Design and Experiment of Air–Fertilizer Separator for Pneumatic Deep Fertilization in Paddy Fields

Abstract

1. Introduction

2. Materials and Methods

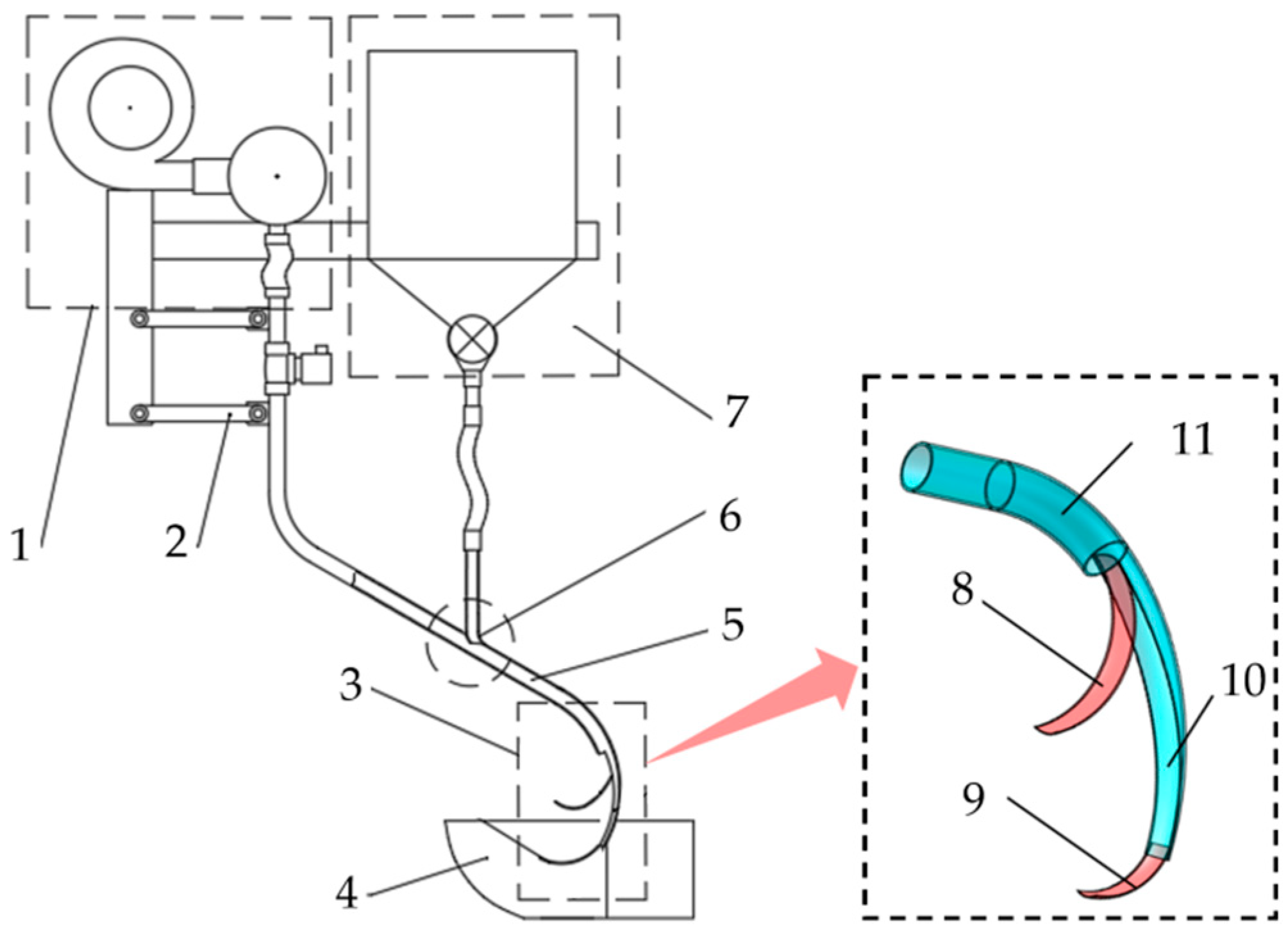

2.1. Structure and Working Process of Pneumatic Deep Fertilization Device for Rice

2.2. Parameter Design of Air–Fertilizer Separator

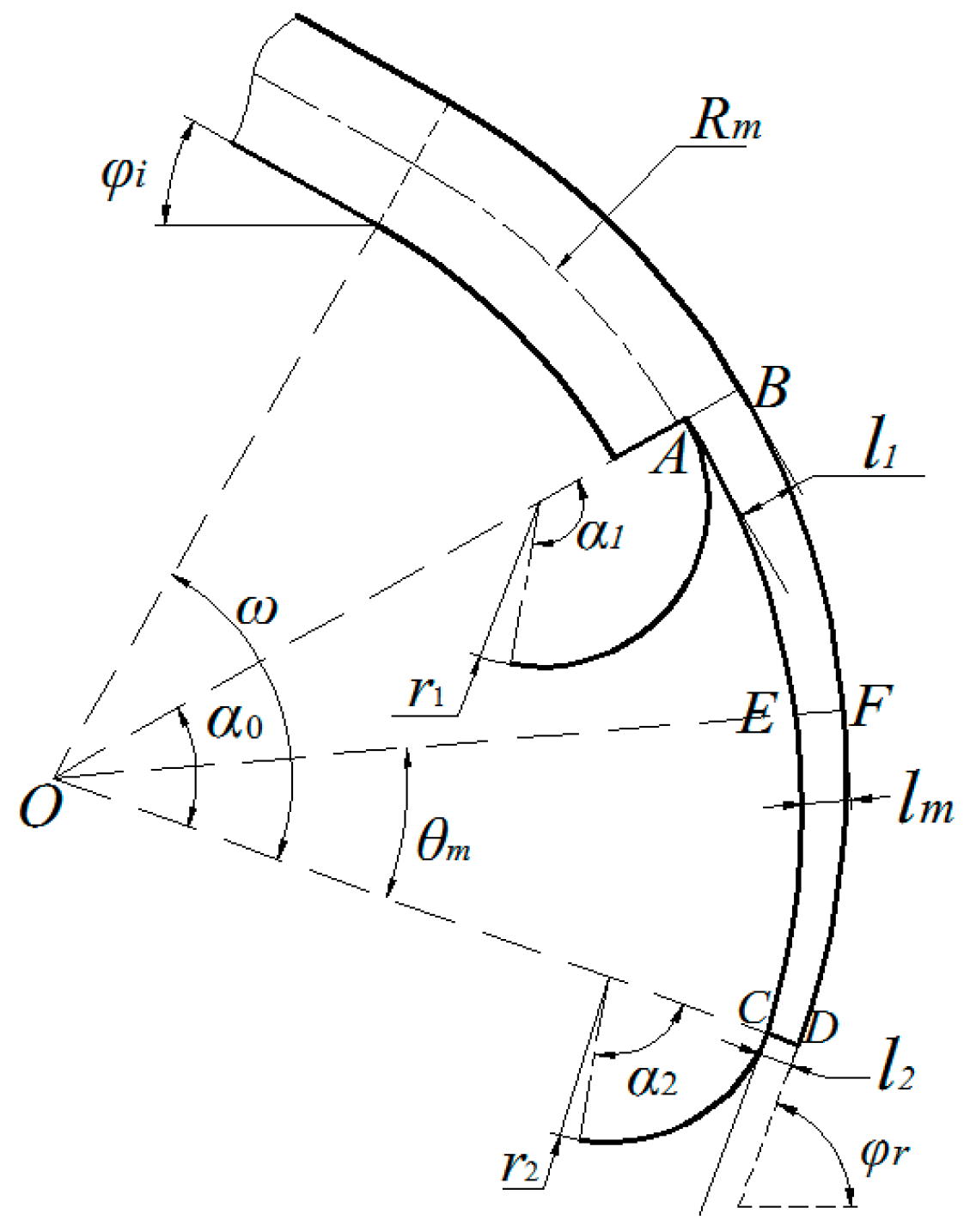

2.2.1. Structural Design and Parameter Determination of the Air–Fertilizer Separator

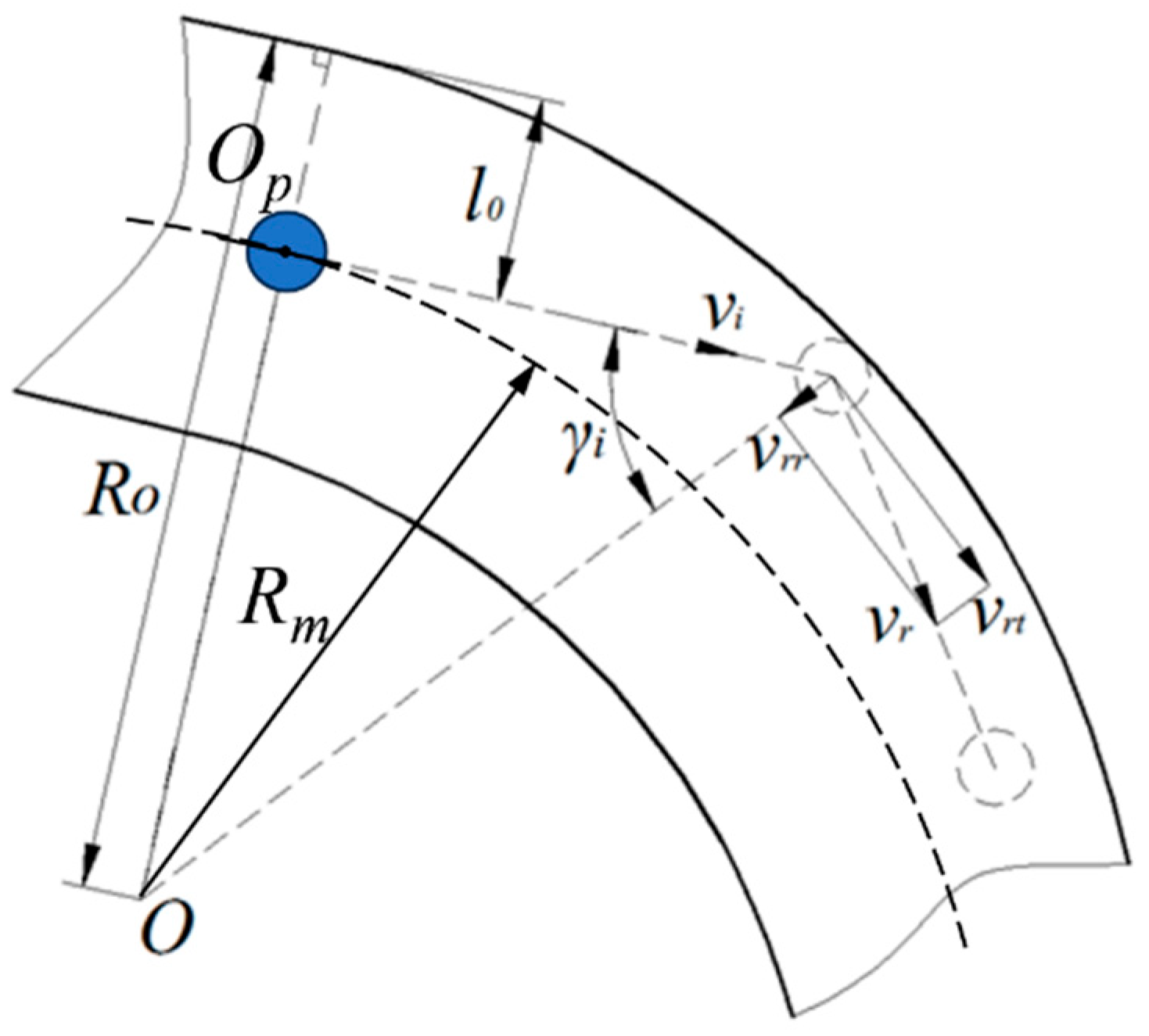

2.2.2. Determination of the AFAST Diameter

2.2.3. Arc Radius of the AFAST

