4.2.1. Design and Analysis of Single-Factor Straw-Paving Tests

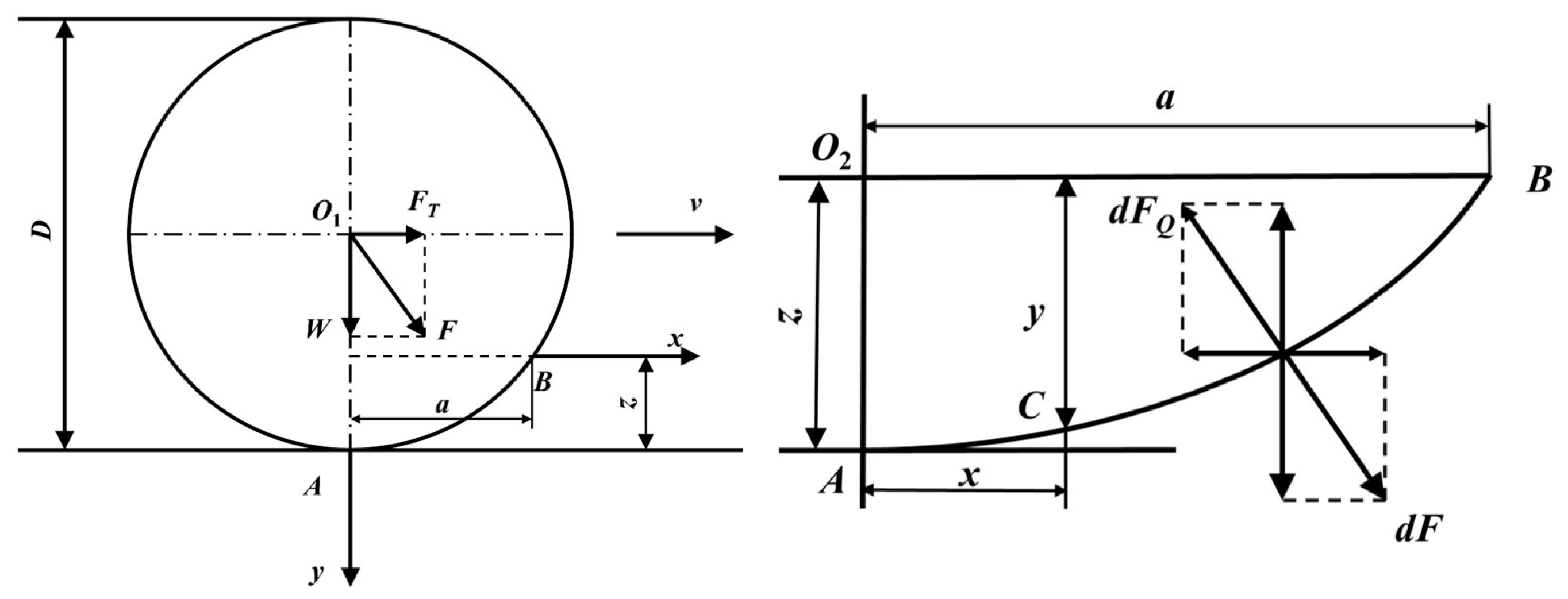

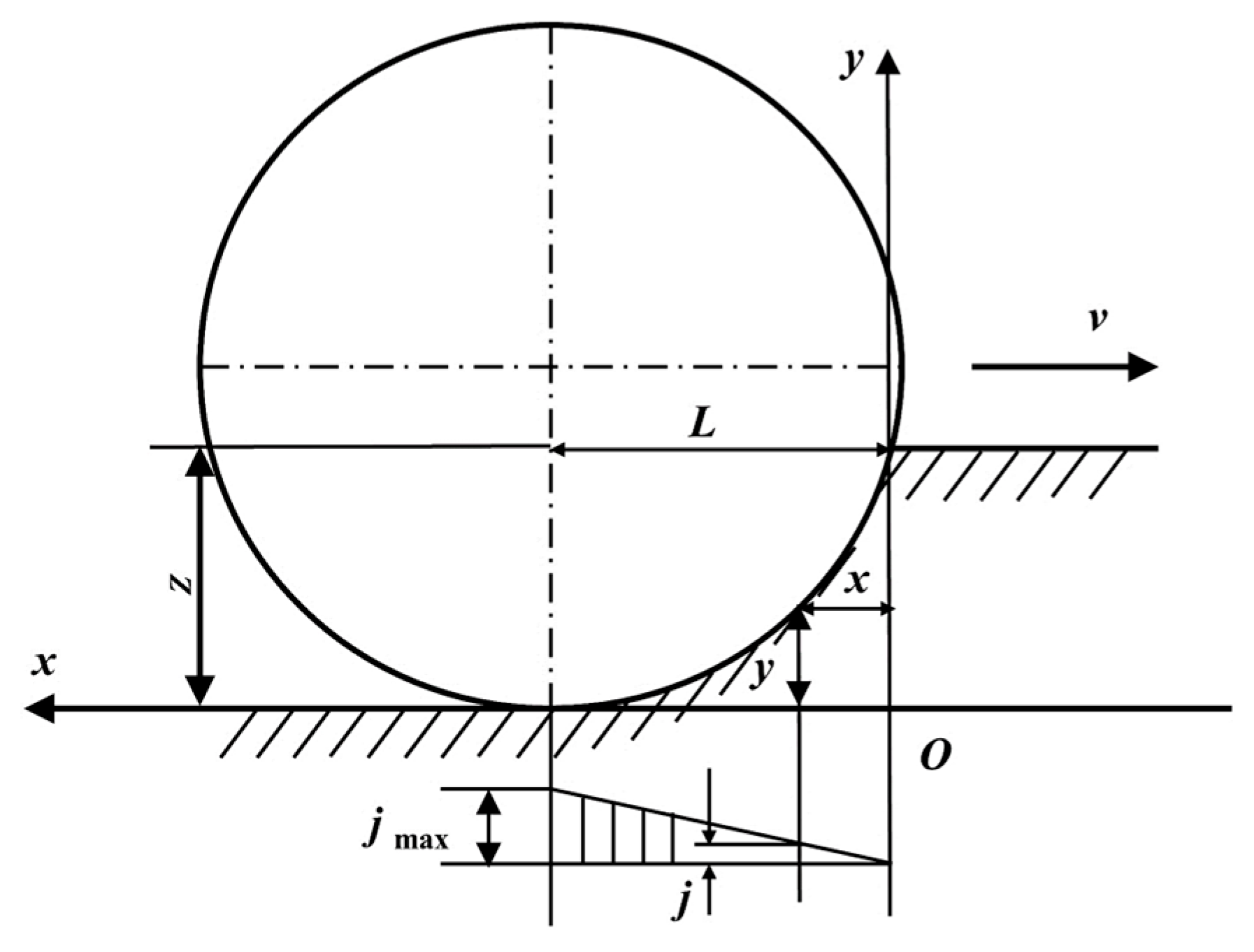

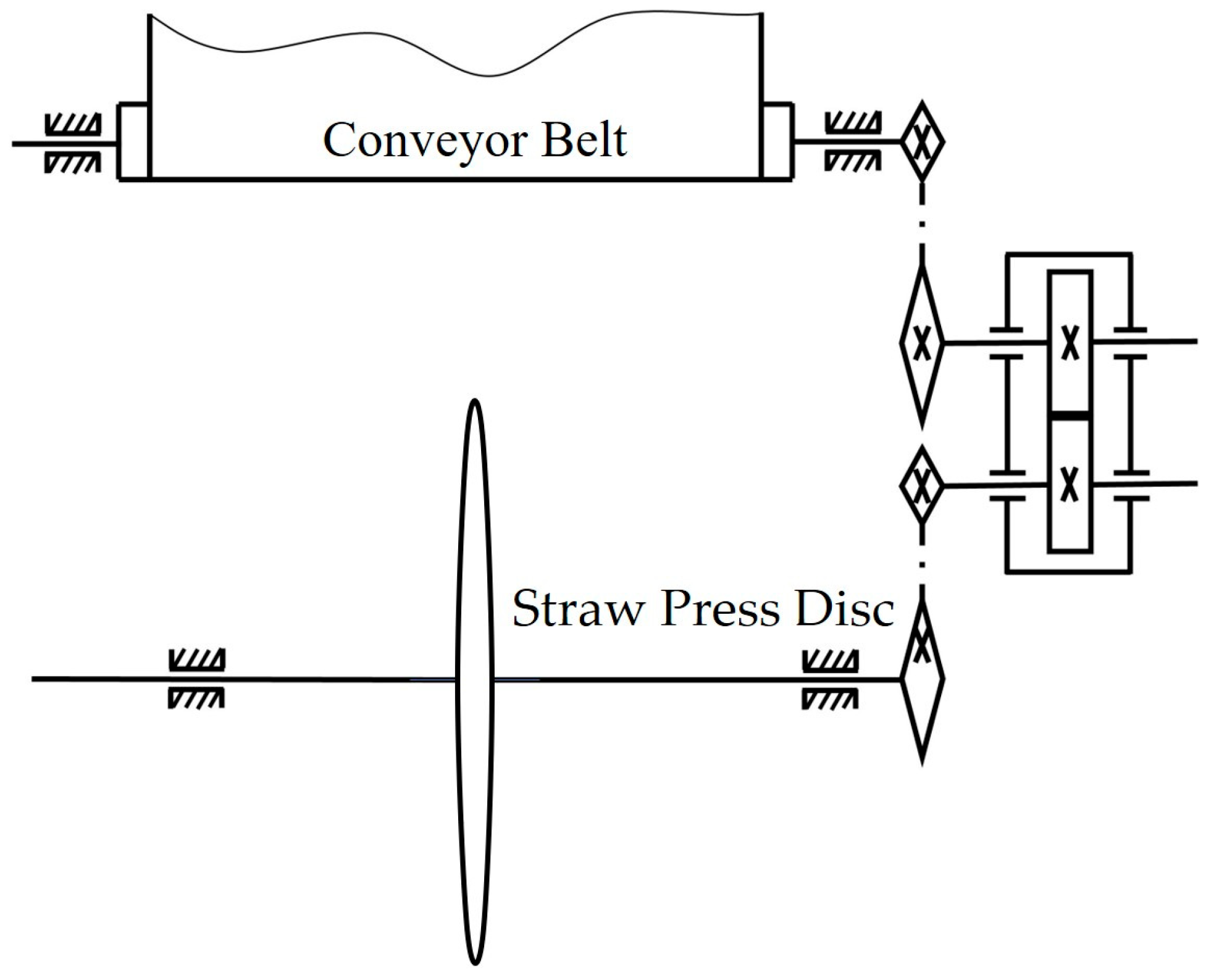

Under tractor traction, the straw press disc rotates and simultaneously drives the paving system forward, ensuring even distribution of straw from the storage box onto the sand surface. In the single-factor experiments, three independent variables were selected: conveyor belt drum speed (A), crankshaft speed (B), and the height of the third-level combing teeth (C). The quality of laid straw per unit length (Q) and the average straw thickness (T) were taken as the primary evaluation metrics. To ensure test reliability and data accuracy, each test consisted of laying three rows of straw; the total row lengths were measured, and five random measurement points per row were selected to determine T.

