Abstract

As a vital oil and cereal crop in China, soybean requires efficient and low-loss harvesting to ensure food security and sustainable agricultural development. However, pod-shattering losses during soybean harvesting in Xinjiang remain severe due to low pod moisture content and poor mechanical strength, while existing studies lack a systematic analysis of the interaction mechanism between reeling devices and pods. The current research on soybean harvester headers predominantly focuses on conventional rigid designs, with limited exploration of flexible reel mechanisms and their biomechanical interactions with soybean pods. To address this, this study proposes an optimization method for low-loss harvesting technology based on mechanical-crop interaction mechanisms, integrating dynamic simulation, contact mechanics theory, and field experiments. Texture analyzer tests revealed pod-shattering force characteristics under different compression directions, showing that vertical compression exhibited the highest shattering risk with an average force of 14.3271 N. A collision model between the spring tooth and pods was established based on Hertz contact theory, demonstrating that reducing the elastic modulus of the spring tooth and increasing the contact area significantly minimized mechanical damage. Simulation verified that the PVC-nylon spring tooth reduced the maximum equivalent stress on pods by 90.3%. Furthermore, the trajectory analysis of spring-tooth tips indicated that effective pod-reeling requires a reel speed ratio (Δ) exceeding 1.0. Field tests with a square flexible spring tooth showed that the optimized reel reduced header loss to 1.371%, a significant improvement over conventional rigid teeth. This study provides theoretical and technical foundations for developing low-loss soybean harvesting equipment. Future work should explore multi-parameter collaborative optimization to enhance adaptability in complex field conditions.

1. Introduction

As a vital oil and cereal crop, soybean is rich in protein—approximately twice that of eggs and pork—and serves as a key ingredient in producing soy-based foods, soybean oil, and fermented condiments like soy sauce, making it an essential staple crop in China [1,2,3,4]. Xinjiang, covering one-sixth of China’s land area, boasts vast agricultural resources, with soybean cultivation expanding annually. In 2023, its total output reached 21.192 million tons, achieving a record-high yield of 453.54 kg/mu, setting a national benchmark. However, Xinjiang’s inland location in Eurasia, characterized by significant diurnal temperature variations, abundant sunlight, and low precipitation, results in low pod moisture content and poor mechanical strength in soybean plants during maturation. In mechanical harvesting operations, losses occur not only in the threshing device [5,6,7,8,9,10] but also as a result of violent collisions between the reel mechanism and low-moisture soybean pods [11,12,13,14], which frequently cause pod shattering and significant pre-harvest grain loss. Moreover, the long-term accumulation of oil- and protein-rich seeds may alter soil microbial communities and disrupt fertility balance. Thus, optimizing reel parameters is critical for equipment durability, environmental protection, and harvest quality. At present, global research on soybean harvesters and combine harvesters emphasizes intelligent, modular design and material innovation. Leading manufacturers such as John Deere and CNH Industrial have combined Internet of Things and artificial intelligence technologies to develop intelligent heads that can automatically adjust the cutting depth, monitor in real time, and diagnose remotely. The extensive use of lightweight materials such as high-strength steel and wear-resistant composite materials not only reduces energy consumption but also enhances durability. The modular design features the rapid replacement of cutting components to adapt to different on-site conditions. The rotating toolbar and inverted arm structure improve the management of stubble. Chinese manufacturers, including Lovol and Zoomlion, are also promoting leading intelligent technologies through autonomous driving systems and policy-driven upgrades. These developments have jointly driven the industry toward higher efficiency, sustainability, and reduced harvest losses.

Extensive research has been conducted globally on low-loss headers for harvesters [15,16,17]. Nie et al. developed a flexible soybean header with synchronous low-level cutting, addressing the shortage of intercropping harvesters and high header losses through dynamic modeling and simulation, with field tests confirming its efficacy [18]. Tong et al. analyzed damage mechanisms during cabbage uprooting, clamping, and cutting, optimizing key parameters to achieve compliant damage rates within specific speed ranges, offering insights for low-loss cabbage harvesting [19]. Xie et al. proposed a 3D point-cloud-based method to synchronously detect lodging position, severity, and orientation, enabling autonomous header adjustment to significantly reduce losses in lodged areas and advancing unmanned harvesting [20]. Zhang et al. designed a bidirectional cutting end-effector, achieving high filament purity and low breakage via mechanical modeling, providing a technical solution for efficient, low-loss safflower harvesting [21]. Zhao et al. incorporated a flexible picking header and modular husking units, optimizing parameters to minimize loss and impurity rates and meet mechanized hybrid seed corn harvesting demands. However, existing studies primarily focus on overall header structure or workflow optimization, lacking component-specific analysis for targeted loss reduction [22]. However, current studies primarily focus on overall header structures or process optimization, while targeted analysis on the interaction mechanism between reel spring teeth and soybean pods for precise loss reduction remains lacking.

This study addresses harvest losses in Xinjiang’s monoculture soybeans, systematically investigating low-loss technologies based on mechanical–crop interaction mechanisms. By analyzing the impact of reel parameters on pod-reeling performance, critical motion ranges are identified. Integrating contact mechanics theory, the impact characteristics of reel components with varying materials and structures on pods are explored to propose damage-mitigation strategies, validated through field trials. The findings will provide theoretical and technical foundations for developing low-loss soybean harvesting equipment, offering practical significance for advancing high-quality soybean industry development.

2. Materials and Methods

2.1. Experimental Materials

This study was conducted in the soybean experimental fields of the Xinjiang Academy of Agricultural Reclamation Sciences, China. Four locally cultivated soybean varieties—Xinzhendou 1, Xindadou 8, Longken 324, and Jiyu 86—were selected as test materials due to their widespread adoption. During the maturity stage, intact pod-bearing plant samples were randomly collected from the field, with 30 plants per variety, ensuring that all samples met the criteria of well-filled pods, the absence of mechanical damage, and uniform maturity.

In the laboratory, the collected pod samples underwent rigorous screening to exclude specimens with insect damage, mold, or abnormal discoloration. Only intact pods with tightly closed husks and evenly distributed seeds were retained for subsequent experiments. The qualified pod-bearing soybean samples were categorized by variety and stored in sealed polyethylene bags to minimize environmental fluctuations in temperature and humidity, which could affect pod moisture content and seed quality. All tests were completed within 48 h of sample collection to maintain physiological consistency.

2.2. Experimental Equipment

The test equipment included the TA.XTplus texture analyzer produced by Stable Micro Systems in London, UK, the AW82G rice and wheat combine harvester manufactured by Yanmar Corporation in Wuxi, China, the high-precision electronic balance from Shanghai Sainyu Hengping Scientific Instrument Co. in Shanghai, China, and a Nanjing-assembled high-performance computer equipped with an NVIDIA RTX 5080 GPU for simulation and data processing, all procured by Jiangsu University in China.

2.3. Experimental Methods

2.3.1. Pod Moisture Content Test

In this study, the moisture content of soybean pods during the harvest period was determined by the oven drying method. As shown in Figure 1, during the experiment, the pod samples to be tested were randomly divided into three groups first, with each group weighing 10 g, and their initial masses were recorded using a high-precision electronic scale.

Figure 1.

Pod moisture content test: (a) electrothermal blowing dry box; (b) determination of moisture content in pods.

Subsequently, the sample was placed in an electrothermal blowing dry box at 105 °C for an initial drying of 24 h. After that, the sample was removed and weighed, then put back into the box to continue drying for 2 h. We repeated this drying and weighing process until the sample mass remained constant, indicating that it was completely dry. We recorded the final mass at this time and calculated the moisture content of the pods according to the following formula:

2.3.2. Investigation of Pod-Shattering Force Under Different Loading Directions

The mechanical properties of soybean pods evolve significantly throughout their lifecycle, directly influencing their susceptibility to shattering. During the early developmental period, pods maintain a high moisture content and corresponding elasticity, which affords them considerable resistance to mechanical impacts. Conversely, the maturation phase is characterized by a progressive dehydration of the pod structure. This loss of moisture leads to increased brittleness in the cell walls and a weakening of the sutural bonding forces, culminating in a heightened vulnerability to mechanical rupture. This condition peaks during the designated harvest period. At this stage, pods attain the specific harvest-ready moisture content required for optimal threshing, which unfortunately also corresponds to their minimum mechanical integrity. Consequently, external forces from harvesting machinery, particularly impacts and compressions from the reel, readily cause pod shatter and subsequent seed loss. Field observations substantiate that shatter-related yield losses occur almost exclusively at this mature, brittle stage. A quantitative assessment of the pod-shattering force threshold is therefore a critical prerequisite for engineering solutions. Accurately determining this threshold is essential for optimizing the structural design of harvesting components like the reel, thereby mitigating mechanical damage and reducing header loss [23,24,25].

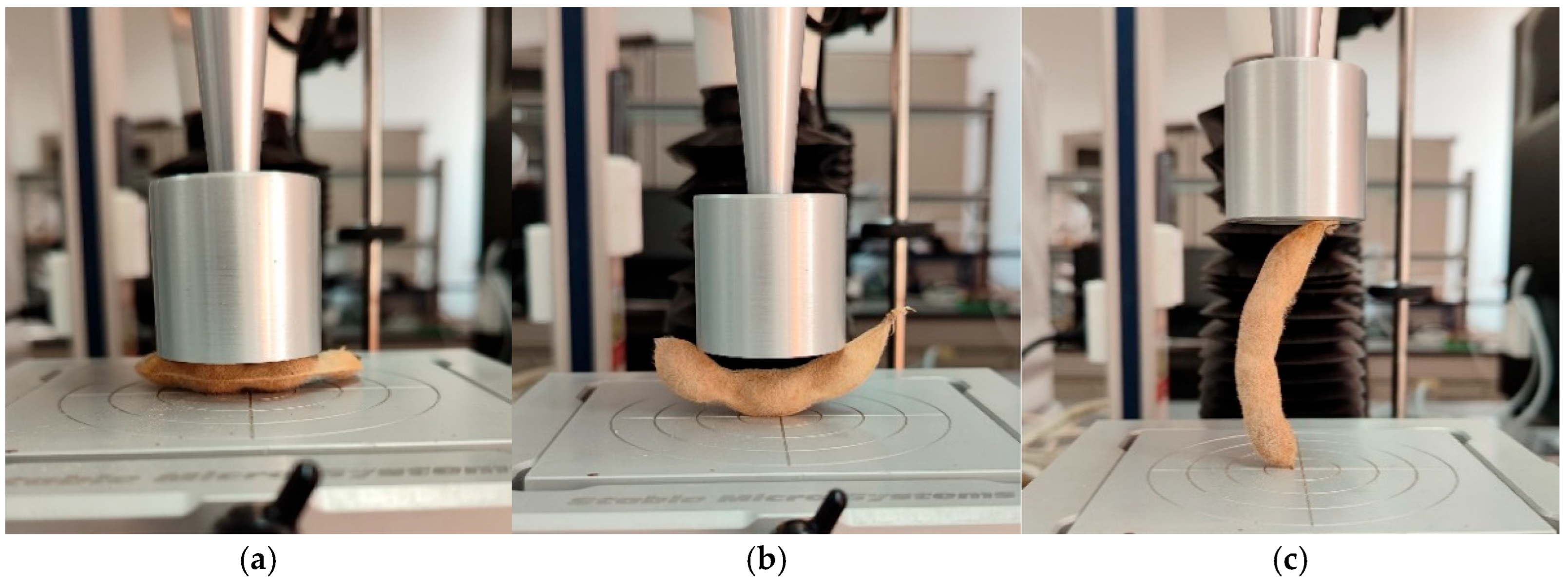

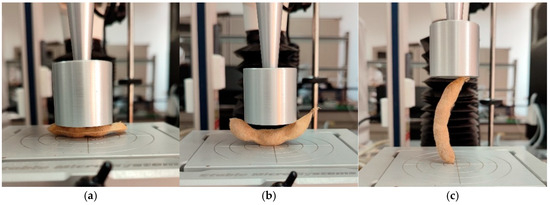

As shown in Figure 2, this study employed a TA.XTplus texture analyzer to evaluate the mechanical properties of mature field-collected soybean pods. The test was conducted using a cylindrical flat-bottomed probe (Model P/50) with a diameter of 50 mm for compression. The working displacement of the texture analyzer was set to 50% of the pod length along the loading direction to simulate the mechanical interaction depth during actual harvesting. All other parameters are the default parameters of the instrument. To simulate the natural conditions of force application on pods in the field, no external clamps or adhesives were used to secure the samples during the mechanical tests. The stability of each pod was maintained solely by its own gravity and the static friction against the testing platform.

