1. Introduction

Precision agriculture (PA) has emerged as a transformative approach to modern farming, designed to address the spatial and temporal variability within agricultural fields by leveraging advanced sensing, data analytics, and decision-support technologies [

1,

2,

3]. With a projected global population of 9 to 10 billion by 2050 [

3,

4,

5], food demand is expected to increase by at least 70% [

1,

6,

7]. This rising demand places additional pressure on already constrained natural resources, highlighting the need for innovative, resource-efficient farming solutions. Precision agriculture offers a powerful response by enhancing input efficiency, increasing productivity, and reducing environmental impacts [

2]. Among agricultural operations, tillage tools have remained less advanced compared to modern planters, sprayers, and harvesters. However, with the emergence of herbicide-resistant weeds, the need for residue management, field smoothing, and data-centric farming, tillage is increasingly recognized as a critical area for innovation to bring into precision agriculture systems.

Recent developments in smart tillage implements have focused on precision, site-specific management to optimize soil preparation while reducing energy use and improving crop growth. For example, the Ecolo-til 2500 subsoiler has been applied for variable-depth deep tillage, targeting only areas where soil compaction exceeds threshold values, thus improving efficiency and reducing unnecessary energy costs [

8]. Similarly, the “Clemson Intelligent Plow” converts a conventional subsoiler into a variable-depth platform guided by soil prescription maps, promoting deeper root growth and reducing fuel consumption [

9]. Major manufacturers such as John Deere, Case IH, and HE-VA have developed automated depth control systems, integrating hydraulic adjustments with GPS-based prescription maps to maintain precise tillage depth across fields [

10,

11]. Research has also advanced sensor-guided control at the individual shank level, using ultrasonic or electro-hydraulic systems to monitor and adjust each subsoiler tine in real time, resulting in more consistent soil loosening and reduced bulk density [

12,

13,

14,

15]. These innovations illustrate the potential of smart tillage implements to integrate sensors to control systems, paving the way for more sustainable and efficient soil management systems.

Globally, soil compaction is a growing concern. Approximately 68 million hectares of land worldwide are already affected by compaction [

16], and this number is expected to increase in the coming decades. The European Union has recognized compaction as a major form of soil degradation, with land use and heavy machinery identified as major contributors [

17]. In particular, Central and Eastern Europe face widespread degradation due to excessive soil loading, making compaction the most pervasive type of degradation in those regions [

18]. These concerns underscore the urgency of accurately assessing compaction levels in commercial agricultural lands and adopting practices that mitigate its effects.

This process involves the rearrangement of soil particles into a denser configuration, resulting in a decrease in void ratio and porosity, and an increase in bulk density [

19]. The Soil Science Society of America defines compaction as “the process by which the soil grains are rearranged to decrease void space and bring them into closer contact with one another, thereby increasing the bulk density” [

19]. This process involves the densification and distortion of the soil matrix, leading to reduced pore space both within and between soil structural units [

20]. As a result, compaction impairs essential soil functions such as aeration, water infiltration, root penetration, and overall microbial activity [

20,

21].

Effective tillage improves soil conditions for seedbed preparation by physically loosening the soil, incorporating organic matter, forming a consistent surface suitable for planting, managing residue, incorporating herbicide, and creating soil conditions that encourage root development. It also plays a central role in managing soil compaction, which can negatively affect crop productivity, water infiltration, nutrient uptake, and stunt downward root growth [

22,

23]. In integrated weed management systems, tillage and herbicide inputs often interact inversely, as reducing herbicide use typically requires increased mechanical intervention, while reduced tillage intensity tends to increase herbicide reliance to maintain effective weed control and minimize yield loss [

24].

Compaction often arises from repeated passes of heavy machinery during agricultural activities such as seedbed preparation and harvesting. Deep compaction, particularly caused by high axle loads, can persist for several years and may not be easily alleviated by conventional tillage practices [

25]. This compaction alters the spatial arrangement, size, and shape of soil clods, which in turn reduces pore space both within soil aggregates and in the spaces between them [

20]. Soils affected by compaction exhibit increased bulk density and mechanical resistance (e.g., penetrometer resistance), which create physical barriers to root expansion and negatively affect root architecture and distribution [

25,

26,

27,

28,

29]. Soil dry bulk density and soil strength, particularly mechanical resistance, are widely used indicators to assess soil compaction status. Among these, penetration resistance is the most adopted metric due to its direct measurement of soil resistance to root penetration and tillage. This mechanical impedance also reduces gas exchange and creates anaerobic conditions in the root zone, severely limiting plant growth and development [

23,

30].

From a mechanical perspective, understanding soil–tool interaction is essential in both geotechnical engineering and precision agriculture. In tillage and other soil-engaging operations, tools exert both vertical and horizontal forces on the soil. Vertical forces primarily control tool penetration, while horizontal forces govern soil cutting, displacement, and shear deformation—key processes influencing energy consumption and soil structural changes. Soil shear resistance is commonly characterized by the Mohr–Coulomb failure criterion. According to this theory, the shear strength (τ) of soil is defined as:

where

c is cohesion,

σ is the normal stress, and

ϕ is the internal friction angle. This criterion forms the basis for understanding soil mechanical behavior under lateral stresses induced by tillage tools. Traditional methods for assessing soil mechanical resistance, such as soil cone penetrometers, are often static, invasive, time-consuming, and difficult to scale [

30,

31]. While accurate, these methods provide only localized and discrete estimates, failing to capture the dynamic interactions between tools and soil during field operations. To address the limitations of static measurements, Hart [

29] proposed a non-dimensional modeling approach to generalize soil–tool interaction across varying tool types and soil conditions. This framework was further refined by Anat [

32] to incorporate dynamic soil behaviors, including compaction and penetration resistance. During tillage, soil properties such as density, moisture content, and compaction influence the dynamic resistance encountered by tools. As a tillage tool moves through the soil, its vibrational response changes according to the resistance it encounters [

33]. Horizontal soil resistance, dominated by shear forces, generates characteristic vibrations that can be measured on the tool. Vibration-based sensing offers a dynamic, non-invasive alternative for estimating horizontal soil resistance, particularly shear strength. Denser, more cohesive soils generate higher resistance, altering both the frequency and amplitude of the tool’s vibrations [

28].

The central question of this work is: Can tillage tools be used to measure soil compaction during regular field operations? We hypothesize that vibration signals generated during tillage operations carry meaningful information about the mechanical properties of the soil, particularly compaction and structural conditions, and can be utilized for real-time monitoring of soil condition during field operations. This information could be used in year-over-year decision-making in precision agriculture management systems. This approach is supported by prior studies across engineering and agricultural domains. For instance, El-Wardany et al. [

34] used vibration data to monitor tool wear, while Gebraeel et al. [

35] applied neural networks to predict bearing failure from similar signals. Zhang [

33] developed microcontroller-based systems for real-time vibration data acquisition. In the agricultural context, vibration data from subsoilers have been shown to support parameter optimization, highlighting the potential of accelerometry and signal analysis in enabling adaptive, sensor-guided machinery operation [

36].

When a field cultivator shank penetrates compacted soil layers, the increased mechanical resistance from the dense soil induces vibrations in the tool. This resistance causes deflection and oscillatory motion of the shank, converting mechanical energy into measurable vibration signals [

37]. Experimental studies further demonstrated that the vibration frequency of the cultivator shank strongly correlates with soil compaction, having a greater influence on draft force and soil fragmentation than factors such as soil moisture or working depth [

37].

To evaluate the relationship between field cultivator shank vibration and soil compaction levels and document soil conditions existing in a field prior to tillage, we developed and compared machine learning models. These models, trained on vibration data, soil moisture, and cone penetrometer measurements, intend to prove a correlation between collected vibration data and soil penetrometer and moisture data. Using two models, XGBoost and Random Forest, we intend to demonstrate that vibration data, when properly processed and interpreted, can serve as a reliable predictor of soil compaction before tillage. Furthermore, this work advances the possibility of developing smart tillage tools capable of sensing subsurface soil conditions in real time and dynamically adjusting their operation. Such technology paves the way for more efficient, sustainable, and intelligent soil management practices in modern precision agriculture, enabling the development of automated cultivators that can make on-the-go tillage decisions.

