Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine

Abstract

1. Introduction

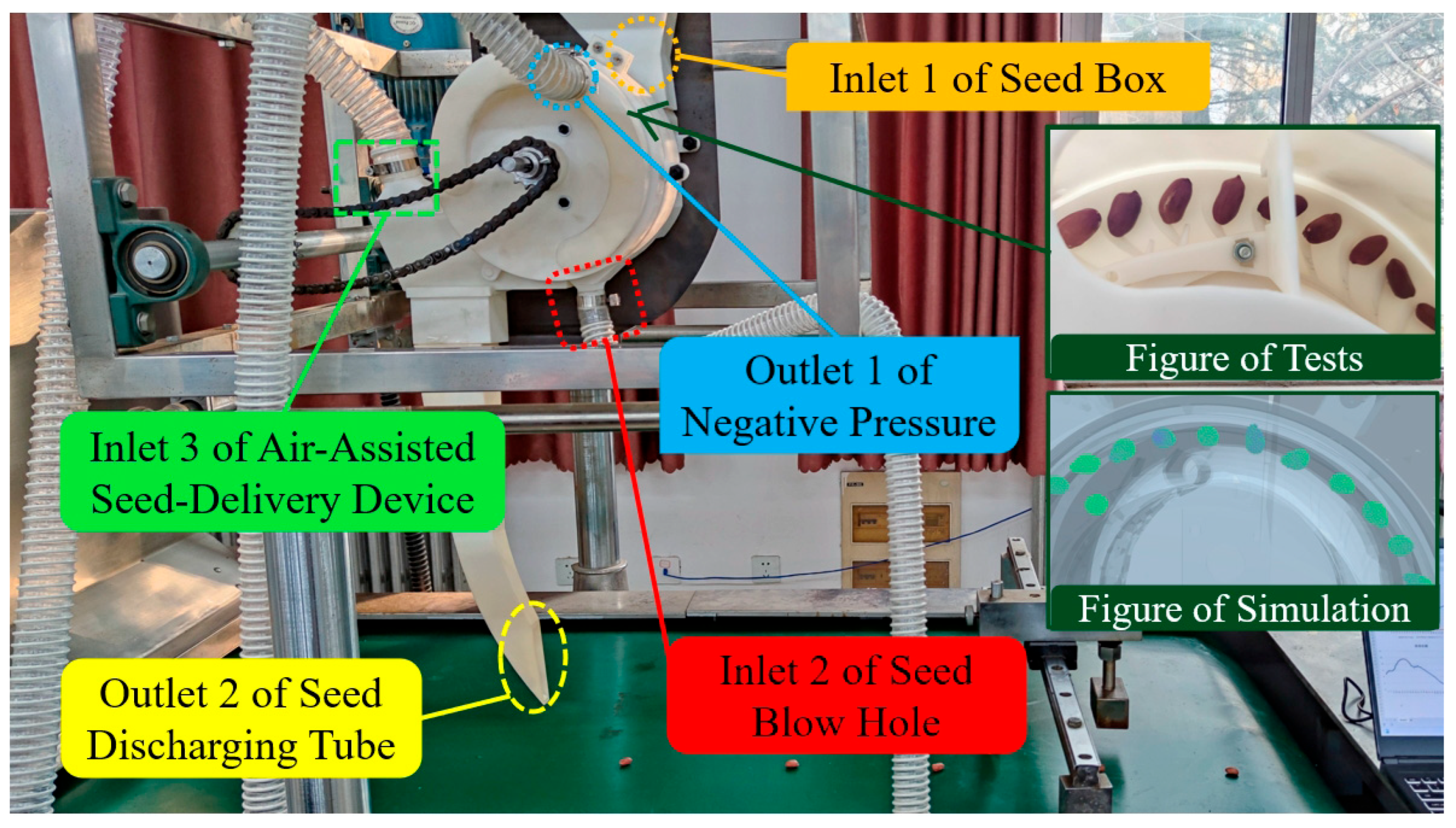

2. Materials and Methods

2.1. Structure and Principle of the Seed-Metering Device

2.2. DEM-CFD Coupling Model

2.2.1. Gas Governing Equation

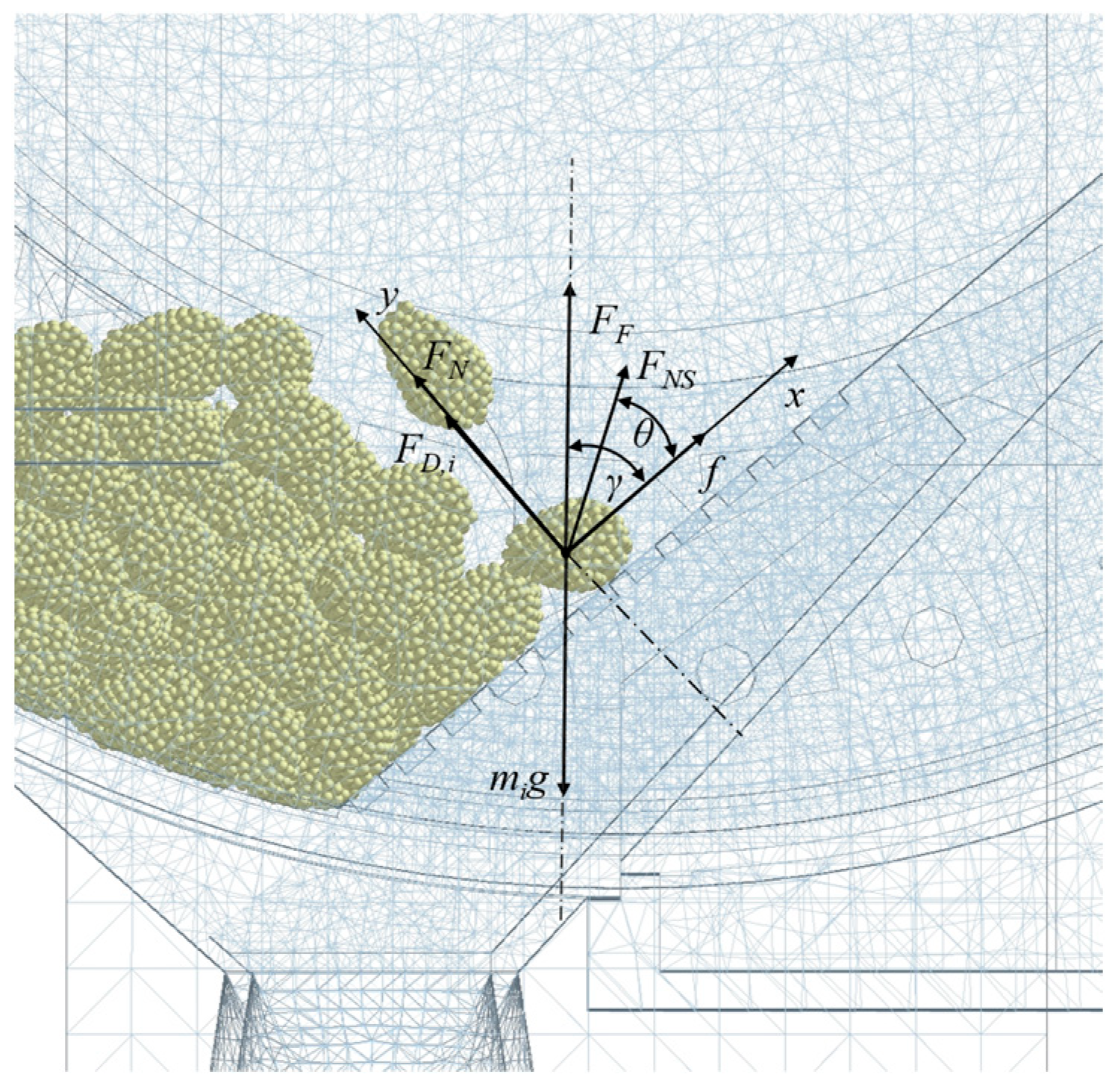

2.2.2. Particle Governing Equation

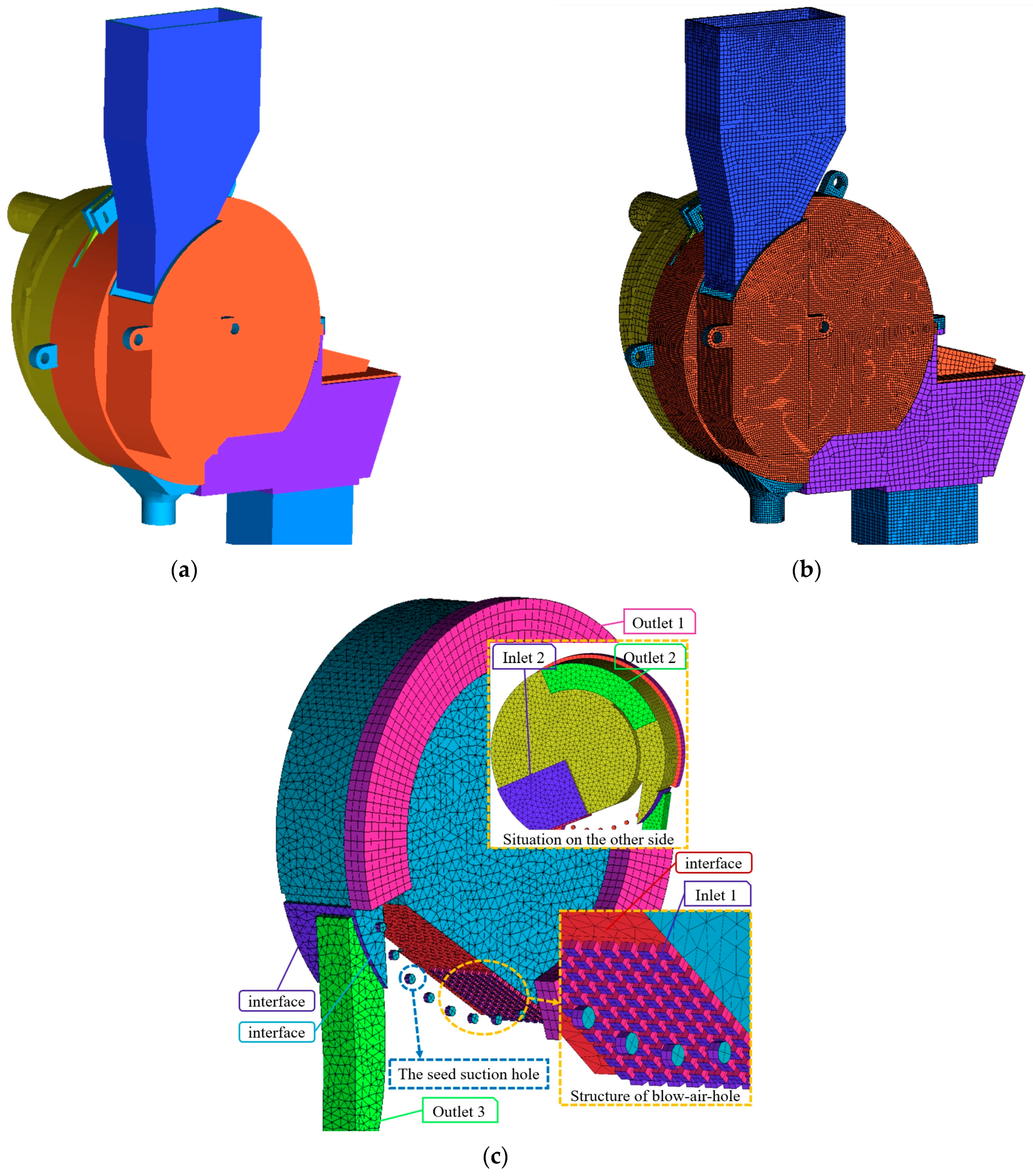

2.3. Simulation Model and Setting of Boundary Conditions

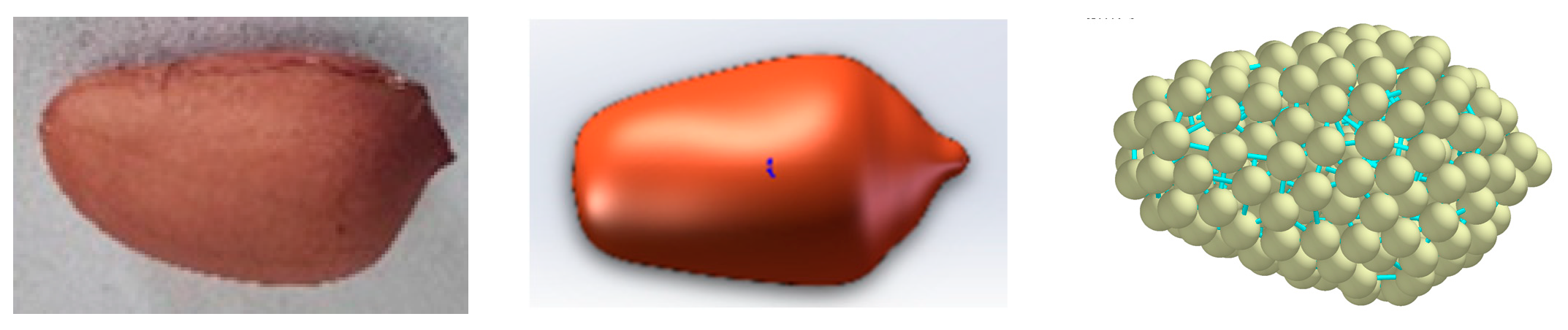

2.3.1. Particle Modeling

2.3.2. Geometry Modeling

2.3.3. Calculation Conditions and Parameters

2.4. Design of Experiments

2.4.1. Design of Experiments for Coupled Simulation Modeling

2.4.2. Design of Experiments for Response Surface Analysis

2.4.3. Test Indicators and Measurement Methods

3. Results and Discussion

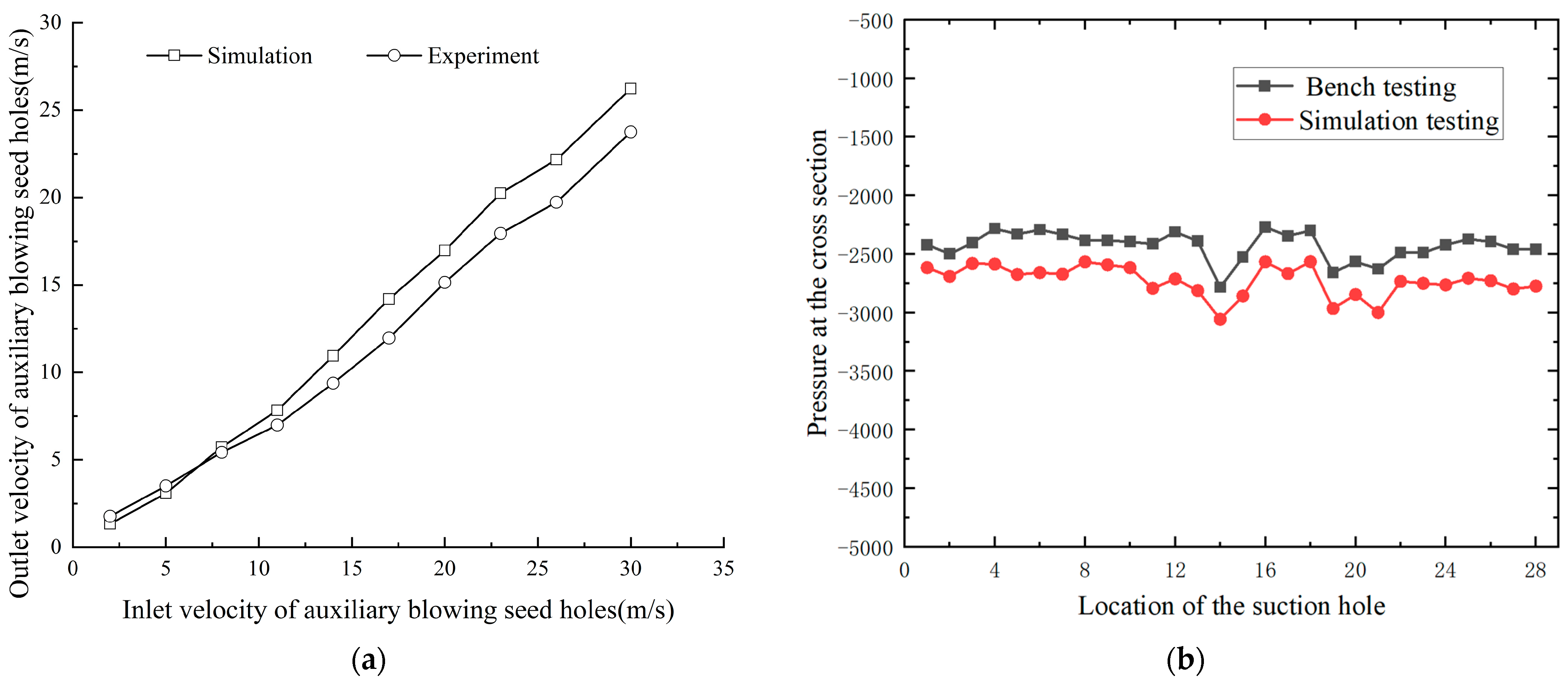

3.1. Model Validation Analysis

3.2. Gas–Solid Coupling Simulation Analysis

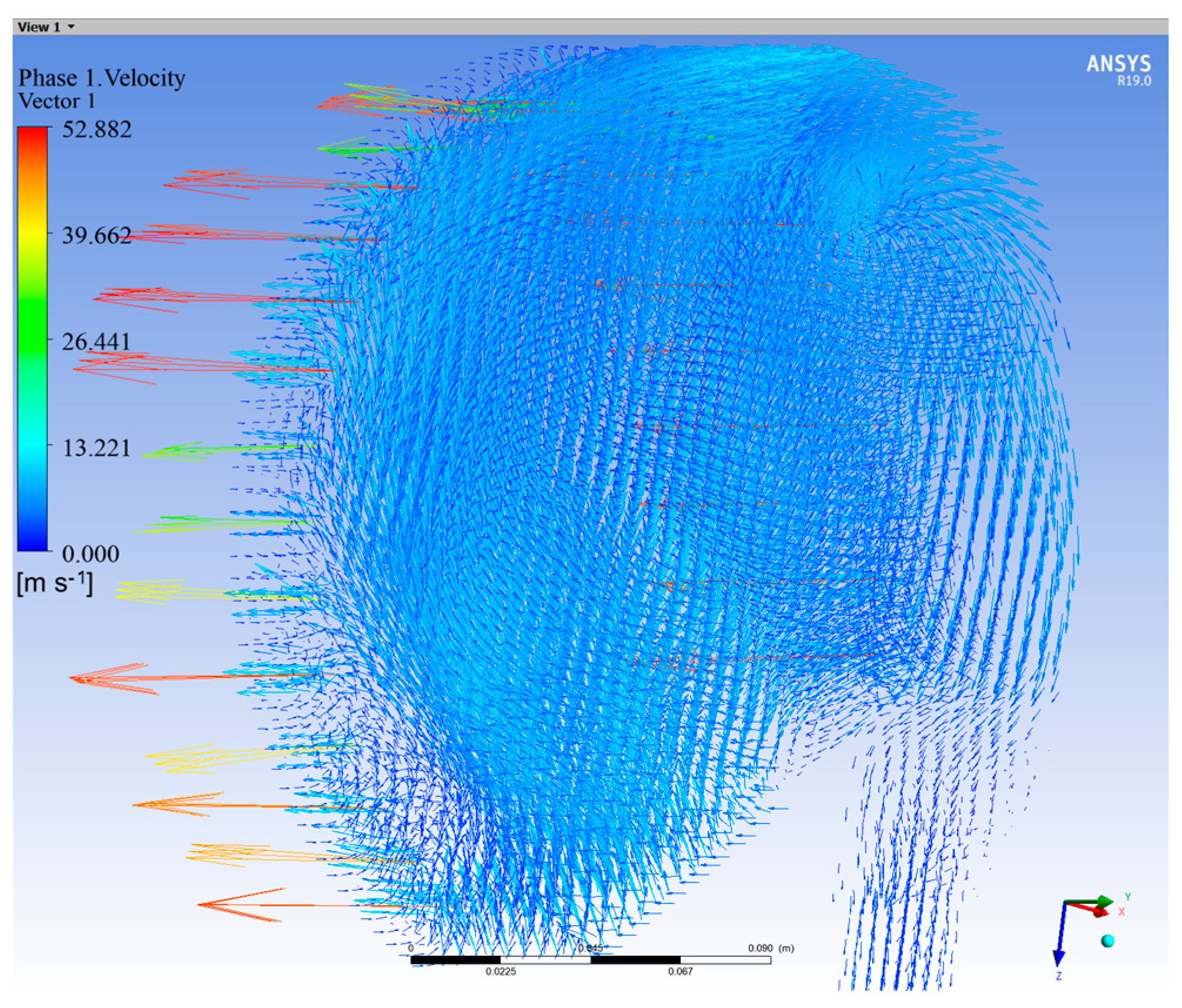

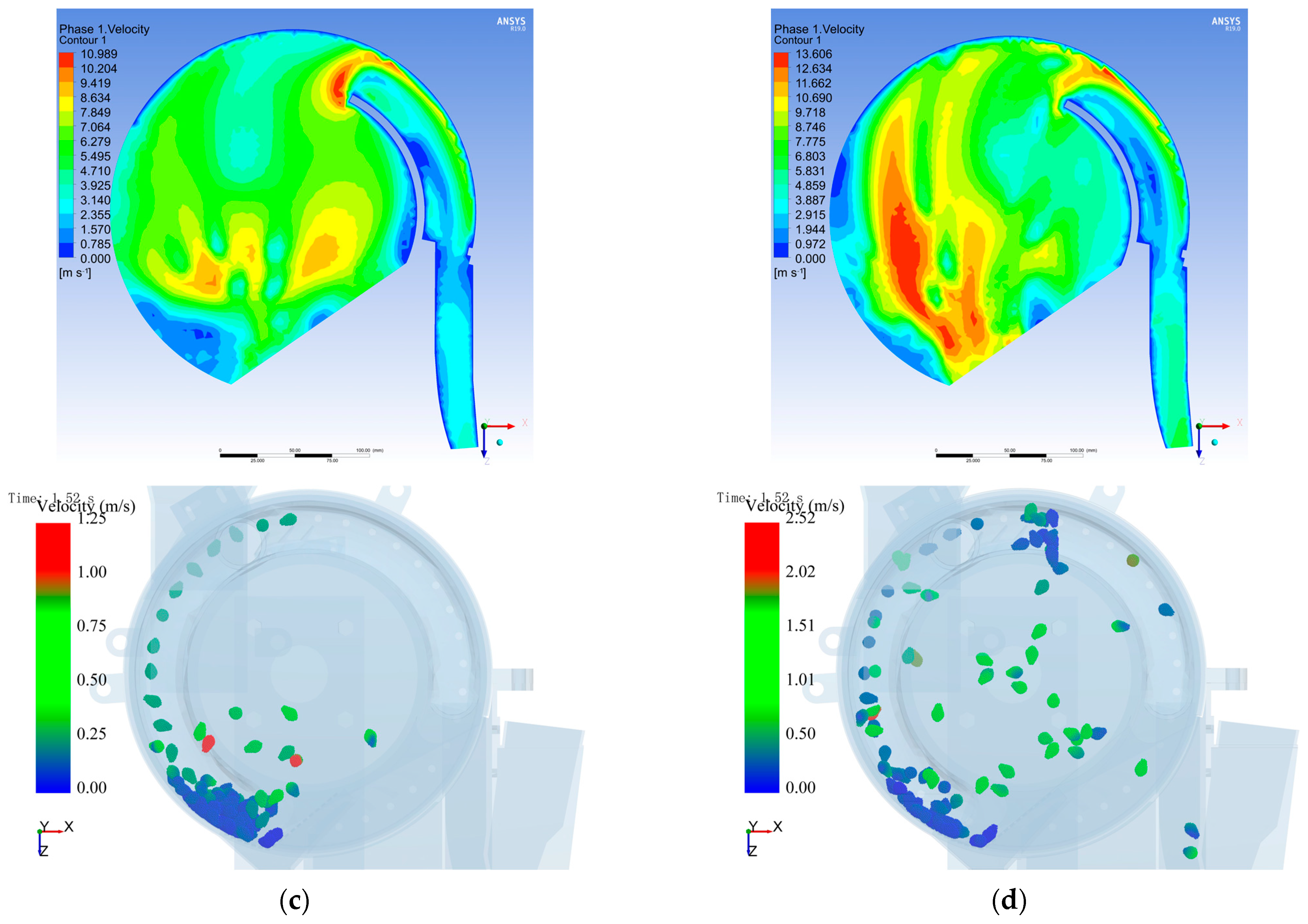

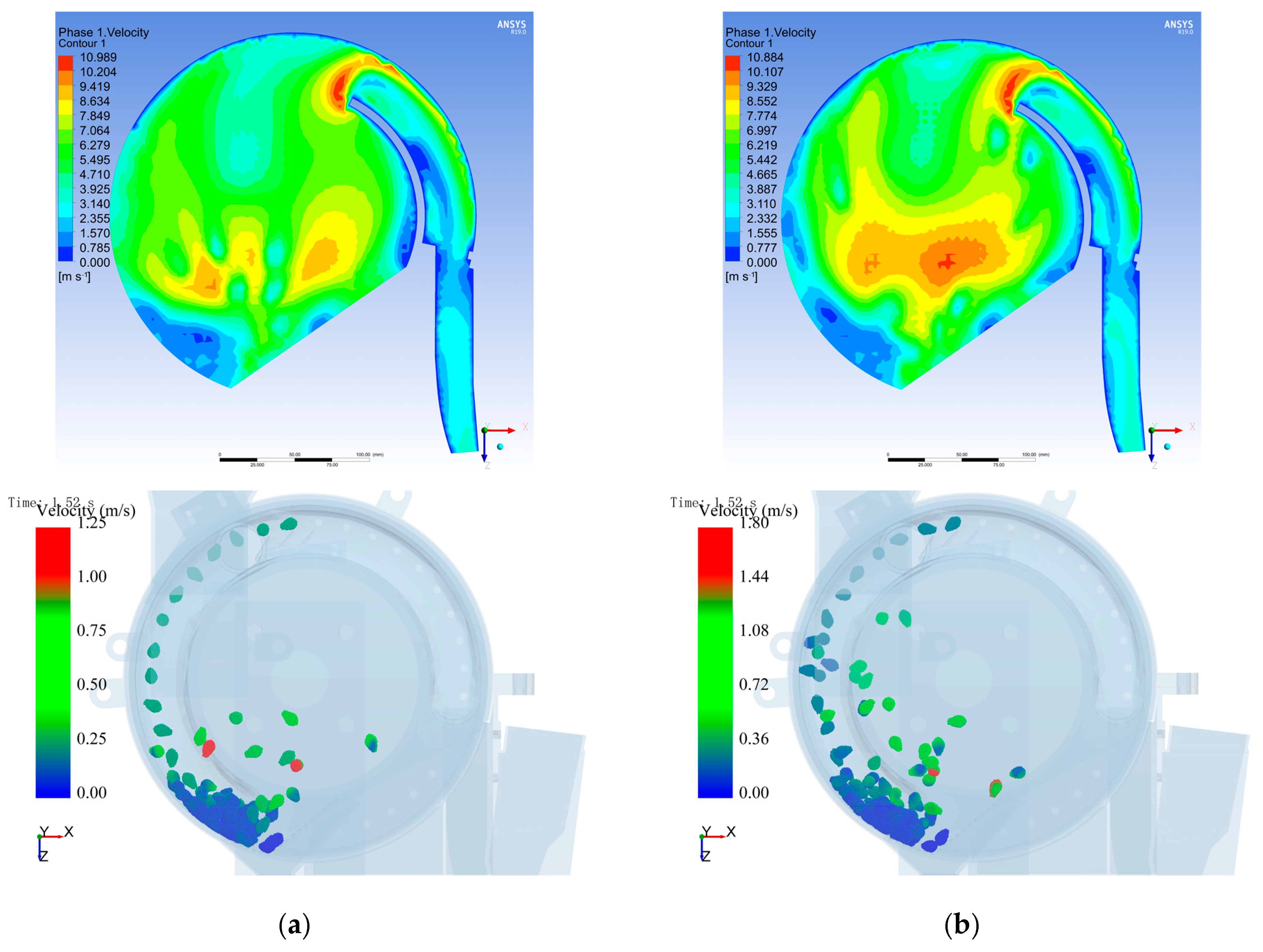

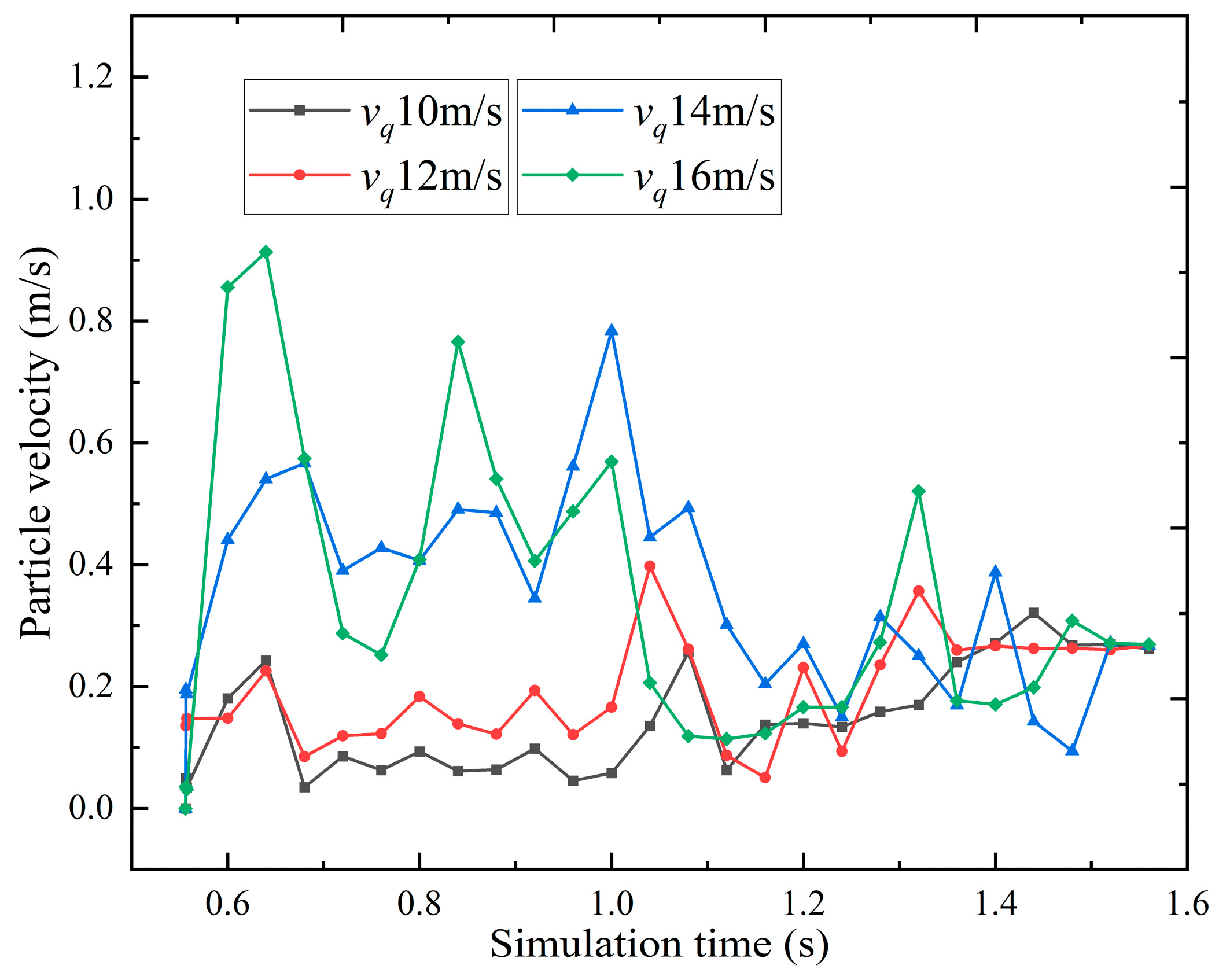