Figure 2.

Three directions of pod compression. (a) Side compress; (b) vertical compress; (c) horizontal compress.

2.3.3. Mechanical Analysis of Pod-Spring Tooth Collision

During field operations of soybean harvesters, the reel mechanism serves as the primary working component, with pod-shattering losses predominantly arising from contact interactions between its spring tooth and soybean pods as documented in prior studies [26,27,28]. To elucidate the underlying mechanisms of header-induced losses and establish a theoretical foundation for header design optimization, this study employs Hertz contact theory in conjunction with impact dynamics to analyze the collision process between pods and spring teeth. The applicability of Hertz theory is justified by the elastic deformation characteristics of the contacting bodies, where the contact area dimensions remain significantly smaller than the radii of curvature of both the spring tooth and pod surfaces, satisfying the fundamental assumptions of small-strain theory and semi-infinite body approximation. For the complex collision dynamics involving velocity, energy, and force variations, a comprehensive contact model was developed to systematically investigate loss mechanisms during pod-reeling operations. The analysis incorporates necessary simplifications based on theoretical impact mechanics principles, including the neglect of pod gravity and elastic forces due to their negligible magnitude relative to spring tooth impact forces, the exclusion of displacement changes given the extremely brief collision duration and minimal pod displacement, and the geometric simplification of the contact area as an isotropic homogeneous ellipsoid to overcome analytical challenges in collision modeling while acknowledging the potential errors introduced by this approximation.

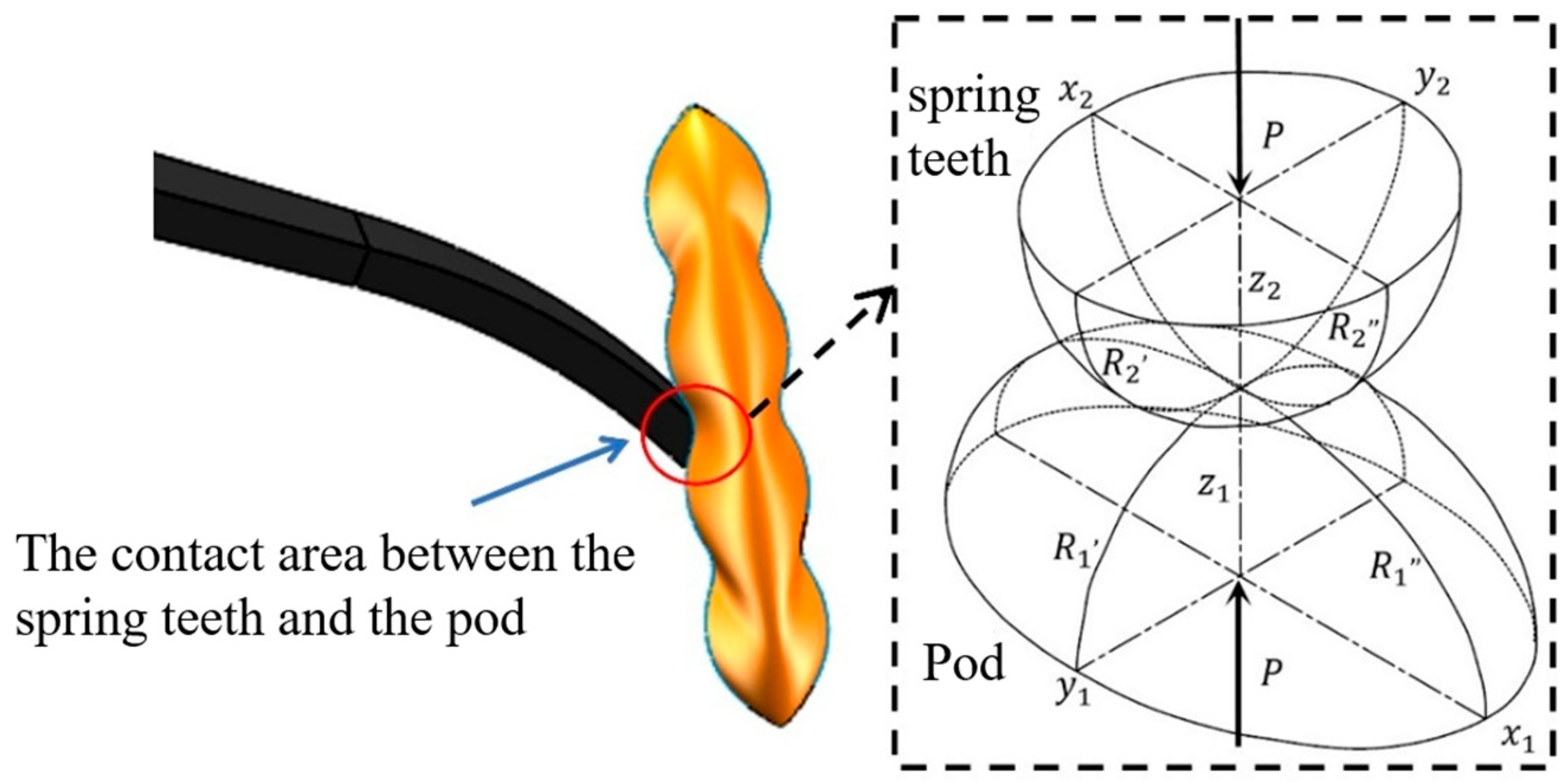

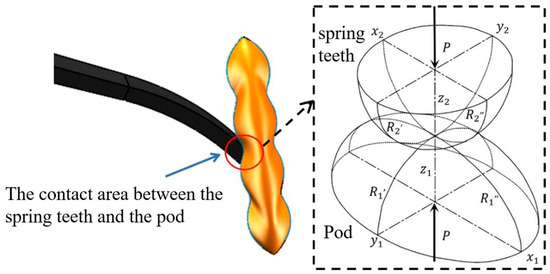

As shown in Figure 3, based on the analysis of the contact schematic between the spring tooth and pod, assuming the contact area forms an elliptical area, the contact area between the spring tooth and pod during collision is determined according to Hertz contact theory as:

where: , , ,

Figure 3.

Schematic diagram of contact interaction between spring tooth and soybean pod.

where:

a—semi-major axis of the elliptical contact area, m.

b—semi-minor axis of the elliptical contact area, m.

c—contact area size between the soybean pod and spring tooth, m.

e—the eccentricity of the elliptical contact area.

F—total load during contact between the pod and spring tooth, N.

—equivalent relative curvature radius of the contact area between the pod and spring tooth, m.

—composite elastic modulus during contact between the pod and spring tooth, Pa.

—relative curvature radii of the spring tooth and pod, m.

—maximum and minimum curvature radii of the spring tooth in any normal plane of contact area, m.

, —maximum and minimum curvature radii of the pod in any normal plane of contact area, m.

, —Poisson’s ratios of the spring tooth and soybean pod.

, —elastic moduli of the spring tooth and soybean pod, Pa.

—correction factor that accounts for the elliptical shape of the contact area. Its value depends on the eccentricity e.

The compression amount in the contact area between the soybean pod and spring tooth is:

where represents the correction factor, which can be determined from the ratio of relative curvatures .

According to the fundamental result derived from Hertz contact theory, the maximum pressure in the contact area between the soybean pod and spring tooth is:

During the collision between soybean pods and spring tooth, elastic deformation induces a mutual displacement δ at the contact center. The relative velocity between the spring tooth and pod during collision is expressed as .

The interaction force F between soybean pods and spring tooth during contact, when expressed as a function of time t, satisfies the impulse theorem as follows:

where:

m1 represents the mass of the spring tooth (kg).

m2 denotes the mass of the pod (kg).

By combining Equations (5) and (6), we obtain:

Rearranging Equation (7) yields:

By rearranging the expression for the compression amount δ from Equation (3) to solve for the interaction force F, we obtain a relationship between force and displacement:

Let . From Equations (8) and (9), it follows:

Integrating both sides of Equation (10) yields:

where represents the relative velocity between the soybean pod and the spring tooth at t = 0. When the compression amount in the contact area reaches its maximum value , the maximum compression can be derived from Equation (11) as:

The maximum compressive force between the soybean pod and spring tooth during contact can be derived from Equation (9) as:

By combining Equations (11) and (12), the relationship between compression δ and time t is obtained through integration as:

During the collision contact process between soybean pods and the spring tooth, when the contact pressure F0 exceeds the uniaxial ultimate strength K of the soybean pod, an elastic limit will be reached in the contact area, indicating that the spring tooth will cause damage to the soybean pod.

The condition for soybean pods to undergo plastic deformation is F0 = K, with t = t*, δ = δ*, and F = F*. According to Equations (2) and (4), the following is obtained:

This relationship also holds at the point of maximum compression. By substituting the maximum contact force into Equation (15), we find the maximum contact pressure :

The critical velocity at which soybean pods sustain damage during collision with the spring tooth can be derived from Equations (12), (13), and (16) as:

This theoretical model provides a clear framework for optimizing the spring tooth’s design to minimize pod damage. Equation (17) specifically identifies the spring tooth’s elastic modulus () and its principal curvature radii () as the key design parameters governing the critical damage velocity (). The formula predicts that a lower elastic modulus and a larger curvature radius will increase , allowing the pod to withstand higher impact speeds without shattering.

To experimentally validate this theoretical prediction, our study was designed to investigate the practical effects of these two parameters. Accordingly, we designed and fabricated two distinct types of spring teeth, which possess different elastic moduli and contact surface curvatures. By comparing the pod-shattering rates associated with each type of tooth, we aimed to verify if a modified spring-tooth design, guided by the principles of Equation (17), could effectively reduce soybean harvesting losses.