2. Materials and Methods

2.1. Data Collection

Data for this study were collected from an agricultural field of approximately 14.5 ha located on Knox Lane in Manhattan, KS, USA (39.202999° N, 96.543221° W). The coordinates are reported in the World Geodetic System 1984 (WGS 1984) geographic coordinate reference system (CRS). Field tests were conducted over two growing seasons, from summer 2023 through November 2024. The soil at the site consists of Reading silt loam (moderately wet, rarely flooded) and Eudora–Bismarck Grove silt loams (occasionally flooded), which are representative of typical soil conditions in the region and are classified as Cambisols under the World Reference Base for Soil Resources (WRB) system. In the 2023 growing season, the field was planted with maize (Zea mays L.) for silage. The first round of data collection took place on 17 August 2023. The second round was conducted on 23 November 2024, following the harvest of soybeans (Glycine max) in late October 2024, and was carried out in select field locations prior to full-width fall tillage. Soil moisture and compaction were measured using a Hydrosense II soil–water sensor (Campbell Scientific, Logan, UT, USA) and a Rimik CP40II cone penetrometer (Rimik Pty Ltd, Toowoomba, QLD 4350, Australia). Data processing and analysis were performed using Python (version 3.12.3), and geographic mapping was done in ArcGIS Pro 3.1 (Esri, Redlands, CA, USA).

2.1.1. Vibration Data Collection

Ridder et al. [

38,

39] developed the avDAQ system, which is designed to collect vibration data during agricultural processes, with capabilities including high sampling rates, spatial data logging via GPS, and compatibility with auxiliary sensors. The system features a central platform based on a National Instruments compactRIO device (Model 9053), paired with NI modules for vibration analog and digital data acquisition. It can support multiple accelerometers and is powered by various DC sources, including tractor power and batteries. The avDAQ system was initially tested in a laboratory using a single field cultivator shank taken from a Sunflower 5035 field cultivator. Vibration data was collected and analyzed in both time and frequency domains in this testing. The results showed that the cultivator shank had a natural frequency of around 21.5 Hz, which was consistent with modal analysis from CAD simulations. Following lab validation, the system was field-tested by instrumenting select field cultivator shanks on the Sunflower 5035 field cultivator with accelerometers. The system successfully collected vibration and spatial data during tillage operations, confirming its reliability in mobile agricultural environments. The software, developed with LabVIEW, offers flexibility for data collection and analysis, including real-time monitoring through a graphical user interface (GUI). However, the system can also function independently without the GUI once data collection is verified.

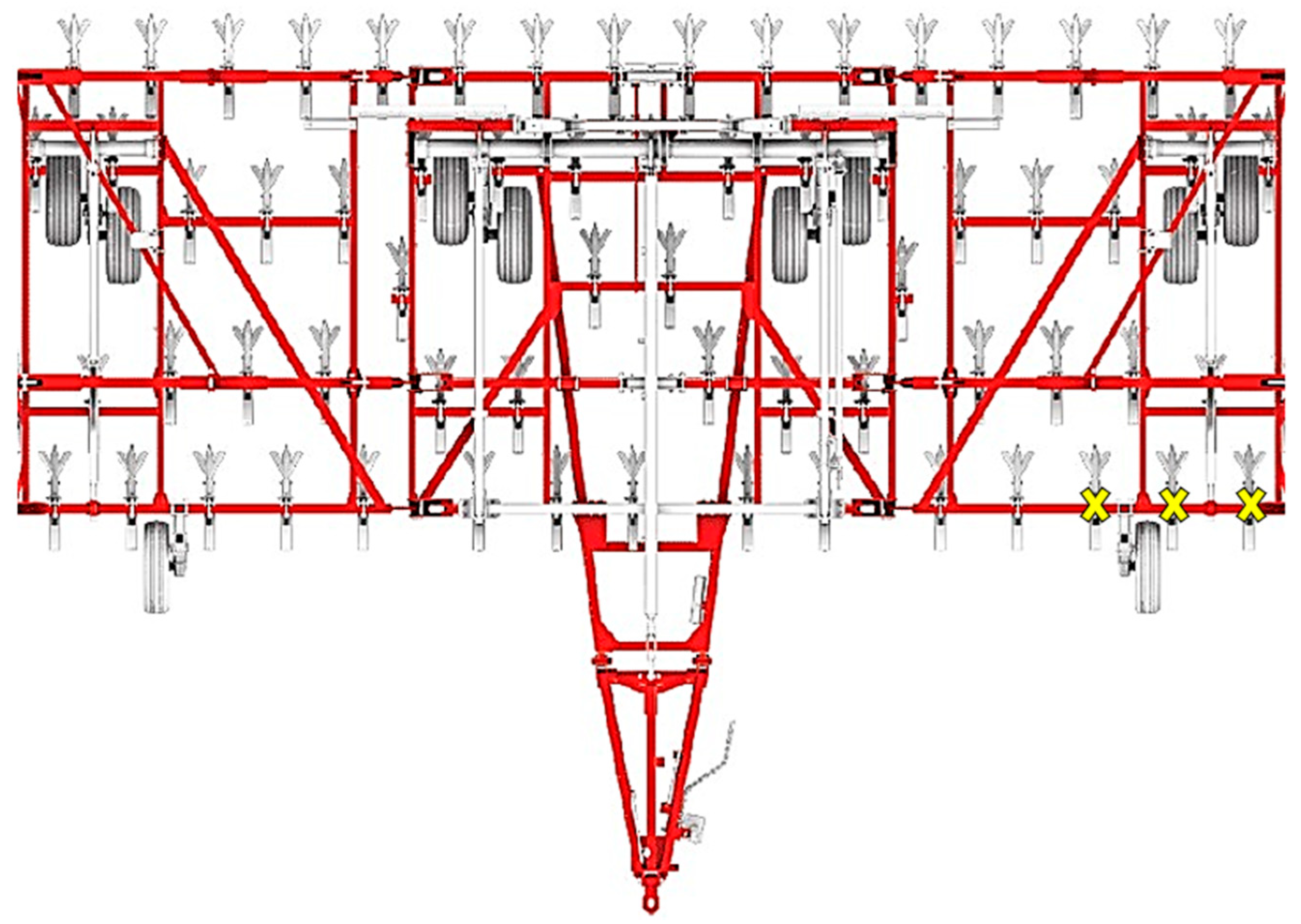

The initial field testing to collect data for vibration analysis involved equipping the Sunflower 5035 field cultivator with the avDAQ system and three single-axis accelerometers. These sensors, labeled ACC1, ACC2, and ACC3, were mounted on three adjacent shanks located on the front rank of shovels on the left side of the cultivator (

Figure 1). The yellow crosses on the shanks in

Figure 1 mark the positions of the accelerometers for reference. ACC1 was positioned on the front, leftmost shank, while ACC3 was mounted furthest in-board of the three. The shanks on the Sunflower 5035 are spaced 22.86 cm apart. Each single-axis accelerometer (x-direction) was installed approximately parallel to the ground surface to measure horizontal vibrations in the direction of implement movement. The sensors were placed at the curved section of the shovel shank, aligned with the shank centerline (

Figure 2), to capture vibrations generated in the direction of travel of the cultivator. For these tests, the cultivator was operated at a forward speed of 9.7 km/h and a working depth of 10 cm, which represents a typical operating depth for this tool [

40].

