An Interpretable Stacked Ensemble Learning Framework for Wheat Storage Quality Prediction

Abstract

1. Introduction

- Grain temperature data were introduced, and spatial dimensionality reduction was conducted to derive Effective Accumulated Temperature, Cumulative High Temperature Deviation, and Cumulative Temperature Gradient features, thus comprehensively characterizing internal temperature dynamics while avoiding the need for complex three-dimensional modeling.

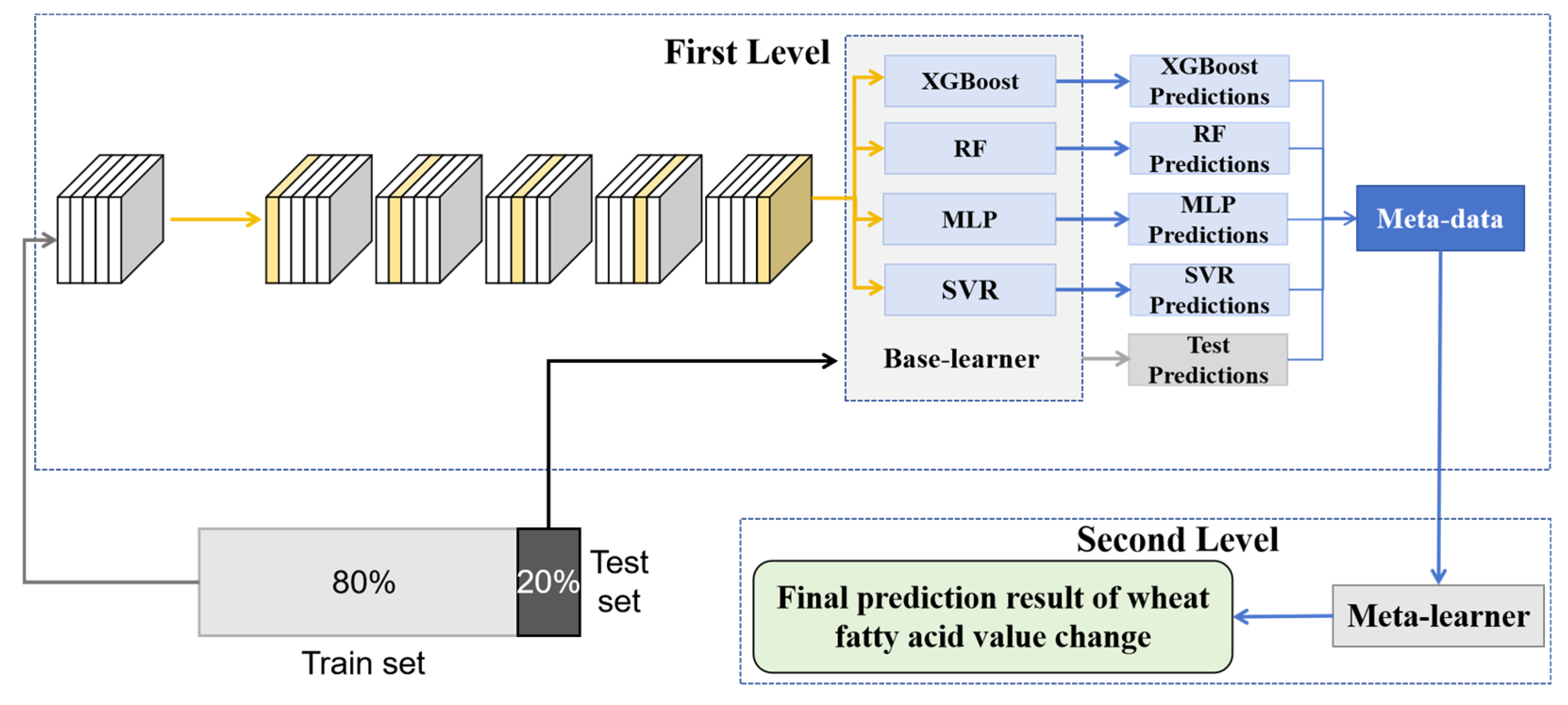

- A stacked ensemble learning approach was applied to effectively handle small sample sizes and multi-source data fusion, leveraging automated feature selection and nonlinear modeling capabilities to uncover complex data patterns, and SHAP analysis was employed to provide interpretability of feature-driving mechanisms.

