Prediction of the Calorific Value and Moisture Content of Caragana korshinskii Fuel Using Hyperspectral Imaging Technology and Various Stoichiometric Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Spectral Collection and Composition Determination

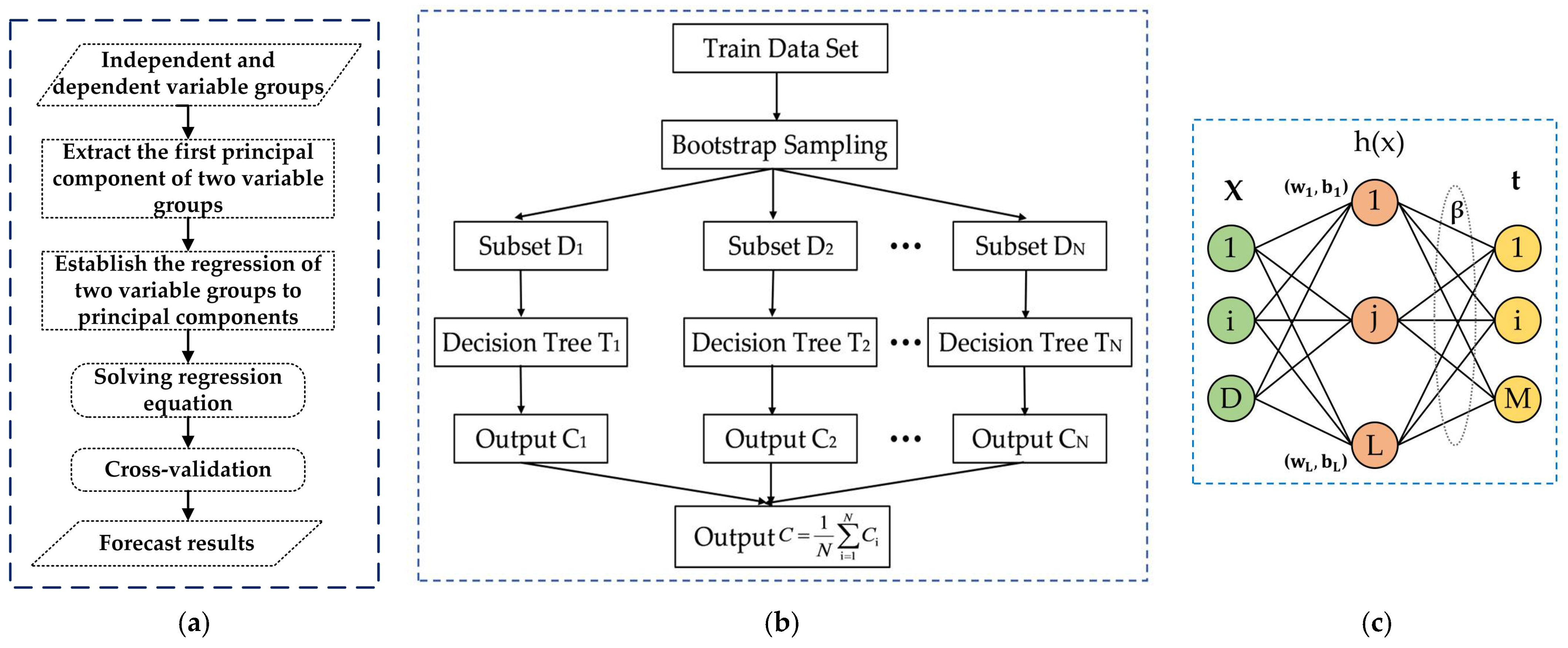

2.3. Data Processing Method

2.3.1. Extraction of Average Spectral Data

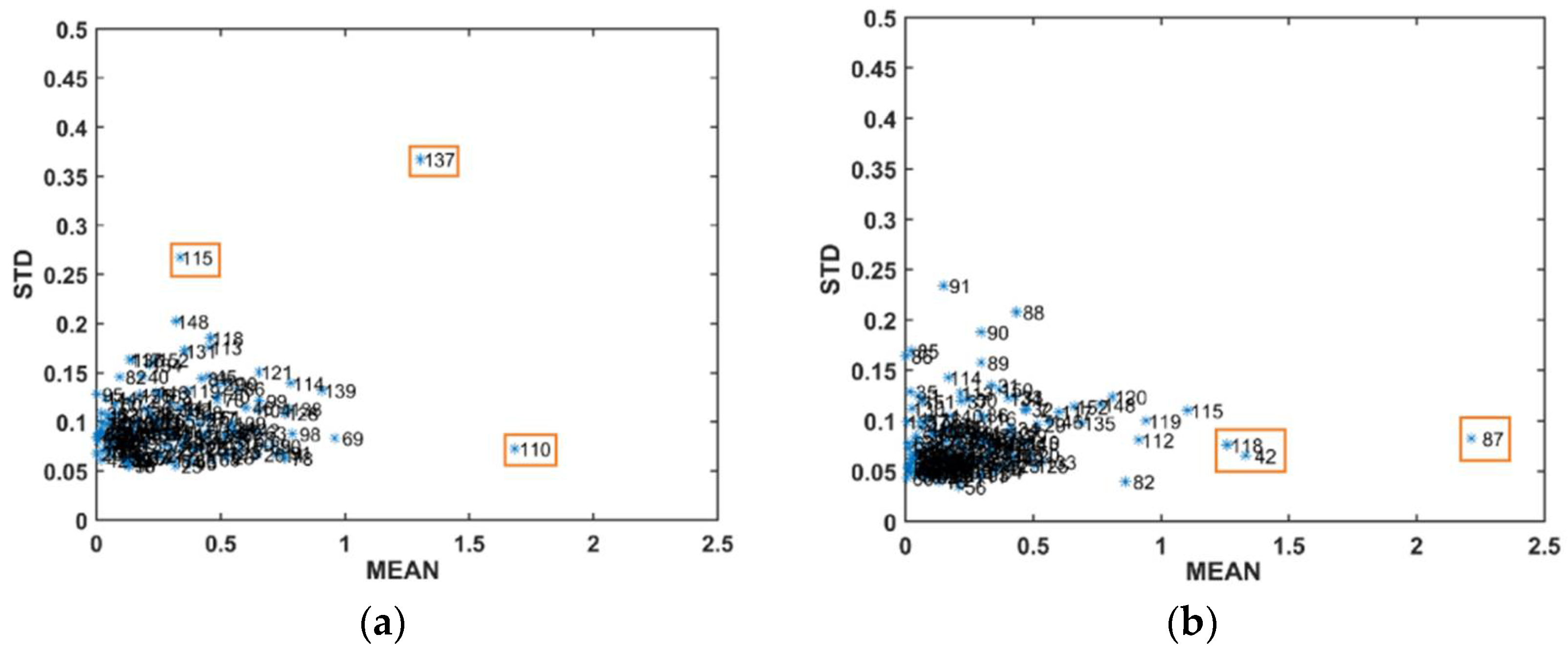

2.3.2. Removal of Abnormal Samples

2.3.3. Spectral Data Preprocessing

2.3.4. Characteristic Variable Screening

2.3.5. Model Establishment and Evaluation

3. Results

3.1. Analysis of Original Data

3.2. Elimination of Abnormal Samples

3.3. Spectral Data Preprocessing

Moisture Content Pretreatment

3.4. Feature Extraction

3.5. Modeling Results and Analysis

3.6. Moisture Content Visualization

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Zhang, J. Study on the Molding Mechanism, Physical Properties, and Combustion Characteristics of Caragana Korshinskii Solid Fuel. Doctoral Dissertation, Shanxi Agricultural University, Taiyuan, China, 2014. [Google Scholar]

- Shao, C.Y.; Zhao, Y.M.; Lu, L.L. Research progress on application of near infrared spectroscopy rapid analysis technology. Chem. Bull. 2024, 87, 898–912. [Google Scholar]

- Costa, M.A.M.; da Silva, B.M.; de Almeida, S.G.C.; Felizardo, M.P.; Costa, A.F.M.; Cardoso, A.A.; Dussán, K.J. Evaluation of the efficiency of a Venturi scrubber in particulate matter collection smaller than 2.5 µm emitted by biomass burning. Environ. Sci. Pollut. Res. Int. 2023, 30, 8835–8852. [Google Scholar] [CrossRef]

