Abstract

Planting tomatoes in enclosed facilities requires manual pollination assistance. Chemically-assisted pollination poses environmental pollution and food safety hazards. Contact vibration pollination is inefficient, ineffective, and prone to plant damage. This study developed a non-contact tomato pollination device based on pulse airflow, and conducted an experimental investigation on it. Firstly, a non-contact tomato pollination device based on pulse airflow was designed, based on the reciprocating motion of tomato flowers under the action of pulse airflow. Subsequently, this study took the coverage rate of pollen on the stigma as an indicator, and the optimal pulse airflow parameters were determined, which were a velocity of 1.22 m·s−1, airflow angle of −19.69°, and pulse frequency of 25.64 Hz. Finally, comparative experiments were conducted between the pollination effect of tomatoes based on pulse airflow and other assisted pollination methods. The results show that tomato flowers produce a composite reciprocating vibration under the coupling effect of the inflorescence elastic force and the pulse airflow force, and the coverage of pollen on the stigma is 11.2% higher than assisted pollination using stable airflow. The use of a pulse airflow pollination method can increase the fruit setting rate by 13.21%, increase the weight per fruit by 11.46%, and increase the weight of fruits per bunch by 33.33%. Compared with chemically-assisted fruit setting, no chemical agents were used to ensure a fruit setting rate similar to chemical methods, and the number of seeds per fruit increased by 74.8. Compared with vibration pollination, it eliminated plant damage and increased the fruit setting rate by 4.45%, and improved efficiency by 18.6%. The results indicated that the pollination method based on pulse airflow is environmentally friendly, high-quality, and efficient. This study breaks through the theoretical and parameter limitations of traditional airflow pollination devices, and provides a theoretical base for the development of clean pollination equipment in facility agriculture.

1. Introduction

In natural environments, a tomato (Lycopersicon esculentum) can be effectively pollinated through insects, such as bumblebees, or wind pollination [,]. Facility crop cultivation achieves temperature and humidity regulation and maintenance through a closed environment, especially in the cold winter [,]. The closed facility environment causes a lack of pollination activities from natural pollinators, and the fruit setting rate, yield, and quality of tomato fruits are greatly restricted [,]. Therefore, the cultivation of facility tomatoes requires a large amount of manually-assisted pollination operations []. The assisted pollination can be mainly divided into chemically-assisted fruit setting, biologically-assisted pollination, and physically-assisted pollination, according to the implementation methods [].

Chemically-assisted fruit setting methods increase tomato fruit setting rate by spraying or dipping tomato flowers with chemical agents. Improper concentration or spraying of chemical agents on tender leaves, flower buds, etc., can easily lead to plant damage or abnormal fruit []. In addition, the use of chemical agents may also pose food safety or soil and water pollution problems in facilities [,], and should be replaced by green pollination methods as soon as possible [].

Biologically-assisted pollination refers to the method of assisting the pollination of crops by releasing pollinators such as bumblebees in greenhouses, which is clean and efficient. This is currently widely used in European countries such as the Netherlands and Italy [,]. Although biological pollination is green and harmless, developing countries lack sufficient facilities and have a significant gap in environmental regulation compared to other developed countries []. Moreover, pesticide application is often required in the cold winter and humid summer, which cannot meet the needs of bee pollination activities and cannot guarantee pollination efficiency [].

Physically-assisted pollination refers to the application of vibrations to tomato plants and inflorescence based on the characteristics of tomato bee pollination, which drives flower vibrations to release pollen and promote tomato pollination []. At present, some growers use electronic vibration pollinators to use vibrating components to contact tomato inflorescence stems to drive the shaking of tomato flowers for pollination []. These contact-based physical pollination methods are fast but labor-intensive, ineffective, and prone to plant damage, which cannot meet the pollination needs of facility tomatoes [].

For fruit tree or field crop pollination, there have been some studies on pollination under the action of airflow [,]. Drawing on relevant experience, some studies have also been conducted on the method of facility tomato pollination using airflow blowing or the downwash flow field of an unmanned aerial vehicle (UAV) to drive tomato flower motion []. In addition, when pulsed airflow acts on the inflorescence, it can achieve a mechanical vibration-like effect [,,], allowing tomato flowers to achieve a regular reciprocating motion, which may improve the pollination efficiency of tomatoes [].

The pollination method through airflow blowing is gradually being applied to facility tomato cultivation. Some growers use an air blower to directly blow the tomato flowers, causing the tomato inflorescence to shake and release pollen [,]. Although this method of using an air blower for the assisted pollination of tomatoes has been proven effective, its effectiveness is not ideal, possibly because the airflow parameters are not suitable for tomato pollination or the pollen released is blown away with the high velocity airflow [].

Shi Qiang et al. established a simulation model for tomato wind-induced pollination based on the strong spatiotemporal pulsation characteristics of an unmanned aerial vehicle (UAV) downwash flow field. They investigated the effects of parameters such as UAV hovering height and average wind speed in the downwash flow field on tomato pollination and conducted pollination experiments. The results indicate that the UVA’s downwash flow field can effectively pollinate, through wind-induced vibration, tomatoes on both sides simultaneously, improving the pollination rate [].

At present, most studies on airflow-assisted pollination technology mainly focus on field crops or fruit trees, and most of them directly use large-scale air blowing to achieve assisted pollination. The determination of airflow parameters is relatively simple and lacks theoretical support. Air blowers or drones with built-in flow fields are often used to directly blow tomatoes for pollination-based airflow. However, there is relatively little research on the pneumatic pollination of facility crops.

To address this issue, Kumar et al. [] designed a tomato pollination device based on pulsed airflow. This pollination device is achieved by installing a 3D-printed barrier plate at the outlet of the air blower, which rotates and helps to block and release the airflow outlet to generate pulse airflow. The experimental results showed that the efficiency of the pulse airflow tomato pollination machine was significantly higher than that of the pollination method using an air blower, and the yield improvement was also significantly higher than that of the tomato pollination method using a blower because it has three airflow outlets on each of its left and right rows []. Wu et al. [] proposed a pulse airflow bundle tomato pollination method and built a corresponding pollination device. Analyzing its oscillation law under the action of pulse airflow, based on the mathematical model of gas–solid two-phase flow, a CFD-DEM coupled simulation model was established to simulate the tomato flower pollination process. Finally, the optimal parameters for pulse airflow bundled tomato pollination were obtained through experiments [].

However, research on pulse airflow in crop pollination is still in the exploratory stage, and there are few relevant reports at present. The device is too large and may not be suitable for the pollination of certain greenhouse tomatoes.

In summary, biologically-assisted pollination is easily affected by facility conditions, especially in the cold winter with inadequate facilities. Chemically-assisted fruit setting is prone to quality decline, which also does not meet the development needs of ecological agriculture. Vibration pollination methods can cause plant damage and spread diseases through contact with crops. Therefore, airflow pollination based on airflow could be a possible clean and non-contact tomato pollination method. While at present the method of using airflow pollination has been proposed, there are few reports on the device design and parameter optimization research using pulse airflow for tomato pollination.

In order to address the aforementioned issues, this study will develop a handheld device for the supplementary pollination of tomatoes in greenhouses. By generating pulsed airflow, the tomato inflorescence vibration is driven to achieve green and harmless pollination of tomatoes. Firstly, based on the pulse airflow pollination needs of tomatoes, the pollination device based on pulse airflow was designed. Then, the pulse airflow velocity, angle, and frequency were determined through orthogonal experiments. Finally, the pollination and fruit setting effects of a pollination device based on pulse airflow were compared and analyzed through tomato pollination experiments.