2.3.4. Study on the Motion Trajectory of Spring Tooth Tip

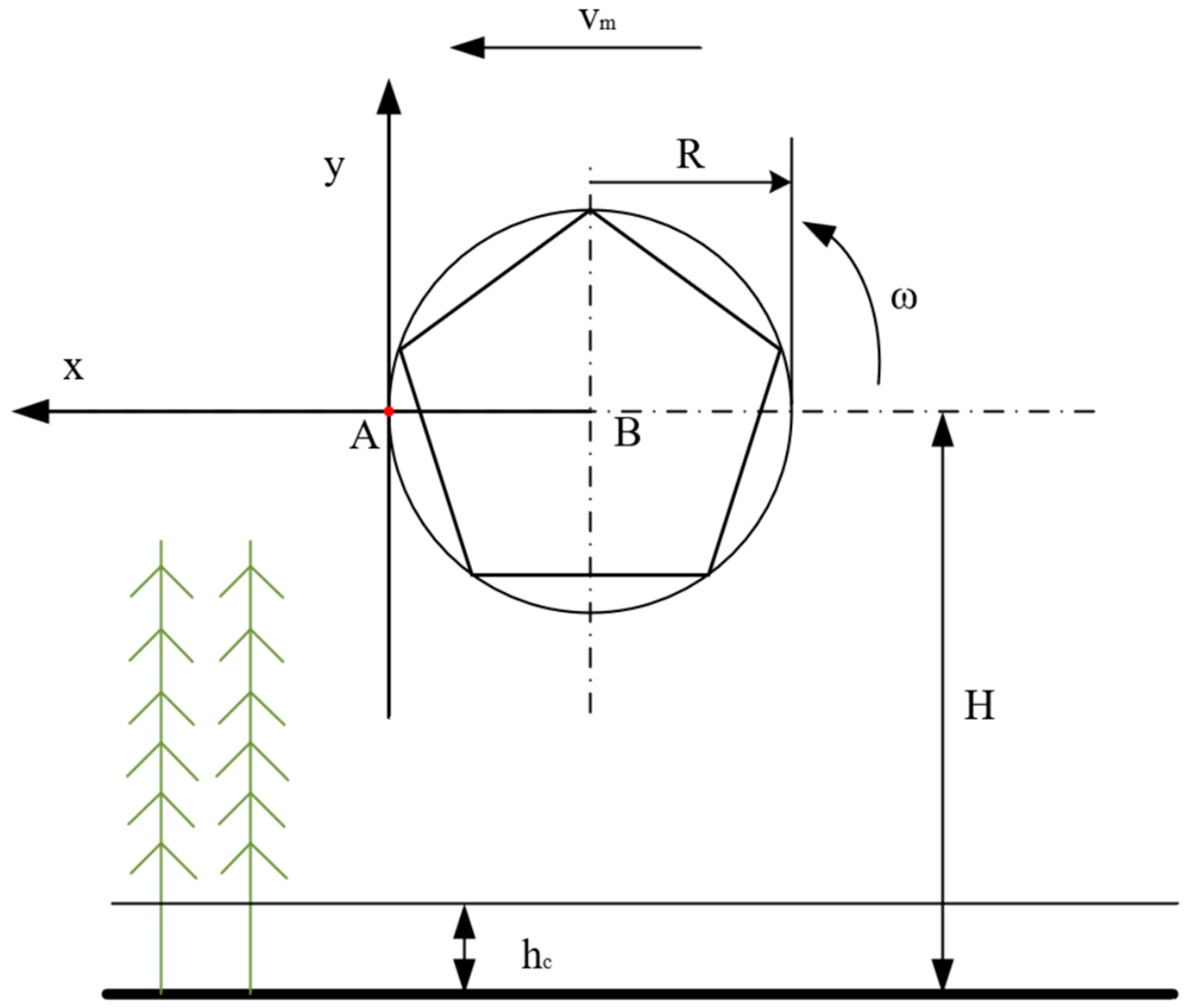

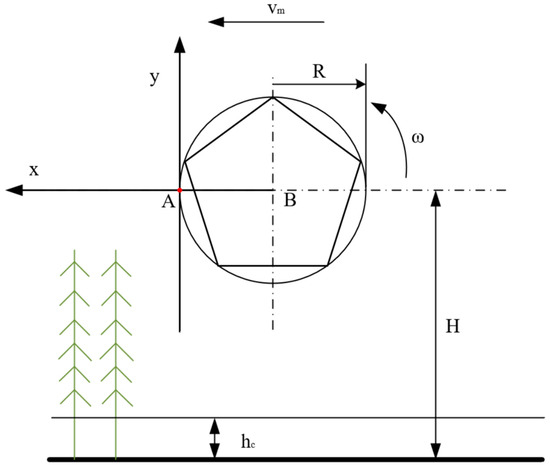

To analyze the motion trajectory of the reel mechanism during soybean harvesting operation, a kinematic model was established with the following [29,30,31]:

- (1)

- The reel rotates counterclockwise at constant speed around fixed center point B.

- (2)

- The combine harvester moves forward at a constant speed.

The motion principal diagram is shown in Figure 4. In order to describe the absolute trajectory, a fixed inertial frame of reference is established. The origin of this system is defined at the initial spatial position of point A (at t = 0), and it remains stationary. The x-axis is aligned with the harvester’s forward motion, and the y-axis is oriented vertically upward. Based on this framework, the equation for the motion trajectory of point A on the heading wheel of the soybean harvester under compound motion is as follows:

where:

Figure 4.

Motion trajectory analysis diagram of the reel mechanism.

x: horizontal displacement of the spring tooth tip in a fixed coordinate system (m).

y: vertical displacement of the spring tooth tip in a fixed coordinate system (m).

: combine harvester forward speed (m/s).

t: time (s).

R: reel radius (m);

ω: angular velocity of the reel (rad/s).

H: installation height of reel main shaft (m).

: stubble height (m).

For trajectory analysis, the reel speed ratio Δ is introduced and defined as:

Substituting φ = ωt into the above equation yields the parametric equations:

where:

φ: rotation angle of the reel (rad), range [0, n × 2π].

Δ: reel speed ratio (dimensionless), representing the ratio of reel peripheral linear velocity to machine forward speed.

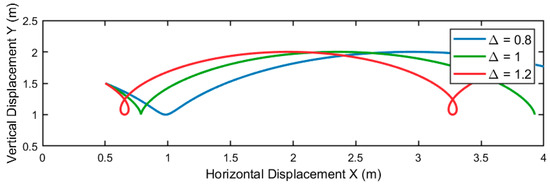

Under MATLAB R2024a environment, with a reel radius R = 0.5 m, main shaft height H = 1.2 m, stubble height = 0.3 m, and machine forward speed = 1.0 m/s, three reel-speed ratios (Δ = 0.8, 1.0, and 1.2) were selected for simulation. The motion trajectories of spring tooth tips under different Δ values were calculated, and trajectory plots were generated to analyze loop characteristics and operational performance variations.

2.3.5. Investigation of Pod-Spring Tooth Collision with Different Parameters

Mechanical analysis based on Hertz contact theory reveals that the collision-induced damage mechanism between the spring tooth and pods is primarily governed by two key parameters: the elastic modulus of the spring tooth and the contact area. According to the MatWeb material property database, conventional cast steel has an elastic modulus of approximately 190 GPa. In contrast, unreinforced nylon exhibits a significantly lower elastic modulus, with values ranging from 0.600 to 12.1 GPa, underscoring the distinct mechanical properties. Theoretical models confirm that replacing the traditional cylindrical rigid spring tooth with nylon material, combined with an appropriate increase in the cross-sectional area of the spring tooth, achieves the dual optimization objectives of reducing the elastic modulus and enlarging the contact area. This material–structure synergistic improvement strategy effectively attenuates the mechanical impact energy transferred to pods during reel operation [25,32,33,34,35,36,37,38]. These findings establish a theoretical framework for the innovative design of harvesting reel mechanisms from the perspective of contact mechanics [39,40,41].

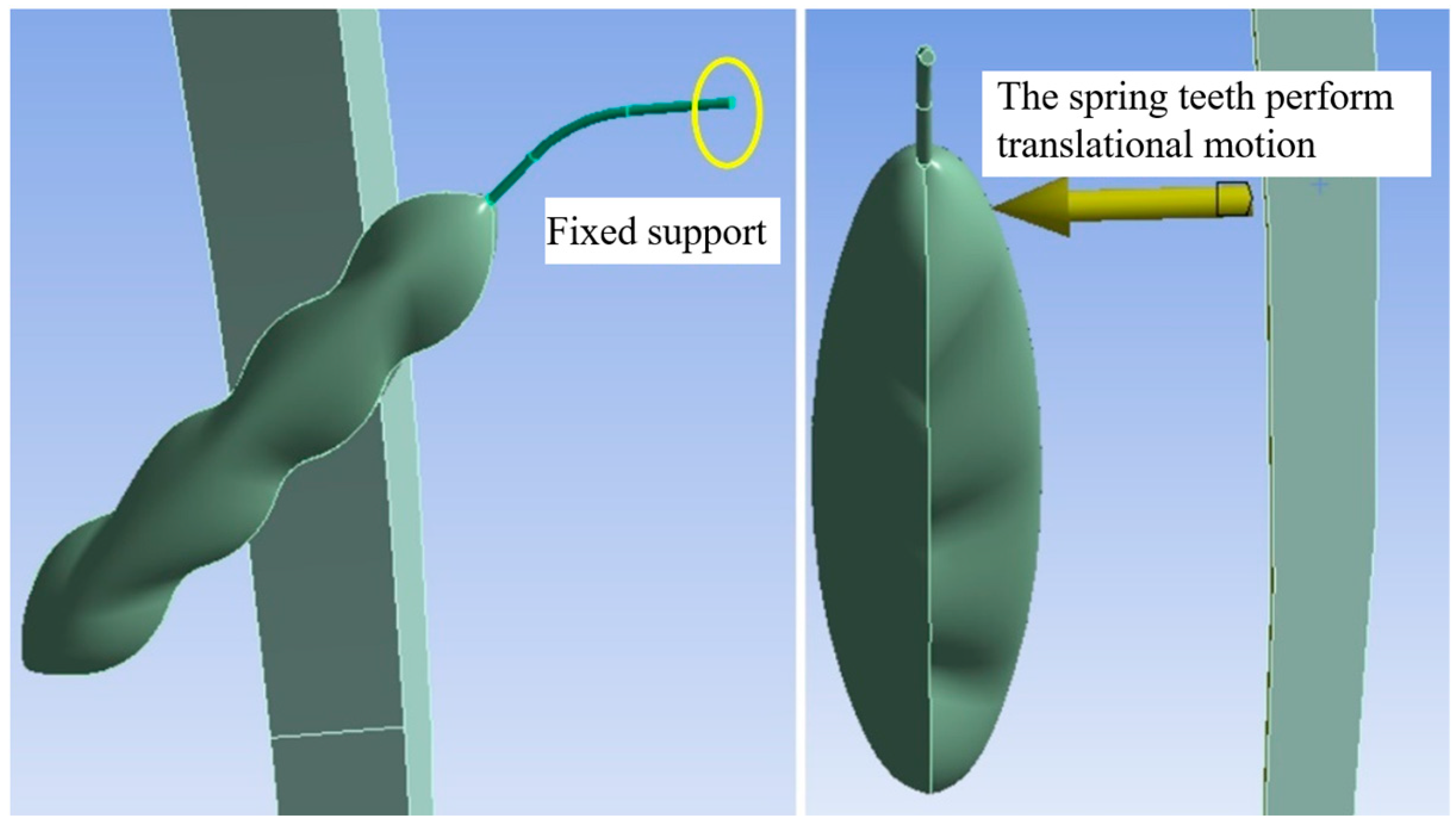

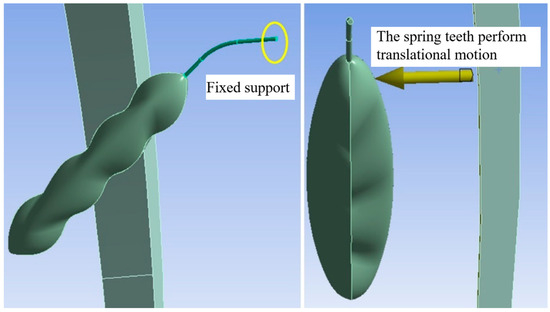

To validate the reliability of the theoretical model, this study developed a multiscale finite element model of the pod–spring tooth collision system based on the ANSYS 2022.R1 platform. The modeling strategy employed the x_t format to import 3D pod contour models with preserved geometric features, ensuring computational accuracy while enhancing solution efficiency. The material constitutive model incorporated experimentally validated soybean seed parameters. Boundary conditions were set as follows: a fixed constraint was applied at the pod–stem connection, and the spring tooth was modeled with a translational contact mode.

The simulation systematically investigated the regulatory effects of spring tooth material of cast steel and nylon and contact area parameters on the equivalent stress field of pods. By extracting stress nephogram features and performing quantitative damage parameter analysis, a mapping relationship between design parameters and mechanical damage risk was established [42,43,44,45]. This evaluation system, based on equivalent stress thresholds, not only simplifies complex contact problems for engineering applications but also provides decision-making support for optimized design through visualized damage risk distribution [16,46,47,48,49]. As shown in Figure 5, the simulation successfully constructed an efficient numerical experimental platform for studying the dynamic interaction between the spring tooth and pods [11,50,51].

Figure 5.

Schematic diagram of pod–spring tooth collision in ANSYS.

2.3.6. Field Harvesting Test of Flexible Spring Tooth

Based on previous studies combining Hertz collision theory and ANSYS finite element simulation, this paper comprehensively analyzed the influencing factors of mechanical forces during pod–spring tooth collisions. The results demonstrated that increasing the contact area between the spring tooth and pods while reducing the elastic modulus of the spring tooth material could effectively minimize the impact damage to pods caused by the reel mechanism.

Building upon these findings, this section designed a flexible spring tooth made of PVC damping material with a square contact surface to validate the feasibility of a theoretical analysis. To accommodate actual harvesting requirements, modifications were made to the reel spring tooth shaft of the Yanmar AW82G combine harvester. First, the original welded spring tooth shaft was removed and replaced with a newly fabricated detachable shaft featuring mounting holes spaced at 11 cm intervals. The modified configuration allowed installation of the novel PVC spring tooth onto the reel, with the specific assembly effect shown in Figure 6.

Figure 6.

Installation effect diagram of PVC spring tooth.

The field harvesting tests were conducted using a Yanmar AW82G combine harvester, which is equipped with a reel radius of 0.5 m. For the test, the machine was operated at its default working parameters: a constant forward velocity of 1.2 m/s, while the reel’s angular velocity was maintained at approximately 3.14 rad/s. Based on Formula (20), the corresponding reel speed ratio (Δ) was calculated to be approximately 1.15. This value is greater than 1.0, satisfying the condition for effective crop gathering.

Field harvesting tests were conducted using these flexible spring teeth to evaluate the effectiveness of these two improvement measures (increased contact area and reduced elastic modulus) in mitigating pod impact damage during actual operations. The results provide practical evidence for optimizing harvesting equipment design.

