1. Introduction

Conservation tillage is an advanced agricultural technique that reduces soil erosion and enhances soil fertility and drought resistance by replacing traditional tillage with minimal tillage, no tillage, and straw mulching [

1,

2]. No-tillage planters can perform seeding operations with minimal soil disturbance. However, surface fluctuations and crop residues can induce significant random vibrations in the seeding unit, which may negatively affect seed implantation stability and crop yield [

3,

4,

5]. Therefore, studying the vibration characteristics of no-tillage planters and optimizing the vibration damping system has become a key challenge in the development of high-speed precision no-till planting technology.

Currently, in order to understand the vibration characteristics of the no-tillage planter, the following methods were used for this research: vibration signal collection through field experiments followed by data processing to determine the main vibration frequencies and amplitudes [

6,

7,

8,

9]. For example, Zhai et al. [

7] tested two different row crop planters under various planting speeds, and the results showed that the row unit vibration linearly increased with planting speeds, whereas the main vibration frequencies were concentrated in the low-frequency range of 3–10 Hz. The effect of ground excitation on the seeding performance of no-tillage planters was studied through a vibration test platform [

10,

11,

12]. Zhang et al. [

10] and Wang et al. [

11] obtained the vibration parameters through the field vibration test of the no-tillage planter and studied the performance of the seed metering device through the bench test. Vibration mathematical models of planters are developed based on fundamental dynamic laws or theorems to study seeding performance [

13,

14,

15]. At the same time, the development of coupled simulation techniques has introduced a new method to study the vibration characteristics of no-tillage planters, He et al. [

16] used the MBD-DEM coupling simulation technology to simulate the furrowing operation of the no-till seeding unit and studied the effects of working speed, the spring stiffness coefficient, and the cone index on the vibration characteristics of the unit. In addition, research on tractor vibration and control has provided important references for understanding planter dynamics. The planter vibration increased linearly with increasing working velocity, but a reasonable selection of downforce size could attenuate seeder vibration. Badua et al. [

6] investigated the variation coefficient of seeding depth at different working velocities and downforce settings (620 N and 980 N) and found that the target seeding depth could be achieved with reasonable downforce settings. In addition, the research on the vibration and control of tractors provides an important reference for understanding the dynamic characteristics of the tractor–no-tillage seeder system [

17,

18,

19]. For example, Nrusingh Charan Pradhan et al. [

20] predicted the vertical vibrations (Z-axis) and frequencies at the different body segments of the seated small tractor operator by an FEM approach.

Most of the above studies were based on field testing and analysis of the entire machine but lack research on the influence of different working components of the no-tillage planter on its own vibrations. In particular, the complex coupling among tractor excitation, planter structure, and field surface has not been adequately addressed. Therefore, this paper addresses the complex issue of tractor–no-tillage planter–field surface coupled vibrations. Tractor engine vibration source impact analysis experiments, no-tillage planter structural vibration source experiments, and light and heavy no-tillage configuration vibration source analysis experiments were conducted, and the main factors affecting the vibration of no-tillage planters were analyzed. By identifying and analyzing the main factors influencing planter vibration, this study provided theoretical references for the subsequent design and optimization of vibration damping systems.