2.3. Experimental Details and Result Analysis of Air–Fertilizer Separator

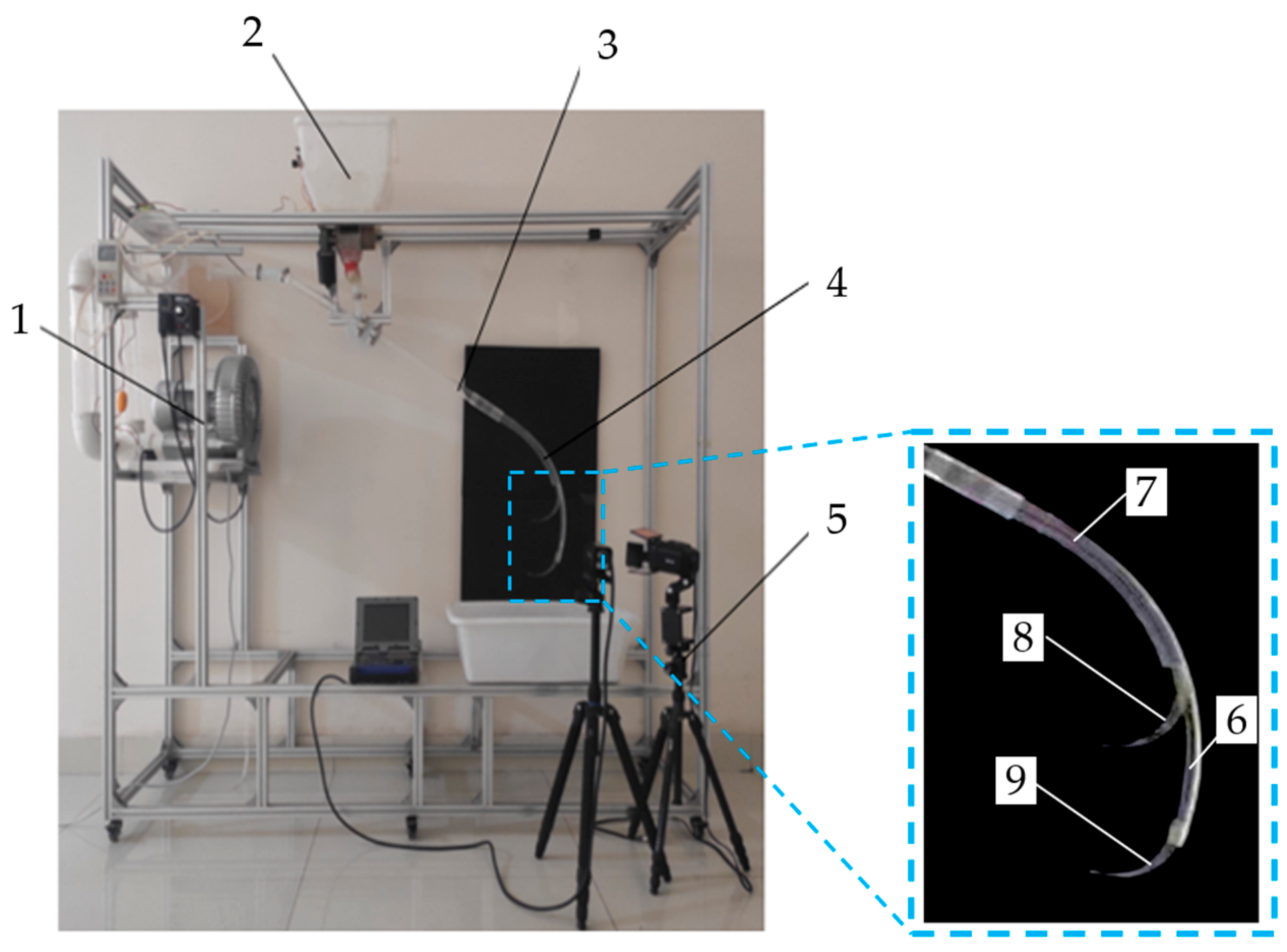

2.3.1. Experimental Equipment and Materials

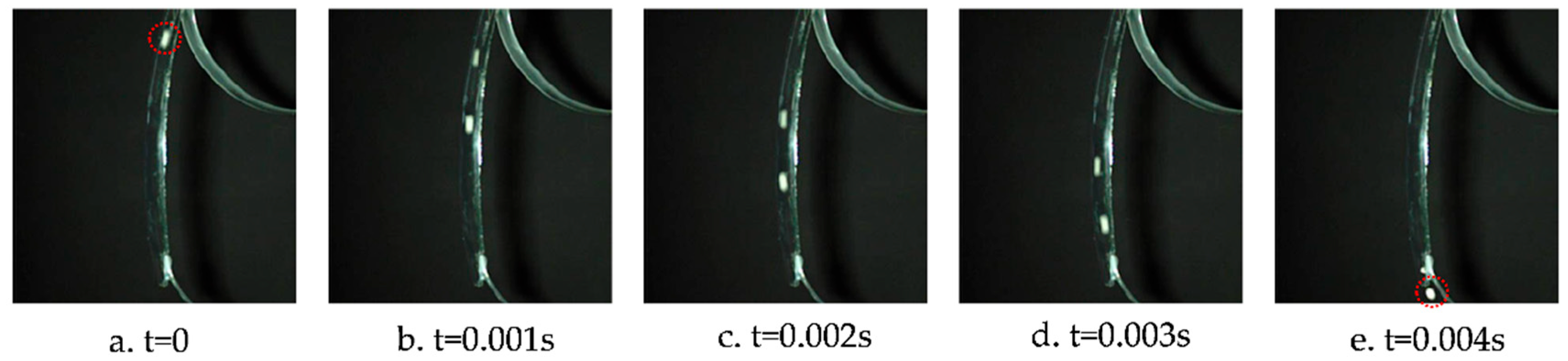

2.3.2. Experimental Indicators and Test Method

2.3.3. Experimental Design

3. Results and Discussion

3.1. Experimental Results

3.2. Analysis of Experimental Results

3.3. Response Surface Analysis

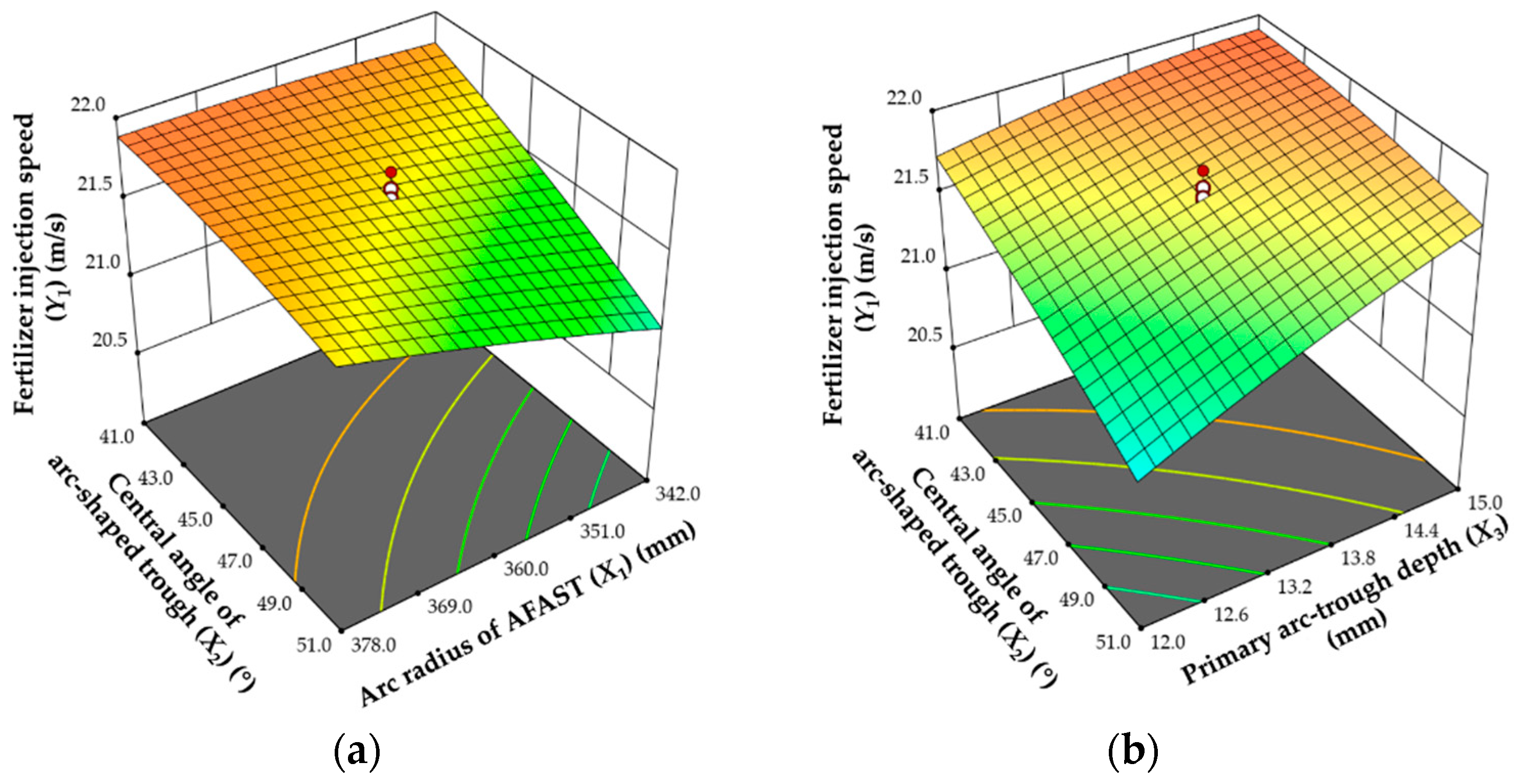

3.3.1. Effect of Factors on Fertilizer Injection Speed and Parameter Optimization

