1. Introduction

Rice plays a pertinent role in Japanese culture [

1] (pp. 94–97), serving as the primary source of carbohydrate intake with an average annual consumption of circa 50 kg per capita [

2]. The harvesting process, a complex and labor-intensive endeavor, is influenced by various factors, including plant phenology, which determines the time-critical harvesting period and, thus, all further operational farm operations [

3] (p. 12), such as transportation to rice collection centers.

Previous studies have typically modeled components related to the agriculture production cycle [

4], such as weather [

5], crop growth [

6,

7,

8] and harvesting logistics [

9,

10,

11], as isolated, domain-specific processes, often without capturing their interdependencies. Well-known models like APSIM (Agricultural Production Systems Simulator) [

12] and DSSAT (Decision Support System for Agrotechnology Transfer) [

6] adopt a modular architecture and have been effective in simulating crop phenology under various environmental conditions. However, these models fall short in representing the complex interactions and emergent behaviors that arise from decentralized decision-making across multiple stakeholders in the real world. For instance, post-harvest logistics such as transportation and handling are rarely integrated, despite being critical to the overall operational performance. Additionally, most existing models are procedurally structured and lack adaptability to real-world disruptions, such as rainfall-induced harvesting delays.

These limitations are particularly relevant in the context of Japanese rice production. Japan has approximately 2.3 million small-scale rice fields, averaging just 0.8 hectares in size [

13,

14]. An aging population [

15] and the need to manage widely scattered fields have increased the complexity of operational planning. Timely harvesting is crucial, as missing the optimal window can lead to significant declines in both crop quantity and quality [

16]. Moreover, external factors such as weather play a pivotal role not only in crop phenology but also in the execution and coordination of post-harvest activities.

To address these challenges, this research proposes a modular and extensible simulation model based on the multi-agent system (MAS) framework, a paradigm that has already been successfully applied to various agricultural use cases [

17,

18,

19].

Unlike traditional models, the MAS framework enables decentralized agents—representing elements such as weather, fields, harvesters, trucks and rice centers—to interact dynamically and respond to changing conditions. Each agent governs a specific aspect of the harvesting process and operates independently, allowing the system to simulate emergent behavior and respond to external events such as rainfall. The model integrates crop growth dynamics and logistics to provide an end-to-end view of rice harvesting operations.

The primary aim of this study is to verify the correct functioning of the model—ensuring that it is implemented accurately and behaves according to the intended logic. While real-world validation is not yet possible due to limited empirical data, the model aims to lay the groundwork for future validation studies as data become available. Key performance indicators such as harvesting time, waiting time and travel time are used to verify internal consistency and assess the model’s potential to evaluate harvesting strategies under varying conditions.

2. Materials and Methods

This chapter consists of three primary components: (1) overview and background of multi-agent systems (MASs) and discrete event simulation methodology; (2) a description of the target system’s design, outlining its key characteristics and functional requirements and (3) the actual implementation of the MAS used for this research.

2.1. Multi-Agent Systems

As mentioned, rice harvesting is a complex, multifaceted agricultural process comprising multiple prior and subsequent activities. In general, a model is a simplified representation of a particular aspect of the real world [

20] (p. 6). It captures the view of a system with specific objectives, such as simulation, analysis, optimization or prediction [

21] (p. 21). The level of detail and abstraction in a model depends on its purpose and the desired level of accuracy [

22]. Consequently, software engineering techniques such as decomposition, abstraction and (hierarchical) organization—comparable to object-oriented design patterns—can be employed to manage complex systems effectively [

23] (p. 27).

