Research on Layered Fertilization Method of Fertilizer Applicator and Optimization of Key Parameters

Abstract

1. Introduction

2. Materials and Methods

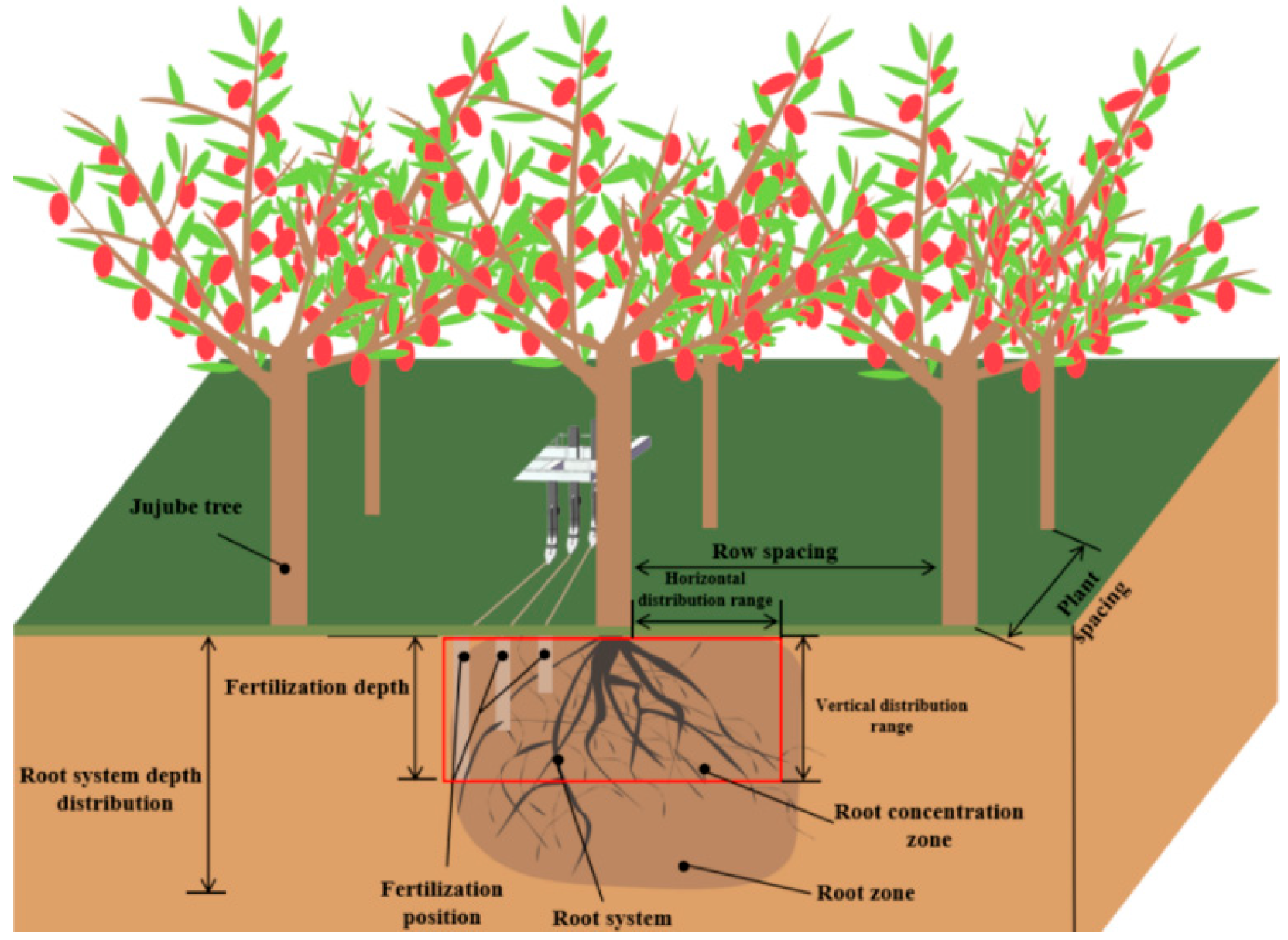

2.1. Agronomic Analysis

2.1.1. Root Distribution Characteristics and the Influence of Fertilization Position

2.1.2. Stimulatory Effects of Stratified Fertilization on Fruit Tree Root Systems

2.2. Determination of Jujube Root System Distribution

2.2.1. Root System Excavation

2.2.2. Root System Sieving

2.3. Fertilizer Applicator Structural Design

2.3.1. Structure and Working Principle of Layered Fertilizer Applicator

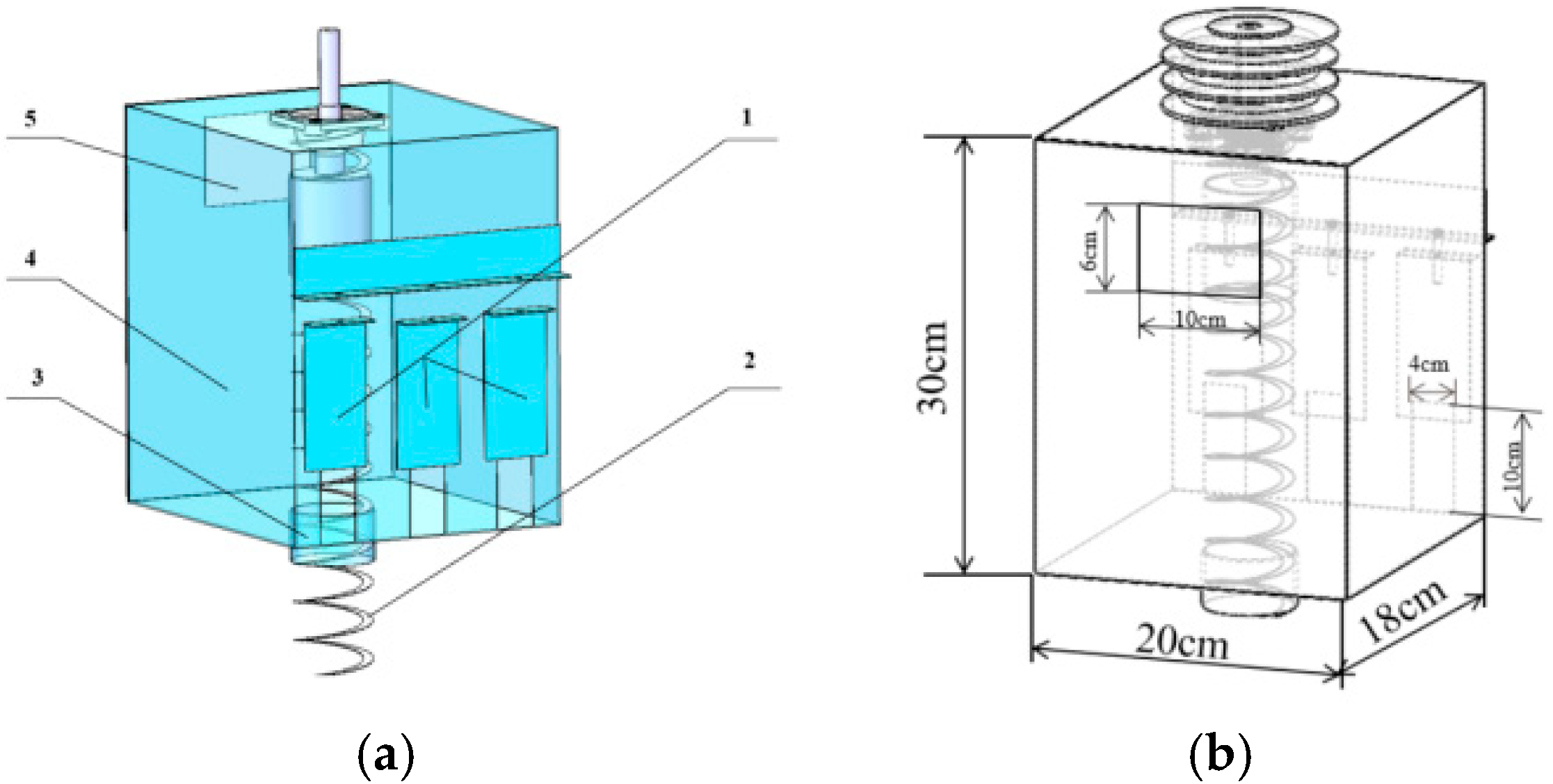

2.3.2. Structural Design of Key Components

2.4. Bench Test

2.4.1. Structural Composition of Fertilizer Delivery Mechanism