2. Materials and Methods

2.1. The Structure and Working Principles of the No-Tillage Planter

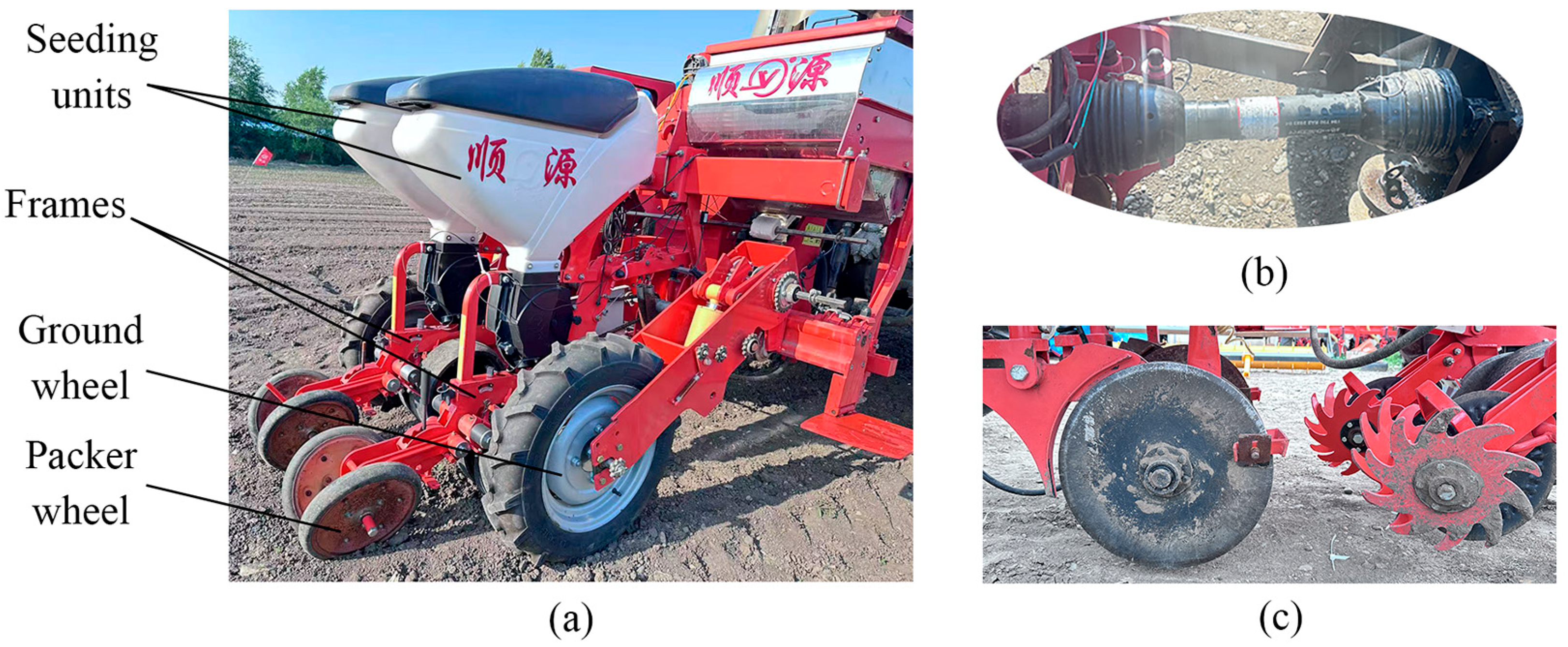

Multi-source vibration testing and analysis were conducted using the 2BMQ-2 pneumatic no-tillage corn planter from Shunyuan Agricultural Machinery Co., Ltd., Ulanhot City, Xing’an League, Inner Mongolia, China. The no-tillage planter consists mainly of gauge wheels, a fertilization and stubble braking device, a clearing device, a depth-limiting device, a frame, a four-bar profiling device, a compression device, and a power output shaft. The four-bar profiling device is composed of a four-bar linkage and two mechanical profiling springs. By adjusting the number and orientation of the mechanical springs, the downforce of the gauge wheels on the soil can be increased or decreased.

During operation, the no-tillage planter is powered by a 90-horsepower tractor. The power output shaft drives the fan, which rotates at high speed to create negative pressure in the vacuum chamber of the seed metering device, thereby drawing the seeds. The tractor’s hydraulic system drives the ground wheel hydraulic cylinder to lift and lower the seeding units, while the three-point hitch system controls the elevation of the no-tillage planter. The fertilization disk, cutting disk, and double-disc furrow openers break the soil by the downforce provided by the deadweight and mechanical springs, as shown in

Figure 1. The rotation angle of the gauge wheels is controlled to adjust the planting depth. Finally, the suppression wheels compact the soil, ensuring consistent planting depth.

2.2. Sensors and Vibration Data Acquisition System

The objective of our experiments was to test and analyze the vibration characteristics of the no-tillage planter and evaluate the impact of various factors on its vibration, providing theoretical support for the design and optimization of the vibration damping system. A vibration test and modal analysis instrument (China Orient Institute of Noise & Vibration, Beijing, China) was used to measure the vibration characteristics of the no-tillage planter under different operating conditions. Two accelerometers were used, each mounted on the frame of a no-till seeding unit which was close to the seed metering device, and the y-axis of the accelerometer was perpendicular to the forward direction of the no-tillage planter, as shown in

Figure 2. The sampling frequency was set to 1000 Hz during the experiment to capture the random vibration signals in the whole field, and the displacement was set as the sampling unit in the INV3062C Data acquisition instrument. The main performance parameters of the instruments used in the experiment are shown in

Table 1.

2.3. Experimental Sites and Soil Characteristics

Multi-source vibration tests of the no-tillage planter under different operating conditions were conducted at the Conservation Tillage Experimental Base in Xing’an League, Inner Mongolia (122.15° E, 46.07° N), as shown in

Figure 3. The average annual temperature of the area is 5 °C, with an average annual precipitation of 442.6 mm. Prior to the experiment, the test field underwent rotary tillage and compaction leveling to minimize surface condition differences. Simultaneously, soil samples were randomly collected from the treated experimental zone, with surface parameters presented in

Table 2.

The experimental area was divided based on the tractor wheel track width, with a length of 200 m. During the experiment, the tractor wheel track area was avoided. A 10 m acceleration zone was reserved in front of the experimental area to ensure the planter reached the set speed when entering the test zone.

2.4. Test Conditions and Experimental Design

To analyze the various factors influencing the vibration of the no-tillage planter under field operating conditions, the experimental design should consider as many factors as possible. Therefore, this study uses multiple experimental combinations and, where feasible, adopts a full-factorial experimental approach.

The study investigates the vibration differences caused by the working components during field operation by disassembling and assembling the no-tillage planter’s structure. Additionally, the impact of downforce on the vibration of the no-tillage planter is examined by changing the number and orientation of the profiling springs. Considering that the soil contact components of the no-tillage planter affect the vibration of the seeding units, the planter’s structure is divided into the following components: ground wheel (A), fertilization and stubble breaking and cleaning devices (B), depth-limiting device (C), compression device (D), and power output shaft (E). Based on the presence or absence of these components, a total of six combinations were used: ABCD (full machine), BCD (ground wheel removed), ACD (fertilization and stubble breaking and clearing devices removed), ABC (compression device removed), AC (fertilization and stubble breaking and clearing devices removed and compression device removed), and ABCDE (added power output shaft on the basis of ABCD). In the AC combination, the fertilization and stubble breaking and clearing devices (

Figure 1c) are removed based on

Figure 4b. In the ABCDE combination, the power output shaft (

Figure 1b) is added to the ABCD configuration (

Figure 1a), with the specific structure shown in

Figure 4.

The experiment consists of the following three main combinations: tractor vibration source impact analysis, no-tillage planter structural vibration source impact analysis, and a comparison of light and heavy no-tillage vibration source impact analysis.

(1) The tractor engine vibration source impact analysis experiment mainly investigated the influence of the tractor engine on the vibration of the no-tillage planter. The engine speed was varied by adjusting the throttle, and the clutch controlled the tractor’s operation. The experiment was conducted in three states: idling at the same location, idling with operation, and normal operation. Unlike in normal operation, the tractor’s engine runs at a lower speed during idling operation. The rear output shaft was connected to the fan drive system of the no-tillage planter to drive the fan.

(2) The no-tillage planter structural vibration source impact analysis experiments primarily focused on disassembling and assembling individual or multiple components of the planter and studying the differences in vibration impact at different working velocities. It also conducted a coupled vibration difference analysis for multiple structures.