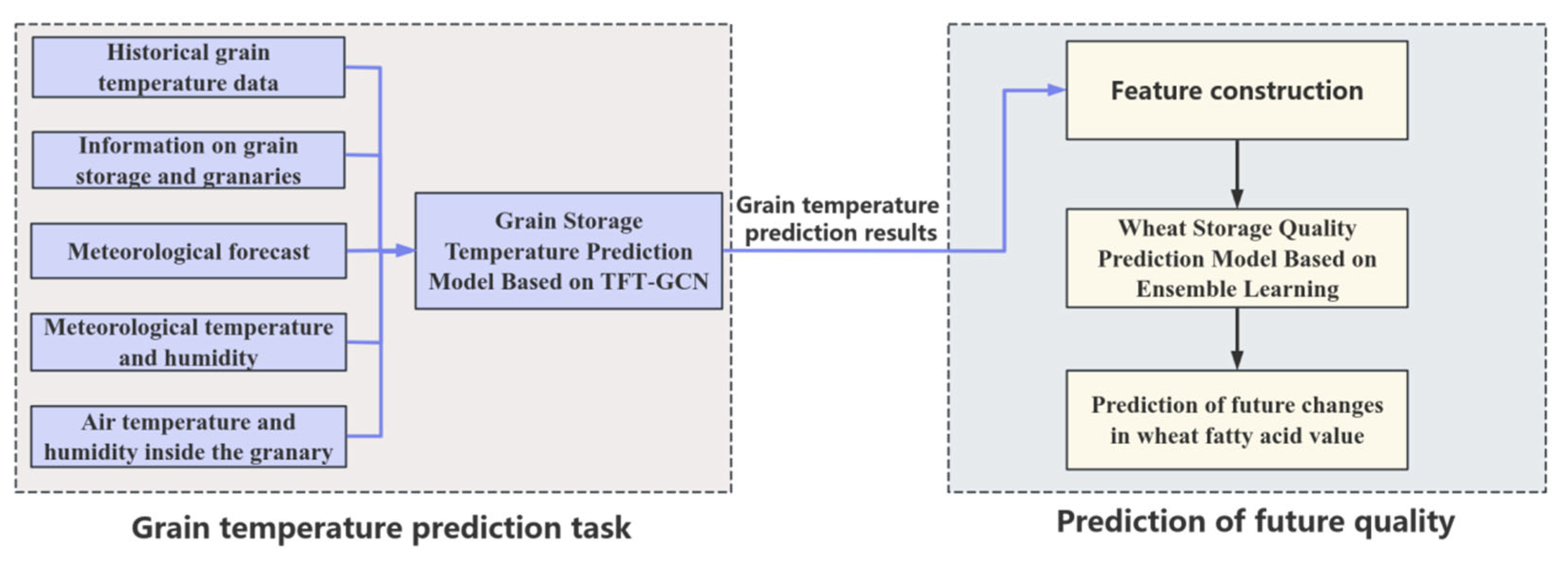

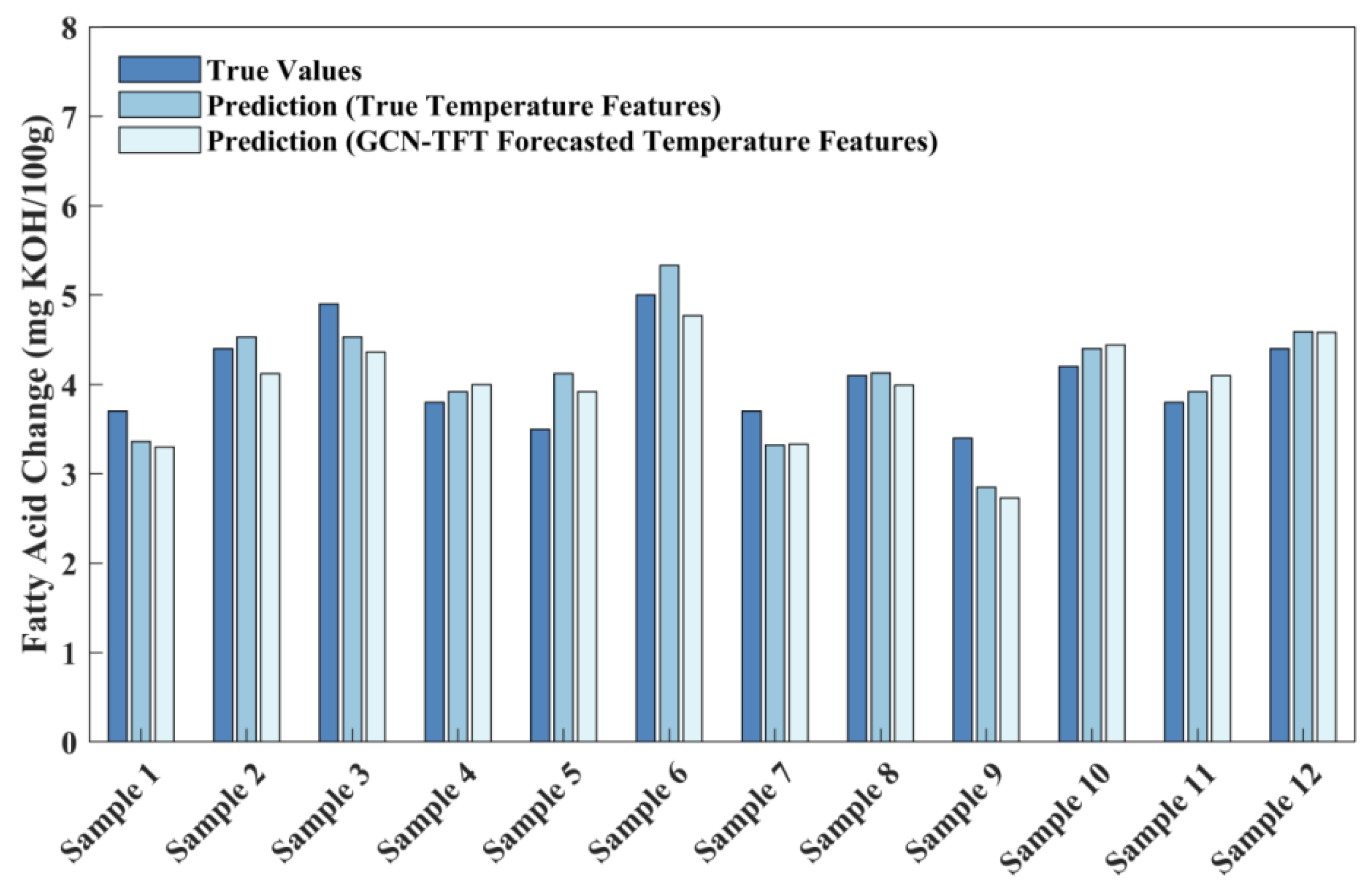

- A multi-model fusion framework was developed to integrate a high precision grain temperature forecasting model with a stacked ensemble quality prediction model, enabling advanced quantitative forecasts of wheat storage quality changes and thereby supporting storage managers in risk assessment and the formulation of intervention strategies based on the predictions.