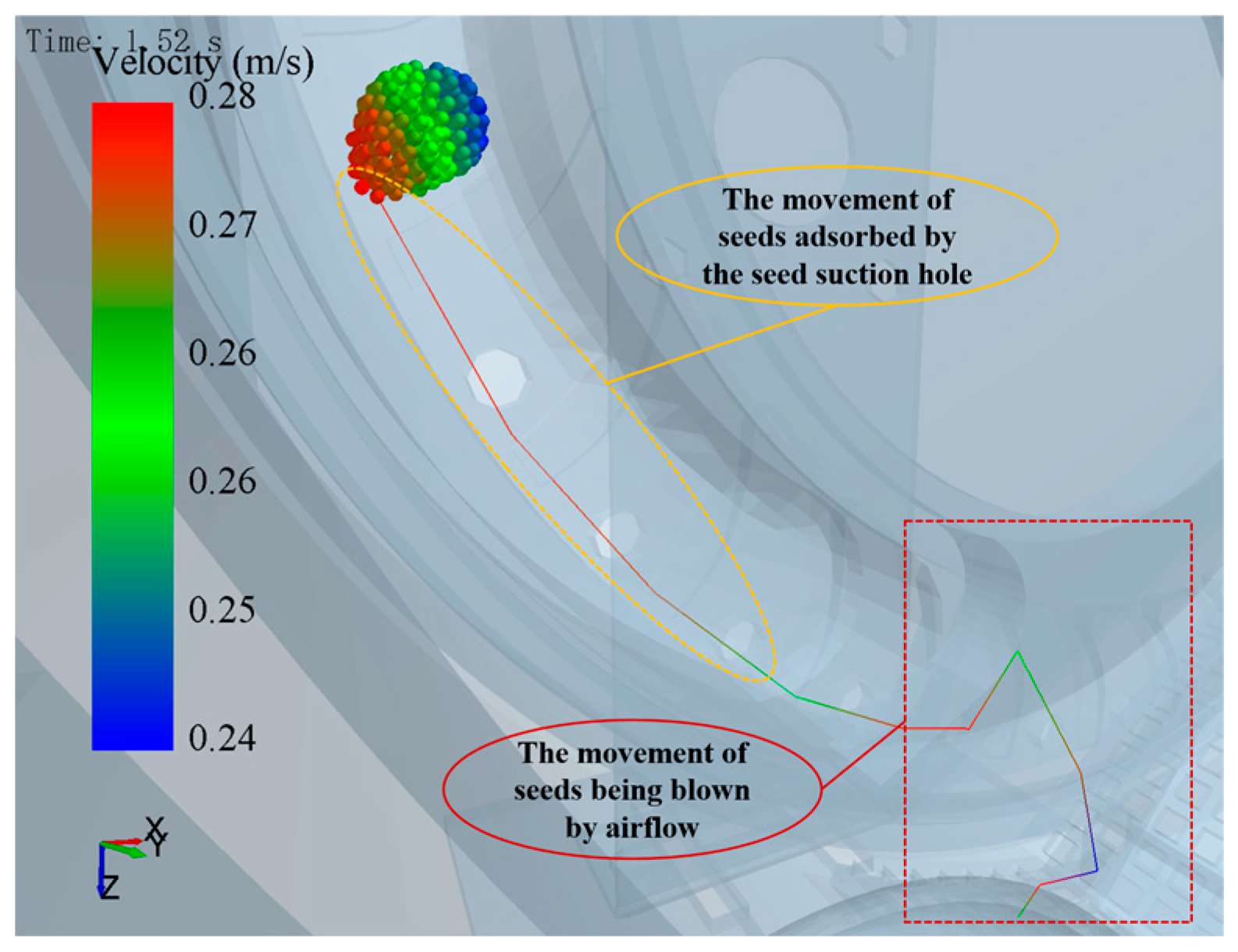

3.2.1. Characterization of the Airflow of Auxiliary Seed-Filling Devices

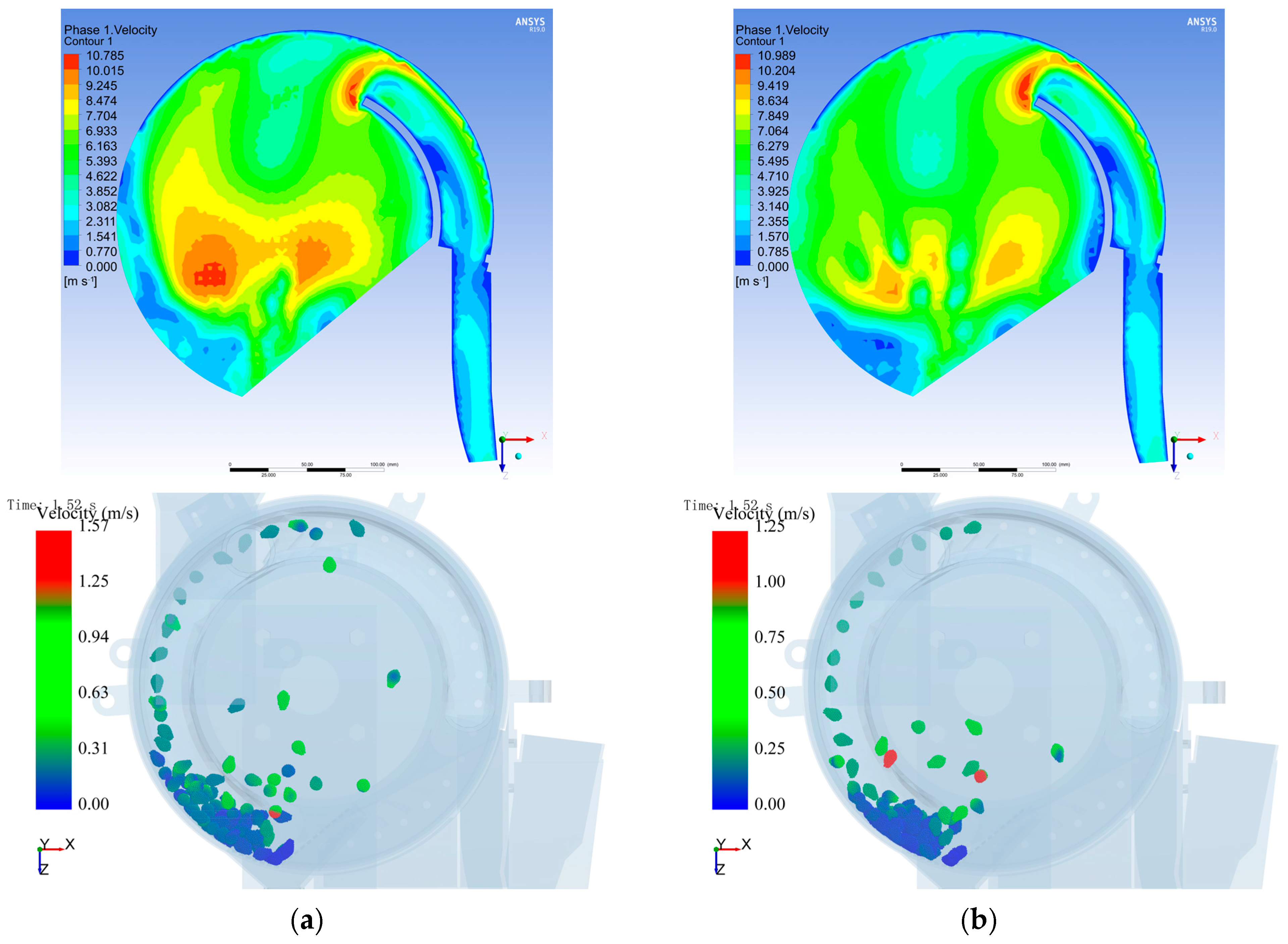

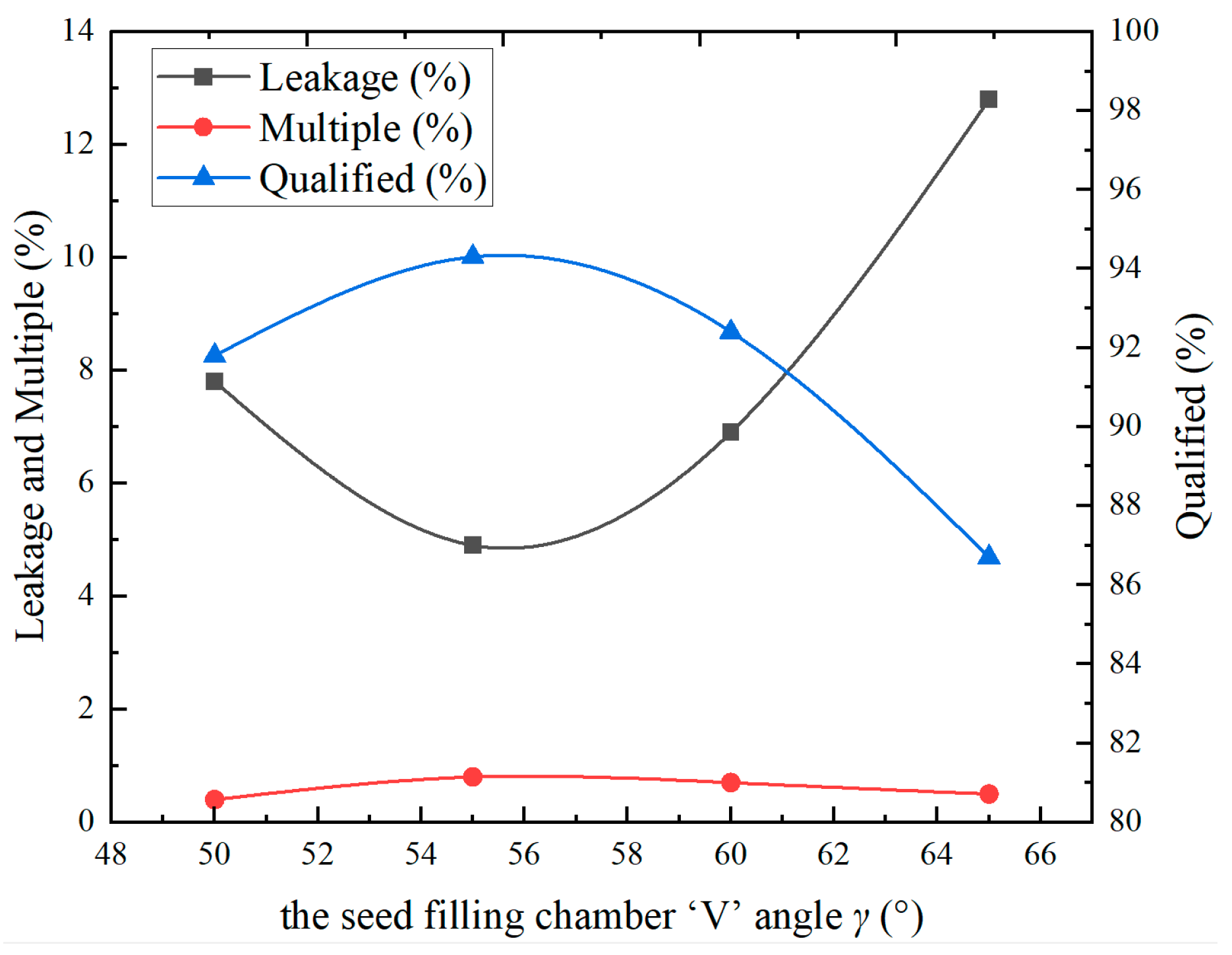

3.2.2. Single-Factor Simulation Test of the Seed-Filling Chamber ‘V’ Angle

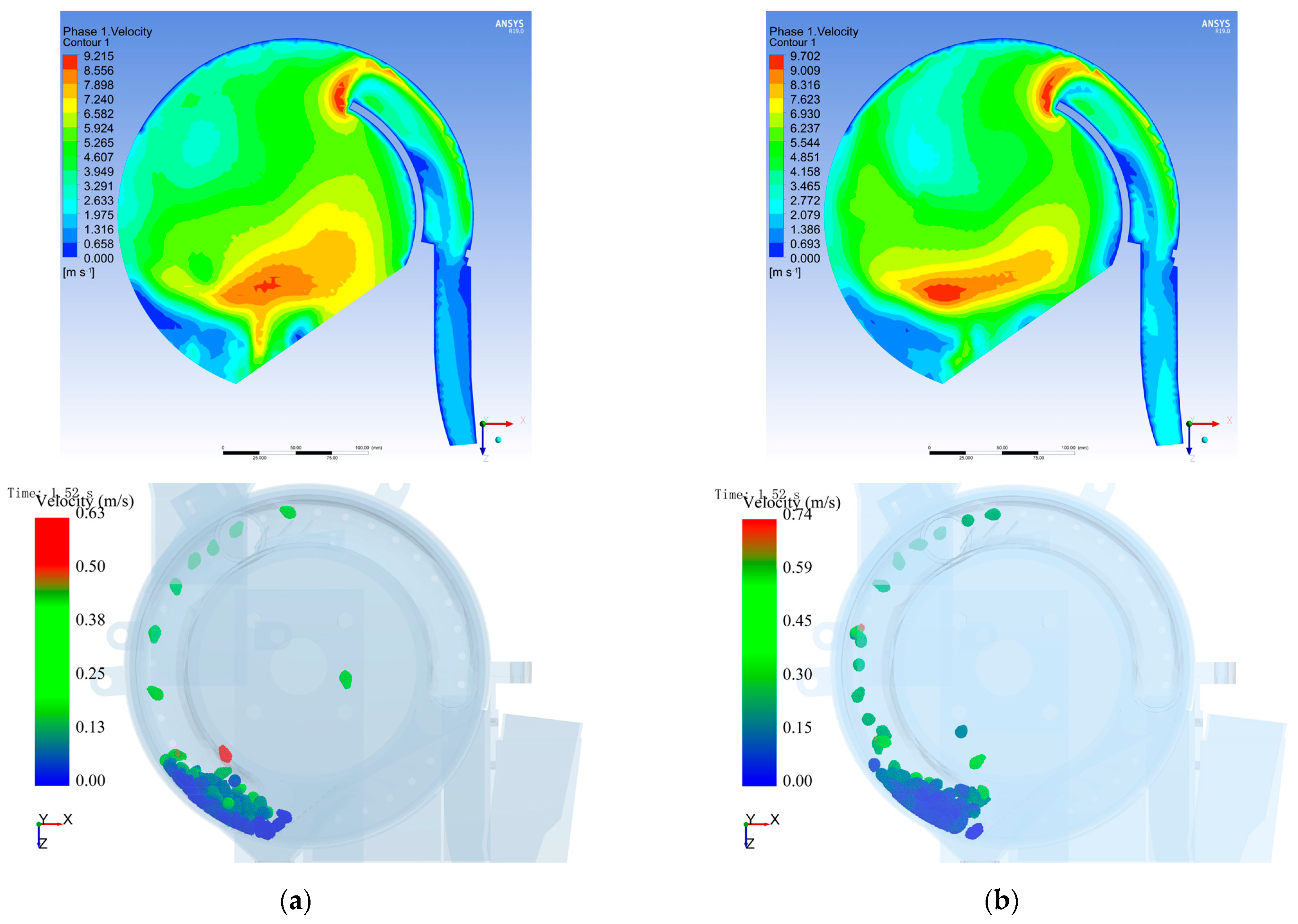

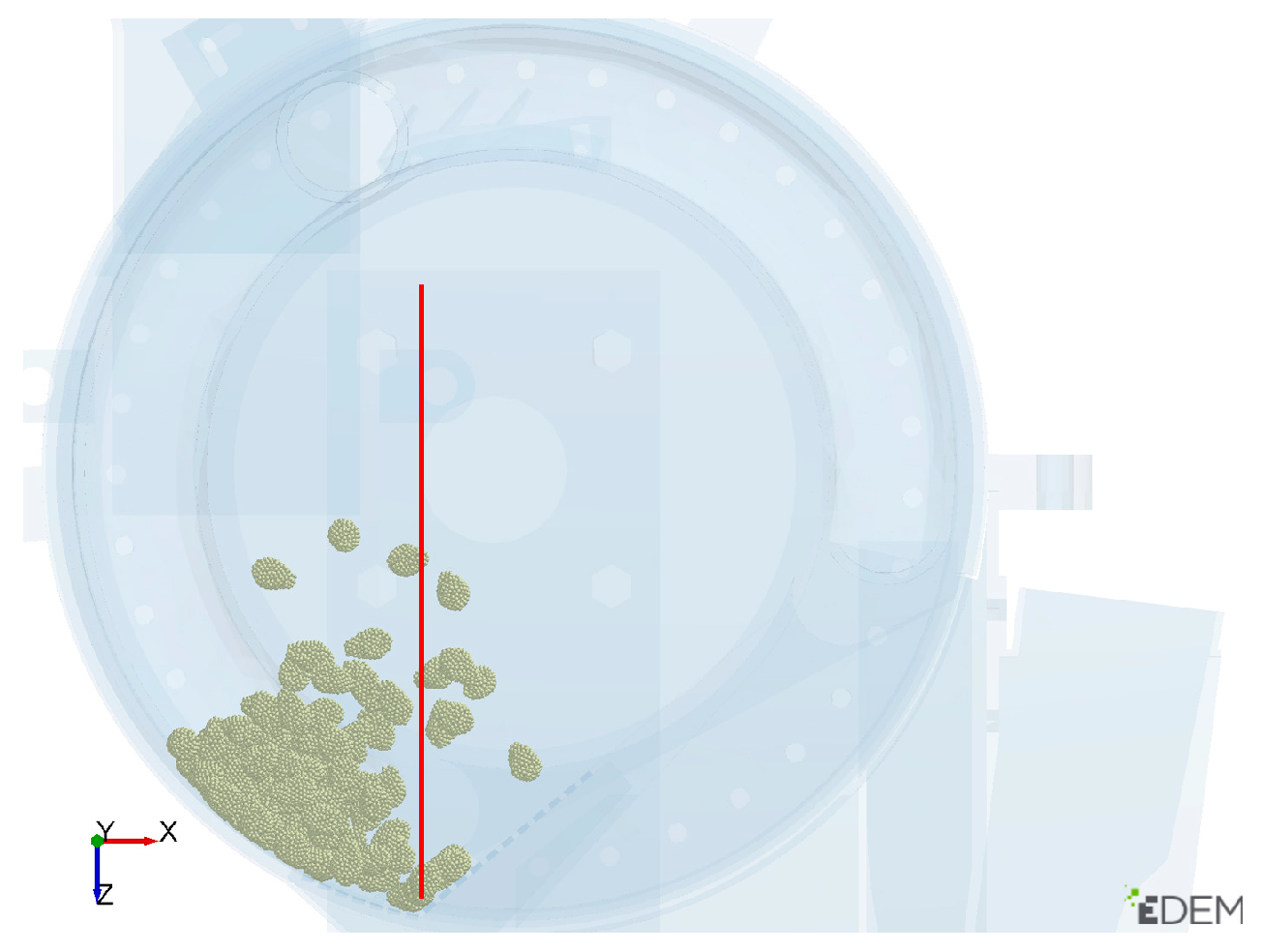

3.2.3. Single-Factor Simulation Test of the Bottom Blow-Air-Hole Cross-Sectional Area

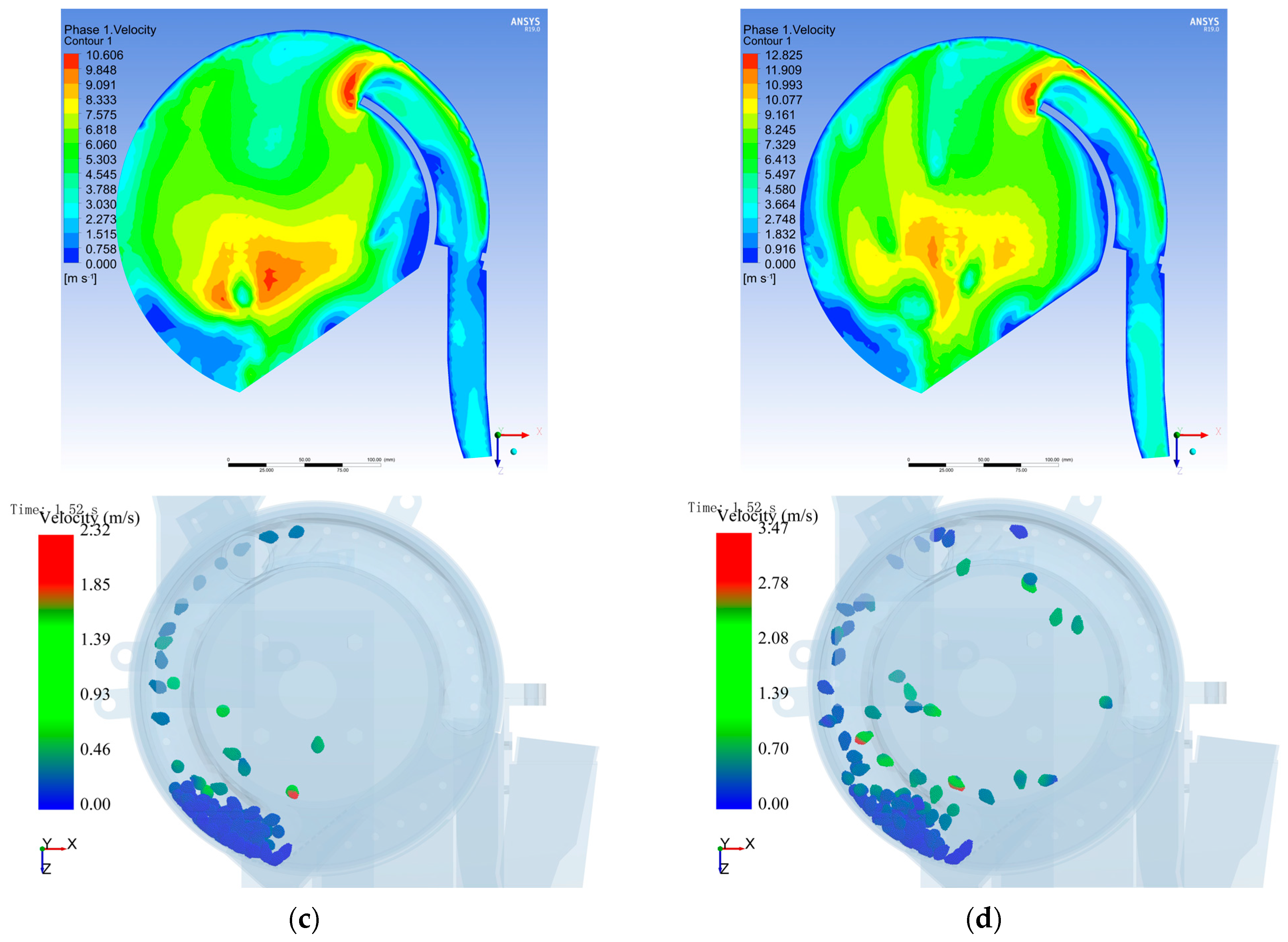

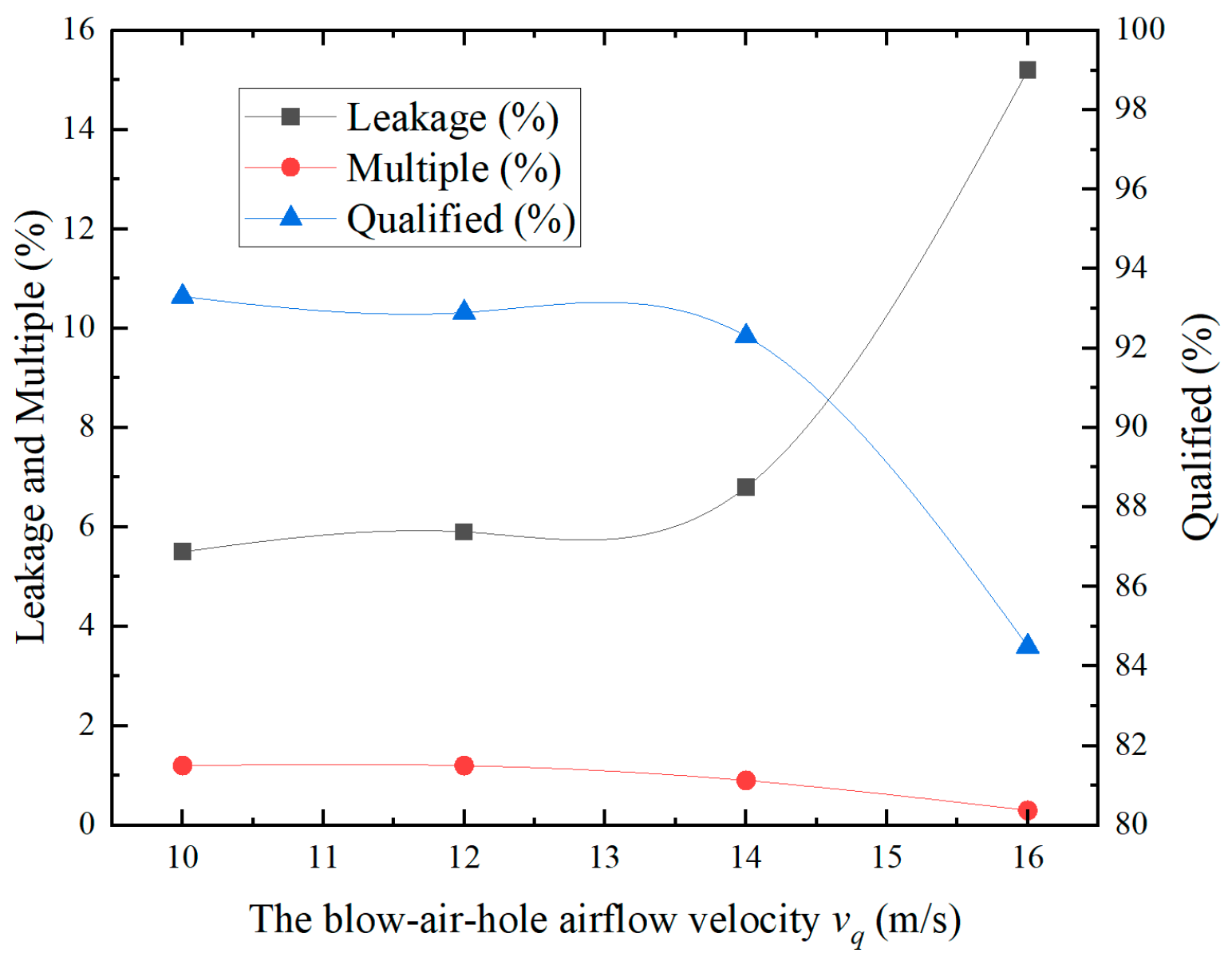

3.2.4. Single-Factor Simulation Test of the Blow-Air-Hole Airflow Velocity

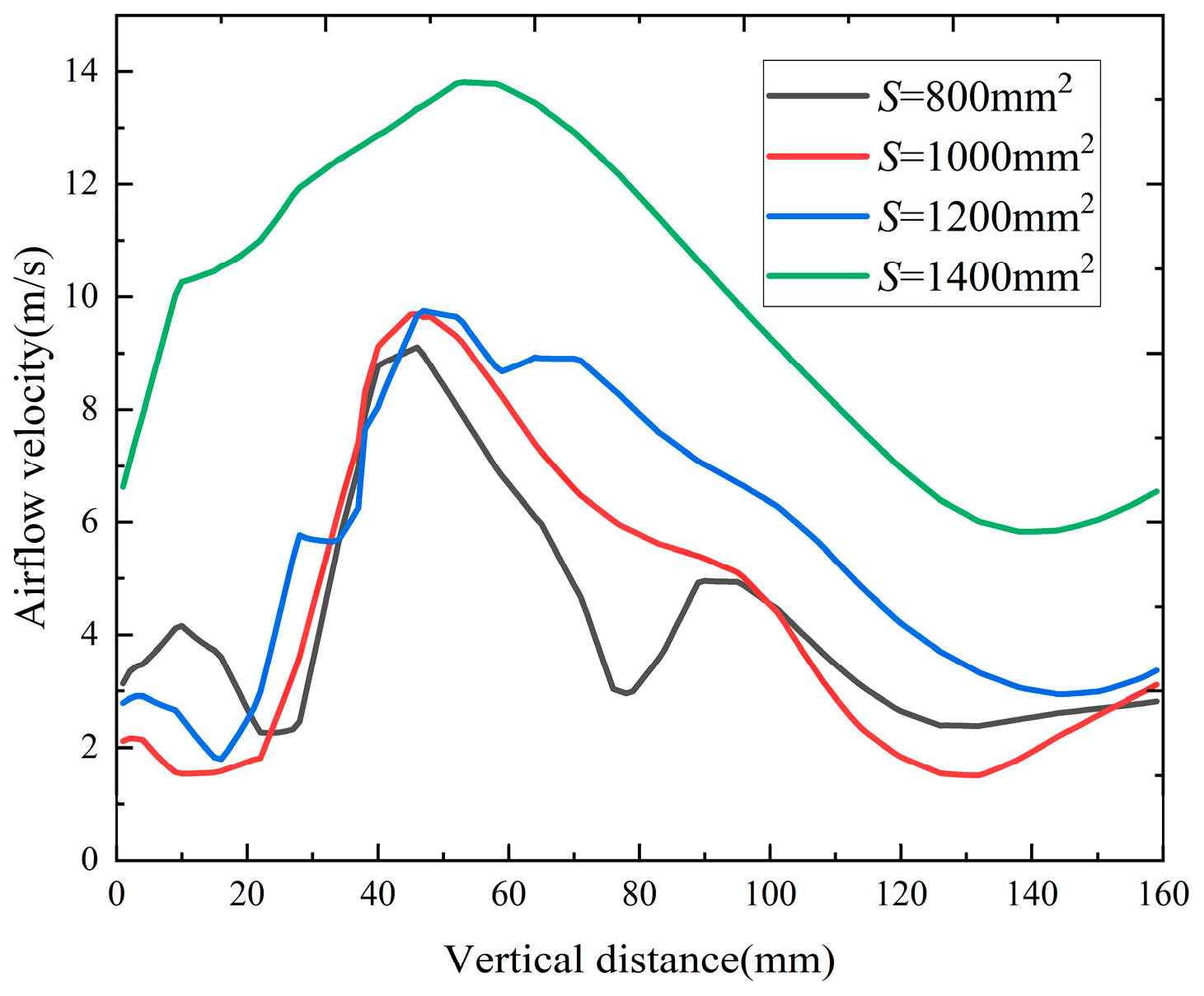

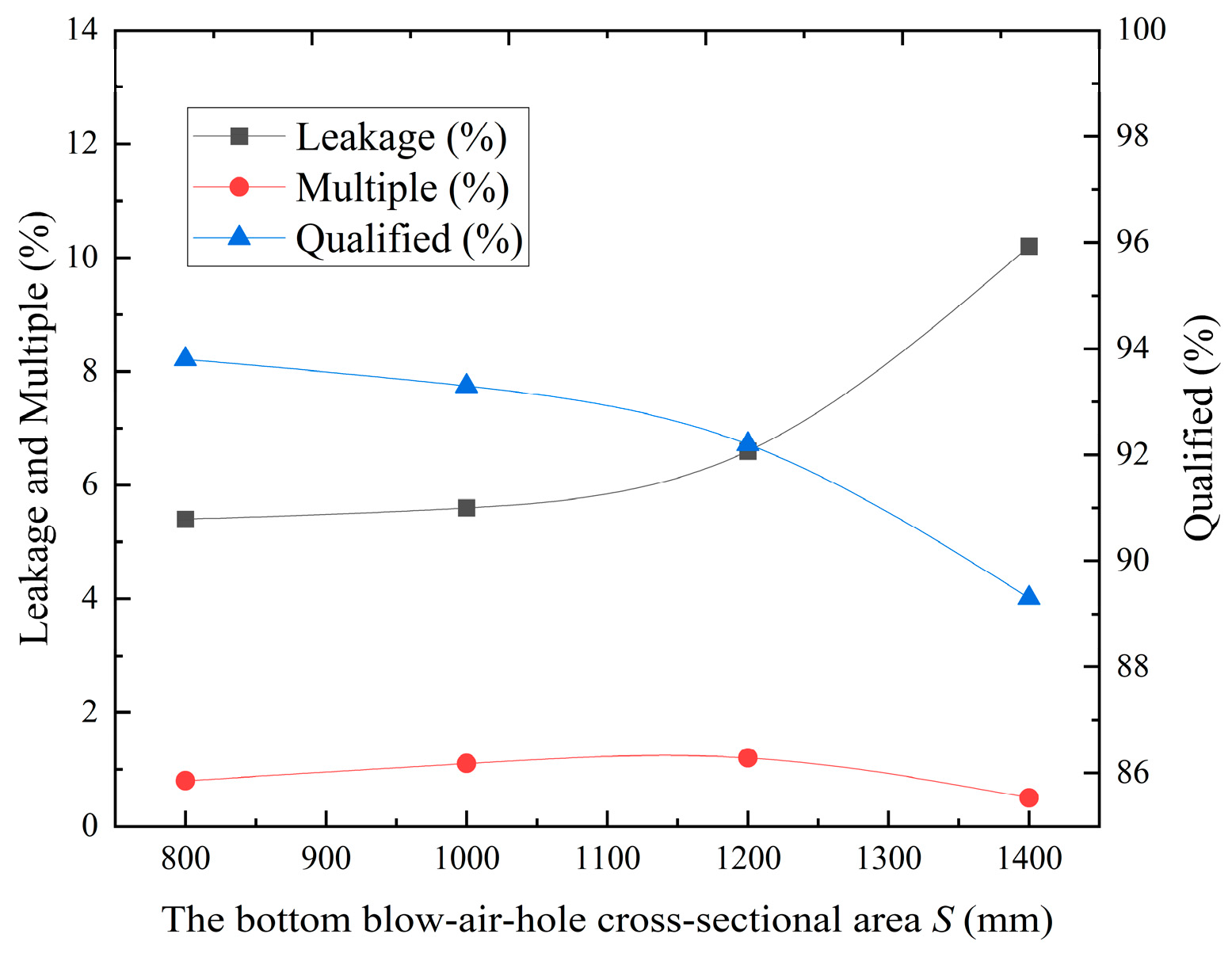

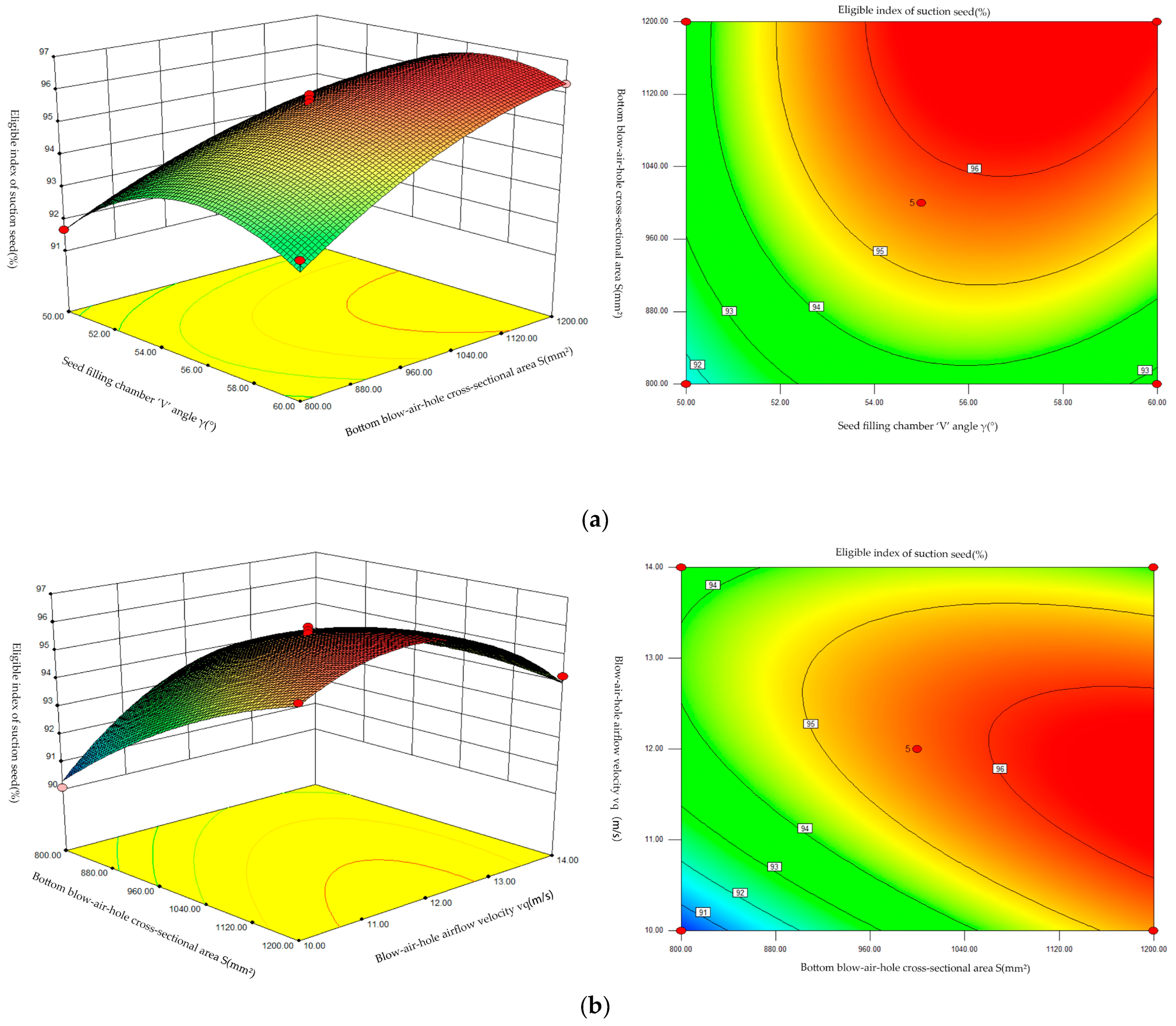

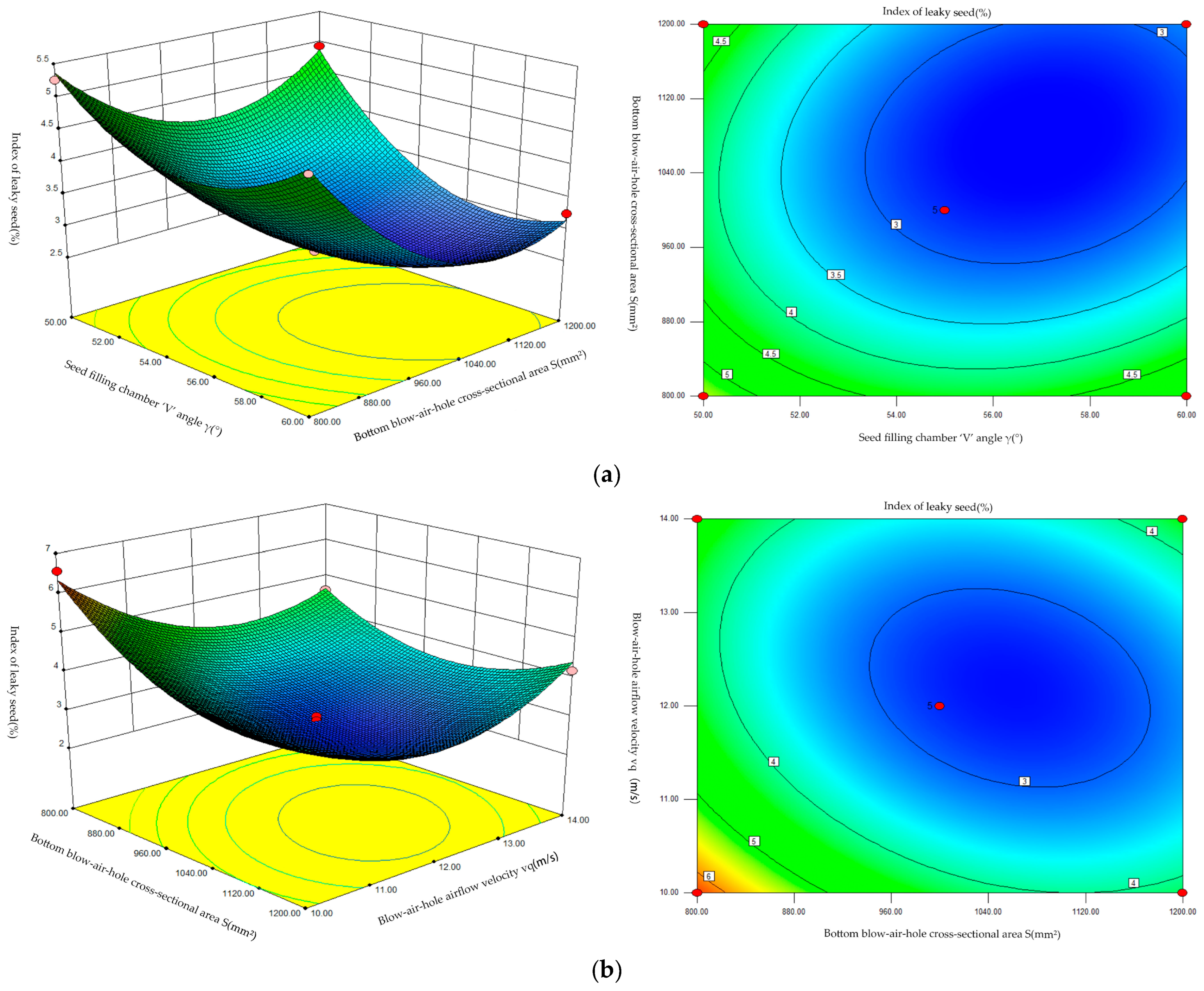

3.3. Response Surface Design Test Analysis

3.3.1. Test Setup

3.3.2. Analysis of Test Results

3.4. Confirmatory Experiment

4. Conclusions

- (a)

- A stress analysis of peanuts in the seed-filling chamber was carried out to compare the stress of peanut seeds close to and away from the wall, and the disturbance principle of the blowing