Field Study of UAV Variable-Rate Spraying Method for Orchards Based on Canopy Volume

Abstract

1. Introduction

2. Materials and Methods

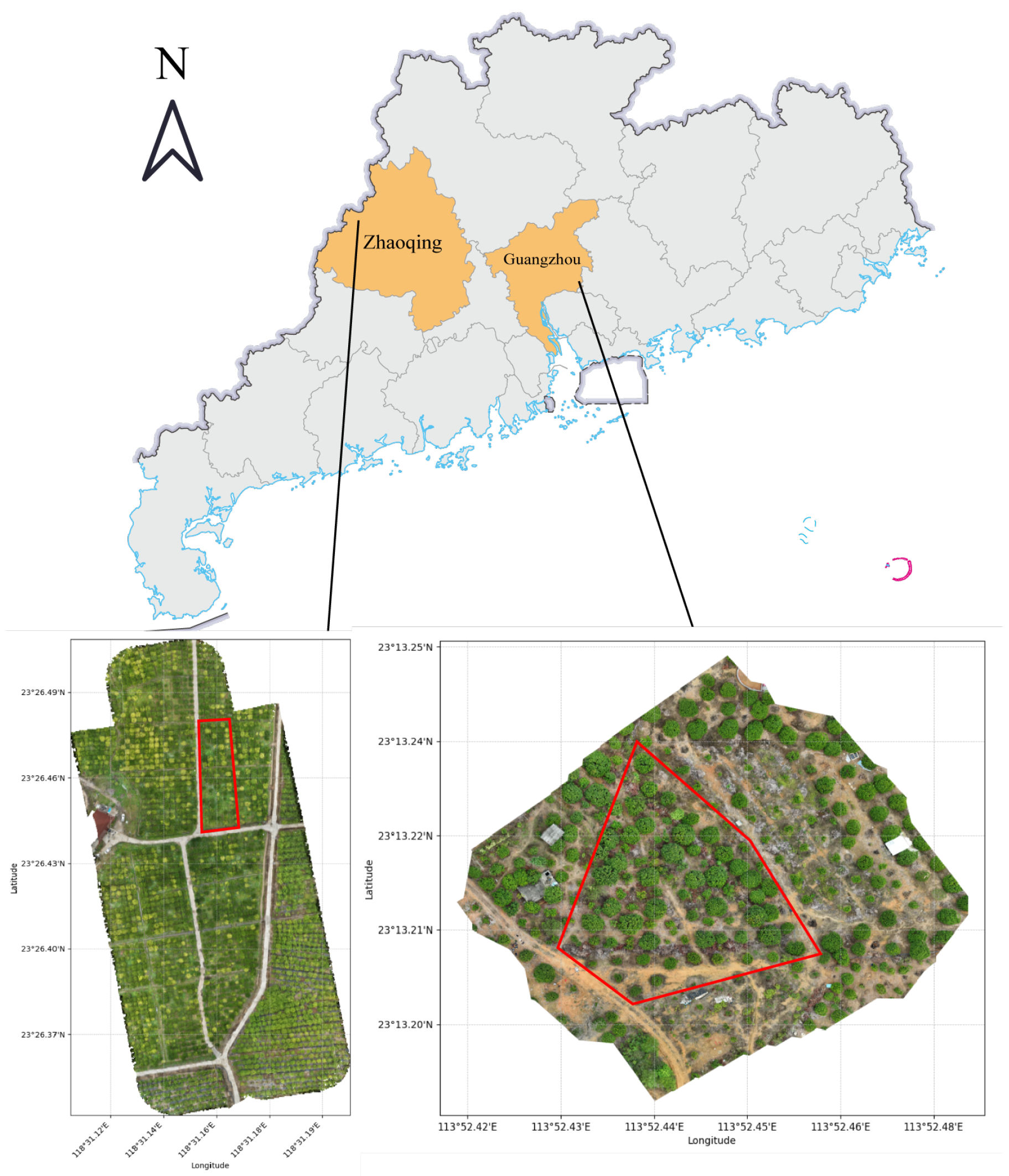

2.1. Experimental Location and Equipment