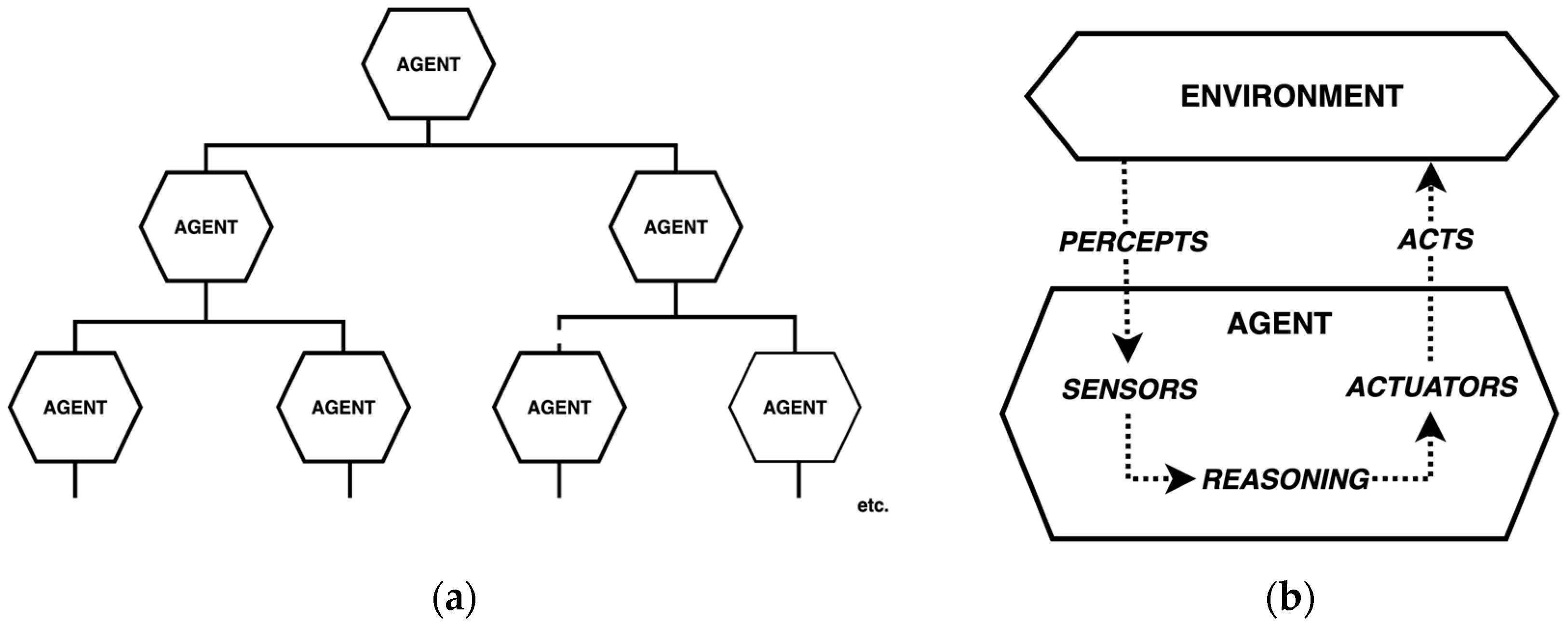

An agent-based system is a computational paradigm characterized by its hierarchical decomposition into smaller, independent agents, as seen in

Figure 1a [

24] (p. 23), that can interact with each other within an agency to achieve the goal of the system [

25] (p. 4).

This cooperative behavior enables individual agents to contribute to the emergence of a larger, integrated system [

26] (p. 20). The resulting architecture is distinguished by its high degree of decoupling and extensibility, facilitating the effective modeling of complex real-world scenarios. This is achieved through the flexible management of organizational structures, such as hierarchies, agent-oriented decomposition and agent-oriented abstraction [

27] (pp. 283–287). Additionally, these agents play a central role in the field of Artificial Intelligence (AI), as they can operate autonomously within an environment, acting as independent entities to achieve their objectives [

26] (pp. 10–12).

As seen in

Figure 1b, one agent (or multiple agents) operates within the system by interacting with its environment. Defined by the sequence of the agent function, an agent perceives certain signals by its sensor, following its own logic or reasoning on how to process the signal and forward a new signal via its actuators, which resolve in an action that influences the environment [

28] (p. 22 ff.) [

24] (p. 37).

Figure 1.

(

a) Hierarchical decomposition of agents in a multi-agent system [

24] (p. 23); (

b) an agent in its environment [

28].

Figure 1.

(

a) Hierarchical decomposition of agents in a multi-agent system [

24] (p. 23); (

b) an agent in its environment [

28].