2.4.2. Experimental Design and Protocol

2.4.3. Fertilization Performance Evaluation

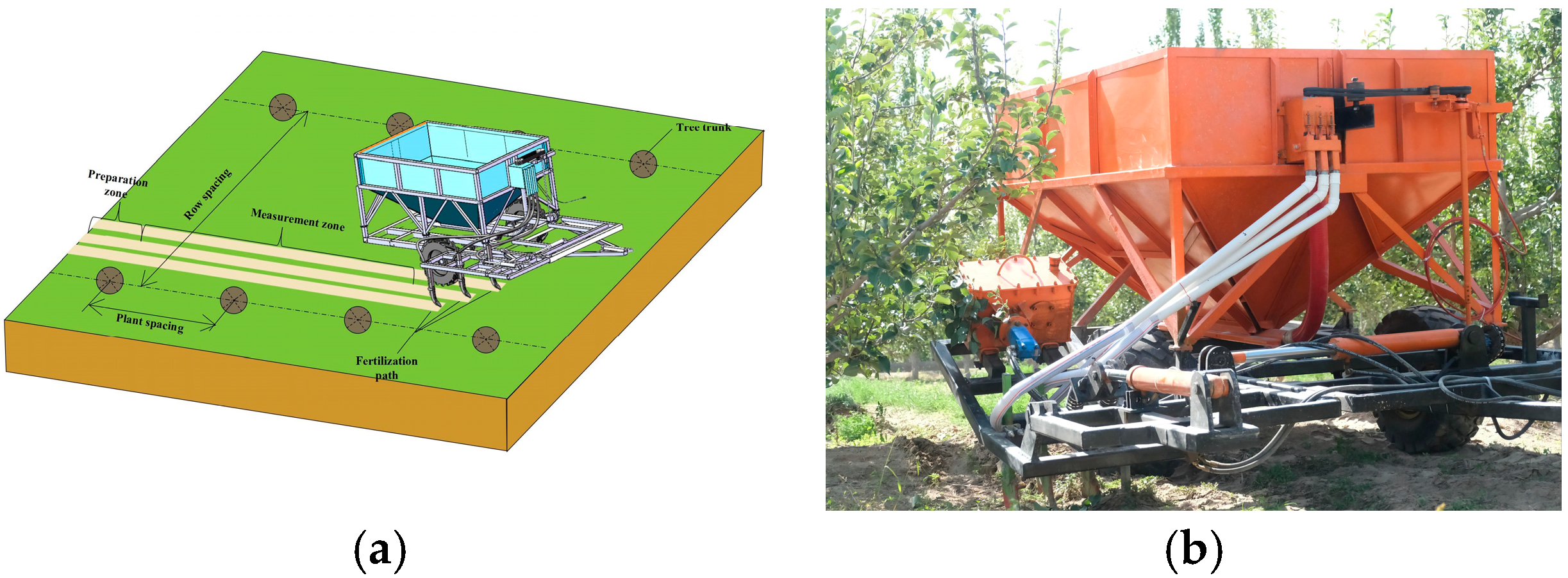

2.5. Field Trials

2.5.1. Field Trial Conditions

2.5.2. Experimental Protocol

2.5.3. Test Equipment and Evaluation Metrics

Measurement Method for Fertilizer Uniformity Coefficient

Measurement Method for Row-to-Row Consistency Coefficient

3. Results and Discussion

3.1. Distribution Results of Jujube Root System Measurement

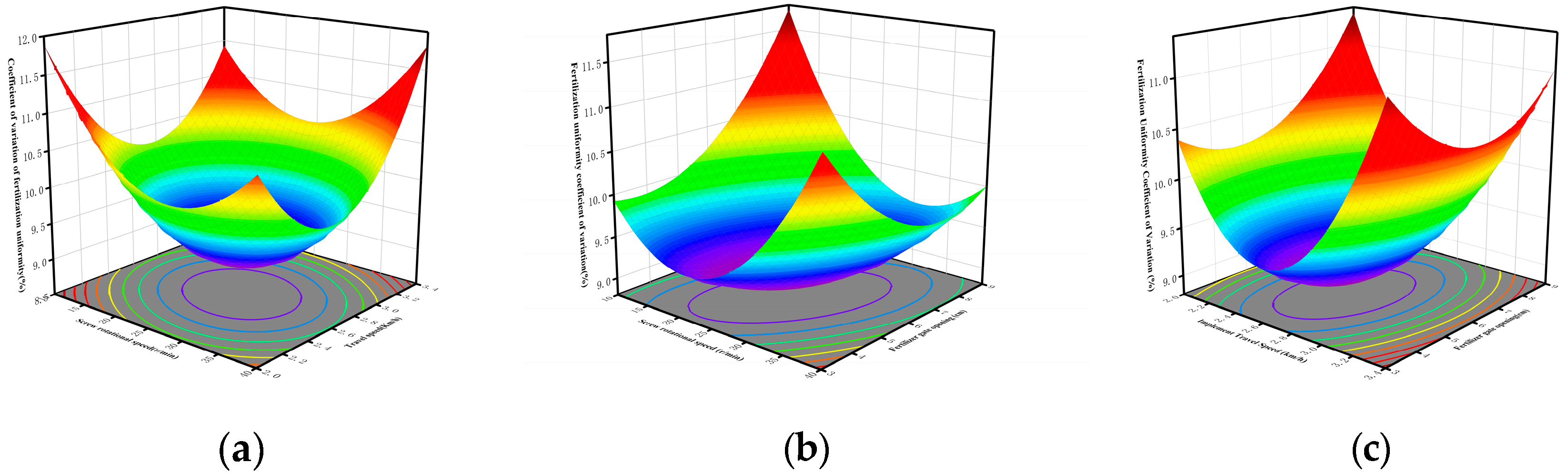

3.2. Analysis of Factors Affecting Fertilization Performance

3.3. Field Fertilization Experiment Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Editorial Committee of China Agricultural Yearbook. China Agricultural Yearbook 2019; China Agriculture Press: Beijing, China, 2020. [Google Scholar]

