Design and Experiment of the Follow-Up Seedling Picking and Depositing Mechanism for the Pepper Plug Seedling Transplanter

Abstract

1. Introduction

2. Materials and Methods

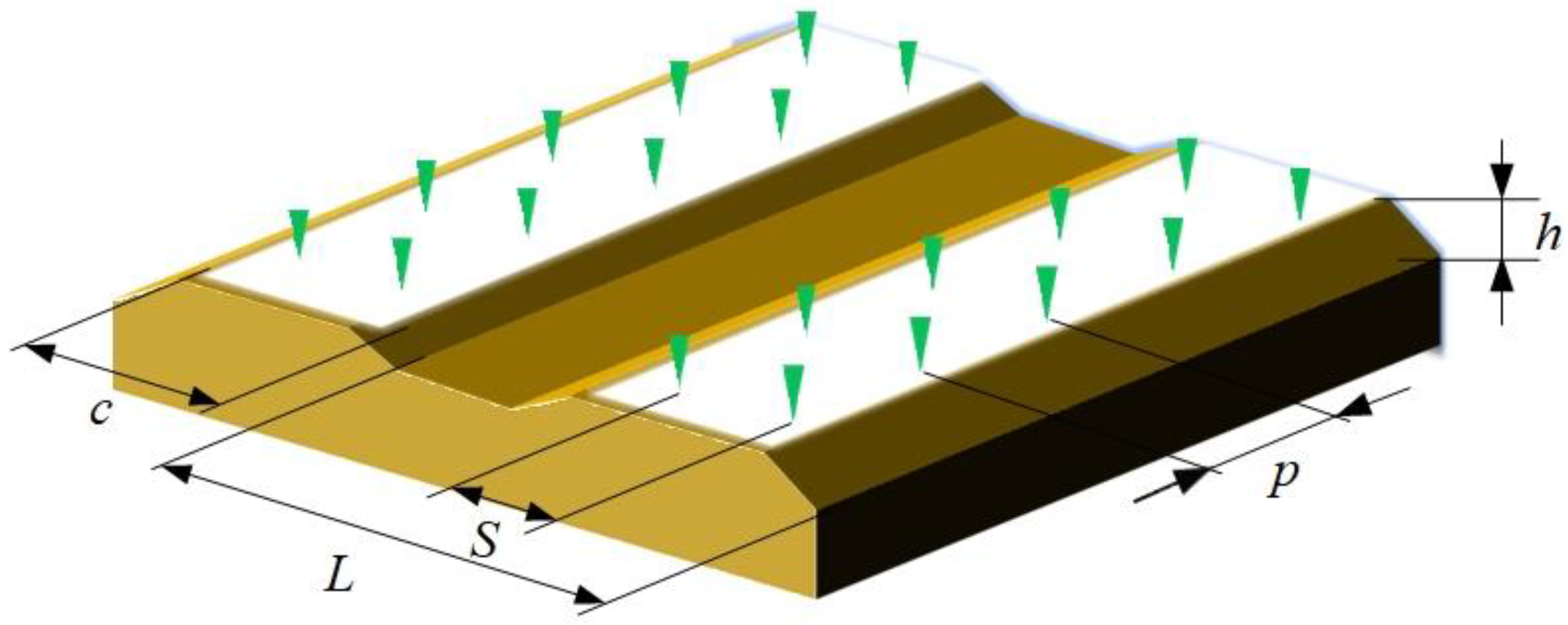

2.1. Agronomic Requirements for Pepper Cultivation

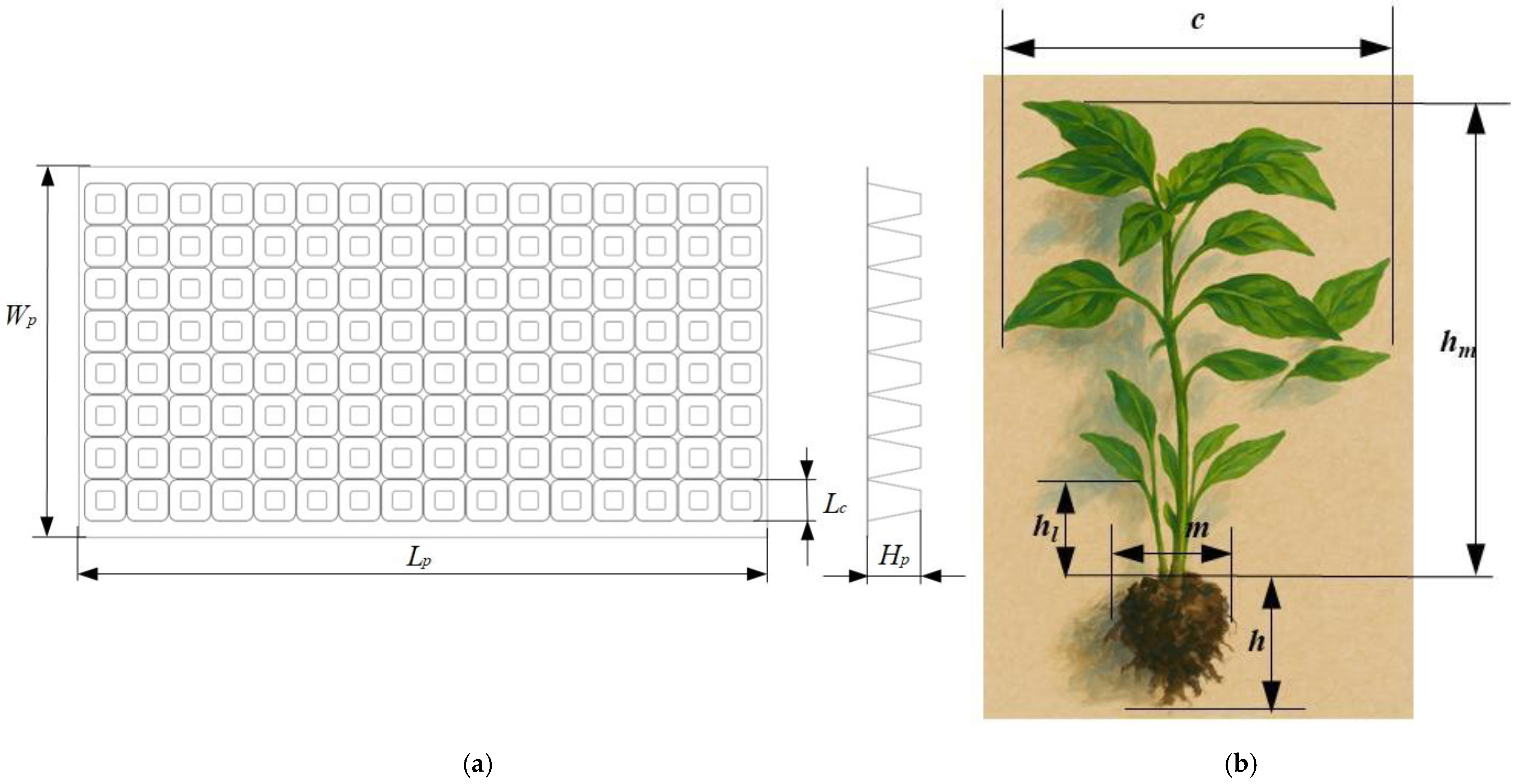

2.2. Morphological Characteristics of Plug Seedlings and Plug Trays

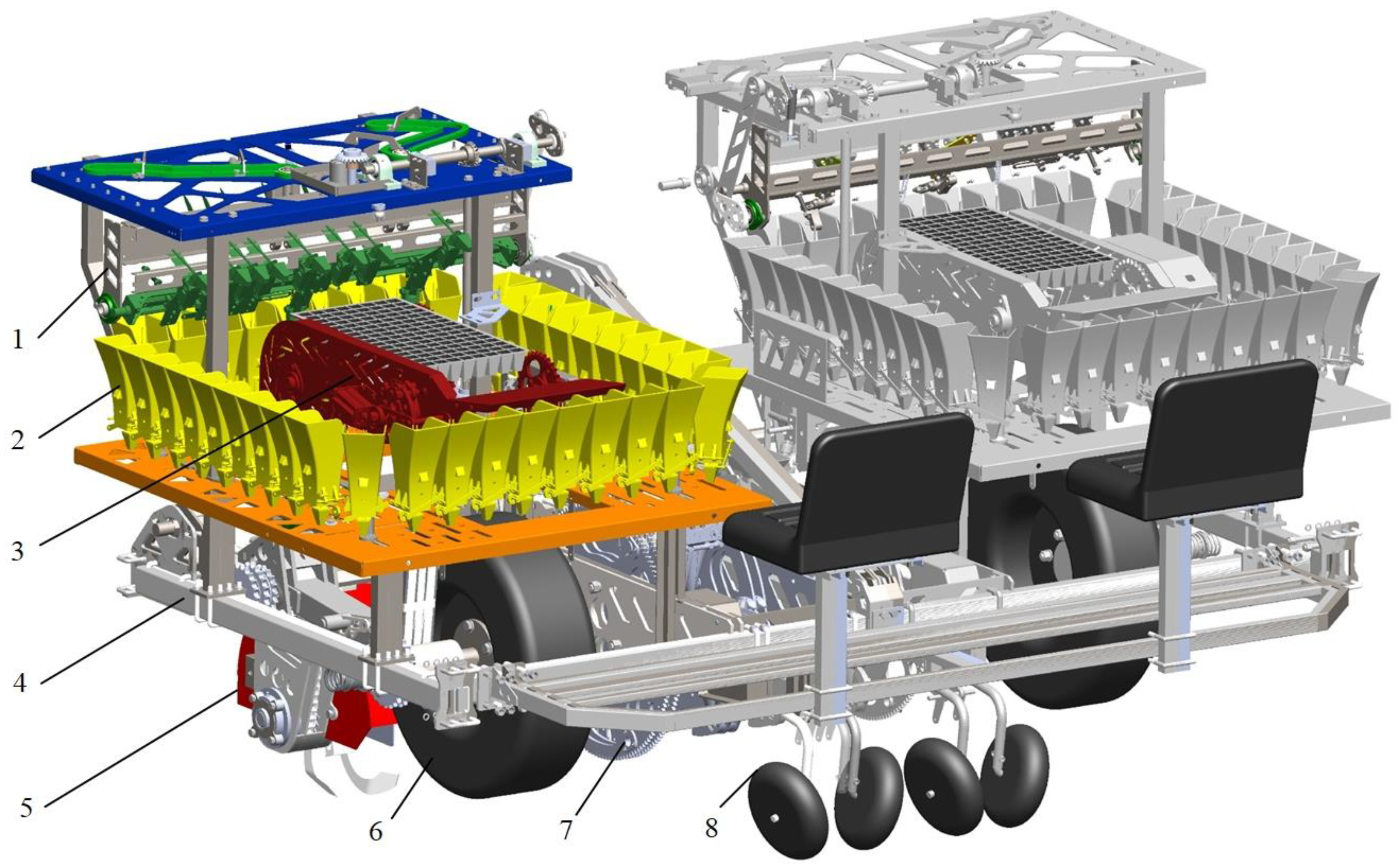

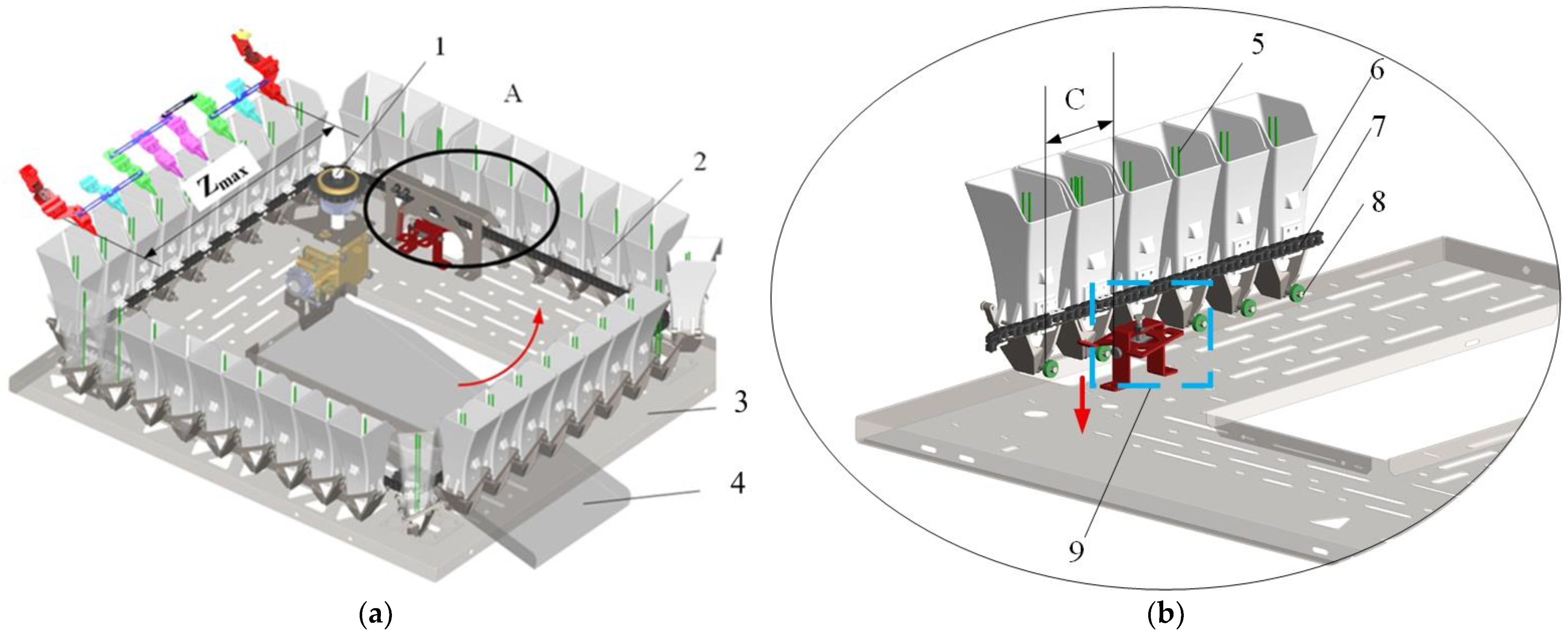

2.3. Overall Machine Structure and Working Principle

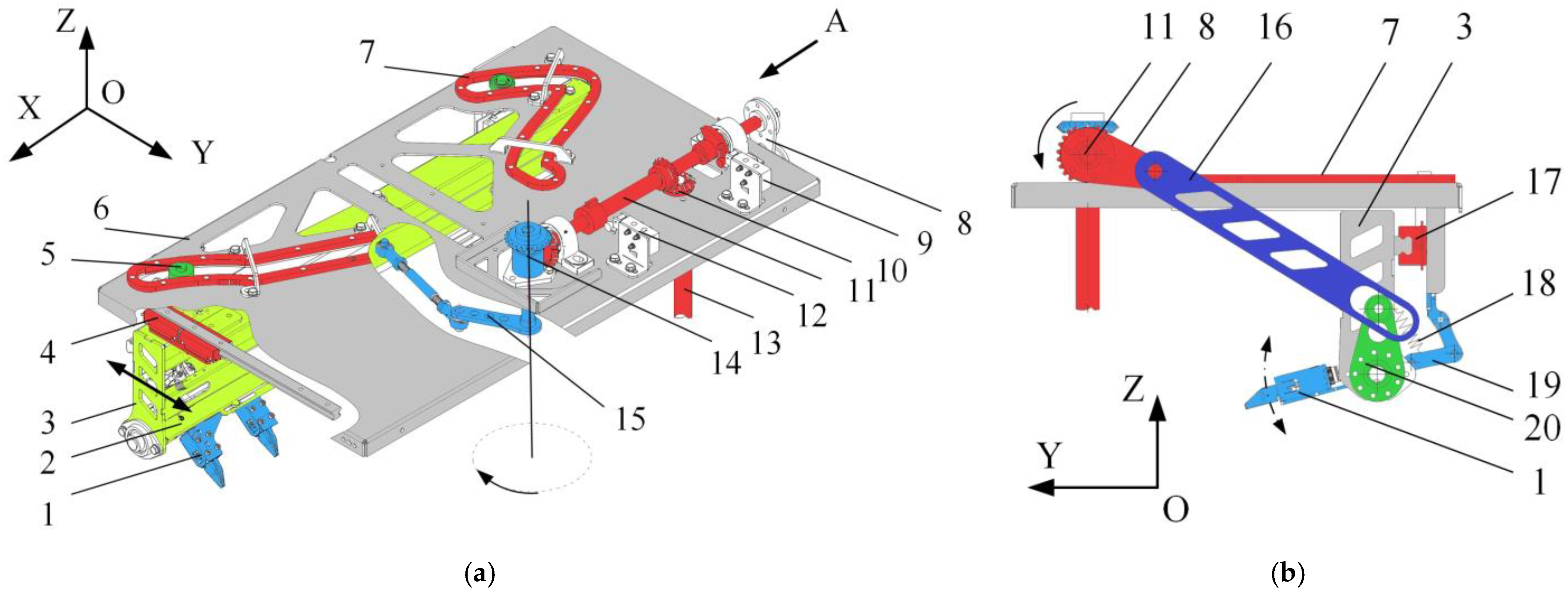

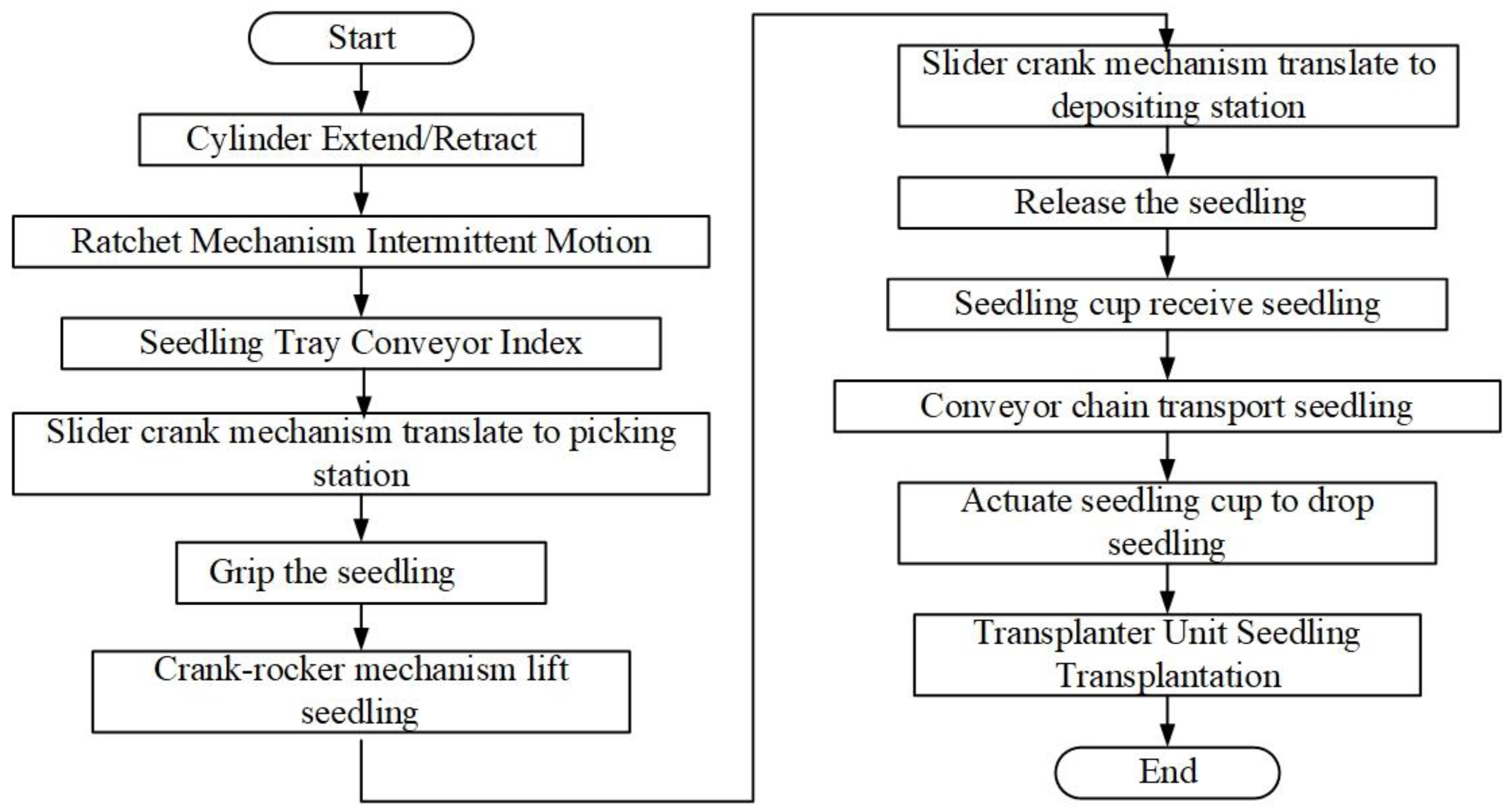

2.4. Working Principle of the Key Mechanisms

2.4.1. Working Principle of the Seedling Separating Mechanism

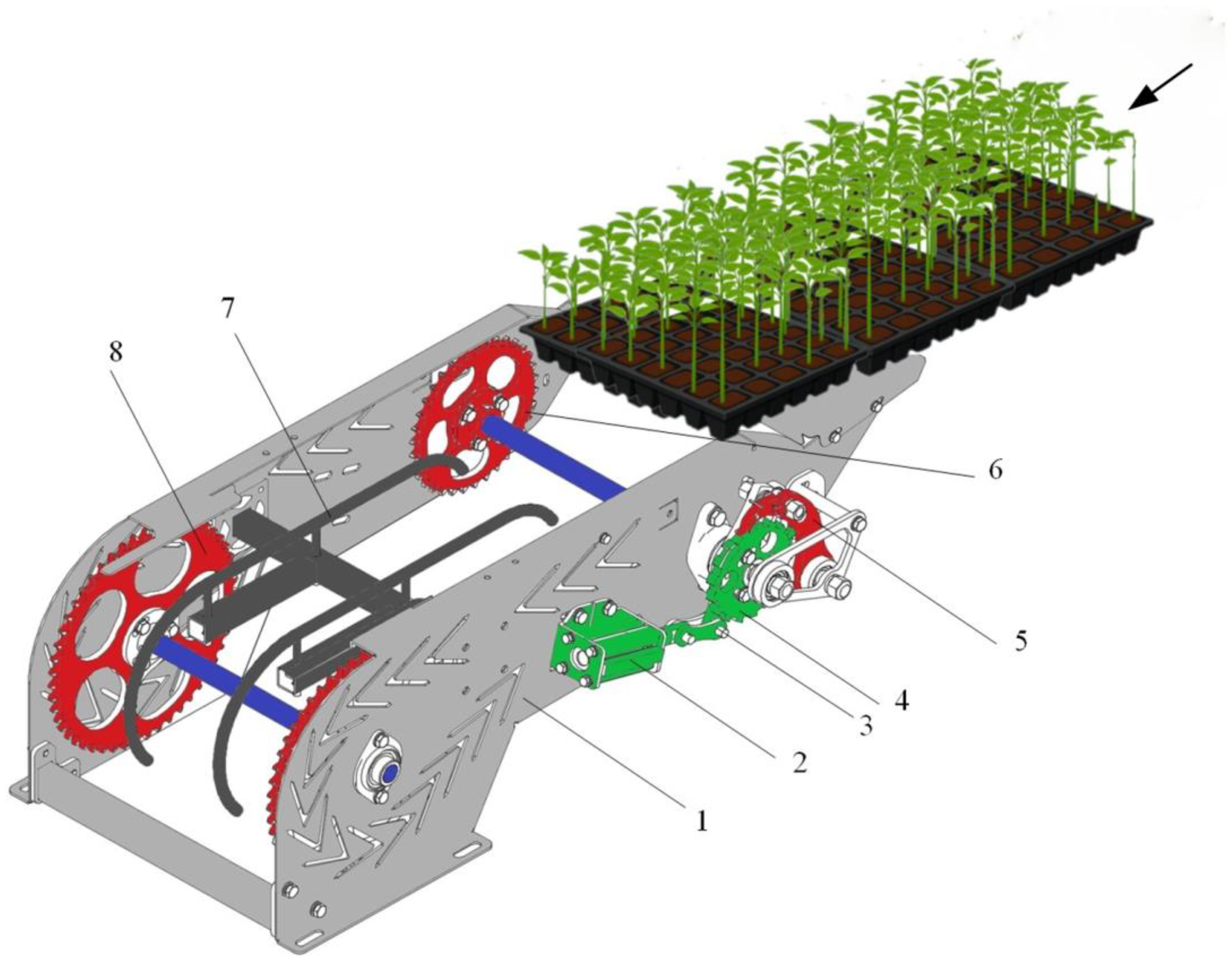

2.4.2. Working Principle of the Seedling Conveying Mechanism

2.4.3. Working Principle of the Automatic Tray Feeding Mechanism

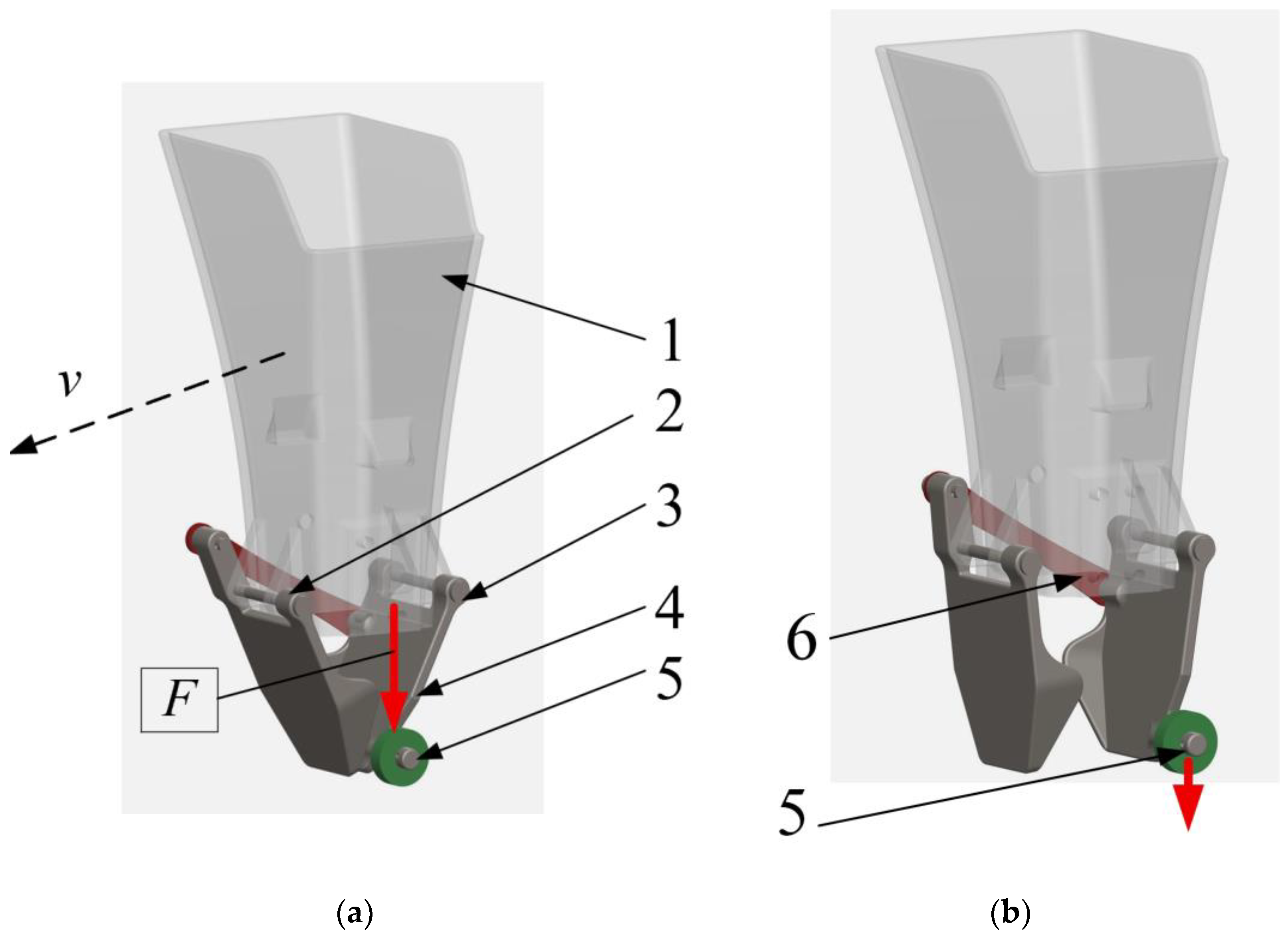