- Wang, F.; Lin, H.; Xu, P.; Bi, X.; Sun, L. Egg Freshness Evaluation Using Transmission and Reflection of NIR Spectroscopy Coupled Multivariate Analysis. Foods 2021, 10, 2176. [Google Scholar] [CrossRef]

- Wu, X.; Liang, X.; Wang, Y.; Wu, B.; Sun, J. Non-Destructive Techniques for the Analysis and Evaluation of Meat Quality and Safety: A Review. Foods 2022, 11, 3713. [Google Scholar] [CrossRef] [PubMed]

- Beć, K.B.; Grabska, J.; Czarnecki, M.A. Spectra-structure correlations in NIR region: Spectroscopic and anharmonic DFT study of n-hexanol, cyclohexanol and phenol. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 197, 176–184. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.Y. Research on Performance Detection of Agricultural and Forestry Biomass Raw Materials and Carbon Briquette Fuel. Master’s Thesis, Zhejiang University, Hangzhou, China, 2013. [Google Scholar]

- Wang, X.Y.; Sun, X.B.; Wang, J.; Xie, G.H. Difference and correlation between ash content and calorific value of waste biomass and its determination method. J. China Agric. Univ. 2022, 27, 160–172. [Google Scholar]

- Guo, G.; Zhang, M.L.; Gong, Z.J.; Zhang, S.Z.; Wang, X.Y. Construction of biomass ash content model based on near infrared spectroscopy and complex sample partition set. Spectrosc. Spectr. Anal. 2023, 43, 3143–3149. [Google Scholar]

- Han, Y.; Dong, C.Q.; Zhang, J.J.; Hu, X.Y.; Xue, J.J.; Zhao, Y.; Wang, X.Q. Moisture prediction of biomass fuel based on near-infrared spectroscopy and deep learning algorithm. Energy Fuels 2024, 38, 6062–6071. [Google Scholar] [CrossRef]

- Li, Y.; Xu, H.K.; Lan, X.Z.; Wang, J.X.; Su, X.M.; Bai, X.P.; Via, B.K.; Pei, Z.Y. Predicting calorific value and ash content of sand shrub using Vis-NIR spectra and various chemometrics. Renew. Energy 2024, 230, 120805. [Google Scholar] [CrossRef]

- Fagan, C.C.; Everard, C.D.; McDonnell, K. Prediction of moisture, calorific value, ash and carbon content of two dedicated bioenergy crops using near-infrared spectroscopy. Bioresour. Technol. 2011, 102, 5200–5206. [Google Scholar] [CrossRef]

- Mancini, M.; Rinnan, Å.; Pizzi, A.; Toscano, G. Prediction of gross calorific value and ash content of woodchip samples by means of FT-NIR spectroscopy. Fuel Process. Technol. 2018, 169, 77–83. [Google Scholar] [CrossRef]

- Noushabadi, A.S.; Dashti, A.; Ahmadijokani, F.; Hu, J.; Mohammadi, A.H. Estimation of higher heating values (HHVs) of biomass fuels based on ultimate analysis using machine learning techniques and improved equation. Renew. Energy 2021, 179, 550–562. [Google Scholar] [CrossRef]

- GB/T 28731-2012; Solid Biofuels Fuel Specification and Classes. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China & Standardization Administration of the People’s Republic of China: Beijing, China, 2012.

- Hao, Y.; Chen, B.; Zhu, R. Analysis of several wavelet denoising methods in near infrared spectral preprocessing. Spectrosc. Spectr. Anal. 2006, 26, 1838–1841. [Google Scholar]

- Sun, J.Y.; Li, M.Z.; Zheng, L.H.; Hu, Y.G.; Zhang, X.J. Real-time analysis of northern fluvo aquic soil parameters based on near infrared spectroscopy. Spectrosc. Spectr. Anal. 2006, 426–429. [Google Scholar]

- Luo, J.; Ying, K.; Bai, J. Savitzky–Golay smoothing and differentiation filter for even number data. Signal Process. 2005, 85, 1429–1434. [Google Scholar] [CrossRef]

- Barnes, R.J.; Dhanoa, M.S.; Lister, S.J. Standard normal variate transformation and de-trending of near-infrared diffuse reflectance spectra. Appl. Spectrosc. 1989, 43, 772–777. [Google Scholar] [CrossRef]