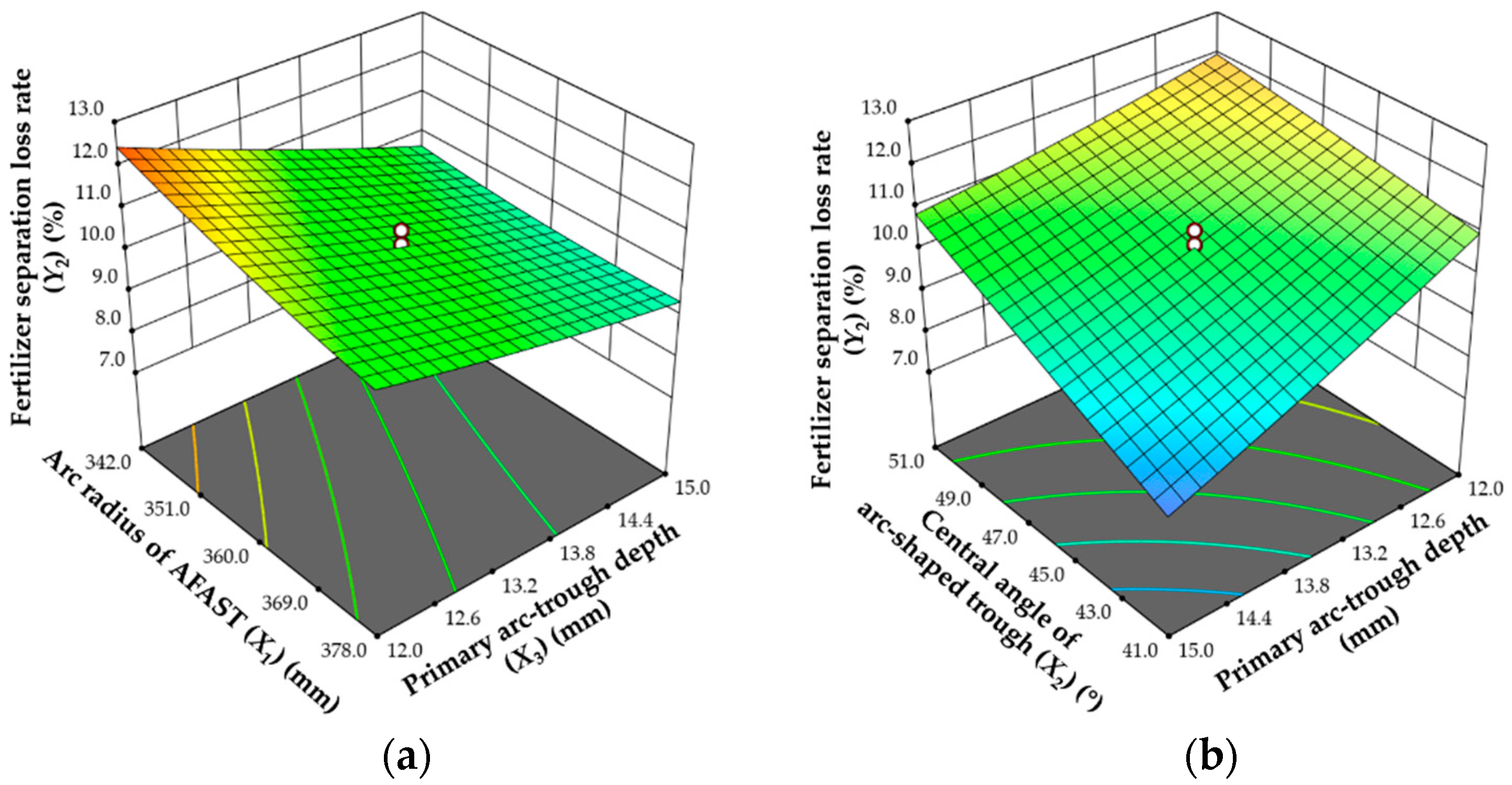

3.3.2. Effect of Factors on Fertilizer Separation Loss Rate and Parameter Optimization

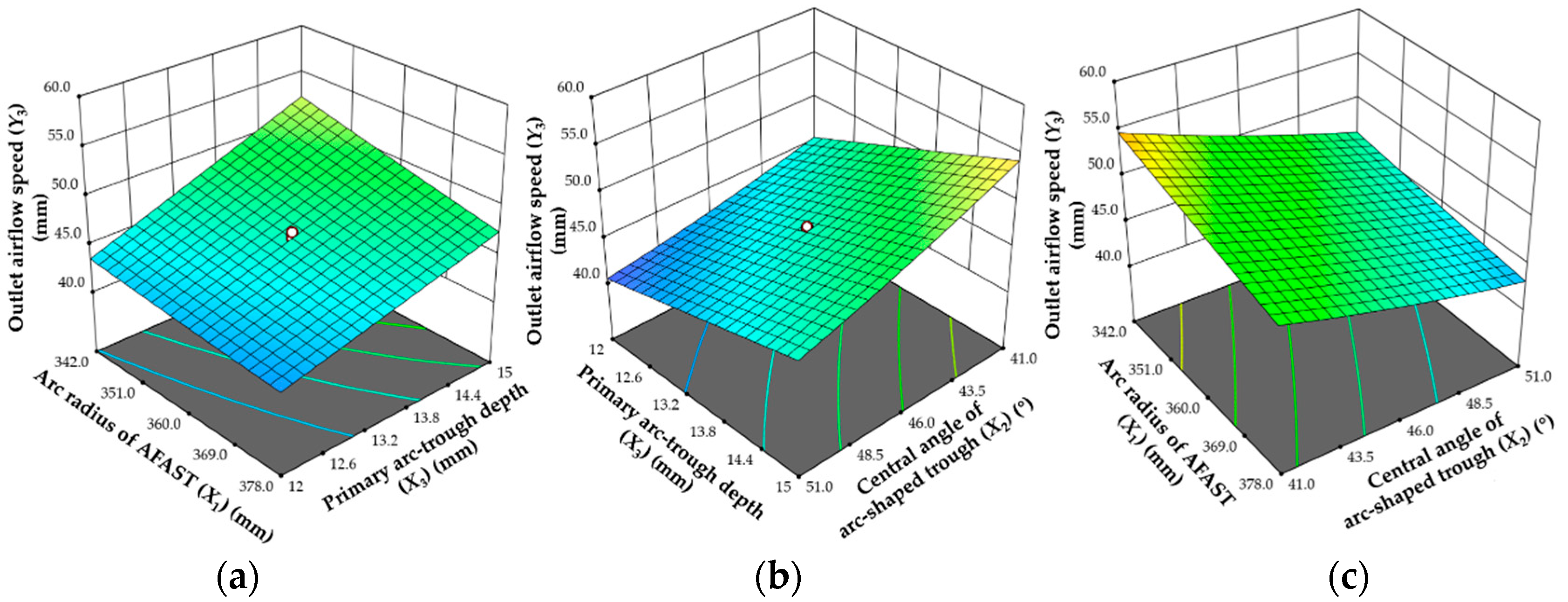

3.3.3. Effect of Factors on Outlet Airflow Speed and Parameter Optimization

3.4. Comprehensive Parameter Optimization and Experimental Verification

4. Conclusions and Discussion

- (1)

- An air–fertilizer separator for a pneumatic deep fertilization machine was designed to separate the air and fertilizer before they enter the paddy soil and to direct the airflow away from the fertilizer. The structural parameters of the air–fertilizer separator were determined.

- (2)

- The testing system was developed, and the bench tests were carried out, and a regression model was established between the fertilizer injection speed, fertilizer separation loss rate, and outlet airflow speed, and the arc radius of the AFAST, central angle of arc-shaped trough, and primary arc-trough depth. Each factor and their interactions had a significant impact on the evaluation index. The regression models have a good fit and can be used for evaluation index prediction.

- (3)

- The optimal parameters of the air–fertilizer separator are determined using multi-objective optimization as follows: arc radius of the AFAST of 380 mm, central angle of the arc-shaped trough of 45°, and depth of the primary arc-shaped trough of 12.5 mm. Three verification tests were repeated using the built test system, and the results are a fertilizer injection speed of 21.45 m/s, a fertilizer separation loss rate of 10.22%, and an outlet airflow speed of 42.54 m/s. The air–fertilizer separator can meet the design requirements for deep pneumatic fertilization.