2. Materials and Methods

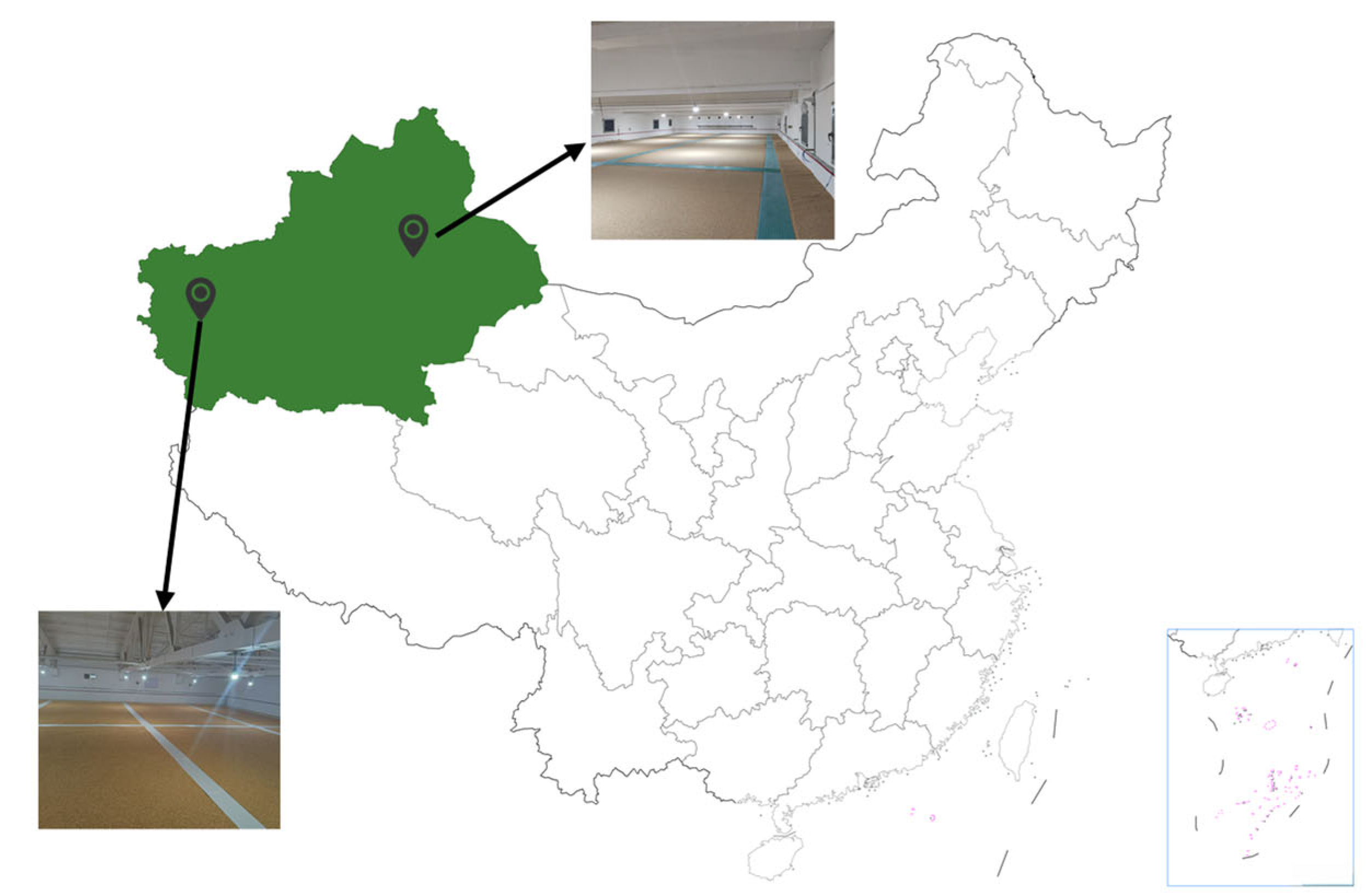

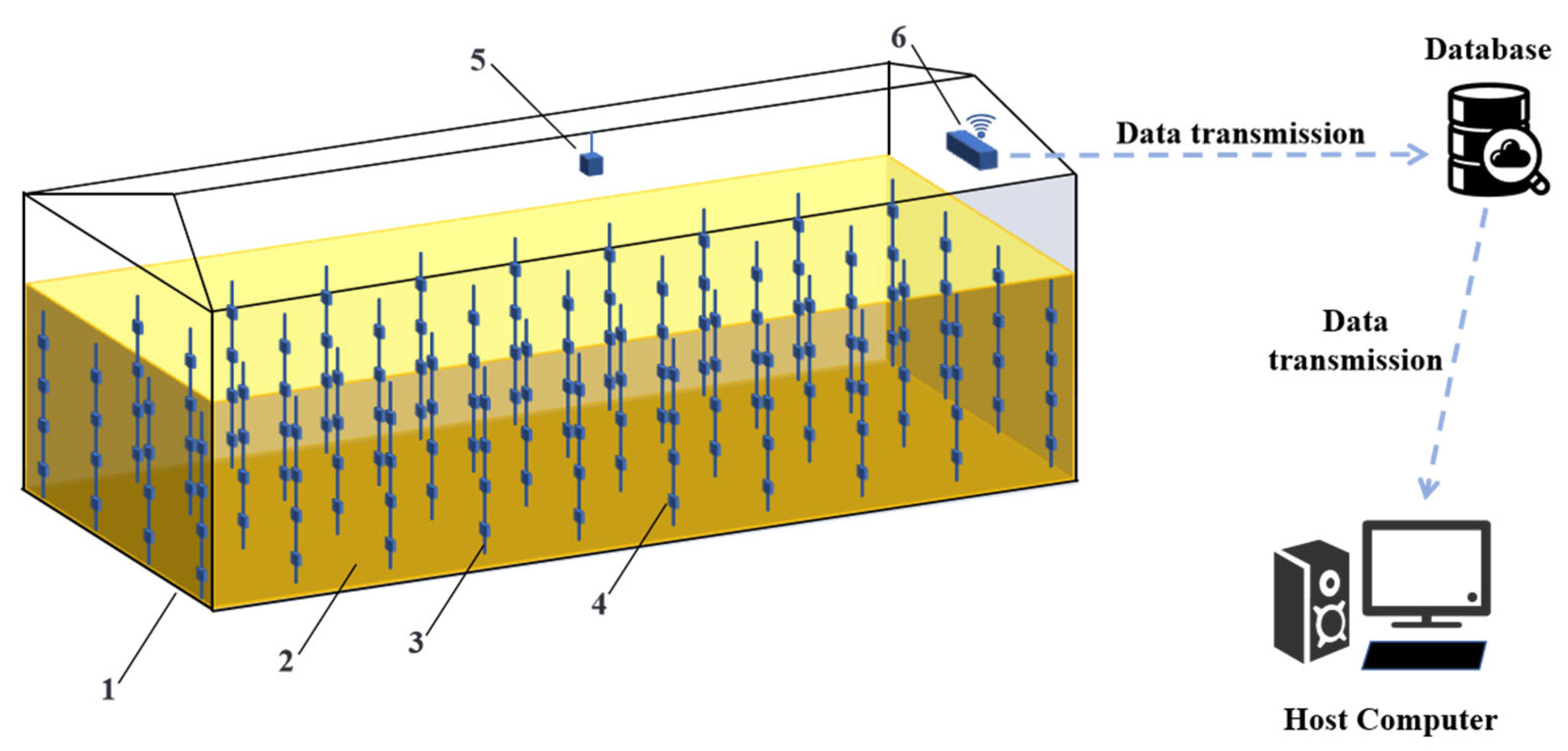

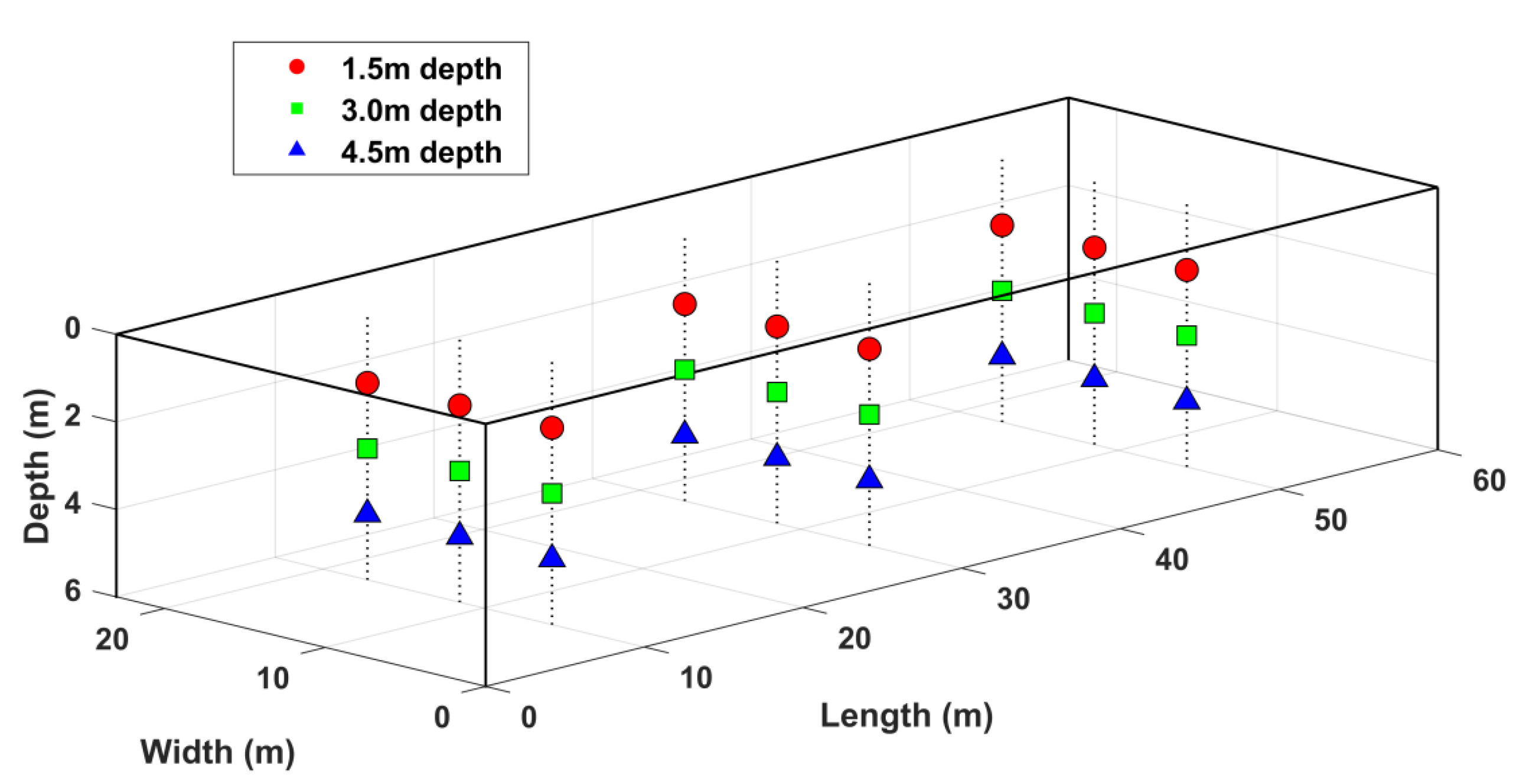

2.1. Dataset

2.2. Data Preprocessing

2.3. Feature Construction

2.4. Feature Selection

2.5. Stacked Ensemble Learning Model

2.6. Future Wheat Storage Quality Prediction Method Based on Multi-Model Fusion

2.7. Evaluation Metrics

3. Results and Discussion

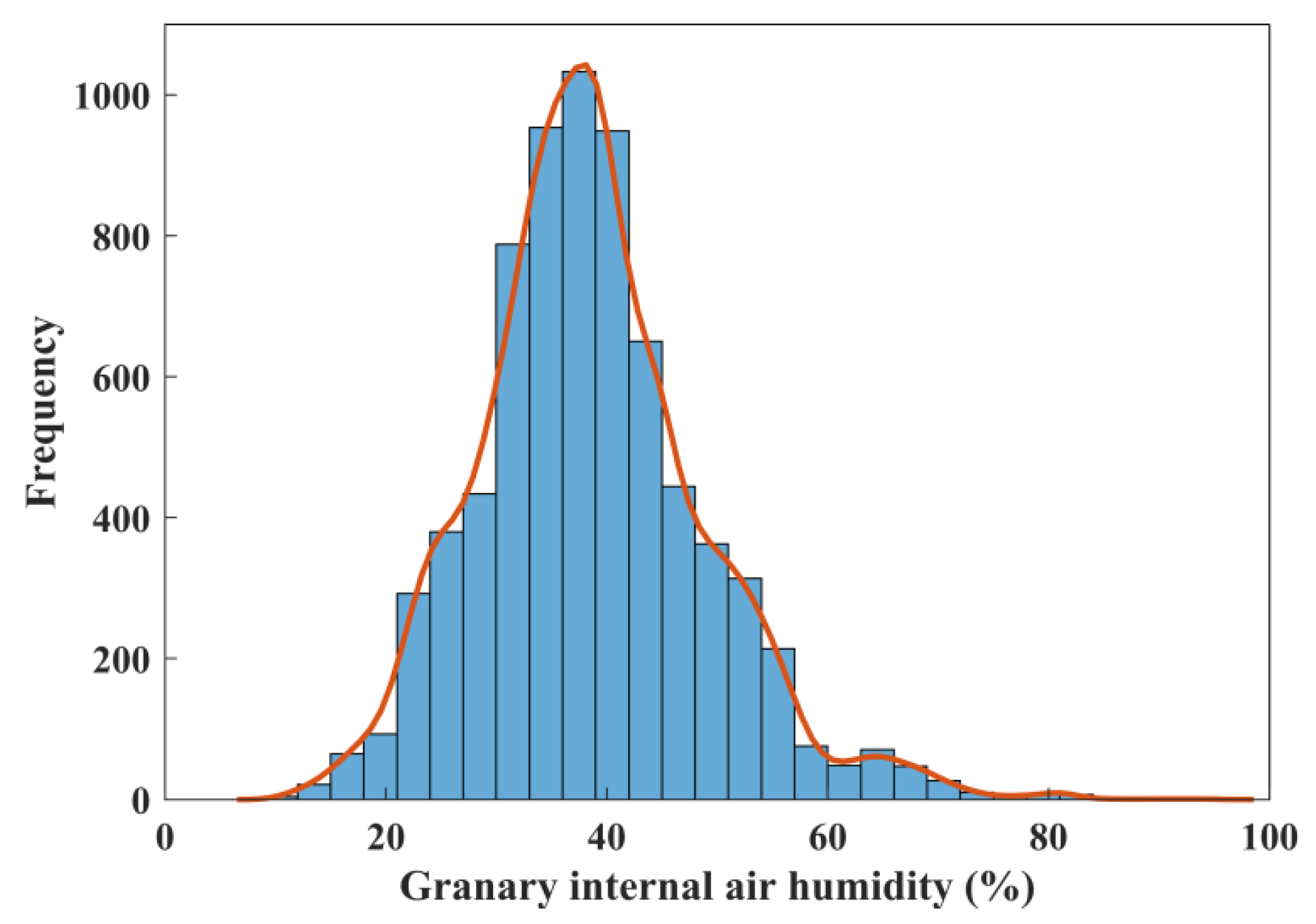

3.1. Data Statistical Description

3.2. Hyperparameter Optimization

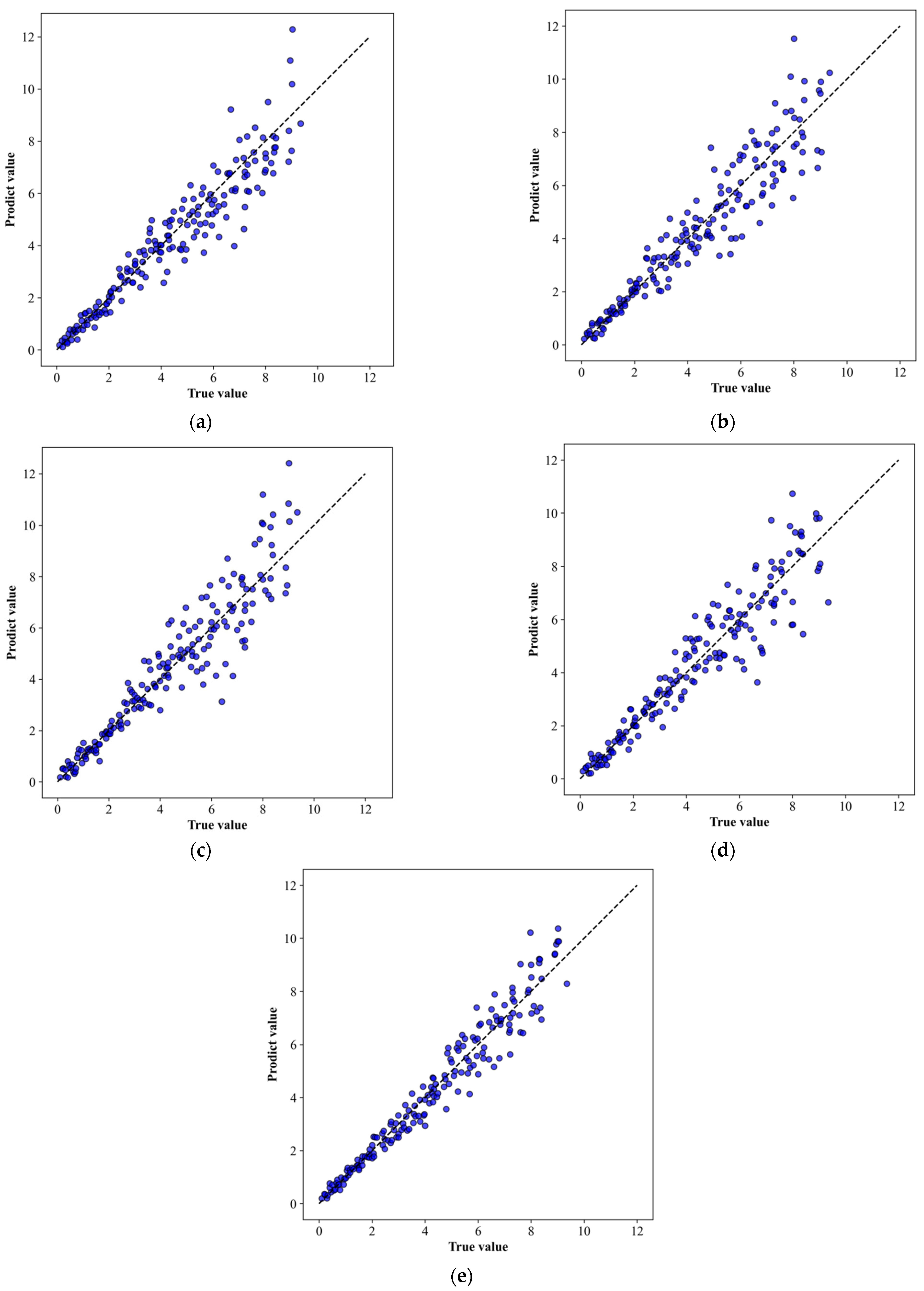

3.3. Comparison of Model Performance

3.4. Interpretability Analysis

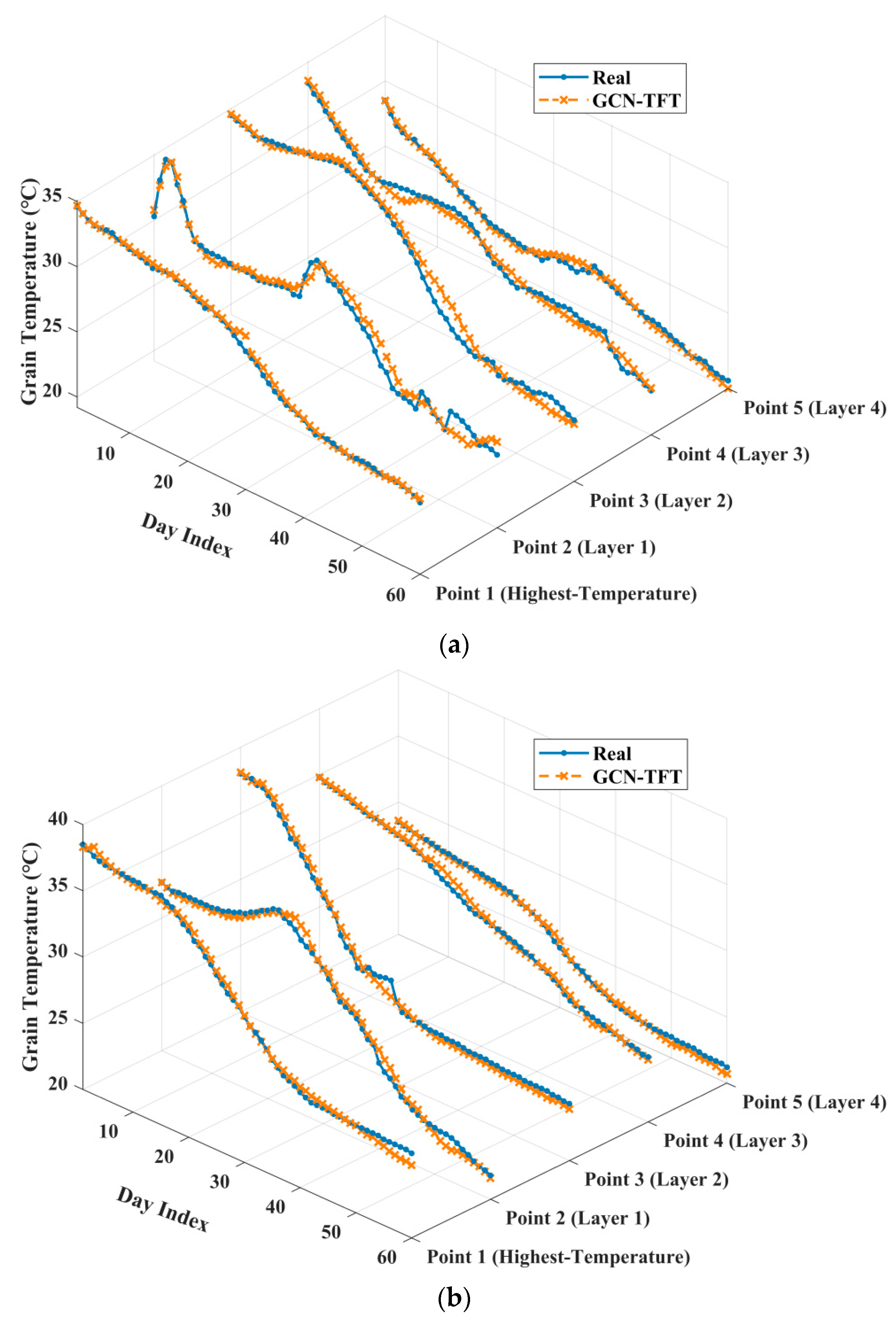

3.5. Future Quality Prediction Experiment

