Design and Parameter Optimization of a Vertical Rotary Fixed-Angle Straw Cleaning Device

Abstract

1. Introduction

2. Materials and Methods

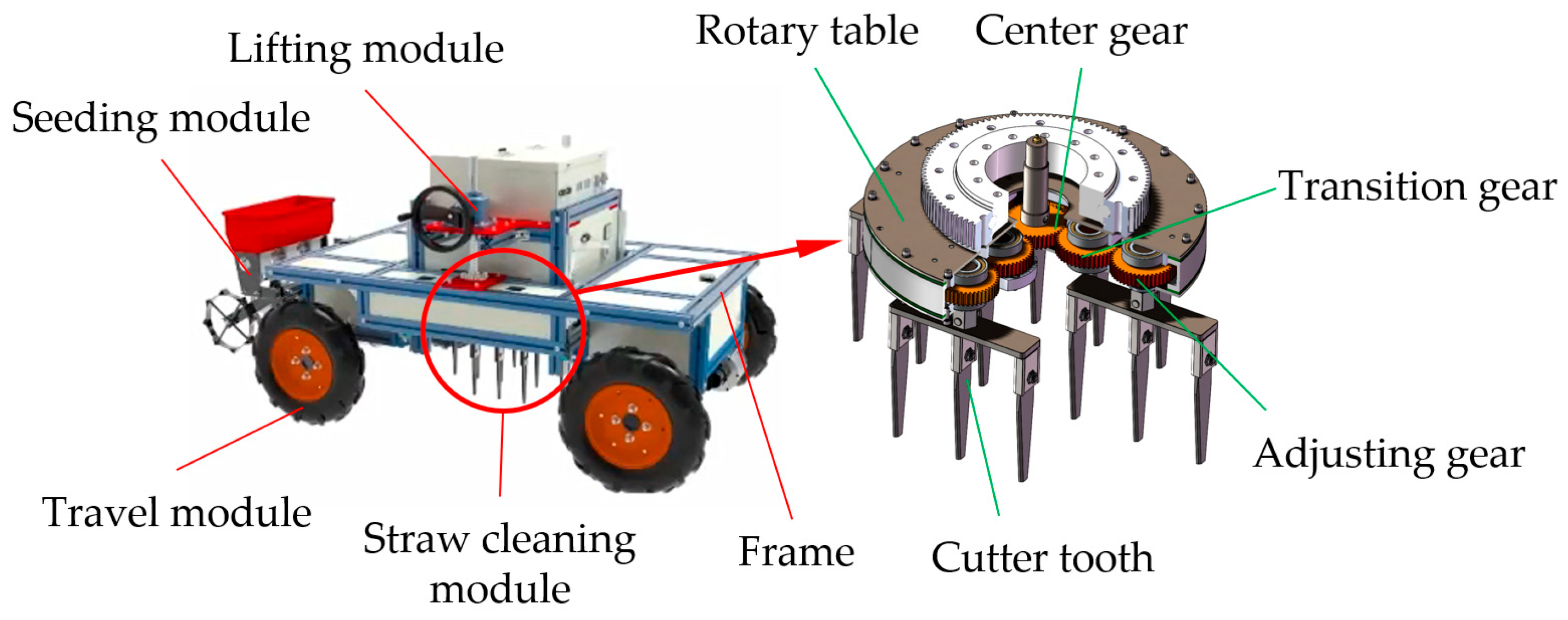

2.1. Structure and Principle of the VFD

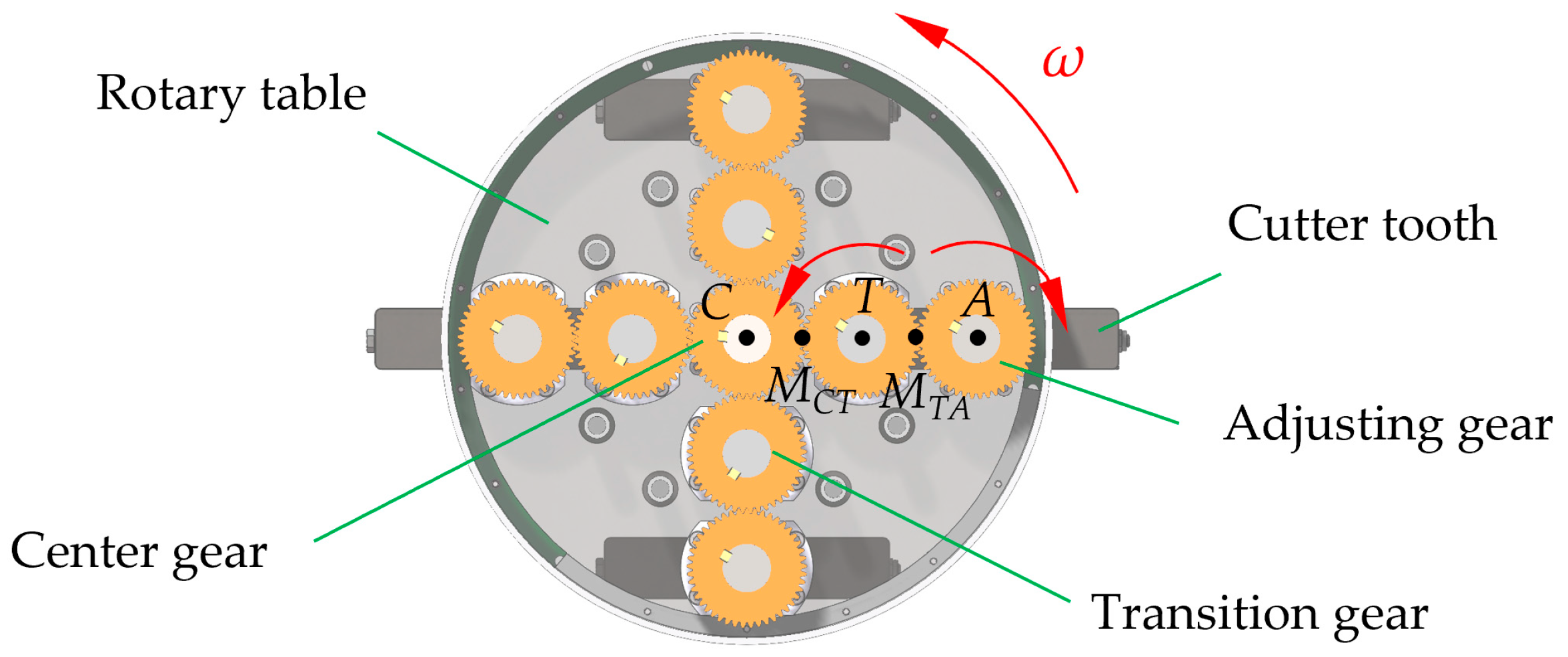

2.2. Analysis of Gear Mechanisms

2.3. Analysis of Cutting Speed for Cutter Tooth

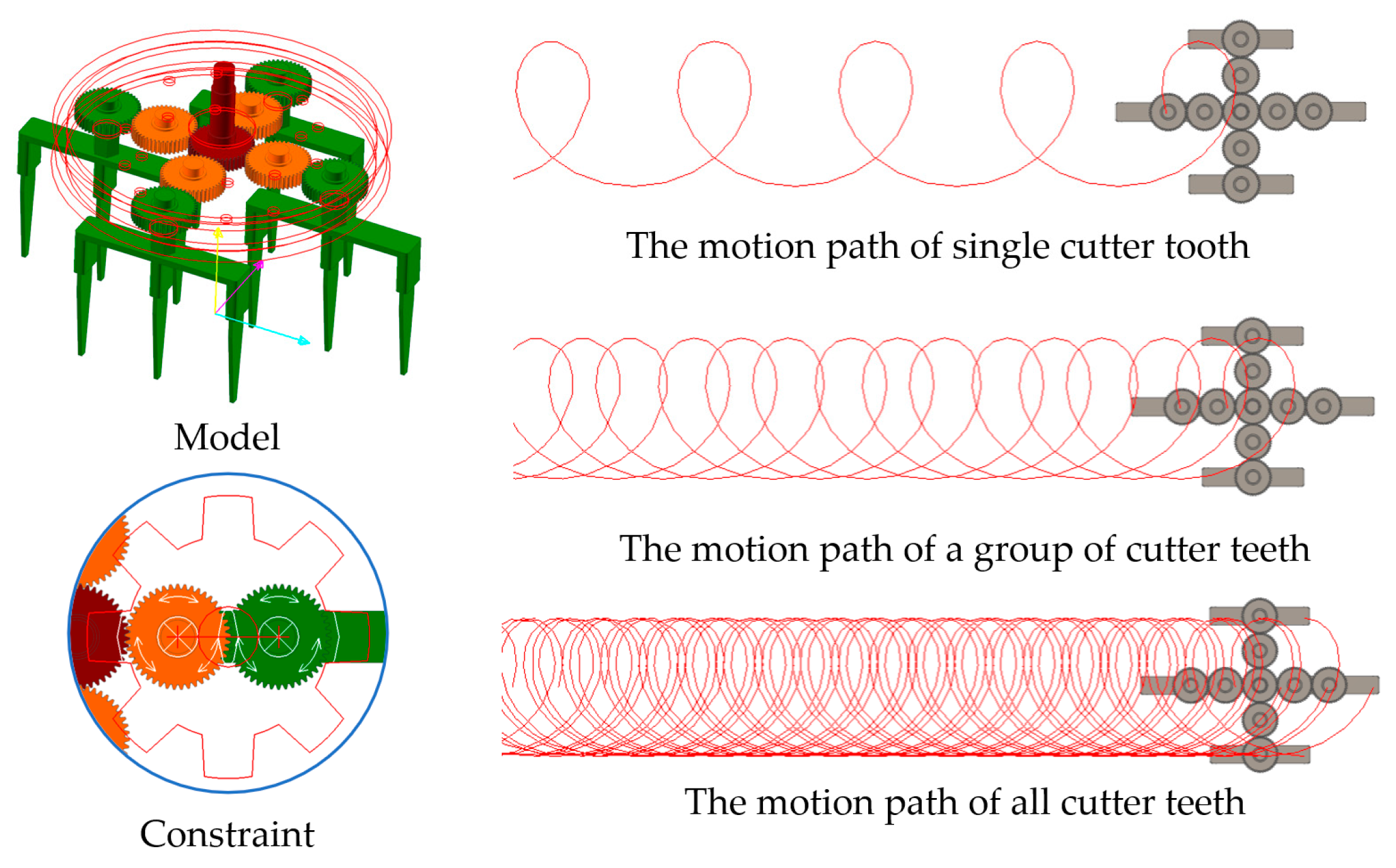

2.4. Coupled Simulation Analysis of EDEM and RecurDyn

2.4.1. Construction of the RecurDyn Simulation Platform

2.4.2. Construction of the EDEM Simulation Platform

2.4.3. Experimental Design Plan

3. Results and Discussion