structure of the AASD for a pneumatic-assisted precision peanut seed-metering machine was explained. Using ANSYS 2019 and EDEM 2018 software, a coupling simulation was carried out on the air-assisted precision peanut seed-metering machine. By analyzing the effects of the seed-filling chamber ‘V’ angle γ, the bottom blow-air-hole cross-sectional area S, and the blow-air-hole airflow velocity vq on the seed motion velocity, the seed stress, and the airflow velocity field in the seed-filling chamber, we found the following results: The seed-filling chamber ‘V’ angle γ was 50–60°, the bottom blow-air-hole cross-sectional area S was 800–1200 mm2, and the blow-air-hole airflow velocity vq was 10–14 m·s−1. Moreover, the disturbance filling had a good performance.

- (b)

- The effects of the seed-filling chamber ‘V’ angle γ, the bottom blow-air-hole cross-sectional area S, and the blow-air-hole airflow velocity vq on the seed-filling performance were determined through experimental analysis. An optimization model was established to determine the optimal parameter combination and we found that the seed-filling chamber ‘V’ angle γ was 56.59°, the bottom blow-air-hole cross-sectional area S was 1088.4 mm2, and the blow-air-hole airflow velocity vq was 12.11 m·s−1. In this case, the eligible index of suction seed and the index of leaky seed of peanut seed assisted blowing for the airflow were optimal. The eligible index of suction seed was 96.33% and the index of leaky seed was 2.59%. The results of field validation trials met the agronomic requirements for the precise planting of peanuts. When processing peanut varieties with rough surfaces or seeds with a high moisture content and poor flowability, it is recommended that the seed-filling chamber ‘V’ angle be set to 50–55°. This slope can help reduce seed accumulation. Additionally, the base range for the blow-air-hole airflow velocity should be set to 10–14 m s−1, and this should be coordinated with the bottom blow-air-hole cross-sectional area to prevent seed collisions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.S.; Ran, W.J.; Hao, J.J. Design and experiment of the double-seed hole seeding precision seed metering device for peanuts. Int. J. Agric. Biol. Eng. 2022, 15, 107–114. [Google Scholar] [CrossRef]