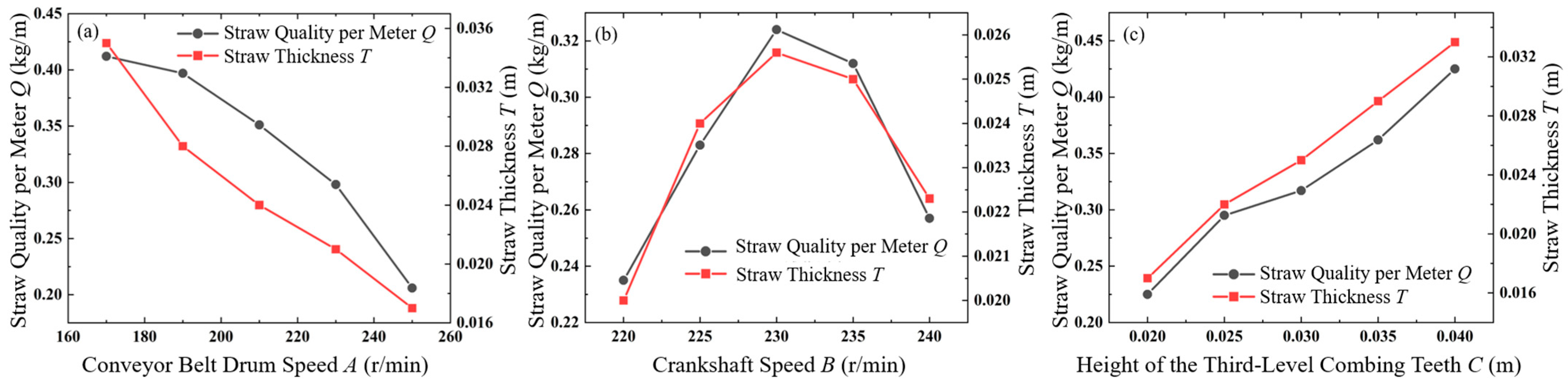

Figure 15a illustrates the influence of variable

A (with

B = 230 r/min,

C = 0.03 m). The results show that as

A increases, both

Q and

T decrease. This trend is attributed to the increased forward velocity of the tractor, which raises the rotational speed of the press disc and conveyor belt, leading to faster laying rates and reduced straw quantity and thickness.

A drum speed range of 170~250 r/min was found to meet the construction requirements of straw–sand barriers. Therefore, three levels of

A (170, 210, and 250 r/min) were chosen for subsequent multi-factor tests.

Figure 15b presents the results for crankshaft speed

B (with

A = 210 r/min,

C = 0.03 m). As

B increases, both

Q and

T first increase and then decrease. Initially, a higher crank speed enhances the frequency of the combing teeth, improving straw dispersion. However, when the frequency becomes excessive, the third-level combing teeth strike the straw too forcefully, resulting in fragmentation and uneven distribution, thereby reducing

Q and

T. Accordingly,

B was set at three levels (220, 230, and 240 r/min) for the multi-factor tests.

Figure 15c shows the effect of combing tooth height

C (with

A = 210 r/min,

B = 230 r/min). The data indicate that increasing

C enhances both

Q and

T. This occurs because a larger gap between the third-level combing teeth and the conveyor belt permits more straw to pass through, increasing both the amount and thickness of straw laid. The tests suggest that the height range of 0.02~0.04 m is optimal, and these three values (0.02, 0.03, and 0.04 m) were selected for the multi-factor experiment.

4.2.2. Design and Analysis of Multi-Factor Straw-Paving Tests

To investigate the interactions between the conveyor belt drum speed

A, crankshaft speed

B, and the height of the third-level combing teeth

C, with straw quality per metre

Q and average straw thickness

T as response variables, multi-factor tests were designed and analyzed using Design-Expert 11. The Box–Behnken design was applied, with the influencing factors and their levels encoded as shown in

Table 7, and the experimental scheme and results are presented in

Table 8.

To investigate the interactions among conveyor belt drum speed (

A), crankshaft speed (

B), and the height of the third-level combing teeth (

C), a series of multi-factor tests were designed and analyzed using Design-Expert 11 software. In this study, straw quality per metre (

Q) and average straw thickness (

T) served as the response variables. The Box–Behnken design method was adopted, with the coded levels of the influencing factors shown in

Table 7. The experimental scheme and corresponding results are summarized in

Table 8.

Based on the data presented in

Table 8, quadratic multiple regression models were developed to predict the response variables

Q and

T within the specified ranges, and are denoted as Equations (37) and (38):

The statistical significance of these regression models was evaluated through analysis of variance (ANOVA), with the results summarized in

Table 9 and

Table 10.