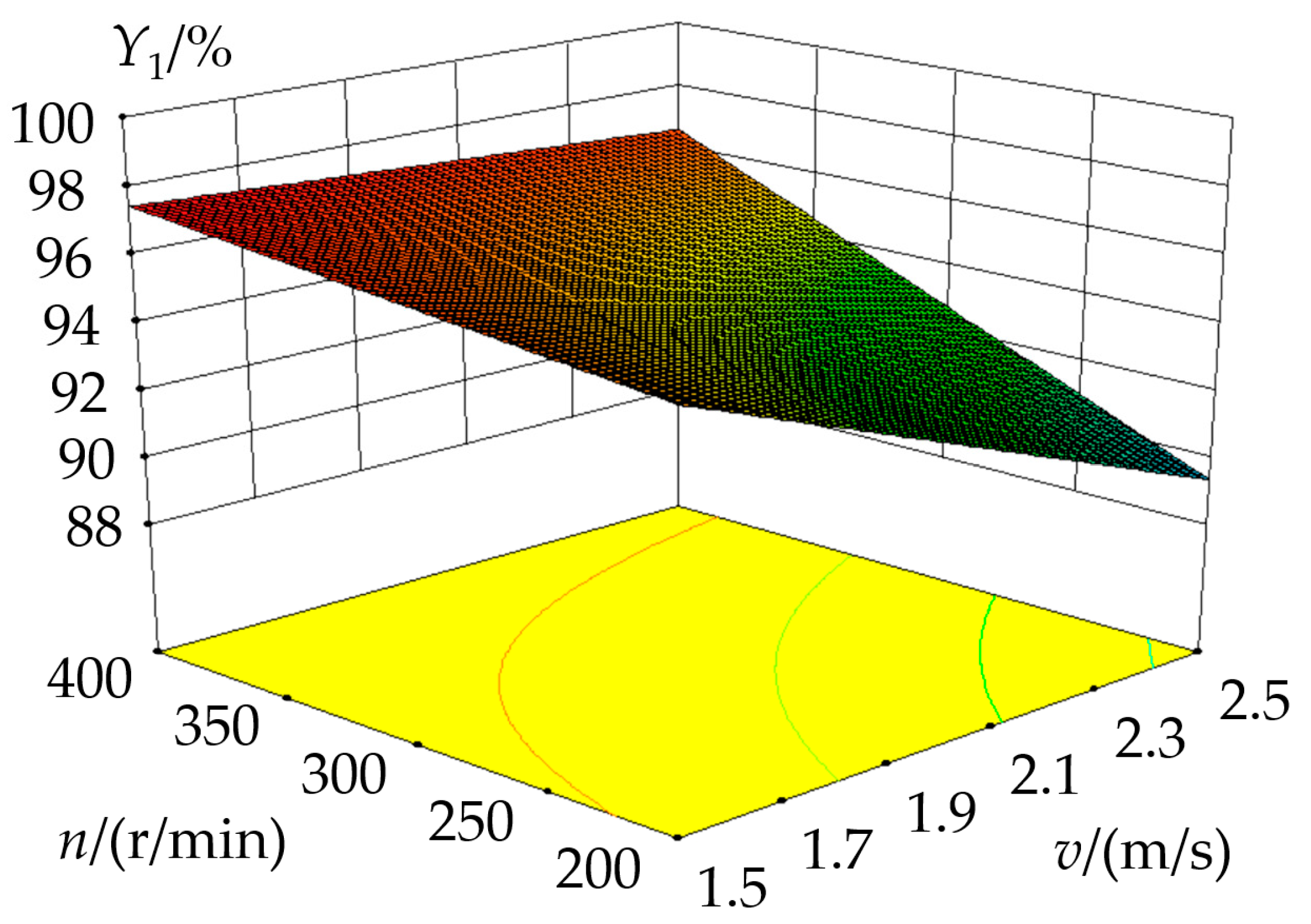

3.1. The Impact Patterns for Straw Cleaning Rate

3.1.1. Variance Analysis and Regression Model on Straw Cleaning Rate

3.1.2. The Impact of Individual Factors on the Straw Cleaning Rate

3.1.3. The Impact of Interaction Factors on the Straw Cleaning Rate

3.2. The Impact of Patterns on the Soil Disturbance Rate

3.2.1. Variance Analysis and Regression Model for Soil Disturbance Rate

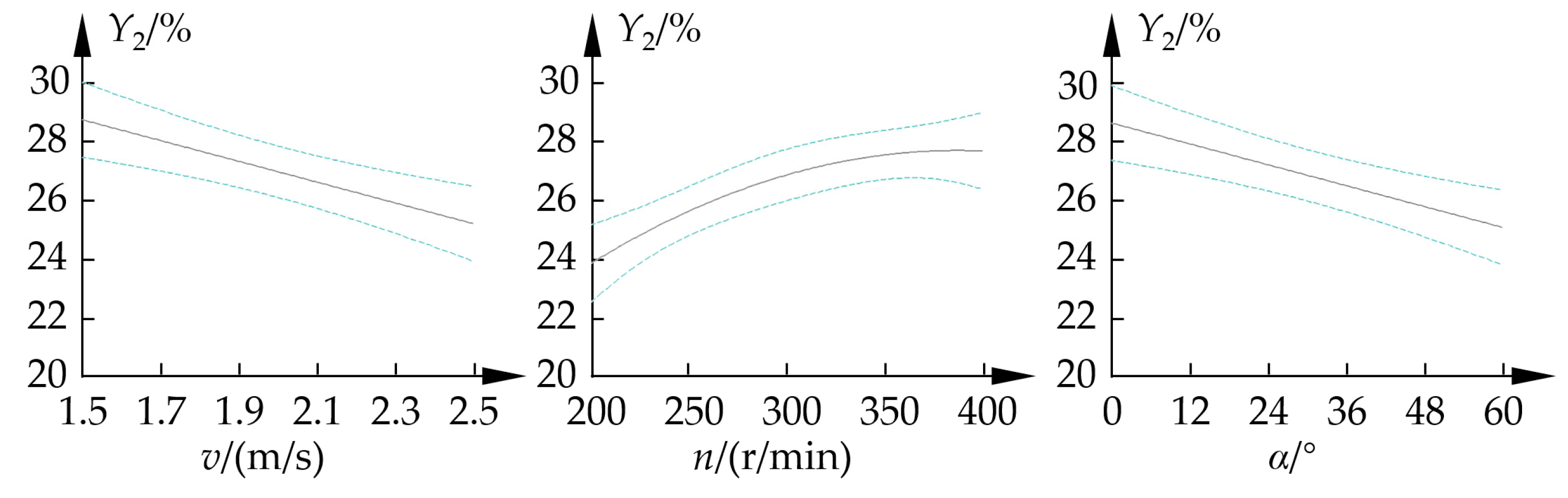

3.2.2. The Impact of Individual Factors on Soil Disturbance Rates

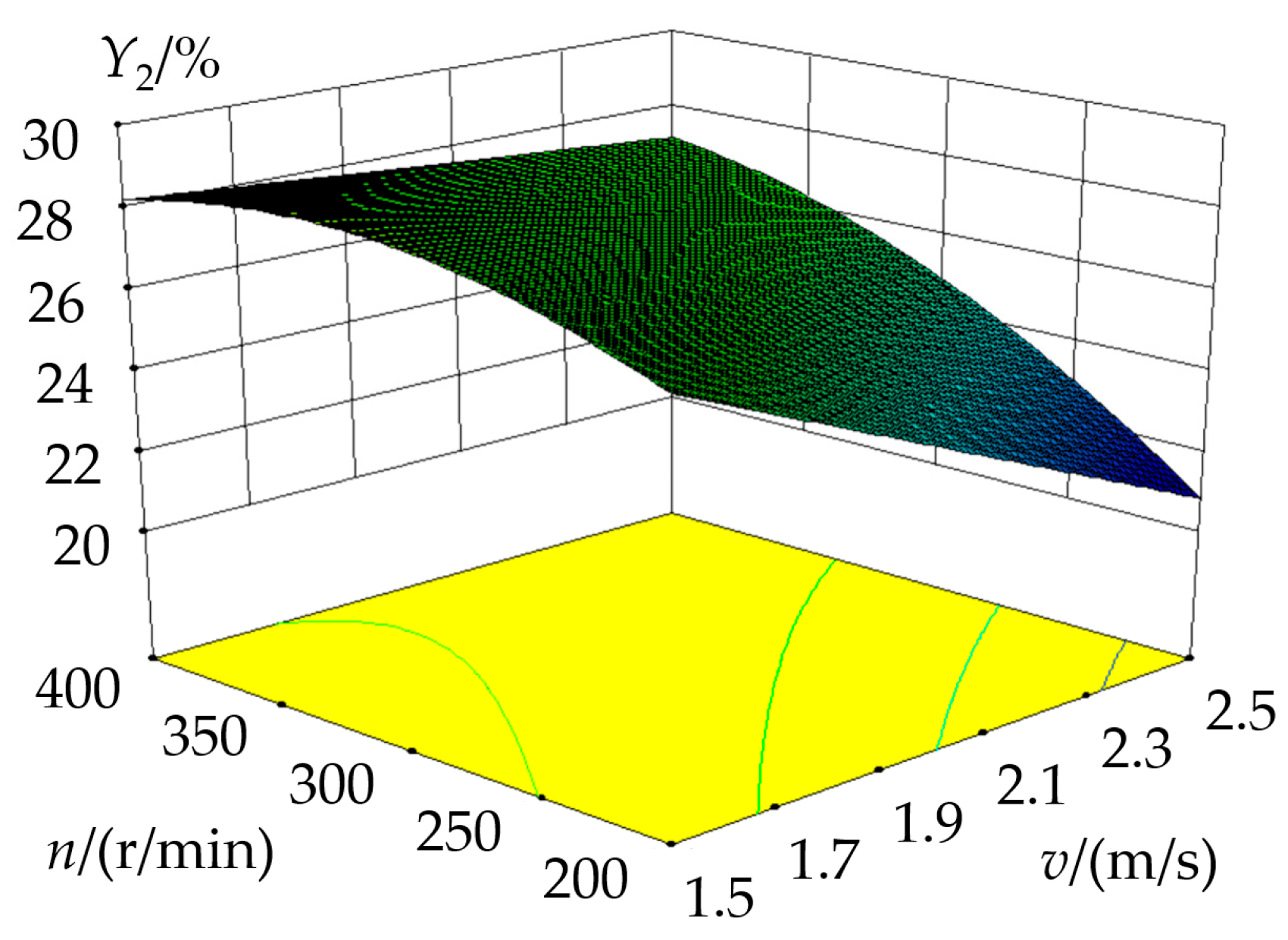