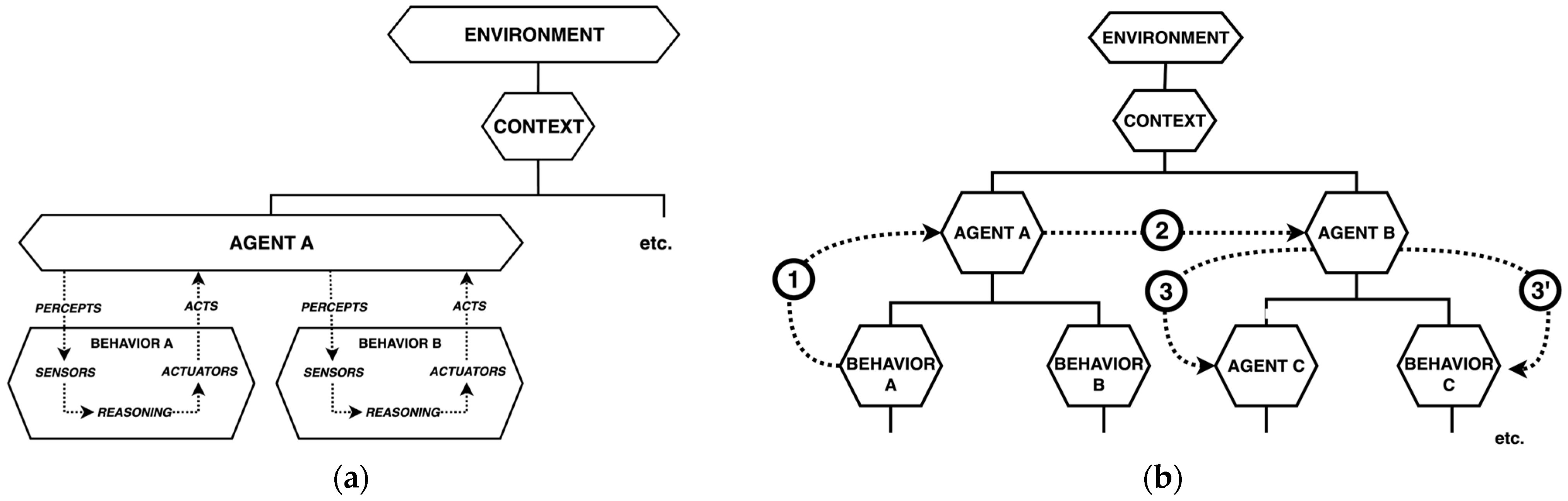

Based on Jennings [

26] (p. 14), the term “behavior” is employed as a generic descriptor for an integrated set of sensors, reasoning and actuators, as seen in

Figure 2a. To mitigate the complexity associated with diverse behaviors, minimize dependencies, increase extensibility and facilitate loosely coupled relationships between them, each behavior is decomposed into smaller sub-behaviors, following the architectural schema of the agent system. Furthermore, each agent follows the belief–desire–intention (BDI) model and has a unique state [

26] (p. 14), controlled by its behavior through its properties and memory, which enables it to maintain current and historical information gained by its sensor or own reasoning. For this research, the agents are rather reactive [

29] (p. 12), meaning they respond to environmental stimuli without engaging in proactive planning or decision-making activities, such that their behavioral responses are determined solely by the current agent state.

As previously stated, one or more agents operate within this model, interacting with their environment through a dynamic exchange of information within their common context [

27] (p. 281). Multiple contexts can exist within one environment, depending on the model simulation goals. Communication between agents occurs via messages with additional information, whereby changes in their state are published as events. To increase loose coupling between agents, behaviors’ emitted messages do not include their recipients; instead, each agent or behavior independently determines whether to act upon received messages or ignore them.

Figure 2b shows a simplified message flow, where (1) Behavior A emits a message via its actuator through its Agent A. (2) Agent B actively listens to messages of Agent A. (3) Agent C receives a message forwarded as child agent of Agent B. (3′) Behavior C receives a message via its sensor and decides further reasoning based on the message.

Based on Russel and Norvic [

30] (pp. 44–46), the environment for this research is characterized as known, partially observable, sequential, semi-dynamic, discrete and deterministic within the bounds set by the initial simulation input parameters. Utilizing the environment as a discrete event simulation enables the solving of queuing problems [

31] by the evaluation of system performance under various operational scenarios [

32] (p. 16) (e.g., using different scheduler agent behaviors). This approach allows the identification of critical bottlenecks and inefficiencies, providing valuable insights into how changes in operational decision-making increase or decrease the overall system performance [

32] (p. 4).

2.2. Rice Harvesting Operation Model

2.2.1. Methodology

By applying previous theoretical concepts, an agricultural context is established that comprises a blueprint of various agents, including the climate, which plays a major role in agriculture and production facilities like farms or rice centers. As seen in

Figure 3a, the hierarchical tree structure supports organizing agents horizontally along the value chain of agricultural production, e.g., passing goods from production facility A for further processing to production facility B. The structure also facilitates the vertical expansion regarding the level of detail to capture specific characteristics of the model. Each agent is capable of having one or more behaviors, each with its own distinct sensors, logic and operational rules.

Building on previous theoretical concepts, we establish an agricultural context using a multi-agent system (MAS) framework. This system includes key agents such as climate and production facilities (e.g., farms and rice centers). As illustrated in

Figure 3a, a hierarchical tree structure organizes agents both horizontally, across the agricultural value chain (e.g., passing goods from one facility to another), and vertically, to allow detailed modeling of specific operations. Each agent can possess one or more behaviors, with distinct sensors, logic and operational rules.

To adapt this MAS framework specifically to Japanese rice harvesting, we incorporate domain-specific knowledge along the rice crop cycle—from pre-harvesting to post-harvesting stages. This includes land preparation, water management [

33] (p. 257 ff.), planting (either direct seeding or transplanting) and the application of fertilizers, pesticides and herbicides [

34] (p. 239 ff.). Post-harvest processes include transportation, cleaning, drying and packaging [

35] (p. 530 ff.). The main focus of this study is on the harvesting phase and closely related logistics, especially transportation.

As shown in

Figure 3b, the adapted model includes three primary agents: weather, rice center and farm.

Weather agent: Emits daily weather observations relevant to the simulation area, influencing crop growth and harvesting decisions.

Farm agent: Serves as the central controller of field operations. It manages planting schedules, monitors field and crop conditions and coordinates harvesters and trucks.

Rice center agent: Acts as a processing hub for rough rice delivered by trucks. It performs post-harvest tasks such as cleaning and drying, ultimately producing brown rice.