The multiple regression model for straw quality per metre (

Q) yielded an

F-value of 29.42 and a

p-value < 0.0001, indicating that the model was statistically highly significant and exhibited a strong goodness of fit (

R2 = 0.9743). The linear terms

A and

C, along with the quadratic terms

A2,

B2, and

C2, had a highly significant effect on

Q (

p < 0.01). In contrast, the linear term

B and the interaction terms

AB and

AC showed statistically significant effects (

p < 0.05). The interaction term

BC and the lack-of-fit term were not statistically significant (

p > 0.05). Based on the

F-values, the order of influence on

Q was

C >

A >

B, indicating that the height of the third-level combing teeth had the most substantial effect on straw quality, followed by the conveyor belt drum speed and then the crankshaft speed. This indicates that the effect of drum speed (

A) on

Q depends on the crank-driven combing frequency (

B) and on the discharge aperture defined by the third-level tooth height (

C). Physically, when

A is high but

B is low, feed starvation may occur; conversely, when both

A and

B are high with a small

C, over-aggressive striking and intermittent clogging can reduce

Q. These interaction patterns are consistent with the stronger surface curvature observed in

Figure 16b,c.

The multiple regression model for average straw thickness (T) yielded a p-value of 0.0021, indicating that the model was statistically significant and exhibited a strong fit. Among the variables, the linear term C and the quadratic term A2 had a highly significant effect on T (p < 0.01), whereas the remaining terms showed no statistically significant influence (p > 0.05). Based on the magnitude of the effects, the influence of the factors on T followed the same trend as for Q, ranked as C > A > B. Notably, none of the interaction terms (AB, AC, or BC) for T reached statistical significance (p > 0.05), implying that layer thickness is primarily governed by the discharge aperture C and the nonlinear (quadratic) response to drum speed A, rather than by cross-factor couplings. From a design standpoint, T can, therefore, be robustly controlled by specifying C within 0.02–0.04 m and tuning A within the validated range, without relying on specific combinations with B.

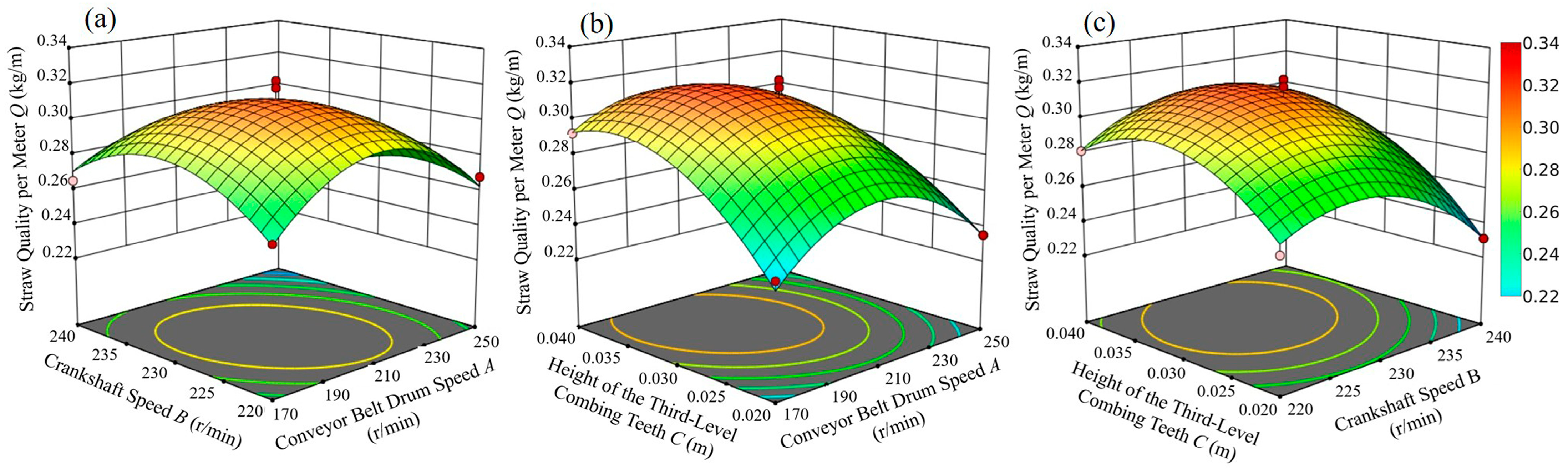

Response surface plots based on the regression models were generated to evaluate the interactive effects of the three factors on straw quality per metre (

Q) and average straw thickness (

T).