3.2.3. The Impact of Interaction Factors on the Soil Disturbance Rate

3.3. Parameter Optimization and Comparative Analysis

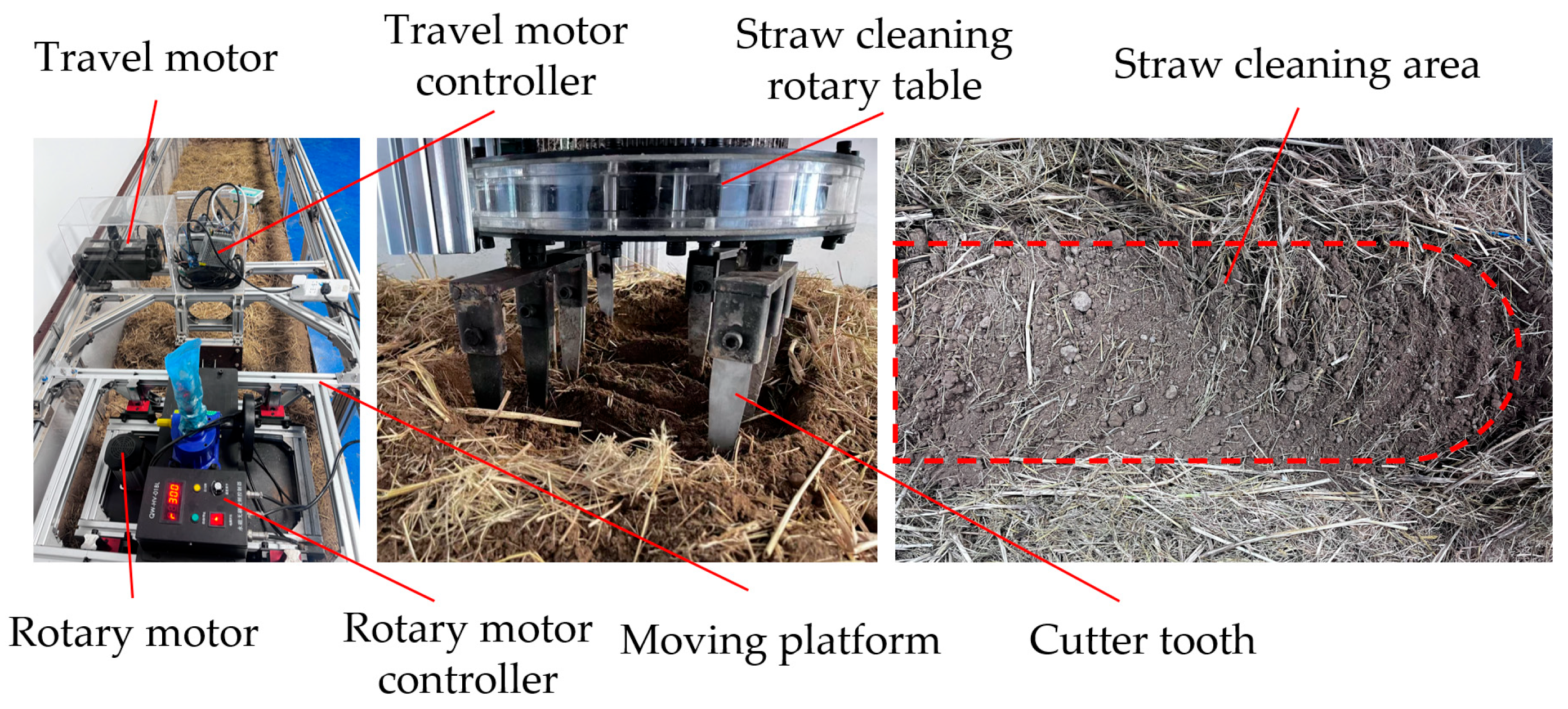

3.4. Test Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ninkuu, V.; Liu, Z.X.; Qin, A.Z.; Xie, Y.J.; Song, X.; Sun., X.W. Impact of straw returning on soil ecology and crop yield: A review. Heliyon 2025, 11, e41651. [Google Scholar] [CrossRef] [PubMed]

- Zikeli, S.; Gruber, S. Reduced tillage and no-till in organic farming systems, germany—Status quo, potentials and challenges. Agriculture 2017, 7, 35. [Google Scholar] [CrossRef]