(3) The light and heavy no-tillage configuration vibration source analysis experiments mainly investigated the effect of downforce and working velocity on the vibration of the no-tillage planter by altering the number (0, 1, and 2) and orientation of the profiling springs. And the difference between heavy no-tillage and light no-tillage configuration was that the profiling spring was used to increase or decrease the downforce for the no-tillage planter.

The three different tractor operating states are achieved by controlling the engine speed. Idle with the same location state refers to the engine running at the lowest speed without a load, typically 500–800 rpm. In the idling operation state, the engine speed is approximately 700–900 rpm. In normal operation, the engine speed is around 1800–2200 rpm.

The tractor is coupled with the no-tillage planter, with three conditions based on whether the planter is lifted or not, as well as the seeding unit. The experimental factor levels are presented in

Table 3.

2.5. Statistical Analysis

Stationary random signals tend to follow a normal distribution with an average value close to zero. Due to the complexity of the field operation conditions, the vibration signal collection was affected, and some random vibration signals had an average value that did not converge to zero. The discovery that the DC offset is constant was made during our experimental analysis. Therefore, we calculated the average value of a certain signal using the EXCEL software and subtracted each sampling point of the original signal from this average value. The resulting signal was then further processed using Matlab R2023 software. The unidirectional accelerometer was exposed to direct sunlight, which caused a rise in temperature and led to overload conditions, resulting in some distorted data. Therefore, this data was excluded from the subsequent statistical analysis.

As vertical vibration was the dominant form of vibration in the planter [

7], the vertical-direction data were analyzed in the time and frequency domains using Matlab software and DASP v11 analysis software. The root mean square (

RMS) value is a statistical parameter used to represent the total energy of random vibration [

21,

22], and it can be calculated using Formula (1):

where

RMS is the root mean square of vibration displacement (mm);

N is the number of signals measured; and

x(

t) is the measured vibration displacement (mm).

In both software programs, we based our analysis on the same analytical framework: a sampling rate of 1000 Hz, an analysis bandwidth of 500 Hz, linear averaging, and application of a Hanning window. Hanning window processing was applied, and the primary vibration frequency and amplitude were obtained. Additionally, a frequency domain analysis of the collected random vibration signals was performed using the Fast Fourier Transformation (FFT) technique.

The ABCD operating conditions under different working velocities were considered as the control group. Therefore, the formula for calculating the peak-to-peak amplitude difference is

where Δ

P is the peak-to-peak amplitude difference (mm);

P0 is the vibration peak under ABCD conditions (mm); and P

i is the vibration peak under other conditions (mm).

Frequency offset refers to the range of deviation in the primary vibration frequency under other conditions compared to the ABCD conditions. Its calculation formula is

where Δ

f is the primary frequency (Hz);

f0 is the primary frequency under ABCD conditions (Hz); and

Pi is the primary frequency under other conditions (Hz).

3. Results

3.1. Influence of Tractor Engine Vibration Source

When the tractor was connected to the no-tillage planter for field operation, the engine vibration was one of the primary vibration sources [

17,

23]. To accurately capture the vibration characteristics of the planter under the influence of the engine, in situ idle and idle operation source influence analysis tests were conducted. A comparative analysis with normal operating tests was also performed. Normal operation is based on the ABCD structure, which utilizes the heavy no-tilling configuration with two profiling springs. The time-domain and frequency-domain analysis results are shown in

Table 4.