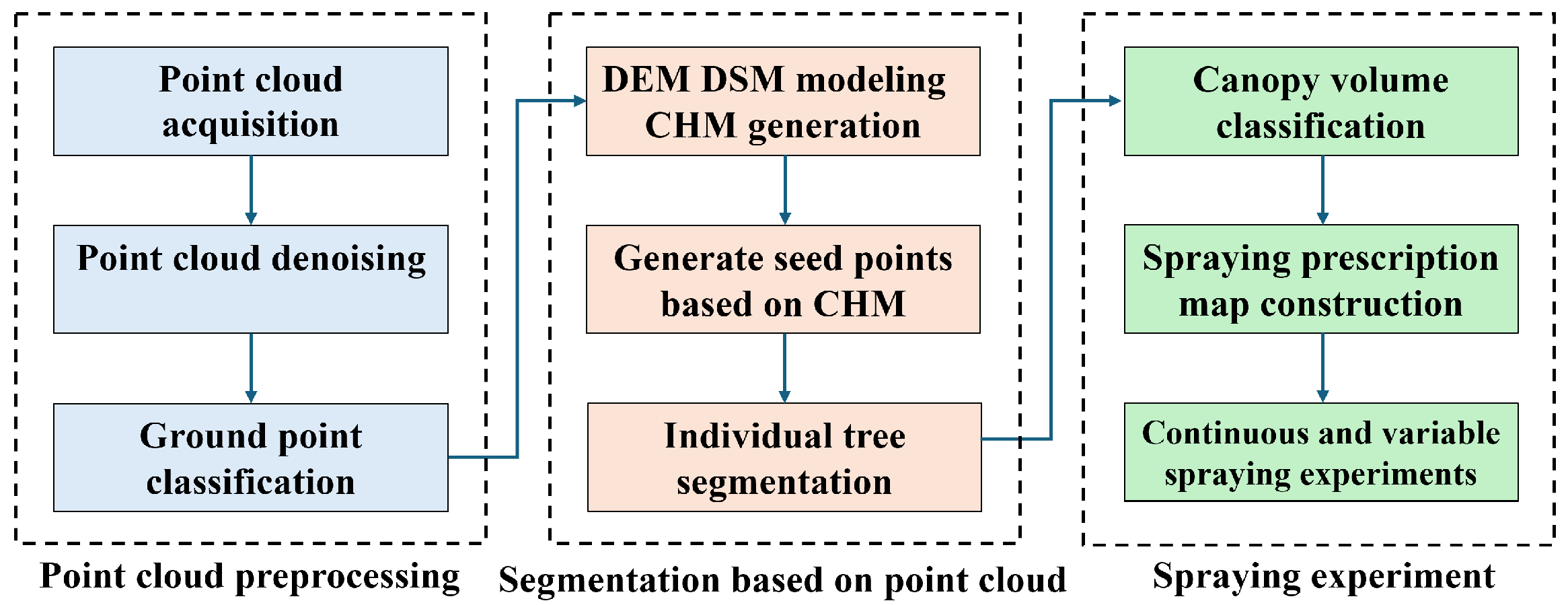

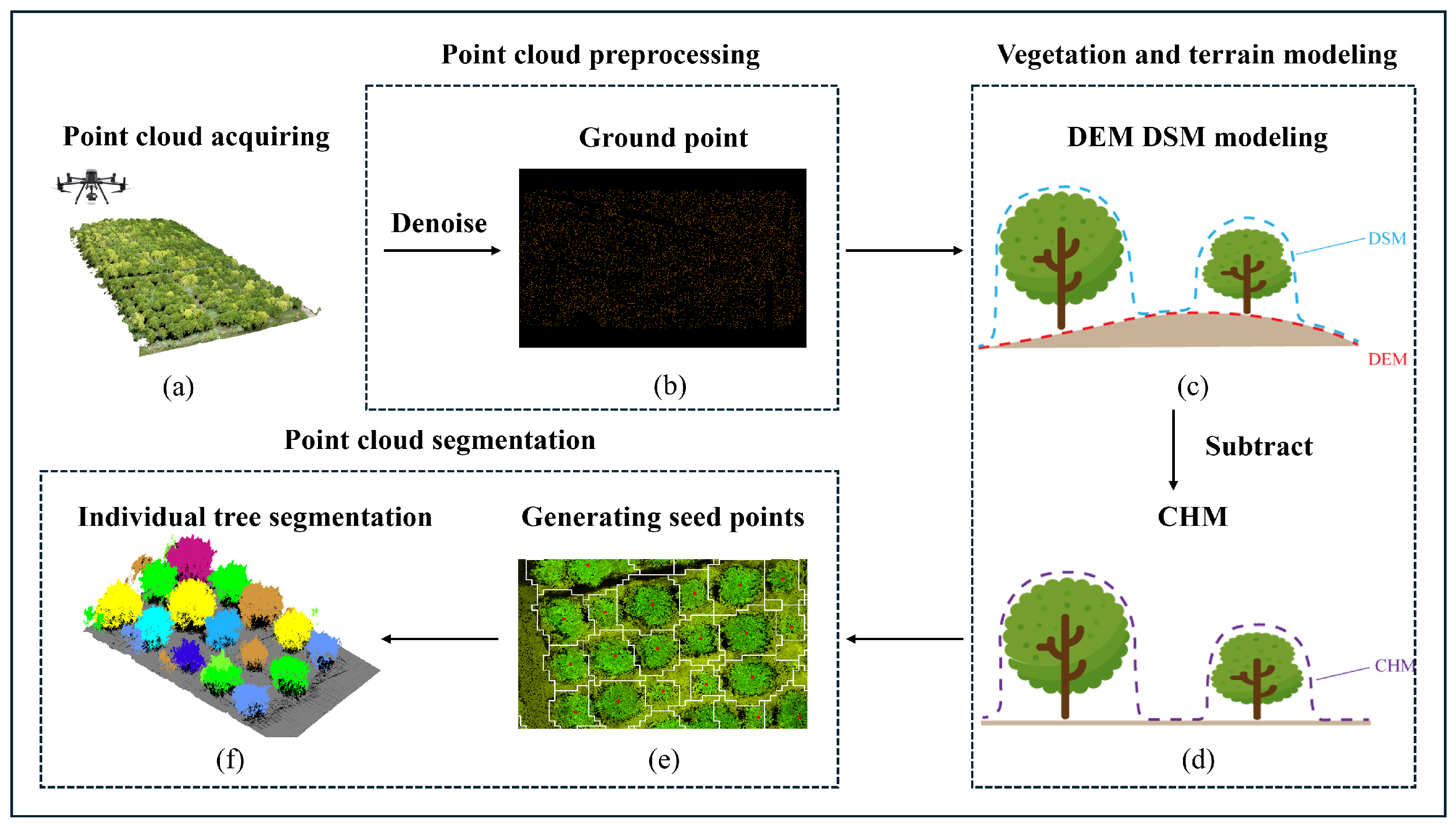

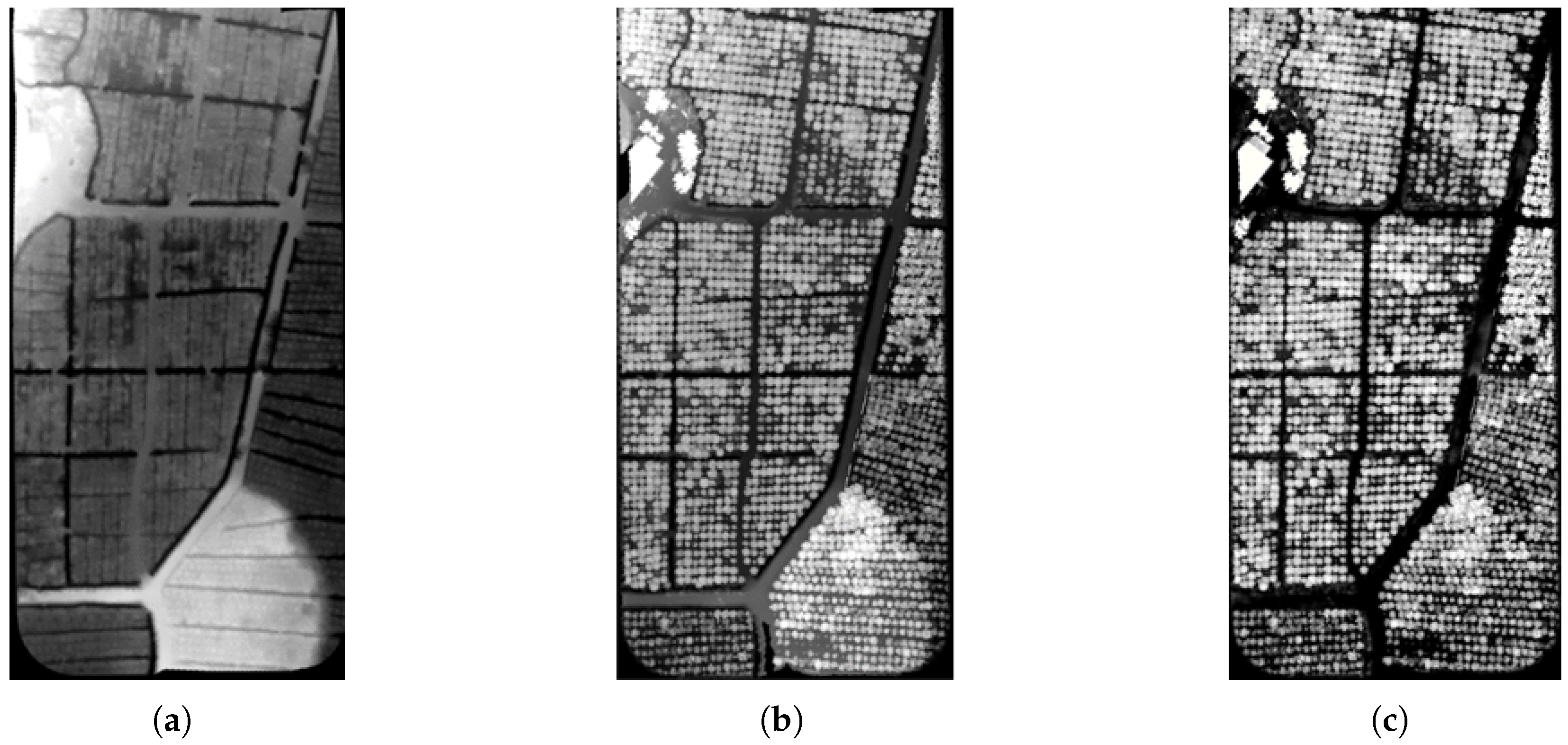

2.2. Orchard Point Cloud Acquisition and Individual Tree Segmentation Method

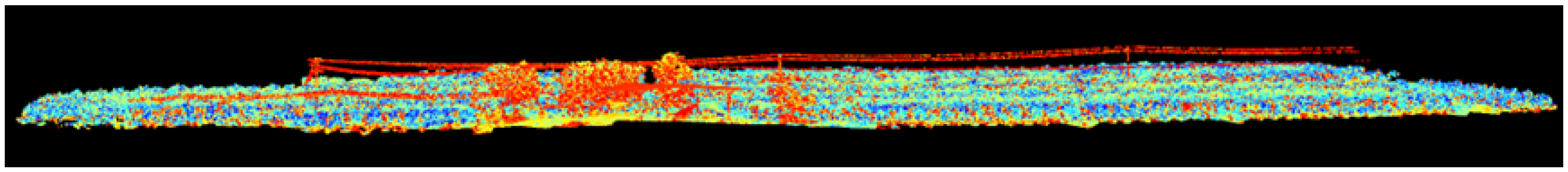