- (4)

- It should be noted that the present study was carried out mainly under controlled laboratory conditions. Field environments may affect the separation performance. In addition, only one type of fertilizer granule was tested. Therefore, a simulation study and field test should be carried out to verify the results of the study and optimize the parameters of the air–fertilizer separator.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Zhao, X.; Jiao, L.; Xing, Z.; Dong, D. Infrared microspectroscopy and machine learning: A novel approach to determine the origin and variety of individual rice grains. Agric. Commun. 2024, 2, 100038. [Google Scholar] [CrossRef]

- Kakar, K.; Xuan, T.D.; Noori, Z.; Aryan, S.; Gulab, G. Effects of Organic and Inorganic Fertilizer Application on Growth, Yield, and Grain Quality of Rice. Agriculture 2020, 10, 544. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, H.; Shang, J.; Guo, L.; Zheng, G. Effect of Angle Between Center-Mounted Blades and Disc on Particle Trajectory Correction in Side-Throwing Centrifugal Spreaders. Agriculture 2025, 15, 1392. [Google Scholar] [CrossRef]

- Xin, M.J.; Jiang, Z.W.; Chen, T.Y.; Song, Y.Q.; Wang, Y.; Huang, W.Z. Design and experiment of the fertilizer centrifugal broadcaster with guiding chute for paddy field. Trans. Chin. Soc. Agric. Eng. 2023, 39, 67–75. [Google Scholar]

- Qi, X.Y.; Zhou, Z.Y.; Yang, C.; Luo, X.; Gu, X.; Zang, Y.; Liu, W. Design and experiment of key parts of pneumatic variable-rate fertilizer applicator for rice production. Trans. Chin. Soc. Agric. Eng. 2016, 32, 20–26. [Google Scholar]

- Tang, H.; Wang, J.W.; Xu, C.S.; Zhou, W.Q.; Wang, J.F.; Wang, X. Research progress analysis on key technology of chemical fertilizer reduction and efficiency increase. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–19. [Google Scholar]

- Ma, X.; Zhao, X.; Liu, S.S.; Wang, Y.W.; Wang, X.C.; Li, Z. Design and experiment of solid particle fertilizer variable rate fertilization device for high-speed rice transplanter. Trans. Chin. Soc. Agric. Mach. 2023, 54, 99–110. [Google Scholar]

- Wang, J.W.; Li, S.W.; Zhang, Z.; Li, Q.C. Design and experiment of electrical drive side deep hill-drop fertilization system for precision rice hill-direct-seeding machine. Trans. Chin. Soc. Agric. Eng. 2018, 34, 43–54. [Google Scholar]

- Chen, X.F.; Luo, X.W.; Wang, Z.M.; Zhang, M.H.; Hu, L.; Zeng, S.; Mo, Z.W. Experiment of synchronous side deep fertilizing technique with rice hill-drop drilling. Trans. Chin. Soc. Agric. Eng. 2014, 30, 1–7. [Google Scholar]

- Zeng, S.; Tang, H.T.; Luo, X.W.; Ma, G.H.; Wang, Z.M.; Zang, Y.; Zhang, M.H. Design and experiment of precision rice hill-drop drilling machine for dry land with synchronous fertilizing. Trans. Chin. Soc. Agric. Eng. 2012, 28, 12–19. [Google Scholar]

- Li, Z.Y. Side Deep Fertilizer Applicator. Chinese Patent CN91209468, 24 June 1992. [Google Scholar]

- Chen, M.; Chen, W.C.; Lin, R.X.; Liu, Z.Z.; Fang, H. An approach to the mechanisms of dibble deep urea applicator for paddy field. Trans. Chin. Soc. Agric. Mach. 1991, 22, 32–37. [Google Scholar]

- Wang, J.F.; Cao, G.B.; Yan, D.W.; Wang, J.W.; Weng, W.X.; Chen, B. Design and experiment of electric control double row deep fertilizing weeder in paddy field. Trans. Chin. Soc. Agric. Mach. 2018, 49, 46–57. [Google Scholar]

- Sikder, R.; Xiaoying, J. Urea super granule (USG) as key conductor in agricultural productivity development in Bangladesh. Dev. Ctries. Stud. 2014, 4, 132–139. [Google Scholar]

- Chatterjee, D.; Mohanty, S.; Guru, P.K.; Swain, C.K.; Tripathi, R.; Shahid, M.; Kumar, U.; Kumar, A.; Bhattacharyya, P.; Gautam, P.; et al. Comparative assessment of urea briquette applicators on greenhouse gas emission, nitrogen loss and soil enzymatic activities in tropical lowland rice. Agric. Ecosyst. Environ. 2018, 252, 178–190. [Google Scholar] [CrossRef]

- Wohab, M.A.; Islam, M.S.; Hoque, M.A.; Hossain, M.A.; Ahmed, S. Design and development of a urea super granule applicator for puddle rice field. J. Agric. Eng. Technol. 2009, 37, 57–62. [Google Scholar]

- Ahamed, M.S.; Ziauddin, A.T.M.; Sarker, R.I. Design of improved urea super granule applicator. Int. J. Appl. Sci. Eng. Res. 2014, 3, 98–104. [Google Scholar]

- Ahmed, M.R.; Billah, M.M.; Ziauddin, A.T.M. Battery operated USG applicator. Prog. Agric. 2012, 23, 75–80. [Google Scholar] [CrossRef]

- Hoque, M.A.; Wohab, M.A.; Hossain, M.A.; Saha, K.K.; Hassan, M.S.H.J. Improvement and evaluation of BARIUSG applicator. Agric. Eng. Int. CIGR J. 2013, 15, 87–94. [Google Scholar]

- Hossen, M.A.; Huda, M.D.; Islam, M.S.; Bhuiyan, M.G.K.; Rahman, M.; Nath, B.C. Design and development of a manually operated urea super granule (USG) applicator. Agric. Mech. Asia Afr. Lat. Am. 2013, 44, 85–91. [Google Scholar]