3.6. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alam, M.F.B.; Tushar, S.R.; Ahmed, T.; Karmaker, C.L.; Bari, A.B.M.M.; de Jesus Pacheco, D.A.; Nayyar, A.; Islam, A.R.M.T. Analysis of the enablers to deal with the ripple effect in food grain supply chains under disruption: Implications for food security and sustainability. Int. J. Prod. Econ. 2024, 270, 109179. [Google Scholar] [CrossRef]

- Jia, S.; Qiu, Y.; Yang, C. Sustainable development goals, financial inclusion, and grain security efficiency. Agronomy 2021, 11, 2542. [Google Scholar] [CrossRef]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; Department of Economic and Social Affairs: New York, NY, USA, 2015. [Google Scholar]

- Tushar, S.R.; Alam, M.F.B.; Zaman, S.M.; Garza-Reyes, J.A.; Bari, A.B.M.M.; Karmaker, C.L. Analysis of the factors influencing the stability of stored grains: Implications for agricultural sustainability and food security. Sustain. Oper. Comput. 2023, 4, 40–52. [Google Scholar] [CrossRef]

- Keskin, S.; Özkaya, H. Effect of storage and insect infestation on the technological properties of wheat. CyTA-J. Food 2015, 13, 134–139. [Google Scholar] [CrossRef]

- Ziegler, V.; Paraginski, R.T.; Ferreira, C.D. Grain storage systems and effects of moisture, temperature and time on grain quality—A review. J. Stored Prod. Res. 2021, 91, 101770. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture 2019: Moving Forward on Food Loss and Waste; Food and Agriculture Organization of the United Nations: Rome, Italy, 2019. [Google Scholar]

- Liu, H.; Zhang, Y.; Don, C.; Zhang, B. Effects of grain storage time and storage temperature on gluten protein structure of wheat. Cereal Chem. 2023, 100, 183–195. [Google Scholar] [CrossRef]

- Kumar, C.; Ram, C.L.; Jha, S.N.; Vishwakarma, R.K. Warehouse storage management of wheat and their role in food security. Front. Sustain. Food Syst. 2021, 5, 675626. [Google Scholar] [CrossRef]

- González-Torralba, J.; Arazuri, S.; Jarén, C.; Arreegui, L.M. Influence of temperature and RH during storage on wheat bread making quality. J. Stored Prod. Res. 2013, 55, 134–144. [Google Scholar] [CrossRef]

- Alconada, T.M.; Moure, M.C. Deterioration of lipids in stored wheat grains by environmental conditions and fungal infection—A review. J. Stored Prod. Res. 2022, 95, 101914. [Google Scholar] [CrossRef]

- Strelec, I.; Mrša, V.; Simović, D.Š.; Petrović, J.; Zahorec, J.; Budžaki, S. Biochemical and Quality Parameter Changes of Wheat Grains during One-Year Storage under Different Storage Conditions. Sustainability 2024, 16, 1155. [Google Scholar] [CrossRef]