2.2.1. Orchard Point Cloud Data Collection

2.2.2. Point Cloud Data Preprocessing

2.2.3. Terrain and Vegetation Modeling

2.2.4. Seed Point Generation Based on CHM

2.2.5. Individual Tree Segmentation Based on Seed Points

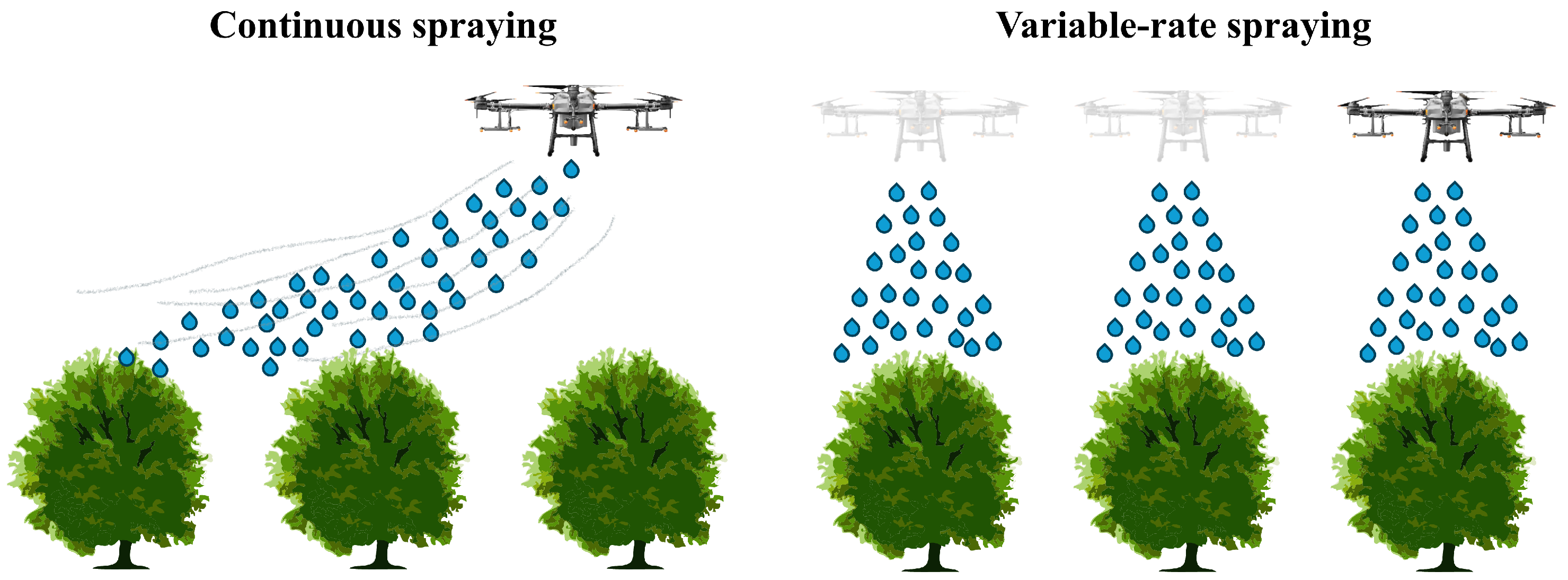

2.3. Spraying Experiment Design

2.3.1. Classification of Variable Spray Levels Based on Canopy Volume

2.3.2. Spraying Route Planning and Operational Parameters

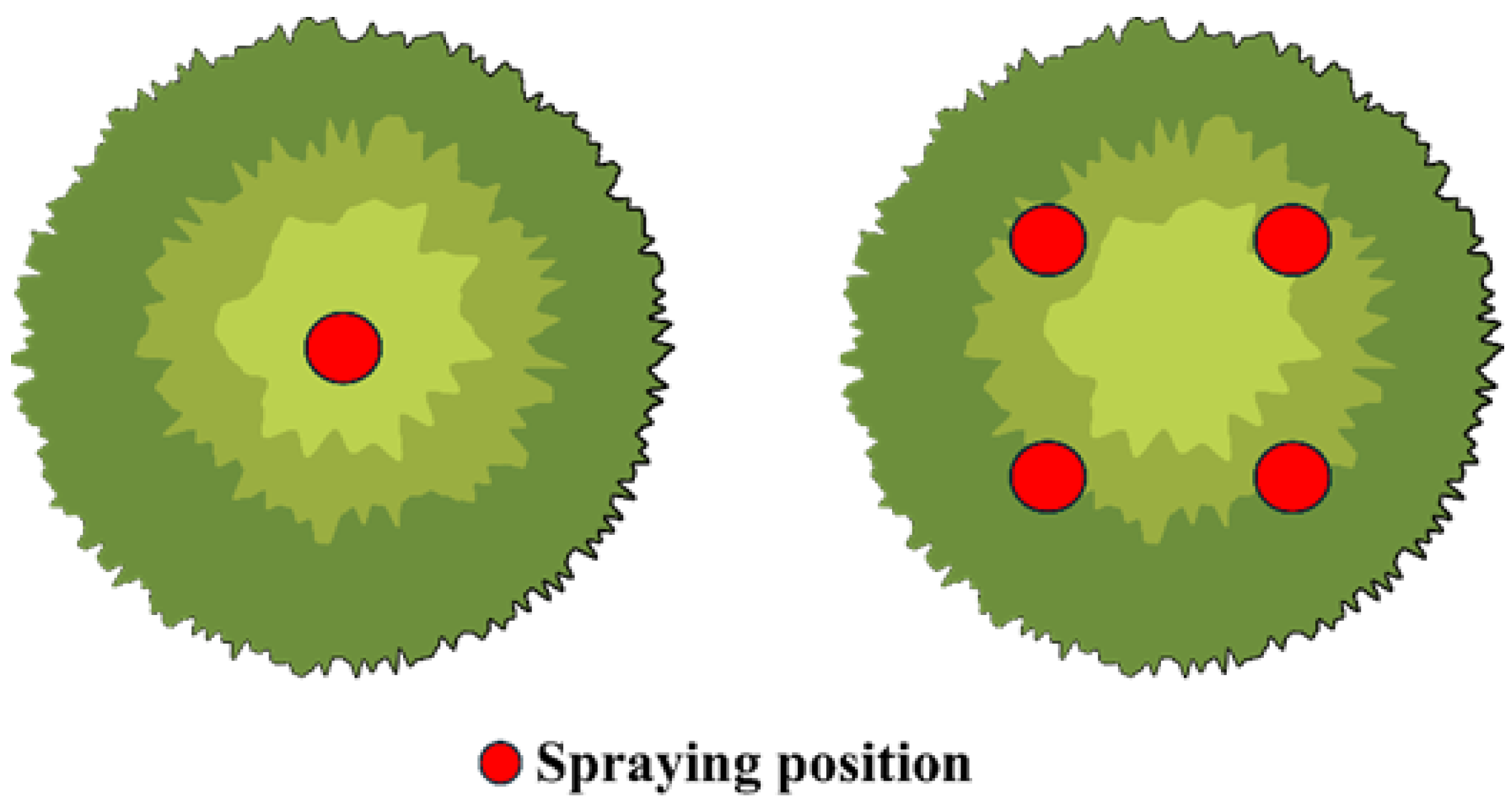