- Wohab, M.A.; Gaihre, Y.K.; Ziauddin, A.T.M.; Hoque, M.A. Design, development and field evaluation of manual-operated applicators for deep placement of fertilizer in puddled rice fields. Agric. Res. 2017, 6, 259–266. [Google Scholar] [CrossRef]

- Zhao, J.; Huang, Y.; Chen, C.Q.; Weng, X.X.; Zhu, J.X.; Bai, Z.F.; Xia, Q.W.; Wang, K.J. Side deep fertilization technology and device for rice. Agric. Eng. 2022, 12, 23–26. [Google Scholar]

- Zuo, X.J.; Wu, G.W.; Fu, W.Q.; Li, L.W.; Wei, X.L.; Zhao, C.J. Design and experiment on air-blast rice side deep precision fertilization device. Trans. Chin. Soc. Agric. Eng. 2016, 32, 14–21. [Google Scholar]

- Li, L.W.; Meng, Z.J.; Wang, X.O.; An, X.F.; Wang, P.; Wu, G.W. Simulation analysis of gas-solid two phase flow in pneumatic conveying fertilizer feeder of rice fertilizer applicator. Trans. Chin. Soc. Agric. Mach. 2018, 49, 171–180. [Google Scholar]

- Wu, C.; Fang, W.; Zhang, D. Process parameters optimization of Nymphaea’s hydraulic-gathering. Trans. Chin. Soc. Agric. Eng. 2012, 28, 288–292. [Google Scholar]

- Xin, M.J.; Jiang, Z.W.; Song, Y.Q.; Kong, A.; Chi, B.; Shan, R. Compression strength and critical impact speed of typical fertilizer particles. Agriculture 2023, 13, 2285. [Google Scholar] [CrossRef]

- Wang, T.Z. The confirming of the argument on airflow transportation mechanism. J. Chin. Agric. Mech. 2008, 4, 74–78. [Google Scholar]

- Fei, H.; Xu, S.; Tang, Z. Investigation on impact responses for rock-like brittle materials. Chin. J. Rock Mech. Eng. 2007, S1, 3416–3420. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Higher Education Press: Beijing, China, 1992. [Google Scholar]

- Ye, Y.; Zeng, Y.W.; Zeng, C.; Jin, L. Experimental study on the normal restitution coefficient of granite spheres. Chin. J. Rock Mech. Eng. 2017, 36, 633–643. [Google Scholar]

- Tan, L.; Ji, A.M.; Huang, J.C. Parameter optimization of industrial hemp conveying mechanism based on ADAMS. J. Chin. Agric. Mech. 2023, 44, 42–47. [Google Scholar]

- Gao, G.B. Design and Experiment of Key Parts of Side-Depth Fertilizer Device with Pneumatic Conveying for Paddy. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2019. [Google Scholar]

- Xu, L.Z.; Li, Y.M. Critical speed of impact damage on a rice kernel. Trans. Chin. Soc. Agric. Mach. 2009, 40, 54–57. [Google Scholar]

- Wang, Y. Dynamic Analysis and Experimental Study on Entry of Fertilizer Particles into Paddy Field with Pneumatic Topdressing and Deep Application. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2023. [Google Scholar]

- Kong, L. Two-Phase Fluid Mechanics; Higher Education Press: Beijing, China, 2004. [Google Scholar]

| Material | Density (kg/m−3) | Poisson’s Ratio | Elastic Modulus (MPa) |

|---|---|---|---|

| Urea | 1332 | 0.25 | 140 |

| PMMA | 1200 | 0.41 | 1.95 × 105 |

| Level | Arc Radius of AFAST X1 (mm) | Central Angle of Arc-Shaped Trough X2 (°) | Primary Arc-Trough Depth X3 (mm) |

|---|---|---|---|

| +1.68 | 390 | 54 | 16 |

| 1 | 378 | 51 | 15 |

| 0 | 360 | 46 | 13.5 |

| −1 | 342 | 41 | 12 |

| −1.68 | 330 | 38 | 11 |

| No. | Arc Radius of AFAST X1 (mm) | Central Angle of Arc-Shaped Trough X2 (°) | Primary Arc-Trough Depth X3 (mm) | Fertilizer Injection Speed Y1 (m/s) | Fertilizer Separation Loss Rate Y2 (%) | Outlet Airflow Speed Y3 (m/s) |

