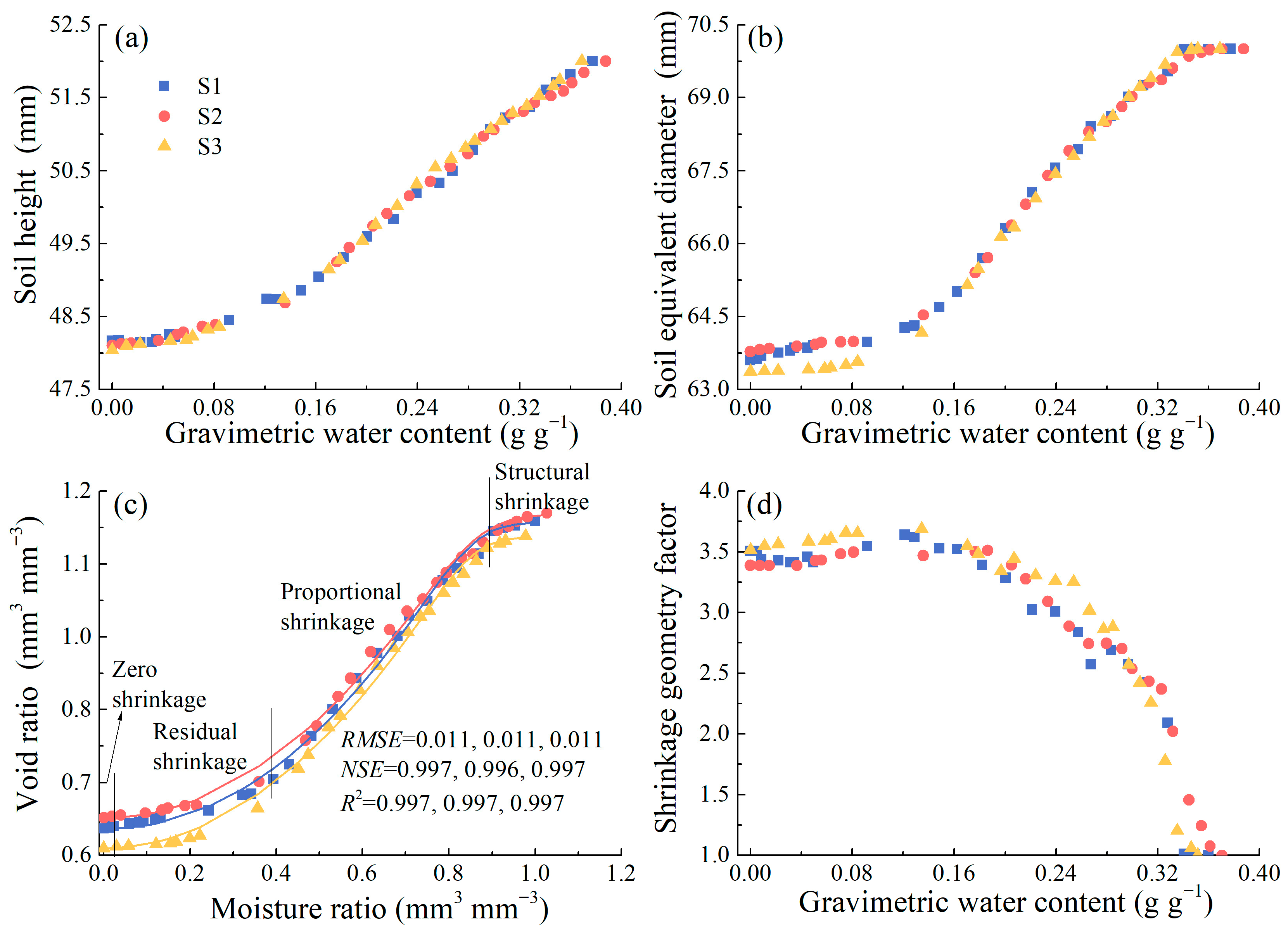

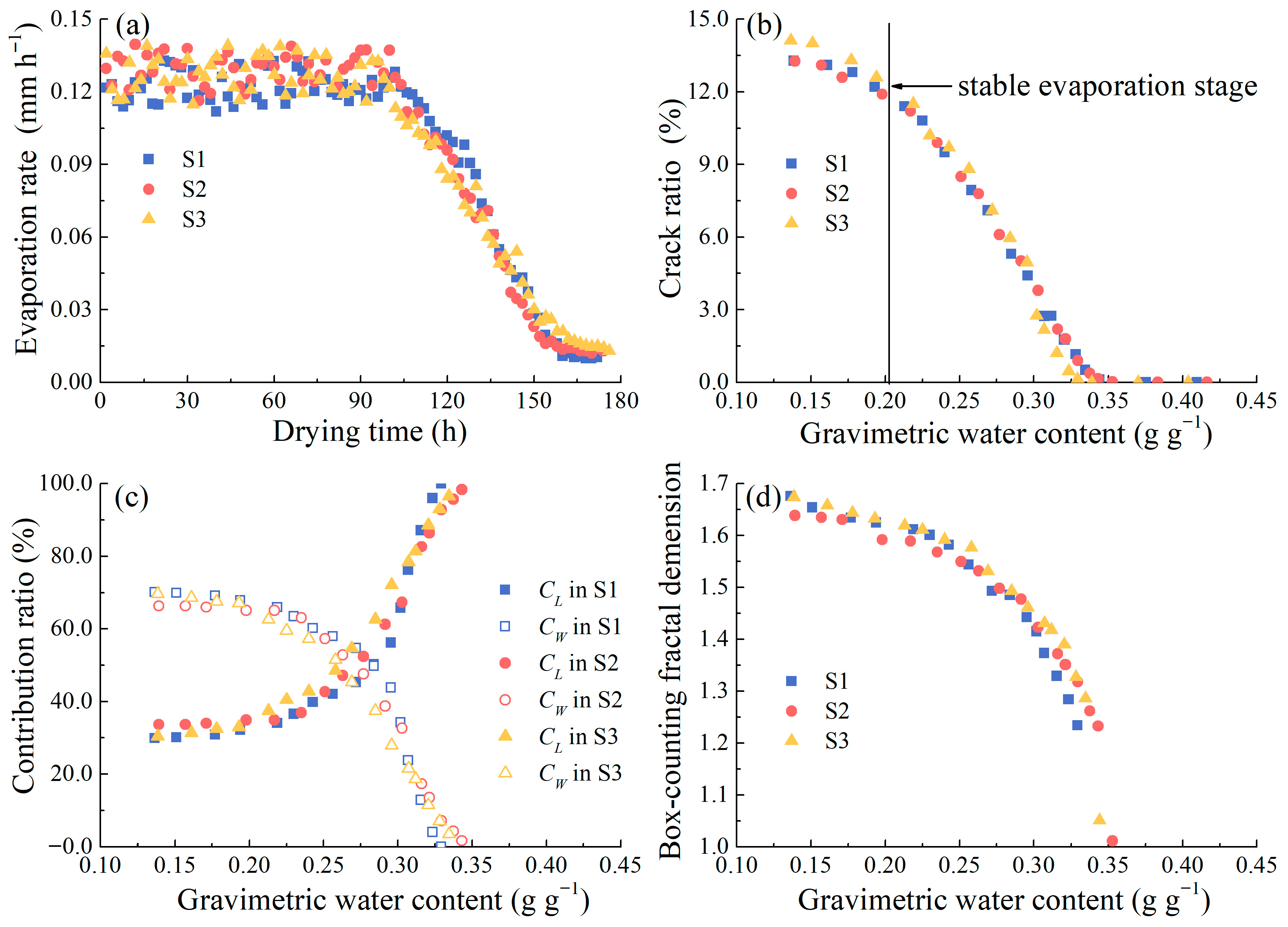

3.1. Experimental Results

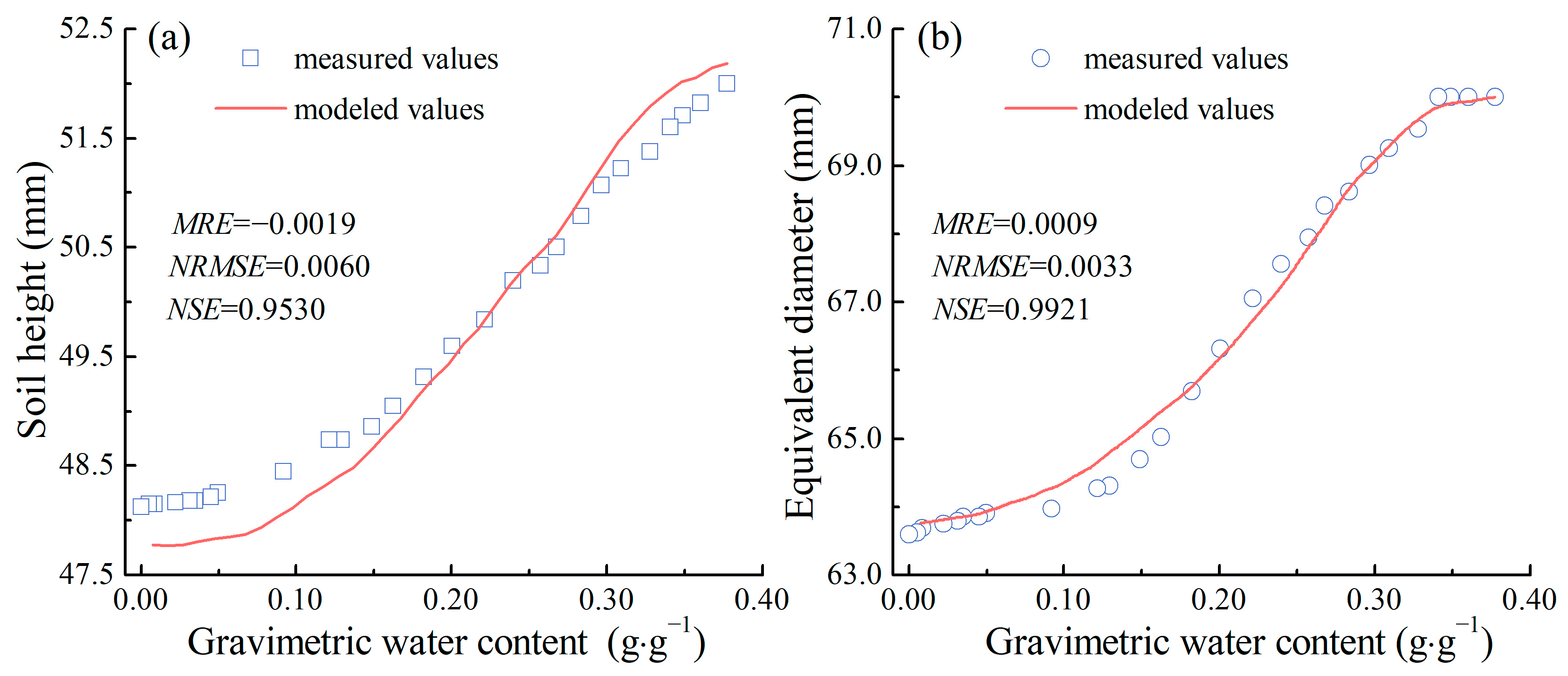

3.1.1. Shrinkage Characteristic

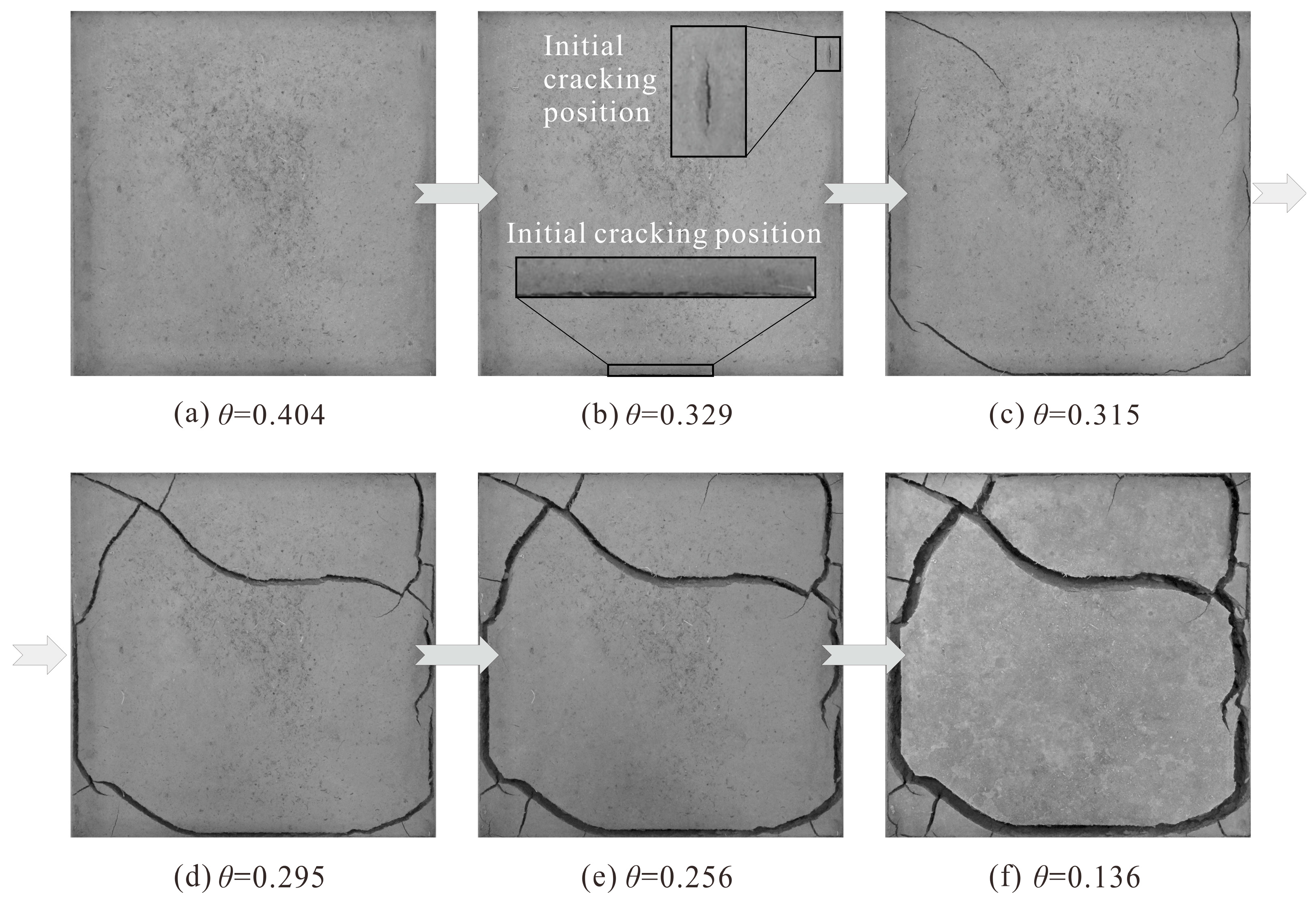

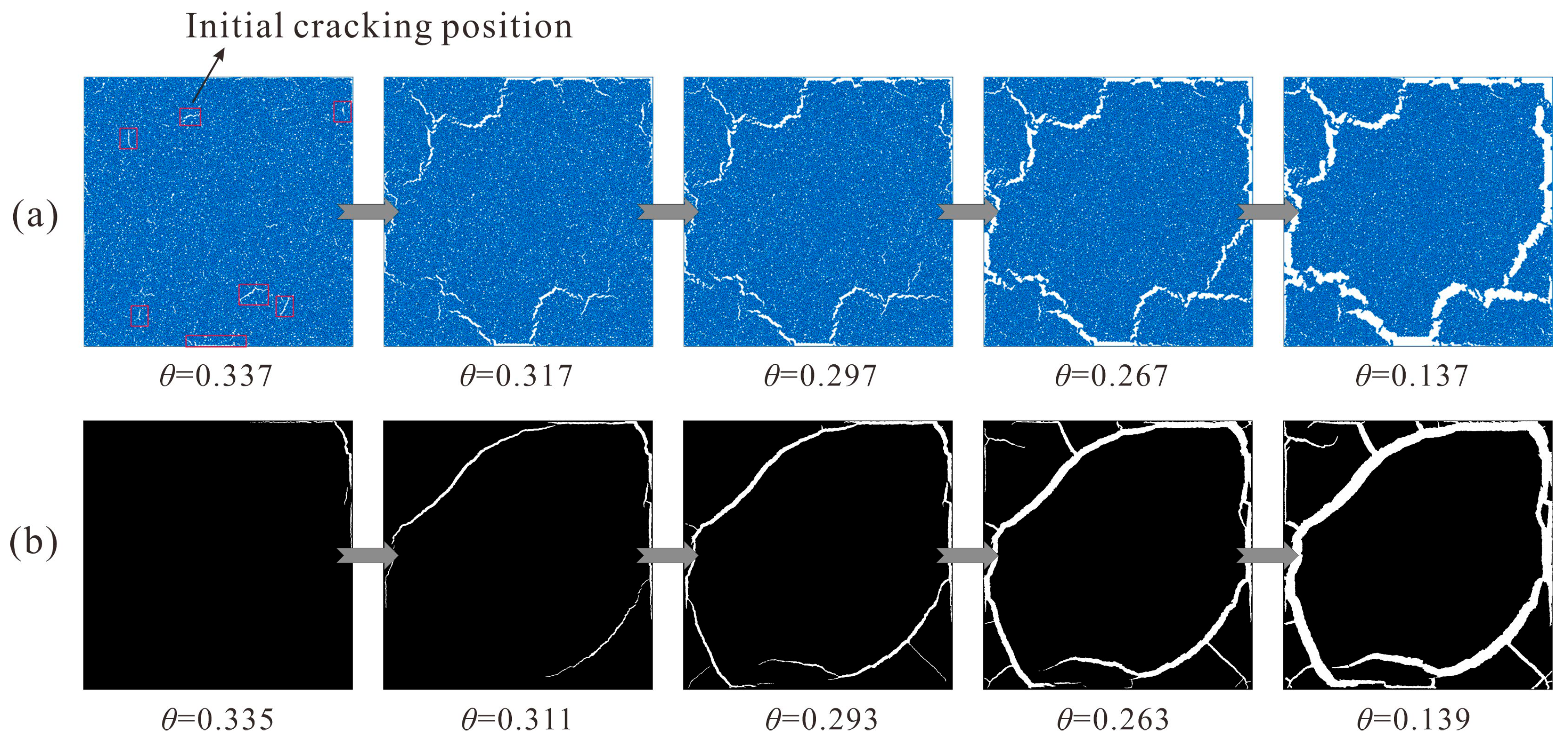

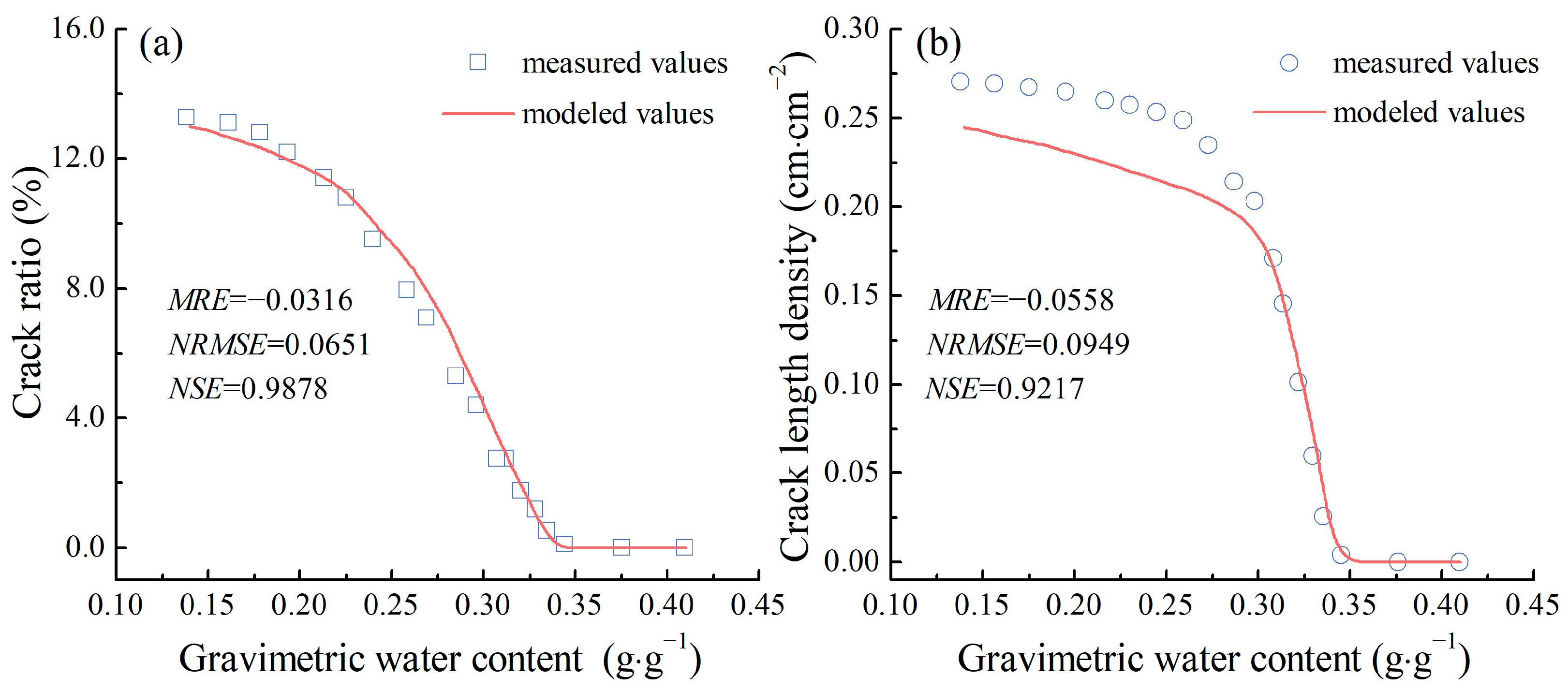

3.1.2. Crack Characteristic

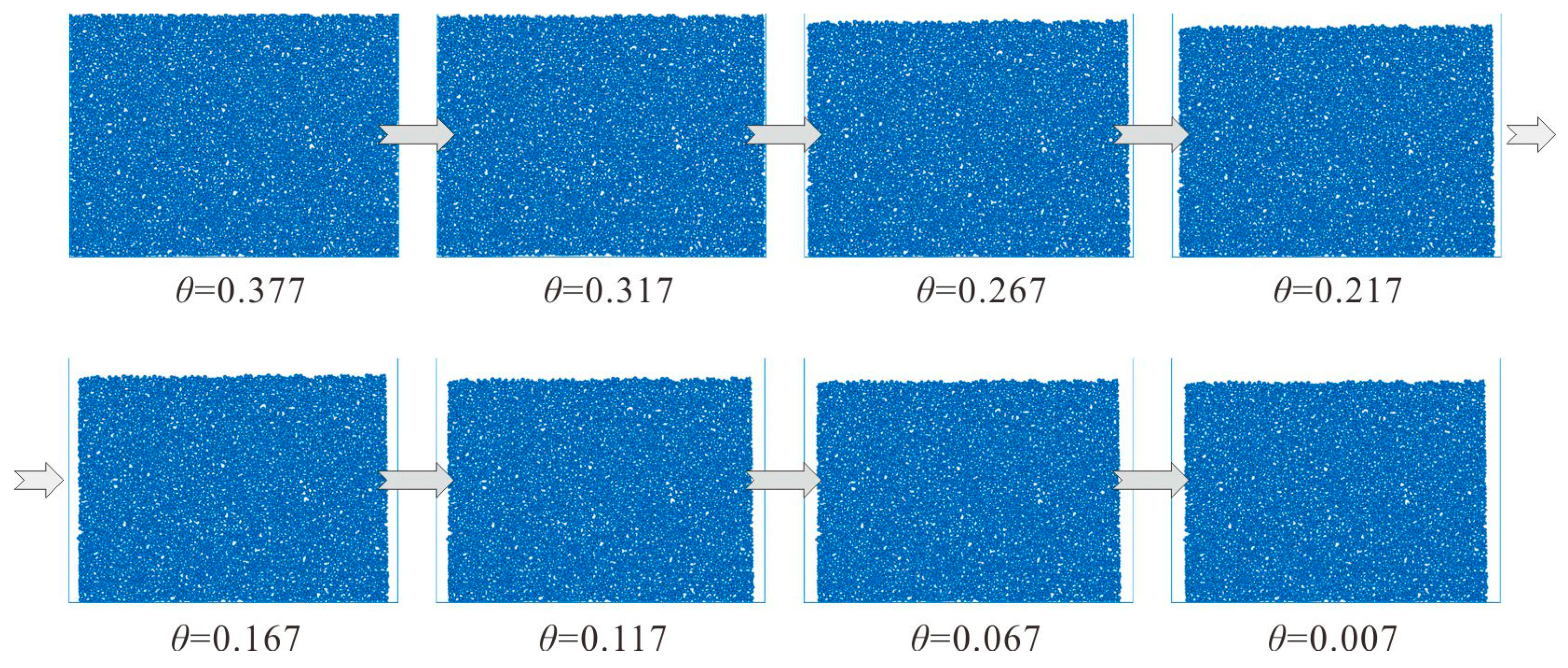

3.2. Model Results

3.2.1. Soil Shrinkage

3.2.2. Soil Cracking

3.3. Discussion

3.3.1. Characteristics of Soil Shrinkage and Cracking

3.3.2. Modeling of Soil Cracking