- Hu, H.; Qiu, M.; Qiu, Z.; Li, S.; Lan, L.; Liu, X. Variation in wheat quality and starch structure under granary conditions during long-term storage. Foods 2023, 12, 1886. [Google Scholar] [CrossRef]

- Zhang, S.B.; Lv, Y.Y.; Wang, Y.L.; Jia, F.; Wang, J.S.; Hu, Y.S. Physicochemical changes in wheat of different hardnesses during storage. J. Stored Prod. Res. 2017, 72, 161–165. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, Z.; Bi, M. Evaluation Model Based on the SGCNiFormer for the Influence of Different Storage Environments on Wheat Quality. Foods 2025, 14, 1715. [Google Scholar] [CrossRef]

- Li, L.; Li, Y.; Chen, Y.; Ding, Q.; He, R.; Liu, Y. Effects of Mechanical Damage for Different Type of Threshing Patterns on Wheat Storage Quality Traits. Foods 2025, 14, 1577. [Google Scholar] [CrossRef]

- Jiang, H.; Zhou, T. Classification of storage wheat grain quality based on multi-index analysis and fisher discriminant criterion. Trans. Chin. Soc. Agric. Eng. 2019, 35, 291–298. [Google Scholar]

- Gao, Y.N. Study on the Changes of Postpartum Quality in Wheat. Ph.D. Thesis, Henan University of Technology, Zhengzhou, China, 2010. [Google Scholar]

- Jiang, H.; Zhang, S.; Zhen, Y.; Zhao, L.K.; Zhou, Y.; Zhou, D. Quality classification of stored wheat based on evidence reasoning rule and stacking ensemble learning. Comput. Electron. Agric. 2023, 214, 108319. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, L.; Zhao, L.; Guo, T.; Zhou, D.; Chen, S. Prediction model of wheat quality index based on Broad-AdaBoost. J. Jilin Univ. (Eng. Technol. Ed.) 2022, 52, 1222–1228. [Google Scholar]

- Zhang, S. Study on the Quality Evaluation Model of Stored Wheat Based on Ensemble Learning. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2023. [Google Scholar]

- Kibar, H. Influence of storage conditions on the quality properties of wheat varieties. J. Stored Prod. Res. 2015, 62, 8–15. [Google Scholar] [CrossRef]

- Han, G. Study on the Effects of Storage Temperature on Mold Occurrence and Quality Changes of Wheat with Different Moisture Contents. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2024. [Google Scholar]

- Zhao, Y.; Han, G.; Li, Y.; Zhang, Y.; Chen, X.; Qiu, Z. Changes in quality characteristics and metabolites composition of wheat under different storage temperatures. J. Stored Prod. Res. 2024, 105, 102229. [Google Scholar] [CrossRef]

- Salman, H.; Copeland, L. Effect of storage on fat acidity and pasting characteristics of wheat flour. Cereal Chem. 2007, 84, 600–607. [Google Scholar] [CrossRef]

- Kechkin, I.A.; Ermolaev, V.A.; Ivanov, V.A.; Romanova, I.V. Dependence of fat acidity value on wheat grain storage conditions. BIO Web Conf. 2020, 17, 00226. [Google Scholar] [CrossRef]

- Qu, Z.K.; Zhang, Y.; Hong, C.; Zhang, C.D.; Dai, Z.W.; Zhao, Y.Y.; Wu, X.D.; Gao, Y.; Jiang, X.M.; Qian, J.; et al. Temperature forecasting of grain in storage: A multi-output and spatiotemporal approach based on deep learning. Comput. Electron. Agric. 2023, 208, 107785. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, Q.; Yin, J.; Wang, X.; Zhang, Z.; Wu, W.; Li, F. Interactions of mutiple biological fields in stored grain ecosystems. Sci. Rep. 2020, 101, 9302. [Google Scholar]

- Jiang, H.; Liu, T.; He, P.; Chen, Q. Quantitative analysis of fatty acid value during rice storage based on olfactory visualization sensor technology. Sens. Actuators B Chem. 2020, 309, 127816. [Google Scholar] [CrossRef]

- Lu, H.; Jiang, H.; Chen, Q. Determination of fatty acid content of rice during storage based on feature fusion of olfactory visualization sensor data and near-infrared spectra. Sensors 2021, 21, 3266. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.; Wu, W.F.; Lan, Y.; Liu, Z.; Han, F.; Xu, Y. Assessment and prediction of free fatty acids changes in maize based on effective accumulated temperature in large granaries. Int. J. Food Prop. 2022, 25, 1156–1170. [Google Scholar] [CrossRef]

- Wang, Q.; Han, F.; Wu, Z.; Lan, T.; Wu, W. Estimation of free fatty acids in stored paddy rice using multiple-kernel support vector regression. Appl. Sci. 2020, 10, 6555. [Google Scholar] [CrossRef]

- GB/T 15684-2015; Inspection of Grain and Oils—Determination of Fatty Acid Value of Grain. Standardization Administration of China: Beijing, China, 2015.

- Yoon, J.; Jarrett, D.; Van der Schaar, M. Time-series generative adversarial networks. Adv. Neural Inf. Process. Syst. 2019, 32, 5508–5518. [Google Scholar]

- Yin, J. Research on Multi-Fields Coupling Model of Wheat Grain and Condensation Prediction. Ph.D. Thesis, Jilin University, Changchun, China, 2015. [Google Scholar]

- Xiong, D. Condensation in the Grain Mass during Mechanical Aeration of Stored Grain and Its Prevention. Food Sci. Technol. Econ. 1999, 4, 25–27. [Google Scholar]

- LS/T 1206-2005; Safe Operation Regulations for Grain Storage Facility. State Administration of Grain: Beijing, China, 2005.