|---|---|---|---|---|---|---|

| 1 | −1 | −1 | −1 | 21.57 | 11.84 | 46.55 |

| 2 | 1 | −1 | −1 | 21.88 | 10.36 | 44.31 |

| 3 | −1 | 1 | −1 | 20.58 | 12.85 | 41.29 |

| 4 | 1 | 1 | −1 | 21.21 | 11.12 | 40.06 |

| 5 | −1 | −1 | 1 | 21.89 | 8.47 | 57.83 |

| 6 | 1 | −1 | 1 | 21.86 | 7.65 | 50.98 |

| 7 | −1 | 1 | 1 | 21.23 | 10.78 | 48.02 |

| 8 | 1 | 1 | 1 | 21.99 | 11.02 | 44.73 |

| 9 | −1.68 | 0 | 0 | 21.41 | 11.6 | 49.1 |

| 10 | 1.68 | 0 | 0 | 21.87 | 9.93 | 43.59 |

| 11 | 0 | −1.68 | 0 | 21.93 | 8.63 | 52.94 |

| 12 | 0 | 1.68 | 0 | 21.23 | 12.17 | 41.39 |

| 13 | 0 | 0 | −1.68 | 21.13 | 12.45 | 40.32 |

| 14 | 0 | 0 | 1.68 | 22.00 | 8.88 | 52.15 |

| 15 | 0 | 0 | 0 | 21.83 | 10.37 | 45.98 |

| 16 | 0 | 0 | 0 | 21.67 | 10.3 | 46.65 |

| 17 | 0 | 0 | 0 | 21.55 | 10.43 | 46.23 |

| 18 | 0 | 0 | 0 | 21.56 | 10.21 | 45.97 |

| 19 | 0 | 0 | 0 | 21.66 | 10.78 | 45.93 |

| 20 | 0 | 0 | 0 | 21.73 | 9.8 | 45.93 |

| 21 | 0 | 0 | 0 | 21.61 | 10.78 | 46.13 |

| 22 | 0 | 0 | 0 | 21.67 | 10.3 | 46.27 |

| 23 | 0 | 0 | 0 | 21.64 | 10.45 | 46.88 |

| Source | Fertilizer Injection Speed, Y1/(m/s) | ||||

| Sum of Squares | df | Mean Square | F-Value | p-Value | |

| Model | 2.40 | 9 | 0.27 | 25.21 | <0.0001 ** |

| X1 | 0.44 | 1 | 0.44 | 41.34 | <0.0001 ** |

| X2 | 0.83 | 1 | 0.83 | 78.5 | <0.0001 ** |

| X3 | 0.75 | 1 | 0.75 | 70.60 | <0.0001 ** |

| X1X2 | 0.15 | 1 | 0.15 | 14.56 | 0.0021 ** |

| X1X3 | 0.01 | 1 | 0.01 | 0.52 | 0.4831 |

| X2X3 | 0.16 | 1 | 0.16 | 15.09 | 0.0019 ** |

| X12 | 0.01 | 1 | 0.01 | 0.59 | 0.4576 |

| X22 | 0.027 | 1 | 0.03 | 2.52 | 0.1363 |

| X32 | 0.034 | 1 | 0.03 | 3.22 | 0.0962 |

| Residual | 0.14 | 13 | 0.01 | - | - |

| Lack of fit | 0.079 | 5 | 0.02 | 2.13 | 0.1632 |

| Pure error | 0.0596 | 8 | 0.01 | - | - |

| Cor total | 2.547 | 22 | - | - | - |

| Source | Fertilizer Separation Loss Rate, Y2/(%) | ||||

| Sum of Squares | df | Mean Square | F-Value | p-Value | |

| Model | 34.38 | 9 | 3.82 | 48.98 | <0.0001 ** |

| X1 | 3.19 | 1 | 3.19 | 40.88 | <0.0001 ** |

| X2 | 13.16 | 1 | 13.16 | 168.66 | <0.0001 ** |

| X3 | 14.88 | 1 | 14.88 | 190.75 | <0.0001 ** |

| X1X2 | 0.08 | 1 | 0.08 | 1.05 | 0.3239 |

| X1X3 | 0.86 | 1 | 0.86 | 11.09 | 0.0054 ** |

| X2X3 | 1.91 | 1 | 1.91 | 24.5 | 0.0003 ** |

| X12 | 0.20 | 1 | 0.2 | 2.59 | 0.1315 |

| X22 | 0.002 | 1 | 0.0042 | 0.05 | 0.8198 |

| X32 | 0.01 | 1 | 0.0952 | 1.22 | 0.2893 |

| Residual | 1.01 | 13 | 0.078 | - | - |

| Lack of fit | 0.31 | 5 | 0.062 | 0.7 | 0.64 |

| Pure error | 0.71 | 8 | 0.09 | - | - |

| Cor total | 35.39 | 22 | - | - | - |

| Source | Outlet Airflow Speed, Y3/(m/s) | ||||

| Sum of Squares | df | Mean Square | F-Value | p-Value | |

| Model | 379.8 | 9 | 42.2 | 267.23 | <0.0001 ** |

| X1 | 38.32 | 1 | 38.32 | 242.67 | <0.0001 ** |

| X2 | 148.24 | 1 | 148.24 | 938.73 | <0.0001 ** |

| X3 | 177.58 | 1 | 177.58 | 1124.48 | <0.0001 ** |

| X1X2 | 2.61 | 1 | 2.61 | 16.53 | 0.0013 ** |

| X1X3 | 5.56 | 1 | 5.56 | 35.22 | <0.0001 ** |

| X2X3 | 5.36 | 1 | 5.36 | 33.96 | <0.0001 ** |

| X12 | 0.08 | 1 | 0.08 | 0.48 | 0.5011 |

| X22 | 2.05 | 1 | 2.05 | 12.96 | 0.0032 ** |

| X32 | 0.01 | 1 | 0.014 | 0.09 | 0.7675 |

| Residual | 2.05 | 13 | 0.16 | - | - |

| Lack of fit | 1.13 | 5 | 0.23 | 1.97 | 0.1875 |

| Pure error | 0.92 | 8 | 0.11 | - | - |

| Cor total | 381.86 | 22 | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, M.; Ding, W.; Chen, D.; Zhang, M.; Ao, Y.; Chi, B.; Jiang, Z.; Song, Y.; Guo, Y. Design and Experiment of Air–Fertilizer Separator for Pneumatic Deep Fertilization in Paddy Fields. Agriculture 2025, 15, 1991. https://doi.org/10.3390/agriculture15181991

Xin M, Ding W, Chen D, Zhang M, Ao Y, Chi B, Jiang Z, Song Y, Guo Y. Design and Experiment of Air–Fertilizer Separator for Pneumatic Deep Fertilization in Paddy Fields. Agriculture. 2025; 15(18):1991. https://doi.org/10.3390/agriculture15181991

Chicago/Turabian StyleXin, Mingjin, Wenrui Ding, Duo Chen, Man Zhang, Yujue Ao, Bowen Chi, Zhiwen Jiang, Yuqiu Song, and Yunlong Guo. 2025. "Design and Experiment of Air–Fertilizer Separator for Pneumatic Deep Fertilization in Paddy Fields" Agriculture 15, no. 18: 1991. https://doi.org/10.3390/agriculture15181991

APA StyleXin, M., Ding, W., Chen, D., Zhang, M., Ao, Y., Chi, B., Jiang, Z., Song, Y., & Guo, Y. (2025). Design and Experiment of Air–Fertilizer Separator for Pneumatic Deep Fertilization in Paddy Fields. Agriculture, 15(18), 1991. https://doi.org/10.3390/agriculture15181991