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bu, F.; Liu, J.; Mei, H.; Song, Z.; Wang, Z.; Dai, C.; Qian, W. Cracking behavior of sisal fiber-reinforced clayey soil under wetting-drying cycles. Soil Tillage Res. 2023, 227, 105596. [Google Scholar] [CrossRef]

- Feng, H.; Xing, X.; Xing, J.; Du, J.; Li, D. Performance and modeling of infiltration flow in cracked saline soils. J. Hydrol. 2025, 656, 133054. [Google Scholar] [CrossRef]

- Novak, V.; Šimůnek, J.; Genuchten, M.T.V. Infiltration of water into soil with cracks. J. Irrig. Drain. Eng. 2000, 126, 41–47. [Google Scholar] [CrossRef]

- Yuliana, Y.; Apriyono, A.; Kamchoom, V.; Boldrin, D.; Cheng, Q.; Tang, C.-S. Seasonal dynamics of root growth and desiccation cracks and their effects on soil hydraulic conductivity. Eng. Geol. 2025, 349, 107973. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Chen, Y.; Kong, L.L.; Wang, C.; Li, W.J. Impacts of desiccation crack geometric characteristics on infiltration in soil. Trans. Chin. Soc. Agric. Mach. 2015, 46, 192–197. [Google Scholar]

- Qi, W.; Zhang, Z.Y.; Wang, C.; Chen, Y.; Zhang, Z.M. Crack closure and flow regimes in cracked clay loam subjected to different irrigation methods. Geoderma 2020, 358, 113978. [Google Scholar] [CrossRef]