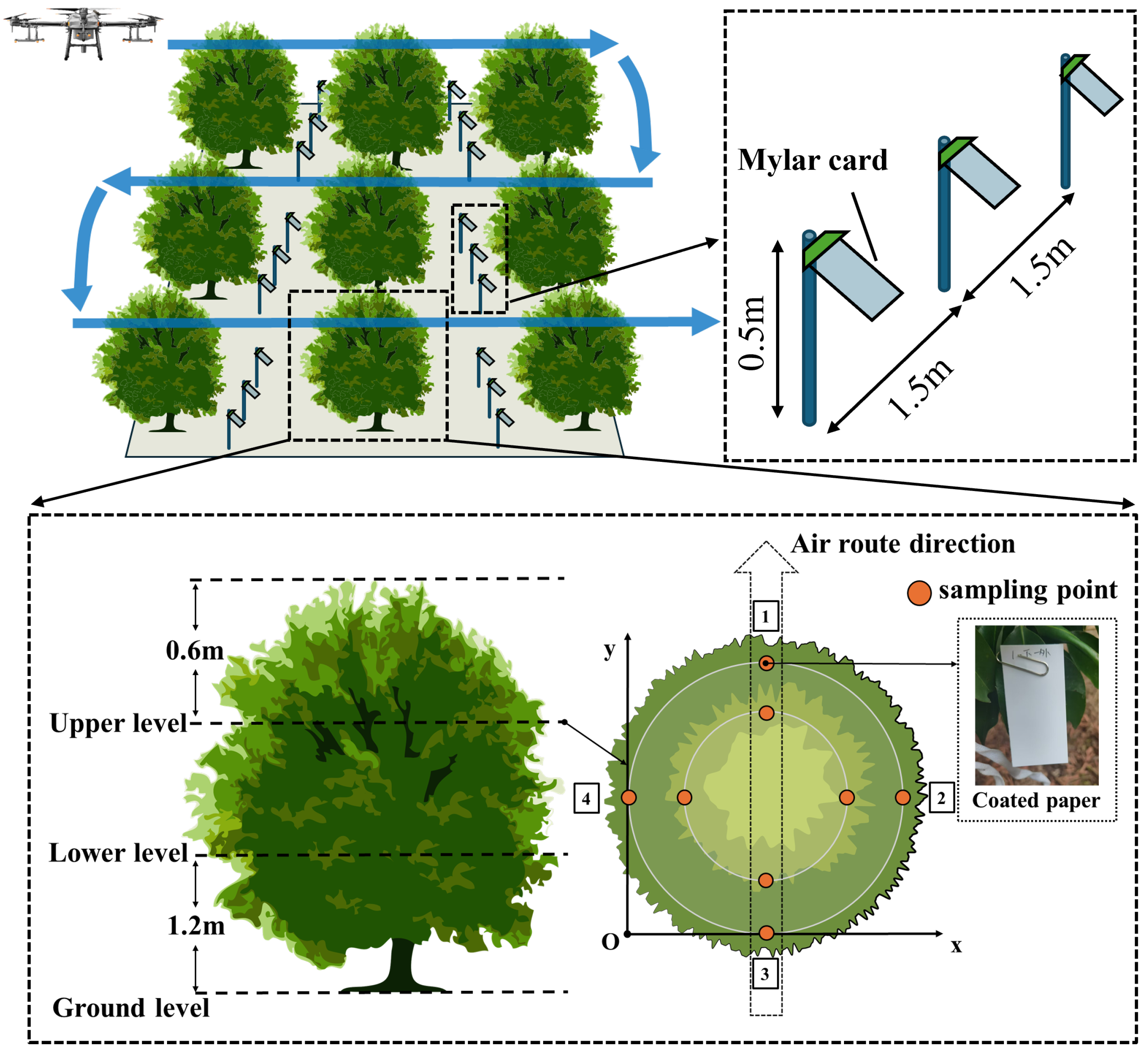

2.3.3. Droplet Sampling Point Arrangement

2.3.4. Experimental Data Processing

3. Results

3.1. Point Cloud-Based Individual Tree Segmentation Results

3.2. Exploration of Variable Spraying Strategies