- Zuo, Z.; Zhao, J.; Yin, B.; Li, L.; Jia, H.; Zhang, B.; Ma, Z.; Hao, J. Optimized Design and Experiment of a Spatially Stratified Proportional Fertilizer Application Device for Summer Corn. ACS Omega 2022, 7, 20779–20790. [Google Scholar] [CrossRef]

- Moreira, S.L.S.; Imbuzeiro, A.M.H.; Dietrich, S.H.O.; Henriques, E.; Flores, M.E.P.; Pimentel, L.D.; Fernandes, R.B.A. Root Distribution of Cultivated Macauba Trees. Ind. Crops Prod. 2019, 137, 646–651. [Google Scholar] [CrossRef]

- Qi, W.Z.; Liu, H.H.; Li, G.; Shao, L.J.; Wang, F.F.; Liu, P.; Dong, S.T.; Zhang, J.W.; Zhao, B. Temporal and Spatial Distribution Characteristics of Super-High-Yield Summer Maize Root. Plant Nutr. Fertil. Sci. 2012, 1, 69–76. [Google Scholar]

- Yuan, W.S.; Wang, Y.L.; Jiang, C.Q.; Feng, Y.G.; Zhang, L.M.; Hu, Y. Different Mechanized Fertilization Methods in Nutrient Utilization and Summer Maize Yield. Agriculture 2023, 13, 310. [Google Scholar] [CrossRef]

- Cheng, H.S.; Zhang, Z.H.; Shen, Y.J.; Ding, J.T.; Meng, H.B.; Zhou, H.B.; Wang, J.; Xu, P.X. Design and Experiment of Layered Near-Root Liquid Manure Fertilization Shovel. Trans. Chin. Soc. Agric. Mach. 2024, 55, 98–107. [Google Scholar]

- Du, X.; Liu, C.; Jiang, M.; Yuan, H. Design and Development of Fertilizer Point-Applied Device in Root-Zone. Appl. Eng. Agric. 2022, 38, 559–571. [Google Scholar] [CrossRef]

- Gao, L.P.; Chen, H.; Liu, J.C.; Qin, Y.H.; Liao, Q.X.; Liao, Y.T.; Wang, T.Y. Effects of Synchronous Layered Fertilization with Machinery on the Root Architecture and Lodging Resistance of Rape. Trans. Chin. Soc. Agric. Eng. 2023, 39, 87–97. [Google Scholar]

