Seeding Status Monitoring System for Toothed-Disk Cotton Seeders Based on Modular Optoelectronic Sensors

Abstract

1. Introduction

2. Materials and Methods

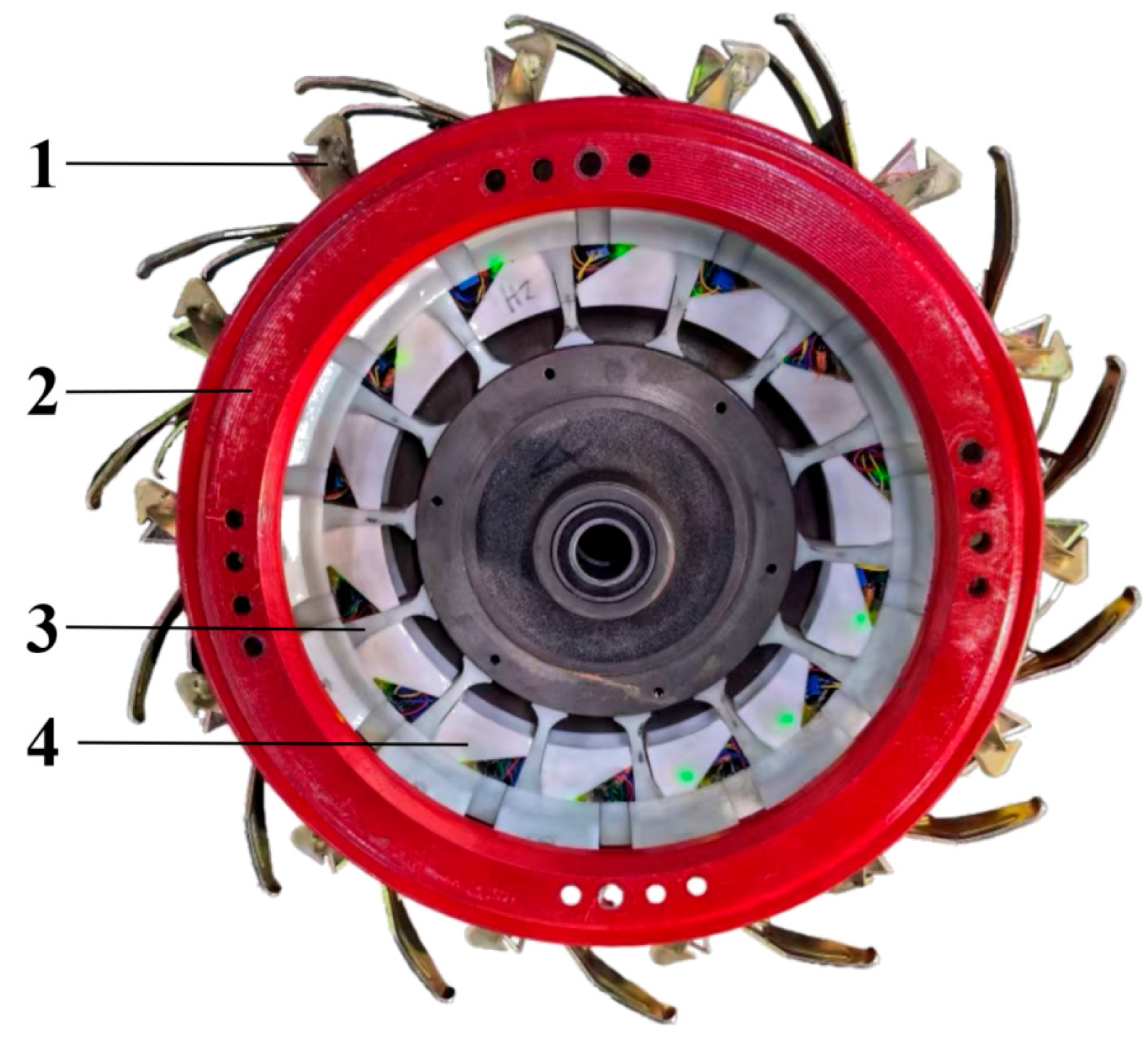

2.1. Structure and Working Principle of Toothed-Disk Seeder

2.2. Sensor Design and Monitoring System Construction

2.2.1. Sensor Circuit Design

2.2.2. Modular Photoelectric Sensing Monitoring System Construction

2.3. System Counting Algorithm Based on Spatiotemporal Correlation Model

2.3.1. Division of Monitoring Time Windows

2.3.2. Seeding State Differentiation and Threshold Segmentation

2.3.3. Spatiotemporal Joint Counting Algorithm

2.4. System Performance Testing Equipment and Methods

2.4.1. Bench Test

2.4.2. Field Test

3. Results and Discussion

3.1. Bench Test

3.2. Field Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Song, W.; Liu, H.Y. Design and testing of the key technology of the cotton direct seeding machine. Front. Plant Sci. 2025, 16, 1530725. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Zhang, X.; Jin, W.; Zhang, H.; Shi, Z.; Yu, Y. Design and analysis of double chamber vertical toothed disc structure hole seeder for cotton. J. Chin. Agric. Mach. 2022, 43, 35. [Google Scholar]

- Xu, L.; Hu, B.; Li, J.; Ren, L.; Guo, M.; Mao, Z.; Cai, Y.; Sun, S. An efficient seeding state monitoring system of a pneumatic dibbler based on an interdigital capacitive sensor. Comput. Electron. Agric. 2023, 209, 107856. [Google Scholar] [CrossRef]

- Ren, L.; Wang, S.; Hu, B.; Li, T.; Zhao, M.; Zhang, Y.; Yang, M. Seed State-Detection Sensor for a Cotton Precision Dibble. Agriculture 2023, 13, 1515. [Google Scholar] [CrossRef]

- Bai, S.; Yuan, Y.; Niu, K.; Shi, Z.; Zhou, L.; Zhao, B.; Wei, L.; Liu, L.; Zheng, Y.; An, S.; et al. Design and experiment of a sowing quality monitoring system of cotton precision hill-drop planters. Agriculture 2022, 12, 1117. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Shi, Z.; Jin, W.; Zhang, H.; Fu, H.; Wang, D. Design and experiment of double-storage turntable cottonvertical disc hole seeding and metering device. Trans. Chin. Soc. Agric. Eng. 2021, 19, 27–36. [Google Scholar]