- Akhtar, K.; Wang, W.Y.; Khan, A.; Ren, G.X.; Afridi, M.Z.; Feng, Y.Z.; Yang, G.H. Wheat straw mulching offset soil moisture deficient for improving physiological and growth performance of summer sown soybean. Agric. Water Manag. 2019, 211, 16–25. [Google Scholar] [CrossRef]

- Outeiro, V.H.; Müller, M.M.L.; Pott, C.A.; Rosset, J.S.; Fuentes-Guevara, M.D.; Rampim, L. Rampim. L. Fixed shanks in the seeder and cover crops improve soil properties and soybean yield in no-tillage system subjected to heavy traffic. Soil Tillage Res. 2026, 255, 106769. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Jensen, T.A.; Blackwell, J. Advances in residue management mechanisms of zero-tillage planters. In 2017 ASABE Annual International Meeting; ASABE Paper No.: 1700449; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017. [Google Scholar]

- Aikins, K.A.; Barr, J.B.; Ucgul, M.; Jensen, T.A.; Antille, D.L.; Desbiolles, J.M. No-tillage furrow opener performance: A review of tool geometry, settings and interactions with soil and crop residue. Soil Res. 2020, 58, 603–621. [Google Scholar] [CrossRef]

- Gürsoy, S. Performance Evaluation of the Row Cleaner on a No-Till Planter. Trans. ASABE 2014, 57, 709–713. [Google Scholar] [CrossRef]