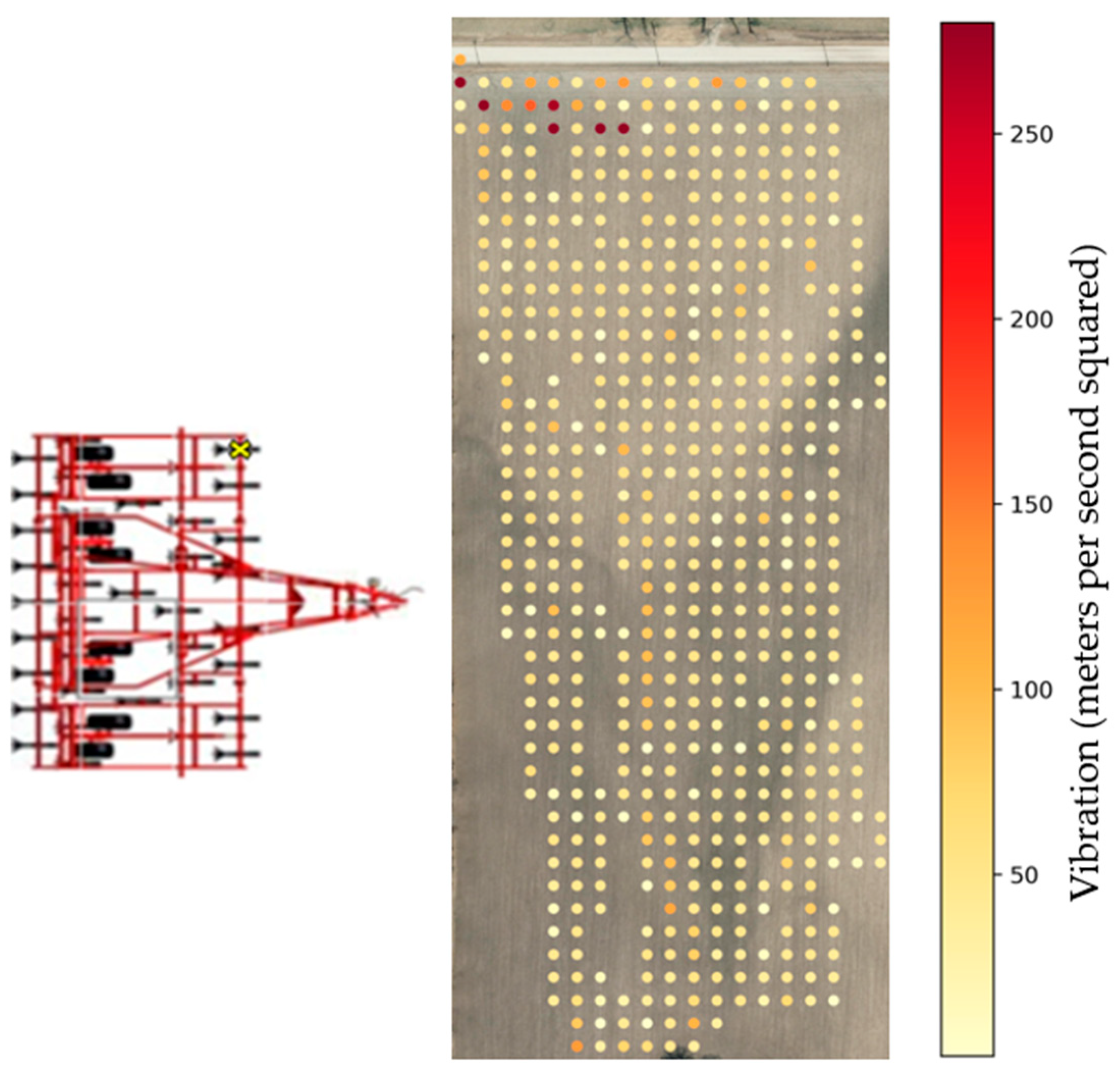

Vibration data were collected on 17 August 2023, following silage maize harvest and prior to any fall tillage operations. Data were sampled at a rate of 102,000 Hz, synchronized with GPS coordinates, and visualized as heatmaps using the Seaborn library in Python (version 3.12.3).