- Liu, C.; Pang, S.; Li, X.; Liu, P.; Zhou, Y.; Lin, X.; Gu, S.; Wang, D. Layered Nitrogen Fertilization Regulates Root Morphology to Promote Synergistic Nitrogen and Phosphorus Absorption in Maize (Zea mays L.). Field Crops Res. 2025, 322, 109737. [Google Scholar] [CrossRef]

- Zhu, X.H.; Li, H.C.; Li, X.D.; Liang, J.H.; Zang, J.J.; Zhao, H.S.; Guo, W.C. Mechanized Ring-Furrow Fertilization of Organic Fertilizers in Orchards. Trans. Chin. Soc. Agric. Eng. 2023, 39, 60–70. [Google Scholar]

- Wang, D.W.; Li, P.; Yi, X.K.; Miao, J.A.; He, Y.C.; Ran, J.H.; Zhang, F.K. Current Situation and Countermeasures in Fertilisation Process and Related Machinery Application in Orchards. J. Fruit Sci. 2021, 38, 792–805. [Google Scholar]

- Yang, Y.M.; Sun, Y.M.; Jia, L.L.; Jia, S.L.; Meng, C.X. Effects of Phosphorus Fertilization Depth on Yield and Root Distribution of Summer Maize. Sci. Agric. Sin. 2018, 8, 1518–1526. [Google Scholar]

- Su, Z.Y.; Han, X.R.; Li, C.Q.; Li, W.X.; Lou, C.R.; Lu, Y. Effect of Deep Placement of Fertilizers on Crop Yields and Use Efficiency of Nitrogen. J. Shenyang Agric. Univ. 1997, 4, 292–296. [Google Scholar]

- Gao, J.; Liu, Z.; Wang, P.; Huang, S. Drip Irrigation Coupled with Appropriate N Input Increased Maize (Zea mays L.) Yield and Lodging Resistance via Optimizing Root and Stem Trait. Eur. J. Agron. 2024, 160, 127298. [Google Scholar] [CrossRef]

- Han, B.; Liu, F.; Mu, J.Y.; Ma, Y. Structural Design of Orchard Digging Fertilizing Machinery. J. Agric. Mech. Res. 2015, 37, 123–125, 129. [Google Scholar]

- Shen, C.J.; Jia, S.X.; Zhang, L.X.; Zhou, Y.; Li, F.; Dai, Y.M.; Zhang, J.; Ma, W.X. Development of Caterpillar Self-Propelled Orchard Gas Explosion Subsoiling and Fertilizer Machine. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–11. [Google Scholar]

- Schepers, J. Precision Agriculture for Sustainability. Precis. Agric. 2019, 20, 1–3. [Google Scholar] [CrossRef]

- Chen, P.L.; Su, J.H.; Xu, J.; Liu, M.H. Design and Experiment of Hilly Orchard Vertical Spiral Ditching-Fertilizing Machine. Trans. Chin. Soc. Agric. Mach. 2024, 55, 223–233, 274. [Google Scholar]

- Han, S.J.; Li, Y.P.; Zhou, X.Z.; Kan, Z.; Meng, H.W.; Qi, J.T. DEM Simulation and Experimental Validation of the Performance of an Orchard Deep Applicator for Manure. Appl. Sci. 2023, 13, 3709. [Google Scholar] [CrossRef]

- Yang, C.C. Spatial Distribution Characteristics of Roots in Young-Middle Aged Jujube Trees in Aksu Region. Master’s Thesis, Xinjiang Normal University, Xinjiang, China, 2013. [Google Scholar]

- Bu, M.N.; Yang, X.W.; Teng, Z.K.; Hu, N.Y.; Zhang, S.; Wang, C.Y.; Yang, J.; Liang, W.X.; Ma, W.Q.; He, D.X.; et al. Effects of Layered Fertilization Under Different Irrigation Conditions on Vertical Distribution of Soil Nutrients and Root. Sci. Agric. Sin. 2024, 57, 2125–2142. [Google Scholar]

- Li, L.S.; Zhao, X.N.; Gao, X.D.; Wu, P. Influences of Stand Age on Root Patterns in a Rain-Fed Jujube (Ziziphus jujube) Plantation of Loess Plateau in China. Trans. Chin. Soc. Agric. Eng. 2015, 31, 140–146. [Google Scholar]