- Hardie, M.A.; Cotching, W.E.; Doyle, R.B.; Holz, G.; Lisson, S.; Mattern, K. Effect of antecedent soil moisture on preferential flow in a texture-contrast soil. J. Hydrol. 2011, 398, 191–201. [Google Scholar] [CrossRef]

- Tuong, T.P.; Cabangon, R.J.; Wopereis, M.C.S. Quantifying flow processes during land soaking of cracked rice soils. Soil Sci. Soc. Am. J. 1996, 60, 872–879. [Google Scholar] [CrossRef]

- Jarvis, N.J. A review of non-equilibrium water flow and solute transport in soil macropores: Principles, controlling factors and consequences for water quality. Eur. J. Soil Sci. 2007, 58, 523–546. [Google Scholar] [CrossRef]

- Greve, A.; Andersen, M.S.; Acworth, R.I. Investigations of soil cracking and preferential flow in a weighing lysimeter filled with cracking clay soil. J. Hydrol. 2010, 393, 105–113. [Google Scholar] [CrossRef]

- Poulsen, T.G.; Cai, W.; Garg, A. Water evaporation from cracked soil under moist conditions as related to crack properties and near-surface wind speed. Eur. J. Soil Sci. 2020, 71, 627–640. [Google Scholar] [CrossRef]

- Xu, J.; Qin, Y.; Kakewati, A.L.; Liu, S.; Hallett, P.D.; Liu, G. Morphology-based mechanism of desiccation cracking in soil and montmorillonite. Soil Tillage Res. 2025, 249, 106474. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Liu, C.; Suo, W.B.; Gao, L. Experimental characterization of shrinkage and desiccation cracking in thin clay layer. Appl. Clay Sci. 2011, 52, 69–77. [Google Scholar] [CrossRef]

- Tang, C.S.; Zhu, C.; Cheng, Q.; Zeng, H.; Xu, J.-J.; Tian, B.G.; Shi, B. Desiccation cracking of soils: A review of investigation approaches, underlying mechanisms, and influencing factors. Earth-Sci. Rev. 2021, 216, 103586. [Google Scholar] [CrossRef]