2.4.4. Working Principle of the Seedling Cup

2.5. Key Mechanism Design of the Transplanter

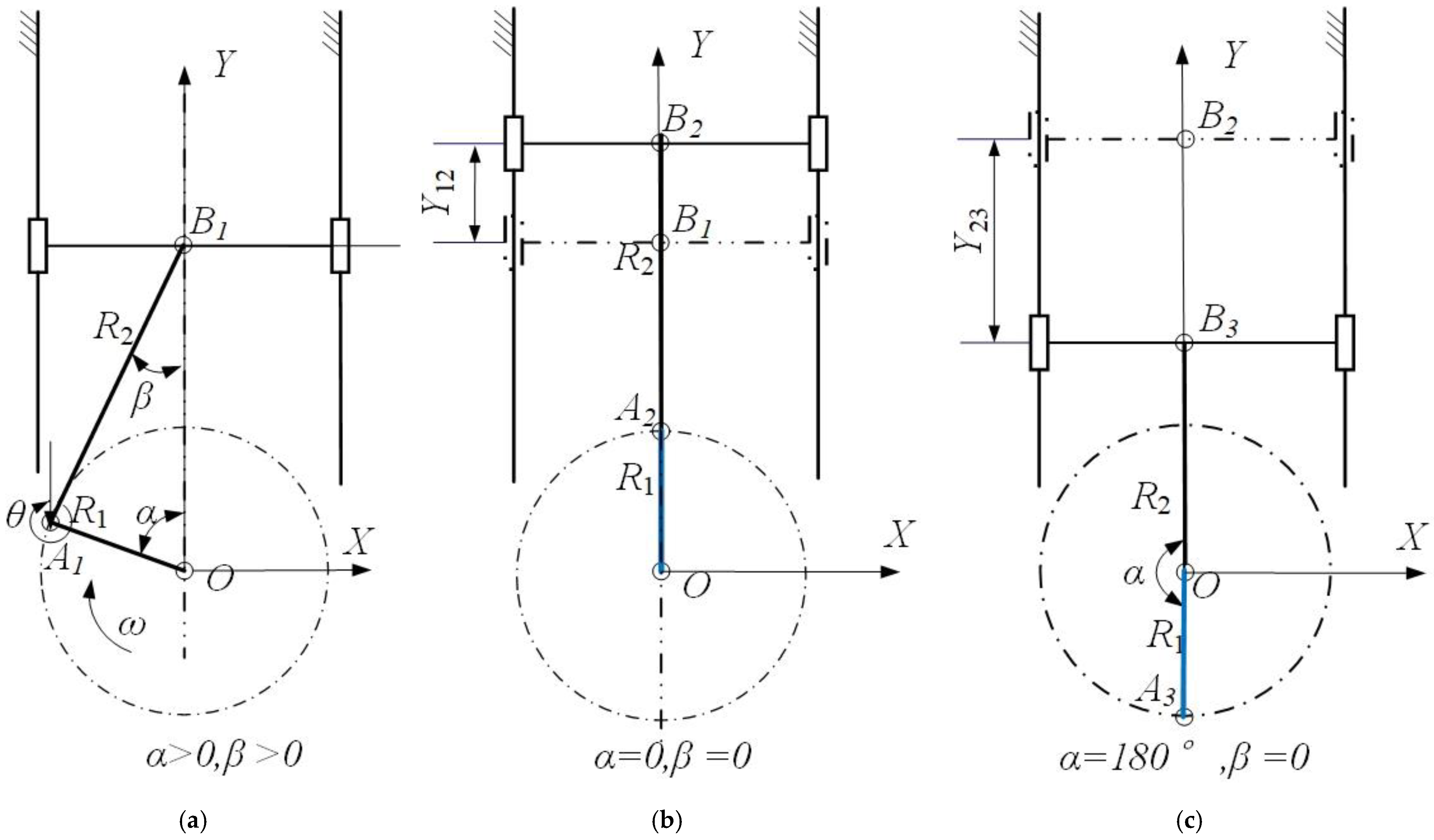

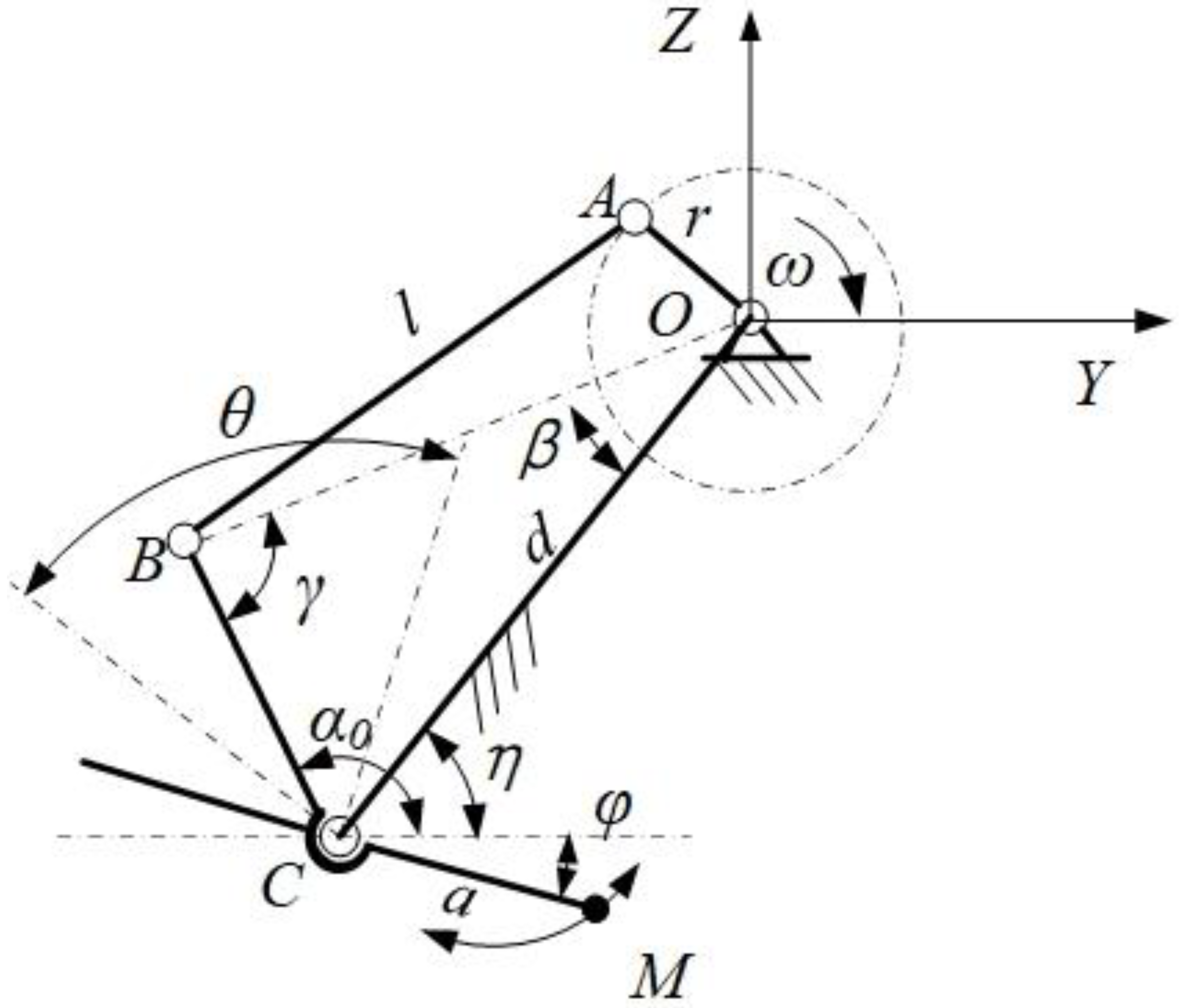

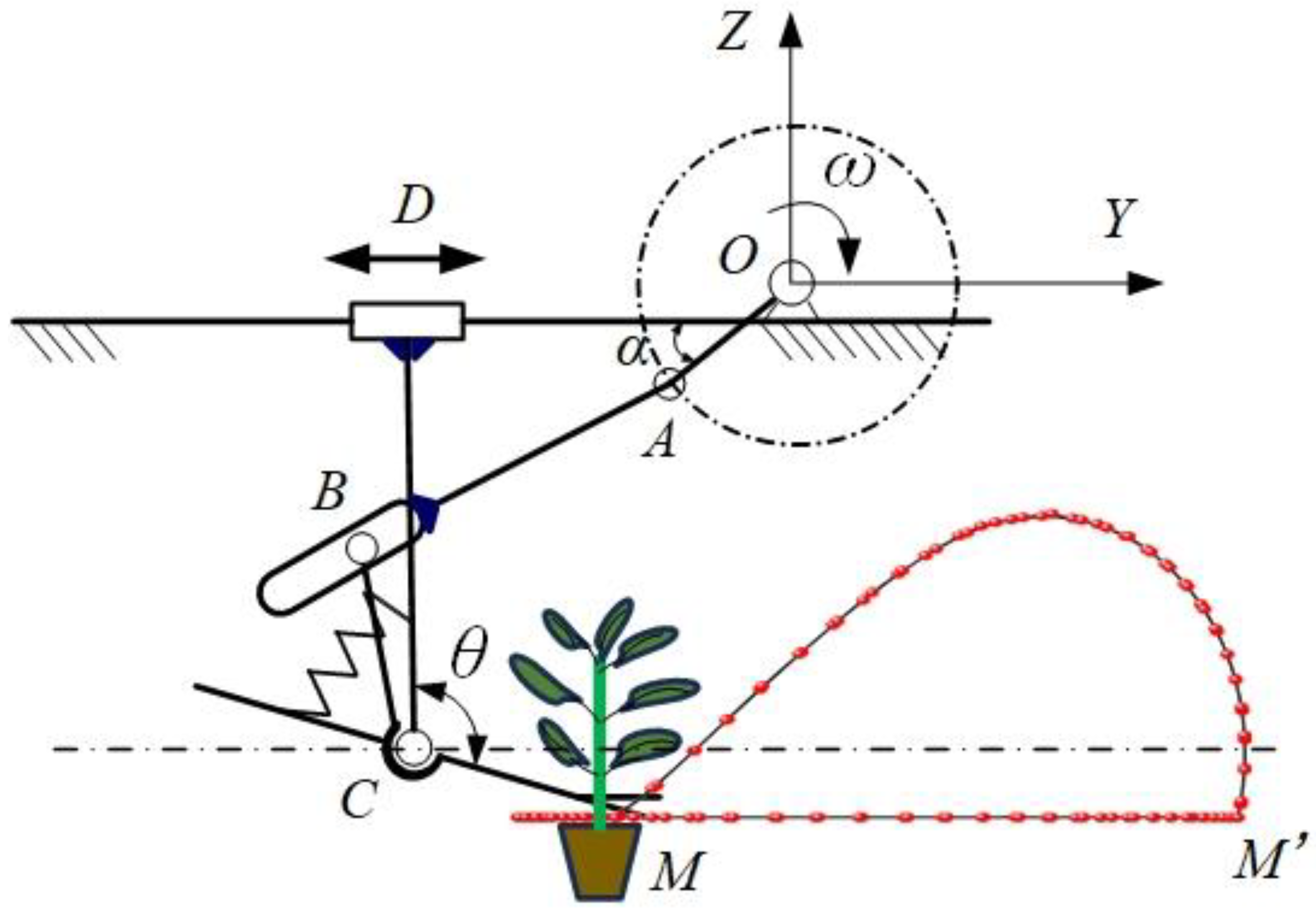

2.5.1. Trajectory Planning for Automated Seedling Picking and Depositing

2.5.2. YOZ Plane Trajectory Planning for Automated Seedling Picking and Depositing Mechanism

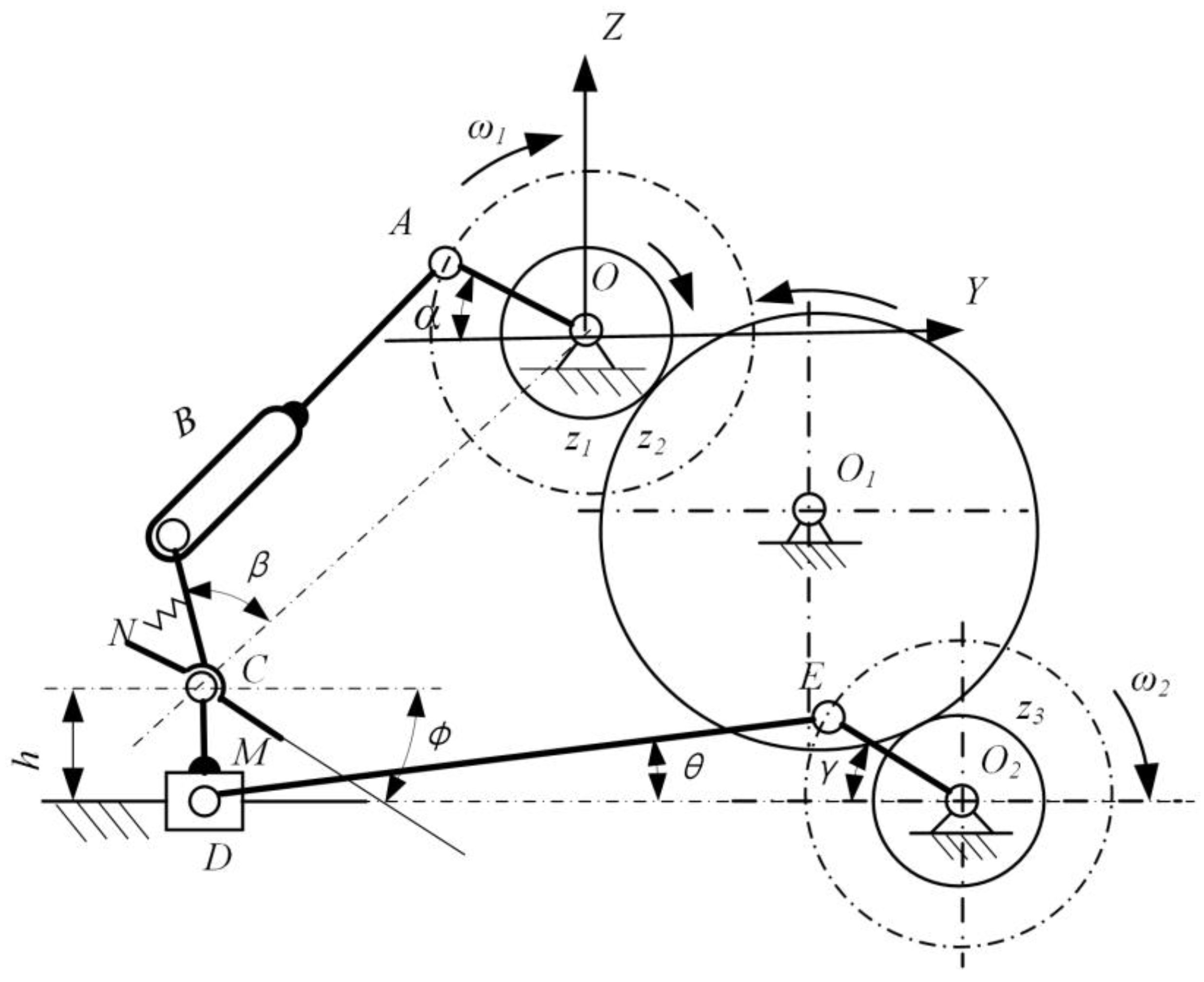

2.5.3. Design of the XOY Plane Crank–Slider Mechanism for Seedling Transplantation

2.5.4. Design of the Seedling-Separation Trajectory for the Seedling-Separation Mechanism in the XOY Plane

2.5.5. Design of the Crank–Rocker Seedling-Picking Mechanism

2.5.6. Coupled Design of Multi-Planar Mechanisms

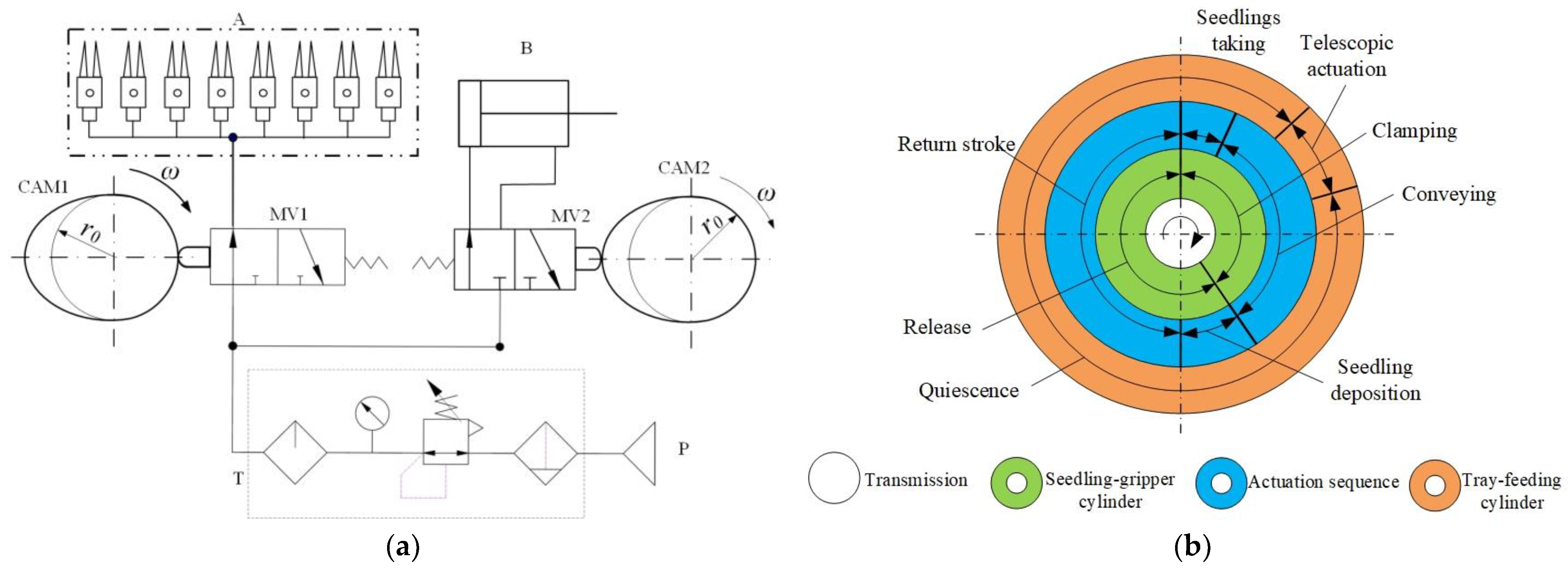

2.6. Pneumatic System Design

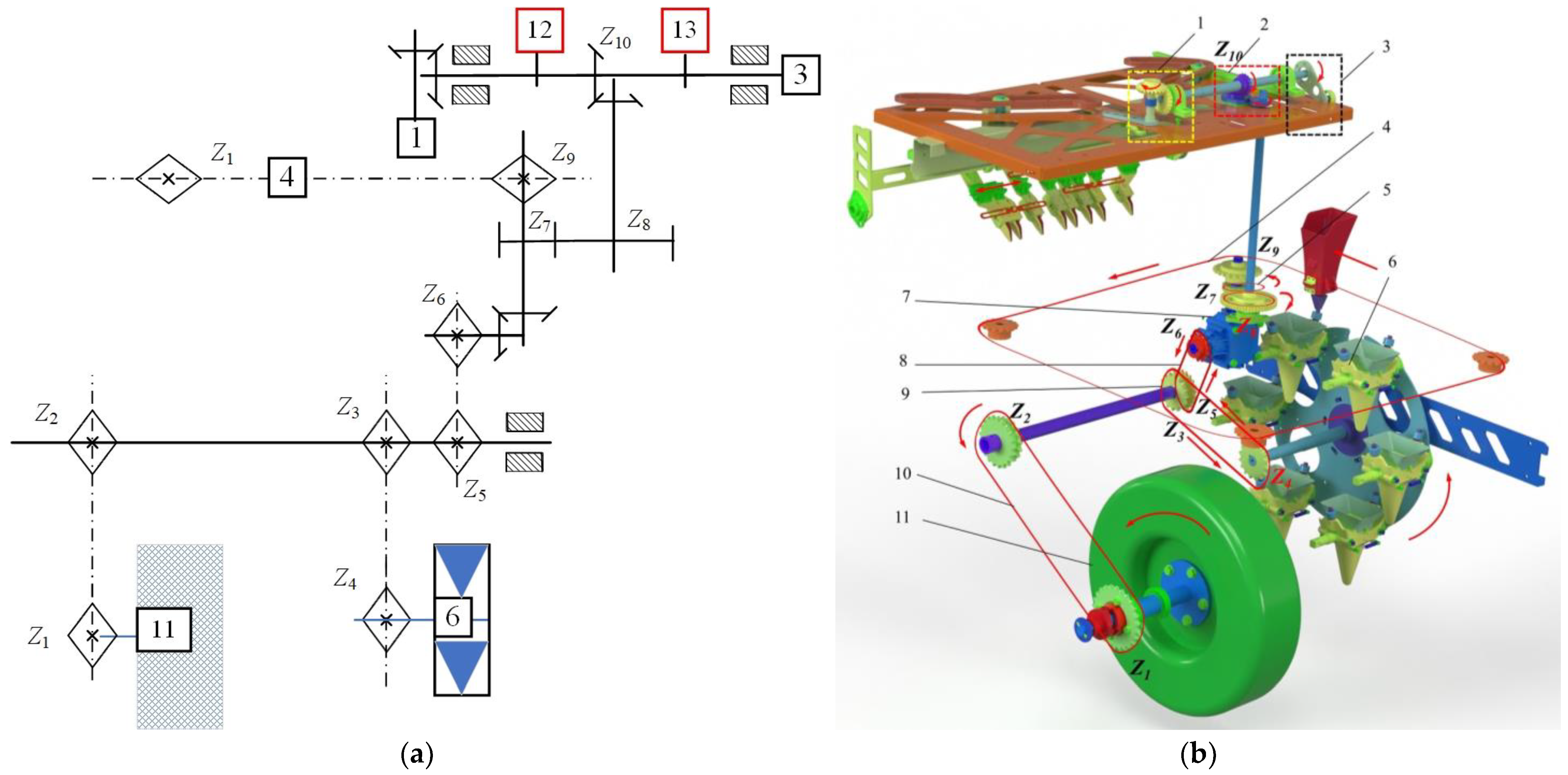

2.7. Power System Design

2.8. Experimental Design

2.8.1. Bench Test

2.8.2. Field Experiment