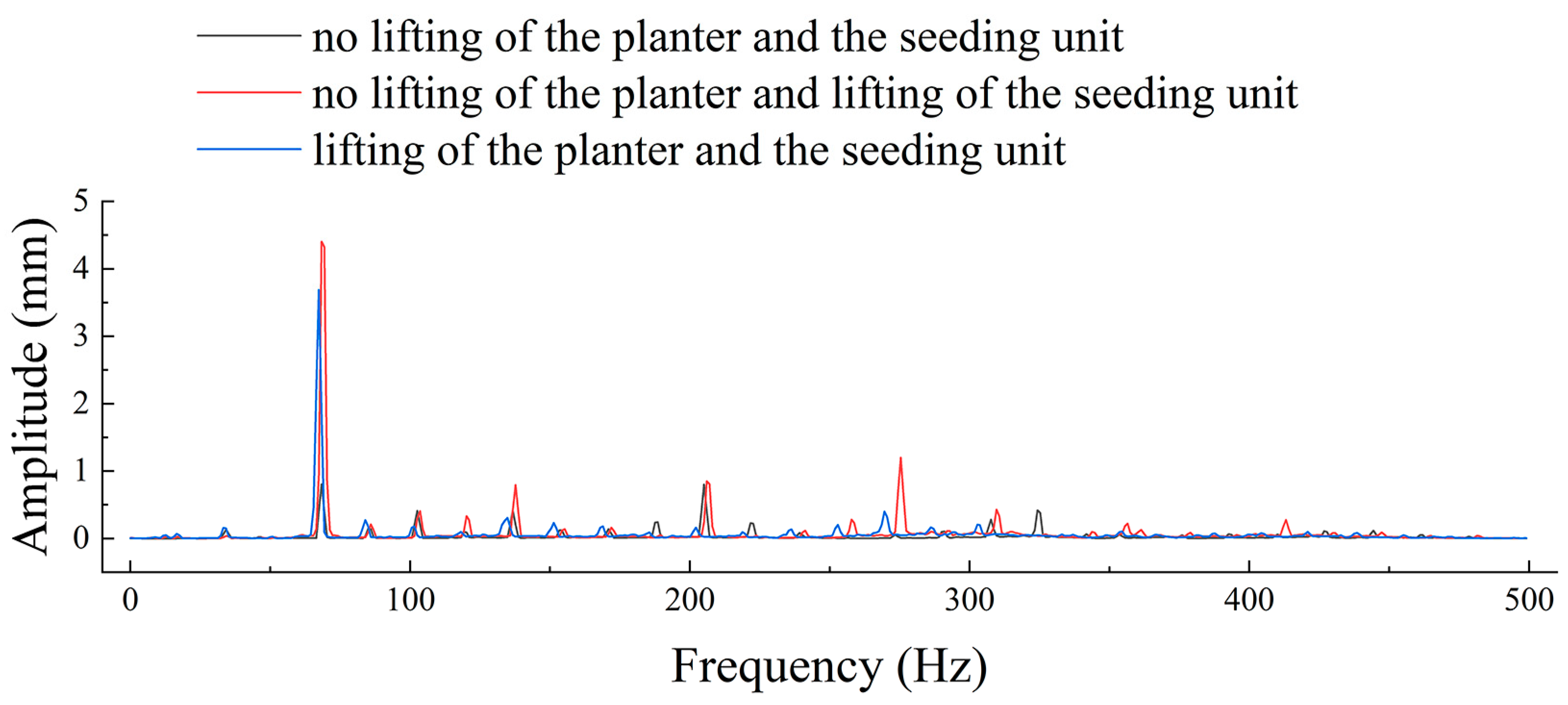

From

Table 4, it can be seen that under the conditions of in situ idle–no lifting of the planter–lifting of the seeding units, the RMS value of the measurement point was 3.98, significantly greater than the other two test conditions. This indicated that as the contact area between the no-tillage planter and the ground increases, the vibration intensity decreases. The ground-contact components, such as the ground wheels and gauge wheels, added support points to the planter and play a role in vibration reduction.

The vibration characteristics of the tractor–no-tillage planter were studied by the in situ idle vibration source impact analysis experiment. As shown in

Figure 5, 68.36 Hz and 67.38 Hz were the main vibration frequencies of the tractor–no-tillage planter system. These frequencies differ from the primary vibration frequency (0–10 Hz) observed in existing studies of the no-tillage planter in field conditions, suggesting that the vibration induced by the tractor engine was the primary influencing factor at idle. The relatively high primary vibration frequency at subsequent low speeds also supported this finding. The peak frequency of the surface dynamic response caused by the tractor–no-tillage planter–field surface coupled vibration is close to the natural frequency of 66.67 Hz, which corresponds to the rated speed of the tractor engine [

24], thus causing resonance. Therefore, future design optimizations or control strategies should actively avoid this resonance frequency.

To further investigate the impact of the tractor engine on the vibration characteristics of the no-tillage planter, a comparative analysis test was conducted between idle operation and normal operation, as shown in

Figure 6. Under idle conditions, high-frequency components are observed. The high-frequency vibration frequencies at 4, 8, and 12 km/h were 60.55 Hz, 58.59 Hz, and 56.64 Hz, with amplitudes of 1.45 mm, 0.91 mm, and 2.05 mm, respectively. At low speed (4 km/h), the vibration intensity of the no-tillage planter under idle operation was significantly higher than during normal operation. However, at medium (8 km/h) and high (12 km/h) speeds, idle operation performs better than normal operation. A peak at 78.13 Hz posed a risk of resonance. Therefore, idle operation may be considered, provided it meets the power requirements of the equipment.

3.2. Impact of the Structure of the No-Tillage Planter on Vibration

3.2.1. Impact of Individual Structural Components of the No-Tillage Planter on Vibration

An analysis was conducted on the vibration characteristics at different working velocities to investigate the impact of the no-tillage planter’s structure on its vibration. The frequency domain analysis data was shown in

Figure 7. Under the BCD (removal of ground wheels) configuration, the vibration peak values at 4, 8, and 12 km/h were 2.11, 3.59, and 5.16 mm, respectively, which were significantly higher than the vibration peak values observed under the ABC, ACD, and ABCDE configurations. This indicated that the ground wheels, as the primary support structure of the no-tillage planter, played a major role in vibration reduction. At 4 km/h, under the BCD configuration, the amplitude in the low-frequency range was significantly higher compared to other configurations. In the mid-to-high-frequency range, the primary frequencies for the ABCD configuration were 81.05 Hz and 139.65 Hz, while the primary frequency for the BCD configuration was 79.10 Hz. The primary frequency components were similar and close to the inherent frequency of the tractor engine, resulting in a significant increase in vibration. As the working velocity increases, the primary vibration frequency in the ABCDE configuration decreases and shifts toward the low-frequency range.

Comparing the amplitude curves in

Figure 7, it could be seen that after removing the fertilizing and stubble breaking and cleaning devices (ACD configuration), the vibration intensity of the no-tillage planter significantly decreases. Based on the placement of the accelerometer, this indicated that the shift in the center of mass of the seeding unit towards the rear enhances its ability to resist random field vibrations. Additionally, the reduction in contact components also lowers the variation in tillage resistance, which helps to reduce the impact of the field surface on the vibration of the no-tillage planter. As the working velocity increased, the maximum peak value for the ABC configuration at 12 km/h was 2.16 mm, which was 0.22 mm lower than the 2.38 mm peak at 8 km/h. This trend was consistent with the amplitude variation observed under the ACD configuration, indicating that removing the suppression wheels also contributes to reducing the vibration intensity of the no-tillage planter during field operations. This effect may be due to the downforce provided by the mechanical profiling spring.