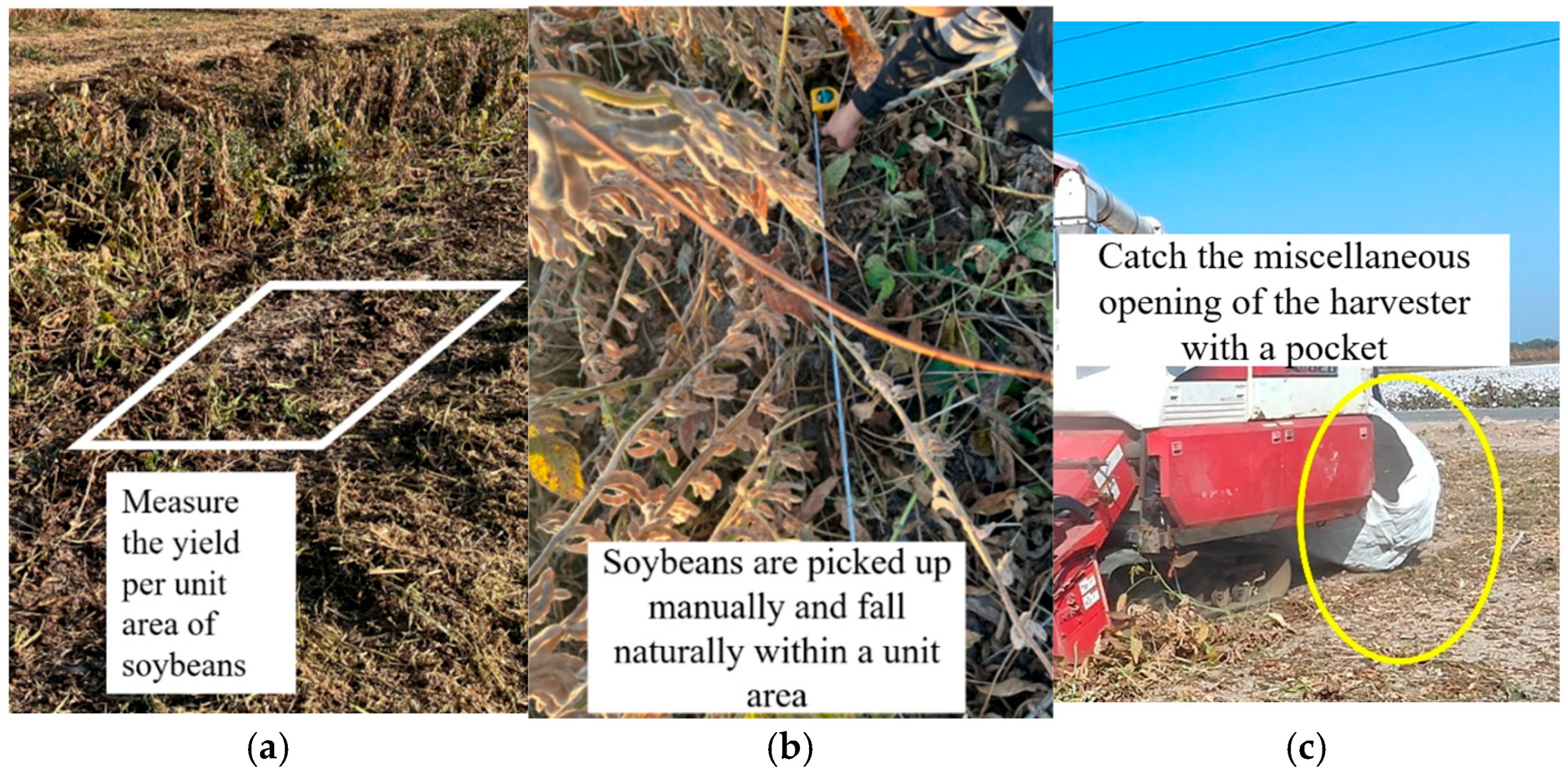

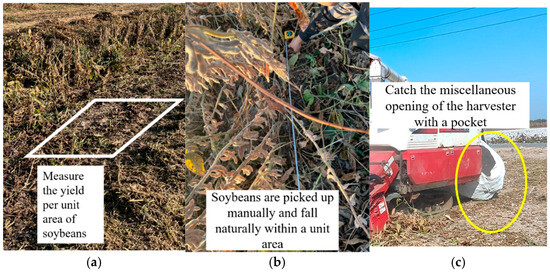

This study aims to verify the actual effect of the flexible spring-tooth reel in reducing soybean pod shattering and grain loss through systematic field experiments. The experiment adopts a rigorous three-stage measurement method.

First, in the unharvested soybean test field, 10 measurement areas of 1 square meter were randomly selected at equal intervals. The pods on the plants were collected, and the grains were separated to weigh the soybean grain mass per unit area as baseline data. Each group of experiments was repeated three times to ensure data reliability. Meanwhile, the number of naturally fallen grains in the same area was recorded, and the natural grain loss per unit area was accurately calculated as the background value by combining the single grain mass obtained from the 1000-grain weight test.

To ensure data accuracy, special treatment was applied to the discharge port at the rear of the harvester before the experiment—it was completely sealed with bags so that all residues were collected without scattering in the field. This ensured that the grains remaining in the field after harvesting only came from natural grain loss and pod shattering caused by the reel.

The test site was designed with three independent working zones of 20 m length each, adopting sequential operation where only one test zone was harvested each time, immediately followed by data collection. The specific operation procedure was as follows: after each harvesting operation, 10 areas of 1 square meter were selected at equal intervals in the harvested zone to comprehensively collect and weigh all fallen grains, pods, and unharvested straw in the area. The obtained grain weight represented the header loss per unit area.

Finally, through statistical analysis of the loss per unit area from the three groups of experiments and taking the average value, the comprehensive loss rate was calculated to objectively evaluate the actual performance of the flexible spring tooth. The preparation work and measurement methods of the entire experimental process are shown in Figure 7.

Figure 7.

Field test preparation for flexible spring tooth harvesting experiment. (a) Soybean yield measurement per unit area. (b) Natural grain loss measurement per unit area. (c) Residue collection using containment bags.

3. Results and Discussion

3.1. Test Results of Moisture Content in Pods

The measured moisture content of the materials is shown in Table 1. The average moisture content of the pods of soybeans harvested in Xinjiang during the harvest period was 9.267%.

Table 1.

Measurement results of moisture content in materials.

3.2. Experimental Results of Pod Shattering Force Under Different Loading Directions

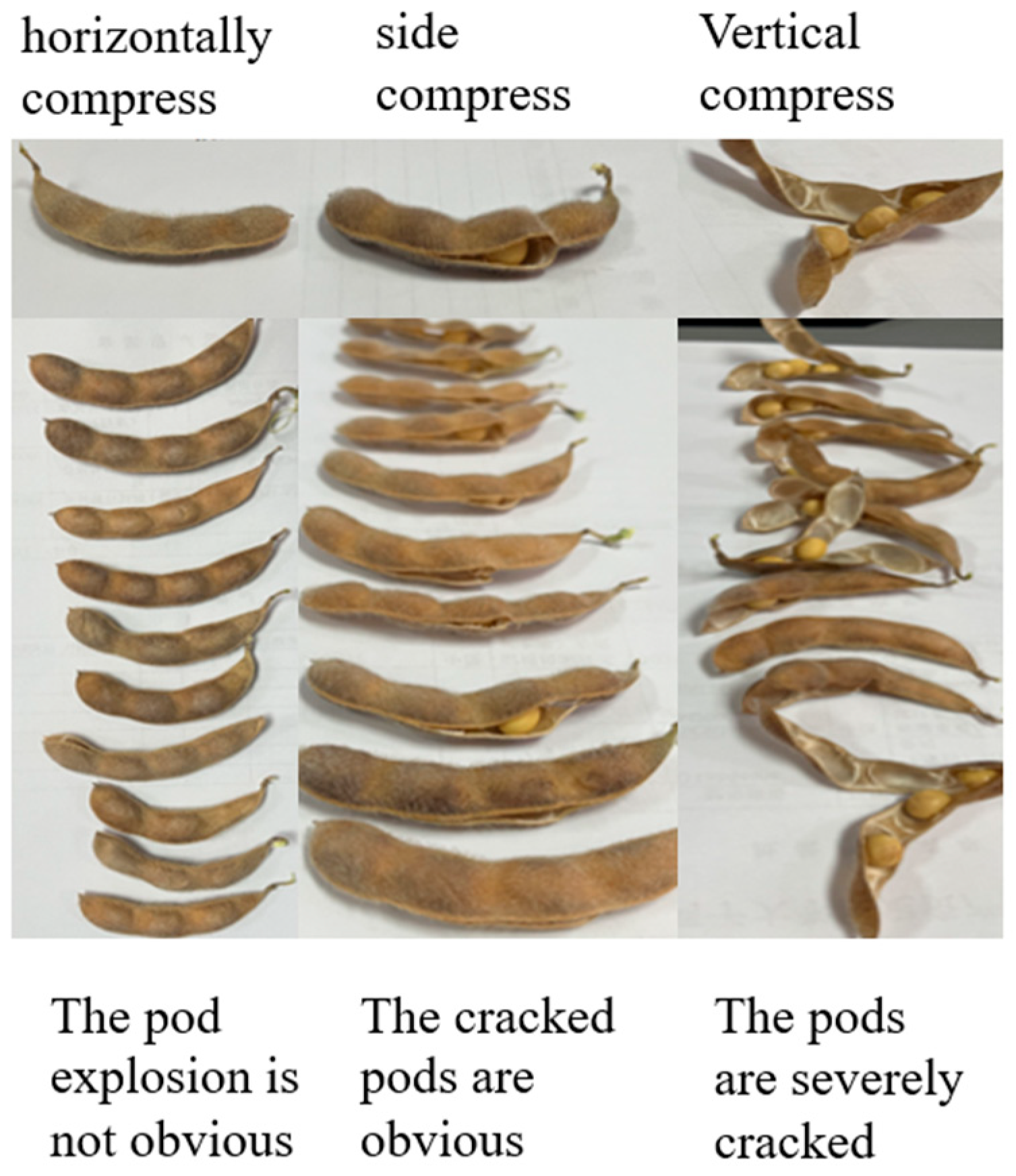

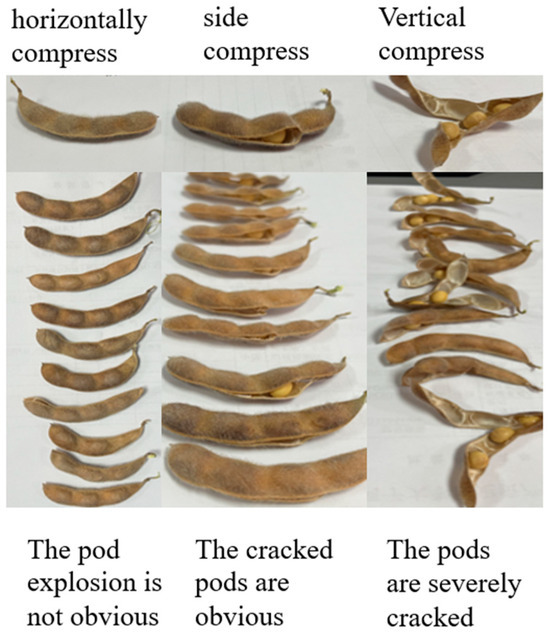

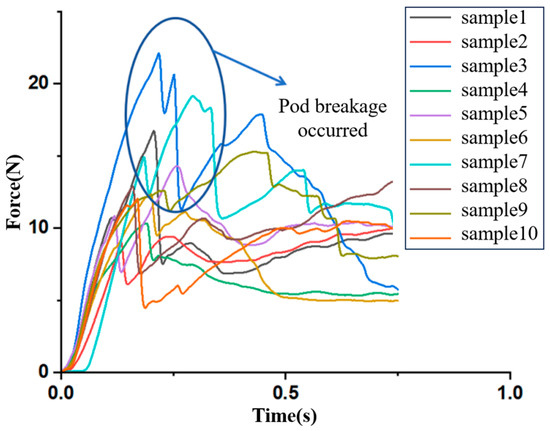

Significant differences were observed in the mechanical response and shattering characteristics of soybean pods under different compression directions. The experimental results demonstrated that during horizontal compression, the pods maintained structural integrity without obvious shattering even when soybean seeds exhibited substantial deformation, owing to their unique structural features. However, under side and vertical compression conditions, the pods were more prone to shattering, with particularly severe pod rupture occurring during vertical compression.