3. Results and Discussion

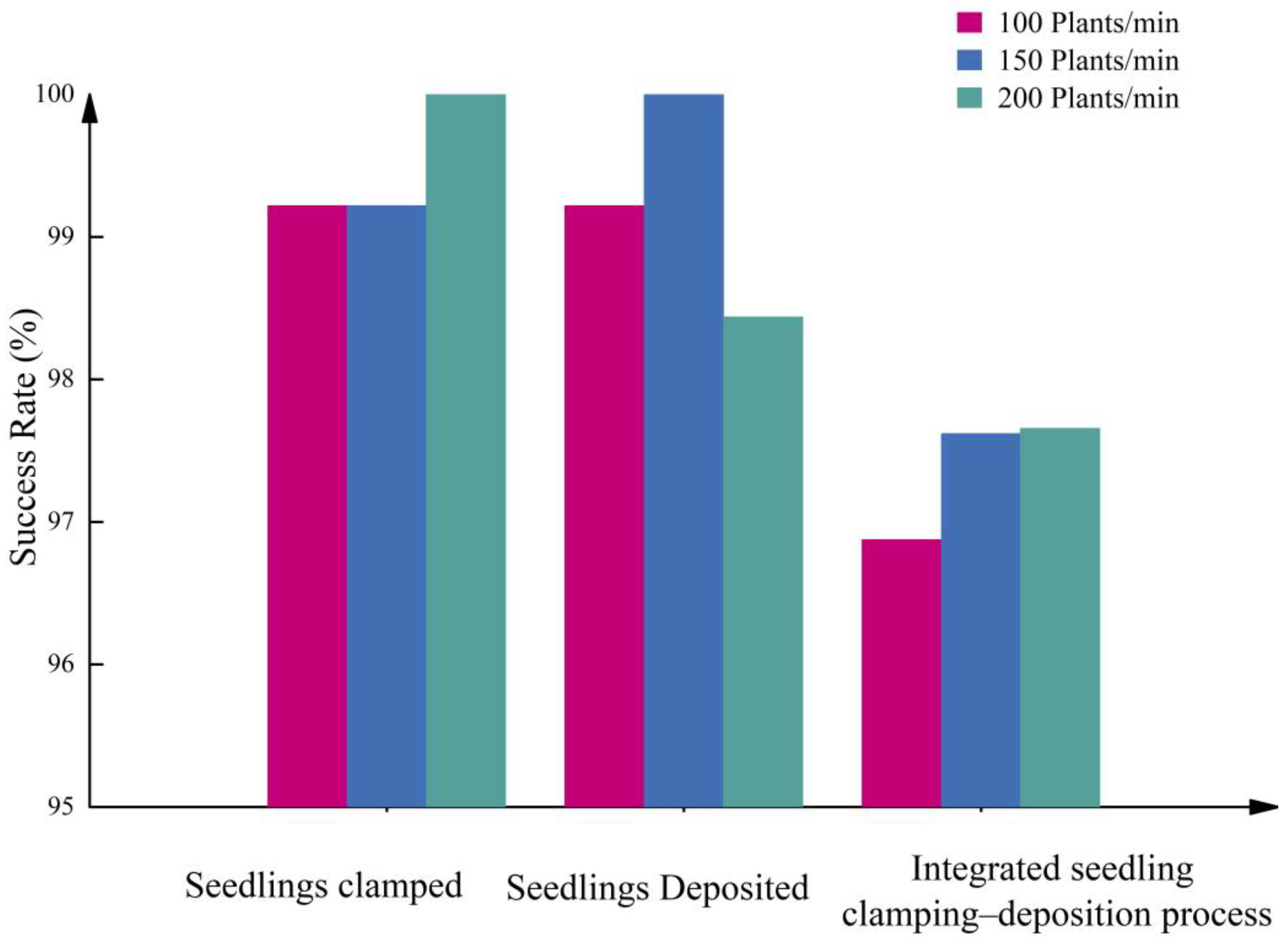

3.1. Bench Test Results and Discussion

3.2. Field Test Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, M.; Sun, H.; Xu, X.; Yang, J.; Wang, G.; Wei, Z.; Xu, T.; Yin, J. Study on the Method and Mechanism of Seedling Picking for Pepper (Capsicum annuum L.) Plug Seedlings. Agriculture 2024, 14, 11. [Google Scholar] [CrossRef]

- Wu, G.; Wang, S.; Zhang, A.; Xiao, Y.; Li, L.; Yin, Y.; Li, H.; Wen, C.; Yan, B. Optimized design and experiment of a self-covering furrow opener for an automatic sweet potato seedling transplanting machine. Sustainability 2023, 15, 13091. [Google Scholar] [CrossRef]

- Yu, G.; Wang, L.; Sun, L.; Zhao, X.; Ye, B. Advancement of mechanized transplanting technology and equipments for field crops. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–20. [Google Scholar]

