Design and Experimental Evaluation of a Pulsating Rubbing-Based Banana Fiber Extractor

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure and Working Principle

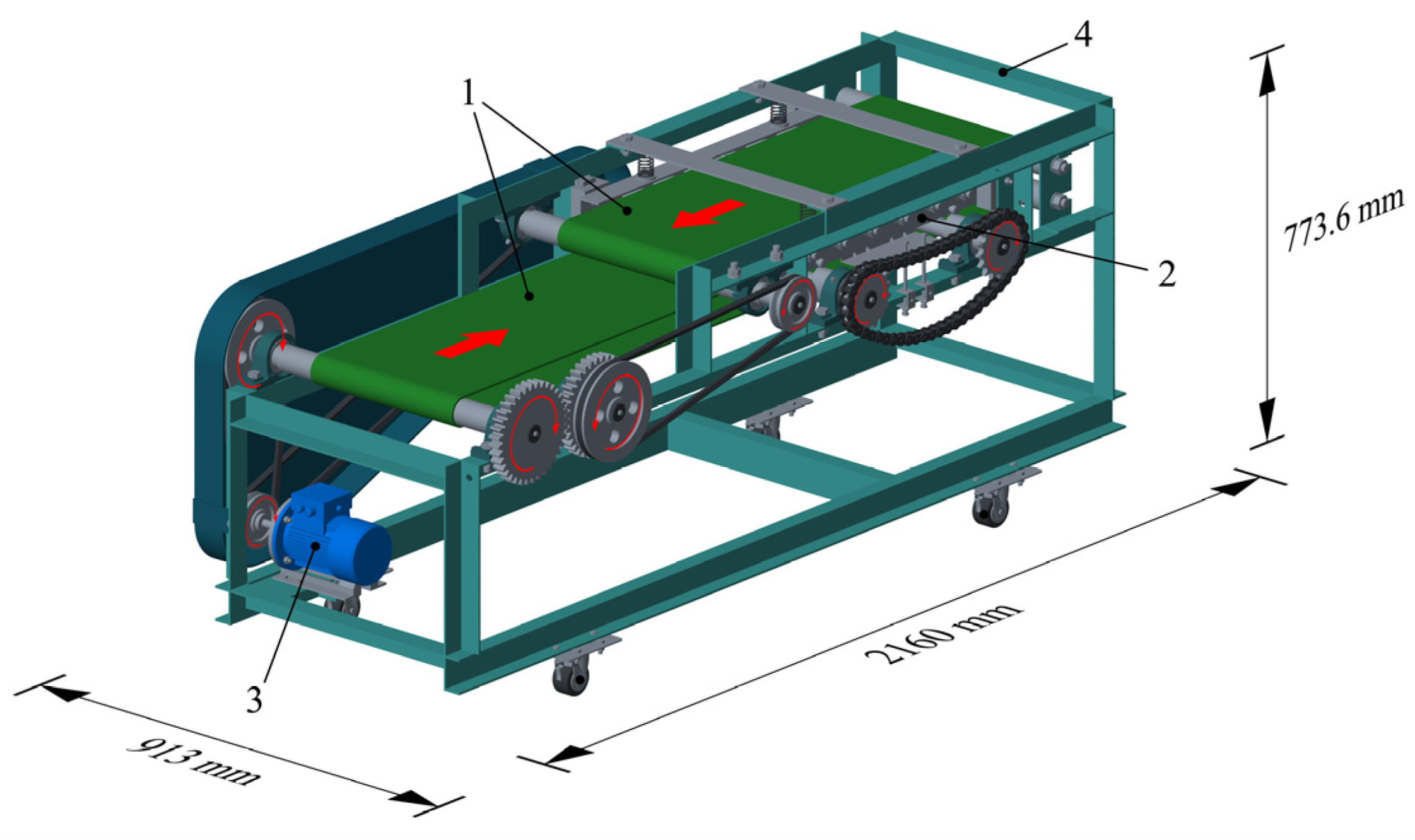

2.1.1. Overall Machine Structure

2.1.2. Working Principle

2.2. Key Component Design

2.2.1. Design of the Rubbing Device

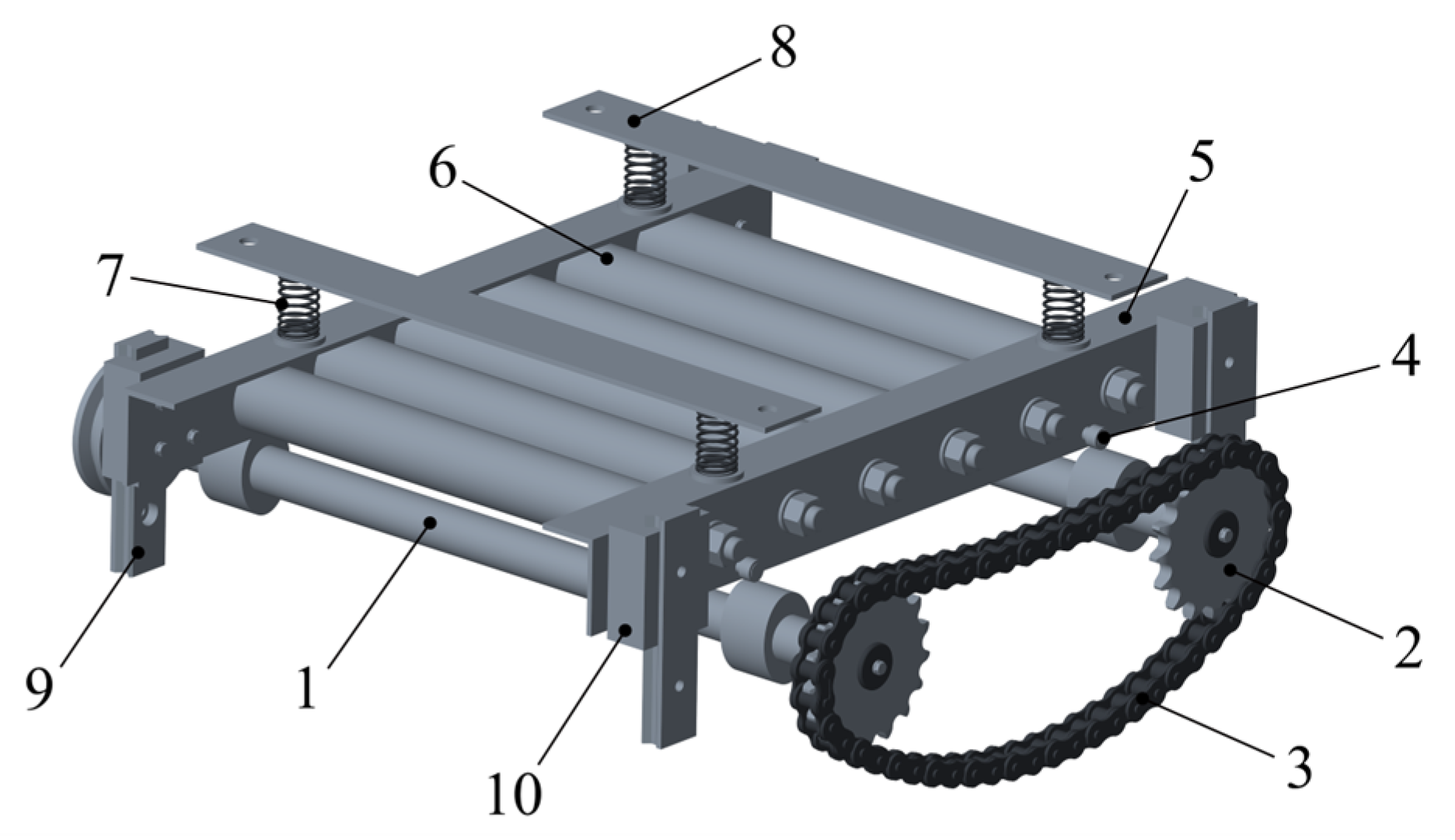

2.2.2. Design of the Pulsating Pressing Device