- Isaksson, T.; Næs, T. The effect of multiplicative scatter correction (MSC) and linearity improvement in NIR spectroscopy. Appl. Spectrosc. 1988, 42, 1273–1284. [Google Scholar] [CrossRef]

- Helland, I.S.; Næs, T.; Isaksson, T. Related versions of the multiplicative scatter correction method for preprocessing spectroscopic data. Chemom. Intell. Lab. Syst. 1995, 29, 233–241. [Google Scholar] [CrossRef]

- Yao, K.; Sun, J.; Cheng, J. Development of Simplified Models for Non-Destructive Hyperspectral Imaging Monitoring of S-ovalbumin Content in Eggs during Storage. Foods 2022, 11, 2024. [Google Scholar] [CrossRef]

- Sun, J.; Cong, S.L.; Mao, H.P.; Wu, X.H.; Zhang, X.D. Hyperspectral-based CARS-ABC-SVR prediction model for water content in lettuce leaves. J. Agric. Eng. 2017, 33, 178–184. [Google Scholar]

- Zhang, J.; Rivard, B.; Rogge, D.M. The successive projection algorithm (SPA), an algorithm with a spatial constraint for the automatic search of endmembers in hyperspectral data. Sensors 2008, 8, 1321–1342. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Tang, K.; Wu, X.H.; Dai, C.X.; Chen, Y.; Shen, G.F. Nondestructive identification of green tea varieties based on hyperspectral imaging technology. J. Food Process Eng. 2018, 41, e12800. [Google Scholar] [CrossRef]

- Yu, L.; Zhang, T.; Zhu, Y.X.; Zhou, Y.; Xia, T. Optimization of hyperspectral characteristic wavelength variables of soybean leaves and estimation of SPAD value based on IRIV algorithm. J. Agric. Eng. 2018, 34, 148–154. [Google Scholar]

- Wang, H.; Xiang, Y.Z.; Li, W.Y.; Shi, H.Z.; Wang, X. Estimation of winter rape aboveground biomass based on UAV multispectral remote sensing. J. Agric. Mach. 2023, 54, 218–229. [Google Scholar]

- Chen, X.C. Nondestructive Detection of Caragana Microparticle Quality Parameters Based on Hyperspectral Technology. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2024. [Google Scholar]

- Zhang, M.Y. Detection and Classification of Silage Corn Feed Quality Based on Hyperspectral Data. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2023. [Google Scholar]

- Song, X.; Xu, Q.; Li, H. Automatic quantification of retinal photoreceptor integrity to predict persistent disease activity in neovascular age-related macular degeneration using deep learning. Front. Neurosci. 2022, 16, 952735. [Google Scholar] [CrossRef]

- Li, J. Quality Detection of Dry Alfalfa Based on Visible/Near Infrared Spectroscopy and Electronic Nose Information Fusion. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2024. [Google Scholar]

- Peng, Y.; Lu, B.L. Discriminative manifold extreme learning machine and applications to image and EEG signal classification. Neurocomputing 2016, 174, 265–277. [Google Scholar] [CrossRef]

- Li, W.; Xiao, Y.M.; Ishag, B.; Akoy, R.; Zhang, J.Y.; Yan, Q. Construction of near-infrared prediction model for key quality indicators of sainfoin hay. Pratacult. Sci. 2024, 45, 123–145. [Google Scholar]

- Yu, Z.H.; Chen, X.C.; Zhang, J.C.; Su, Q.; Wang, K.; Liu, W.H. Rapid and non-destructive estimation of moisture content in Caragana korshinskii pellet feed using hyperspectral imaging. Sensors 2023, 23, 7592. [Google Scholar] [CrossRef]

- Seilkhan, A. An Overview of Green Applications of Natural Products for Pharmaceutical, Biofuel, and Rubber Industries: Case Study of Kazakh Dandelion (Taraxacum kok-saghyz Rodin). ES Energy Environ. 2024, 25, 1171. [Google Scholar] [CrossRef]

- Zhubanova, A.; Abdieva, G.; Ualieva, P.; Akimbekov, N.; Malik, A.; Tastambek, K. Whey-to-Bioethanol Valorisation: Fermentation with Immobilized Yeast Cells. Eng. Sci. 2024, 27, 995. [Google Scholar] [CrossRef]