- Conte, O.; Levien, R.; Debiasi, H.; Stürmer, S.L.K.; Mazurana, M.; Müller, J. Soil disturbance index as an indicator of seed drill efficiency in no-tillage agrosystems. Soil Tillage Res. 2011, 114, 37–42. [Google Scholar] [CrossRef]

- Torotwa, I.; Ding, Q.; Makange, N.R.; Liang, L.; He, R. Performance evaluation of a biomimetically designed disc for dense-straw mulched conservation tillage. Soil Tillage Res. 2021, 212, 105068. [Google Scholar] [CrossRef]

- Tahir, H.T. Evaluation and Comparative study of row cleaner modification through improving performance of the no-till planter and wheat production. Plant Arch. 2020, 20, 159–163. [Google Scholar]

- Li, X.; Zhang, Y.P.; He, H.J.; Wang, B.; Zhou, H.; Geng, D.Y.; Zhang, Y.Z. Design and experiment of row cleaner with staggered disc teeth for no-till planter. Agriculture 2023, 13, 1373. [Google Scholar] [CrossRef]

- Kumar, M.; Pandey, H.S.; Singh, K.P.; Verma, C.; Singh, S.K.; Singh, D. Sustainable no–tillage practices with a disc type novel residue cleaning mechanism: Design, development and field evaluation. Soil Tillage Res. 2025, 251, 106560. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Jensen, T.A.; Blackwell, J. Performance comparison of residue management units of no-tillage sowing systems: A review. Eng. Agric. Environ. Food 2019, 12, 181–190. [Google Scholar] [CrossRef]

- Hou, S.Y.; Zou, Z.; Wei, Z.P.; Ji, W.Y.; Chen, H.T. Design and experiment of rectifier for multi-stage lateral movement of corn straw. Trans. Chin. Soc. Agric. Mach. 2021, 52, 45–56. [Google Scholar]

- Yao, W.Y.; Zhao, D.B.; Miao, H.Q.; Cui, P.D.; Wei, M.J.; Diao, P.S. Design and experiment of oblique anti -blocking device for no-tillage planter with shallow plowing stubble cleaning. Trans. Chin. Soc. Agric. Mach. 2022, 53, 42–52. [Google Scholar]

- Matin, M.A.; Hossain, M.I.; Gathala, M.K.; Timsina, J.; Krupnik, T.J. Optimal design and setting of rotary strip-tiller blades to intensify dry season cropping in Asian wet clay soil conditions. Soil Tillage Res. 2021, 207, 104854. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.Y.; Xia, J.F.; Zheng, K.; Cheng, J.; Wei, Y.S.; Guo, L.W.; Li, X.F.; Zhang, J.M. Design and experiments of the barrier type rotary anti-adhesion blade roller with vibration crosspiece. Trans. CSAE 2022, 38, 29–40. [Google Scholar]

- Feng, X.; Xie, C.G.; Tong, J.R.; Guo, S.C.; Qi, B.D.; Gao, Y.P.; Wang, L.J.; Wang, Q. Design and test of vertical axis rotating cutters for cutting corn roots and crown. Agriculture 2025, 15, 717. [Google Scholar] [CrossRef]

- Wei, Z.X.; He, R.Y.; Li, Y.N.; Xu, G.M.; Ding, Q.S. Analysis of strip vertical rotation working parameters on seedbed straw cleaning and flatness effect in rice stubble field. J. Nanjing Agric. Univ. 2024, 47, 1037–1048. [Google Scholar]

- Tamás, K. Modelling the interaction of soil with a passively-vibrating sweep using the discrete element method. Biosyst. Eng. 2024, 245, 199–222. [Google Scholar] [CrossRef]

- Guo, J.B.; Wang, S.; Guo, Z.Y.; Pan, J.L.; Wang, G.Q.; Chen, Z.; Liu, Z.B.; Wu, S.W.; Guan, W. Dynamic characteristics analysis and optimization of track-soil interaction based on DEM-MBD coupling method. Powder Technol. 2026, 468, 121678. [Google Scholar] [CrossRef]

- Maraveas, C.; Tsigkas, N.; Bartzanas, T. Agricultural processes simulation using discrete element method: A review. Comput. Electron. Agric. 2025, 237, 110733. [Google Scholar] [CrossRef]

- Mohammadi, M.; Karparvarfard, S.H.; Razavizadeh, N.; Tekeste, M.; Moazeni_kalat, A.; Nematollahi, M.A.; Namjoo, M.; Rostami, M.A. Simulation of interaction between soil and rotary tiller to predict the power consumption and investigation of surface soil mixing. Soil Tillage Res. 2025, 252, 106626. [Google Scholar] [CrossRef]

- Makange, N.R.; Ji, C.Y.; Nyalala, I.; Sunusi, I.I.; Opiyo, S. Prediction of precise subsoiling based on analytical method, discrete element simulation and experimental data from soil bin. Sci. Rep. 2021, 11, 11082. [Google Scholar] [CrossRef] [PubMed]

- Celik, A.; Altikat, S. The effect of power harrow on the wheat residue cover and residue incorporation into the tilled soil layer. Soil Tillage Res. 2022, 215, 105202. [Google Scholar] [CrossRef]

- Issa, I.I.M.; Zhang, Z.G.; ElKolaly, W.; Wang, F.A.; Wang, Y. Innovated design, simulation and evaluation of potato harvester excavation and separation conveyors. Int. J. Agric. Biol. Eng. 2025, 18, 132–145. [Google Scholar] [CrossRef]

- Tamás, K.; Bernon, L. Role of particle shape and plant roots in the discrete element model of soil–sweep interaction. Biosyst. Eng. 2021, 211, 77–96. [Google Scholar] [CrossRef]