2.2.3. Transmission System Design

2.3. Simulation Analysis of the Pulsating Rubbing Process

2.3.1. Simulation Model Establishment

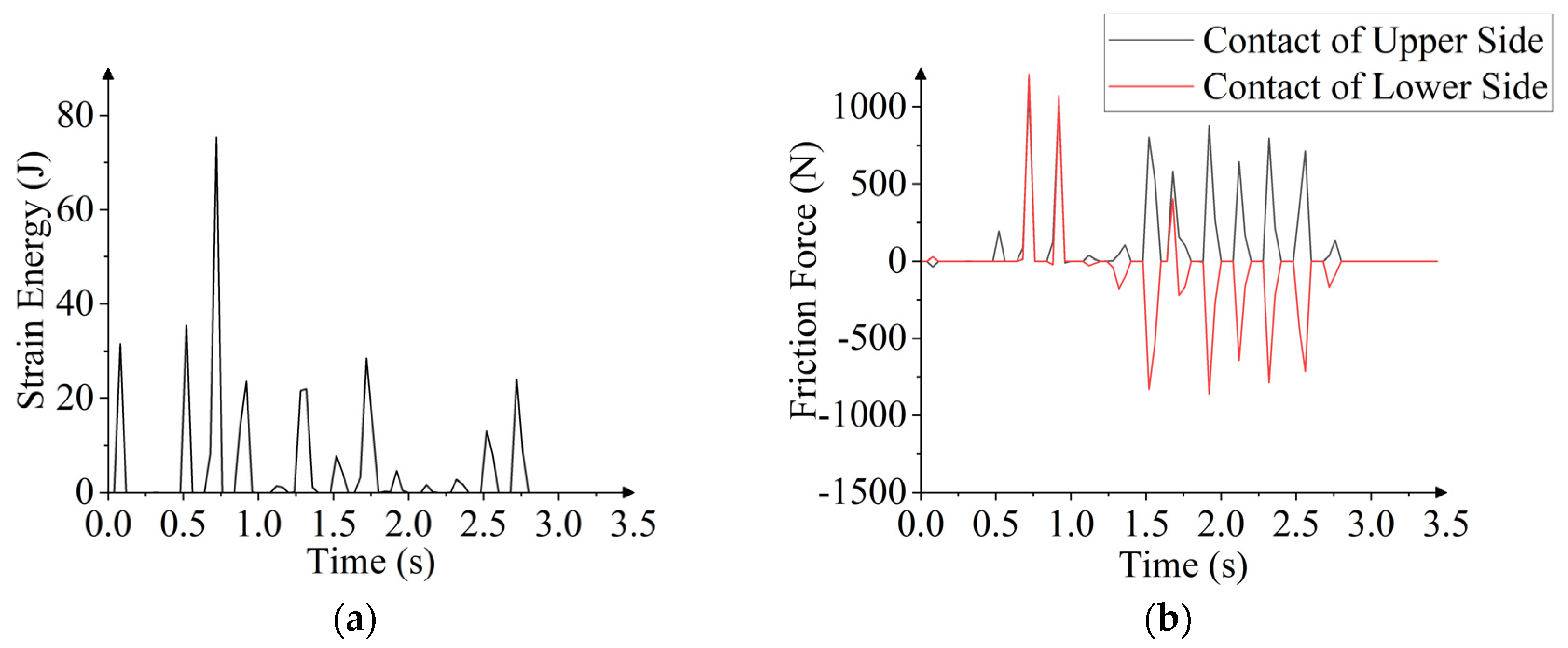

2.3.2. Simulation Results and Analysis

3. Results and Discussion

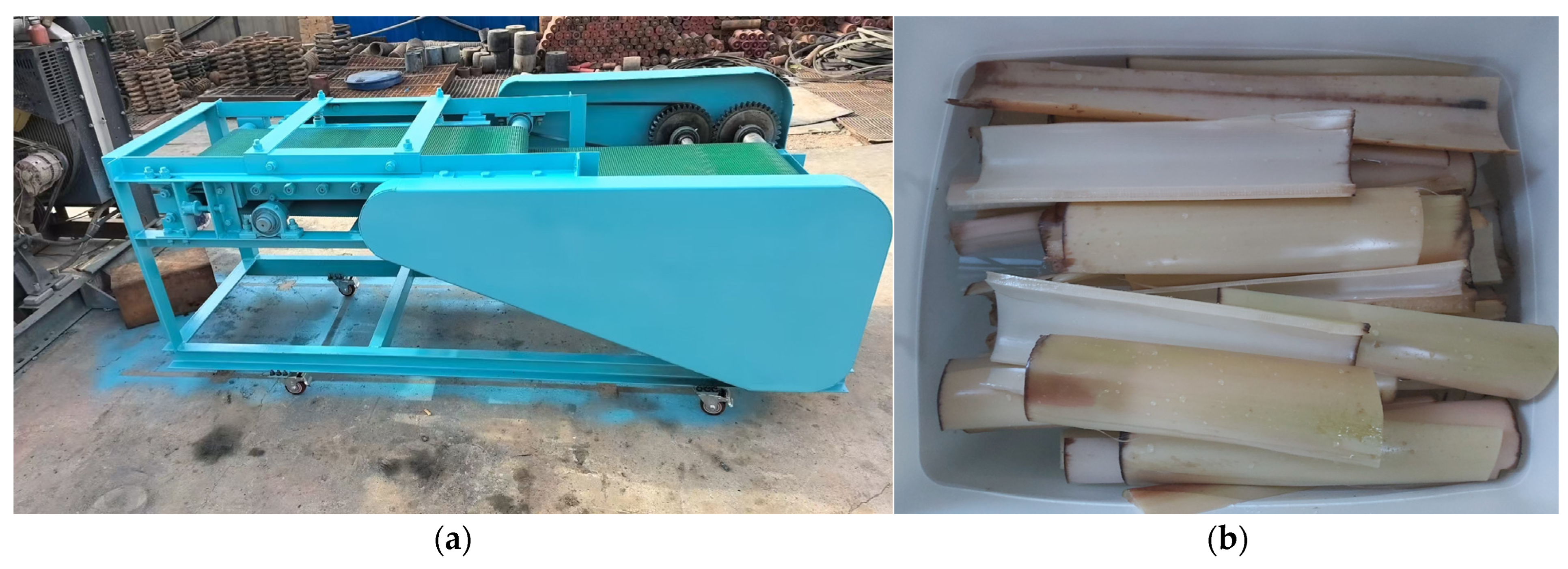

3.1. Prototype Manufacturing and Preparation of Banana Stem Material

3.2. Evaluation Indicators

3.2.1. Extraction Rate

3.2.2. Impurity Rate

3.2.3. Integrity Rate

3.3. Selection of Experimental Factors

3.3.1. Spring Outer Diameter

3.3.2. Feeding Interval of the Stem Slices

3.3.3. Clamping Angle Between the Stem Slices and the Rubbing Belts

3.4. Box–Behnken Test

3.4.1. Test Design

3.4.2. Analysis of Variance

3.4.3. Response Surface Analysis

3.4.4. Parameter Optimization and Experimental Verification

4. Conclusions

- (1)

- The structural scheme of the device was established, featuring key components, including a dual-belt differential-speed rubbing device and a cam-based pulsating pressing device, enabling periodic rubbing and pressing of the banana stem slices. A simulation analysis verified the mechanical feasibility of the extraction process, showing that the surface stress on the stem slices exceeded the shear strength, enabling effective fiber detachment.