While planting is not the study’s focus, a planter agent is included to complete the system architecture. It executes a predefined planting plan, placing rice varieties into specific fields on scheduled dates and initializing the crop cycle. In practice, planting dates are often determined by farmers’ experience.

Other specialized agents include the following:

Truck agent: Listens for signals (e.g., full grain tanks from harvesters), navigates to the field to collect harvested rice and delivers it to the nearest rice center.

Field agent: Detects planting events and spawns a subordinate crop agent that grows in response to daily weather updates. It also monitors and reports crop and harvesting status. Once harvesting is complete, the crop agent is removed.

Harvester agent: Receives orders from the farm agent, travels to the target field and performs harvesting. Harvesting may pause or end due to (i) field completion, (ii) grain tank full, (iii) end of the working day or (iv) exceeding the time window for harvesting—risking crop loss. Additionally, switching between rice varieties requires a cleaning process to avoid contamination.

2.2.2. Implementation

The proposed solution is based on the discrete event simulation library SimPy (Version 4.1.1) [

36], which builds the foundation of the discrete environment. The multi-agent system is realized by introducing a generic agent, which encompasses a memory of different properties and the current state. This agent can also accommodate multiple message listener capabilities, allowing it to directly consume messages from other agents. The proposed design enables agents to be generic in nature, and they are mainly identified by their attached behaviors (also called ‘duck typing’). Behaviors can be triggered by specific messages, perform an action, change the state of the agent and distribute messages based on their own logic and reasoning.

The main focus of this research work is primarily on the harvesting and unloading process, with specific requirements derived from interviews with Japanese rice farmers in Central Japan. The following preconditions were established:

Harvester Operations

While only one harvester can work on a single field at a time, multiple machines are able to operate independently on different paddy fields;

When switching between rice varieties, harvesters require a time-consuming cleaning procedure to avoid contamination of the rough rice;

Once the end of the workday approaches, no new harvesting orders will be sent out to harvesters;

Harvesting typically only occurs during daylight hours, with a fixed number of working hours to prevent major overtime and the limitation that rice centers, operated by Japan Agricultural Cooperatives, have fixed opening times.

Unloading/Logistics

Trucks must transport all harvested rice to the closest rice center during the day;

By the day’s end, all grain tanks need to be completely cleared of the rice to avoid moisture damage, due to the absence of farmers’ own on-site storage facilities;

In Central Japan, it is common that machines remain at their final location each day, rather than being returned to a central garage facility.

Crop Management

By considering these local requirements, the following specific behaviors have been implemented: The farm agent has multiple scheduler behaviors, which enables them to manage planters, trucks and harvesters. Therefore, the farm is capable of assigning specific vehicle agents to designated field agents based on their current states and specific tasks. The selection criteria of these agent pairings can be predetermined through queuing policies. As seen in

Figure 4a, it evaluates the state of a specific harvester (e.g., idle) and matches it with an evaluated field, which is ready to be harvested. Different queueing policies can be applied, like the basic First In, First Out (FIFO), or more advanced ones like the closest field policy. FIFO always serves that item which arrived first, while closest field selects the item pairs which have the smallest distance from each other.

The weather agent behavior is able to process historical or synthetically generated weather data based on existing approaches like WGEN [

37]. On a daily basis, the behavior emits weather observations, including properties like precipitation, solar irradiance and temperature for a specific region through the model’s environment. Initiated by a planter, the field agent detects the planting of a crop and generates a sub-agent, which receives the regional weather observations. The crop growth behavior is based on an adapted version of the rice crop model SIMRIW (SImulation Model for RIce-weather relations) [

7]. SIMRIW simulates rice growth considering temperature and solar radiation. Once the farm agent’s behavior evaluates the maturing field state by parameters like the Difference Vegetation Index (DVI) provided by the crop model, the field will automatically be added to the harvesting queue. Idling harvesters can then receive a work order to harvest a specific field. While processing the work order, the harvester can be in different states like driving, maintenance (cleaning), unloading, waiting or the actual (combined) harvesting state, as seen in

Figure 4b. Once the truck reaches the specified rough rice carrying capacity or the workday is over, the behavior enables the truck to drive to the closest rice center to unload its goods.

2.3. Experiment

Two simulations are run with the model covering different scenarios to evaluate the functionality and impact of different input parameters as well as adjusted behaviors to real-world scenarios. General farm polygon data is utilized from a local farm in the Chita area, Aichi Prefecture, Japan. Together, three farmers manage hundreds of small paddy fields with multiple rice varieties and two different planting types (transplanting and direct seeding). The fields are scattered within a radius of around 12 km with a median field size of around 0.13 ha. Two Kubota combined harvesters (DR595 and DR472) with an average harvesting speed of 21 sqm/min are used. A truck for unloading with a loading capacity of around 7.2 cubic meters of rough rice is utilized for daily delivery to the closest three rice centers. According to farmers, rice can only be harvested during a two-week time window after the maturity date, before crop loss occurs.