2. Materials and Methods

In this research, all materials and experimental sites were sourced from Shengdao Agricultural Industrial Park, Taiji Town, Beipiao City, Liaoning Province (E 120.72°, N 41.81°). The tomato variety used in the experiments is L-402 type pink tomato, which is a common tomato variety with middle size fruit in northern China. It is an infinite growth tomato variety, with a plant height of 80 to 100 cm when harvested from three ears, and an opening degree of about 50 cm. The tomato of L-402 variety has about 4 to 6 flowers per inflorescence, with an average flowering period of about 4 days, and usually takes 40 to 50 days from flowering to fruit ripening. After the flowers fully open, there is a lot of pollen within the barrel shaped anthers of stamens, making it easier to achieve self-pollination. However, tomatoes have a poor disease resistance in facilities with large temperature changes in winter, requiring frequent pesticide application operations, which greatly reduces the activity and pollination efficiency of pollinators such as bumblebees. Therefore, the pulse airflow pollination method proposed in this study is suitable for tomato pollination under these conditions.

2.1. Design of Tomato Pollination Device Based on Pulse Airflow

2.1.1. Principle of Tomato Pollination Based on Pulse Airflow

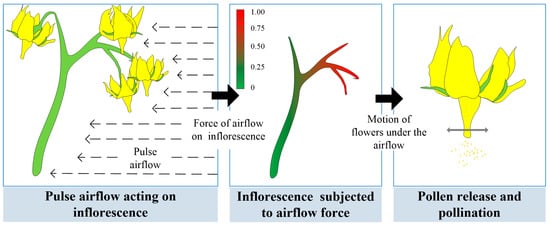

The principle of pulse airflow pollination for tomatoes is shown in Figure 1. When the pulse airflow acts on the tomato inflorescence, various parts such as flowers and inflorescence stems will be affected by the force of the airflow, resulting in displacement. The displacement generated by various parts will ultimately drive the tomato flowers at the tip of the inflorescence to significant displacement. The motion direction and displacement will rapidly change under changes in force, which results in the reciprocating motion of tomato flowers. This reciprocating motion is similar to the vibration generated by pollinators such as bumblebees when they come into contact with tomato flowers for pollination. The reciprocating motion will cause the tomato anthers to release pollen and complete effective pollination.

Figure 1.

The implementation principle of tomato pollination based on pulse airflow.

2.1.2. Construction of Tomato Pollination Device Based on Pulse Airflow

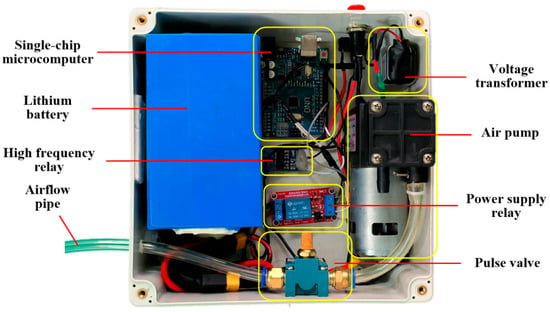

In order to achieve effective tomato pollination with pulse airflow, an electronic tomato pollination device was designed. It can generate pulsed airflow to achieve non-contact tomato pollination, as shown in Figure 2, which has a size of 250 mm × 150 mm × 100 mm, and a weight of 1.5 kg. It has the advantages of a simple structure and compactness, which make it suitable for non-contact pollination operations of facility tomatoes.

Figure 2.

Main components of pulse airflow tomato pollinator.

The designed pollination device based on pulse airflow is mainly powered by a 12V lithium battery, which drives the air pump with a rated power of 42 W, a maximum flow rate of 40 L·min−1, and an outlet diameter of 6 mm. It should be noted that a ASL-6 pressure regulating valve (Shannais Automation (Ningbo) Group TWSNS, Ningbo, China) is installed at the outlet of the pump to ensure stable and adjustable airflow velocity. The pulse airflow was emitted through a PWM (Pulse Width Modulation) type signal of the micro-controller. In order to ensure the uniformity of the airflow force on the tomato flowers, we adjusted the duty cycle of the PWM signal to 50%. Therefore, the opening and closing times of the valve were consistent. The micro-controller generates a frequency-adjustable PWM wave signal, which drives the pulse valve through a high-frequency relay. Driven by these signals, it is possible to result in a pulse airflow with regular on–off patterns at the airflow outlet.

The key components of the designed pulse airflow tomato pollinator based on pulse airflow and their main parameters are shown in Table 1.

Table 1.

Key components and parameters of pollination device based on pulse airflow.

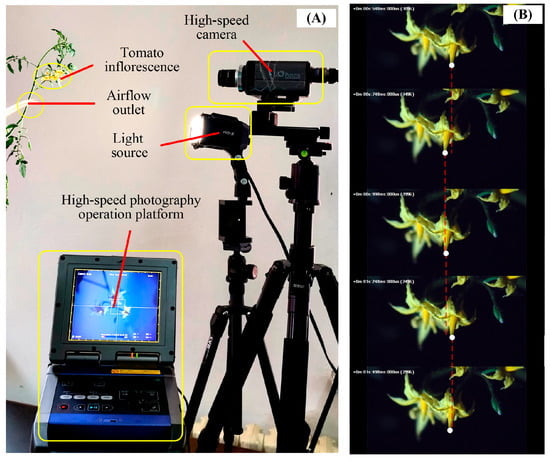

In order to observe and analyze the motion characteristics of tomato flowers under pulsed airflow pollination, a high-speed photography system, as shown in Figure 3A, was built. The high-speed photography system (Photron PhotoCam Speeder v2, Photron Limited, Yonezawa City, Japan) can capture continuous motion process images of tomato flowers under the action of pulsed airflow at a speed of 2000 fps. Figure 3B shows the position (white points) and displacement comparison (red lines) of tomato flowers at different times under the action of pulsed airflow at the same time interval (250 ms). It can be seen that tomato flowers have different displacements under the action of pulsed airflow. Subsequently, their movement trajectory and characteristics can be analyzed based on their coordinates to further analyze the movement pattern of tomato flowers under the action of pulsed airflow and their relationship with pollination.

Figure 3.

High-speed photography system and tomato flower motion trajectory under pulse airflow. (A) High-speed camera system. (B) Tomato flower positions and displacements under pulse airflow.

2.2. Determination and Optimization of Pulse Airflow Pollination Parameters

According to the principle of tomato pollination based on pulse airflow, it can be inferred that different pulse airflows acting on the tomato inflorescence will cause different motions of the flower, resulting in different pollination effects. Therefore, in order to optimize the pollination and fruit setting effects of pulse airflow on tomato pollination, a study was conducted to determine the pulse airflow parameter influence rules for tomato pollination, and to determine the optimal parameter combination through an orthogonal test.

2.2.1. Determination of Key Parameters for Pulse Airflow Pollination

When the pulse airflow acts on the tomato inflorescence, if the airflow velocity is too slow, it is difficult to drive the tomato inflorescence and tomato flower to realize effective reciprocating motion and pollination. If the airflow velocity is too fast, the force generated on the flowers may be too large, making it difficult for the tomato flowers to achieve reciprocating motion, and even blowing the inflorescence structure, making it impossible to achieve effective pollination.