- Goss, M.; Miller, M.; Bailey, L.; Grant, C. Root Growth and Distribution in Relation to Nutrient Availability and Uptake. Eur. J. Agron. 1993, 2, 57–67. [Google Scholar] [CrossRef]

- Shen, J.; Li, C.; Mi, G.; Li, L.; Yuan, L.; Jiang, R.; Zhang, F. Maximizing Root/Rhizosphere Efficiency to Improve Crop Productivity and Nutrient Use Efficiency in Intensive Agriculture of China. J. Exp. Bot. 2013, 64, 1181–1192. [Google Scholar] [CrossRef] [PubMed]

- Yan, M.; Zhang, C.; Li, H.; Zhang, L.; Ren, Y.; Chen, Y.; Cai, H.; Zhang, S. Root pruning improves maize water-use efficiency by root water absorption. Front. Plant Sci. 2023, 13, 1023088. [Google Scholar] [CrossRef] [PubMed]

- Geisler, D.; Ferree, D.C. The Influence of Root Pruning on Water Relations, Net Photosynthesis, and Growth of Young ‘Golden Delicious’ Apple Trees [Root/Shoot Ratio]. J. Am. Soc. Hortic. Sci. 1984, 109, 827–831. [Google Scholar] [CrossRef]

- Bravdo, B.A.; Levin, I.; Assaf, R. Control of Root Size and Root Environment of Fruit Trees for Optimal Fruit Production. J. Plant Nutr. 1992, 15, 699–712. [Google Scholar] [CrossRef]

- Gao, S.B. Scientific Fertilization Techniques for Northern Shaanxi Jujube. Northwest Hortic. (Fruit Spec. Issue) 2009, 4, 41–42. [Google Scholar]

- Feng, L.; Yang, Y.T.; Liu, X.; Liu, Z.L.; Guo, Y.L.; Li, Y. Design and Application of Layered Fertilization Equipment for Root Zone Soil in Facility Vegetables. Agric. Eng. 2024, 14, 55–60. [Google Scholar]

- Zhang, M.Q. Study on Flow Fluctuation Characteristics and Key Parameter Optimization of Spiral Fertilizer Discharger. Master’s Thesis, Tarim University, Xinjiang, China, 2023. [Google Scholar]

- Wang, X.Y. Research on Extrusion-Shearing Method for Walnut Shell Breaking. Master’s Thesis, Tarim University, Xinjiang, China, 2024. [Google Scholar]

- GB/T 20346.2-2022; Fertilizer Machinery-Part 2: Inter-Row Fertilizer Applicator. State Administration for Market Regulation: Beijing, China, 2022.

- Liu, X.D.; Wang, X.P.; Chen, L.Y.; Zhang, C.Y.; Liu, W.B.; Ding, Y.C. Design and Experiments of Layered and Quantitative Fertilization Device for Rapeseed Seeder. Trans. Chin. Soc. Agric. Eng. 2021, 37, 1–10. [Google Scholar]

- Zhang, M.; Niu, H.; Han, Y.; Zhi, Y.; Yuan, T.; Zhang, H.; He, Y.; Tang, Z.; Lan, H. A Simulation and Experiment of the Flow Fluctuation Characteristics of a Fertilizer Distribution Apparatus with a Screw from the Perspective of the Force Chain. Appl. Sci. 2024, 14, 1122. [Google Scholar] [CrossRef]

- Gao, Y.; Feng, K.; Yang, S.; Han, X.; Wei, X.; Zhu, Q.; Chen, L. Design and Experiment of an Unmanned Variable-Rate Fertilization Control System with Self-Calibration of Fertilizer Discharging Shaft Speed. Agronomy 2024, 14, 2336. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Q.; Xu, Z.; Zhang, T.; Niu, X. Evaluating the Navigation Performance of Multi-Information Integration Based on Low-End Inertial Sensors for Precision Agriculture. Precis. Agric. 2020, 22, 627–646. [Google Scholar] [CrossRef]

- Zhang, J.L.; Wang, X.G.; Tian, H.L.; Lu, Y.; Guo, C.J.; Liu, H.L. A Fertilizer Discharge Detection System Based on Point Cloud Data and an Efficient Volume Conversion Algorithm. Comput. Electron. Agric. 2021, 185, 106131. [Google Scholar] [CrossRef]

