Distribution Characteristics of Rotor Airflow and Droplet Deposition of Plant Protection UAVs Under Varying Rotor–Nozzle Distances

Abstract

1. Introduction

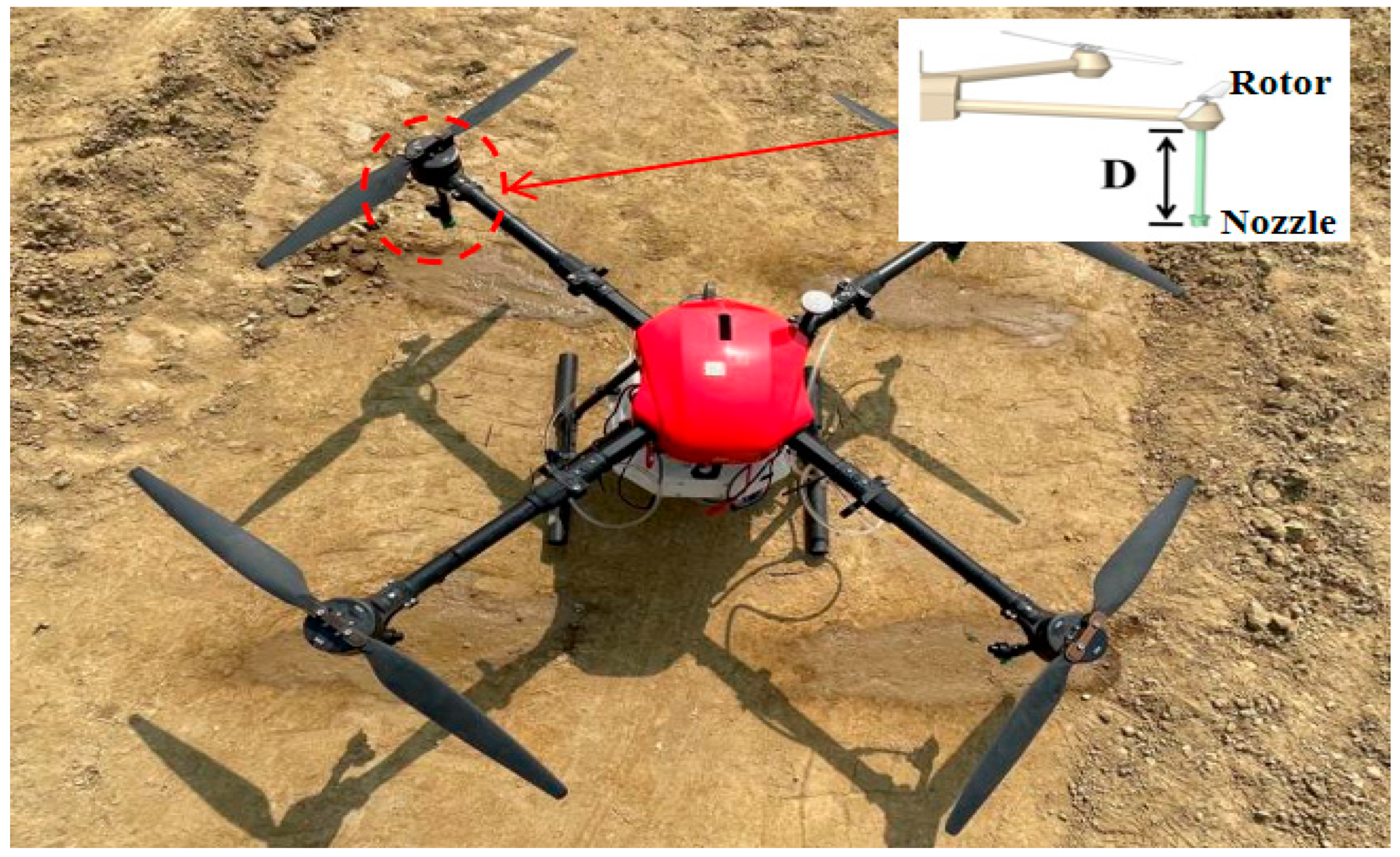

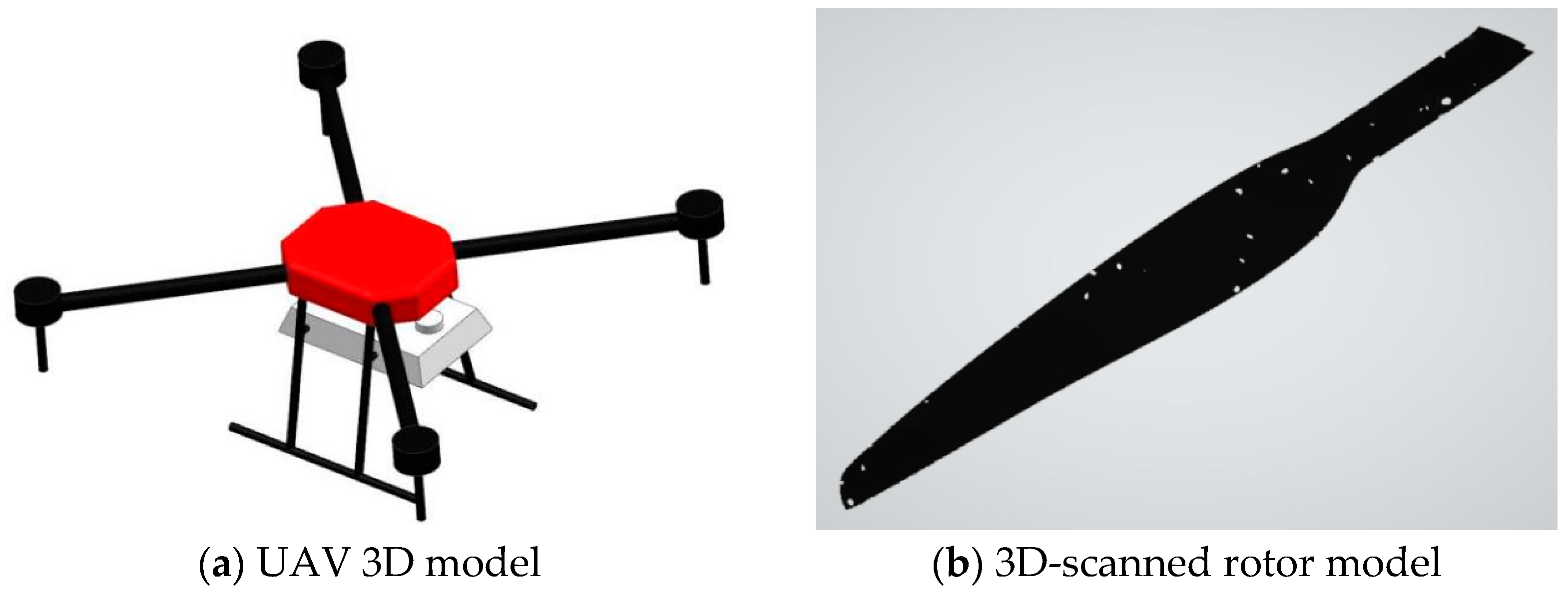

2. Physical Model

2.1. UAV Structure and Operating Parameters

2.2. Modeling and Rotor Scanning

3. Numerical Simulation

3.1. Computing Domain Construction

3.2. Turbulence Model

3.3. Discrete Phase Model

3.4. Boundary Condition

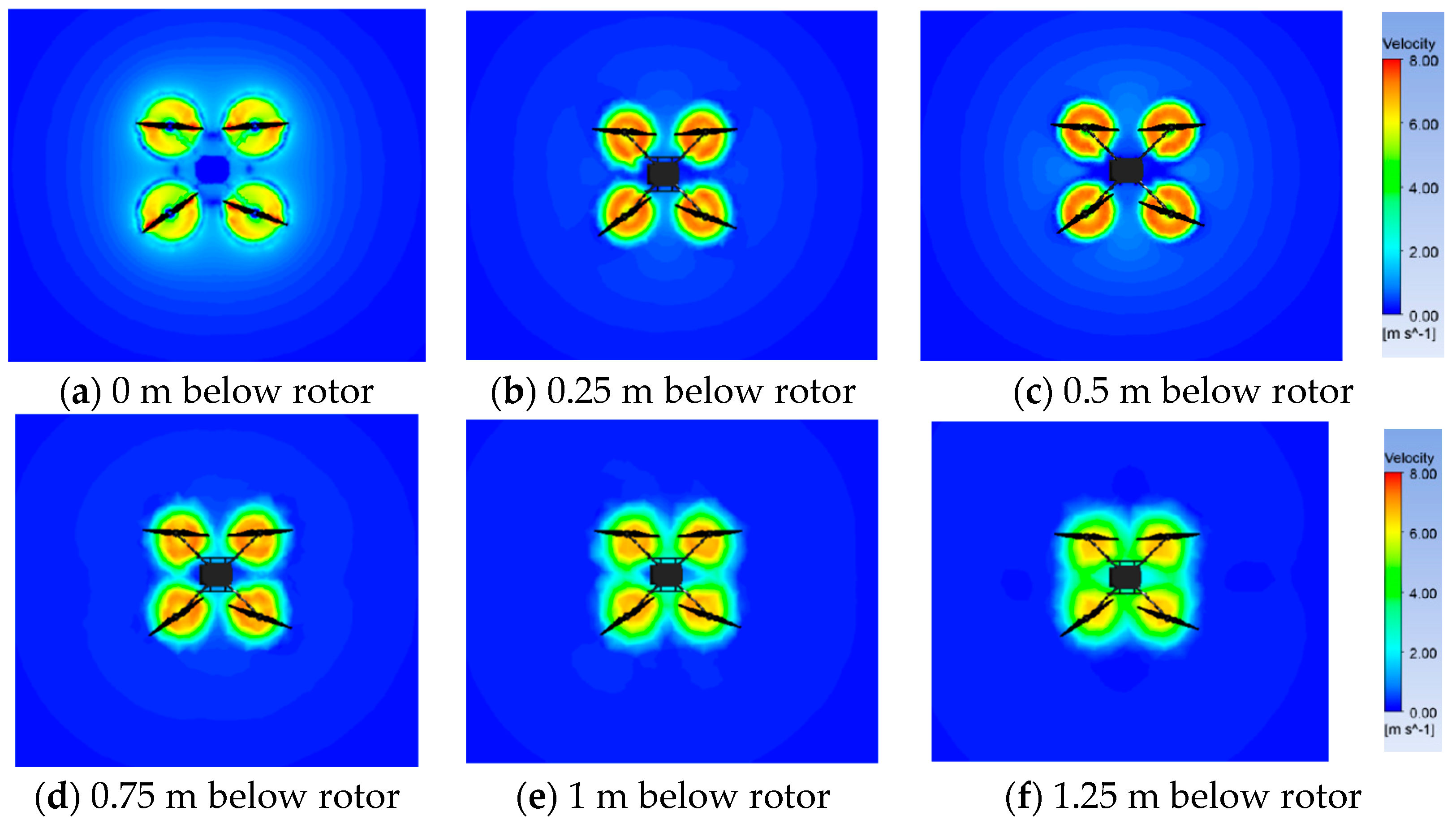

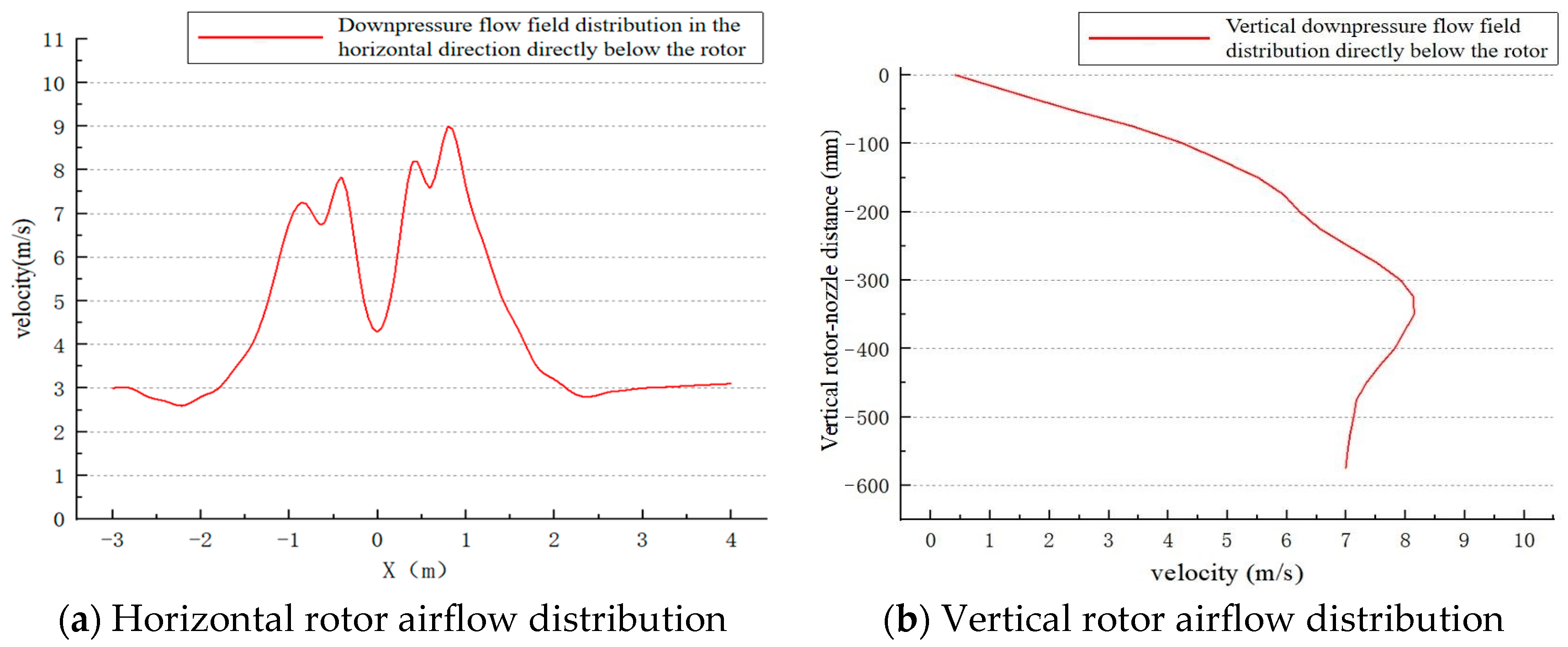

4. Simulation Result Analysis

4.1. Spatial Distribution Analysis of Rotor Airflow