2.3.1. Model Verification Scenario

The primary objective of the simulation is to verify the overall functionality of the model by comparing its output with historical data on harvesting operations. Due to a lack of historical agricultural operational data in 2023, a limited KSAS (Kubota Smart Agriculture Solutions) [

38] dataset is leveraged, which provides daily harvesting data for a single rice variety (Aichinokaori) across 160 fields (0.10 ha median field size, 18.24 ha total area) with different planting methods. To compensate for missing historical planting data, a built-in crop simulation (based on SIMRIW) is utilized. This retrospectively estimates the initial planting dates for each field based on their maturity dates and historical weather data obtained from the closest AMeDAS (Automated Weather Observation System) [

39] station. This leads to a planting plan of 118 transplanted and 42 direct-seeded fields from June to July 2023. Two harvesters are utilized and the impact of the scenarios on agricultural productivity is analyzed by comparing total harvested area to the historical KSAS dataset.

2.3.2. Operational Efficiency Scenario

The objective is to explore simulation model capabilities (i.e., different harvesting strategies and external events that affect the overall efficiency of rice harvest). It covers the harvesting and post-harvesting operations.

Additionally, the extensibility of the model is shown by adding rice processing behavior to the rice center agents: the rough rice is accepted, immediately processed and then added to the stock, discounted by a factor that appears during cleaning and drying.

To perform the experiment, two different rice varieties (Aichinokaori and Koshihikari) are virtually assumed on the 160 fields from the first experiment. To avoid rice contamination between these varieties, the harvester has to be cleaned when a variety is switched. A narrow planting plan, simulating closely aligned maturity dates of the rice, is executed. This strategy creates an overall shortened harvest window which reflects the reality according to the farmers. Harvesting rice is not feasible during rainy weather conditions: if the daily precipitation level exceeds 2 mm, the harvesting process will be halted for the whole day. The default selection of a work order (harvester and field) is a FIFO queue policy. To evaluate alternative strategies, a closest field queuing policy is evaluated, prioritizing harvester deployments to the nearest available field. As a baseline for the harvester scheduler, a FIFO queueing policy is applied. The model is run with one and two harvesters to assess the impact on the overall harvesting efficiency by comparing the harvested area and the duration of specific harvesting agent states, like harvesting, driving, cleaning and idling.