3.2.2. Impact of Multi-Structural Coupling Vibrations in the No-Tillage Planter

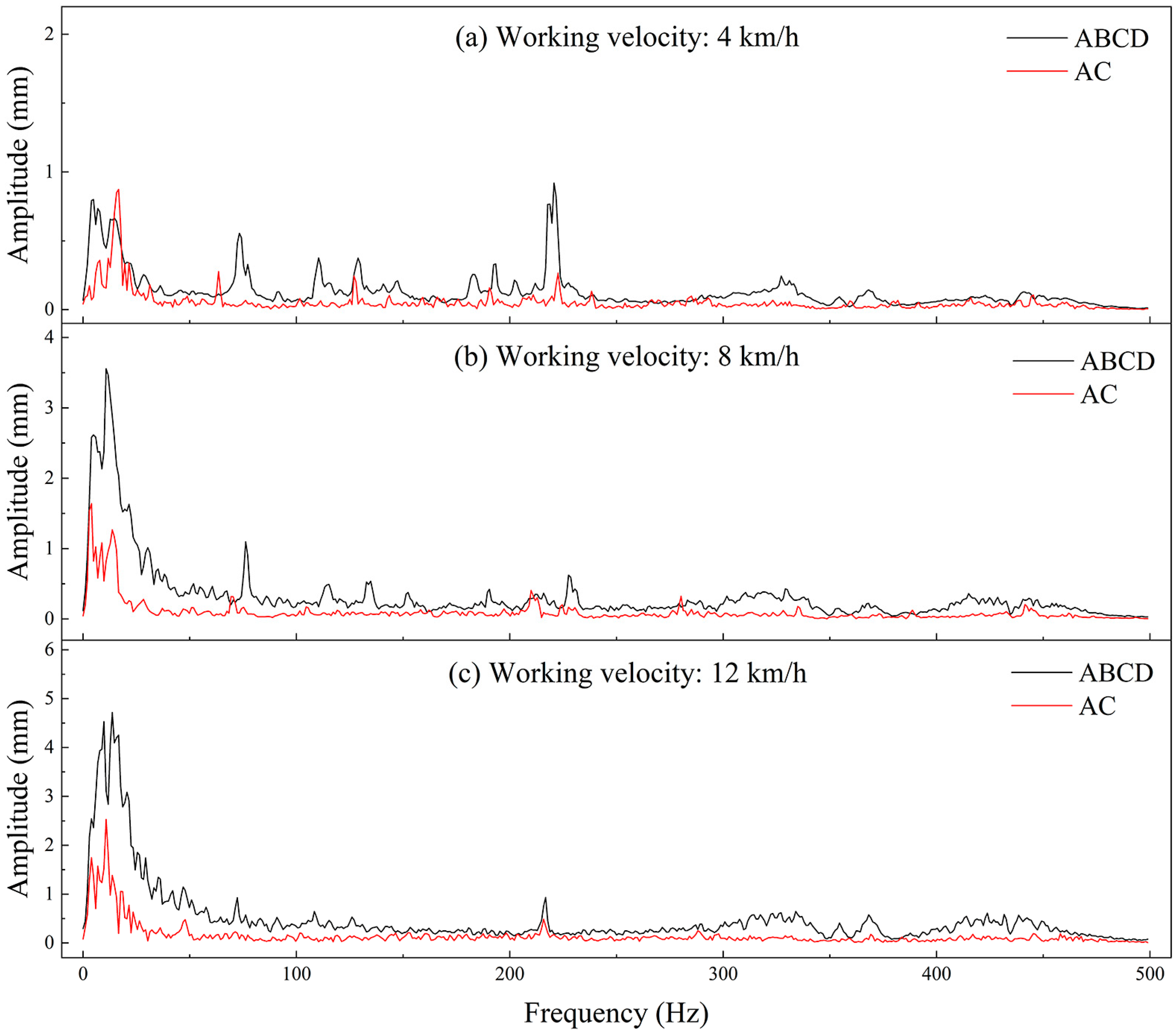

To comprehensively analyze the complex dynamic behavior of the no-tillage planter during field operations, a study was conducted on its multi-structural coupling vibrations. The amplitude spectrum curves under the AC configuration, which involved removing the fertilizing and stubble breaking and cleaning devices and the suppression wheels, are shown in

Figure 8. By gradually disassembling key components (ground wheels; fertilizing and stubble breaking and cleaning devices; suppression wheels; and power output shaft), the contribution of each subsystem to the overall random vibration of the no-tillage planter was investigated, while also analyzing the coupling effects of multiple subsystems on vibrations.

By statistically analyzing the amplitude peak values, peak-to-peak amplitude differences, primary frequencies, and frequency shifts of the random vibrations in the no-tillage seeding units under different configurations, the independent contributions and coupling effects of each working component on the vibration were quantified. As shown in

Table 5, at the working velocity of 4 km/h, removing the fertilizing and stubble breaking and cleaning devices resulted in the best vibration reduction, with a decrease of 0.17 mm (18%). However, the removal of multiple structures led to a negative effect on vibration reduction, approximately 13%. This indicated that the suppression wheels and fertilizing and stubble breaking and cleaning devices generate a negative coupling effect. The rearward shift of the center of mass of the no-tillage seeding unit increases the demand for supporting force from the suppression wheels.

Comparing the peak-to-peak amplitude differences in the amplitude spectra in

Table 5, it was observed that as the working velocity increases, the most effective vibration reduction measures were the removal of the fertilizing and stubble breaking and cleaning devices; suppression wheels; fertilizing and residue cutting devices combined with the suppression wheels; and the power output shaft. In contrast, removing the ground wheels exacerbated the vibration in the no-tillage seeding unit. It should be noted that at a high working velocity, after removing the fertilizing and stubble breaking and cleaning devices, the primary vibration frequency of the no-tillage seeding unit becomes close to the inherent frequency (66.67 Hz) of the tractor engine’s rated speed, which can lead to resonance.

3.3. Impact of Light and Heavy No-Till Configuration on Vibrations

The downforce on the no-tillage seeding unit was primarily provided by its deadweight and the downforce from the profiling springs. By adjusting the number of profiling springs and altering their installation directions, the effect of downforce on unit vibrations was studied. The amplitude spectrum curves under light and heavy no-till configurations, no profiling spring configurations, and the ABCD structure adopting a heavy no-tillage configuration with two profiling springs are shown in

Figure 9.