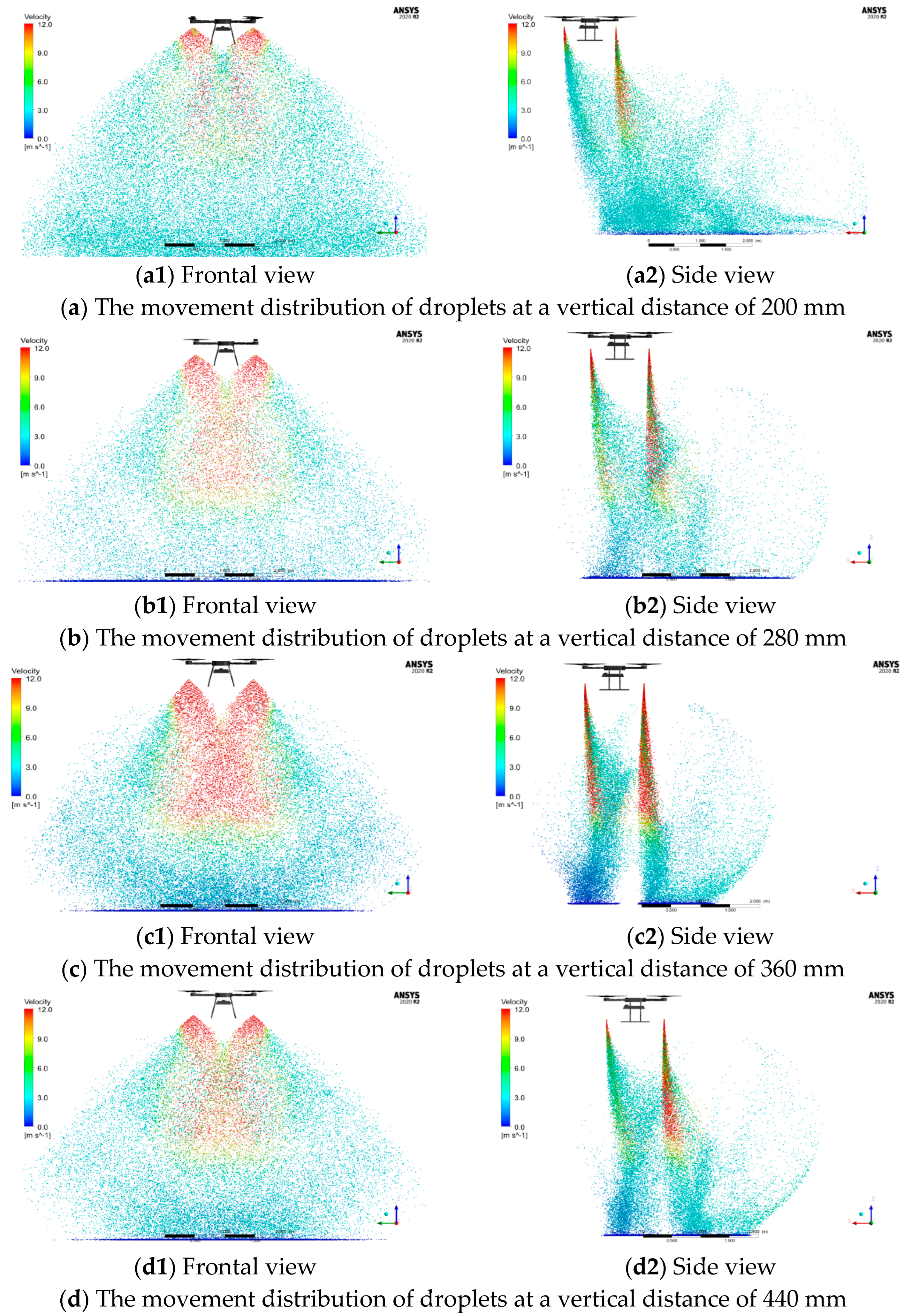

4.2. Analysis of Droplet Deposition Movement

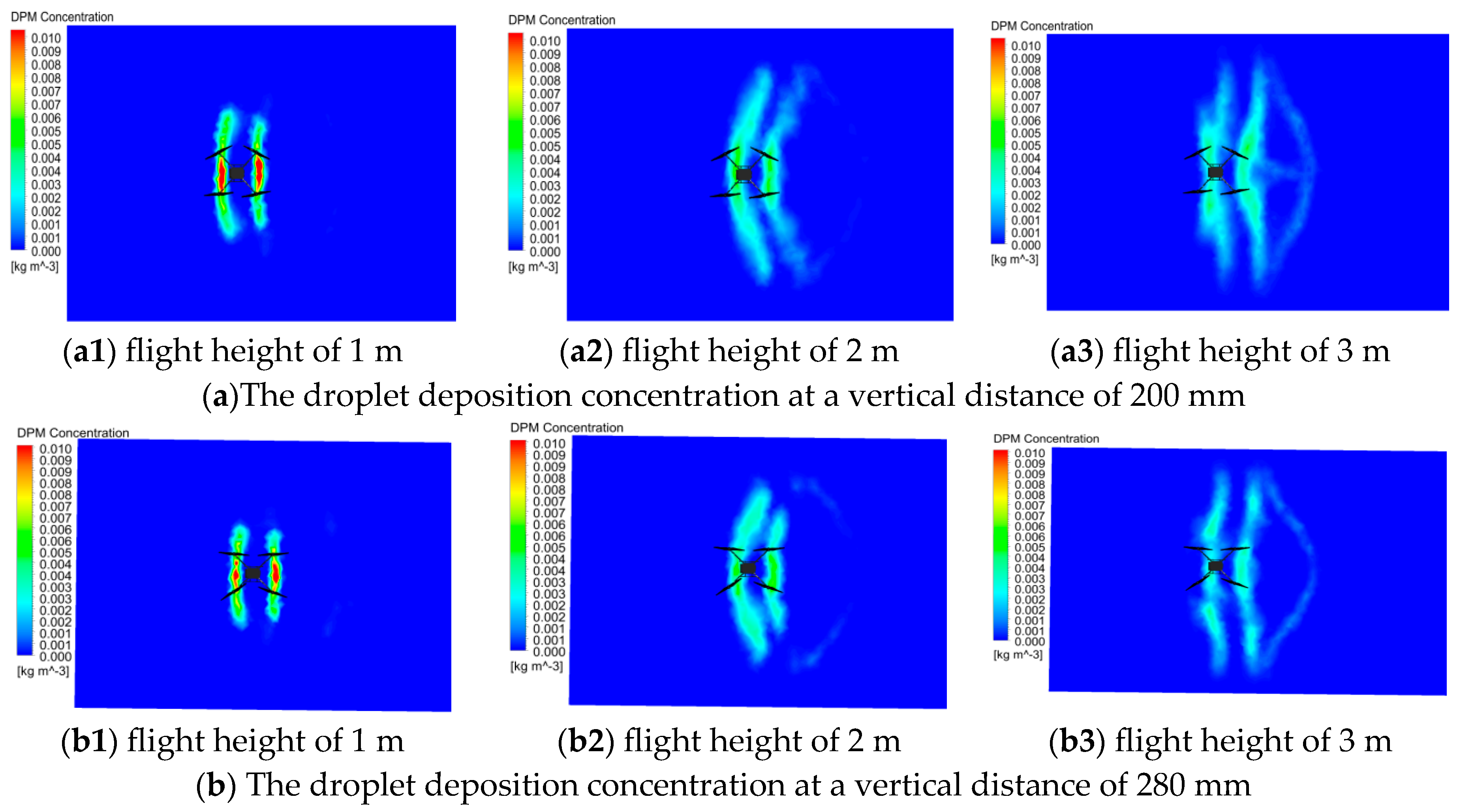

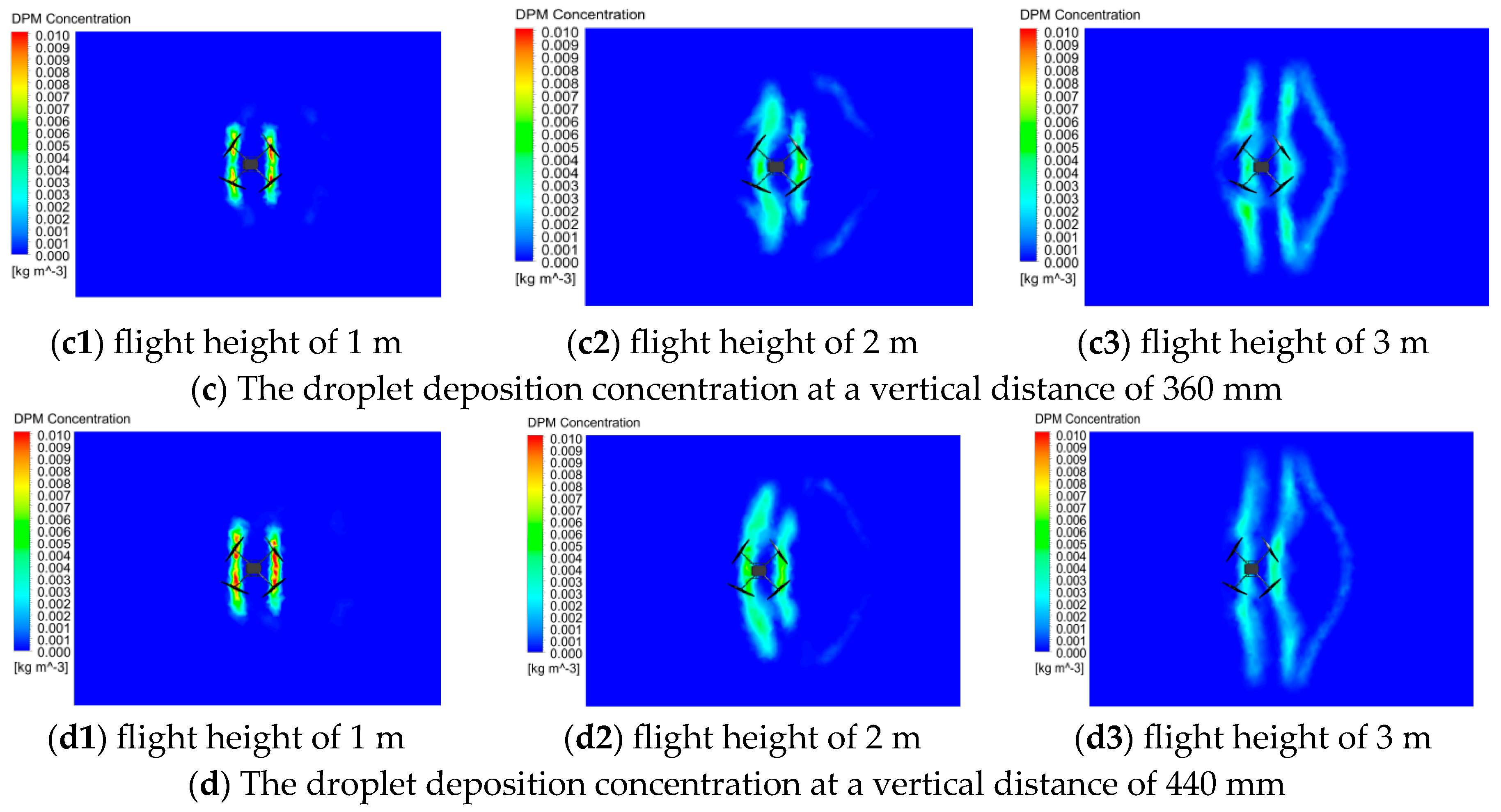

4.3. Cloud Map Analysis of Droplet Deposition Concentration

5. Field Trial Validation

5.1. Materials and Methods

5.1.1. Instrument and Equipment

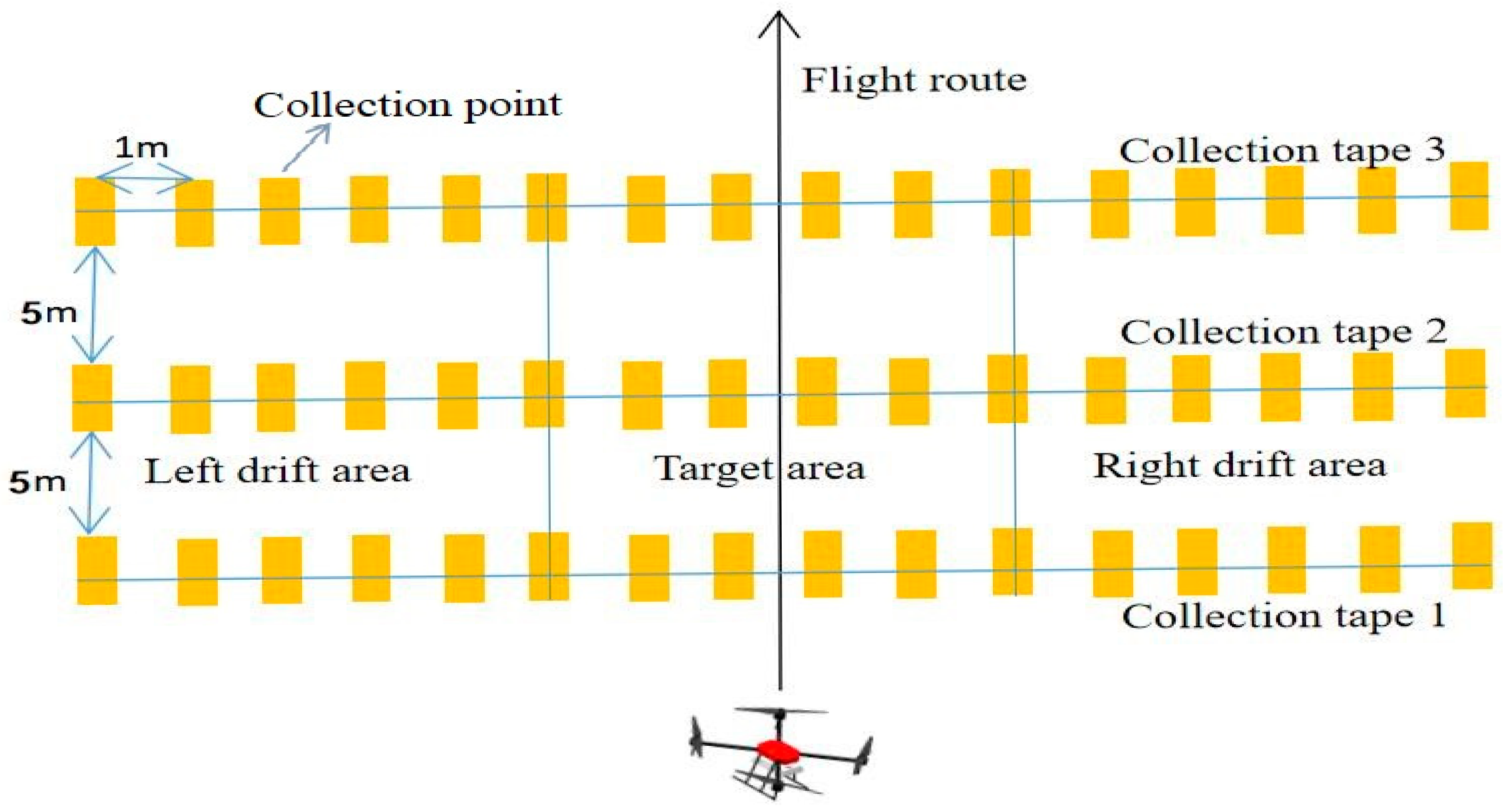

5.1.2. Test Method

5.1.3. Operation Parameters

5.1.4. Data Processing and Analysis

5.2. Test Results and Analysis

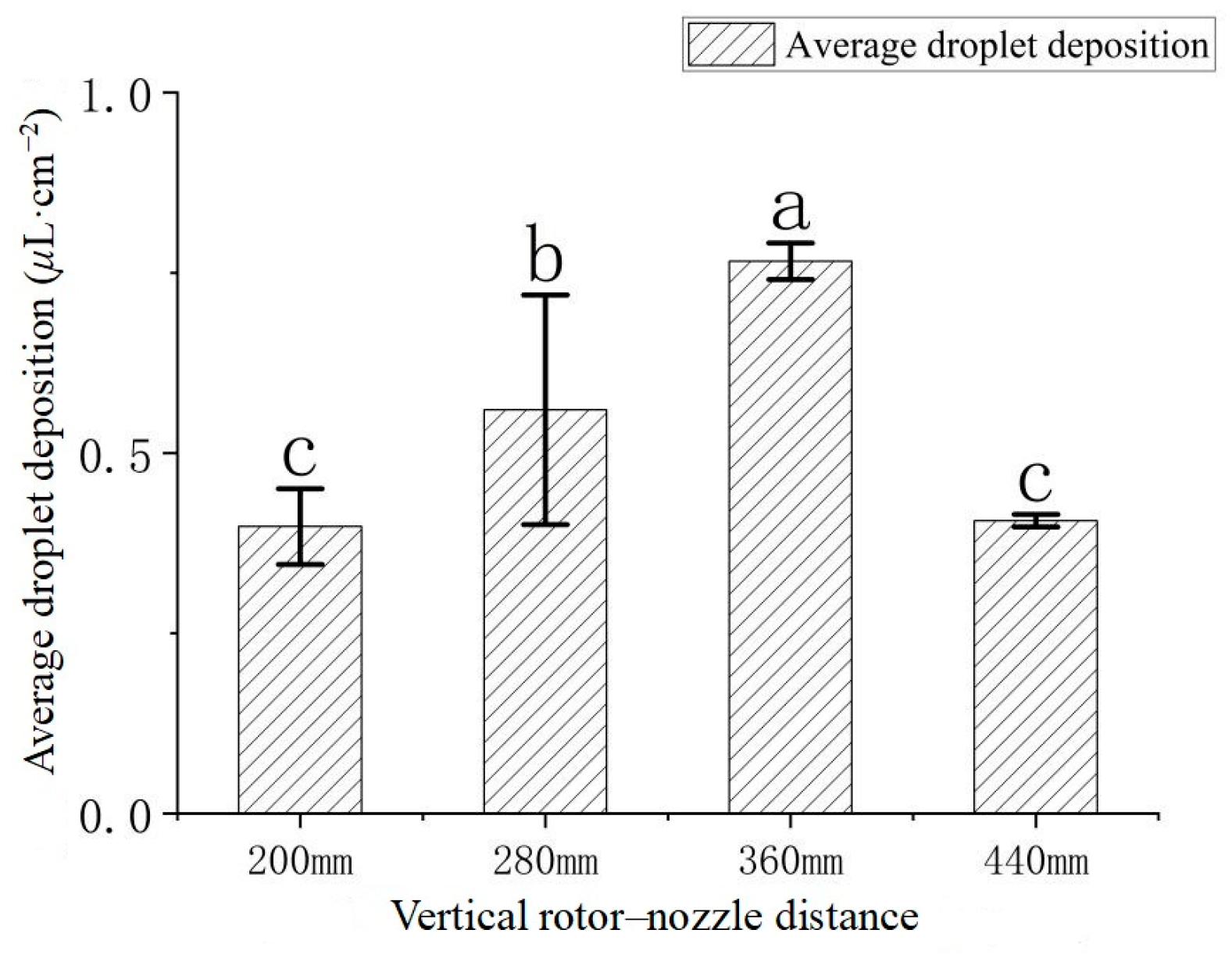

5.2.1. Analysis of Droplet Deposition Distribution in the Target Area

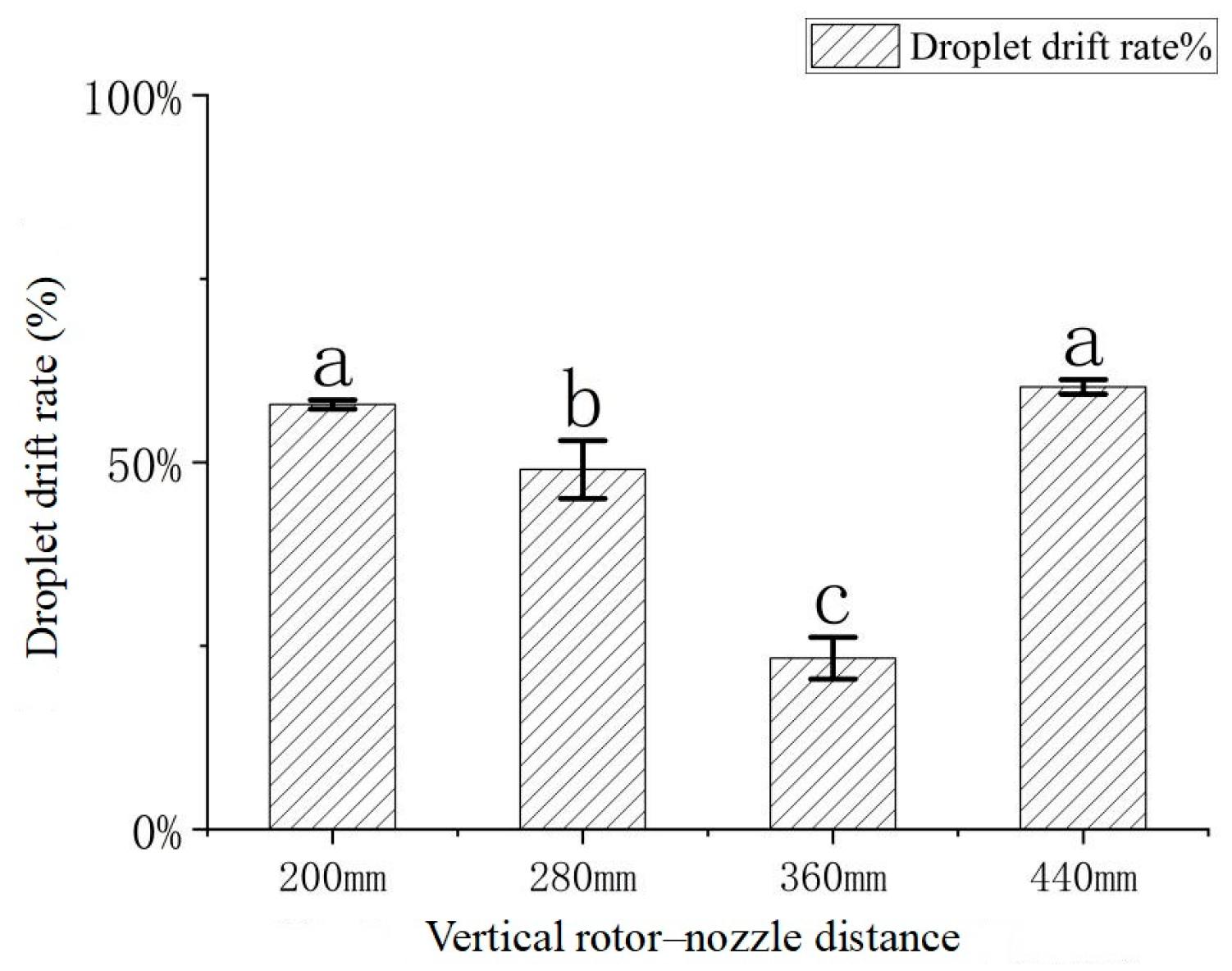