3. Results

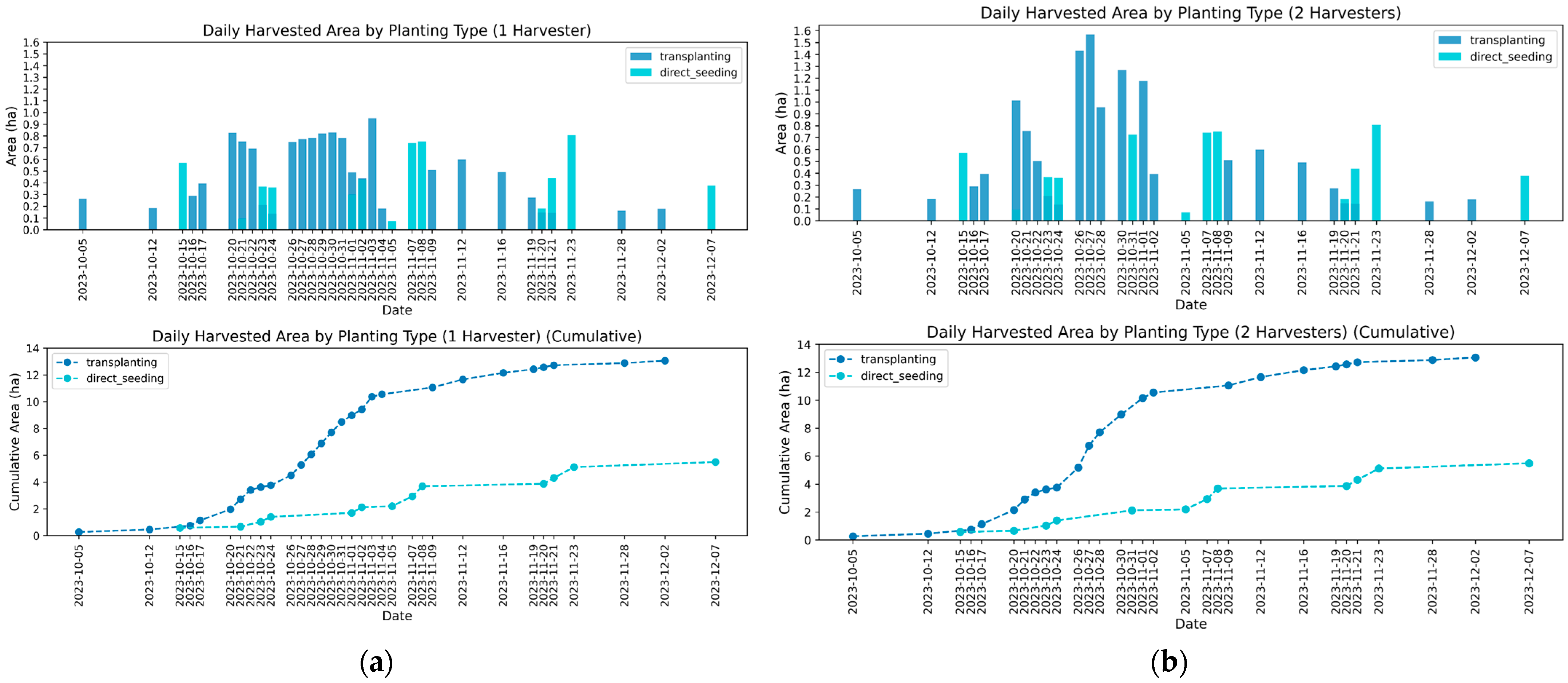

3.1. Model Verification Scenario

The simulations generated around 12,000 to 17,000 messages between over 330 agents, depending on the scenario. The initial verification simulation experiment demonstrated that one or two harvesters can harvest all fields of around 18 ha within the given harvesting season, as seen in

Figure 5. The main difference observed between the peak harvesting time (end of October) is that one harvester needs more days to complete harvesting. Utilizing two harvesters operating independently and parallel on separate fields resulted in parity of daily harvested area comparable to that observed in the historical dataset, where two harvesters were also used by farmers.

As seen in

Table 1, using two harvesters decreased the overall harvesting time, but also increased the relative idle time during the harvesting season per vehicle.

The use of two harvesters allowed a distribution of the overall workload and expedited the harvesting of mature fields, but also decreased the efficiency, as indicated by increased idle time.

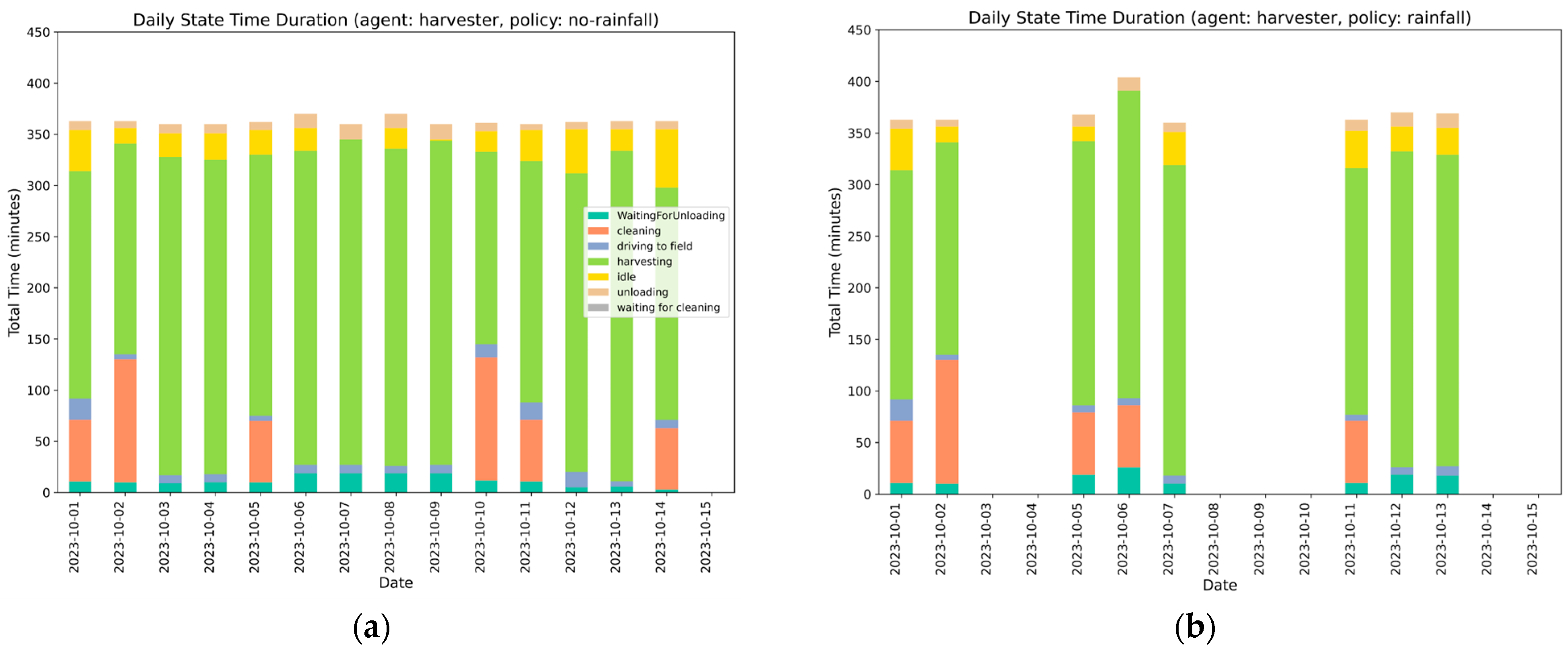

3.2. Operational Efficiency Scenario

The second simulation scenario provides insights into the operational efficiency of the harvesting model under external effects such as rainfall and different harvesting strategies. It also demonstrates the model’s extensibility and examines the effects of these factors on new agents.