- Bartenev, I.M.; NLysych, M.N.; Shabanov, M.L.; Bukhtoyarov, L.D. Comparative studies of physical models of soil implemented by the method of discrete elements (DEM) on the example of a simple loosening tillage tool. IOP Conf. Ser. Earth Environ. Sci. 2019, 392, 012050. [Google Scholar] [CrossRef]

- Li, J.W.; Tong, J.; Hu, B.; Wang, H.B.; Mao, C.Y.; Ma, Y.H. Calibration of parameters of interaction between clayey black soil with different moisture content and soil-engaging component in northeast China. Trans. CSAE 2019, 35, 130–140. [Google Scholar]

- Xia, J.F.; Zhang, P.; Yuan, H.W.; Du, J.; Zheng, K.; Li, Y.F. Calibration and verification of flexible rice straw model by discrete element method. Trans. Chin. Soc. Agric. Mach. 2024, 55, 174–184. [Google Scholar]

- Wang, J.F.; Yang, D.Z.; Wang, Z.T.; Fu, Z.D.; Wang, J.W.; Weng, W.X. Design and experiment of rice straw biaxial deep-buried returning machine. Trans. Chin. Soc. Agric. Mach. 2023, 54, 21–30. [Google Scholar]

- Shan, F.K.; Kang, S.; Zhu, J.X.; Wang, Y.W.; Wang, J. Study on Tillage Fertilizer Mixing Effect Under Vertical Smashing Rotary Tillage and Rotary Tillage Based on EDEM. J. Agric. Sci. Technol. 2023, 11, 90–102. [Google Scholar]

- Awuah, E.; Zhou, J.; Liang, Z.; Aikins, K.A.; Gbenontin, B.V.; Mecha, P.; Makange, N.R. Parametric analysis and numerical optimisation of jerusalem artichoke vibrating digging shovel using discrete element method. Soil Tillage Res. 2022, 219, 105344. [Google Scholar] [CrossRef]

- Szpisják-Gulyás, N.; Al-Tayawi, A.N.; Horváth, Z.H.; László, Z.; Kertész, S.; Hodúr, C. Methods for experimental design, central composite design and the Box–Behnken design, to optimise operational parameters: A review. Acta Aliment. 2023, 52, 521–537. [Google Scholar] [CrossRef]

- Miressa, S.B.; Ding, Q.S.; Li, Y.N.; Amisi, E.O. Optimization of tillage operation parameters to enhance straw incorporation in rice-wheat rotation field. Agriculture 2024, 15, 54. [Google Scholar] [CrossRef]

- Zhang, S.L.; Huang, Y.X.; Zhao, H.B.; Fu, Z.L.; Liu, Z.D.; Shi, J.T. Design and experiment of cutting and throwing combined anti-blocking device for wide-seedbed seeding of wheat. Trans. Chin. Soc. Agric. Mach. 2024, 55, 40–52. [Google Scholar]

- Chen, H.T.; Lu, Y.D.; Wang, X.; Zhang, Y.; Yu, C.P. Design and test of lateral stubble clearing blade for high-speed operation in corn stubble field. Trans. Chin. Soc. Agric. Mach. 2025, 56, 163–173. [Google Scholar]

| Materials | Parameters | Values |

|---|---|---|

| Soil particles [29] | Poisson’s ratio | 0.46 |

| Shear modulus/Pa | 1.00 × 106 | |

| Density/(kg·m−3) | 1516.40 | |

| Straw [30] | Poisson’s ratio | 0.40 |

| Shear modulus/Pa | 1.00 × 106 | |

| Density/(kg·m−3) | 241.00 | |

| Normal stiffness per unit area/(N·m−2) | 3.04 × 1010 | |

| Shear stiffness per unit area/(N·m−2) | 2.30 × 1010 | |

| Critical normal stress/Pa | 5.50 × 108 | |

| Critical shear stress/Pa | 5.50 × 108 | |

| Cutter tooth [29] | Poisson’s ratio | 0.29 |

| Shear modulus/Pa | 7.90 × 1010 | |

| Density/(kg·m−3) | 7861.00 | |

| Soil particles [29] | Coefficient of restitution | 0.50 |

| Coefficient of static friction | 0.80 | |

| Coefficient of rolling friction | 0.23 | |

| Surface energy/(J·m−2) | 8.41 | |

| Straw and cutter tooth [30] | Coefficient of restitution | 0.30 |

| Coefficient of static friction | 0.15 | |

| Coefficient of rolling friction | 0.10 | |

| Soil particles and straw [31] | Coefficient of restitution | 0.60 |

| Coefficient of static friction | 0.55 | |

| Coefficient of rolling friction | 0.20 | |

| Soil particles and cutter tooth [29] | Coefficient of restitution | 0.61 |

| Coefficient of static friction | 0.57 | |

| Coefficient of rolling friction | 0.06 | |

| Surface energy/(J·m−2) | 5.50 | |

| Straw and cutter tooth [30] | Coefficient of restitution | 0.30 |

| Coefficient of static friction | 0.16 | |

| Coefficient of rolling friction | 0.09 |

| Measurement Interval/cm | Average Length/cm | Average Diameter/mm | Proportion of Mass/% |