- Zhang, X.; Zhang, H.; Shi, Z.; Jin, W.; Chen, Y.; Yu, Y. Design and experiments of seed pickup status monitoring system for cotton precision dibblers. Trans. Chin. Soc. Agric. Eng. 2022, 38, 9–19. [Google Scholar]

- Rossi, S.; Scola, I.; Bourges, G.; Šarauskis, E.; Karayel, D. Improving the seed detection accuracy of piezoelectric impact sensors for precision seeders. Part I: A comparative study of signal processing algorithms. Comput. Electron. Agric. 2023, 215, 108449. [Google Scholar] [CrossRef]

- Rossi, S.; Scola, I.; Bourges, G.; Šarauskis, E.; Karayel, D. Improving the seed detection accuracy of piezoelectric impact sensors for precision seeders. Part II: Evaluation of different plate materials. Comput. Electron. Agric. 2023, 215, 108448. [Google Scholar] [CrossRef]

- Al-Mallahi, A.; Takashi, K. Monitoring the flow of seeds in grain drill using fiber sensor. IFAC Proce. Volum. 2013, 46, 311–314. [Google Scholar] [CrossRef]

- Al-Mallahi, A.; Kataoka, T. Application of fibre sensor in grain drill to estimate seed flow under field operational conditions. Comput. Electron. Agric. 2016, 121, 412–419. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Zhao, X.; Pan, H.; Lakhiar, I.; Wang, W. Development and experimental analysis of an intelligent sensor for monitoring seed flow rate based on a seed flow reconstruction technique. Comput. Electron. Agric. 2019, 164, 104899. [Google Scholar] [CrossRef]

- Liu, W.; Hu, J.; Zhao, X.; Yao, M.; Lakhiar, I.; Zhao, J.; Liu, J.; Wang, W. An adaptive roller speed control method based on monitoring value of real-time seed flow rate for flute-roller type seed-metering device. Sensors 2020, 21, 80. [Google Scholar] [CrossRef] [PubMed]

- Karimi, H.; Navid, H.; Besharati, B.; Eskandari, I. Assessing an infrared-based seed drill monitoring system under field operating conditions. Comput. Electron. Agric. 2019, 162, 543–551. [Google Scholar] [CrossRef]