- Li, X.; Qiao, X.; Wang, W.; Wuyun, S.; Wu, W.; Guo, H.; Lu, Y. Grain Storage Condensation Risk Prediction Method Based on 3DCNN Combined with TFT. Trans. Chin. Soc. Agric. Mach. 2025, 56, 549–557. [Google Scholar]

- Zhang, Z.; Guo, J.; Gao, Y.; Zhang, Y.; Chen, X.; Li, Y. Increasing yield estimation accuracy for individual apple trees via ensemble learning and growth stage stacking. Comput. Electron. Agric. 2025, 237, 110648. [Google Scholar] [CrossRef]

- Priyadarshi, M.; Das, P.; Hussain, A.; Aswathy, R.; Lasker, S.M. Prediction of specific methanogenic activity of anaerobic sludges from sewage treatment plants of Delhi, India based on SVR model. Fuel 2025, 385, 134119. [Google Scholar] [CrossRef]

- Yu, H.; Zhao, H.; Liu, D.; Wang, L.; LI, L.; Li, X.; Dong, Y.; Nai, M. Prediction of myofascial pelvic pain syndrome based on random forest model. Heliyon 2024, 10, e32123. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A scalable tree boosting system. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining (KDD’16), San Francisco, CA, USA, 13–17 August 2016; Association for Computing Machinery: New York, NY, USA, 2016; pp. 785–794. [Google Scholar]

- Biswas, M.A.R.; Robinson, M.D.; Fumo, N. Prediction of residential building energy consumption: A neural network approach. Energy 2016, 117, 84–92. [Google Scholar] [CrossRef]

- Thakkar, A.; Lohiya, R. Analyzing fusion of regularization techniques in the deep learning-based intrusion detection system. Int. J. Intell. Syst. 2021, 36, 7340–7388. [Google Scholar] [CrossRef]

- Sercan, B.; Murat, U. Data-driven prediction of copper leaching yield from brass waste using stacking ensemble learning. Sep. Purif. Technol. 2025, 378, 134691. [Google Scholar]

- Chen, Z.; Luan, X.; Liu, F. Near-infrared fault detection based on stacked regularized auto-encoder network. Chemom. Intell. Lab. Syst. 2020, 204, 104101. [Google Scholar]

- Li, X.; Wu, W.; Guo, H.; Qiao, X.; Wu, Y.; Qiao, G. An interpretable temperature prediction method for grain in storage based on improved temporal Fusion Transformers. Comput. Electron. Agric. 2025, 236, 110414. [Google Scholar] [CrossRef]

- Shao, K.; Li, D.; Tang, H.; Zhang, Y.; Xu, B.; Bhatti, U.A. Improving multi-step dissolved oxygen prediction in aquaculture using adaptive temporal convolution and optimized transformer. Comput. Electron. Agric. 2025, 235, 110329. [Google Scholar] [CrossRef]

- Zhang, G.; Ren, S.; Zhao, P.; Liu, Y.; Chen, X.; Chen, H. Damage prediction of ship cabins subjected to underwater contact explosion by deep neural network with grid search algorithm. Ocean Eng. 2024, 312, 119278. [Google Scholar] [CrossRef]

- Lundberg, S.M.; Lee, S.I. A unified approach to interpreting model predictions. Adv. Neural Inf. Process. Syst. 2017, 4768–4777. [Google Scholar]

- Jian, F.; Jayas, D.S.; White, N.D.G. Temperature fluctuations and moisture migration in wheat stored for 15 months in a metal silo in Canada. J. Stored Prod. Res. 2009, 45, 82–90. [Google Scholar] [CrossRef]

- Thorpe, G.R. Moisture diffusion through bulk grain subjected to a temperature gradient. J. Stored Prod. Res. 1982, 18, 9–12. [Google Scholar] [CrossRef]

| Mean | Standard Deviation | Maximum | Minimum | |

|---|---|---|---|---|

| Grain temperature (°C) | 5.9 | 10.7 | 36.9 | −23.8 |

| Granary internal air temperature (°C) | 9.8 | 13.1 | 37.5 | −21.9 |

| Granary internal air humidity (%) | 37.7 | 10.5 | 93.8 | 11.3 |

| FAV (mg KOH/100 g) | 23.3 | 3.55 | 32.9 | 15.9 |

| Base Learner | Parameter | Search Range | Rational Parameter Settings |

|---|---|---|---|

| XGBoost | Learning Rate | 0.01, 0.05, 0.1 | 0.05 |

| n_estimators | 100, 200, 300 | 200 | |

| Max Depth | 3, 5, 7 | 5 | |

| MLP | hidden_layer_sizes | (30,), (50,), (100,) | (50,) |

| alpha | 0.0001, 0.001, 0.01 | 0.001 | |

| RF | n_estimators | 100, 200, 300 | 200 |

| Max Depth | 5, 10, 15 | 10 | |

| SVR | C | 0.1, 1, 10 | 1 |

| ε | 0.001, 0.01, 0.1 | 0.01 |

| Model | MAE (mg KOH/100 g) | RMSE (mg KOH/100 g) | R2 |

|---|---|---|---|

| RF | 0.63 | 0.87 | 0.88 |

| XGBoost | 0.57 | 0.81 | 0.90 |

| MLP | 0.64 | 0.94 | 0.86 |

| SVR | 0.63 | 0.88 | 0.88 |

| Stacking | 0.44 | 0.59 | 0.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, W.; Pan, B.; Zhu, S.; Zhang, J.; Ma, Y.; Guo, H.; Liu, Z.; Wu, W.; Xu, Y. An Interpretable Stacked Ensemble Learning Framework for Wheat Storage Quality Prediction. Agriculture 2025, 15, 1844. https://doi.org/10.3390/agriculture15171844

Li X, Wang W, Pan B, Zhu S, Zhang J, Ma Y, Guo H, Liu Z, Wu W, Xu Y. An Interpretable Stacked Ensemble Learning Framework for Wheat Storage Quality Prediction. Agriculture. 2025; 15(17):1844. https://doi.org/10.3390/agriculture15171844

Chicago/Turabian StyleLi, Xinze, Wenyue Wang, Bing Pan, Siyu Zhu, Junhui Zhang, Yunzhao Ma, Hongpeng Guo, Zhe Liu, Wenfu Wu, and Yan Xu. 2025. "An Interpretable Stacked Ensemble Learning Framework for Wheat Storage Quality Prediction" Agriculture 15, no. 17: 1844. https://doi.org/10.3390/agriculture15171844

APA StyleLi, X., Wang, W., Pan, B., Zhu, S., Zhang, J., Ma, Y., Guo, H., Liu, Z., Wu, W., & Xu, Y. (2025). An Interpretable Stacked Ensemble Learning Framework for Wheat Storage Quality Prediction. Agriculture, 15(17), 1844. https://doi.org/10.3390/agriculture15171844