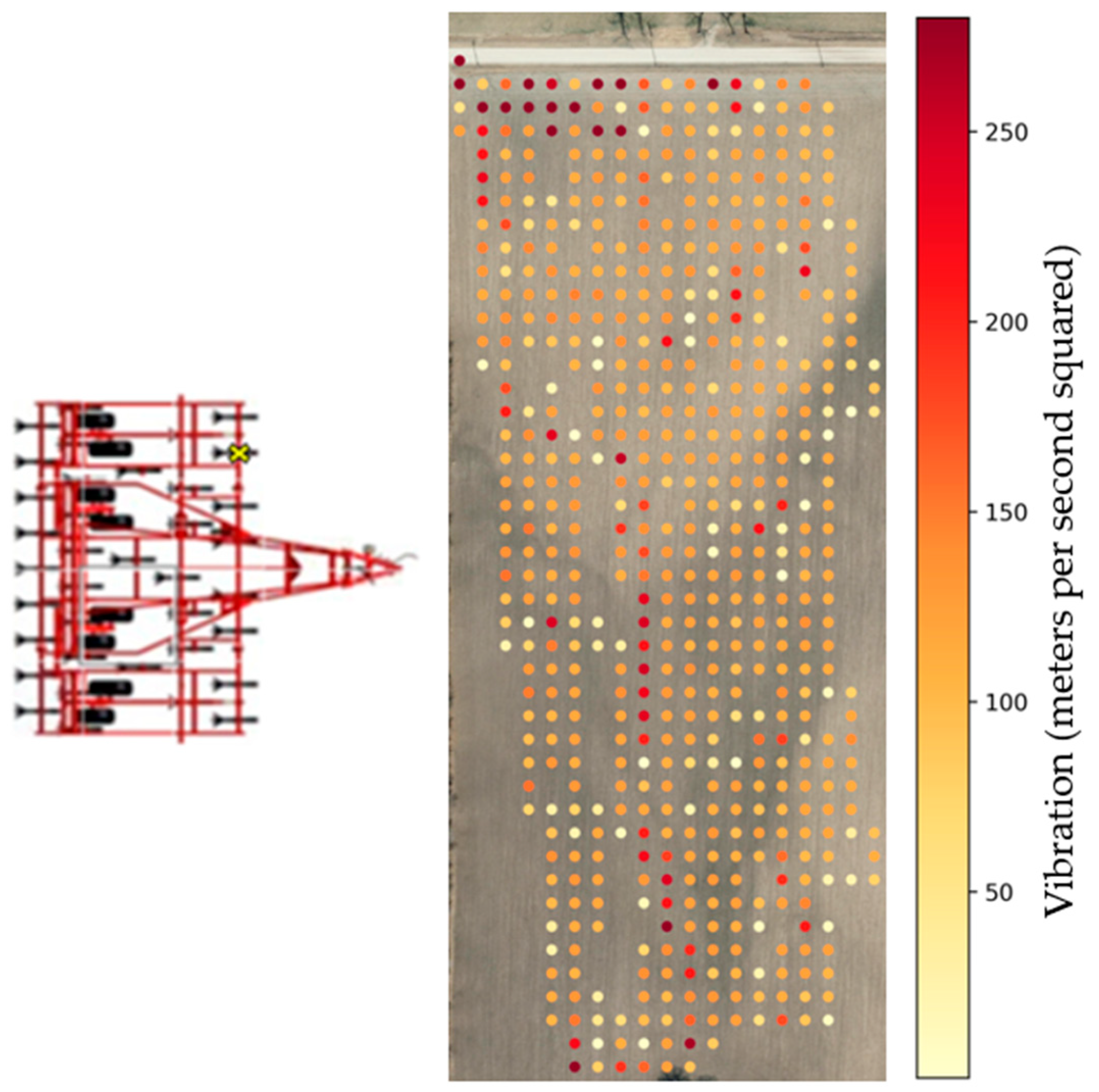

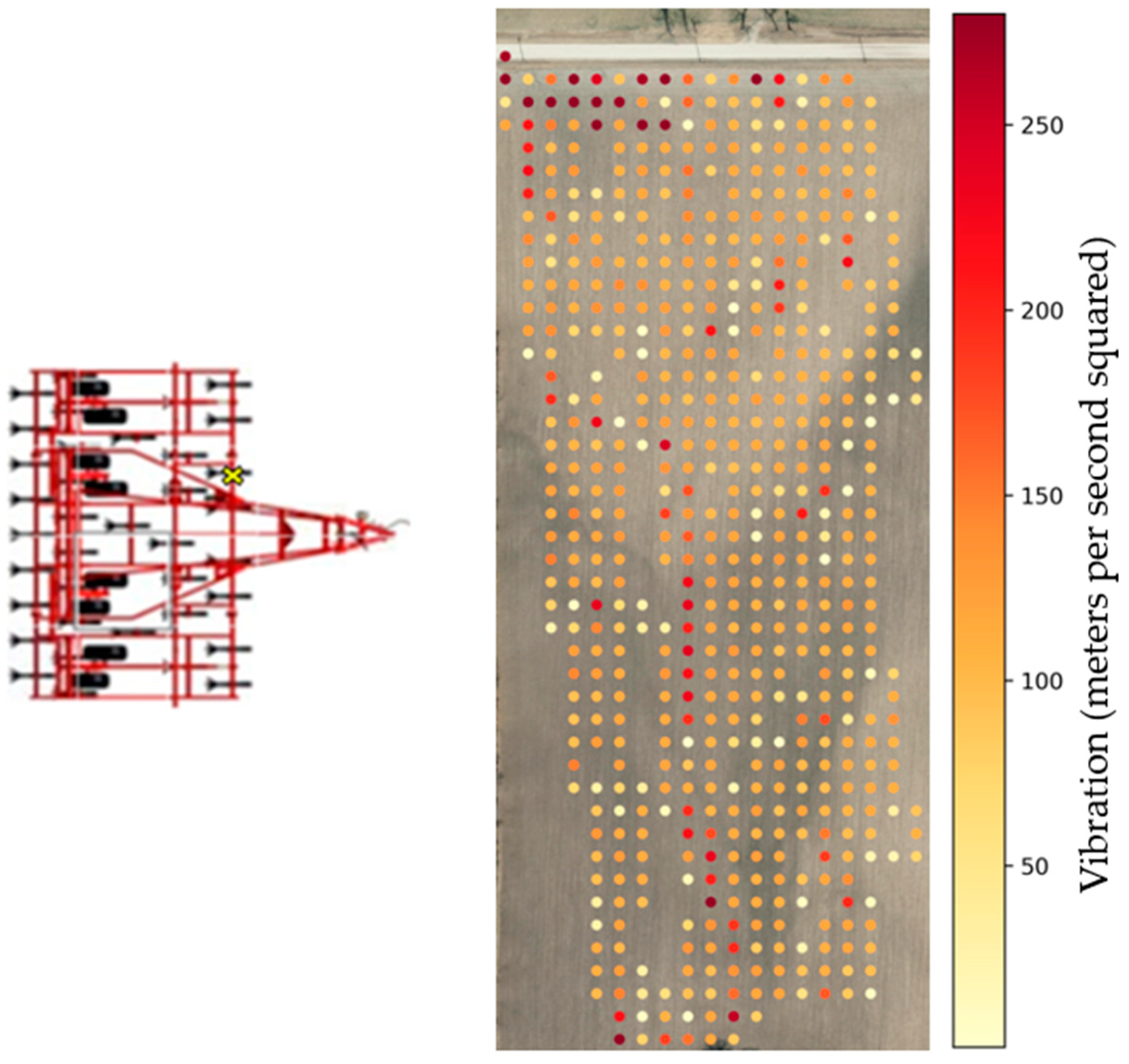

Figure 3,

Figure 4 and

Figure 5 present the frequency distribution of vibration (m/s

2) recorded by the three accelerometers. ACC1, mounted on the leftmost field cultivator shank, exhibited limited frequency variation, due to it being mostly operated in previously tilled soil. This is shown in

Figure 3, where minimal color transitions across most of the field indicate a narrow frequency range. Only the entrance section, shown in darker red tones, displayed relatively higher vibration levels [

38]. The yellow crosses on the shanks of the cultivator in the figures mark the positions of the accelerometers for reference.

As explained by Horn [

41], shading of imagery maps, also known as shaded relief or hill shading, is a technique where brightness or tone reflects the surface slope. In

Figure 4 and

Figure 5, background gradients resemble this shading effect and correspond to elevation variations across the field, as detected by the avDAQ system and known soil compaction areas [

38].

The upper left region of the heatmaps corresponds to the field entrance, where the field is heavily trafficked as equipment enters and exits. This area was subject to repeated loading by loaded silage trucks carrying material away from the field. The central region of the field, where dark shading reflects a bottoming out elevation variability, exhibited high vibration levels recorded by the shank. This zone likely experiences increased mechanical stress due to soil heterogeneity. Notably, a visible channel has formed in the middle of the field as a result of historical river overflows and erosion from seasonal rainfall. This feature likely contributed to reduced soil compaction in that area, as indicated by the lighter tones observed in the heatmaps [

38].

While the initial test with the full-size field cultivator provided an indication that shank vibration could provide some soil compaction information, more fidelity in compaction information was desired. Experimental studies by Esehaghbeygi et al. [

37] demonstrated that the vibration frequency of a cultivator shank strongly correlates with soil compaction, which has a greater impact on draft force and soil fragmentation than factors such as soil moisture or working depth. Given the strong influence of soil moisture on soil mechanical behavior and the tool’s vibrational response, soil moisture was concurrently measured with compaction to more accurately interpret the vibration signals [

19]. Moisture content directly affects soil strength and shear resistance: wetter soils reduce penetration resistance and increase vibration damping, resulting in lower-amplitude signals, while drier soils produce higher-amplitude vibrations due to increased rigidity [

19]. Therefore, including soil moisture measurements was essential to enhance the accuracy and reliability of compaction assessment using vibration data [

42]. To investigate this relationship more deeply, a field test was devised for crop year 2024 where compaction, soil moisture, and vibration data would be collected in controlled locations. The test would have soil moisture and soil compaction information collected at geolocated points of interest within the Knox Lane field. A single field cultivator shank fitted with an accelerometer would pass through points where soil compaction and moisture content data had been collected. GPS data would be collected with vibration data to provide a direct comparison of field compaction, soil moisture content, and shank vibration.

A single field cultivator shank and shovel assembly taken from the Sunflower 5035 was mounted on the Cultivation Assessment Test Apparatus, known as the “CAT App.” Developed by Zeller [

43], the CAT App is a mobile testing platform designed to evaluate various tillage and planting tools under field conditions across a wide range of operating speeds. The shank was fitted with an accelerometer as in the previous test and the avDAQ was used to record vibration and GPS data. Field testing was conducted at locations where notable variation in soil resistance was observed in the previous tests.

The field cultivator shank was mounted on the CAT App frame, as shown in

Figure 6, to till the ground between the tracks of the towing tractor tires. The single accelerometer was shown in

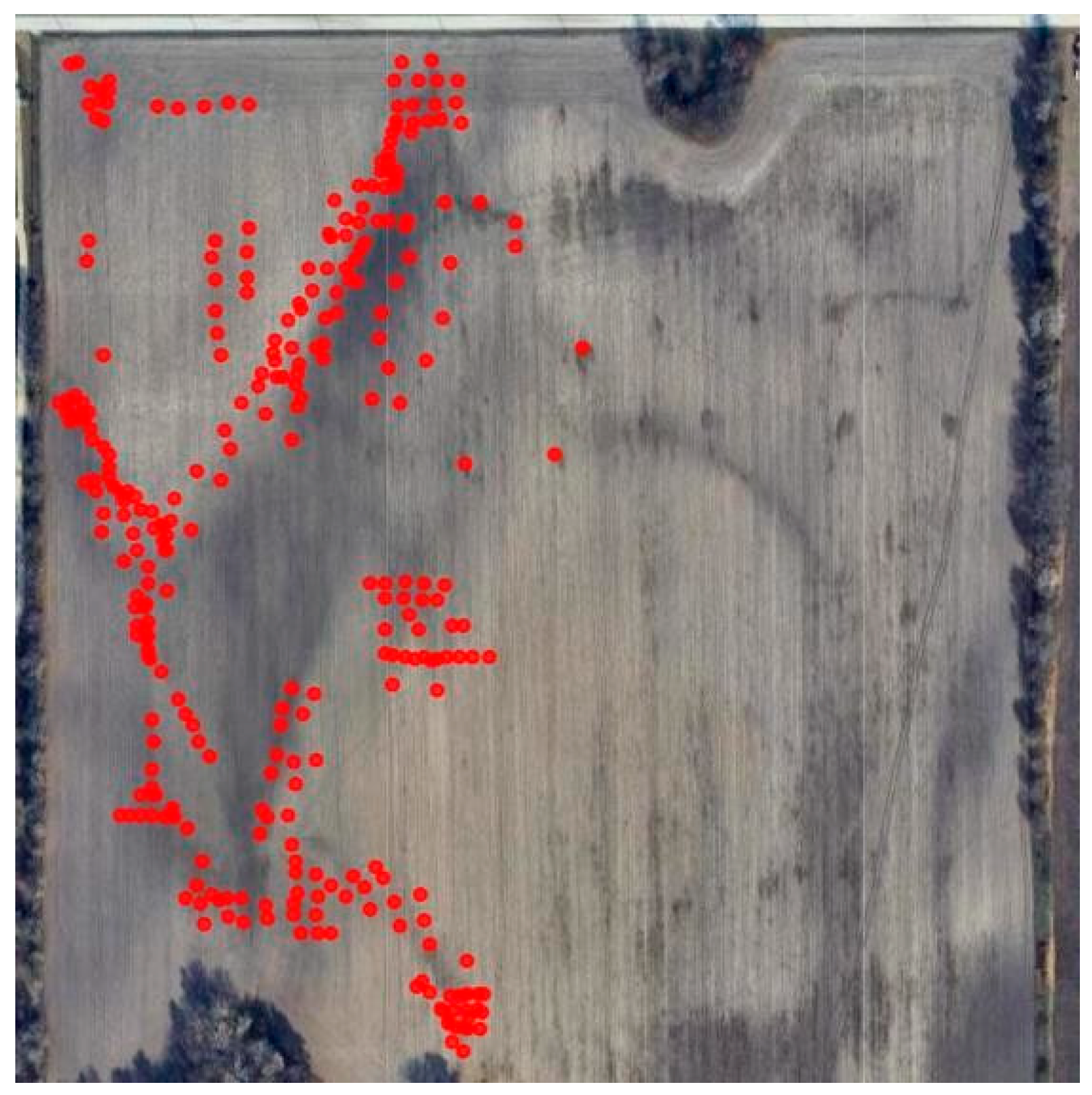

Figure 2. The selected test locations, highlighted as red spots in

Figure 7, exhibited distinct variations in vibration response across the field, enabling a more detailed and controlled evaluation of vibration behavior in relation to soil conditions.