For buzz pollination plants, the motion direction of the anther has an influence on the release of pollen []. Therefore, the direction of airflow is also an important factor that directly affects the tomato flower’s motion. In this study, the airflow angle is defined as the angle between the horizontal plane and the airflow direction. When the airflow direction is parallel to the horizontal plane, that means the airflow angle is 0°. If the airflow direction is inclined upward from the horizontal plane, the angle is a positive value; otherwise, it is a negative value.

In addition, the frequency of the pulse airflow is also very important for the motion of tomato flowers, because at a faster frequency, tomato flowers may not be able to produce significant displacement, and if the frequency is too low, it may not be able to cause the tomato inflorescence to produce regular motion and release pollen.

A single-factor experiment was conducted to compare and analyze the motion characteristics of flowers, and feasible ranges for each parameter were obtained. When the airflow velocity is less than 0.5 m·s−1, the airflow force on tomato flowers is too small to produce effective vibration. When the airflow velocity is greater than 1.5 m·s−1, the flowers are blown too heavily to return, resulting in vibration. When the airflow angle is less than −30° or greater than 30°, the tomato flowers are blown over, unable to form stable vibrations. Furthermore, when the frequency of the pulse airflow is below 10 Hz, the reciprocating motion amplitude of tomato flowers is large, but the vibration effect produced is not significant. When the frequency is higher than 50 Hz, the rapid change in airflow causes the movement direction of tomato flowers to change too quickly and unevenly.

Through single-factor experiments, it can be concluded that the airflow velocity between 0.5 to 1.5 m·s−1, the airflow angle between −30° to 30°, and the airflow pulse frequency between 10 to 50 Hz were suitable parameter ranges to achieve tomato pollination with non-contact pulse airflow. Based on these pulse airflow parameter ranges, the optimal parameter selection can be made according to the actual pollination effect.

2.2.2. Evaluation of Pollination Effect of Pulse Airflow Pollination

Under the effect of pulsed airflow, tomato pollen is released from the anthers’ holes. Due to the proximity of the anther holes to the stigma, the pollen will easily adhere to the sticky stigma during its release process. Thus, the pollen tube elongates until the egg cell completes fertilization, achieving effective pollination, ensuring fruit setting, increasing the number of seeds in the fruit and, thus, improving the taste and weight and quality of the fruit. In theory, the more pollen particles are deposited on the stigma, the higher the possibility of effective pollination []. Therefore, in order to quickly and intuitively observe and analyze the pollination effect of tomatoes, an image processing-based algorithm for pollen coverage on tomato stigma recognition was designed, which can help to intuitively evaluate the pollination results of tomatoes after pulse airflow pollination.

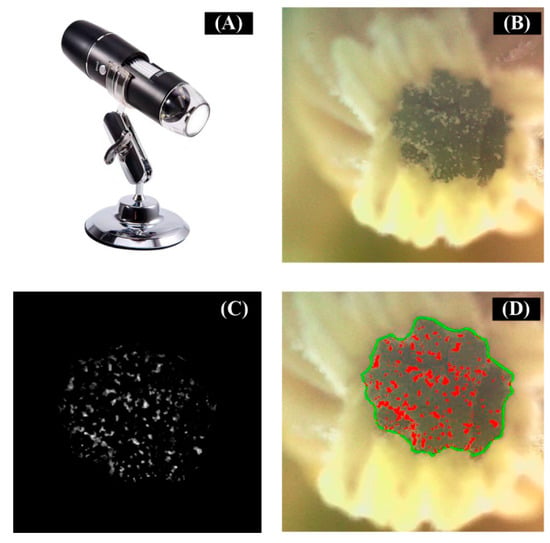

Firstly, an electronic micro-camera with the model of SHH-303 (Guangdong Shangshihua Technology Co., Ltd., Guangzhou, China) is used to directly face the tomato flower stigma, as shown in Figure 4A. The magnification is set to 200 times to capture images of tomato stigma, as shown in Figure 4B. Then, the color image was decomposed into red, green, and blue channels, and a mask with a size of 59 × 59 pixels was selected for image dynamic enhancement based on differential mean filtering using the red channel image []. The contrast between the stigma region and the pollen particle regions was significantly enhanced, as shown in Figure 4C. Finally, after binary processing, the pollen particle area A1 on the tomato stigma and the entire stigma area A2 were obtained, resulting in the tomato pollen stigma coverage Cp, as shown in Figure 4D and Formula (1).

Figure 4.

Identification of pollen coverage on tomato stigma based on image-processing method. (A) Electronic micro-camera. (B) Original image acquired with a micro-camera with a magnification factor of 200 times. (C) Enhanced stigma regions with pollen particles. (D) Recognition results of pollen particles: number and coverage.

To verify the accuracy of the proposed pollen deposition coverage image processing algorithm, the number of pollen patches obtained from image processing of 20 tomato stigma images was compared with the results of manual counting. Among them, a total of 4352 pollen patches were identified by manual counting, and 189 pollen patches were not correctly identified (including over-identification and under-identification) using image processing algorithms. The relative error between the pollen deposition targets identified using image processing algorithms and the manual counting results was 4.34%, which can meet the needs of evaluating tomato pollen deposition and pollination effects.

2.2.3. Orthogonal Test of Pulse Airflow Parameters Influence on Pollination Effect

An orthogonal test has the advantages of fewer test times, a simple method, and high efficiency, which has a wide range of applications in agricultural technology research and development []. Considering the test demand of this study, the orthogonal rotation test design method was selected to develop the test plan. In this study, three factors and three levels of an orthogonal test scheme were selected based on the test design principle of an orthogonal test to analyze the influence of airflow parameters on the pollination effect in this study. The test is carried out using the pollination device based on pulse airflow established in Section 2.1. The factor levels of the test selected are based on a single factor test result, which is shown in Table 2.

Table 2.

Test factors and levels for the orthogonal experiment of airflow parameters-pollination effect.

There were a total of 17 tests carried out according to the orthogonal rotation combination test design scheme with the Design Expert 12.0 professional analysis software. Although this experimental protocol has taken into account the impact of data reproducibility on the results, this study still conducted three replicates of each experiment and took the average to improve the accuracy of the study. However, it can still be seen that in different experimental groups with the same parameters (such as 2, 3, 5, etc.), the final experimental results were not completely the same, but this does not affect the analysis of the results.

This was according to the identification method of pollen coverage on stigma, as shown in Figure 4. We took the pollen coverage on the stigma, recognized via the image processing algorithm proposed in Section 2.2.2, as the effective pollination amount; the statistics of pollen coverage on the stigma under the combination of various factor levels are shown in Table 3.

Table 3.

Test-grouping scheme and results.

The corrected determination coefficient R2 in the regression model is 0.9345, indicating that the model has only 6.55% variation, which indicates that the regression model has been well fitted. The response function P of the effective pollination amount of tomatoes guided by airflow is used to establish a regression mathematical model with the actual values of each influencing factor as the independent variable, and the secondary response surface regression analysis is carried out. The multiple secondary response surface regression model is obtained via regression fitting the test data.

where P is pollen coverage on stigma, v is airflow velocity, a is airflow angle, and f is airflow pulse frequency.