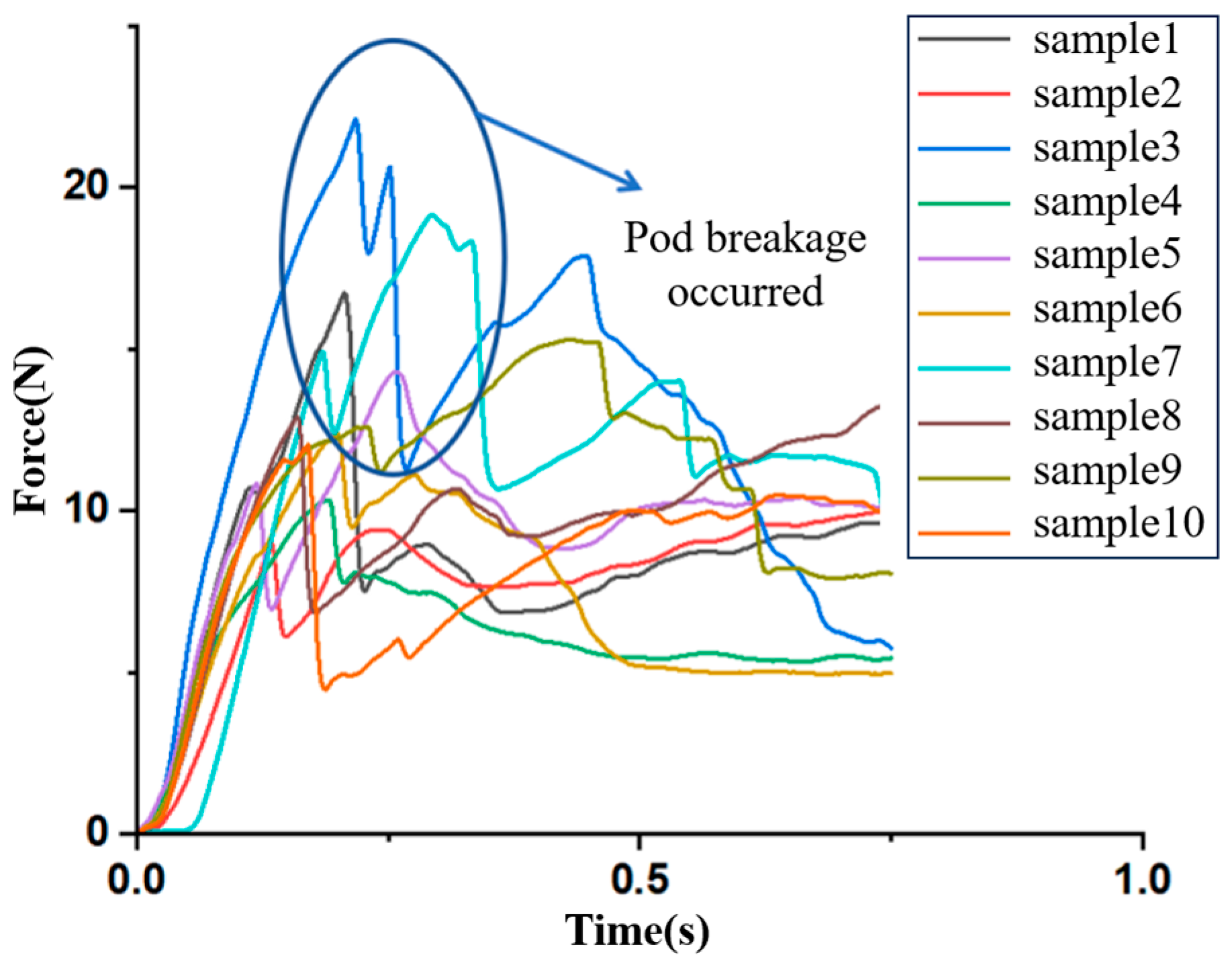

As shown in Figure 8, this directional dependence clearly indicates anisotropic mechanical properties of soybean pods, with the vertical orientation exhibiting the poorest structural stability. These findings provide critical guidance for optimizing operational parameters of harvesting equipment.

Figure 8.

Soybean pods under loading in different directions.

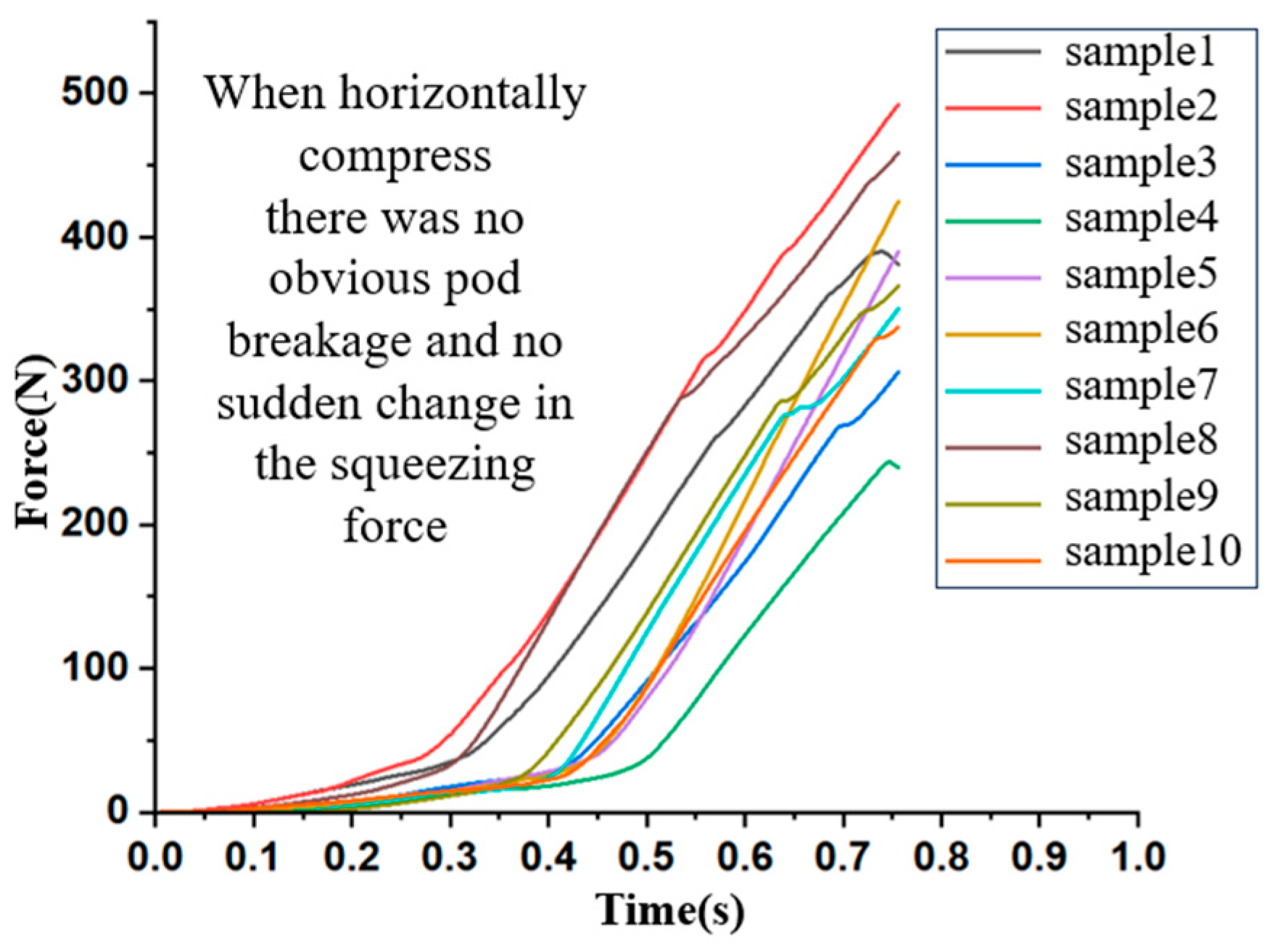

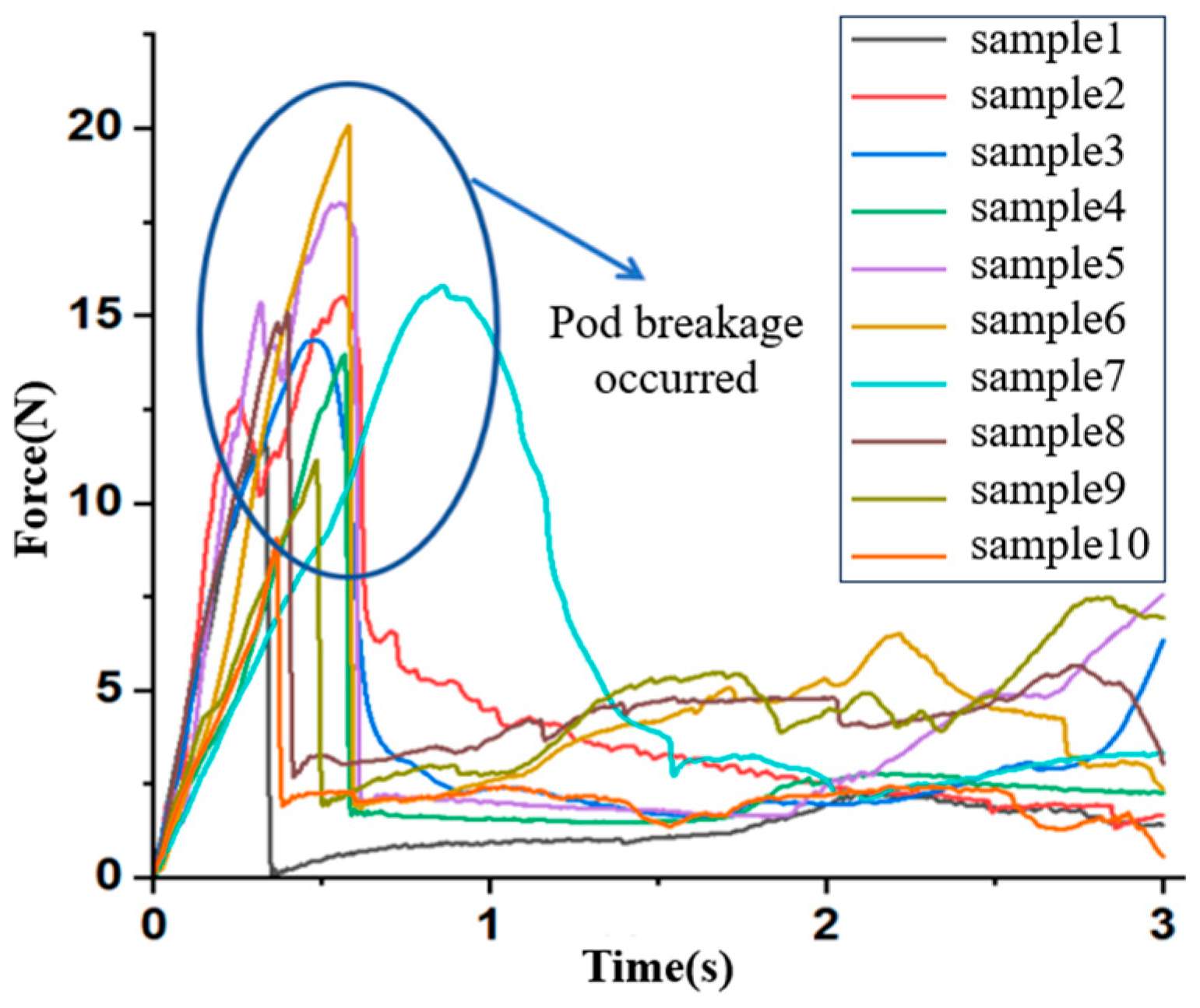

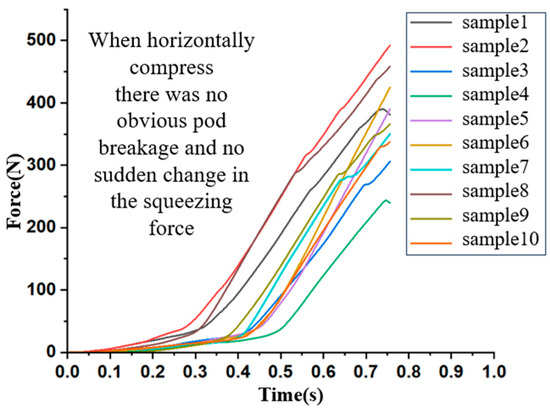

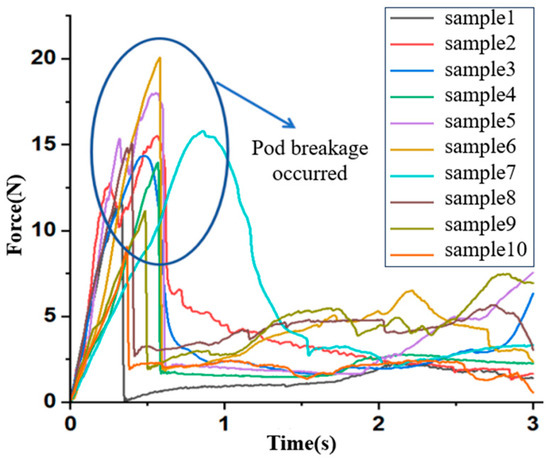

The texture analyzer continuously recorded the force–displacement curves during the pod compression tests, revealing characteristic failure patterns in the mechanical behavior of soybean pods. As shown in Figure 9, Figure 10 and Figure 11, the compressive force exhibited a progressive increase with deformation during the initial loading phase. Upon reaching a critical point, sudden pod shattering occurred, manifested by an abrupt force drop in the curve. The peak force at this transition point represents the pod-shattering force, which accurately reflects the ultimate load-bearing capacity of pods against mechanical damage. These characteristic force–deformation profiles provide reliable experimental evidence for the quantitative analysis of mechanical damage properties in soybean pods.