Figure 16 illustrates the response surface for

Q. As shown in

Figure 16a, when conveyor belt drum speed

A remained constant,

Q first increased and then decreased with increasing crankshaft speed

B, and vice versa. In

Figure 16b, with

A constant,

Q increased and then plateaued as the height of the third-level combing teeth

C increased; with

C constant,

Q increased initially and then declined with increasing

A.

Figure 16c shows that with B constant,

Q first rose and then dropped as

C increased, while with

C constant,

Q exhibited a gradual rise followed by a sharp decline with increasing

B. Among the three surfaces,

Figure 16b,c displayed greater convexity than

Figure 16a, indicating more pronounced interactions between factor

C and both

A and

B. These graphical features are consistent with the ANOVA results for

Q, in which

AB and

AC were statistically significant while

BC was not (

Table 9).

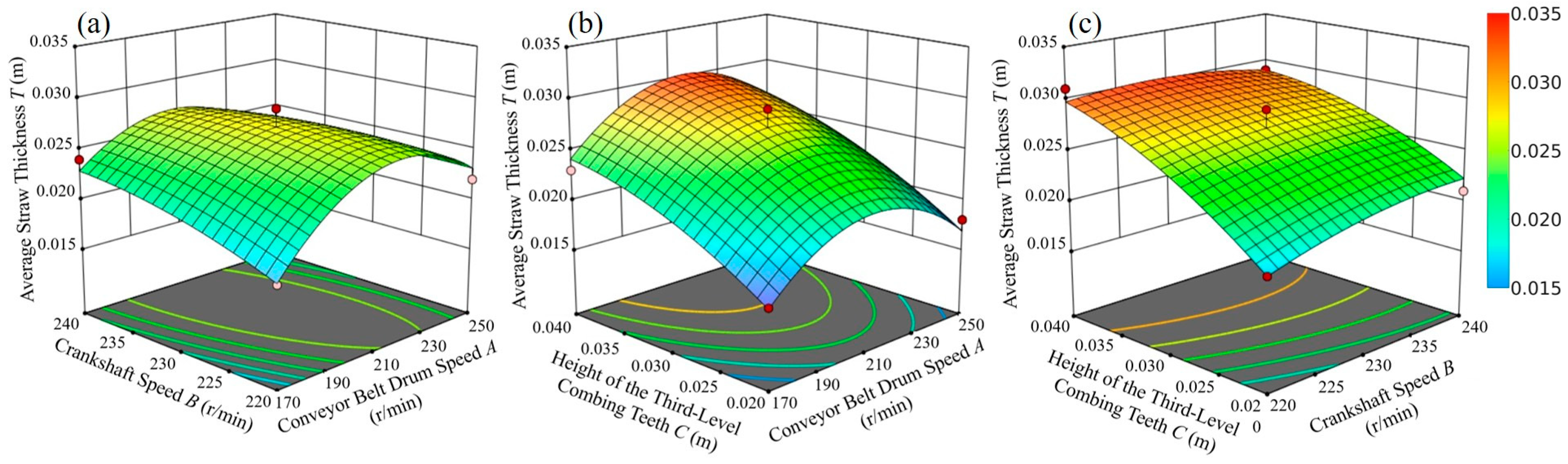

Figure 17 illustrates the response surface for average straw thickness (

T). In

Figure 17a, the interaction between conveyor roller speed

A and crankshaft speed B reveals that

T remained relatively stable with increasing

B when

A was held constant, while it initially increased and then decreased with increasing

A when

B was constant. In

Figure 17b, as

C increased,

T gradually increased when

A was fixed; conversely, with fixed

C,

T first increased and then declined as

A increased.

Figure 17c shows that

T steadily increased with increasing

C when

B was constant, whereas it increased slightly and then declined slowly with increasing

B when

C was constant. Overall, the three-factor interactions significantly affected

T, with

Figure 17b displaying the most pronounced convexity, indicating that the interaction between third-level combing teeth height (

C) and conveyor roller speed (

A) exerted the greatest influence on average straw thickness.