- Karimi, H.; Navid, H.; Besharati, B.; Behfar, H.; Eskandari, I. A practical approach to comparative design of non-contact sensing techniques for seed flow rate detection. Comput. Electron. Agric. 2017, 142, 165–172. [Google Scholar] [CrossRef]

- Besharati, B.; Navid, H.; Karimi, H.; Behfar, H.; Eskandari, I.; Behfar, H.; Eskandari, I. Development of an infrared seed-sensing system to estimate flow rates based on physical properties of seeds. Comput. Electron. Agric. 2019, 162, 874–881. [Google Scholar] [CrossRef]

- Kumar, R.; Raheman, H. Detection of flow of seeds in the seed delivery tube and choking of boot of a seed drill. Comput. Electron. Agric. 2018, 153, 266–277. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, Y.; Ji, W.; Zheng, P.; Yan, S.; Hou, S.; Cai, C. Evaluation of a Real-Time Monitoring and Management System of Soybean Precision Seed Metering Devices. Agronomy 2023, 13, 541. [Google Scholar] [CrossRef]

- Ding, Y.; Yang, J.; Zhu, K.; Zhang, L.; Zhou, Y.; Liao, Q. Design and experiment on seed flow sensing device for rapeseed precision metering device. Trans. Chin. Soc. Agric. Eng. 2017, 33, 29–36. [Google Scholar]

- Kim, S.-J.; Lee, H.-S.; Hwang, S.-J.; Kim, J.-H.; Jang, M.-K.; Nam, J.-S. Development of Seeding Rate Monitoring System Applicable to a Mechanical Pot-Seeding Machine. Agriculture 2023, 13, 2000. [Google Scholar] [CrossRef]

- Li, J.; Zhang, M.; Zhang, G.; Ge, D.; Li, M. Real-Time Monitoring System of Seedling Amount in Seedling Box Based on Machine Vision. Agriculture 2023, 13, 371. [Google Scholar] [CrossRef]

- Nikolay, Z.; Nikolay, K.; Huang, Y.; Adilet, S.; Xian, J. Line laser based sensor for real-time seed counting and seed miss detection for precision planter. Opt. Laser Technol. 2023, 167, 109742. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, X.; Wang, J.; Han, Z. A high-precision strain seeding spacing monitoring system based on a combined bionic strain sensor and strain peak recognition algorithm. Comput. Electron. Agric. 2023, 212, 108061. [Google Scholar] [CrossRef]

- Xie, C.; Zhang, D.; Yang, L.; Cui, T.; He, X.; Du, Z. Precision seeding parameter monitoring system based on laser sensor and wireless serial port communication. Comput. Electron. Agric. 2021, 190, 106429. [Google Scholar] [CrossRef]

- Wang, G.; Sun, W.; Zhang, H.; Liu, X.; Li, H.; Yang, X.; Zhu, L. Research on a kind of seeding-monitoring and compensating control system for potato planter without additional seed-metering channel. Comput. Electron. Agric. 2020, 177, 105681. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Wang, Z.; Wang, Q.; Wang, J. Optimized design, monitoring system development and experiment for a long-belt finger-clip precision corn seed metering device. Front. Plant Sci. 2022, 13, 814747. [Google Scholar] [CrossRef] [PubMed]

- Zhao, P.; Gao, X.; Su, Y.; Xu, Y.; Huang, Y. Investigation of seeding performance of a novel high-speed precision seed metering device based on numerical simulation and high-speed camera. Comput. Electron. Agric. 2024, 217, 108563. [Google Scholar] [CrossRef]

- Yan, B.; Cui, Z.; Deng, G.; Li, G.; Zheng, S.; He, F.; Li, L.; Chen, P.; Wang, X.; Zhou, S.; et al. Design and validation of a real-time cassava planter seed quality monitoring system based on optical fiber sensors and rotary encoders. Front. Plant Sci. 2024, 15, 1481909. [Google Scholar] [CrossRef] [PubMed]

- Navid, H.; Fathipour, A.; Karimi, H.; Ghaffarnezhad, A.; Wang, N. An approach to compensation of dust effects on seed flow sensors. Agric. Eng. Int. CIGR J. 2023, 25, 43–58. [Google Scholar]