Figure 9.

Variation of loading force on pods under horizontal compression.

Figure 10.

Variation of loading force on pods under side compression.

Figure 11.

Variation of loading force on pods under vertical compression.

The test results show significant differences in the mechanical properties of pods under different compression directions. Since no obvious pod shattering was observed during horizontal compression, the study focused on analyzing shattering force data under vertical and side compression conditions, as shown in Table 2.

Table 2.

Pod-shattering force under side and vertical compression.

The test results indicate that the shattering force under side compression varied between 9.0234 N and 21.8909 N, with a mean value of 13.3664 N and a standard deviation of 3.5362 N. The median force was 12.4917 N, suggesting that 50% of the samples fractured below this threshold. The notable discrepancy between the mean and median, coupled with the relatively high standard deviation, indicates substantial variability in the data, including an outlier at 21.8909 N.

In contrast, vertical compression tests yielded forces ranging from 9.0606 N to 20.0636 N, with a mean of 14.3271 N, a standard deviation of 3.1967 N, and a median of 14.7100 N. The closer alignment between the mean and median in this case implies a more consistent and symmetric distribution of mechanical performance under vertical loading, reflecting greater structural stability compared to side compression.

These findings provide an important basis for understanding pod failure mechanisms under different loading conditions.

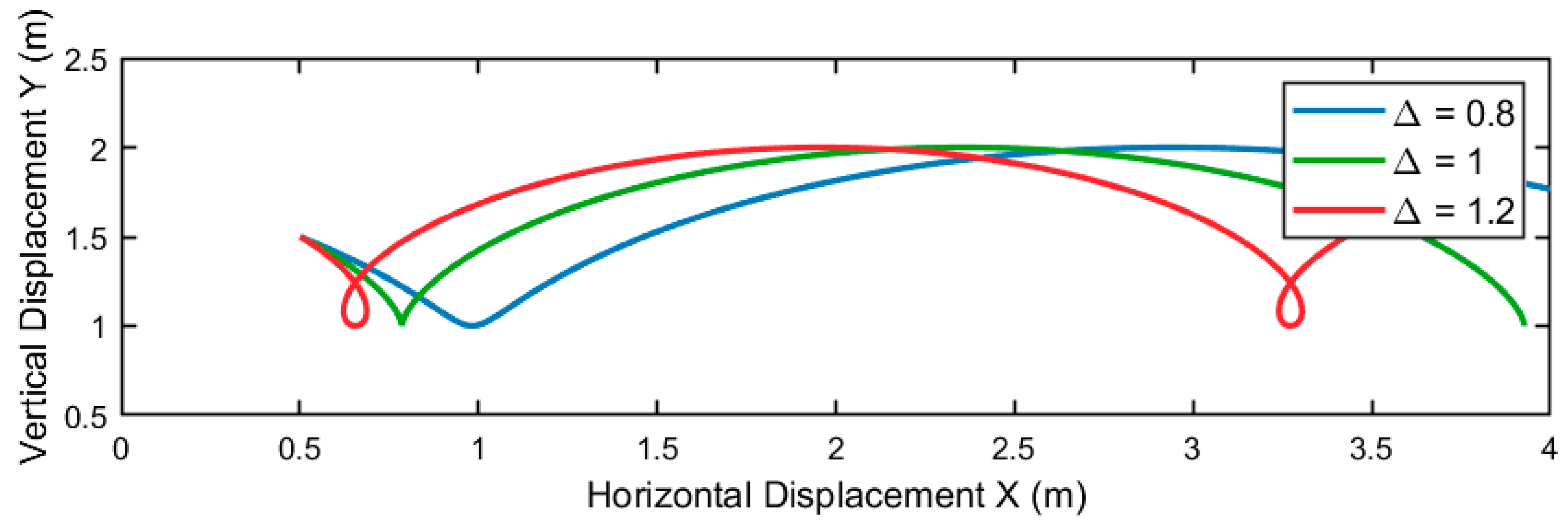

3.3. Analysis of Spring Tooth Tip Trajectory Simulation Results

As shown in Figure 12, the motion trajectories of the reel spring tooth tips were simulated and plotted using MATLAB. The results demonstrate that when the reel speed ratio Δ is 0.8 or 1.0, the trajectory curves exhibit non-looping patterns with periodic fluctuations. In these cases, the spring tooth tip speed remains greater than or equal to the machine forward speed, preventing effective backward hooking action on crop stems and resulting in loss of reel functionality.

Figure 12.

Trajectory curves of reel spring tooth under different reel speed ratios (Δ).

Particularly at Δ = 1.0, the trajectory reaches a critical state yet still lacks loop structures, further confirming unsatisfactory operational performance at this speed ratio. However, when Δ increases to 1.2, distinct looping patterns emerge in the trajectory, enabling the spring tooth tips to perform backward hooking motions relative to the ground. This facilitates effective stem pushing and achieves optimal reel performance.

The simulation analysis reveals that looping trajectories are essential characteristics for effective reel operation. Moreover, the reel speed ratio must exceed 1.0 to ensure the spring tooth tip speed surpasses the machine forward speed, thereby generating the required backward hooking motion. These findings provide theoretical guidance for optimizing both structural and operational parameters of reel mechanisms.

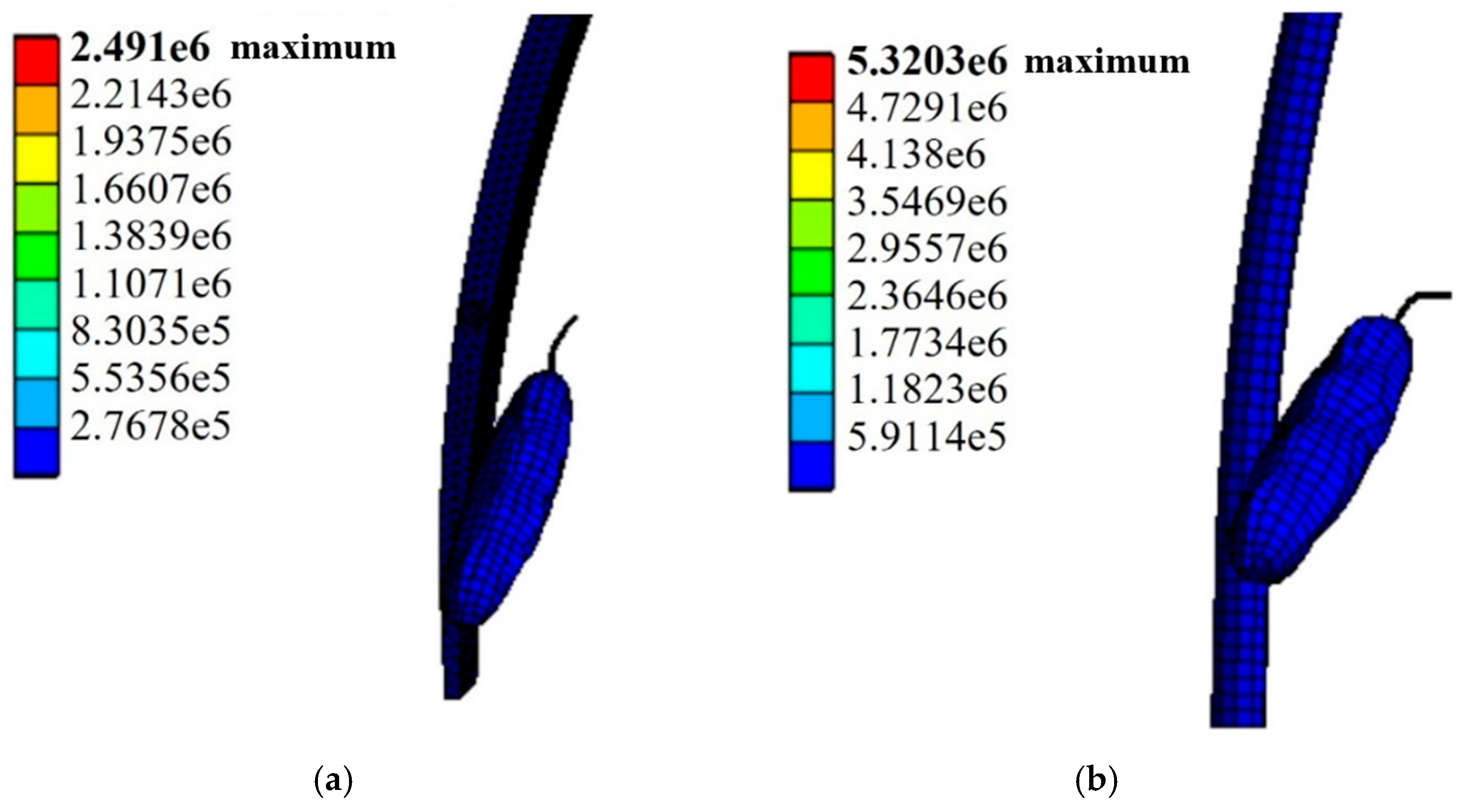

3.4. Simulation Results of Spring Tooth Effects on Pods Under Different Parameters

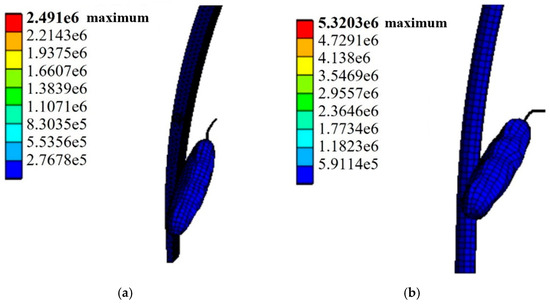

To investigate the influence of spring tooth with different contact areas on pod mechanical response, this study conducted a comparative analysis of circular and square-shaped spring tooth using the ANSYS simulation platform. Both types of spring tooth were made of PVC-nylon flexible spring teeth. Under the condition of maintaining identical mass, the square-shaped spring tooth achieved a larger contact area due to its geometric characteristics. The simulation focused on examining the influence mechanism of contact area differences on pod stress state, providing a theoretical basis for spring-tooth design optimization through a comparative analysis of stress distribution features between the circular spring tooth (smaller contact area) and the square-shaped spring tooth (larger contact area).

The simulation results are shown in Figure 13. The ANSYS comparative analysis revealed that the spring tooth contact area significantly affects the pod stress state. The results demonstrate that when using a square-shaped spring tooth with a larger contact area, the maximum equivalent stress on pods during collision was 2.491 × 106 Pa, with an average equivalent stress of 4.5286 × 105 Pa. In contrast, a circular spring tooth with a smaller contact area subjected pods to higher stresses, with the maximum equivalent stress on pods reaching 5.3203 × 106 Pa and an average equivalent stress of 5.227 × 105 Pa.

Figure 13.

Comparison of stress contours from collisions with (a) square and (b) circular cross-section spring teeth: (a) Collision results between square PVC spring tooth and pods; (b) Collision results between circular PVC spring tooth and pods.

Under identical conditions of PVC-nylon flexible spring teeth and mass, changing the spring tooth shape from circular to square reduced the maximum equivalent stress on pods by 53.2% (from 5.3203 × 106 Pa to 2.491 × 106 Pa) and the average equivalent stress by 13.4% (from 5.227 × 105 Pa to 4.5286 × 105 Pa).

These results are highly consistent with previous Hertz contact theory analysis, confirming that increasing the spring tooth contact area can effectively reduce pod collision stress, thereby minimizing pod-shattering losses during harvesting operations.