- Wang, S.Y.; Hu, Z.C.; Chen, Y.Q. Integration of agricultural machinery and agronomy for mechanised peanut production using the vine for animal feed. Biosyst. Eng. 2022, 219, 135–152. [Google Scholar] [CrossRef]

- He, S.N.; Chen, Y.; Xiang, W. Carbon and nitrogen footprints accounting of peanut and peanut oil production in China. J. Clean. Prod. 2021, 291, 125964. [Google Scholar] [CrossRef]

- Wang, D.W.; Ji, R.Q.; He, X.N. Drive-guided Combination Slot-assisted Seed-attached Air-absorbing Peanut High-speed Precision Seed Meter. Transact. Chin. Soc. Agric. Mach. 2023, 54, 59–70+149. [Google Scholar] [CrossRef]

- Yin, X.W.; Yang, L.; Zhang, D.X. Design and experiment of balance and low-loss air allotter in air pressure maize precision planter. Transact. Chin. Soc. Agric. Eng. 2016, 32, 9–17. [Google Scholar]

- Zang, Y.; Huang, Z.S.; Qin, W. Design of hybrid rice air-suction single seed metering device. Transact. Chin. Soc. Agric. Eng. 2024, 40, 181–191. [Google Scholar] [CrossRef]

- Zhang, M.H.; Jiang, Y.C.; He, S.Y. Design and experiment of the air suction wheel precision seed metering device for vegetables. Transact. Chin. Soc. Agric. Eng. 2023, 39, 98–109. [Google Scholar] [CrossRef]

- Li, Y.H.; Yang, L.; Zhang, D.X. Design and Experiment of Pneumatic Precision Seed-metering Device with Single Seed-metering Plate for Double-row. Transact. Chin. Soc. Agric. Mach. 2019, 50, 61–73. [Google Scholar] [CrossRef]

- Li, Y.H.; Yang, L.; Zhang, D.X. Analysis and test of linear seeding process of maize high speed precision metering device with air suction. Transact. Chin. Soc. Agric. Eng. 2020, 36, 26–35. [Google Scholar] [CrossRef]

- Liu, R.; Liu, Z.J.; Liu, L.J. Design and Experiment of Corn High Speed Air Suction Seed Metering Device with Disturbance Assisted Seed-filling. Transact. Chin. Soc. Agric. Mach. 2022, 53, 50–59. [Google Scholar] [CrossRef]

- Chen, Y.L.; Liu, Z.Q.; Han, J. Design and experiments of the flat seed-adsorbing posture adjustment mechanism for the air-suction metering device. Transact. Chin. Soc. Agric. Eng. 2022, 38, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Li, J.D.; Wang, D.W. Orthogonal Experiment Optimization on Air-suction Precision Seed-metering Device. Transact. Chin. Soc. Agric. Mach. 2012, 43, 54–58+89. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, H.W.; Hu, H.N. A noncontact self-suction wheat shooting device for sustainable agriculture: A preliminary research. Comput. Electr. Agric. 2022, 197, 106927. [Google Scholar] [CrossRef]

- Yang, L.; Yan, B.; Cui, T. Global overview of research progress and development of precision maize planters. Int. J. Agric. Biol. Eng. 2016, 9, 9–26. [Google Scholar] [CrossRef]

- Wang, L.; Liao, Y.T.; Li, M.L. Motion characteristics of rapeseeds and wheat seeds within mixing components of air-assisted centralized metering device based on DEM-CFD. Comput. Electr. Agric. 2024, 221, 108986. [Google Scholar] [CrossRef]

- Yan, Y.Q.; Liu, L.J.; Liu, Y.Q. Design and Test of Four-stage Seed Cleaning Mechanism for Air-Suction Vagetables Seed-Metering Device. Transact. Chin. Soc. Agric. Mach. 2023, 54, 57–65. Available online: https://link.cnki.net/urlid/11.1964.S.20230913.1130.016 (accessed on 9 October 2024).