As seen in

Figure 6, it is shown clearly that the implementation of a rainfall-based or non-rainfall-based harvesting policy has an effect on daily productivity. On days with precipitation, as seen in

Figure 6b, harvesting operations are temporarily halted as the harvesting scheduler receives daily weather observations, which trigger a suspension of harvester dispatching by the agent’s behavior. Therefore, harvesting agents remain inactive, and no state time is recorded.

As seen in

Table 2, in both cases, not all fields can be harvested within the narrow harvesting time window with one harvester. By ignoring rainfall on 73 fields, crop loss occurs. Including rainfall in the simulation leads to the loss of 107 fields due to senescence. This shows insufficient harvesting capacity in both cases, highlighting the substantial impact of precipitation on operation efficiency.

By applying different policies (closest field vs. FIFO) to the harvesting scheduler utilizing two harvesters, the impact on each state duration can be seen in

Table 3: general driving time decreases using the closest field policy, but cleaning time increases compared to the FIFO policy. The differences in the state durations result from the strategy of selecting the nearest field, which reduces travel distance but increases the mixing of different rice varieties, resulting in greater cleaning efforts.

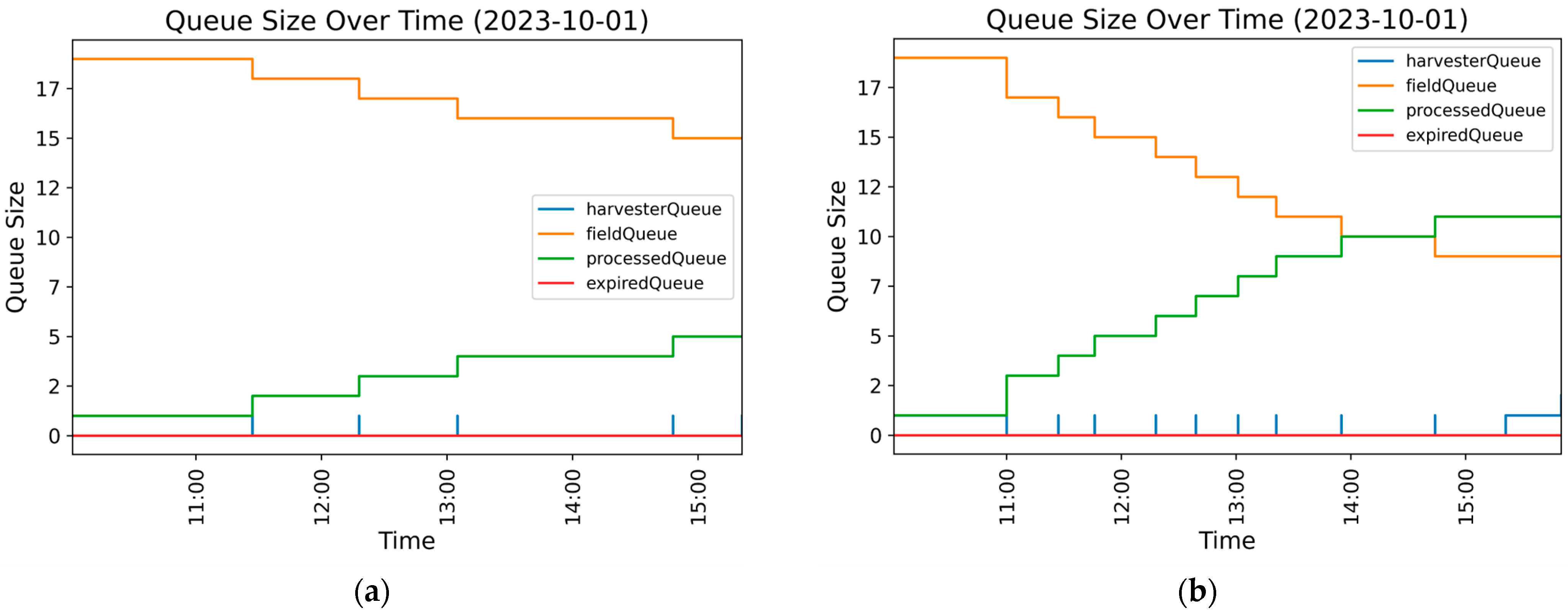

Figure 7 describes the queue size over time of the harvesting scheduler: the four queues are defined as follows: ‘harvesterQueue’ represents the set of all available (idling) harvesters; ‘fieldQueue’ contains all fields that reached maturity and are ready to harvest; ‘processedQueue’ records all harvested fields; and ‘expiredQueue’ contains all fields that have undergone senescence. The presented time window of

Figure 7 is set to the first day of the harvesting season, so no expired fields have yet been detected, as all fields are still within the optimum harvesting period.