5.2.2. Analysis of Droplet Drift

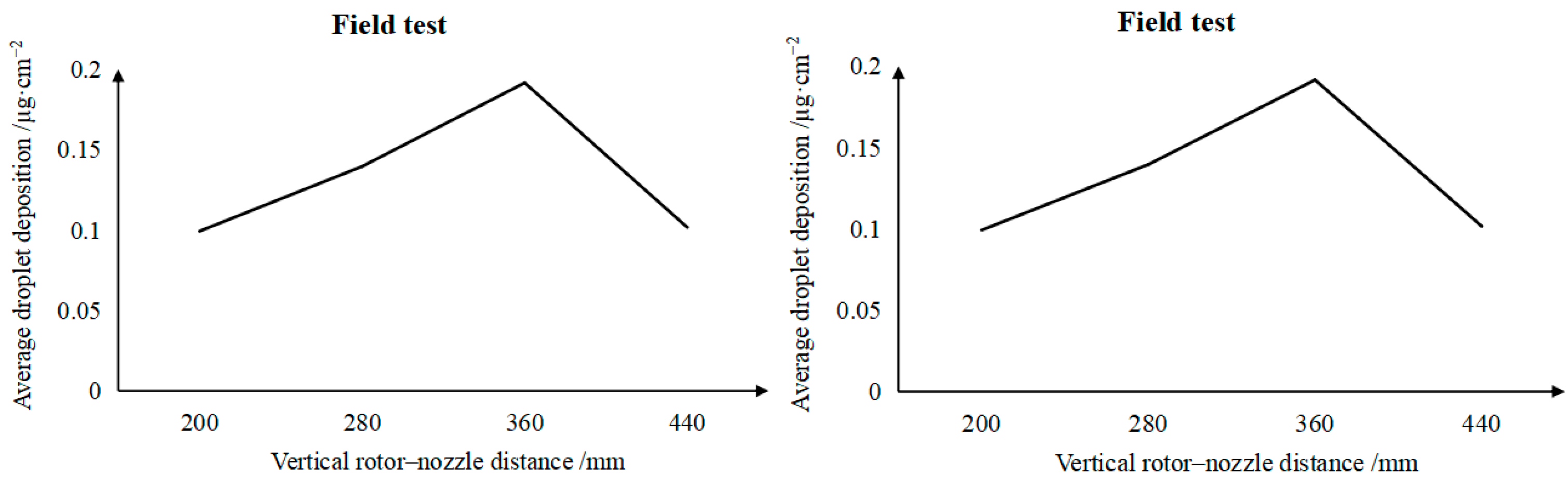

5.3. Comparison of Simulation and Field Test Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, S.; Xu, X.; Liu, J.; Guo, J.; Guan, R.; Zhou, Z.; Lan, Y.; Chen, S. Movement Characteristics of Droplet Deposition in Flat Spray Nozzle for Agricultural UAVs. Agriculture 2024, 14, 1994. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhang, S.; Lin, T.; Jiao, Y.; Cai, C.; Xue, C.; Ye, J.; Xue, X. The Impact of Fluroxypyr Drift on Soybean Phytotoxicity and the Safety Drift Thresholds. Agriculture 2024, 14, 2203. [Google Scholar] [CrossRef]