- (2)

- Structural parameters were optimized using Box–Behnken experimental design. The results indicated that, when the spring outer diameter was 30 mm, the feeding interval was 4 s, and the clamping angle was 90°, the extraction rate reached 60.85%, the impurity rate was 12.76%, and the integrity rate reached as high as 99.61%. This demonstrated a good balance between extraction efficiency and fiber quality.

- (3)

- This study demonstrated the feasibility of flexible, low-damage fiber extraction. The proposed structural scheme and parameter optimization path provide a reference for processing similar crop stalks.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C. High-quality and high-yield cultivation and management techniques for Hainan banana. Spec. Econ. Anim. Plants 2021, 24, 60–61. [Google Scholar]

- Hainan Provincial Bureau of Statistics; Survey Office of National Bureau of Statistics in Hainan. Hainan Statistical Yearbook 2024; China Statistics Press: Beijing, China, 2024; ISBN 978-7-5230-0558-3.

- Xu, S.; Zhang, Y.; Li, J.; Lin, C.; Lin, Z. Research progress and improvement direction of squeezing dehydration technology and equipment of banana pseudostem. Trans. Chin. Soc. Agric. Eng. 2018, 34, 76–84. [Google Scholar] [CrossRef]

- Bordón, P.; Elduque, D.; Paz, R.; Javierre, C.; Kusić, D.; Monzón, M. Analysis of Processing and Environmental Impact of Polymer Compounds Reinforced with Banana Fiber in an Injection Molding Process. J. Clean. Prod. 2022, 379, 134476. [Google Scholar] [CrossRef]

- Sivaranjana, P.; Arumugaprabu, V. A Brief Review on Mechanical and Thermal Properties of Banana Fiber Based Hybrid Composites. SN Appl. Sci. 2021, 3, 176. [Google Scholar] [CrossRef]

- Doshi, A. Banana Fiber to Fabric: Process Optimization for Improving Its Spinnability and Hand. Ph.D. Thesis, Maharaja Sayajirao University of Baroda, Vadodara, India, 2017. [Google Scholar]

- Muralikrishna, M.V.V.; Surya Kumari, T.S.A.; Gopi, R.; Babu Loganathan, G. Development of Mechanical Properties in Banana Fiber Composite. Mater. Today Proc. 2020, 22, 541–545. [Google Scholar] [CrossRef]

- Anil Kumar, S.V.; Gandhinathan, R. Studies on Mechanical Properties of Banana Fibre Reinforced Polyster Composites. AIP Conf. Proc. 2019, 2057, 20018. [Google Scholar] [CrossRef]

- Alzate Acevedo, S.; Díaz Carrillo, Á.J.; Flórez-López, E.; Grande-Tovar, C.D. Recovery of Banana Waste-Loss from Production and Processing: A Contribution to a Circular Economy. Molecules 2021, 26, 5282. [Google Scholar] [CrossRef]

- Al-Daas, A.; Azmi, A.S.; Ali, F.B.; Anuar, H. The Effect of Alkaline Treatment to Pseudo-Stem Banana Fibers on the Performance of Polylactic Acid/Banana Fiber Composite. J. Nat. Fibers 2023, 20, 2176401. [Google Scholar] [CrossRef]

- Parida, P.K.; Pandit, M.K.; Pradhan, A.K. Extraction of Natural Cellulosic Fiber from Myriostachia Wightiana Stems Using Chemical Retting and Its Characterization for Bio-Composite Applications. Cellulose 2023, 30, 8819–8837. [Google Scholar] [CrossRef]

- Yu, X.; Xia, Y.; Liang, D.; Fu, W.; Yin, C. Effect of Warm-Water Retting Pretreatment on the Physical Properties of Banana Stem and Its Fibre. Materials 2022, 15, 8462. [Google Scholar] [CrossRef]

- Kaur, A.; Varghese, L.M.; Battan, B.; Patra, A.K.; Mandhan, R.P.; Mahajan, R. Bio-Degumming of Banana Fibers Using Eco-Friendly Crude Xylano-Pectinolytic Enzymes. Prep. Biochem. Biotechnol. 2020, 50, 521–528. [Google Scholar] [CrossRef] [PubMed]