As the number of harvesters increases from one (a) to two harvesters (b), the harvesting scheduler queues change, such that the field queue rapidly declines. Conversely, the processed field queue increases at the same pace.

Furthermore, the simulations reveal that the sequence of harvested fields is dynamically influenced by the increase in harvester numbers and the implementation of different harvester scheduling policies, resulting from the parallel operation of multiple harvesters. This dynamic behavior is a direct consequence of the parallel processing of harvesting tasks, which enables the system to adapt to changing conditions and share workload between multiple harvester agents.

Figure 8 illustrates the daily rice production at the additionally created rice center agent. In the first scenario (a), rice of the Aichinokaori variety primarily arrives at the rice center—indicating that this variety was generally matured and harvested first. In the second scenario (b), which applied the closest field policy, two different rice varieties were delivered to the rice center. Lower overall rice stock reflects inefficiencies in farmers’ harvesting practices. Adding rainfall to the closest field policy, as shown in scenario (c), reveals that the rice center’s stock remains unchanged during rainy periods because no rice is harvested and delivered.

4. Discussion/Summary

The experiments demonstrate that the newly developed harvesting model simulates the historical harvesting behavior of farmers. Due to the limited historical data, the verification is currently restricted to simulating and comparing daily accumulated harvested areas. However, the model is capable of operating at a minute-level granularity, enabling more precise simulations.

The model highlights the negative impact of under- or over-allocation of harvesting resources. Furthermore, with minor adjustments to harvesting queuing policies, the multi-agent framework facilitates the simulation and analysis of individual agent behaviors. This includes dependencies on other agents (e.g., idle time or travel time) and the effects on overall performance metrics such as total harvested area.

The extensible multi-agent model allows the integration of external events (such as rainfall) with little effort and enables the analysis of the far-reaching effects that farmers face during their daily work. Since unharvested rice fields have an expiration date, it is important to take these external events into account in order to avoid crop loss.

The different harvesting queuing policies (such as closest fields) lead to decreased traveling time but an increased cleaning time as varieties are switched within a day. This needs to be carefully included in the decision-making process when scheduling the right harvesting order.

The model can be extended by incorporating additional agents of the value chain, such as a rice center, enabling high-level simulations to provide a comprehensive overview of the entire farm operation process. The interactions and dependencies among agents illustrate the harvesting complexity while highlighting the flexibility of the multi-agent model to adapt agent behaviors to various real-world scenarios.

By decoupling agents from one another, the model achieves a high degree of extensibility. This modularity enables the integration of existing domain-specific knowledge without requiring a complete redesign of the model. For instance, the model has been successfully extended by incorporating crop models, harvesting queuing policies, unloading processes and additional post-harvest operations. By simplifying specific decisions into localized queuing problems, the model facilitates the simulation of targeted changes and their cascading effects on the overall farm operation.

Despite the model’s strong performance across various scenarios, several limitations and challenges remain that must be addressed. One of the primary concerns is scalability, as the model’s performance may degrade when applied to larger or more complex scenarios involving thousands of additional agents and computationally intensive behaviors, potentially generating millions of messages. Although the model aligns well with real-world farmer behavior, additional interviews are necessary to gather further insights—either to refine and incorporate more precise behaviors or to extend the model to other regions or crops.

5. Conclusions/Outlook

The multi-agent farm operation model has demonstrated its capability to accurately simulate real-world harvesting behavior. Additionally, it supports farmers’ decision-making by enabling the application of various harvesting policies and calculating critical operational parameters such as harvested area, travel time, cleaning time and unloading time.

The model’s design emphasizes flexibility and extensibility by decoupling agents, allowing the seamless integration of domain-specific knowledge without requiring substantial changes to the underlying architecture. This adaptability extends across the agricultural value chain, making the model a versatile tool for simulating real-world scenarios and accommodating diverse agent behaviors. In particular, the simple implementation of new harvesting schedulers facilitates rapid prototyping and testing.

The model’s utility spans farmers, researchers and policymakers, offering insights to optimize farm management practices, reduce waste and enhance efficiency. Furthermore, its ability to simulate the impact of external factors, such as climate-change-induced weather variability, highlights its potential for building resilience in agricultural operations. By exploring different agent behaviors, policies and scenarios, the model can provide actionable recommendations for improving agricultural efficiency and sustainability.

Future research should address the need for more accurate historical data from farmers across multiple crop seasons to further validate the model, particularly for optimization purposes. Improved data availability will enhance the model’s precision and reliability, ensuring it remains a valuable resource for advancing agricultural practices. Additionally, the multi-agent system architecture is well-suited for the integration of reinforcement learning algorithms. This approach can enable the continuous improvement of specific agent behaviors by adapting and evolving in response to a changing environment, with a focus, e.g., on optimizing operational efficiency.