- Xie, C.; Zhang, D.; Yang, L.; Cui, T.; Yu, T.; Wang, D.; Xiao, T. Experimental analysis on the variation law of sensor monitoring accuracy under different seeding speed and seeding spacing. Comput. Electron. Agric. 2021, 189, 106369. [Google Scholar] [CrossRef]

- Xie, C.; Yang, L.; Zhang, D.; Cui, T.; He, X.; Du, Z.; Xiao, T. A signal output quantity (SOQ) judgment algorithm for improving seeding quantity accuracy. Comput. Electron. Agric. 2022, 201, 107321. [Google Scholar] [CrossRef]

- TB 6973-2005; Test Methods for Single Grain (Precision) Seeders. China Agriculture Publishing House: Beijing, China, 2005.

| Seed Drop Port Number | Monitoring Time Window | Time Interval Description |

|---|---|---|

| 1 | [t(n, 1), t(n, 2)] | Between 1st and 2nd pulse |

| 2 | [t(n, 2), t(n, 3)] | Between 2nd and 3rd pulse |

| … | … | … |

| 13 | [t(n, 13), t(n, 14)] | Between 13th and 14th pulse |

| 14 | [t(n, 14), t(n+1, 1)] | Between 14th and next cycle’s 1st pulse |

| Dimension Type | Range (mm) | Mean (mm) | Standard Deviation (mm) | Coefficient of Variation (%) |

|---|---|---|---|---|

| Length | 8.5~9.5 | 9.0 | 0.5 | 5.56 |

| Width | 4.5~5.5 | 5.0 | 0.5 | 10.00 |

| Thickness | 4.0~4.4 | 4.2 | 0.2 | 4.76 |

| Speed (r/min) | Category | Test Group Number | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| Actual Single Seeding | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| 30 | Monitor single seeding | 289 | 296 | 295 | 297 | 294 | 296 | 297 |

| Monitor missed seeding | 2 | 4 | 5 | 3 | 6 | 4 | 3 | |

| Monitor multiple seeding | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Misjudged | 2 | 4 | 5 | 3 | 6 | 4 | 3 | |

| Accuracy (%) | 99.33 | 98.67 | 98.33 | 99.00 | 98.00 | 98.67 | 99.00 | |

| 40 | Monitor single seeding | 293 | 291 | 295 | 294 | 293 | 295 | 292 |

| Monitor missed seeding | 7 | 9 | 5 | 8 | 7 | 6 | 8 | |

| Monitor multiple seeding | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Misjudged | 7 | 9 | 5 | 8 | 7 | 6 | 8 | |

| Accuracy (%) | 97.67 | 98.33 | 97.00 | 97.33 | 97.67 | 98.00 | 97.33 | |

| 50 | Monitor single seeding | 289 | 291 | 290 | 287 | 288 | 290 | 289 |

| Monitor missed seeding | 11 | 9 | 10 | 12 | 11 | 10 | 12 | |

| Monitor multiple seeding | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Misjudged | 11 | 9 | 10 | 12 | 11 | 10 | 12 | |

| Accuracy (%) | 96.33 | 97.00 | 96.67 | 96.00 | 96.33 | 96.67 | 96.00 | |

| Speed (r/min) | Category | Test Group Number | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| Monitor Missed Seeding | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| 30 | Actual missed seeding | 297 | 295 | 296 | 298 | 295 | 297 | 298 |