- Sundaram, P.K.; Mani, I.; Lande, S.D.; Parray, R.A. Design and development of a tractor-drawn liquid fertilizer applicator. Agric. Mech. Asia Afr. Lat. Am. 2023, 54, 28. [Google Scholar]

- Zhang, Y.; Zhang, K.; Yu, Y.; Zhang, D.; Yang, L.; Cui, T.; He, X. Remnant fertilizer monitoring system for maize fertilizer applicators. Int. J. Agric. Biol. Eng. 2023, 16, 173–180. [Google Scholar] [CrossRef]

| Encoding | Implement Travel Speed (A) km/h | Screw Rotational Speed (B) r/min | Fertilizer Gate Opening (C) cm |

|---|---|---|---|

| 1 | 2 | 10 | 3 |

| 0 | 2.7 | 25 | 6 |

| −1 | 3.4 | 40 | 9 |

| Stroke | Measurement Zone Length (m) | Time (s) | Velocity (km/h) |

|---|---|---|---|

| First stroke | 50 | 56″95 | 3.2 |

| Second stroke | 50 | 50″90 | 3.2 |

| Test Serial Number | Experimental Factor | Experimental Index | |||

|---|---|---|---|---|---|

| Screw Rotational Speed A | Implement Travel Speed B | Fertilizer Gate Opening C | Uniformity Coefficient of Variation (%) | Consistency Coefficient of Variation (%) | |

| 1 | 25 | 2 | 3 | 5.1 | 8.89 |

| 2 | 25 | 3.4 | 9 | 7.9 | 8.08 |

| 3 | 40 | 2.7 | 9 | 8.5 | 8.69 |

| 4 | 25 | 3.4 | 3 | 7 | 9.97 |

| 5 | 40 | 3.4 | 6 | 7.8 | 8.82 |

| 6 | 10 | 2 | 6 | 5.1 | 9.97 |

| 7 | 25 | 2.7 | 6 | 6 | 7.23 |

| 8 | 40 | 2.7 | 3 | 6.8 | 9.88 |

| 9 | 10 | 3.4 | 6 | 6.7 | 10 |

| 10 | 10 | 2.7 | 9 | 7.2 | 10.05 |

| 11 | 25 | 2.7 | 6 | 6.1 | 6.95 |

| 12 | 25 | 2.7 | 6 | 5.9 | 7.05 |

| 13 | 25 | 2 | 9 | 7.5 | 9.98 |

| 14 | 10 | 2.7 | 3 | 5.3 | 9.56 |

| 15 | 40 | 2 | 6 | 7.4 | 9.37 |

| Serial Number | Uniformity Coefficient of Variation (%) | Consistency Coefficient of Variation (%) |

|---|---|---|

| 1 | 8.90 | 8.31 |

| 2 | 8.25 | 7.18 |

| 3 | 7.64 | 8.02 |

| 4 | 6.86 | 9.77 |

| 5 | 7.20 | 9.01 |

| Mean value | 7.77 | 8.46 |

| Predicted value | 6.86 | 8.09 |

| Relative error (%) | 0.91 | 0.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Li, T.; Zhang, D.; Fan, X.; Zhang, H.; Niu, H. Research on Layered Fertilization Method of Fertilizer Applicator and Optimization of Key Parameters. Agriculture 2025, 15, 1876. https://doi.org/10.3390/agriculture15171876

Zhang Y, Li T, Zhang D, Fan X, Zhang H, Niu H. Research on Layered Fertilization Method of Fertilizer Applicator and Optimization of Key Parameters. Agriculture. 2025; 15(17):1876. https://doi.org/10.3390/agriculture15171876

Chicago/Turabian StyleZhang, Yabo, Tongxi Li, Dong Zhang, Xiuwen Fan, Hong Zhang, and Hao Niu. 2025. "Research on Layered Fertilization Method of Fertilizer Applicator and Optimization of Key Parameters" Agriculture 15, no. 17: 1876. https://doi.org/10.3390/agriculture15171876

APA StyleZhang, Y., Li, T., Zhang, D., Fan, X., Zhang, H., & Niu, H. (2025). Research on Layered Fertilization Method of Fertilizer Applicator and Optimization of Key Parameters. Agriculture, 15(17), 1876. https://doi.org/10.3390/agriculture15171876