- Tang, Q.; Zhang, R.; Chen, L.; Xu, G.; Deng, W.; Ding, C.; Xu, M.; Yi, T.; Wen, Y.; Li, L. High-accuracy, high-resolution downwash flow field measurements of an unmanned helicopter for precision agriculture. Comput. Electron. Agric. 2020, 173, 105390. [Google Scholar] [CrossRef]

- Jin, Z.; Guo, S.; Li, S.; Yu, F.; Xu, T. Research on the rice fertiliser decision-making method based on UAV remote sensing data assimilation. Comput. Electron. Agric. 2024, 216, 108508. [Google Scholar] [CrossRef]

- Yu, F.; Xiang, S.; Xu, C.; Jin, Z. PIOSL-PRO: Construction of the PIOSL Model Considering the Distribution of Multiple Elements. IEEE T. Geosci. Remote. 2024, 62, 1–12. [Google Scholar]

- Huang, J.; He, W.; Yang, D.; Lin, J.; Ou, Y.; Jiang, R.; Zhou, Z. Quantity Monitor Based on Differential Weighing Sensors for Storage Tank of Agricultural UAV. Drones 2024, 8, 92. [Google Scholar] [CrossRef]

- Zhang, H.; Qi, L.; Wu, Y.; Musiu, E.; Cheng, Z.; Wang, P. Numerical simulation of airflow field from a six–rotor plant protection drone using lattice Boltzmann method. Biosyst. Eng. 2020, 197, 336–351. [Google Scholar] [CrossRef]

- Fan, G.; Liu, Z.; Qin, Y.; Long, B.; Li, H.; Li, J. Airflow characteristics of rotorcraft plant protection UAV operating in rice fields. Biosyst. Eng. 2023, 226, 209–222. [Google Scholar] [CrossRef]