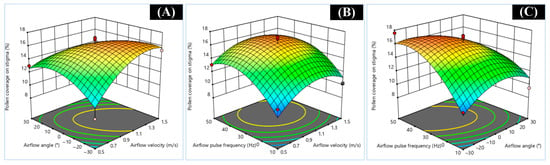

In order to further study the influence of airflow parameters on pollen coverage on the stigma, the test data were further processed to obtain the response surface of the interaction of each of the two factors, as shown in Figure 5. All three of these response surface curves show the opening downward trend; that is, with the increase in factor level, the effective pollination amount shows a trend of first increasing and then decreasing. The contour lines of these interaction surface curves were oval, indicating that there is an obvious interaction between each of the two factors.

Figure 5.

Response surface curves of airflow velocity, angle and pulse frequency for pollen coverage on stigma. (A) The response surface curve of airflow velocity and angle. (B) The response surface curve of airflow velocity and pulse frequency. (C) The response surface curve of airflow angle and pulse frequency.

Through comparative analysis of response surface curves, it can be concluded that a higher effective pollination amount is acquired when the airflow velocity is between 1.0 to 1.3 m·s−1, the airflow angle is between −25 to 0°, and the airflow frequency is between 20 to 40 Hz. Through optimization analysis within the above ranges, it was found that the optimal pollination effect can achieve a stigma coverage rate of 17.17% at an airflow velocity of 1.22 m/s, an airflow angle of −19.69° and a pulse frequency of 25.64 Hz.

2.3. Evaluation Methods of Fruit Setting Effect for Tomato

2.3.1. Experimental Conditions and Plans

The tomato planting facility used in this study is currently one of the most advanced solar greenhouses, at Chaoyang City, Liaoning Province, China (E 120.71, N 41.81), measuring 100 m in length and 7.5 m in width, and planted using a large ridge double row dense planting method. The plant spacing for tomato cultivation is 80 mm, and the row spacing is 150 mm. The tomato crops used in the experiment were planted in September 2023, and the pollination experiment was conducted between February and March 2024. The experimental targets were the second inflorescence of each tomato plant.

During the experiment, the tomato crops were divided into four groups based on the method of assisted pollination and fruit setting, which were the control group, chemically-assisted fruit setting group, vibration pollination group, and pulse airflow pollination group. In order to avoid the impact of inconsistent temperature, humidity, and their changes in the greenhouse head and tail areas on the experimental results, a 40 m long area in the middle of the greenhouse was selected as the experimental area. This experimental area was divided into four groups, with each different assisted pollination and fruit setting method group corresponding to a 10 m long area.

The first group is the control group used to compare the effects of various assisted pollination and fruit setting methods, and this group of tomatoes is not treated with any assisted pollination or fruit setting methods.

The second group is the chemical agent spraying group, which sprays chemical hormones twice a week based on greenhouse humidity to promote tomato ovary enlargement and achieve assisted fruit setting, as shown in Figure 6A.

Figure 6.

Operation scenarios of different assisted tomato fruit setting methods. (A) Assisted fruit setting with chemical agent spraying. (B) Assisted fruit setting with vibration pollinator. (C) Assisted fruit setting with pulse airflow pollination.

The third group is the vibration pollination group, which uses a specialized electric vibrating pollinator (CS-88, Guangzhou Lvbang Landscape Machinery Co., Ltd., Shenzhen, China) to achieve supplementary pollination for tomatoes. When the electric vibrating pollinator is working, the vibration rod will contact the inflorescence, driving the tomato flowers to shake and achieve assisted fruit setting, as shown in Figure 6B.

The fourth group is the pulse airflow pollination group, which uses the tomato pulse airflow pollination device constructed in this study for assisted pollination. Due to the handheld operation of the pulse airflow pollination device designed, it can ensure that the distance between the airflow outlet and the inflorescence is between 200 and 300 mm. By adjusting the output flow rate of the air pump, the airflow velocity reaching the tomato inflorescence can be ensured to be 1.2 m·s−1 to 1.25 m·s−1. In addition, due to limitations in installation accuracy, the angle between the airflow outlet and the horizontal plane is −20°, and the pulse airflow frequency is 25 Hz, as shown in Figure 6C. Additionally, due to the fixed installation angle of the airflow outlet, it is only necessary to keep the center of the airflow outlet aligned with the tomato inflorescence during pollination operation. During the pulse airflow pollination operation, the pollination time for each inflorescence is 2 s, which is similar to the pollination time of bumblebees. Additionally, it has been verified that after 2 s, the pollen coverage on the stigma will hardly increase.

When performing different pollination operations, the pollination operations of vibration pollination and pulse airflow pollination were both carried out every 3 to 5 days on sunny mornings from 9 a.m. to 11 a.m. The temperature range in the experiment is from 20 °C to 28 °C, with an average light intensity of about 20 kLux and an average relative humidity of about 70% to 80%. This is because, only under such conditions, tomato pollen particles will be more easily released under vibration [].

Except for pollination, all other management processes in each group were consistent, and efforts should be made to avoid movement or vibration of tomato plants in other management operations to avoid any impact on tomato fruit setting.

2.3.2. Evaluation Method of Fruit Setting Effect

The fruit setting effect not only includes the number and yield of fruits produced after assisted pollination and fruit setting operations, but also requires a more comprehensive analysis of the fruit setting situation and the condition of the fruits. Therefore, this study divides the evaluation of fruit setting effects into two parts, which are fruit setting effect analysis and fruit quality analysis, as follows:

- (1)

- Fruit setting effect evaluation

In this study, the fruit setting rate, number of fruits per plant and weight of fruit per bunch were selected as parameters for evaluating the fruit setting effect. In the experiment, 100 tomato inflorescences were randomly selected from each group, and the above three parameters were statistically analyzed. The average value was taken as the final fruit setting effect result. The fruit setting rate could be calculated using Formula (3).

where Rf is the fruit setting rate, F1 is the total number of flowers, and F2 is the total number of fruits produced.

- (2)

- Fruit quality evaluation

The weight per fruit, fruit shape, and seed numbers per fruit were taken as the evaluation parameters for fruit quality evaluation. We randomly selected 10 mature tomatoes from each group, weighed each tomato using an electronic scale with an accuracy of 0.1 g, and calculated the average weight of tomatoes in each group as the weight per fruit of that group.

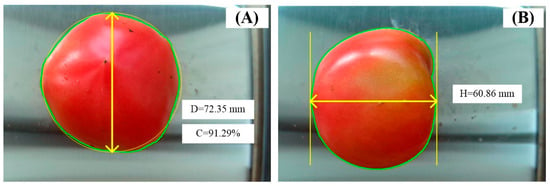

The fruit diameter, height, and shape index of tomatoes can express the quality of tomato shape, which is crucial for the marketability of tomatoes. The tomato shape characteristics recognition algorithm was designed for rapid detection of tomato fruit diameter, height, and shape index, as shown in Figure 7. Fruit diameter refers to the diameter of a circle when the tomato contours in the top view are fitted into a circle. Fruit height refers to the distance from the tomato stem to the tip of the tomato contour in the side view. Due to the significant impact of tomato shape on its marketability, the closer the tomato is to a circular shape when viewed from above, the better the quality of the tomato. Therefore, in this study, the tomato shape index is defined as the circularity of its contour when viewed from above, calculated using Formula (4).

where C is the tomato circularity, Area is the area of a region, and Rmax is the maximum distance between the points and the center of the region.

Figure 7.

Tomato fruit shape quality identification based on image processing. (A) Top view of tomato fruit and its fruit diameter, shape index results. (B) Side view of tomato fruit and its fruit height result.