- Kapoor, L.; Mohan, T.B.G.; Ranjith, K. Evaluating Fuel Properties and Chemical Composition of Biofuel Produced Via Co Pyrolysis of Rice Straw and Groundnut Shell. ES Energy Environ. 2024, 25, 1124. [Google Scholar] [CrossRef]

- Hou, J.Y.; Liu, L.X. Laboratory determination of coal calorific value and study on its influencing factors. Inn. Mong. Coal Econ. 2025, 58–60. [Google Scholar]

- Guo, H.R.; Zhao, Z.X.; Bao, Z.; Qiu, Y.H.; Peng, B.; Liu, Q.Y.; He, L. Evaluation of uncertainty in determining the heat value of biomass raw materials using a bomb calorimeter. Chem. Res. Appl. 2022, 34, 399–406. [Google Scholar]

- Guan, J. Study on the Determination Method of Calorific Value of Solid Biomass Formed Fuel. Master’s Thesis, Guangdong Technological University, Guangzhou, China, 2020. [Google Scholar]

| Region | Procurement Location | Particle Size (mm) | Number of Samples | Total |

|---|---|---|---|---|

| Hohhot City | Inner Mongolia Agricultural University Machinery Factory | 8 | 41 | 152 |

| Tongliao City | Xingwei Biotechnology Co., Ltd. | 8 | 35 | |

| Xing’an League City | Rui’er Biomass Energy Development Co., Ltd. | 6 | 40 | |

| Wulanchabu City | Longshunzhuang Agriculture and Animal Husbandry Co., Ltd. | 4 | 36 |

| Sample Quality Parameters | Number of Samples | Min | Max | Mean | Standard Error |

|---|---|---|---|---|---|

| Moisture content (%) | 152 | 6.08% | 11.06% | 7.96% | 1.33 |

| High calorific value (kj/g) | 152 | 18.01 | 20.72 | 19.54 | 0.68 |

| Model | Pretreatment Method | Number of Latent Variables/Number of Neurons | Training Set | Test Set | |||

|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | RPD | |||||

| PLSR | RAW | 11 | 0.9701 | 0.2151 | 0.8853 | 0.4349 | 3.5008 |

| MMN | 10 | 0.9655 | 0.2300 | 0.9239 | 0.3791 | 3.9669 | |

| MSC | 9 | 0.9693 | 0.2176 | 0.9161 | 0.3648 | 3.9596 | |

| SG | 10 | 0.9578 | 0.2629 | 0.9288 | 0.3302 | 4.1716 | |

| SNV | 11 | 0.9691 | 0.2212 | 0.9433 | 0.3387 | 4.3748 | |

| RFR | RAW | 0.9653 | 0.2552 | 0.8382 | 0.4748 | 2.5184 | |

| MMN | 0.9715 | 0.2208 | 0.8884 | 0.4600 | 3.0330 | ||

| MSC | 0.9741 | 0.2139 | 0.8989 | 0.4196 | 3.1863 | ||

| SG | 0.9687 | 0.2446 | 0.8499 | 0.4449 | 2.6151 | ||

| SNV | 0.9738 | 0.2193 | 0.9043 | 0.3857 | 3.2749 | ||

| ELM | RAW | 20 | 0.9049 | 0.4140 | 0.8047 | 0.5624 | 2.2938 |

| MMN | 26 | 0.9412 | 0.3175 | 0.9195 | 0.3902 | 3.5725 | |

| MSC | 22 | 0.9476 | 0.2969 | 0.8801 | 0.4825 | 2.9277 | |

| SG | 21 | 0.8938 | 0.4409 | 0.8839 | 0.4216 | 2.9751 | |

| SNV | 30 | 0.9588 | 0.2696 | 0.9242 | 0.3638 | 3.6813 | |

| Model | Pretreatment Method | Number of Latent Variables/Number of Neurons | Training Set | Test Set | |||