- Khadatkar, A.; Sawant, C.P.; Magar, A.P.; Kumar, V. Agricultural robots and automated machinery for handling of nursery seedlings with special reference to the transplanting devices. Discov. Appl. Sci. 2025, 7, 916. [Google Scholar] [CrossRef]

- Sun, L.; Xu, H.; Zhou, Y.; Shen, J.; Yu, G.; Hu, H.; Miao, Y. Kinematic Synthesis and Simulation of a Vegetable Pot Seedling Transplanting Mechanism with Four Exact Task Poses. Int. J. Agric. Biol. Eng. 2023, 16, 85–95. [Google Scholar] [CrossRef]

- Yang, J.; Zhou, M.; Yin, D.; Yin, J. Design and development of rice pot-seedling transplanting machinery based on a non-circular gear mechanism. Appl. Sci. 2024, 14, 1027. [Google Scholar] [CrossRef]

- Hu, S.; Hu, M.; Zhang, W. Design and Experiment of Flexible Clamping Device for Pepper Plug Seedlings. Adv. Mech. Eng. 2022, 14, 16878132221107254. [Google Scholar] [CrossRef]

- Sharma, A.; Khar, S. Design and development of a vegetable plug seedling transplanting mechanism for a semi-automatic transplanter. Sci. Hortic. 2024, 326, 112773. [Google Scholar] [CrossRef]

- Khadatkar, A.; Pandirwar, A.P.; Paradkar, V. Design, Development and Application of a Compact Robotic Transplanter with Automatic Seedling Picking Mechanism for Plug-Type Seedlings. Sci. Rep. 2023, 13, 1883. [Google Scholar] [CrossRef] [PubMed]

- Markumningsih, S.; Seok-Joon, H.; Jeong-Hun, K.; Moon-Kyeong, J.; Ju-Seok, N. Stress Simulation on Four-Bar Link-Type Transplanting Device of Semiautomatic Vegetable Transplanter. Agriculture 2024, 14, 42. [Google Scholar] [CrossRef]

- Cao, X.; Wang, Q.; Li, H.; He, J.; Lu, C.; Xu, D.; Wang, X. Design and Experiment of the Pneumatic Pressure Control Device for No-till Planter. Int. J. Agric. Biol. Eng. 2023, 16, 37–46. [Google Scholar] [CrossRef]

- Wang, Y.; He, Z.; Wang, J.; Wu, C.; Yu, G.; Tang, Y. Experiment on transplanting performanceof automatic vegetable pot seedling transplanter for dry land. Trans. Chin. Soc. Agric. Mach. 2018, 34, 19–25. [Google Scholar]