- Gusovius, H.-J.; Lühr, C.; Hoffmann, T.; Pecenka, R.; Idler, C. An Alternative to Field Retting: Fibrous Materials Based on Wet Preserved Hemp for the Manufacture of Composites. Agriculture 2019, 9, 140. [Google Scholar] [CrossRef]

- Pappu, A.; Patil, V.; Jain, S.; Mahindrakar, A.; Haque, R.; Thakur, V.K. Advances in Industrial Prospective of Cellulosic Macromolecules Enriched Banana Biofibre Resources: A Review. Int. J. Biol. Macromol. 2015, 79, 449–458. [Google Scholar] [CrossRef] [PubMed]

- Veera Ajay, C.; Vignesh Ramamoorthy, K.; Subash, V.; Robinston, R.; Ragashwar, M.; Justus Panicker, C.T. Design and Fabrication of Manually Operated Banana Fiber Extracting Machine for Agriculture Applications. Mater. Today Proc. 2021, 45, 8199–8202. [Google Scholar] [CrossRef]

- Xiang, W.; Yan, B.; Duan, Y.; Tang, Z.; Ma, L.; Liu, J.; Lv, J. Design and Parameter Optimization of Transverse-Feed Ramie Decorticator. Agriculture 2023, 13, 1175. [Google Scholar] [CrossRef]

- Cheng, Q.; Wang, J.; Liu, K.; Chao, J.; Liu, D. Design of Rice Straw Fiber Crusher and Evaluation of Fiber Quality. Agriculture 2022, 12, 729. [Google Scholar] [CrossRef]

- Mahmoud, W.A.E.-M.; Elkaoud, N.S.M.; Salah, A.; Mousa, A.M.M. Mechanical Processing of Banana Slices-Stem for Fiber Extraction. CIGR J. 2023, 25, 236–245. [Google Scholar]

- Oreko, B.U.; Okiy, S.; Emagbetere, E.; Okwu, M. Design and Development of Plantain Fibre Extraction Machine. Niger. J. Technol. 2018, 37, 397–406. [Google Scholar] [CrossRef][Green Version]

- Awais, H.; Ahmad, F.; Azam, F.; Shahid, S.; Nawab, Y.; Ahmad, S. An Economical and Environmentally Benign Approach to Extract Banana Fibres from Agricultural Waste for Fibre Reinforced Composites. J. Text. Inst. 2022, 113, 1967–1973. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, D.; Li, Y.; Wang, C. Development and experiment of full feeding and movable combined machine for banana stalk fiber extraction. Trans. Chin. Soc. Agric. Eng. 2015, 31, 22–30. [Google Scholar] [CrossRef]

- Zeng, C.; Liang, D.; Zhang, X.; Li, Y. The Bionic Design of the Blade on the Banana Fiber Extraction Based on the Structure of Mantis’s Foreleg. J. Agric. Mech. Res. 2018, 40, 79–83. [Google Scholar] [CrossRef]

- Treeamnuk, K.; Pathaveerat, S.; Terdwongworakul, A.; Bupata, C. Design of Machine to Size Java Apple Fruit with Minimal Damage. Biosyst. Eng. 2010, 107, 140–148. [Google Scholar] [CrossRef]

- Franco, W.; Iarussi, F.; Quaglia, G. Human Powered Press for Producing Straw Bales for Use in Construction during Post-Emergency Conditions. Biosyst. Eng. 2016, 150, 170–181. [Google Scholar] [CrossRef]

- Cheng, D. Handbook of Mechanical Design, 6th ed.; Chemical Industry Press: Beijing, China, 2016; Volume 3, ISBN 978-7-122-26049-9. [Google Scholar]

- Liu, S.; Yang, X.; Zhang, Z.; Xu, J.; Zhao, P.; Tian, S.; Wei, L.; Ning, X. Design and Simulation of Chinese Cabbage Harvester. Agriculture 2025, 15, 831. [Google Scholar] [CrossRef]