When conducting the image processing operation for tomato shape characteristics recognition, images of tomatoes in the top and side views were collected, and we extracted the contour lines of tomatoes in two different directions. We fitted the tomato contour in the top view to obtain the circularity C of the tomato fruit. At the same time, a circle was fitted based on the tomato contour, of which the diameter is taken as the fruit diameter D, as shown in Figure 7A. Then, we calculated the difference in the horizontal axis of the contour in the side view direction as the fruit height H, as shown in Figure 7B.

In the study by Klatt et al., the experimental results showed that tomatoes with more seeds have better taste and flavor than those with fewer seeds; therefore, the number of seeds per fruit is important for tomato quality []. When testing the number of seeds per fruit, we randomly selected five mature tomato fruits from each group, chopped the fruits, sorted and counted the number of tomato seeds, and took the average as the number of single fruit seeds in each group.

3. Results and Discussion

3.1. Pollination Effect Analysis of Pulse Airflow Pollination for Tomatoes

To analyze the process and effect of tomato pollination under pulsed airflow, this study conducted research on the recognition and analysis of tomato flower trajectory characteristics based on a high-speed photography system and the recognition of tomato pollen coverage on the stigma based on image processing. Additionally, a comparative analysis was conducted on the movement of tomato flowers and pollen coverage under pulsed airflow and normal stable airflow.

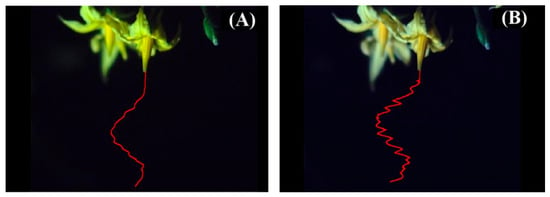

3.1.1. Flower Motion Characteristics Analysis

To compare the tomato flower motion characteristics and trajectories under the action of pulse airflow and stable airflow, the high-speed photography system shown in Figure 3 was used to capture the movement process of one tomato inflorescence under different types of airflow. In order to observe the motion trajectories of the tomato flower more clearly, this study increased the horizontal coordinates of the trajectory by three times and elongated the trajectories vertically to suit the image size, as shown in Figure 8. It can be seen that under the action of stable airflow, the trajectory of tomato flowers is close to a stable reciprocating motion, as shown in Figure 8A. Under the action of pulsed airflow, the motion trajectory of the tomato flower is near to a composite reciprocating vibration that is relatively regular, as shown in Figure 8B.

Figure 8.

Motion trajectories of the tomato flower under pulse airflow and stable airflow. (A) Motion trajectory of the tomato flower under pulse airflow. (B) Motion trajectory of the tomato flower under stable airflow.

Based on the positions of tomato flowers in each image and the time intervals between adjacent images, the displacement, velocity, and acceleration of tomato flowers can be obtained. Table 4 shows the results of various parameters of tomato flower motion under steady airflow and pulse airflow. By comparing these tomato flower motion parameters, it can be concluded that under the action of pulse airflow and steady airflow, the maximum displacement, average velocity, and maximum velocity of tomato flowers were close. The maximum acceleration of the tomato flower increased significantly. Compared with stable airflow, the maximum acceleration of tomato flower motion was relatively increased by 17.76% under the action of pulse airflow.

Table 4.

Tomato flower motion characteristic parameters under stable and pulse airflows.

3.1.2. Analysis of Pollen Coverage of Stigma After Pollination

Figure 9 shows the coverage of stigma pollen and identification results before and after pollination of the same tomato flower. From Figure 9A, it can be visually observed that the tomato flower did not have any pollen particles deposited on its stigma before being subjected to pulsed airflow. There was significant pollen deposition after being pollinated by pulsed airflow, as shown in Figure 9B,C. The pollen coverage is relatively uniform, which will greatly increase the possibility of successful pollination of tomatoes and have a certain effect on improving the quality and yield of tomatoes [].

Figure 9.

Pollen coverage recognition based on image processing. (A) Image of stigma before pollination operation. (B) Image of stigma after pollination operation. (C) Pollen coverage on stigma recognition result of (B).

In addition, this study used a tomato pollination method based on pulse airflow and stable airflow for assisted pollination operations separately, and randomly selected 100 tomato flowers for identification and comparison of the pollen coverage on the stigma. The average pollen coverage on the stigma was 15.21% and 13.44%, respectively, for the pulse airflow and stable airflow pollination methods. That means the coverage of pollen on the stigma using the pulse airflow pollination method is relatively increased by 13.44% compared to the ordinary stable airflow pollination method, which may be more likely to improve the fruit setting effect of tomatoes.

3.2. Fruit Setting Effect Comparison Results

3.2.1. Fruit Setting Effect Analysis Results

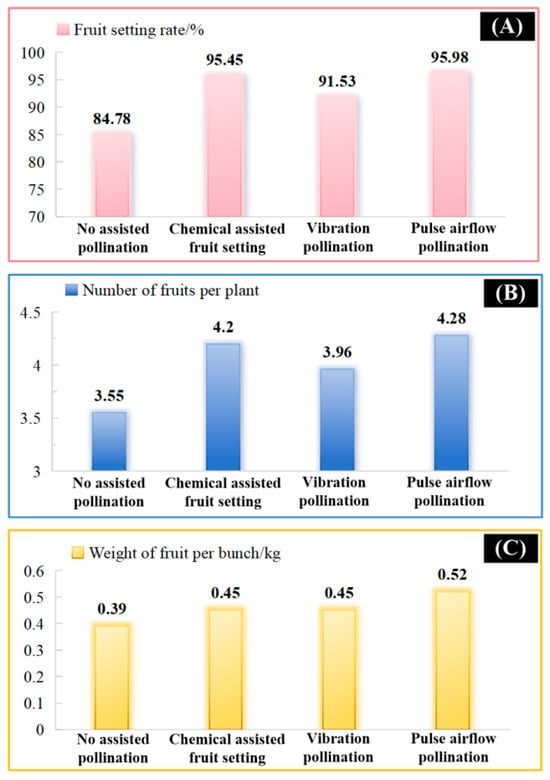

This study separately analyzed the fruit setting rate, number of fruits per plant, and weight of fruit per bunch with different assisted fruit setting methods; the results are shown in Figure 10.

Figure 10.

Fruit setting effects with different assisted fruit setting methods. (A) The result of the fruit setting rate. (B) The result of the number of fruits per plant. (C) The result of the weight of fruit per bunch.

In Figure 10A, it can be concluded that the fruiting rate of using chemical agents and pollination devices based on pulse airflow was similar, which was obviously higher than the control group and vibration pollination group. The fruiting rate of the pulse airflow pollination group is 11.2% higher than the control group. Compared with vibration pollination, it eliminated plant damage and increased fruit setting rate by 4.45%. The average time for assisted pollination of each inflorescence using vibration and pulse airflow methods was 4.3 s and 3.5 s, respectively. That means the pulse airflow-assisted pollination method increased the efficiency by 18.6% compared to the contact vibration-assisted pollination method.

Figure 10B shows the comparison of the number of fruits per plant. The group of pulse airflow has the largest number of fruits per plant, which is relatively 20.56% higher than the number of the control group, which means there were more fruits set during one within a growth cycle. The total weight of fruits per bunch of these four groups is shown in Figure 10C. It can be concluded that the pulse airflow pollination group has the highest total weight of fruits per bunch, which is relatively 33.33% higher than that in the control group. That means the output is also the highest of the pulse airflow pollination group in a growth cycle.