- Grossman, R.; Brasher, B.; Franzmeier, D.; Walker, J.L. Linear extensibility as calculated from natural-clod bulk density measurements1. Soil Sci. Soc. Am. J. 1968, 32, 570–573. [Google Scholar] [CrossRef]

- Klopp, H.W.; Arriaga, F.J.; Likos, W.J.; Bleam, W.F. Atterberg limits and shrink/swell capacity of soil as indicators for sodium sensitivity within a gradient of soil exchangeable sodium percentage and salinity. Geoderma 2019, 353, 449–458. [Google Scholar] [CrossRef]

- Valle, S.R.; Dörner, J.; Zúñiga, F.; Dec, D. Seasonal dynamics of the physical quality of volcanic ash soils under different land uses in southern Chile. Soil Tillage Res. 2018, 182, 25–34. [Google Scholar] [CrossRef]

- Deng, C.; Teng, X.; Peng, X.; Zhang, B. Effects of simulated puddling intensity and pre-drying on shrinkage capacity of a paddy soil under long-term fertilization. Soil Tillage Res. 2014, 140, 135–143. [Google Scholar] [CrossRef]

- Peng, X.H.; Horn, R. Anisotropic shrinkage and swelling of some organic and inorganic soils. Eur. J. Soil Sci. 2007, 58, 98–107. [Google Scholar] [CrossRef]

- Chertkov, V.Y. An integrated approach to soil structure, shrinkage, and cracking in samples and layers. Geoderma 2012, 173–174, 258–273. [Google Scholar] [CrossRef]

- Groenevelt, P.H.; Grant, C.D. Re-evaluation of the structural properties of some British swelling soils. Eur. J. Soil Sci. 2001, 52, 469–477. [Google Scholar] [CrossRef]

- McGarry, D.; Malafant, K.W.J. The analysis of volume change in unconfined units of soil. Soil Sci. Soc. Am. J. 1987, 51, 290–297. [Google Scholar] [CrossRef]

- Braudeau, E.; Costantini, J.M.; Bellier, G.; Colleuille, H. New device and method for soil shrinkage curve measurement and characterization. Soil Sci. Soc. Am. J. 1999, 63, 525–535. [Google Scholar] [CrossRef]

- Xing, X.; Nie, W.; Chang, K.; Zhao, L.; Li, Y.; Ma, X. A numerical approach for modeling crack closure and infiltrated flow in cracked soils. Soil Tillage Res. 2023, 233, 105794. [Google Scholar] [CrossRef]

- Tang, C.S.; Cui, Y.J.; Shi, B.; Tang, A.M.; Liu, C. Desiccation and cracking behaviour of clay layer from slurry state under wetting–drying cycles. Geoderma 2011, 166, 111–118. [Google Scholar] [CrossRef]

- DeCarlo, K.F.; Shokri, N. Effects of substrate on cracking patterns and dynamics in desiccating clay layers. Water Resour. Res. 2014, 50, 3039–3051. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Z.; Liu, Y.; Fan, S. Geometric and fractal analysis of dynamic cracking patterns subjected to wetting-drying cycles. Soil Tillage Res. 2017, 170, 1–13. [Google Scholar] [CrossRef]

- Lachenbruch, A.H. Mechanics of Thermal Contraction Cracks and Ice-Wedge Polygons in Permafrost. Geol. Soc. Am. 1962, 70, 69–262. [Google Scholar]

- Goehring, L.; Conroy, R.; Akhter, A.; Clegg, W.J.; Routh, A.F. Evolution of mud-crack patterns during repeated drying cycles. Soft Matter 2010, 6, 3562–3567. [Google Scholar] [CrossRef]

- Hallett, P.D.; Newson, T.A. A simple fracture mechanics approach for assessing ductile crack growth in soil. Soil Sci. Soc. Am. J. 2001, 65, 1083–1088. [Google Scholar] [CrossRef]

- Bittencourt, T.N.; Wawrzynek, P.A.; Ingraffea, A.R.; Sousa, J.L. Quasi-automatic simulation of crack propagation for 2D LEFM problems. Eng. Fract. Mech. 1996, 55, 321–334. [Google Scholar] [CrossRef]

- Kodikara, J.; Barbour, S.L.; Fredlund, D.G. An idealized framework for the analysis of cohesive soils undergoing desiccation: Discussion. Can. Geotech. J. 1998, 35, 1112–1114. [Google Scholar] [CrossRef]

- Chertkov, V.Y. Physical modeling of the soil swelling curve vs. the shrinkage curve. Adv. Water Resour. 2012, 44, 66–84. [Google Scholar] [CrossRef][Green Version]

- Stewart, R.D.; Rupp, D.E.; Abou Najm, M.R.; Selker, J.S. A unified model for soil shrinkage, subsidence, and cracking. Vadose Zone J. 2016, 15, 1–15. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Z.; Cao, D.; Chen, Y.; Qi, W.; Ma, L. Crack porosity estimation model based on VG-PENG shrinkage characteristic curve and soil shrinkage anisotropy. Trans. Chin. Soc. Agric. Eng. 2021, 37, 112–121. [Google Scholar]