- Yan, H.; Liu, C.; Li, P.; Chen, R.; Zhou, H.; Zhuang, T. Design and Experiment of Duckbill Planting Device with Adjustable Static Trajectory for Planting Vegetable Transplanters. Trans. Chin. Soc. Agric. Mach. 2023, 54, 71–81. [Google Scholar]

- Han, C.; Yang, W.; Zhang, X.; Guo, H.; Yin, W. Design and test of automatic feed system for tray seedlings transplanter. Trans. CSAE 2013, 29, 51–61. [Google Scholar]

- Wen, Y.; Zhang, J.; Yuan, T.; Tan, Y. Current situation and analysis of automatic pick-up technology for vegetable plug seedlings. J. China Agric. Univ. 2021, 26, 128–142. [Google Scholar]

- Parish, R. Current developments in seeders and transplanters for vegetable crops. HortTechnology 2005, 15, 346. [Google Scholar] [CrossRef]

- Tian, Z.; Ma, W.; Yang, Q.; Yao, S.; Zhang, M.; Duan, F.; Xu, H. Research status and problem analysis of the transplanting machinery of greenhouse pot seedling. J. China Agric. Univ. 2022, 27, 22–38. [Google Scholar]

- Yu, G.H.; Wang, X.L.; Liu, J.G.; Ye, B.L.; Li, X.; Zhao, X. Design and Experiment of Multi Row Seedling Taking Mechanism for Dense Planting and Transplanting of Vegetable Pot Seedlings. Trans. Chin. Soc. Agric. Mach. 2023, 54, 94–103. [Google Scholar]

- Cao, L.; Liu, C.; Zhang, C. Structure Design and Simulation of Plug-Seedling Gripping Device. In Proceedings of the 2016 International Conference on Mechanics, Materials and Structural Engineering (ICMMSE), Jeju Island, Republic of Korea, 18–20 March 2016; pp. 50–54. [Google Scholar]

- Yao, M.; Hu, J.; Liu, W.; Shi, J.; Jin, Y.; Lv, J.; Sun, Z.; Wang, C. Precise Servo-Control System of a Dual-Axis Positioning Tray Conveying Device for Automatic Transplanting Machine. Agriculture 2024, 14, 1431. [Google Scholar] [CrossRef]