From Figure 10A,B it can be seen that the fruit setting rate and fruit quantity were similar when using chemically-assisted fruit setting and pulse airflow pollination. This is similar to the impact pattern of pollination methods on tomato pollination efficiency that was previously reported in reference []. However, although chemical methods can also ensure fruit setting rate and fruit quantity, the number of seeds in the fruit is very small, resulting in a lower weight of a single fruit. With the development of green agriculture, the use of chemical fruit setting agents should be minimized as much as possible in the future.

3.2.2. Fruit Quality Analysis Results

The fruit qualities comparison results of different assisted fruit setting methods is shown in Table 5. In Table 5, the average weight per fruit, average fruit diameter, average fruit height, average fruit shape index and average amount of seeds per fruit with different assisted pollination methods were compared. It can be seen directly that the weight per fruit and the seed numbers per fruit in the group of pulse airflow pollination were obviously higher than other groups. The fruit diameter, fruit height, weight per fruit and shape index in the pulse airflow pollination group were 5.37%, 3.66%, 11.46%, and 7.78% higher than the control group. These results indicate that tomato fruits pollinated via pulsed airflow have better quantity and quality than other groups.

Table 5.

Fruit qualities with different assisted fruit setting methods.

Furthermore, compared with chemical assisted fruit setting, no chemical agents were used to ensure a fruit setting rate similar to chemical methods, and the number of seeds per fruit increased by 74.8, which will significantly improve the quality of the fruit, such as taste, sweetness, single fruit weight, and fruit morphology [].

3.3. Result Analysis and Discussions

From the above experimental results, it can be concluded that pulse airflow achieves higher acceleration in tomato flower motion compared to stable airflow, and also produces more pollen coverage on the stigma. Moreover, fruit setting experiments have shown that tomato pollination based on pulse airflow not only has better fruit setting effects but also improves the quality of the fruit compared to other assisted pollination and fruit setting methods. The reasons for the above effects and the issues that need to be further addressed were discussed, as follows.

3.3.1. Analysis of the Mechanism of Tomato Flower Movement Mechanics

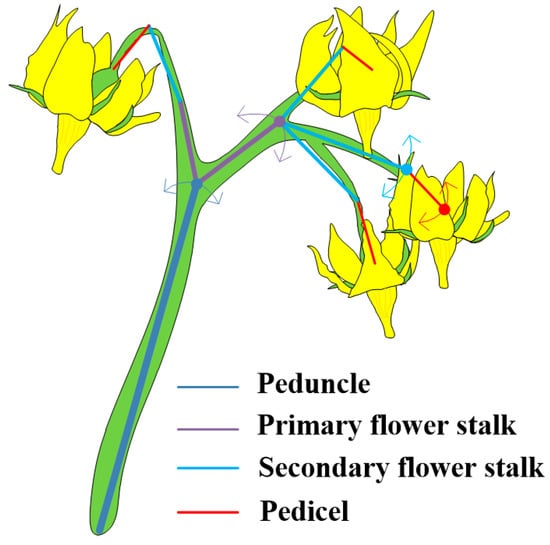

In the authors’ previous research, the tomato inflorescence structural skeleton was divided into four parts, which were peduncle, primary flower stalk, secondary flower stalk, and pedicel []. The elastic coefficients of tomato inflorescence four key structures were measured, and a simplified mechanical model of tomato inflorescence was established, as shown in Figure 11.

Figure 11.

Tomato inflorescence structural skeleton and its simplified mechanical model.

Based on this mechanical model, we can conclude that when airflow acts on the inflorescence, the four key structures will form a joint motion under the action of the airflow force. Different airflow drives tomato flowers to achieve different forms of movement, resulting in different pollination effects.

When the airflow acts on the inflorescence, the flower becomes the main location of stress due to its maximum force area. After the flower is subjected to the force of the airflow, it will move in the direction of the airflow and gradually drive the flower pedicel, secondary flower stalk, primary flower stalk and peduncle. Thus, a series of movements of the whole inflorescence was generated. The movement of various parts of the tomato inflorescence also affects the movement characteristics of the tomato flowers, resulting in the tomato flowers not completely drifting with the airflow, but being subjected to the combined action of airflow force and elastic force of various parts during the movement process. Therefore, for the analysis of tomato inflorescence under stable and pulsed airflow, it is necessary to consider the aerodynamic and elastic forces during the movement process.

When the tomato inflorescence was subjected to airflow force under stable airflow, the force of airflow drove tomato flowers to move in the direction of airflow until the elastic force of the tomato inflorescence overcame the airflow force. Then, it drove the tomato flowers to move in the opposite direction of airflow to approach the initial position and produce a reciprocating motion under the combined action of airflow force and elastic force. In theory, there is a close relationship between acceleration and energy during the motion of tomato flowers. Therefore, the maximum acceleration position of tomato flowers within the motion process under stable airflow may occur within the process of the inflorescence resisting the airflow force and returning to its initial position under the action of elastic force. During this process, the elastic potential energy of the tomato inflorescence is rapidly released, resulting in a significant acceleration.

Similarly, under the action of pulsed airflow, the force and motion process of the tomato inflorescence can be mainly divided into three stages. At the first stage, the airflow force acting on the tomato inflorescence is greater than the elastic force of the inflorescence and, therefore, the flowers will move in the airflow direction. When the airflow stopped, the airflow force suddenly disappeared at the times when the tomato flowers had not reached their maximum displacement. During this period, under the action of elastic force coupled with elastic force, tomato flowers move in the direction of the airflow. However, at this stage, before reaching the starting position, they were subjected to the airflow force again, resulting in a new displacement consistent with the direction of airflow. This process is accompanied by the continuous on–off of the airflow. At the second stage, until the superimposed motion causes the tomato inflorescence to reach its peak elastic force, the elastic potential energy of the tomato inflorescence gradually releases until it returns to its initial position.

During this process, a composite reciprocating motion is generated. At each moment when the airflow suddenly disappears or appears and acts on the tomato inflorescence, there may be significant changes in the direction of the tomato flower’s motion due to the combined action of airflow and elastic forces. These kinds of motions were similar to the vibrations caused by pollinators. During these flowers’ motion processes, the energy changes were more intense and frequent, which can promote the release of pollen from tomato anthers and achieve more effective pollination.

3.3.2. Analysis of Tomato Pollination and Fruit Setting Effect

In theory, the force and energy received by the tomato inflorescence when pollinated by vibration pollination should be significantly greater than the force and energy that is pollinated with pulse airflow, which means the pollination effect and fruit setting effect should be better with the vibration pollination method. However, experimental results show that the pulse airflow pollination method has a better fruit setting rate and fruit quality compared to the vibration pollination method.

This may be due to the fact that when the pulse airflow acts on the inflorescence, it mainly acts on the flower area with a larger contact area, that is, each tomato flower is subjected to a relatively uniform force. The contact area between the vibrating rod of the vibrating pollinator and the inflorescence is very small. When contacted with the vibration pollinator, there may be some flowers shaking violently when in contact with the inflorescence, but some flowers may not achieve effective vibration. This is also the reason why the fruit setting rate and the number of fruits per bunch in the vibration pollination group were relatively lower than those in the pulse airflow pollination group. This further indicates that although the position of flowers on tomato inflorescence varies, pulse airflow has stronger adaptability for tomato non-contact pollination.