- Lin, Z.Y.; Wang, Y.S.; Tang, C.S.; Cheng, Q.; Zeng, H.; Liu, C.; Shi, B. Discrete element modelling of desiccation cracking in thin clay layer under different basal boundary conditions. Comput. Geotech. 2021, 130, 103931. [Google Scholar] [CrossRef]

- Guo, Y.; Han, C.; Yu, X. Laboratory characterization and discrete element modeling of shrinkage and cracking in clay layer. Can. Geotech. J. 2018, 55, 680–688. [Google Scholar] [CrossRef]

- Yan, C.; Zheng, Y.; Ke, W.; Wang, G. A FDEM 3D moisture migration-fracture model for simulation of soil shrinkage and desiccation cracking. Comput. Geotech. 2021, 140, 104425. [Google Scholar] [CrossRef]

- Tran, K.M.; Bui, H.H.; Sánchez, M.; Kodikara, J. A DEM approach to study desiccation processes in slurry soils. Comput. Geotech. 2020, 120, 103448. [Google Scholar] [CrossRef]

- Peron, H.; Delenne, J.Y.; Laloui, L.; El Youssoufi, M.S. Discrete element modelling of drying shrinkage and cracking of soils. Comput. Geotech. 2009, 36, 61–69. [Google Scholar] [CrossRef]

- Qi, W.; Wang, C.; Zhang, Z.; Huang, M.; Xu, J. Experimental Investigation on the Impact of Drying–Wetting Cycles on the Shrink–Swell Behavior of Clay Loam in Farmland. Agriculture 2022, 12, 245. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Z.Y.; Qi, W.; Fan, S.M. Morphological approach to quantifying soil cracks: Application to dynamic crack patterns during wetting-drying cycles. Soil Sci. Soc. Am. J. 2018, 82, 751–771. [Google Scholar] [CrossRef]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern.-Syst. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- Peng, X.H.; Horn, R. Modeling soil shrinkage curve across a wide range of soil types. Soil Sci. Soc. Am. J. 2005, 69, 584–592. [Google Scholar] [CrossRef]

- Bronswijk, J.J.B. Shrinkage geometry of a heavy clay soil at various stress. Soil Sci. Soc. Am. J. 1990, 54, 1500–1502. [Google Scholar] [CrossRef]

- Qi, W.; Zhang, Z.Y.; Wang, C. Desiccation and cracking behaviour of clay loam subjected to different irrigation methods during wetting-drying cycles. Eur. J. Soil Sci. 2020, 72, 793–809. [Google Scholar] [CrossRef]

- Sima, J.; Jiang, M.; Zhou, C. Numerical simulation of desiccation cracking in a thin clay layer using 3D discrete element modeling. Comput. Geotech. 2014, 56, 168–180. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, S.; Xu, Y. Fractal Dimension Characteristics of the Soil Cracking Process When Saline-Alkali Soil Is Mixed with Hippophae Roots. Fractal Fract. 2022, 6, 504. [Google Scholar] [CrossRef]

- Nahlawi, H.; Kodikara, J.K. Laboratory experiments on desiccation cracking of thin soil layers. Geotech. Geol. Eng. 2006, 24, 1641–1664. [Google Scholar] [CrossRef]

- Tang, C.S.; Cheng, Q.; Lin, L.; Tian, B.G.; Zeng, H.; Shi, B. Study on the dynamic mechanism of soil desiccation cracking by surface strain/displacement analysis. Comput. Geotech. 2022, 152, 104998. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qi, W.; He, Y.; Mai, Z.; Zhang, W.; Gu, N.; Wang, C. Laboratory Characterization and Discrete Element Modeling of Shrinkage and Cracking Behavior of Soil in Farmland. Agriculture 2025, 15, 2122. https://doi.org/10.3390/agriculture15202122

Qi W, He Y, Mai Z, Zhang W, Gu N, Wang C. Laboratory Characterization and Discrete Element Modeling of Shrinkage and Cracking Behavior of Soil in Farmland. Agriculture. 2025; 15(20):2122. https://doi.org/10.3390/agriculture15202122

Chicago/Turabian StyleQi, Wei, Yupu He, Zijun Mai, Wei Zhang, Nan Gu, and Ce Wang. 2025. "Laboratory Characterization and Discrete Element Modeling of Shrinkage and Cracking Behavior of Soil in Farmland" Agriculture 15, no. 20: 2122. https://doi.org/10.3390/agriculture15202122

APA StyleQi, W., He, Y., Mai, Z., Zhang, W., Gu, N., & Wang, C. (2025). Laboratory Characterization and Discrete Element Modeling of Shrinkage and Cracking Behavior of Soil in Farmland. Agriculture, 15(20), 2122. https://doi.org/10.3390/agriculture15202122