- Zhu, J.; Li, B.; Mu, H.; Li, Q. Kinematic Analysis of a Flexible Planar 2-DOF Parallel Manipulator. In Proceedings of the Intelligent Robotics and Applications, Xi’an, China, 31 July–2 August 2024; Springer International Publishing: Cham, Switzerland, 2019; Volume 11744, pp. 696–706. [Google Scholar]

- Dobrotă, D.; Petrescu, V.; Dimulescu, C.S.; Oleksik, M. Preparation and Characterization of Composites Materials with Rubber Matrix and with Polyvinyl Chloride Addition (PVC). Polymers 2020, 12, 1978. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, X.; Liu, J.; Yang, Y.; Li, Y. Calibration and Verification of Bonding Parameters of Banana Straw Simulation Model Based on Discrete Element Method. Trans. Chin. Soc. Agric. Mach. 2023, 54, 121–130. [Google Scholar] [CrossRef]

- Xiong, X.; Shen, S.Z.; Hua, L.; Liu, J.Z.; Li, X.; Wan, X.; Miao, M. Finite Element Models of Natural Fibers and Their Composites: A Review. J. Reinf. Plast. Compos. 2018, 37, 617–635. [Google Scholar] [CrossRef]

- Soomro, A.; Rossi, F. SOLIDWORKSTM Design, Fabrication and Performance Analysis of a Banana Fiber Extraction Machine and Its Components. Mehran Univ. Res. J. Eng. Technol. 2024, 43, 190–204. [Google Scholar] [CrossRef]

- GB/T 12411-2006; Test Methods for Jute and Kenaf Fibres. General Administration of Quality Supervision; Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China Standards Press of China: Beijing, China, 2006.

- Badanayak, P.; Jose, S.; Bose, G. Banana Pseudostem Fiber: A Critical Review on Fiber Extraction, Characterization, and Surface Modification. J. Nat. Fibers 2023, 20, 2168821. [Google Scholar] [CrossRef]

- Xie, L.; Wang, J.; Cheng, S.; Zeng, B.; Yang, Z. Optimisation and Finite Element Simulation of the Chopping Process for Chopper Sugarcane Harvesting. Biosyst. Eng. 2018, 175, 16–26. [Google Scholar] [CrossRef]

- Li, Y.; Hu, C. Experiment Design and Data Processing; Chemical Industry Press: Beijing, China, 2017; ISBN 978-7-122-29990-1. [Google Scholar]