| Actual single seeding | 3 | 4 | 3 | 2 | 3 | 2 | 2 | |

| Actual multiple seeding | 0 | 1 | 1 | 0 | 2 | 1 | 0 | |

| Misjudged | 3 | 5 | 4 | 2 | 5 | 3 | 2 | |

| Accuracy (%) | 99.00 | 98.33 | 98.67 | 99.33 | 98.33 | 99.00 | 99.33 | |

| 40 | Actual missed seeding | 291 | 293 | 291 | 292 | 289 | 293 | 290 |

| Actual single seeding | 7 | 6 | 6 | 7 | 8 | 5 | 7 | |

| Actual multiple seeding | 2 | 1 | 3 | 1 | 3 | 2 | 3 | |

| Misjudged | 9 | 7 | 9 | 8 | 11 | 7 | 10 | |

| Accuracy (%) | 97.00 | 97.67 | 97.00 | 97.33 | 96.33 | 97.67 | 96.67 | |

| 50 | Actual missed seeding | 289 | 291 | 287 | 290 | 288 | 291 | 289 |

| Actual single seeding | 8 | 7 | 10 | 8 | 9 | 8 | 9 | |

| Actual multiple seeding | 3 | 2 | 3 | 2 | 3 | 1 | 2 | |

| Misjudged | 11 | 9 | 13 | 10 | 12 | 9 | 11 | |

| Accuracy (%) | 96.33 | 97.00 | 95.67 | 96.67 | 96.00 | 97.00 | 96.33 | |

| Speed (r/min) | Category | Test Group Number | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | ||

| Actual Multiple Seeding | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| 30 | Monitor multiple seeding | 295 | 297 | 298 | 297 | 296 | 298 | 295 |

| Monitor single seeding | 4 | 2 | 2 | 2 | 3 | 2 | 3 | |

| Monitor missed seeding | 1 | 1 | 0 | 1 | 0 | 0 | 2 | |

| Misjudged | 5 | 3 | 2 | 3 | 4 | 2 | 5 | |

| Accuracy (%) | 98.33 | 99.00 | 99.33 | 99.00 | 98.67 | 99.33 | 98.33 | |

| 40 | Monitor multiple seeding | 293 | 291 | 294 | 292 | 293 | 291 | 292 |

| Monitor single seeding | 5 | 6 | 5 | 6 | 5 | 6 | 6 | |

| Monitor missed seeding | 2 | 3 | 1 | 2 | 2 | 3 | 2 | |

| Misjudged | 7 | 9 | 6 | 8 | 7 | 9 | 8 | |

| Accuracy (%) | 97.67 | 97.00 | 98.00 | 97.33 | 97.67 | 97.00 | 97.33 | |

| 50 | Monitor multiple seeding | 289 | 287 | 290 | 288 | 291 | 288 | 289 |

| Monitor single seeding | 9 | 10 | 8 | 9 | 7 | 10 | 8 | |

| Monitor missed seeding | 2 | 3 | 2 | 3 | 2 | 2 | 3 | |

| Misjudged | 11 | 13 | 10 | 12 | 9 | 12 | 11 | |

| Accuracy (%) | 97.00 | 95.67 | 96.67 | 96.00 | 97.00 | 96.00 | 96.33 | |

| Speed (r/min) | Category | Test Group Number | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | ||

| 30 | Actual single seeding | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 |

| Monitor single seeding | 1596 | 1603 | 1595 | 1590 | 1597 | 1601 | 1592 | 1600 | 1594 | 1602 | 1598 | 1591 | 1599 | |

| Accuracy (%) | 98.22 | 98.65 | 98.15 | 97.85 | 98.28 | 98.52 | 97.97 | 98.46 | 98.09 | 98.58 | 98.34 | 97.91 | 98.40 | |

| Actual missed seeding | 47 | 52 | 41 | 48 | 54 | 46 | 53 | 51 | 54 | 49 | 44 | 48 | 50 | |

| Monitor missed seeding | 48 | 53 | 42 | 49 | 55 | 47 | 54 | 52 | 56 | 50 | 45 | 49 | 51 | |

| Accuracy (%) | 97.92 | 98.11 | 97.62 | 97.96 | 98.18 | 97.87 | 98.15 | 98.08 | 96.43 | 98.00 | 97.78 | 97.96 | 98.04 | |

| Actual multiple seeding | 49 | 52 | 50 | 45 | 50 | 53 | 42 | 51 | 49 | 48 | 55 | 47 | 50 | |

| Monitor multiple seeding | 48 | 51 | 51 | 44 | 49 | 51 | 41 | 50 | 48 | 47 | 54 | 46 | 49 | |

| Accuracy (%) | 97.96 | 98.08 | 98.04 | 97.78 | 98.00 | 96.23 | 97.62 | 98.04 | 97.96 | 97.92 | 98.18 | 97.87 | 98.00 | |

| 40 | Actual single seeding | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 |

| Monitor single seeding | 1582 | 1576 | 1580 | 1583 | 1579 | 1581 | 1577 | 1584 | 1578 | 1580 | 1576 | 1581 | 1585 | |