- Ding, L.; Yang, L.; Zhang, D.X. Effect of Seed Adsorption Posture of Corn Air-suction Metering Device on Seed Feeding Performance. Transact. Chin. Soc. Agric. Mach. 2021, 52, 40–50. [Google Scholar] [CrossRef]

- Gu, F.W.; Zhao, Y.Q.; Wu, F. Simulation analysis and experimental validation of conveying device in uniform rrushed straw throwing and seed-sowing Machines using CFD-DEM coupled approach. Comput. Electr. Agric. 2022, 193, 106720. [Google Scholar] [CrossRef]

- Guzman, L.; Chen, Y.; Landry, H. Coupled CFD-DEM Simulation of Seed Flow in an Air Seeder Distributor Tube. Processes 2020, 8, 1597. [Google Scholar] [CrossRef]

- Li, H.C.; Li, Y.M.; Gao, F. CFD-DEM simulation of material motion in air-and-screen cleaning device. Comput. Electr. Agric. 2012, 88, 111–119. [Google Scholar] [CrossRef]

- Wang, Y.B.; Li, H.W.; Hu, H.N. DEM-CFD coupling simulation and optimization of a self-suction wheat shooting device. Power Technol. 2021, 393, 494–509. [Google Scholar] [CrossRef]

- Huang, J.S.; Wen, J.P.; Li, H. Particle erosion in 90-Degree elbow pipe of pneumatic conveying System: Simulation and validation. Comput. Electr. Agric. 2024, 216, 108534. [Google Scholar] [CrossRef]

- He, S.Y.; Qian, C.; Jiang, Y.C. Design and optimization of the seed feeding device with DEM-CFD coupling approach for rice and wheat. Comput. Electr. Agric. 2024, 219, 108814. [Google Scholar] [CrossRef]

- Xing, H.; Cao, X.M.; Zhong, P. DEM-CFD coupling simulation and optimisation of rice seed particles seeding a hill in double cavity pneumatic seed metering device. Comput. Electr. Agric. 2024, 224, 109075. [Google Scholar] [CrossRef]

- Xiao, Y.; Ma, Z.T.; Wu, M.L. Numerical Study of Pneumatic Conveying of Rapeseed through a Pipe Bend by DEM-CFD. Agriculture 2022, 12, 1845. [Google Scholar] [CrossRef]

- Guzman, L.; Chen, Y.; Landry, H. Coupled CFD-DEM Simulation of Seed Flow in Horizontal-Vertical Tube Transition. Processes 2023, 11, 909. [Google Scholar] [CrossRef]

- Lei, X.L.; Liao, Y.T.; Liao, Q.X. Simulation of seed motion in seed feeding device with DEM-CFD coupling approach for rapeseed and wheat. Comput. Electr. Agric. 2016, 131, 29–39. [Google Scholar] [CrossRef]

- Xu, J.; Sun, S.L.; He, Z.K. Design and optimisation of seed-metering plate of air-suction vegetable seed-metering device based on DEM-CFD. Biosyst. Eng. 2023, 230, 277–300. [Google Scholar] [CrossRef]

- Gao, X.J.; Xu, Y.; Yang, L. Simulation and Experiment of Uniformity of Venturi Feeding Tube Based on DEM-CFD Coupling. Transact. Chin. Soc. Agric. Mach. 2018, 49, 92–100. [Google Scholar] [CrossRef]

- Wang, G.W.; Xia, X.M.; Zhu, Q.H. Design and Experiment of Soybean High-speed Precision Vacuum Seed Metering with Auxiliary Filling Structure Based on DEM-CFD. J. Jilin Technol. Univ. 2022, 52, 1208–1221. [Google Scholar] [CrossRef]

- Ding, L.; Yang, L.; Wu, D.H. Simulation and Experiment of Corn Air Suction Seed Metering Device Based on DEM-CFD Coupling Method. Transact. Chin. Soc. Agric. Mach. 2018, 49, 48–57. [Google Scholar] [CrossRef]

- Shi, S.; Liu, H.; Wei, G.J. Optimization and Experiment of Pneumatic Seed Metering Device with Guided Assistant Filling Based on EDEM CFD. Transact. Chin. Soc. Agric. Mach. 2020, 51, 54–66. [Google Scholar] [CrossRef]

- Han, D.D.; Zhang, D.X.; Jing, H.R. DEM-CFD coupling simulation and optimization of an inside-filling air-blowing maize precision seed-metering device. Comput. Electr. Agric. 2018, 150, 426–438. [Google Scholar] [CrossRef]

- Kuang, S.B.; Li, K.; Zou, R.P. Application of periodic boundary conditions to CFD-DEM simulation of gas-solid flow in pneumatic conveying. Chem. Eng. Sci. 2013, 93, 214–228. [Google Scholar] [CrossRef]

- Zhou, B.C.; Ma, S.C.; Li, W.Q. CFD-DEM coupling simulation and parameter optimization of sugarcane harvester extractor. Biosyst. Eng. 2025, 250, 80–93. [Google Scholar] [CrossRef]

- Kloss, C.; Goniva, C.; Hager, A. Models, algorithms and validation for opensource DEM and CFD-DEM. Prog. Comput. Fluid. Dyn. 2012, 12, 140–152. [Google Scholar] [CrossRef]

- Zhou, F.B.; Hu, S.Y.; Liu, Y.K. CFD-DEM simulation of the pneumatic conveying of fine particles through a horizontal slit. Particuology 2014, 16, 196–205. [Google Scholar] [CrossRef]

- Yu, Y.J.; Fu, H.; Yu, J.Q. DEM-based simulation of the corn threshing process. Adv. Powder Technol. 2015, 26, 1400–1409. [Google Scholar] [CrossRef]

- Antonyuk, S.; Khanal, M.; Tomas, J. Impact breakage of spherical granules: Experimental study and DEM simulation. Chem. Eng. Process 2006, 45, 838–856. [Google Scholar] [CrossRef]

- Wu, M.C.; Cong, J.L.; Yan, Q. Calibration and experiments for discrete element simulation parameters of peanut seed particles. Transact. Chin. Soc. Agric. Eng. 2020, 36, 30–38. [Google Scholar] [CrossRef]

- GB/T 6973-2005; Testing Methods of Single Seed Drills (Precision Drills). China Standards Press: Beijing, China, 2005.

- JB/T 10293-2013; Specifications for Single Seed Drills (Precision Drills). China Machine Press: Beijing, China, 2013.

| Physical Property | Parameters |

|---|---|

| Average size of three axes (mm) | 15 × 10 × 8.5 |

| Thousand grains weight (g) | 7802.15 |

| Densities (kg·m−3) | 1049 |

| Moisture content (%) | 8.87 |

| The Forward Speed of the Machine (km·h−1) | The Rotation Speed of the Seed-Discharging Disk (rpm) |

|---|---|

| 10 | 23.8 |

| Type | Parameter | Peanut Seed | Nylon Plastic |

|---|---|---|---|

| Solid phase | Poisson’s ratio | 0.362 | 0.38 |

| Shear modulus (Pa) | 5.06 × 107 | 3.11 × 109 | |

| Density (kg·m−3) | 1.04 × 103 | 1130 | |

| Coefficient of restitution | 0.501 | 0.519 | |

| Static friction coefficient | 0.213 | 0.441 | |

| Rolling friction coefficient | 0.035 | 0.126 | |

| Solid time step | 2 × 10−6 | ||

| Gas phase | Fluid | Air | |

| Gravity acceleration (m·s−2) | 9.81 | ||

| Density (kg·m−3) | 1.225 | ||

| Viscosity (kg·m−1·s−1) | 1.7984 × 10−5 | ||

| Fluid time step | 1 × 10−4 |

| Level Code | Experimental Factors | ||

|---|---|---|---|

| X1 (°) | X2 (mm2) | X3 (m·s−1) | |

| −1 | 50 | 800 | 10 |

| 0 | 55 | 1000 | 12 |

| 1 | 60 | 1200 | 14 |

| Test Number | Experimental Factors | Eligible Index of Suction Seed | Index of Leaky Seed | ||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Y1% | Y2% | |

| 1 | −1 | 0 | 1 | 92.13 | 5.26 |

| 2 | 0 | −1 | 1 | 93.51 | 4.62 |

| 3 | 0 | 0 | 0 | 95.12 | 2.86 |

| 4 | 0 | 1 | 1 | 94.26 | 4.19 |

| 5 | −1 | −1 | 0 | 91.67 | 5.26 |

| 6 | 0 | 0 | 0 | 95.78 | 2.62 |

| 7 | 0 | 0 | 0 | 95.71 | 2.93 |

| 8 | 1 | 0 | 1 | 93.53 | 3.86 |

| 9 | 1 | −1 | 0 | 93.06 | 4.98 |

| 10 | 0 | 1 | −1 | 95.42 | 4.24 |

| 11 | 1 | 1 | 0 | 96.29 | 3.25 |

| 12 | 0 | 0 | 0 | 95.92 | 2.77 |

| 13 | 1 | 0 | −1 | 92.87 | 4.63 |

| 14 | 0 | 0 | 0 | 95.67 | 2.81 |

| 15 | −1 | 0 | −1 | 91.09 | 5.38 |

| 16 | −1 | 1 | 0 | 93.22 | 4.93 |

| 17 | 0 | −1 | −1 | 90.05 | 6.56 |

| Source | Eligible Index of Suction Seed | Index of Leaky Seed | ||||||

|---|---|---|---|---|---|---|---|---|

| Sum of Squares | Degrees of Freedom | F | p | Sum of Squares | Degrees of Freedom | F | p | |

| Model | 56.0993 | 9 | 51.4265 | <0.0001 | 21.3407 | 9 | 61.6682 | <0.0001 |

| X1 | 7.2962 | 1 | 60.1961 | 0.0001 | 2.1115 | 1 | 54.9148 | 0.0001 |

| X2 | 14.8513 | 1 | 122.5278 | <0.0001 | 2.8920 | 1 | 75.2135 | <0.0001 |

| X3 | 2 | 1 | 16.5007 | 0.0048 | 1.0368 | 1 | 26.9644 | 0.0013 |

| X1X2 | 0.7056 | 1 | 5.8214 | 0.0466 | 0.49 | 1 | 12.7436 | 0.0091 |

| X1X3 | 0.0361 | 1 | 0.2978 | 0.6022 | 0.1056 | 1 | 2.7470 | 0.1414 |

| X2X3 | 5.3361 | 1 | 44.0246 | 0.0003 | 0.8930 | 1 | 23.2252 | 0.0019 |

| X12 | 9.3792 | 1 | 77.3815 | <0.0001 | 2.9958 | 1 | 77.9116 | <0.0001 |

| X22 | 1.4533 | 1 | 11.9901 | 0.0105 | 3.9088 | 1 | 101.6566 | <0.0001 |

| X32 | 12.7845 | 1 | 105.476 | <0.0001 | 5.4816 | 1 | 142.5618 | <0.0001 |

| Residual | 0.8485 | 7 | 0.2692 | 7 | ||||

| Lack of fit | 0.4743 | 3 | 1.6898 | 0.3056 | 0.2153 | 3 | 5.3273 | 0.0699 |

| Errors | 0.3742 | 4 | 0.0539 | 4 | ||||

| Total | 56.9478 | 16 | 21.6099 | 16 | ||||

| R2 = 0.9851, Adj R2 = 0.9659 | R2 = 0.9875, Adj R2 = 0.9715 | |||||||

| Type | Working Speed (km·h−1) | Eligible Index of Suction Seed (%) | Index of Leaky Seed (%) |

|---|---|---|---|

| Air-assisted seeding | 6 | 95.89 | 2.98 |

| 8 | 95.22 | 3.59 | |

| 10 | 93.22 | 4.13 | |

| No air-assisted seeding | 6 | 89.32 | 9.62 |

| 8 | 87.68 | 11.21 | |

| 10 | 84.26 | 14.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, P.; Sun, B.; Shang, S.; Hou, J.; Wang, D.; Zhao, Z.; Elshafie, A.; Zheng, X.; Eltoum, F. Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine. Agriculture 2025, 15, 1678. https://doi.org/10.3390/agriculture15151678

Guo P, Sun B, Shang S, Hou J, Wang D, Zhao Z, Elshafie A, Zheng X, Eltoum F. Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine. Agriculture. 2025; 15(15):1678. https://doi.org/10.3390/agriculture15151678

Chicago/Turabian StyleGuo, Peng, Bin Sun, Shuqi Shang, Jialin Hou, Dongwei Wang, Zhuang Zhao, Ahmed Elshafie, Xiaoshuai Zheng, and Farid Eltoum. 2025. "Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine" Agriculture 15, no. 15: 1678. https://doi.org/10.3390/agriculture15151678

APA StyleGuo, P., Sun, B., Shang, S., Hou, J., Wang, D., Zhao, Z., Elshafie, A., Zheng, X., & Eltoum, F. (2025). Effect of Auxiliary Air-Suction Seed-Filling Structure on Seed Discharge Performance of Peanut High-Speed Seed-Metering Machine. Agriculture, 15(15), 1678. https://doi.org/10.3390/agriculture15151678