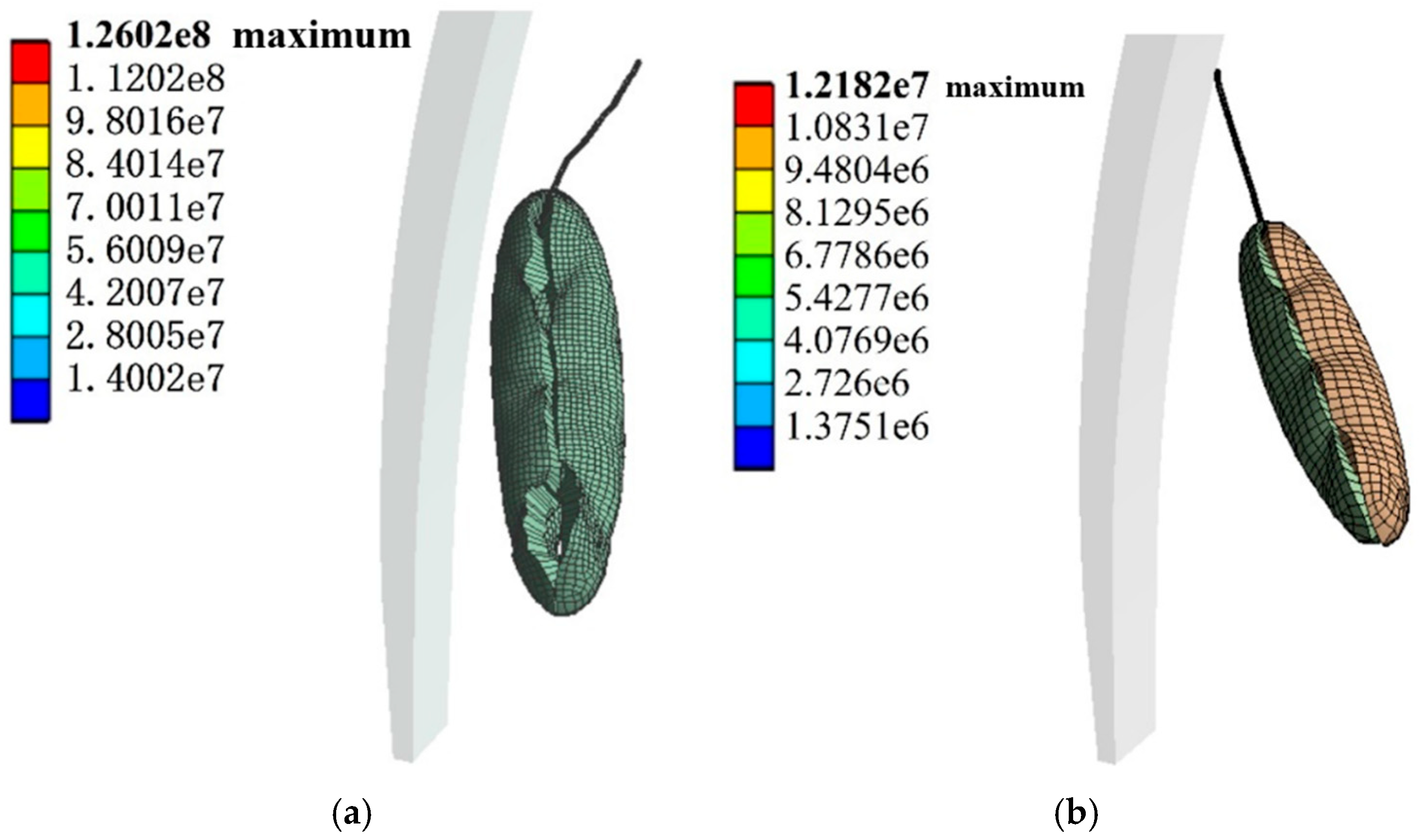

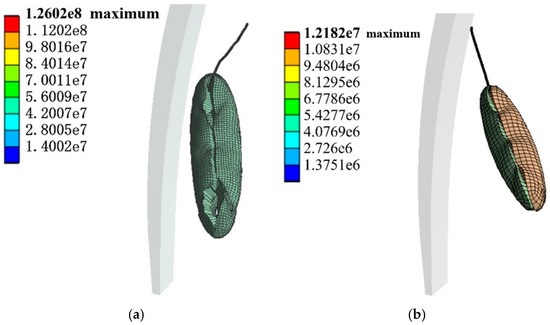

A comparative analysis was conducted using the ANSYS simulation platform to investigate the influence of spring tooth materials on pod stress. Identical geometric models were employed for comparison, focusing on the mechanical property differences between structural steel and PVC-nylon flexible spring teeth, with PVC nylon exhibiting significantly lower elastic modulus than structural steel. Simulation data revealed that the structural steel spring tooth induced the maximum equivalent stress on pods of 1.2602 × 108 Pa and ab average equivalent stress of 2.5287 × 106 Pa on pods during collision, while the PVC nylon spring tooth reduced the maximum equivalent stress on pods to 1.2182 × 107 Pa (90.3% reduction) and the average equivalent stress to 1.0737 × 106 Pa (57.5% reduction). These results confirm the critical role of material elastic modulus, demonstrating that reducing spring tooth material stiffness significantly decreases pod collision stress. Specifically, material substitution achieved an approximately 10-fold reduction in the maximum equivalent stress on pods and an approximately 2-fold reduction in the average equivalent stress. These findings fully align with Hertz contact theory predictions. As shown in Figure 14, the simulation results visually demonstrate stress distribution variations, confirming that PVC nylon’s low elastic modulus effectively mitigates mechanical damage to pods. This provides crucial guidance for optimizing harvester material selection and reducing soybean harvest losses.

Figure 14.

Comparison of stress contours from collisions with spring teeth made of (a) structural steel and (b) nylon: (a) collision results between structural steel spring tooth and pods; (b) collision results between nylon spring tooth and pods.

The collision process between the pods and spring tooth was simulated and analyzed in ANSYS, with a particular focus on the effects of different contact areas and elastic moduli on collision outcomes. The simulation results demonstrate that both increasing the contact area between the spring tooth and pods and reducing the elastic modulus of the spring tooth can effectively decrease the equivalent stress experienced by pods during collision. These findings are consistent with the analytical results derived from Hertz contact theory, thereby validating the theoretical analysis. The study provides important guidance for the structural design and material selection of spring teeth, contributing to performance optimization and the reduction in pod damage risks during harvesting operations. When the moisture content of the pods increases, leading to enhanced flexibility, or when the crop type, operation speed, or header structure changes, the model conclusions need to be reverified.

3.5. Field Test Results of Flexible Spring Tooth

3.5.1. Test Results of Soybean Grain Mass per Unit Area

Analysis of the data in Table 3 reveals that the mean soybean grain mass per unit area from three repeated trials was 4.260 kg, 4.213 kg, and 4.198 kg, respectively, with a final average of 4.224 kg/m2. This indicates good repeatability and reliability of the experimental results.

Table 3.

Measurement results of mass per unit area of soybeans.

The maximum value of 4.49 kg was recorded in Plot 9 of Trial 1, while the minimum value of 3.93 kg was observed in Plot 3 of Trial 3, reflecting inherent spatial variability in field soybean yield. All three trials exhibited a coefficient of variation below 5%, demonstrating the stability and reliability of the measurement method. The determined yield of 4.224 kg/m2 serves as a crucial baseline parameter for subsequent calculations of pod-shattering loss rates and the optimization of harvesting equipment design.

3.5.2. Thousand-Grain Weight of Soybean Seeds

To determine the thousand-grain weight of soybean seeds, manual selection of one thousand soybean seeds was employed for testing. Each experimental group underwent ten repeated weighing measurements, with three parallel trials conducted to minimize error effects. The test data are recorded in Table 4, and the obtained thousand-grain weight data will serve as a crucial basis for subsequent calculations of natural grain loss mass per unit area and pod-shattering loss mass.

Table 4.

Measurement data of 1000-grain weight of soybean seeds.

3.5.3. Natural Grain Loss per Unit Area

The experimental results indicate that the natural grain loss mass per unit area accounts for a relatively small proportion of the total mass, with the maximum natural grain loss ratio reaching only 0.44‰ (detailed experimental data are shown in Table 5). This finding demonstrates that soybean plants exhibit minimal grain loss under natural conditions.

Table 5.

Data on the natural grain drop quality of soybeans per unit area.

3.5.4. Header Loss Test per Unit Area

During soybean field harvesting, collection bags were installed at the combine harvester’s discharge outlet to measure header harvest loss. After harvesting completion, soybean grains within unit areas were manually collected and counted. The header loss caused by reel impact on pods was determined by subtracting the natural grain loss quantity from the total collected grain count.

The natural grain loss quantity adopted the experimental mean value, with specific data recorded in Table 6, where the grain counts had already excluded the natural loss portion. The experimental results showed that the three sets of flexible spring tooth harvesting tests achieved a mean header loss, accounting for 1.371% of the total soybean yield, with the standard deviation of the thirty “percentage of the total mass” values being 0.2423, indicating a consistent and stable performance across the trials. Compared with existing research on low-loss soybean headers, this study further reduced header losses during harvesting by optimizing the spring tooth contact area and reducing elastic modulus, achieving a lower header loss rate.

Table 6.

Soybean head loss per unit area in the field after harvest with flexible elastic teeth.

4. Conclusions

Through finite element simulation based on theoretical analysis and field experiments, the contact theory and motion parameters of the collision between pods and elastic teeth were studied, and the following experimental and simulation results were obtained:

- (1)

- The mechanical properties of soybean pods from Xinjiang, with an average moisture content of 9.267%, exhibit significant anisotropy. The results of compression tests in different loading directions revealed that the average shattering force of these pods reached 14.3271 N under vertical compression, which posed the highest risk of pod shattering. This finding provides theoretical guidance for optimizing the operational parameters of harvesting mechanisms for soybeans under these specific conditions.

- (2)

- The collision damage mechanism between reel spring teeth and soybean pods is significantly influenced by the elastic modulus and contact area of the spring teeth. Based on Hertzian contact theory and finite element simulation, increasing the contact area and decreasing the elastic modulus of the spring teeth effectively reduced the maximum equivalent stress on the pods by 90.3%, thereby mitigating mechanical damage during harvesting.

- (3)

- The reel spring tooth tip trajectory analysis indicated that a spring tooth speed ratio (Δ) greater than 1 is necessary to achieve effective crop gathering. Simulation results demonstrated that only when Δ > 1.0 did the spring tooth tip trajectory form a looping path, enabling the backward hooking motion essential for efficient plant lifting and gathering.

- (4)

- Field trials confirmed the practical effectiveness of flexible PVC spring teeth in reducing harvest losses. The optimized flexible spring tooth reel achieved 1.371%, which is significantly lower than that of conventional rigid steel spring teeth, thus verifying the reliability of the theoretical and simulation-based design improvements in actual field operations.