| Technical Parameter | Design Value |

|---|---|

| Overall dimensions/mm | 2160 × 913 × 773.6 |

| Motor power/kW | 0.75 |

| Maximum output speed/rpm | 120–150 |

| Machine weight/kg | 850 |

| Extraction rate/% | ≥65 |

| Impurity rate/% | ≤25 |

| Integrity rate/% | ≥85 |

| Technical Parameter | Design Value |

|---|---|

| Stroke of lower rubbing belt/mm | 1800 |

| Stroke of upper rubbing belt/mm | 1000 |

| Roller diameter/mm | 60 |

| Speed of lower rubbing belt | 200–250 mm/s |

| Speed ratio of upper to lower belt | 2 |

| Technical Parameter | Design Value |

|---|---|

| Cam spacing/mm | 430 |

| Slider stroke/mm | 10 |

| Pressing drum diameter/mm | 60 |

| Pulsating pressing frequency/Hz | 4–6 |

| Density/(kg/m3) | Poisson’s Ratio | Elastic Modulus/Pa |

|---|---|---|

| 137 | 0.41 | 1.35 × 109 |

| № | X1/mm | X2/s | X3/° |

|---|---|---|---|

| −1 | 30 | 4 | 0 |

| 0 | 32.5 | 5 | 45 |

| 1 | 35 | 6 | 90 |

| № | ||||||

|---|---|---|---|---|---|---|

| 1 | −1 | 0 | 0 | 60.85 | 12.76 | 99.61 |

| 2 | 0 | −1 | −1 | 65.49 | 57.48 | 92.32 |

| 3 | 0 | −1 | 0 | 79.17 | 57.21 | 93.24 |

| 4 | −1 | −1 | 0 | 96.47 | 50.87 | 91.41 |

| 5 | 0 | 1 | 1 | 64.08 | 60.22 | 65.58 |

| 6 | 1 | 1 | 0 | 47.36 | 64.86 | 89.62 |

| 7 | 0 | 0 | 0 | 77.40 | 18.60 | 59.64 |

| 8 | 0 | 1 | 0 | 50.62 | 66.79 | 97.22 |

| 9 | 0 | 0 | −1 | 68.18 | 60.65 | 95.03 |

| 10 | 1 | 0 | 1 | 55.00 | 63.78 | 80.61 |

| 11 | 0 | 1 | 0 | 86.99 | 53.37 | 98.57 |

| 12 | 0 | 0 | 1 | 88.75 | 52.49 | 98.80 |

| 13 | 0 | 0 | −1 | 63.99 | 63.72 | 99.49 |

| 14 | 0 | 0 | 0 | 72.23 | 58.63 | 74.66 |

| 15 | 0 | 1 | −1 | 77.73 | 44.19 | 75.96 |

| 16 | −1 | 0 | 0 | 52.47 | 59.63 | 81.25 |

| 17 | 0 | −1 | 1 | 70.21 | 45.34 | 97.39 |

| Source | Sum of Squares | Degrees of Freedom | Mean Square | F-Value | p-Value | Significance |

|---|---|---|---|---|---|---|

| Model | 2790.68 | 5 | 558.14 | 6.58 | 0.0046 | * |

| 1039.82 | 1 | 1039.82 | 12.26 | 0.005 | * | |

| 200.96 | 1 | 200.96 | 2.37 | 0.1519 | ||

| 424.32 | 1 | 424.32 | 5 | 0.0469 | * | |

| 651.58 | 1 | 651.58 | 7.68 | 0.0182 | * | |

| 474.01 | 1 | 474.01 | 5.59 | 0.0375 | * | |

| Residual | 932.7 | 11 | 84.79 | |||

| Lack of fit | 614.28 | 7 | 87.75 | 1.1 | 0.4911 | |

| Pure error | 318.42 | 4 | 79.61 | |||

| Corrected total | 3723.38 | 16 |

| Response Indicator | Test Result | Predicted Value | Error |

|---|---|---|---|

| Extraction rate | 61.35% | 69.24% | 7.89% |

| Impurity rate | 9.01% | 5.04% | 3.97% |

| Integrity rate | 96.22% | 87.67% | 8.55% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, D.; Yu, S.; Fu, W.; Shen, Y.; Yang, Z.; Zeng, W.; Liu, J. Design and Experimental Evaluation of a Pulsating Rubbing-Based Banana Fiber Extractor. Agriculture 2025, 15, 1746. https://doi.org/10.3390/agriculture15161746

Liang D, Yu S, Fu W, Shen Y, Yang Z, Zeng W, Liu J. Design and Experimental Evaluation of a Pulsating Rubbing-Based Banana Fiber Extractor. Agriculture. 2025; 15(16):1746. https://doi.org/10.3390/agriculture15161746

Chicago/Turabian StyleLiang, Dong, Shaojie Yu, Wei Fu, Yijun Shen, Zeqin Yang, Wei Zeng, and Ji Liu. 2025. "Design and Experimental Evaluation of a Pulsating Rubbing-Based Banana Fiber Extractor" Agriculture 15, no. 16: 1746. https://doi.org/10.3390/agriculture15161746

APA StyleLiang, D., Yu, S., Fu, W., Shen, Y., Yang, Z., Zeng, W., & Liu, J. (2025). Design and Experimental Evaluation of a Pulsating Rubbing-Based Banana Fiber Extractor. Agriculture, 15(16), 1746. https://doi.org/10.3390/agriculture15161746