- Wei, X.; Zhang, Z.; Li, H.; Wu, H.; Lv, J.; Wu, L.; Zhou, M.; Li, J. Influences of wind vortex intensity of rotor UAV on rice morphology and yield. Precis. Agric. 2023, 24, 1766–1791. [Google Scholar] [CrossRef]

- Zhang, J.; He, X.; Song, J.; Zeng, A.; Liu, Y.; Li, X. Influence of spraying parameters of unmanned aircraft on droplets deposition. Trans. Chin. Soc. Agric. Mach. 2012, 43, 94–96, (In Chinese with English Abstract). [Google Scholar]

- Qiu, B.; Wang, L.; Cai, D.; Wu, J.; Ding, G.; Guan, X. Effects of flight altitude and speed of unmanned helicopter on spray deposition uniform. Trans. Chin. Soc. Agric. Eng. 2013, 29, 25–32, (In Chinese with English Abstract). [Google Scholar]

- Qin, W.; Xue, X.; Zhou, L.; Zhang, S.; Sun, Z.; Kong, W.; Wang, B. Effects of spraying parameters of unmanned aerial vehicle on droplets deposition distribution of maize canopies. Trans. Chin. Soc. Agric. Eng. 2014, 30, 50–56, (In Chinese with English Abstract). [Google Scholar]

- Qin, W.; Xue, X.; Zhang, S.; Gu, W.; Chen, C. Optimization and test of spraying parameters for P20 multi-rotor electric unmanned aerial vehicle based on response surface method. J. Jiangsu Univ. 2016, 37, 548–555, (In Chinese with English Abstract). [Google Scholar]