At different working velocities, the influence of downforce varies with the vibration of the no-tillage planter. At the same time, greater planter downforce is not necessarily better. Under the heavy no-tillage configuration with one spring, the maximum amplitude at 8 km/h was 3.67 mm, while at 12 km/h, it decreased to 2.55 mm, a reduction of 1.12 mm. This suggested that the heavy no-tillage configuration with one spring provides sufficient downforce to counteract the increased vibration at higher speeds. It was important to note that, rather than reducing vibration as intended, increasing the downforce actually caused the planter’s vibration intensity to rise at 12 km/h (

Figure 7c). In contrast, under the light no-tillage configuration with one spring, the maximum amplitude at 8 km/h was 2.14 mm, while at 12 km/h, the vibration significantly increased, reaching 8.43 Hz with an increase of 6.29 mm. Therefore, during no-tillage seeding operations, the downforce installation should be appropriately designed based on the working velocity and the soil characteristics. The integration of an intelligent downforce control system should be a key focus of future research.

4. Discussion

In this study, the tractor engine vibration source impact analysis experiments, no-tillage planter structural vibration source experiments, and light and heavy no-tillage configuration vibration source analysis experiments were conducted to analyze the main factors affecting the vibration of the no-tillage planter. Based on the analysis of the structural impact of the no-tillage planter on vibration, this study further investigates the influence of the tractor engine on the vibration transmission characteristics of the no-tillage planter. Meanwhile, we found that setting the profiling mechanical springs significantly affects the seeder’s vibration. Future research should further evaluate the downforce’s influence on no-tillage planter vibration. The main novelty value of the research is the analysis of the impact of different structural configurations on unit vibrations by disassembling the no-tillage planter. Additionally, the effects of tractor engine vibration sources and profiling devices applying downforce on the no-tillage seeding unit were incorporated, which provides a theoretical basis for the design and optimization of subsequent vibration damping systems.

At present, there is hardly any research on the influence of the vibration characteristics of no-tillage seeders on the seeding quality. In this research, some components of the no-tillage planter were removed, which made it difficult to conduct sowing operations under certain experimental conditions. Therefore, only part of the experiments was carried out concurrently with the sowing operation, as required by the GB/T20856-2017 No or Little-tillage Fertilizes Planter. The results showed that the seed spacing qualification rate exceeded 85%. However, it is unclear whether the vibration conditions affected the spacing rates significantly. Future research should further explore the impact of no-tillage planter vibration on seeding quality, with a particular focus on how maximum amplitude and dominant frequency affect seeding performance. Furthermore, the effects of vibration on the performance of stubble breaking, furrow trenching, seed performance, and soil compaction could also be investigated. The multi-coupled operation during different seeding processes and its combined effect on the vibration of the no-tillage planter will be a key challenge in future studies.

5. Conclusions

In this study, tractor engine vibration source impact analysis experiments, no-tillage planter structural vibration source experiments, and light and heavy no-tillage configuration vibration source analysis experiments were conducted to analyze the main factors affecting the vibration of a no-tillage planter.

(1) The resonant frequency of the tractor–no-tillage planter was identified. In situ idle revealed that the primary vibration frequencies of the tractor–no-tillage planter system were 68.36 Hz and 67.38 Hz, which corresponded to the second-order natural frequency of the tractor engine.

(2) The impact of the no-tillage planter’s structure on its vibration was established. The results show that the effects of the ground wheels, the fertilizing and stubble breaking and cleaning devices, the packer wheels, and the power output shaft gradually diminish.

(3) This study provided a relative assessment of the correlation between planter downforce and its vibration intensity. In the future, research on the vibration test of field no-tillage planters should focus on the relative relationship between the downforce and vibration intensity under different soil conditions.

Author Contributions

Conceptualization, D.H. and H.L.; methodology, D.H., J.B. and H.L.; software, Z.W. and R.L.; writing—original draft preparation, D.H.; writing—review and editing, Y.W., C.W. and C.L.; visualization, J.B. and R.L.; funding acquisition, H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China, grant number 2024YFD1500402.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- He, J.; Li, H.; Chen, H.; Lu, C.; Wang, Q. Research Progress of Conservation Tillage Technology and Machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar] [CrossRef]

- Kassam, A.; Friedrich, T.; Derpsch, R.; Kienzle, J. Overview of the Worldwide Spread of Conservation Agriculture. Field Actions Sci. Rep. 2015, 8, 1–11. [Google Scholar]

- Cay, A.; Kocabiyik, H.; May, S. Development of an electro-mechanic control system for seed-metering unit of single seed corn planters Part I: Design and laboratory simulation. Comput. Electron. Agr. 2018, 144, 71–79. [Google Scholar] [CrossRef]

- Kuş, E. Field-scale evaluation of parameters affecting planter vibration in single seed planting. Measurement 2021, 184, 109959. [Google Scholar] [CrossRef]

- Virk, S.S.; Porter, W.M.; Li, C.; Rains, G.C.; Snider, J.L.; Whitaker, J.R. On-farm evaluation of planter downforce in varying soil textures within grower fields. Precis. Agric. 2021, 22, 777–799. [Google Scholar] [CrossRef]

- Badua, S.A.; Sharda, A.; Strasser, R.; Ciampitti, I. Ground speed and planter downforce influence on corn seed spacing and depth. Precis. Agric. 2021, 22, 1154–1170. [Google Scholar] [CrossRef]

- Zhai, C.; Long, J.; Taylor, R.; Weckler, P.; Wang, N. Field scale row unit vibration affecting planting quality. Precis. Agric. 2020, 21, 589–602. [Google Scholar] [CrossRef]

- Badua, S.A.; Sharda, A.; Flippo, D.; Ciampitti, I.A. Real-Time Gauge Wheel Load Variability of a Row-Crop Planter During Field Operation. Trans. ASABE 2018, 61, 1517–1527. [Google Scholar] [CrossRef]