- Tong, J.; Qiu, Z.; Zhou, H.; Bashir, M.K.; Yu, G.; Wu, C.; Du, X. Optimizing the Path of Seedling Transplanting with Multi-End Effectors by Using an Improved Greedy Annealing Algorithm. Comput. Electron. Agric. 2022, 201, 107276. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, Y.; Tian, J.; Yuan, T.; Zhang, J.; Tan, Y. Design and experiment of vegetable transplanting pot seedling detection and missing seedling compensation system. Trans. Chin. Soc. Agric. Mach. 2020, 51, 124–125. [Google Scholar]

- Zhang, Z. Current status and technical key points of industrial chili pepper cultivation in Yanqi County, Xinjiang. Agric. Eng. Technol. 2023, 43, 84–85. [Google Scholar]

- Rasool, K.; Ali, M.; Chowdhury, M.; Kwon, H.J.; Swe, K.M.; Chung, S.O. Theoretical analysis of velocity, acceleration and torque calculation of a five-bar onion transplanting mechanism. IOP Conf. Ser. Earth Environ. Sci. 2021, 733, 012019. [Google Scholar] [CrossRef]

- Ye, B.; Zeng, G.; Deng, B.; Yang, C.; Liu, J.; Yu, G. Design and Tests of a Rotary Plug Seedling Pick-up Mechanism for Vegetable Automatic Transplanter. Int. J. Agric. Biol. Eng. 2020, 13, 70–78. [Google Scholar] [CrossRef]

- Chen, B. Research on Automatic Seedling Supply Device of Chili Pot Seedling Transplanter. Ph.D. Thesis, Hunan Agricultural University, Changsha, China, 2023. [Google Scholar]

- Zhou, B.; Miao, H.; Guan, C.; Ji, X.; Wang, X. Design and Test of Seedling-Picking Mechanism of Fully Automatic Transplanting Machine. Appl. Sci. 2024, 14, 9235. [Google Scholar] [CrossRef]

- Du, F.; Liu, J.; Qi, P. Research on the Seedling Picking Trajectory Error of the Gear Train Seedling Picking Mechanism Considering Tooth Backlash. Eng. Rep. 2024, 12840. [Google Scholar] [CrossRef]

- Cui, Z.C.; Guan, C.S.; Xu, T.; Fu, J.; Chen, Y.; Zhen, S. Design and Experiment of Double-Row Chain Planting Device for Cabbage Substrate Block Seedling Transplanter. Trans. Chin. Soc. Agric. Mach. 2023, 54, 46–54. [Google Scholar]

- Choi, W.C.; Kim, D.C.; Ryu, I.H.; Kim, K.U. Development of a Seedling Pick-up Device for Vegetable Transplanters. Trans. Am. Soc. Agric. Eng. 2002, 45, 13–19. [Google Scholar]

- Zhou, T. Design and Experiments of An Arc Expansion Type Automatic Seedling Taking and Throwing Device for Vegetable Plug Seedlings. Master’s Thesis, Xinjiang Agriculture University, Urumqi, China, 2023. [Google Scholar]

- Xiao, L.Q. Design and Experiment of High-Speed Automatic Transplanting Machine for Plug Seedlings. Master’s Thesis, Xinjiang Agriculture University, Urumqi, China, 2023. [Google Scholar]

- Ma, G.; Mao, H.; Zhang, K.; Gao, F.; Liu, Y.; Han, L. Design of a whole row pneumatic seedling pick-up device for fully-automatic field transplanters with reciprocating movement and intelligent control system. In Proceedings of the ASABE Annual International Meeting, Boston, MA, USA, 7–10 July 2019; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA; p. 1. [Google Scholar]

- Yang, Q.; Huang, G.; Shi, X.; He, M.; Ahmad, I.; Zhao, X.; Addy, M. Design of a control system for a mini-automatic transplanting machine of plug seedling. Comput. Electron. Agric. 2020, 169, 105226. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, J.; Jin, Y.; Bai, Z.; Liu, J.; Zhou, X. Design and Testing of an Intelligent Multi-Functional Seedling Transplanting System. Agronomy 2022, 12, 2683. [Google Scholar] [CrossRef]

| Serial No. | Parameters | Value (mm) |

|---|---|---|

| 1 | Row spacing (S) | 700 |

| 2 | Plant spacing (p) | 180–230 |

| 3 | Film surface width (c) | 1250 |

| 4 | Ridge distance (L) | 1550 |

| 5 | Ridge height (h) | 80–120 |

| Serial No. | Parameters | Value |

|---|---|---|

| 1 | Structure size (length × width × height) (mm) | 2700 × 2200 × 2450 |

| 2 | Weight (kg) | 1050 |

| 3 | Number of working rows (mm) | 2 |

| 4 | Matched power (kW) | 40 |

| 5 | Transplanting efficiency (n/h) | ≥14,400 |

| 6 | Hill-drop spacing adjustment range (mm) | 160~500 |

| 7 | Row spacing adjustment range (mm) | 360~750 |

| 8 | Planting depth (mm) | 30–80 |

| 9 | Structural type | Towed |

| V (Plants/min) | n | N (Plants) | Nq (Plants) | Nt (Plants) | Aq (%) | At (%) | Az (%) |

|---|---|---|---|---|---|---|---|

| 100 plants/min | 1 | 128 | 127 | 124 | 99.22 | 97.64 | 96.88 |

| 2 | 128 | 127 | 125 | 99.22 | 98.43 | 97.66 | |

| 3 | 128 | 128 | 125 | 100.00 | 97.66 | 97.66 | |

| Average | 99.48 | 97.91 | 97.40 | ||||

| 150 plants/min | 4 | 128 | 127 | 125 | 99.22 | 98.43 | 97.66 |

| 5 | 127 | 127 | 126 | 100.00 | 99.21 | 99.21 | |

| 6 | 128 | 126 | 126 | 98.44 | 100.00 | 98.44 | |

| Average | 99.22 | 99.21 | 98.44 | ||||

| 200 plants/min | 7 | 128 | 124 | 121 | 96.88 | 97.58 | 94.53 |

| 8 | 126 | 123 | 120 | 97.62 | 97.56 | 95.24 | |

| 9 | 128 | 125 | 122 | 97.66 | 97.60 | 95.31 | |

| Average | 97.38 | 97.58 | 95.03 |

| Planting Speed | Serial Number | Number of Seedlings in Plug Tray | Number of Successfully Picked and Planted Seedlings (Plants) | Success Rate of Seedling Picking and Depositing (%) | Number of Planted Seedlings (Plants) | Planting Success Rate | Transplanting Success Rate (%) |

|---|---|---|---|---|---|---|---|

| 90 plants/min | 1 | 128 | 125 | 97.66 | 125 | 100.00 | 97.66 |

| 2 | 128 | 126 | 98.44 | 126 | 100.00 | 98.44 | |

| 3 | 127 | 126 | 99.21 | 126 | 100.00 | 99.21 | |

| Average | 98.44 | 100.00 | 98.44 | ||||

| 120 plants/min | 1 | 128 | 124 | 96.88 | 123 | 99.19 | 96.09 |

| 2 | 126 | 123 | 97.62 | 122 | 99.19 | 96.83 | |

| 3 | 127 | 123 | 96.85 | 121 | 98.37 | 95.28 | |

| Average | 97.11 | 98.92 | 96.06 | ||||

| 150 plants/min | 1 | 127 | 118 | 92.91 | 115 | 97.46 | 90.55 |

| 2 | 126 | 116 | 92.06 | 112 | 96.55 | 88.89 | |

| 3 | 126 | 117 | 92.86 | 111 | 94.87 | 88.10 | |

| Average | 92.61 | 96.29 | 89.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Xu, Y.; Han, C.; Liang, J.; Luo, Y.; Mao, H.; Cao, G. Design and Experiment of the Follow-Up Seedling Picking and Depositing Mechanism for the Pepper Plug Seedling Transplanter. Agriculture 2025, 15, 2026. https://doi.org/10.3390/agriculture15192026

Li G, Xu Y, Han C, Liang J, Luo Y, Mao H, Cao G. Design and Experiment of the Follow-Up Seedling Picking and Depositing Mechanism for the Pepper Plug Seedling Transplanter. Agriculture. 2025; 15(19):2026. https://doi.org/10.3390/agriculture15192026

Chicago/Turabian StyleLi, Guangxin, Yang Xu, Changjie Han, Jia Liang, Yan Luo, Hanping Mao, and Guangqiao Cao. 2025. "Design and Experiment of the Follow-Up Seedling Picking and Depositing Mechanism for the Pepper Plug Seedling Transplanter" Agriculture 15, no. 19: 2026. https://doi.org/10.3390/agriculture15192026

APA StyleLi, G., Xu, Y., Han, C., Liang, J., Luo, Y., Mao, H., & Cao, G. (2025). Design and Experiment of the Follow-Up Seedling Picking and Depositing Mechanism for the Pepper Plug Seedling Transplanter. Agriculture, 15(19), 2026. https://doi.org/10.3390/agriculture15192026