|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | RPD | |||||

| PLSR | RAW | 6 | 0.7243 | 0.3060 | 0.5864 | 0.3960 | 1.9711 |

| MMN | 12 | 0.7364 | 0.3203 | 0.6692 | 0.3690 | 1.7877 | |

| MSC | 12 | 0.7424 | 0.3063 | 0.6891 | 0.3747 | 1.9979 | |

| SG | 11 | 0.7669 | 0.2969 | 0.7234 | 0.3304 | 2.1217 | |

| SNV | 12 | 0.7080 | 0.3282 | 0.6324 | 0.3651 | 1.9415 | |

| RFR | RAW | 0.8090 | 0.3020 | 0.6241 | 0.4242 | 1.6524 | |

| MMN | 0.7634 | 0.3262 | 0.6787 | 0.4206 | 1.7873 | ||

| MSC | 0.7547 | 0.3345 | 0.6378 | 0.4343 | 1.6834 | ||

| SG | 0.8235 | 0.2861 | 0.7435 | 0.3663 | 2.0002 | ||

| SNV | 0.7240 | 0.3653 | 0.6687 | 0.3906 | 1.7601 | ||

| ELM | RAW | 8 | 0.7596 | 0.3445 | 0.5510 | 0.4119 | 1.5118 |

| MMN | 14 | 0.6356 | 0.4135 | 0.5644 | 0.4554 | 1.5355 | |

| MSC | 24 | 0.7189 | 0.3399 | 0.6155 | 0.4775 | 1.6338 | |

| SG | 15 | 0.7544 | 0.3505 | 0.6112 | 0.4009 | 1.6252 | |

| SNV | 16 | 0.7732 | 0.3233 | 0.6086 | 0.4515 | 1.6194 | |

| Model | Feature Extraction Method | Number of Latent Variables/Number of Neurons | Feature Points | Training Set | Test Set | |||

|---|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | RPD | ||||||

| PLSR | RAW | 11 | 0.9691 | 0.2212 | 0.9433 | 0.3387 | 4.3748 | |

| CARS | 10 | 27 | 0.9689 | 0.2311 | 0.9475 | 0.2863 | 4.6447 | |

| SPA | 8 | 25 | 0.9560 | 0.2802 | 0.9404 | 0.2888 | 4.1180 | |

| GA | 7 | 32 | 0.9650 | 0.2540 | 0.9540 | 0.2599 | 4.4559 | |

| IRIV | 9 | 46 | 0.9712 | 0.2207 | 0.9693 | 0.2358 | 5.6792 | |

| RFR | RAW | 0 | 0.9738 | 0.2193 | 0.9043 | 0.3857 | 3.2749 | |

| CARS | 27 | 0.9675 | 0.2438 | 0.9247 | 0.3356 | 3.6912 | ||

| SPA | 25 | 0.9765 | 0.2076 | 0.9318 | 0.3161 | 3.8796 | ||

| GA | 32 | 0.9605 | 0.2573 | 0.9102 | 0.4202 | 3.3798 | ||

| IRIV | 46 | 0.9656 | 0.2288 | 0.8949 | 0.4687 | 3.1244 | ||

| ELM | RAW | 30 | 0 | 0.9588 | 0.2696 | 0.9242 | 0.3638 | 3.6813 |

| CARS | 27 | 27 | 0.9719 | 0.2193 | 0.9514 | 0.3019 | 4.5960 | |

| SPA | 30 | 25 | 0.9672 | 0.2403 | 0.9455 | 0.2972 | 4.3401 | |

| GA | 27 | 32 | 0.9723 | 0.2222 | 0.9227 | 0.3615 | 3.6445 | |

| IRIV | 23 | 46 | 0.9557 | 0.2805 | 0.9331 | 0.3373 | 3.9181 | |

| Algorithm Combinations | Number of Latent Variables/Number of Neurons | Feature Points | Training Set | Test Set | RPD | SE | ||

|---|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | |||||||

| SNV-IRIV-PLSR | 9 | 46 | 0.9712 | 0.2207 | 0.9693 | 0.2358 | 5.6792 | 0.1761 |

| SNV-CARS-ELM | 27 | 27 | 0.9719 | 0.2193 | 0.9514 | 0.3019 | 4.5960 | 0.2175 |

| SNV-SPA-RFR | 25 | 0.9765 | 0.2076 | 0.9318 | 0.3161 | 3.8796 | 0.2578 | |

| Model | Feature Extraction Method | Number of Latent Variables/Number of Neurons | Feature Points | Training Set | Test Set | |||