3.3.3. Issues to Be Solved

- (1)

- Limitations of the experimental plan

The experiment of this study was conducted in a solar greenhouse where temperature and humidity could not be accurately adjusted. Therefore, it is impossible to compare the adaptability of devices under different temperatures and humidity. Only a mechanical model of a large fruit tomato was established in the early stage, so this study only conducted research on one tomato variety (L-402), although it can provide a reference for the pollination of other varieties of large fruit tomatoes.

In addition, since the pollination mechanism of this study is to promote pollen release through the vibration of inflorescences and flowers driven by pulsed airflow, we chose to adjust the operational parameters of inflorescences with fully open flowers without considering different growth stages. Further research can be conducted on the adaptability and parameter adjustment schemes of pulse airflow for different tomato flower opening states in subsequent studies.

- (2)

- Possible improvement of pollination effect

Although it can be concluded from the above experimental results that pulse airflow pollination improves tomato pollination effect, fruit setting effect, and yield, current research still lacks the reasons why tomato flowers achieve compound reciprocating motion and effective pollination under pulse airflow. In particular, how the forces on various parts of the tomato inflorescence change during the pulse airflow-assisted pollination operation. This requires further exploration of the mechanics and kinematics models of tomato inflorescence under the pulse airflow.

In addition, the pollination device designed in this research is still required to be handheld for pollination operations, which is inefficient and difficult to ensure that the airflow outlet accurately focuses on the target tomato inflorescence to be pollinated. Therefore, more research is needed in the future on intelligent automatic pollination devices based on pulse airflow. Therefore, in future studies, it is necessary to combine the optimal pulse airflow parameters for pollination operations obtained in this study, and carry out intelligent pollination target recognition and positioning, an automatic target pollination operation platform, and support intelligent chassis to achieve intelligent automatic pollination.

4. Conclusions

The study in this paper focused on the clean and non-contact tomato pollination device design and its airflow parameters optimization and pollination experiments. The designed pulse airflow pollination method and device have shown good performance and feasibility compared with other pollination methods in the facility. The main conclusions of this study were as follows.

- (1)

- A non-contact tomato pollination device was designed, and the pulse airflow parameters of the pollination device were optimized. Through conducting an orthogonal test that takes the coverage of tomato pollen on the stigma as the test index, the optimal parameter combination was obtained as an airflow velocity of 1.22 m·s−1, an airflow angle of −19.69°, and a pulse frequency of 25.64 Hz.

- (2)

- When pollination is performed under pulsed airflow, tomato flowers produce a composite reciprocating vibration that is more suitable for tomato pollination. Compared with the stable airflow pollination method, the maximum acceleration of tomato flower motion was relatively increased by 17.76% under the action of pulse airflow, and the coverage of pollen on the stigma is relatively 13.44% higher, which is important to the tomato pollination effect.

- (3)

- The tomato pollination method based on pulse airflow can improve the fruit setting effect, yield, and fruit quality. Compared with the control group with an assisted pollination operation, the pulse airflow pollination method can increase the fruit setting rate by 13.21%, increase the weight per fruit by 11.46%, and increase the weight of fruits per bunch by 23.33%.

- (4)

- Compared with chemically-assisted fruit setting, no chemical agents were used to ensure a fruit setting rate similar to chemical methods, and the number of seeds per fruit increased by 74.8. Compared with vibration pollination, it eliminated plant damage and increased fruit setting rate by 4.45%, and improved efficiency by 18.6%. The results indicated that the pollination method based on pulse airflow is environmentally friendly, high-quality, and efficient.

The experimental results indicate that the pollination device based on pulse airflow designed in this study has been verified to effectively improve tomato pollination and fruit setting effects. The research results play a crucial role in the development of non-contact pulse airflow pollination technology for tomatoes. The proposed pulse airflow pollination method will provide a technical basis for green production in tomato cultivation. The designed non-contact pulse airflow pollination device for tomatoes and its application in facility tomato production will effectively improve tomato pollination efficiency and reduce labor intensity. In the future, combining machine vision technology, automation technology, and the pulse airflow pollination method in this research will provide a technical foundation for the development of precision pulse airflow pollination equipment for automatic positioning.

Author Contributions

Data curation, Z.Z.; Funding acquisition, S.L.; Investigation, S.T.; Methodology, Z.Z.; Project administration, S.T. and T.L.; Resources, S.L. and T.L.; Software, S.L. and L.L.; Supervision, S.T. and T.L.; Visualization, L.L.; Writing—original draft, S.L.; Writing—review and editing, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Postdoctoral Fellowship Program of CPSF under Grant Number GZB20240464 and the Young Scientists Fund of the National Natural Science Foundation of China under Grant Number 32401716.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that they have no conflict of interest.

References

- Duc Tai, N.; Minh Trieu, N.; Truong Thinh, N. Modeling Positions and Orientations of Cantaloupe Flowers for Automatic Pollination. Agriculture 2024, 14, 746. [Google Scholar] [CrossRef]

- Turkten, H.; Ceyhan, V. Environmental efficiency in greenhouse tomato production using soilless farming technology. J. Clean. Prod. 2023, 398, 136482. [Google Scholar] [CrossRef]

- Zhang, H.; Han, C.; Breeze, T.D.; Li, M.; Mashilingi, S.K.; Hua, J.; An, J. Bumblebee Pollination Enhances Yield and Flavor of Tomato in Gobi Desert Greenhouses. Agriculture 2022, 12, 795. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Sato, S.; Tabata, S.; Hirakawa, H.; Asamizu, E.; Shirasawa, K.; Isobe, S.; Kaneko, T.; Nakamura, Y.; Shibata, D.; Aoki, K.; et al. The tomato genome sequence provides insights into fleshy fruit evolution. Nature 2012, 485, 635–641. [Google Scholar] [CrossRef]

- Sheikh, U.A.A.; Ahmad, M.; Aziz, M.A.; Imran, M.; Rahim, J.; Roulston, T.; Guo, S.; Sun, C. Rearing of Native Bumblebee Species Bombus haemorrhoidalis for Greenhouse Pollination in Pakistan. Agriculture 2024, 14, 590. [Google Scholar] [CrossRef]

- Wachira, J.M.; Mshenga, P.M.; Saidi, M. Comparison of the profitability of smallscale greenhouse and open-field tomato production systems in Nakuru-North district Kenya. Asian J. Agric. Sci. 2014, 6, 54–61. [Google Scholar] [CrossRef]

- Zhou, J.; Wu, Y.H.; Zhang, A.P. Effects of Different Pollination Ways on Growth and Development of Tomato in Greenhouse. North. Hortic. 2017, 10, 47–53. [Google Scholar] [CrossRef]

- Dingley, A.; Anwar, S.; Kristiansen, P.; Warwick, N.W.M.; Wang, C.-H.; Sindel, B.M.; Cazzonelli, C.I. Precision Pollination Strategies for Advancing Horticultural Tomato Crop Production. Agronomy 2022, 12, 518. [Google Scholar] [CrossRef]

- Crenna, E.; Sala, S.; Polce, C.; Collina, E. Pollinators in life cycle assessment: Towards a framework for impact assessment. J. Clean. Prod. 2017, 140, 525–536. [Google Scholar] [CrossRef]

- Wahizatul, A.A.; Nurhidayah, S.; Muhammad Firdaus, M.H.; Roziah, G.; Seng, C. Effects of stingless bee (Heterotrigona itama) pollination on greenhouse cucumber (Cucumis sativus). Malaysian Appl. Biol. J. 2017, 46, 51–55. [Google Scholar]