The synchronized vibration data collected from the accelerometers, together with soil moisture measurements taken at specific geolocated points, formed the basis for developing machine learning models aimed at predicting soil compaction. By pairing these continuous sensor inputs with ground-truth compaction values obtained from the cone penetrometer, a labeled dataset was created. This dataset was used to develop and train predictive models to compare the relative contributions of vibration and moisture signals in estimating soil compaction.

2.1.2. Soil Compactness Using Penetrometer

The Cone Index, expressed as force per unit basal area (typically in kPa or psi/in2), is a standard measure of soil penetration resistance obtained using a soil cone penetrometer equipped with a 30° circular cone, as specified in ASABE Standard S313.3. For this study, the Rimik CP40II Cone Penetrometer was used to measure soil compaction at select field locations. This device records cone index values along with time, date, and GPS coordinates, enabling spatially referenced analysis across soil depth profiles.

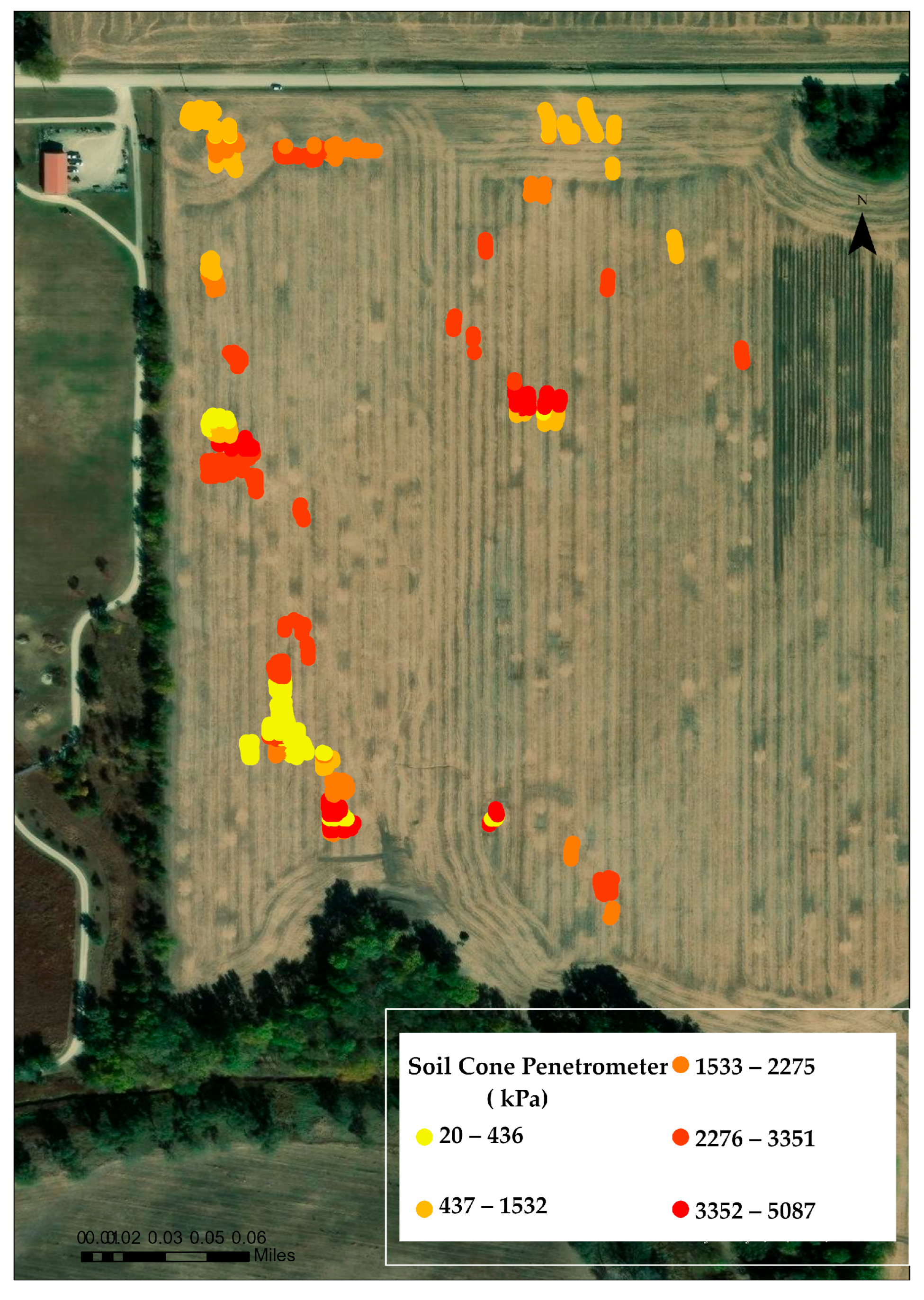

Although compaction data were collected to the full depth capability of the Rimik CP40II at each location, the analysis in this study focuses specifically on penetrometer readings at 10 cm depth, corresponding to the planned tillage depth. Cone index values at this depth ranged from 20 to 5087 kPa. These values are visualized in

Figure 8 using a graduated color scale, where each point represents soil resistance at its respective location.

All measurements followed standardized data acquisition and analysis protocols commonly adopted in soil compaction studies. As noted by Birl and Morrison [

30], penetrometer readings may be unreliable in highly compacted soils due to resistance to penetration and difficulty characterizing deeper layers. At geographic locations with extremely compacted soil where the penetrometer could not be inserted, the maximum cone index value recorded in the same field on the same day was assigned to represent extreme compaction, ensuring dataset continuity.

2.1.3. Soil Moisture Data Collection

Soil compaction is significantly influenced by moisture content, as higher moisture levels reduce soil strength and shear resistance, making soils more susceptible to deformation under mechanical stress [

19]. In wetter conditions, reduced penetration resistance and increased vibration damping allow the cultivator shank to move more freely through the soil, resulting in lower-amplitude vibration signals. Conversely, drier soils exhibit greater rigidity, leading to amplified vibrational responses. Given this relationship, soil moisture is a critical parameter for interpreting the vibration signals collected from tillage tools [

42].

During the experimental period, the field conditions were generally very dry, reflecting below-average soil moisture levels. Soil moisture was measured using a Hydrosense II soil–water sensor (HSII), which recorded volumetric water content (VWC) at a depth of 10 cm. Sensor readings were stored internally and later retrieved for analysis. Measurements were taken concurrently with cone penetrometer tests and vibration data collection. VWC values across the field ranged from 0.16% to 12.69%, indicating notable spatial variability. Incorporating soil moisture data into the analysis enhances the accuracy of vibration-based compaction assessments by contextualizing variations in vibrational behavior under different moisture regimes.

2.2. Data Preprocessing

Data cleaning was performed to address missing values caused by occasional GPS disconnections in the penetrometer and avDAQ systems. Subsequently, soil moisture and cone index data collected at the same depth (10 cm) and geographic coordinates were merged. To spatially integrate vibration data with these measurements, the buffer tool in ArcGIS Pro was employed. Within each buffer zone, vibration data points were assigned the same soil moisture and compaction values, assuming relative uniformity over short distances. The final dataset was stored in a CSV file, containing columns for geographic coordinates (latitude and longitude) along with corresponding vibration data, soil moisture measurements, and soil cone penetrometer readings. Soil moisture and compaction data were obtained at discrete sampling points, whereas vibration signals were recorded continuously as the tillage tool traversed the field. To ensure accurate spatial alignment between datasets, the tool was operated directly over the designated sampling locations. The dataset used for modeling consisted of 5345 observations (rows) and 5 variables (columns), including vibration data, soil moisture, soil compaction, and the corresponding latitude and longitude coordinates.