| Accuracy (%) | 97.35 | 96.98 | 97.23 | 97.42 | 97.17 | 97.29 | 97.05 | 97.48 | 97.11 | 97.23 | 96.98 | 97.29 | 97.54 | |

| Actual missed seeding | 59 | 55 | 51 | 56 | 59 | 53 | 60 | 58 | 56 | 54 | 59 | 57 | 61 | |

| Monitor missed seeding | 61 | 57 | 53 | 58 | 61 | 55 | 63 | 60 | 58 | 56 | 62 | 59 | 63 | |

| Accuracy (%) | 96.72 | 96.49 | 96.23 | 96.55 | 96.72 | 96.36 | 95.24 | 96.67 | 96.55 | 96.43 | 95.16 | 96.61 | 96.83 | |

| Actual multiple seeding | 59 | 61 | 54 | 65 | 57 | 62 | 60 | 67 | 55 | 63 | 58 | 64 | 56 | |

| Monitor multiple seeding | 57 | 59 | 52 | 62 | 55 | 60 | 58 | 64 | 53 | 61 | 56 | 62 | 54 | |

| Accuracy (%) | 96.61 | 96.72 | 96.30 | 95.38 | 96.49 | 96.77 | 96.67 | 95.52 | 96.36 | 96.83 | 96.55 | 96.88 | 96.43 | |

| 50 | Actual single seeding | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 | 1625 |

| Monitor single seeding | 1564 | 1568 | 1562 | 1567 | 1573 | 1560 | 1565 | 1561 | 1572 | 1563 | 1570 | 1566 | 1571 | |

| Accuracy (%) | 96.25 | 96.49 | 96.12 | 96.43 | 96.80 | 96.00 | 96.31 | 96.06 | 96.74 | 96.18 | 96.62 | 96.37 | 96.68 | |

| Actual missed seeding | 61 | 57 | 63 | 58 | 60 | 56 | 62 | 59 | 61 | 65 | 58 | 60 | 63 | |

| Monitor missed seeding | 64 | 60 | 66 | 61 | 63 | 59 | 65 | 62 | 64 | 62 | 61 | 63 | 66 | |

| Accuracy (%) | 95.31 | 95.00 | 95.45 | 95.08 | 95.24 | 94.92 | 95.38 | 95.16 | 95.31 | 95.38 | 95.08 | 95.24 | 95.45 | |

| Actual multiple seeding | 62 | 65 | 61 | 66 | 63 | 60 | 62 | 59 | 63 | 64 | 66 | 58 | 60 | |

| Monitor multiple seeding | 59 | 62 | 58 | 63 | 60 | 57 | 59 | 56 | 60 | 61 | 63 | 55 | 57 | |

| Accuracy (%) | 95.16 | 95.38 | 95.08 | 95.45 | 95.24 | 95.00 | 95.16 | 94.91 | 95.24 | 95.31 | 95.45 | 94.83 | 95.00 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, T.; Zhang, X.; Shi, Z.; Liu, J.; Jin, W.; Yan, J.; Wang, D.; Chen, J. Seeding Status Monitoring System for Toothed-Disk Cotton Seeders Based on Modular Optoelectronic Sensors. Agriculture 2025, 15, 1594. https://doi.org/10.3390/agriculture15151594

Jiang T, Zhang X, Shi Z, Liu J, Jin W, Yan J, Wang D, Chen J. Seeding Status Monitoring System for Toothed-Disk Cotton Seeders Based on Modular Optoelectronic Sensors. Agriculture. 2025; 15(15):1594. https://doi.org/10.3390/agriculture15151594

Chicago/Turabian StyleJiang, Tao, Xuejun Zhang, Zenglu Shi, Jingyi Liu, Wei Jin, Jinshan Yan, Duijin Wang, and Jian Chen. 2025. "Seeding Status Monitoring System for Toothed-Disk Cotton Seeders Based on Modular Optoelectronic Sensors" Agriculture 15, no. 15: 1594. https://doi.org/10.3390/agriculture15151594

APA StyleJiang, T., Zhang, X., Shi, Z., Liu, J., Jin, W., Yan, J., Wang, D., & Chen, J. (2025). Seeding Status Monitoring System for Toothed-Disk Cotton Seeders Based on Modular Optoelectronic Sensors. Agriculture, 15(15), 1594. https://doi.org/10.3390/agriculture15151594