- Gao, Y.; Yang, Y.; Hu, Y.; Han, X.; Feng, K.; Li, P.; Wei, X.; Zhai, C. Study on Operating Vibration Characteristics of Different No-Tillage Planter Row Units in Wheat Stubble Fields. Agriculture 2024, 14, 1878. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, F.; Zhao, M.; Liu, Y.; Li, F.; Chen, C.; Zhang, Y. Movement law of maize population in seed room of seed metering device based on discrete element method. Trans. Chin. Soc. Agric. Eng. 2016, 32, 27–35. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, L.; Li, M.; Huang, D.; Jia, H.; Zhuang, J. Vibration characteristics of corn no-tillage finger-type precision planter and its effect on seeding performance. Trans. Chin. Soc. Agric. Mach. 2019, 35, 9–18. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Luo, X.; Zang, Y.; Ma, L.; Zhang, W.; Liu, J.; Zeng, S. Effect of Vibration Conditions on the Seed Suction Performance of an Air-Suction Precision Seeder for Small Seeds. Agriculture 2024, 14, 559. [Google Scholar] [CrossRef]

- Zhang, X.; Li, C.; Li, J.; Zou, M. Mathematic Vibration Model of Spade Punch Planter of Maize. Trans. Chin. Soc. Agric. Mach. 2014, 45, 88–93. [Google Scholar] [CrossRef]

- Sharipov, G.M.; Paraforos, D.S.; Griepentrog, H.W. Modelling and simulation of the dynamic performance of a no-till seeding assembly with a semi-active damper. Comput. Electron. Agr. 2017, 139, 187–197. [Google Scholar] [CrossRef]

- Sharipov, G.M.; Paraforos, D.S.; Griepentrog, H.W. Implementation of a magnetorheological damper on a no-till seeding assembly for optimising seeding depth. Comput. Electron. Agr. 2018, 150, 465–475. [Google Scholar] [CrossRef]

- He, D.; Li, H.; He, J.; Lu, C.; Wang, C.; Wang, Y.; Wu, Z.; Tong, Z.; Gao, Z. Research on vibration characteristics of no-tillage seeding unit based on the MBD-DEM coupling. Comput. Electron. Agr. 2025, 230, 109877. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Bhalekar, D.G.; Mani, I.; Kumar, K.; Singh, A.K.; Kumar, M.; Makwana, Y.; V., S.K.; et al. ANN-PID based automatic braking control system for small agricultural tractors. J. Field Robot. 2024, 41, 2805–2831. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Mani, I.; Kumar, M. Actuating force for transmission controls in small farm tractor considering driver’s comfort. Indian J. Agric. Sci. 2022, 92, 876–881. [Google Scholar] [CrossRef]

- Lin, J.; Liao, Q.; Zhang, Q.; Kang, Y.; Zhang, J. Vibration characteristics analysis and structural improvement of the shovel type seedbed preparation machine suitable for rapeseed mechanical direct seeding. Trans. Chin. Soc. Agric. Eng. 2023, 39, 39–48. [Google Scholar] [CrossRef]

- Pradhan, N.C.; Sahoo, P.K.; Kushwaha, D.K.; Makwana, Y.; Mani, I.; Kumar, M.; Aruna, T.N.; Soumya Krishnan, V. A finite element modeling-based approach to predict vibrations transmitted through different body segments of the operator within the workspace of a small tractor. J. Field Robot. 2023, 40, 1543–1561. [Google Scholar] [CrossRef]

- Xiong, S.; Xiong, X.; Liu, Y. Mechanical Engineering Test Technology Fundation; Mechanical Industry Press: Beijing, China, 2023; pp. 193–202. [Google Scholar]

- Yan, J. Study on Vibration Characteristics of Tractor Based on Excitation of Agricultural Terrain Roughness. Ph.D. Dissertation, Inner Mongolia Agricultural University, Hohhot, China, 2020. [Google Scholar]

- Yu, D.; Peng, F.; Zeng, Z.; Zhang, M.; Yang, W.; Zang, Y.; He, J.; Huang, Y.; Wu, Y.; Zhong, W.; et al. Vibrational Dynamics of Rice Precision Hole Seeders and Their Impact on Seed Dispensation Efficacy. Agriculture 2024, 14, 324. [Google Scholar] [CrossRef]

- Zhang, X. Analysis of Vibration Test on Engine of a Wheeled Tractor. Trans. Chin. Soc. Agric. Mach. 2000, 31, 69–71. [Google Scholar] [CrossRef]

Figure 1.

Structure of 2BMQ-2 air suction no-tillage planter: (a) schematic diagram of the assembly position of the no-tillage unit; (b) structure of power output shaft; (c) structure of fertilizing and stubble breaking and cleaning devices.

Figure 1.

Structure of 2BMQ-2 air suction no-tillage planter: (a) schematic diagram of the assembly position of the no-tillage unit; (b) structure of power output shaft; (c) structure of fertilizing and stubble breaking and cleaning devices.

Figure 2.

The location of the vibration signal test point.

Figure 2.

The location of the vibration signal test point.

Figure 3.

Field vibration test.

Figure 3.

Field vibration test.

Figure 4.

Different structures of the no-tillage planter: (a) ground wheel removed, representing BCD; (b) compression wheel removed, representing ABC; (c) spring installation direction under light no-till configuration; (d) spring installation direction under heavy no-till configuration.

Figure 4.

Different structures of the no-tillage planter: (a) ground wheel removed, representing BCD; (b) compression wheel removed, representing ABC; (c) spring installation direction under light no-till configuration; (d) spring installation direction under heavy no-till configuration.

Figure 5.

Amplitude spectrum curves under different statuses of the planter and seeding units at in situ idle.

Figure 5.

Amplitude spectrum curves under different statuses of the planter and seeding units at in situ idle.

Figure 6.

Comparison of idle operation and normal operation: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 6.

Comparison of idle operation and normal operation: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 7.

Amplitude signal curves under different structures of planter: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 7.