- Zhang, H.; Qi, L.; Wu, Y.; Cheng, Z.; Liu, W.; Elizabeth, M.; Xiao, Y.; Yang, Z. Distribution characteristics of rotor downwash airflow field under spraying on orchard using unmanned aerial vehicle. Trans. Chin. Soc. Agric. Eng. 2019, 35, 44–54, (In Chinese with English Abstract). [Google Scholar]

- Lian, Q. Study on the Variation of Downwash and the Installation Position of Nozzles in a Six-Rotor Plant Protection Drone; Heilongjiang Bayi Agricultural University: Mishan, China, 2019. [Google Scholar]

- Xie, Y.; Wang, G.; Wang, B.; Shang, C.; Lan, Y. Selection of nozzle type and parameter optimization in herbicide spraying process of plant protection UAV. J. Chin. Agric. Mach. 2021, 42, 61–69, (In Chinese with English Abstract). [Google Scholar]

- Wang, C.; He, X.; Bonds, J.; Qi, P.; Yang, Y.; Gao, W. Effect of Downwash Airflow Field of 8-rotor Unmanned Aerial Vehicle on Spray Deposition Distribution Characteristics under Different Flight Parameters. Smart Agric. 2020, 2, 124–136, (In Chinese with English Abstract). [Google Scholar]

- Chen, S.; Lan, Y.; Li, J.; Zhou, Z.; Liu, A.; Mao, Y. Effect of wind field below unmanned helicopter on droplet deposition distribution of aerial spraying. Int. J. Agric. Biol. Eng. 2017, 10, 67–77. [Google Scholar]

- Yang, F.; Xue, X.; Cai, C.; Zhou, Q. Effect of down wash airflow in hover on droplet motion law for multi-rotor unmanned plant protection machine. Trans. Chin. Soc. Agric. Eng. 2018, 34, 64–73, (In Chinese with English Abstract). [Google Scholar]

- Zhan, Y.; Chen, P.; Xu, W.; Chen, S.; Han, Y.; Lan, Y.; Wang, G. Influence of the downwash airflow distribution characteristics of a plant protection UAV on spray deposit distribution. Biosyst. Eng. 2022, 216, 32–45. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Q.; Hou, Q.; Chen, D.; Wang, S. Vertical distribution law of six-rotor plant protection UAV based on multi-feature parameters. Trans. Chin. Soc. Agric. Mach. 2022, 53, 75–83, (In Chinese with English Abstract). [Google Scholar]

- Li, J.; Guo, S.; Yao, W.; Zhan, Y.; Li, Y. Distribution characteristics of droplet size in rice field and wind tunnel simulation test under airflow operation. Trans. Chin. Soc. Agric. Mach. 2019, 50, 148–156, (In Chinese with English Abstract). [Google Scholar]

- He, Y.; Xiao, S.; Fang, H.; Dong, T.; Tang, Y.; Nie, P.; Wu, J.; Luo, S. Development situation and spraying decision of spray nozzle for plant protection UAV. Trans. Chin. Soc. Agric. Eng. 2018, 34, 113–124, (In Chinese with English Abstract). [Google Scholar]

| Main Parameter | Specifications and Values |

|---|---|

| Overall dimension | 1470 × 1470 × 482 mm |

| Paddle size | 21 inches (540 mm) |

| Operating height | 1–5 m |

| Maximum drug load | 10 L |

| Operating speed | 0–8 m/s |

| Spray flow | 2.1 L/min |

| Spray width | 2–6 m |

| Distance/mm | Collection Tape | Total Droplet Deposition/(μL·cm−2) | Average Droplet Deposition/(μL·cm−2) |

|---|---|---|---|

| 200 | 1 | 0.425 | 0.398 ± 0.025 |

| 2 | 0.404 | ||

| 3 | 0.365 | ||

| 280 | 1 | 0.589 | 0.560 ± 0.075 |

| 2 | 0.634 | ||

| 3 | 0.457 | ||

| 360 | 1 | 0.761 | 0.766 ± 0.012 |

| 2 | 0.754 | ||

| 3 | 0.782 | ||

| 440 | 1 | 0.401 | 0.406 ± 0.004 |

| 2 | 0.411 | ||

| 3 | 0.407 |

| Distance/mm | Collection Tape | Total Droplet Drift/(μL·cm−2) | Average Droplet Drift/(μL·cm−2) | Drift Rate/% |

|---|---|---|---|---|

| 200 | 1 | 0.560 | 0.546 ± 0.015 | 57.87 |

| 2 | 0.553 | |||

| 3 | 0.525 | |||

| 280 | 1 | 0.497 | 0.536 ± 0.048 | 49.12 |

| 2 | 0.507 | |||

| 3 | 0.603 | |||

| 360 | 1 | 0.299 | 0.235 ± 0.051 | 23.31 |

| 2 | 0.231 | |||

| 3 | 0.175 | |||

| 440 | 1 | 0.625 | 0.617 ± 0.031 | 60.27 |

| 2 | 0.576 | |||

| 3 | 0.652 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Chen, S.; Li, Z.; Wu, Z.; Tan, Y.; Huang, S.; Lan, Y. Distribution Characteristics of Rotor Airflow and Droplet Deposition of Plant Protection UAVs Under Varying Rotor–Nozzle Distances. Agriculture 2025, 15, 1995. https://doi.org/10.3390/agriculture15191995

Xu X, Chen S, Li Z, Wu Z, Tan Y, Huang S, Lan Y. Distribution Characteristics of Rotor Airflow and Droplet Deposition of Plant Protection UAVs Under Varying Rotor–Nozzle Distances. Agriculture. 2025; 15(19):1995. https://doi.org/10.3390/agriculture15191995

Chicago/Turabian StyleXu, Xiaojie, Shengde Chen, Zhihong Li, Zehong Wu, Yuxiang Tan, Shimin Huang, and Yubin Lan. 2025. "Distribution Characteristics of Rotor Airflow and Droplet Deposition of Plant Protection UAVs Under Varying Rotor–Nozzle Distances" Agriculture 15, no. 19: 1995. https://doi.org/10.3390/agriculture15191995

APA StyleXu, X., Chen, S., Li, Z., Wu, Z., Tan, Y., Huang, S., & Lan, Y. (2025). Distribution Characteristics of Rotor Airflow and Droplet Deposition of Plant Protection UAVs Under Varying Rotor–Nozzle Distances. Agriculture, 15(19), 1995. https://doi.org/10.3390/agriculture15191995