Higher cone index values obtained from a penetrometer generally reflect greater levels of soil compaction [

31]. In addition, soil moisture significantly influences compaction susceptibility; elevated moisture content reduces soil shear strength, making it more prone to compaction under mechanical stress [

39].

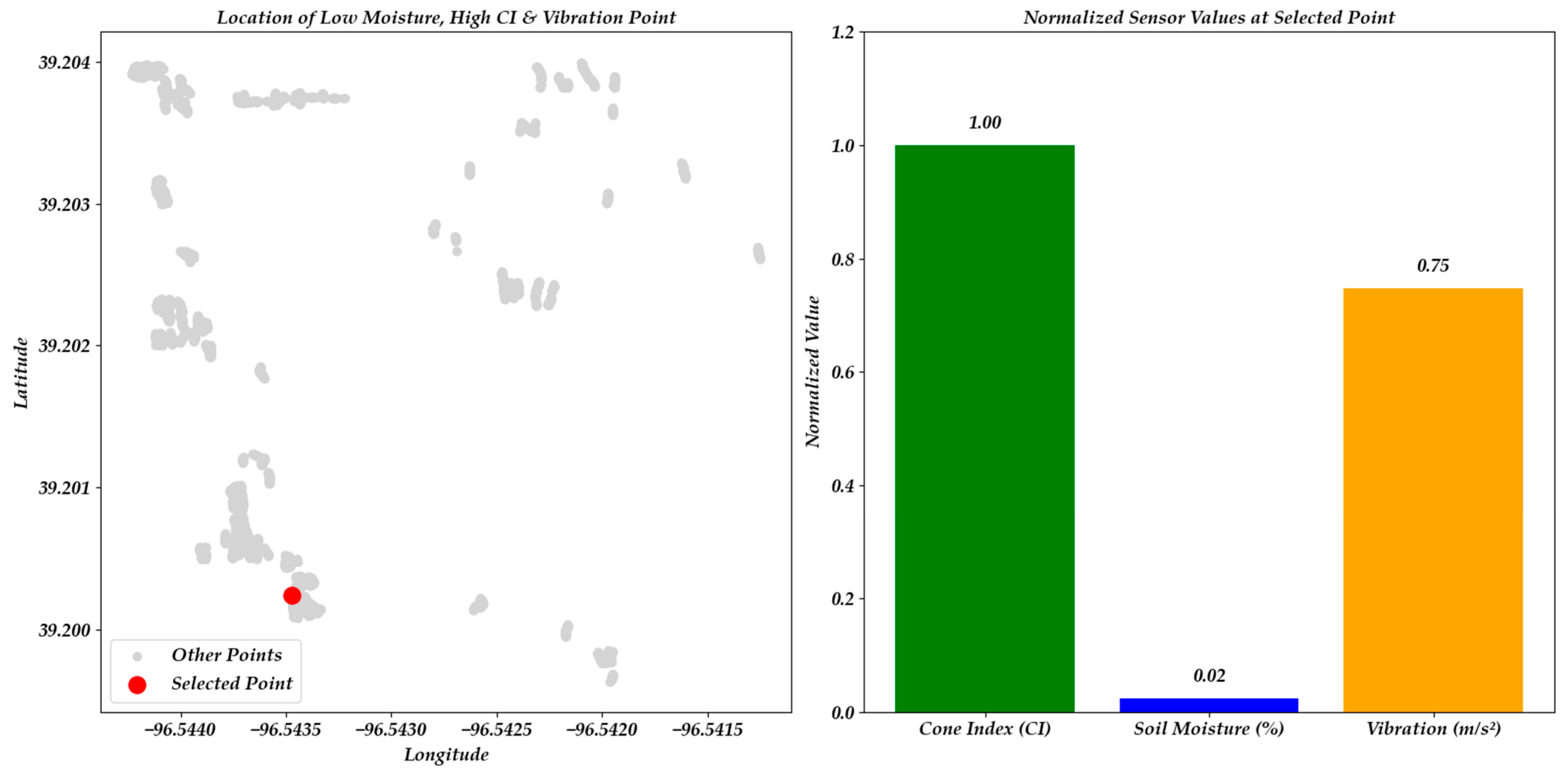

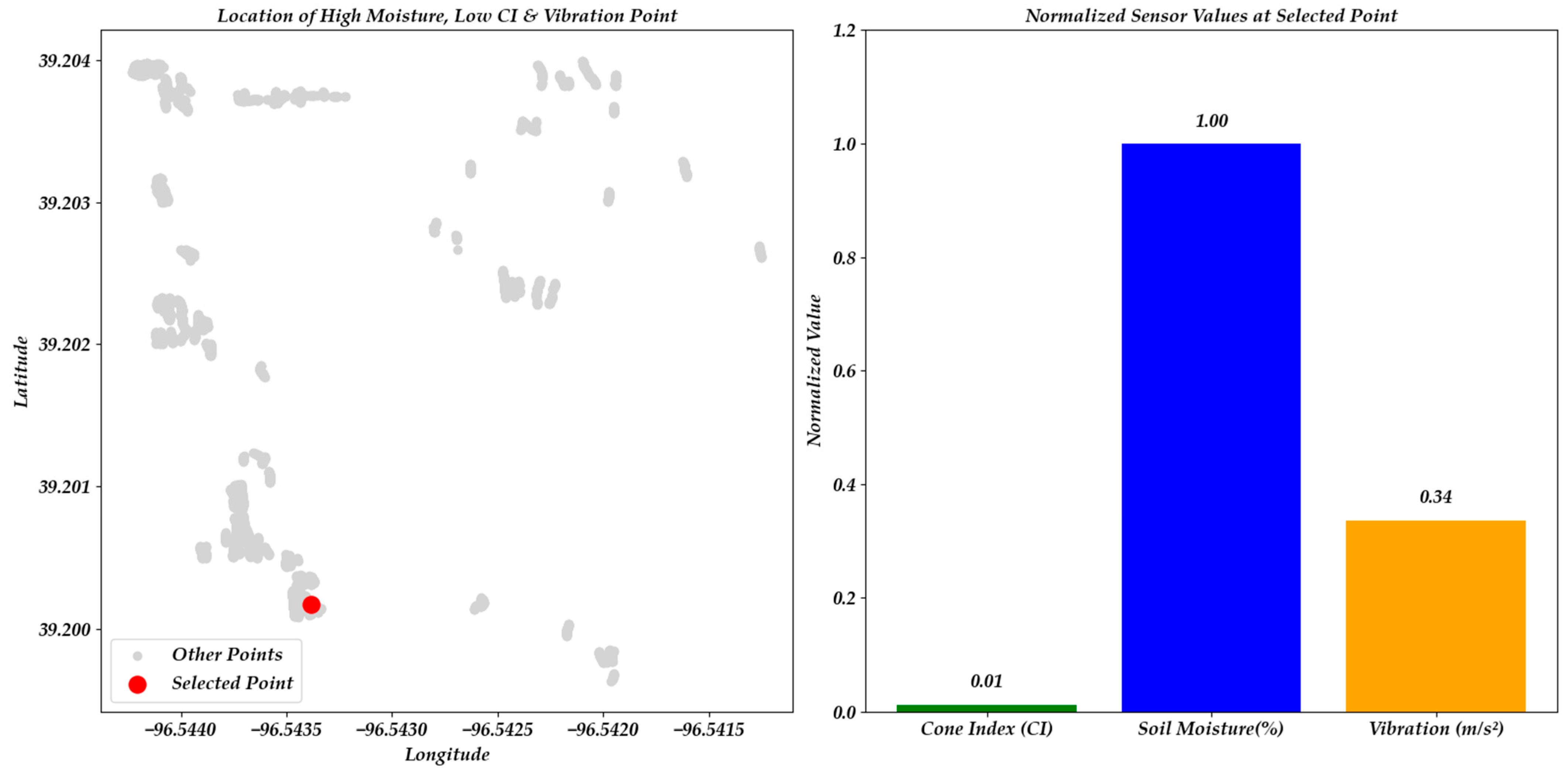

Figure 9 and

Figure 10 illustrate sensor outputs from selected sampling locations representing contrasting soil conditions. Each figure includes normalized values for geographic coordinates, cone penetrometer measurements (Cone Index, CI), soil moisture content, and corresponding vibration intensity. To visually compare all parameters on the same scale, each dataset was normalized to a range from 0 to 1 using Min-Max scaling. In this scale, a value of 1 represents the maximum observed value within each dataset (e.g., a soil moisture value of 1 corresponds to the actual maximum of 12.69%).