- Zhao, Z.; Shan, R.; Sun, X.; Sun, J.; Wang, B.; Wang, Z. Mapping and assessing supply and demand of crop pollination services in Shandong Province, China. J. Clean. Prod. 2023, 426, 139024. [Google Scholar] [CrossRef]

- De Luca, P.A.; Bussiere, L.F.; Souto-Vilaros, D.; Goulson, D.; Mason, A.C.; Vallejo-Marin, M. Variability in bumblebee pollination buzzes affects the quantity of pollen released from flowers. Oecologia 2023, 172, 805–816. [Google Scholar] [CrossRef]

- Mesquita-Neto, J.N.; Bluethgen, N.; Schlindwein, C. Flowers with poricidal anthers and their complex interaction networks-Disentangling legitimate pollinators and illegitimate visitors. Funct. Ecol. 2018, 32, 2321–2332. [Google Scholar] [CrossRef]

- Bartelli, B.F.; Nogueira-Ferreira, F.H. Pollination Services Provided by Melipona quadrifasciata Lepeletier (Hymenoptera: Meliponini) in Greenhouses with Solanum lycopersicum L. (Solanaceae). Sociobiology 2014, 61, 510–516. [Google Scholar] [CrossRef]

- Tacconi, G.; Michelotti, V.; Cacioppo, O.; Vittone, G. Kiwifruit pollination: The interaction between pollen quality, pollination systems and flowering stage. J. Berry Res. 2016, 6, 417–426. [Google Scholar] [CrossRef]

- Dellinger, A.S.; Pollabauer, L.; Loreti, M.; Czurda, J.; Schonenberger, J. Testing functional hypotheses on poricidal anther dehiscence and heteranthery in buzz pollinated flowers. Acta ZooBot Austria 2019, 156, 197–214. [Google Scholar]

- Liu, D.F.; Song, Y.; Li, Y.F.; Guo, X.Z.; Hu, D.; Lin, S.S.; Huang, W.B. Application of Different Artificial Assisted Pollination Methods in Pomelo Production. J. Zhejiang Agr. Sci. 2021, 62, 1756–1757+1820. [Google Scholar] [CrossRef]

- Averkova, O.A.; Logachev, I.N.; Logachev, K.I. Peculiarities of air entrainment with a loose material flow at the variable aerodynamic resistance of falling particles. In Proceedings of the 7th International Conference on Coupled Problems in Science and Engineering, Rhodes, Greece, 12–14 June 2017; pp. 636–644. [Google Scholar]

- Wang, Y.W.; Tang, C.; Wang, J.; Hu, J.; Ren, Q. Optimization and experiment on pollination tube of collision and air-blowing hybrid rice pollination machine. Trans. Chin. Soc. Agric. Eng. (Tran. CSAE) 2015, 31, 101–106. [Google Scholar] [CrossRef]

- Shi, Q. Study on Mechanism and Method of Wind-Induced Vibration Pollination of Greenhouse Tomato Based on UAV Downwash. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

- Ding, S.; Xue, X.; Fang, J.; Sun, Z.; Cai, C.; Zhou, L.; Qin, W. Parameter optimization and experiment of air-assisted pollination device. Trans. Chin. Soc. Agric. Eng. 2015, 31, 68–75. [Google Scholar]

- Sun, Y.; Xu, G.; Gao, W.; Li, D.; Shi, L.; Han, B. Effects of different pollination methods on yield, quality and benefit of tomato in solar greenhouse. China Veg. 2017, 6, 38–41. [Google Scholar] [CrossRef]

- Akhavan, F.; Kamgar, S.; Nematollahi, M.A.; Golneshan, A.A.; Nassiri, S.M.; Khaneghah, A.M. Design, development, and performance evaluation of a ducted fan date palm (Phoenix dactylifera L.) pollinator. Sci. Hortic. 2021, 277, 109808. [Google Scholar] [CrossRef]

- Wu, W.Q.; Li, C.; Wu, Z.C. Economic and Ecological Benefits of Different Pollination Methods on Facility Tomatoes. Agric. Sci. Eng. China 2018, 30, 80–85. [Google Scholar] [CrossRef]

- Liu, S.; Wang, X.; Chen, X.; Hou, X.; Zhang, X.; Jiang, T.; Zhang, X. Simulation and experiment of tomato pollen particles release and motion characteristics based on optical flow target tracking method. Comput. Electron. Agric. 2022, 198, 107106. [Google Scholar] [CrossRef]

- Liu, S.Y.; Zhang, X.M.; Wang, X.Y. Vibration inducing and airflow guiding coupled tomato pollination method research based on gas-solid two-phase flow model. Comput. Electron. Agric. 2023, 216, 108472. [Google Scholar] [CrossRef]

- Matsui, T.; Kobayasi, K.; Yoshimoto, M.; Hasegawa, T.; Tanaka, T.S.; Tian, X. Factors determining the occurrence of floret sterility in rice in a hot and low-wind paddy field in Jianghan Basin. China Field Crops Res. 2021, 267, 108161. [Google Scholar] [CrossRef]

- Kumar, A.; Mahadik, A.S.; Kushwaha, H.L.; Bhowmik, A.; Singh, A.K. Pulsating Air Pollinator for Greenhouse Cultivation. J. Sci. Ind. Res. India 2021, 80, 477–485. [Google Scholar]

- Wu, J.X.; Zhang, X.M.; Xu, J.; Zeng, B.L.; Li, Z.Y.; Wng, Y.J. Pulse Cluster Tomato Pollination Method Based on Gas-Solid Coupling. Trans. Chin. Soc. Agric. Mach. 2024, 55, 306–316. [Google Scholar] [CrossRef]

- Cortez, P.A.; de Souza Caetano, A.P.; Carmello-Guerreiro, S.M.; Teixeira, S.P. Elucidating the mechanism of poricidal anther dehiscence in Miconia species (Melastomataceae). Flora 2014, 209, 571–579. [Google Scholar] [CrossRef]

- Xiong, H.; Zou, F.; Yuan, D.; Zhang, X.; Tan, X. Orthogonal test design for optimising the culture medium for in vitro pollen germination of feijoa (cv. Unique). N. Z. J. Crop Hort. 2016, 44, 192–202. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, F.; Zhao, P.; Tian, S.; Zhao, Q. Morel (Morchella spp.) target recognition and size measurement based on machine vision. Comput. Electron. Agric. 2025, 229, 109823. [Google Scholar] [CrossRef]

- Klatt, B.K.; Holzschuh, A.; Westphal, C.; Clough, Y.; Smit, I.; Pawelzik, E.; Tscharntke, T. Bee pollination improves crop quality, shelf life and commercial value. Proc. R. Soc. B Biol. Sci. 2014, 281, e20132440. [Google Scholar] [CrossRef] [PubMed]

- Hazel, C.; Vallejo-Marín, M. Buzz-Pollinated Crops: A Global Review and Meta-analysis of the Effects of Supplemental Bee Pollination in Tomato. J. Econ. Entomol. 2021, 114, 505–519. [Google Scholar] [CrossRef]

- Liu, S.; Tian, S.; Zhang, Z.; Liu, L.; Li, T. Dynamic growth tomato inflorescence modeling with elastic mechanics data. Smart Agric. Technol. 2025, 11, e100884. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).