Author Contributions

Conceptualization, Y.C. and W.Z.; methodology, Y.C. and B.L.; software, W.Z. and Y.C.; validation, Y.C. and S.W.; formal analysis, Y.C. and J.J.; investigation, Z.T. and Y.L.; resources, Y.C.; data curation, Y.C. and X.H.; writing—original draft preparation, Y.C.; writing—review and editing, Z.T. and B.L.; supervision, Z.T. and S.W.; project administration, Z.T.; funding acquisition, Z.T. and B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Agricultural GG Project of the Xinjiang Production and Construction Corps and the Key Laboratory Equipment of Modern Agricultural Equipment and Technology (Jiangsu University), Ministry of Education (MAET202306).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data used to support the findings of this study are available from the corresponding author upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dai, C.; Hou, Y.; Xu, H.; Huang, L.; Dabbour, M.; Mintah, B.K.; He, R.; Ma, H. Effect of solid-state fermentation by three different Bacillus species on composition and protein structure of soybean meal. J. Sci. Food Agric. 2022, 102, 557–566. [Google Scholar] [CrossRef] [PubMed]

- Dai, C.; Hou, Y.; Xu, H.; Umego, E.C.; Huang, L.; He, R.; Ma, H. Identification of a thermophilic protease-producing strain and its application in solid-state fermentation of soybean meal. J. Sci. Food Agric. 2022, 102, 2359–2370. [Google Scholar] [CrossRef] [PubMed]

- Heng, X.; Chen, H.; Lu, C.; Feng, T.; Li, K.; Gao, E. Study on synergistic fermentation of bean dregs and soybean meal by multiple strains and proteases. LWT-Food Sci. Technol. 2022, 154, 112626. [Google Scholar] [CrossRef]

- Zhu, H.; Chen, J.; He, Z.; Hao, W.; Liu, J.; Kwek, E.; Zhao, Y.; Ma, K.Y.; He, W.-S.; Chen, Z.-Y. Soybean germ oil reduces blood cholesterol by inhibiting cholesterol absorption and enhancing bile acid excretion. Food Funct. 2019, 10, 1836–1845. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, J.; Zhao, X.; Zhang, L.; Zhou, D.; Yu, C.; Hu, W.; Zhang, Q. Optimising maize threshing by integrating DEM simulation and interpretive enhanced predictive modelling. Biosyst. Eng. 2024, 244, 93–106. [Google Scholar] [CrossRef]

- Fang, X.; Zhang, J.; Zhao, X.; Zhang, Q.; Zhang, L.; Zhou, D.; Yu, C.; Hu, W.; Wang, H. Maize kernel damage dynamic prediction in threshing through PSO-LSTM and discrete element modelling. Biosyst. Eng. 2024, 242, 179–195. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Ji, K.; Yu, Z.; Ma, Z.; Xu, L.; Niu, C. Development of a hydraulic variable-diameter threshing drum control system for combine harvester part I: Adaptive monitoring method. Biosyst. Eng. 2025, 250, 174–182. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Y.; Ji, K.; Yu, Z.; Ma, Z.; Xu, L.; Niu, C. Development of a hydraulic variable-diameter threshing drum control system for combine harvester part II: Controller design and field performance. Biosyst. Eng. 2025, 254, 104160. [Google Scholar] [CrossRef]

- Qian, Z.; Jin, C.; Ni, Y.; Zhang, D. Modelling threshing using an entropy regularisation approach with frictional contact dynamics and a flexible threshing mechanism. Biosyst. Eng. 2023, 226, 144–154. [Google Scholar] [CrossRef]

- Zhang, Q.; Fang, X.; Gao, X.; Zhang, J.; Zhao, X.; Yu, L.; Yu, C.; Zhou, D.; Zhou, H.; Zhang, L.; et al. Optimising maize threshing process with temporal proximity soft actor-critic deep reinforcement learning algorithm. Biosyst. Eng. 2024, 248, 229–239. [Google Scholar] [CrossRef]

- Cao, Z.; Li, Q.; Chen, L.; Zhou, Y.; Nie, J.; Chen, Q.; Xiao, Y.; Zhou, S.; Zhang, L. Structural Design and Testing of a Corn Header for Soybean-Corn Intercropping. Agriculture 2025, 15, 123. [Google Scholar] [CrossRef]

- Luo, H.; Wang, J.; Lian, X.; Geng, B.; Li, F. Design and experiment of small narrow range segmented soybean harvester in hilly area. Agric. Res. Arid Areas 2024, 42, 283–293. [Google Scholar]

- Wang, S.; Li, B.; Chen, S.; Tang, Z.; Zhou, W.; Guo, X. Design and Performance Test of Soybean Profiling Header Suitable for Harvesting Bottom Pods on Film. Agriculture 2024, 14, 1058. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, R.; Xi, X.; Zhang, X.; Ding, W.; Liu, J.; Xiao, S.; Lin, M.; Xing, J.; Yang, S.; et al. Numerical simulation and optimisation of depodding performance in a fresh green soybean harvester. Biosyst. Eng. 2025, 253, 104127. [Google Scholar] [CrossRef]

- Cong, C.; Guangqiao, C.; Jinlong, Z.; Jianping, H. Dynamic Monitoring of Harvester Working Progress Based on Traveling Trajectory and Header Status. Eng. Agric. 2023, 43, e20220196. [Google Scholar] [CrossRef]

- Liu, H.; Han, X.; Fadiji, T.; Li, Z.; Ni, J. Prediction of the cracking susceptibility of tomato pericarp: Three-point bending simulation using an extended finite element method. Postharvest Biol. Technol. 2022, 187, 111876. [Google Scholar] [CrossRef]

- Pang, J.; Li, Y.; Ji, J.; Xu, L. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Nie, J.; Luo, H.; Zhou, Y.; Li, Q.; Qiu, Q.; Zhang, L. Design and Test of a Low-Loss Soybean Header Based on Synchronous Profiling. Agriculture 2023, 13, 1580. [Google Scholar] [CrossRef]

- Tong, W.; Zhang, J.; Cao, G.; Song, Z.; Ning, X. Design and Experiment of a Low-Loss Harvesting Test Platform for Cabbage. Agriculture 2023, 13, 1204. [Google Scholar] [CrossRef]

- Xie, B.; Wang, J.; Jiang, H.; Zhao, S.; Liu, J.; Jin, Y.; Li, Y. Multi-feature detection of in-field grain lodging for adaptive low-loss control of combine harvesters. Comput. Electron. Agric. 2023, 208, 107772. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, M.; Xing, Z.; Liu, X. Design and Test of Double-acting Opposite Direction Cutting End Effector for Safflower Harvester. Trans. Chin. Soc. Agric. Mach. 2022, 53, 160–170. [Google Scholar]

- Zhao, Y.; Dai, F.; Shi, R.; Chen, J.; Xin, S.; Zhao, W.; Zhang, F. Design and Experiment of Self-propelled Seed Corn Combine Harvester. Trans. Chin. Soc. Agric. Mach. 2024, 55, 121–134. [Google Scholar]

- Li, D.; Wang, Z.; Liang, Z.; Zhu, F.; Xu, T.; Cui, X.; Zhao, P. Analyzing Rice Grain Collision Behavior and Monitoring Mathematical Model Development for Grain Loss Sensors. Agriculture 2022, 12, 839. [Google Scholar] [CrossRef]

- Liang, Z.; Huang, Y.; Li, D.; Wada, M.E. Parameter determination of a viscoelastic-plastic contact model for potatoes during transient collisions. Biosyst. Eng. 2023, 234, 156–171. [Google Scholar] [CrossRef]

- Wang, G.; He, B.; Han, D.; Zhang, H.; Wang, X.; Chen, Y.; Chen, X.; Zhao, R.; Li, G. Investigation of Collision Damage Mechanisms and Reduction Methods for Pod Pepper. Agriculture 2024, 14, 117. [Google Scholar] [CrossRef]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving Cleaning Performance of Rice Combine Harvesters by DEM-CFD Coupling Technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- Hu, J.; Pan, J.; Dai, B.; Chai, X.; Sun, Y.; Xu, L. Development of an Attitude Adjustment Crawler Chassis for Combine Harvester and Experiment of Adaptive Leveling System. Agronomy 2022, 12, 717. [Google Scholar] [CrossRef]

- Huang, J.; Tan, L.; Tian, K.; Zhang, B.; Ji, A.; Liu, H.; Shen, C. Formation mechanism for the laying angle of hemp harvester based on ANSYS-ADAMS. Int. J. Agric. Biol. Eng. 2023, 16, 109–115. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Ji, K.; Zhu, R. A Fault Diagnosis Method for a Differential Inverse Gearbox of a Crawler Combine Harvester Based on Order Analysis. Agriculture 2022, 12, 1300. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.Z.; Li, Y.; Lv, L.; Shi, M. Modeling and control methods of a multi-parameter system for threshing and cleaning in grain combine harvesters. Comput. Electron. Agric. 2024, 225, 109251. [Google Scholar] [CrossRef]

- Lian, Y.; Chen, J.; Guan, Z.; Song, J. Development of a monitoring system for grain loss of paddy rice based on a decision tree algorithm. Int. J. Agric. Biol. Eng. 2021, 14, 224–229. [Google Scholar] [CrossRef]

- Bertin, V. Similarity solutions in elastohydrodynamic bouncing. J. Fluid Mech. 2024, 986, A13. [Google Scholar] [CrossRef]

- Cai, S.L.; Ding, G.; Duan, G.H.; Jing, X.H.; Dai, L.H.; Jiang, M.Q. Scaling laws for two-metallic spheres in a head-on collision. Int. J. Impact Eng. 2025, 200, 105257. [Google Scholar] [CrossRef]

- Gorin, B.; Ribe, N.M.; Bonn, D.; Kellay, H. Impacts of poroelastic spheres. Commun. Phys. 2025, 8, 104. [Google Scholar] [CrossRef]

- He, J.; Zhu, W.; Pang, Z.; Zhao, Z.; Du, Z. Parameter Feasible Region Analysis of the Tethered Net Shooting Error Aiming at UAV. J. Astronaut. 2024, 45, 711–719. [Google Scholar]

- Lin, S.; Shi, D.; Zhou, L.; Chen, L.; Li, Z. Probing the contact time of droplet impacts: From the Hertz collision to oscillation regimes. Phys. Rev. E 2024, 110, L053101. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Y.; Zhu, R.; Qin, L.; Deng, J.; Yang, Z.; Qin, Z.; Chu, F. Dynamic analysis of vibro-impact energy harvester with acoustic black hole. Int. J. Mech. Sci. 2025, 291, 110193. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Xu, X.; Wei, W.; Shang, K. Research on the Contact Dynamics of Binary Non-Spherical Particles Based on Hertz Theory. J. Food Process Eng. 2025, 48, e70070. [Google Scholar] [CrossRef]

- Liang, Z.; Li, J.; Liang, J.; Shao, Y.; Zhou, T.; Si, Z.; Li, Y. Investigation into Experimental and DEM Simulation of Guide Blade Optimum Arrangement in Multi-Rotor Combine Harvesters. Agriculture 2022, 12, 435. [Google Scholar] [CrossRef]

- Liang, Z.; Wada, M.E. Development of cleaning systems for combine harvesters: A review. Biosyst. Eng. 2023, 236, 79–102. [Google Scholar] [CrossRef]

- Luo, Y.; Wei, L.; Xu, L.; Zhang, Q.; Liu, J.; Cai, Q.; Zhang, W. Stereo-vision-based multi-crop harvesting edge detection for precise automatic steering of combine harvester. Biosyst. Eng. 2022, 215, 115–128. [Google Scholar] [CrossRef]

- Chen, X.; Chen, R.; Wang, J.; Li, H.; Zhang, W. Evaluation of water distribution and uniformity of sprinkler irrigation based on harmonic analysis and finite element method. Biosyst. Eng. 2024, 248, 308–320. [Google Scholar] [CrossRef]

- Li, W.; Shi, Y.; Huang, X.; Li, Z.; Zhang, X.; Zou, X.; Hu, X.; Shi, J.; Tomovic, V. Study on the Diffusion and Optimization of Sucrose in Gaido Seak Based on Finite Element Analysis and Hyperspectral Imaging Technology. Foods 2024, 13, 249. [Google Scholar] [CrossRef]

- Wang, J.; Chen, R. An improved finite element model for the hydraulic analysis of drip irrigation subunits considering local emitter head loss. Irrig. Sci. 2020, 38, 147–162. [Google Scholar] [CrossRef]

- Wang, W.; Lv, X.; Yi, Z. Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture 2022, 12, 2131. [Google Scholar] [CrossRef]

- Hao, C.; Yang, D.; Zhao, L.; Yang, J.; Wang, T.; He, J. Compressive Characteristics and Fracture Simulation of Cerasus Humilis Fruit. Agriculture 2025, 15, 88. [Google Scholar] [CrossRef]

- Liu, C.; Li, B.; Xu, C. Analysis of Bruising Characteristics of Large-Stone Fruits upon Impact Using Finite Element Method-A Case Study of Postharvest Loquats. Horticulturae 2025, 11, 440. [Google Scholar] [CrossRef]

- Looh, G.A.; Xie, F.; Wang, X.; Looh, A.N.; Hind, H. Grain kernel damage during threshing: A comprehensive review of theories and models. J. Agric. Eng. 2025, 56. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, Q.; Fang, X.; Zhang, J.; Feng, W.; Zhang, L.; Zhou, D.; Yu, C.; Wang, H.; Gao, X.; et al. Finite element analysis of corn kernel damage: A viscoelastic model approach for impact-induced damage prediction. J. Sci. Food Agric. 2025, 105, 3993–4004. [Google Scholar] [CrossRef]

- Aina, A.M.; Harith, H.H.; Hashim, N.; Shukery, M.F.M. Finite element modelling of the mechanical behavior of papaya fruit under compression. Postharvest Biol. Technol. 2025, 226, 113565. [Google Scholar] [CrossRef]

- Chen, H.; Guo, T.; Jin, L.; Wang, J.; Zhu, Y.; Ban, Z.; Di, J. Prediction of damage characteristics of apple fruit based on test and finite element method. J. Stored Prod. Res. 2025, 111, 102543. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).