Vibration data were recorded as acceleration signals expressed in units of g, where 1 g corresponds to the acceleration due to Earth’s gravity (9.81 m/s2). Raw acceleration values ranged approximately from −0.43 to 0.40 g and were normalized between 0 and 1 to enable direct comparison across variables. For example, a normalized vibration value of 0.75 corresponds to an actual acceleration level of approximately 0.19 g (≈1.86 m/s2), indicating relatively high vibration intensity.

CI values ranged from 20.49 to 5087.0 kPa, so a normalized value of 1 corresponds to a CI of 5087, representing the highest measured soil resistance.

Figure 9 represents a location with high normalized vibration intensity and CI values, coupled with low normalized soil moisture, suggesting a compacted soil profile. Conversely,

Figure 10 shows lower normalized vibration and CI values along with higher normalized soil moisture content, indicating reduced soil compaction under wetter conditions.

2.3. Prediction of Compaction

Machine learning models were implemented in Python 3.11. Given the high volume, velocity, and complexity of continuous vibration data collected during the second round of field testing in November 2024, machine learning techniques were selected for their ability to efficiently process large datasets and model complex nonlinear relationships. Their capacity to extract valuable insights from heterogeneous data sources, such as soil moisture and vibration signals, makes them well suited to predict soil compaction levels. In this study, vibration and moisture data served as input features to train models aimed at estimating soil compaction, with cone penetrometer measurements as the ground truth. Predicted compaction values were then compared to actual cone index (CI) measurements to evaluate model accuracy and the strength of the relationship.

Tree-based machine learning models are particularly effective at capturing complex nonlinear patterns in structured agricultural datasets [

14]. Initially, a stacking ensemble model combining Random Forest and Gradient Boosting regressors with a linear regression meta-learner was evaluated. However, this approach yielded limited predictive performance on our dataset, achieving a correlation coefficient of only 0.3704. This outcome likely reflects the complexity of the stacking strategy combined with the large volume and high variability of the data.

To improve prediction accuracy, two individual models known for their robustness in handling nonlinear relationships were selected: Random Forest and XGBoost. Random Forest reduces variance by averaging predictions from multiple decision trees trained on random data subsets (bagging). In contrast, XGBoost builds trees sequentially, correcting residual errors via gradient boosting to enhance overall model performance.

Soil moisture and vibration signals were selected because they reflect key physical and mechanical properties of soil. Moisture affects the soil’s susceptibility to compaction, while vibrations measured during tillage capture real-time resistance experienced by the cultivator shank. In practice, the models learn to associate patterns in these two features with corresponding cone index values. This enables the prediction of soil compaction intensity at locations where only discrete data points are available, offering the potential for continuous, on-the-go compaction monitoring.

Both models were trained using soil moisture content and cultivator shank vibration signals as input features. The target variable was soil compaction measured through cone index values collected in the field.

Hyperparameter tuning was performed using randomized search with cross-validation. The optimization targeted parameters such as number of trees, maximum tree depth, learning rate (specific to XGBoost), and subsampling ratios. For Random Forest, the best-performing model used 200 trees with a maximum depth of 10, minimum samples per split of 2, minimum samples per leaf of 1, and bootstrap sampling enabled. For XGBoost, the optimal configuration included 500 trees, a maximum depth of 3, a learning rate of 0.05, L2 regularization (λ = 1.5), and subsampling ratios of 0.8 for both rows and columns. The dataset was split into 60% training and 40% testing subsets to enable a rigorous model evaluation.

3. Results

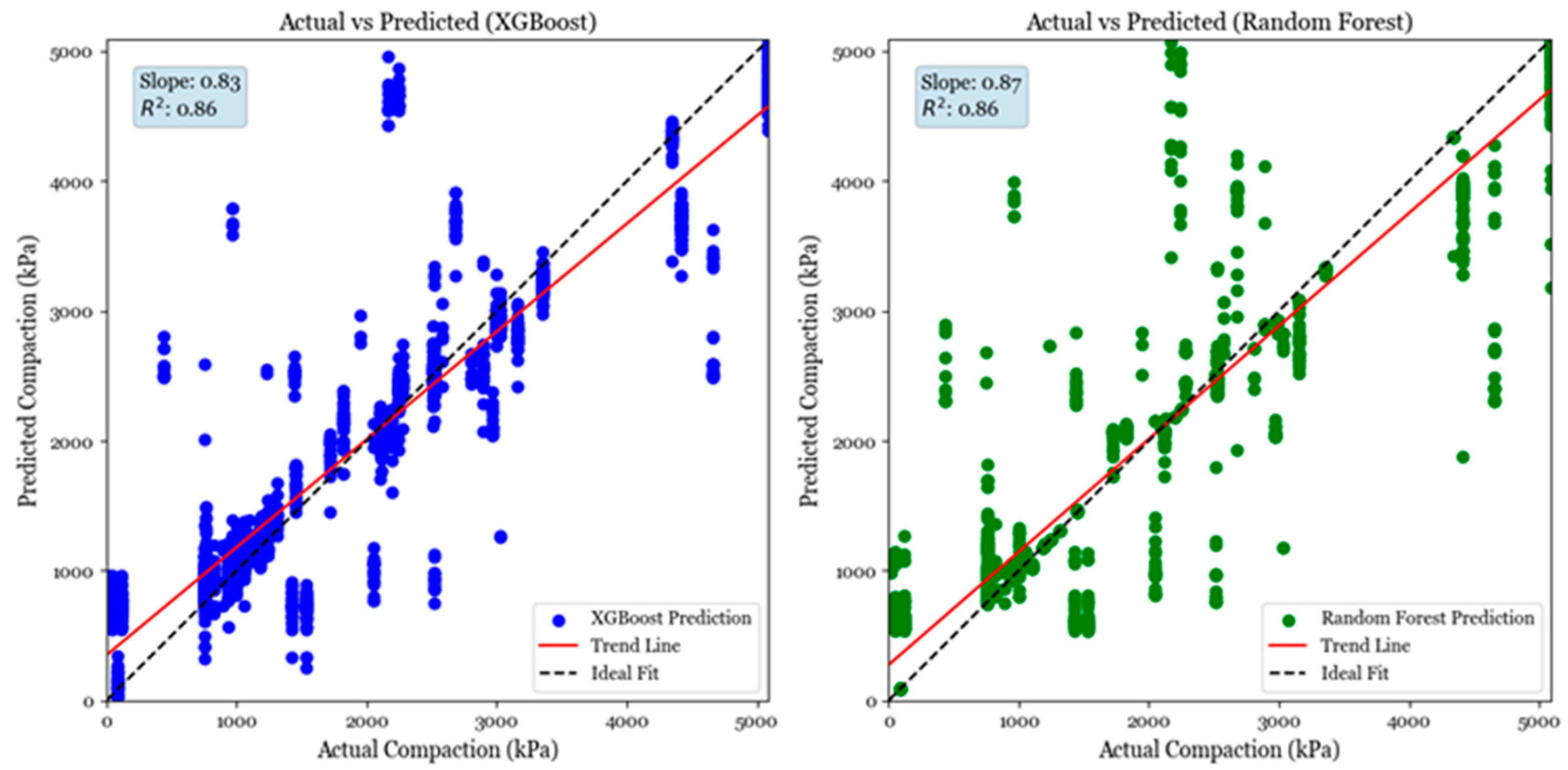

Figure 11 shows scatter plots of actual versus predicted soil compaction values (kPa) for the XGBoost and Random Forest models, based on 40% of data reserved for testing. These models were developed using the vibration and soil moisture data collected during the second round of field testing on 23 August 2024. Each plot includes a red trend line, a dashed black ideal fit line, and annotations indicating the slope and coefficient of determination (R

2). Notably, several predicted values are vertically aligned at specific actual compaction levels, including approximately 800, 900, 1200, 1500, 2000, 2500, and 3000 kPa. This clustering results from multiple observations in the dataset sharing the same actual compaction value while yielding different predicted values, due to variations in other input features such as soil moisture content and vibration response. Such patterns are common in field datasets where measurements are discretized or recorded at standard operational levels.