|---|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | RPD | ||||||

| PLSR | RAW | 11 | 0 | 0.7669 | 0.2969 | 0.7234 | 0.3304 | 2.1217 |

| CARS | 9 | 53 | 0.7558 | 0.3037 | 0.7415 | 0.3163 | 2.2764 | |

| CARS | 9 | 53 | 0.7558 | 0.3037 | 0.7415 | 0.3163 | 2.2764 | |

| SPA | 9 | 28 | 0.7849 | 0.2890 | 0.7383 | 0.3728 | 1.9214 | |

| GA | 6 | 40 | 0.7794 | 0.2890 | 0.7494 | 0.3174 | 2.3306 | |

| IRIV | 11 | 33 | 0.7726 | 0.2928 | 0.7272 | 0.3398 | 2.1563 | |

| RFR | RAW | 0 | 0.8235 | 0.2861 | 0.7435 | 0.3663 | 2.0002 | |

| CARS | 53 | 0.8130 | 0.2941 | 0.8037 | 0.3219 | 2.2864 | ||

| SPA | 28 | 0.8029 | 0.2975 | 0.7784 | 0.3503 | 2.1522 | ||

| GA | 40 | 0.8045 | 0.3015 | 0.7235 | 0.3640 | 1.9268 | ||

| IRIV | 33 | 0.8027 | 0.3025 | 0.7670 | 0.3355 | 2.0987 | ||

| ELM | RAW | 15 | 0 | 0.7544 | 0.3505 | 0.6112 | 0.4009 | 1.6252 |

| CARS | 30 | 53 | 0.7836 | 0.3244 | 0.6962 | 0.3725 | 1.8386 | |

| SPA | 13 | 28 | 0.7718 | 0.3351 | 0.7051 | 0.3616 | 1.8661 | |

| GA | 8 | 40 | 0.7777 | 0.3411 | 0.6538 | 0.3487 | 1.7224 | |

| IRIV | 15 | 33 | 0.7686 | 0.3190 | 0.6801 | 0.4327 | 1.7917 | |

| Algorithm Combinations | Number of Latent Variables/Number of Neurons | Feature Points | Training Set | Test Set | RPD | SE | ||

|---|---|---|---|---|---|---|---|---|

| RMSEC | RMSEP | |||||||

| SG-GA-PLSR | 6 | 40 | 0.7794 | 0.2890 | 0.7494 | 0.3174 | 2.3306 | 0.4291 |

| SG-SPA-ELM | 13 | 28 | 0.7718 | 0.3351 | 0.7051 | 0.3616 | 1.8661 | 0.5359 |

| SG-CARS-RFR | 53 | 0.8130 | 0.2941 | 0.8037 | 0.3219 | 2.2864 | 0.4374 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

De, X.; Li, H.; Zhang, J.; Li, N.; Wan, H.; Ma, Y. Prediction of the Calorific Value and Moisture Content of Caragana korshinskii Fuel Using Hyperspectral Imaging Technology and Various Stoichiometric Methods. Agriculture 2025, 15, 1557. https://doi.org/10.3390/agriculture15141557

De X, Li H, Zhang J, Li N, Wan H, Ma Y. Prediction of the Calorific Value and Moisture Content of Caragana korshinskii Fuel Using Hyperspectral Imaging Technology and Various Stoichiometric Methods. Agriculture. 2025; 15(14):1557. https://doi.org/10.3390/agriculture15141557

Chicago/Turabian StyleDe, Xuehong, Haoming Li, Jianchao Zhang, Nanding Li, Huimeng Wan, and Yanhua Ma. 2025. "Prediction of the Calorific Value and Moisture Content of Caragana korshinskii Fuel Using Hyperspectral Imaging Technology and Various Stoichiometric Methods" Agriculture 15, no. 14: 1557. https://doi.org/10.3390/agriculture15141557

APA StyleDe, X., Li, H., Zhang, J., Li, N., Wan, H., & Ma, Y. (2025). Prediction of the Calorific Value and Moisture Content of Caragana korshinskii Fuel Using Hyperspectral Imaging Technology and Various Stoichiometric Methods. Agriculture, 15(14), 1557. https://doi.org/10.3390/agriculture15141557