|---|---|---|---|

| (0,5] | 4.65 | 6.2 | 10.5 |

| (5,10] | 7.55 | 7.4 | 12.7 |

| (10,15] | 13.61 | 8.2 | 35.1 |

| (15,∞) | 18.49 | 6.7 | 41.7 |

| Code No. | OS v/(m·s−1) | RS n/(r·min−1) | DA α/° |

|---|---|---|---|

| −1 | 1.5 | 200 | 0 |

| 0 | 2.0 | 300 | 30 |

| +1 | 2.5 | 400 | 60 |

| NO. | Experimental Factors | Experimental Index | |||

|---|---|---|---|---|---|

| v/(m·s−1) | n/(r·min−1) | α/(°) | Y1/% | Y2/% | |

| 1 | 1.5 | 200 | 30 | 97.1 | 27.3 |

| 2 | 2.5 | 200 | 30 | 89.5 | 21.4 |

| 3 | 1.5 | 400 | 30 | 97.3 | 28.7 |

| 4 | 2.5 | 400 | 30 | 95.3 | 27.8 |

| 5 | 1.5 | 300 | 0 | 95.2 | 32.3 |

| 6 | 2.5 | 300 | 0 | 92.8 | 27.7 |

| 7 | 1.5 | 300 | 60 | 94.2 | 26.2 |

| 8 | 2.5 | 300 | 60 | 91.6 | 23.4 |

| 9 | 2.0 | 200 | 0 | 92.4 | 25.1 |

| 10 | 2.0 | 400 | 0 | 96.6 | 27.4 |

| 11 | 2.0 | 200 | 60 | 87.5 | 21.7 |

| 12 | 2.0 | 400 | 60 | 95.1 | 26.9 |

| 13 | 2.0 | 300 | 30 | 93.7 | 25.9 |

| 14 | 2.0 | 300 | 30 | 94.9 | 26.1 |

| 15 | 2.0 | 300 | 30 | 96.0 | 28.1 |

| 16 | 2.0 | 300 | 30 | 93.9 | 26.5 |

| 17 | 2.0 | 300 | 30 | 95.7 | 25.8 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F Values | p Values |

|---|---|---|---|---|---|

| Model | 98.34 | 9 | 10.93 | 5.74 | 0.0156 ** |

| v | 26.65 | 1 | 26.65 | 14.00 | 0.0073 *** |

| n | 39.60 | 1 | 39.60 | 20.80 | 0.0026 *** |

| α | 9.25 | 1 | 9.25 | 4.86 | 0.0634 * |

| v-n | 7.84 | 1 | 7.84 | 4.12 | 0.0820 * |

| v-α | 0.01 | 1 | 0.01 | <0.01 | 0.9443 |

| n-α | 2.89 | 1 | 2.89 | 1.52 | 0.2577 |

| v2 | 0.27 | 1 | 0.27 | 0.14 | 0.7158 |

| n2 | 0.37 | 1 | 0.37 | 0.19 | 0.6741 |

| α2 | 11.39 | 1 | 11.39 | 5.98 | 0.0443 ** |

| Residual | 13.33 | 7 | 1.90 | ||

| Lack of fit | 9.06 | 3 | 3.02 | 2.83 | 0.1706 |

| Pure error | 4.27 | 4 | 1.07 | ||

| Total | 111.66 | 16 |

| Sources | Sum of Squares | Degree of Freedom | Mean Square | F Values | p Values |

|---|---|---|---|---|---|

| Model | 98.31 | 9 | 10.92 | 8.59 | 0.0049 *** |

| v | 25.21 | 1 | 25.21 | 19.81 | 0.0030 *** |

| n | 29.26 | 1 | 29.26 | 23.00 | 0.0020 *** |

| α | 25.56 | 1 | 25.56 | 20.09 | 0.0029 *** |

| v-n | 6.25 | 1 | 6.25 | 4.91 | 0.0622 * |

| v-α | 0.81 | 1 | 0.81 | 0.64 | 0.4511 |

| n-α | 2.10 | 1 | 2.10 | 1.65 | 0.2395 |

| v2 | 3.98 | 1 | 3.98 | 3.13 | 0.1202 |

| n2 | 5.59 | 1 | 5.59 | 4.40 | 0.0742 * |

| α2 | 0.012 | 1 | 0.012 | <0.01 | 0.9266 |

| Residual | 8.91 | 7 | 1.27 | ||

| Lack of fit | 5.34 | 3 | 1.78 | 1.99 | 0.2571 |

| Pure error | 3.57 | 4 | 0.89 | ||

| Total | 107.22 | 16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, N.; Li, H.; Jiang, B.; Chen, Y.; Cui, J.; Ji, W.; Zhang, H. Design and Parameter Optimization of a Vertical Rotary Fixed-Angle Straw Cleaning Device. Agriculture 2025, 15, 2113. https://doi.org/10.3390/agriculture15202113

Shi N, Li H, Jiang B, Chen Y, Cui J, Ji W, Zhang H. Design and Parameter Optimization of a Vertical Rotary Fixed-Angle Straw Cleaning Device. Agriculture. 2025; 15(20):2113. https://doi.org/10.3390/agriculture15202113

Chicago/Turabian StyleShi, Naiyu, He Li, Bailin Jiang, Yan Chen, Jiaxing Cui, Wenyi Ji, and Huaiyu Zhang. 2025. "Design and Parameter Optimization of a Vertical Rotary Fixed-Angle Straw Cleaning Device" Agriculture 15, no. 20: 2113. https://doi.org/10.3390/agriculture15202113

APA StyleShi, N., Li, H., Jiang, B., Chen, Y., Cui, J., Ji, W., & Zhang, H. (2025). Design and Parameter Optimization of a Vertical Rotary Fixed-Angle Straw Cleaning Device. Agriculture, 15(20), 2113. https://doi.org/10.3390/agriculture15202113