Both models exhibited strong predictive capabilities, with predicted values closely approximating the observed soil compaction measurements. This alignment indicates that the models effectively captured the relationship between the input features, including vibration signals and soil moisture content, and the response variable, soil compaction as measured by the cone index. The XGBoost model achieved a test R2 of 0.87, a training R2 of 0.87, and a Pearson correlation coefficient of 0.937, demonstrating substantial concordance between predicted and actual values. Similarly, the Random Forest model yielded a test R2 of 0.87, a training R2 of 0.907, and a correlation coefficient of 0.938. Feature importance analysis indicated that soil moisture had a stronger contribution than vibration in both models, highlighting its dominant role in determining soil compaction under the tested field conditions.

Root mean squared error (RMSE) values were 536.96 kPa for XGBoost and 527.82 kPa for Random Forest, corresponding to approximately 10.7% and 10.6% error, respectively, based on a compaction range of 0 to 5000 kPa. These values indicate relatively low prediction errors across the full compaction spectrum.

While both models performed consistently across most compaction levels, the Random Forest model exhibited slightly greater dispersion at higher compaction values (above 3500 kPa). This suggests some degree of overestimation or underestimation under extreme conditions. In contrast, XGBoost maintained tighter clustering in this range, indicating more stable performance for highly compacted soils. This characteristic is critical for real-time monitoring in field applications.

These results demonstrate the effectiveness of both models in predicting soil compaction from vibration and moisture data. They support the potential integration of these models into smart tillage and precision soil management systems.

To statistically validate the similarity between predicted and actual values, a one-way ANOVA was conducted. For the XGBoost model, the F-statistic was 0.38 with a p-value of 0.54, while for the Random Forest model, the F-statistic was 0.11 with a p-value of 0.74. In both cases, the p-values exceed the conventional significance threshold of 0.05, indicating no statistically significant difference between the predicted and observed means. This finding reinforces that both models not only capture overall trends but also closely approximate the true distribution of soil compaction within the dataset.

The combination of high coefficients of determination (R2), low root mean squared error (RMSE), and strong Pearson correlation coefficients demonstrates the effectiveness of both XGBoost and Random Forest models in predicting soil compaction using vibration and moisture data. Furthermore, the ANOVA results confirm that the differences between predicted and actual soil compaction values are not statistically significant (p > 0.05), supporting the consistency between model predictions and observed measurements.

4. Discussion

A central objective of this study was to demonstrate high-resolution subsurface mapping of soil conditions at tillage depth using a scalable, field-operable sensing system. Traditional methods such as cone penetrometers provide only point-based data, rendering field-scale mapping labor-intensive and spatially limited. In contrast, integration of sensors into a tillage implement enables continuous data acquisition along the tillage path, facilitating high-resolution compaction maps to support precision agriculture. Although this approach captures soil conditions only prior to the tillage pass and only to the tool’s working depth, it provides valuable insight into spatial variability from the previous growing season, informing site-specific soil management strategies.

Incorporation of vibration-based sensing into a tillage implement enabled effective detection of subsurface features such as hard spots and spatial heterogeneity in soil strength. These outputs provide detailed spatial information for precision tillage, facilitating targeted soil management practices that improve soil health and operational efficiency.

A field cultivator was selected due to its structural compatibility with sensor mounting and its applicability for shallow tillage operations. Its consistent working depth facilitated installation of accelerometers on the shanks to effectively capture soil–tool interaction forces. With further refinement of signal processing and interpretation, this methodology may be extended to other soil-engaging tools such as coulters, subsoiler shanks, and planter row units, broadening its applicability across a range of field operations. Although cone penetrometers remain the most widely used instrument for soil compaction assessment, their limitations in field-scale applications are well documented. Accurate measurement in heterogeneous or dry soils is challenging due to the probe’s sensitivity to local variations in soil texture, moisture content, and root density, which often introduce high variability and complicate data interpretation [

21,

24]. Furthermore, cone penetrometer use is labor-intensive, time-consuming, and susceptible to operator-induced variability related to insertion technique, speed, and soil moisture conditions, particularly under dry circumstances [

31]. These factors constrain the feasibility of cone penetrometers for high-resolution, large-scale compaction mapping.

Dynamic penetration devices have been used in other sectors such as pavement engineering but generally lack the spatial resolution, adaptability, and operational integration required for precision agriculture applications [

30]. This highlights the need for implement-mounted systems capable of providing continuous, real-time data on soil mechanical properties during routine field operations. To address soil heterogeneity and operational efficiency, several smart tillage implements have been developed, including the Clemson Intelligent Plow [

9], John Deere’s TruSet system [

10], CASE AFS Soil Command [

9], HE-VA Combi-Disc [

11], JAMES self-excited vibrating subsoiler [

15], Wu’s ultrasonic sensor-based deep cultivator [

12], Lou et al.’s electro-hydraulic control system [

44], and Wang et al.’s electric-hydraulic flexible tine subsoilers [

13,

14]. All of these systems relied on cone penetrometer measurements to evaluate soil compaction and guide variable-depth or precision tillage. While they optimize tillage depth based on compaction data, no current smart tillage implement can measure soil compaction directly in real time during operation.

To address these challenges, the AVDAQ system was developed as an embedded vibration-based platform for real-time soil compaction monitoring. By collecting vibration signals via accelerometers affixed to tillage shanks, AVDAQ enables continuous, non-invasive compaction mapping without disrupting field activities. Machine learning models, including XGBoost and Random Forest, demonstrated strong predictive performance in estimating soil compaction from vibration data, with Random Forest achieving the highest correlation of 93.8%. These findings confirm the system’s potential as an effective alternative to traditional penetrometer measurements for high-resolution, field-scale compaction assessment.

AVDAQ overcomes several limitations of conventional approaches by providing automated, operator-independent, and spatially explicit data in real time. Its seamless integration with tillage equipment facilitates informed, site-specific soil management decisions and advances precision tillage practices, thereby contributing to sustainable agriculture.

Future research will focus on improving signal quality by mitigating mechanical noise generated by the towing tractor and machine field motion as well as identifying signals that indicate common field features such as rocks, slopes, and tracks. The development of advanced filtering and signal processing algorithms to isolate soil–shank interaction frequencies is expected to enhance measurement accuracy and the robustness of associated machine learning models.

Moreover, AVDAQ’s sensitivity to vibration signals may enable detection of machine load dynamics, such as individual wheel or track passes and their localized effects on soil compaction, providing finer spatial resolution. Further investigation of these capabilities may expand the system’s utility in operational monitoring and tillage optimization.

It should be emphasized that the AVDAQ system currently captures soil conditions prior to tillage. While this is valuable for retrospective analysis and operational planning, future research should consider extending its use to post-tillage assessments, providing a more accurate representation of seedbed quality at planting. Furthermore, it should be noted that the resulting compaction maps represent relative compaction levels within the field rather than absolute cone index (CI) values.

5. Conclusions

Soil compaction is a major challenge in sustainable agriculture, as it reduces pore space, increases bulk density and penetration resistance, and degrades soil structure. Repeated use of heavy machinery for tillage, planting, spraying, and harvesting exacerbates this problem, leading to long-term declines in soil health, crop growth, and yield.

A key contribution of this study is the finding that data-collecting shanks should be positioned away from tractor tire tracks and previously tilled paths to obtain representative field vibration measurements. This research addressed the central question: Can tillage tools be used to measure soil compaction during regular field operations? The results show that when equipped with vibration sensors and paired with soil moisture data, tillage tools can reliably estimate soil compaction. Two machine learning models, XGBoost and Random Forest, were trained using these features, with cone index values serving as ground truth. Both models showed strong predictive performance, with Pearson correlation coefficients of 0.937 for XGBoost and 0.938 for Random Forest. A one-way ANOVA test confirmed no statistically significant differences between predicted and observed means (p = 0.54 for XGBoost, p = 0.74 for Random Forest), indicating that the models accurately capture both overall trends and local compaction levels.

This study demonstrates that combining shank vibration and soil moisture data enables continuous, in-field monitoring of soil compaction. Unlike cone penetrometers, which provide discrete point measurements, the AVDAQ system allows for spatially continuous sensing during regular tillage operations.