Amplitude signal curves under different structures of planter: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 8.

The comparison of ABCD configuration and AC configuration: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 8.

The comparison of ABCD configuration and AC configuration: (a–c) working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 9.

The amplitude spectrum curves under light and heavy no-tillage configurations and no profiling spring configurations: (a–c) the working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Figure 9.

The amplitude spectrum curves under light and heavy no-tillage configurations and no profiling spring configurations: (a–c) the working velocities of 4 km/h, 8 km/h, and 12 km/h, respectively.

Table 1.

Test instrument performance parameters.

Table 1.

Test instrument performance parameters.

| Device Name | Performance Target | Value | Company |

|---|

| INV3062C Data acquisition instrument | Sampling frequency range | 0.4~216 k | China Orient Institute of Noise & Vibration, Beijing, China |

| Resolution (bits) | 24 |

| Scan bandwidth (Hz) | 108 k |

| INV9832-50 Three-axis accelerometer | Range (g) | ±50 | China Orient Institute of Noise & Vibration, Beijing, China |

| Frequency response (Hz) | 0.4~10 k |

| Sensitivity (mV·g−1) | 100 |

| INV9828 Unidirectional accelerometer | Range (g) | ±10 | China Orient Institute of Noise & Vibration, Beijing, China |

| Frequency response (Hz) | 0.2~2.5 k |

| Sensitivity (mV·g−1) | 500 |

Table 2.

Soil properties of the three experimental sites.

Table 2.

Soil properties of the three experimental sites.

| Depth (cm) | Soil Water Content (%) | Cone Index (MPa) |

|---|

| 0~5 | 9.49% | 0.09 |

| 5~10 | 10.15% | 0.23 |

| 10~15 | 11.86% | 0.53 |

Table 3.

Test factor levels and code table.

Table 3.

Test factor levels and code table.

| Levels | Tractor Status | Status of Planter Status | Status of Seeding Units | Structure of Planter | Working Velocity (km·h−1) | Number of Profiling Springs |

|---|

| 1 | In situ idle | Lifting | Lifting | ABCD | 4 | 0 |

| 2 | Idle operation | No lifting | No lifting | BCD | 8 | 1 |

| 3 | Normal operation | | | ACD | 12 | 2 |

| 4 | | | | ABC | | |

| 5 | | | | AC | | |

| 6 | | | | ABCDE | | |

Table 4.

Vibration signals under different tractor operating conditions and status of no-tillage planter.

Table 4.

Vibration signals under different tractor operating conditions and status of no-tillage planter.

| Operating Condition | Status of Planter Status | Status of Seeding Units | Working Velocity (km·h−1) | RMS | Peak Number |

|---|

| 1 | 2 | 3 |

|---|

| Frequency (Hz) | Amplitude (mm) | Frequency (Hz) | Amplitude (mm) | Frequency (Hz) | Amplitude (mm) |

|---|

| In situ idle | No lifting | No lifting | / | 1.21 | 68.36 | 0.81 | 205.08 | 0.80 | 324.22 | 0.42 |

| No lifting | Lifting | 3.98 | 68.36 | 4.40 | 69.34 | 4.33 | 275.39 | 1.20 |

| Lifting | Lifting | 2.88 | 67.38 | 3.69 | 66.41 | 2.21 | 68.36 | 1.84 |

| Idle operation | / | 4 | 4.51 | 4.88 | 1.72 | 7.81 | 1.56 | 6.84 | 1.52 |

| 8 | 4.38 | 12.70 | 1.85 | 11.72 | 1.72 | 14.65 | 1.70 |

| 12 | 7.90 | 12.70 | 3.63 | 13.67 | 3.51 | 4.88 | 3.20 |

| Normal operation | / | 4 | 2.27 | 220.70 | 0.92 | 221.68 | 0.82 | 4.88 | 0.80 |

| 8 | 6.46 | 10.74 | 3.56 | 11.72 | 3.46 | 12.70 | 3.16 |

| 12 | 10.02 | 13.67 | 4.72 | 9.77 | 4.53 | 16.60 | 4.25 |

Table 5.

Vibration signals under different configurations of no-tillage planter.

Table 5.

Vibration signals under different configurations of no-tillage planter.

| Working Velocity (km·h−1) | Parameters | Structure of Planter |

|---|

| | | ABCD | BCD | ABC | ACD | ABCDE | AC |

|---|

| 4 | Amplitude peak (mm) | 0.92 | 2.11 | 1.17 | 0.75 | 2.06 | 0.87 |

| Peak-to-peak amplitude differences (mm) | / | 1.19 | 0.25 | −0.16 | 1.14 | −0.05 |

| Dominant frequency (Hz) | 220.70 | 5.86 | 220.70 | 214.84 | 139.65 | 16.60 |

| Frequency offset (Hz) | / | −214.84 | 0 | −5.86 | −81.05 | −204.10 |

| 8 | Amplitude peak (mm) | 3.56 | 3.59 | 2.38 | 1.60 | 2.34 | 1.54 |

| Peak-to-peak amplitude differences (mm) | / | 0.03 | −1.18 | −1.96 | −1.22 | −2.02 |

| Dominant frequency (Hz) | 10.74 | 4.88 | 3.91 | 14.65 | 3.91 | 2.93 |

| Frequency offset (Hz) | / | −5.86 | −6.83 | 3.91 | −6.83 | −7.81 |

| 12 | Amplitude peak (mm) | 4.72 | 5.16 | 2.16 | 1.32 | 3.38 | 2.53 |

| Peak-to-peak amplitude differences (mm) | / | 0.44 | −2.56 | −3.40 | −1.34 | −2.19 |

| Dominant frequency (Hz) | 13.67 | 3.91 | 3.91 | 63.48 | 3.91 | 10.74 |

| Frequency offset (Hz) | / | −9.76 | −9.76 | 49.61 | −9.76 | −2.93 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).