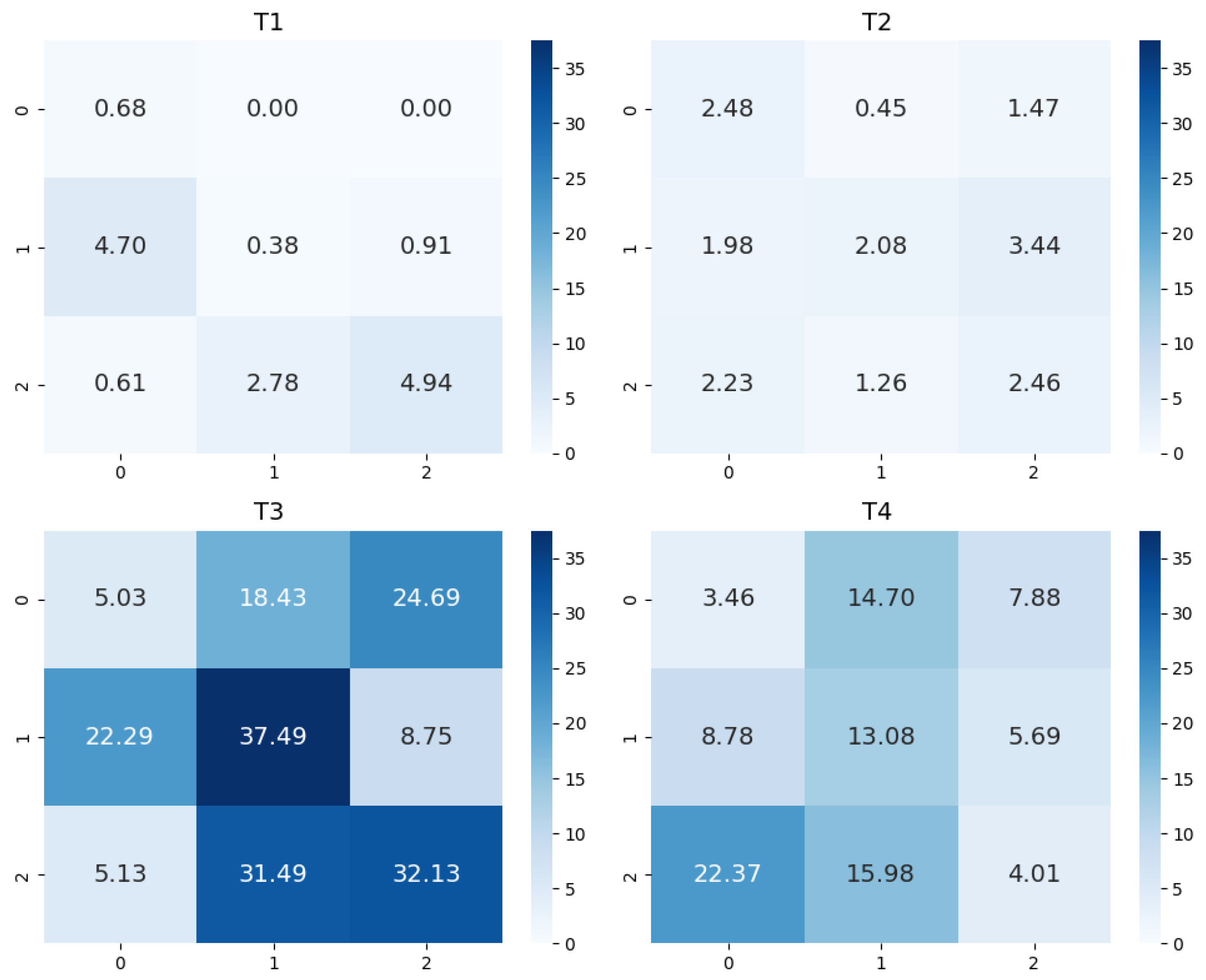

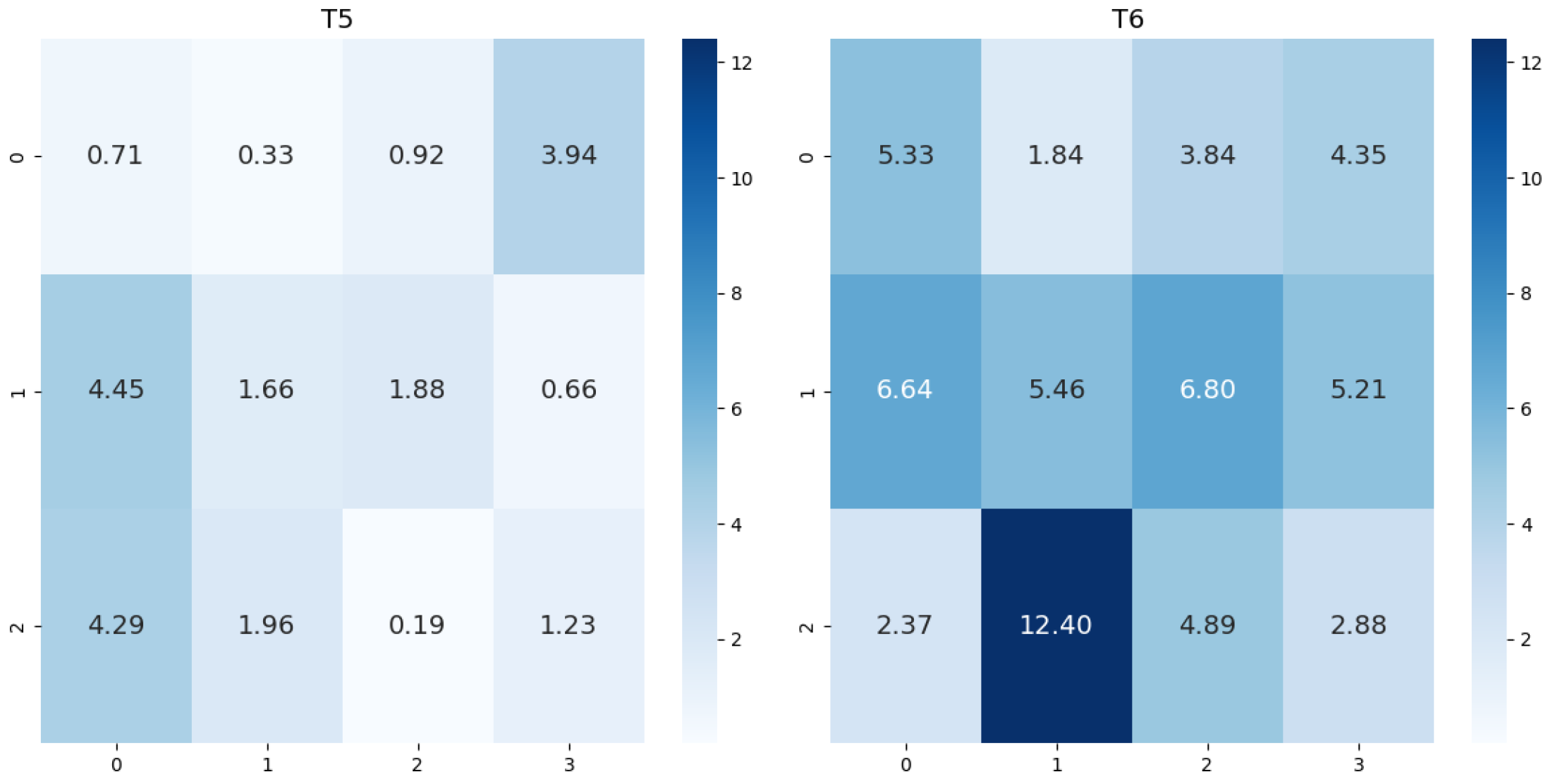

3.3. Spraying Effect Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Tudi, M.; Daniel Ruan, H.; Wang, L.; Lyu, J.; Sadler, R.; Connell, D.; Chu, C.; Phung, D.T. Agriculture Development, Pesticide Application and Its Impact on the Environment. Int. J. Environ. Res. Public Health 2021, 18, 1112. [Google Scholar] [CrossRef] [PubMed]

- Dou, H.; Zhai, C.; Chen, L.; Wang, X.; Zou, W. Comparison of orchard target-oriented spraying systems using photoelectric or ultrasonic sensors. Agriculture 2021, 11, 753. [Google Scholar] [CrossRef]

- Wang, B.; Yan, Y.; Zhao, J.; Kaousar, R.; Lan, Y. Status and prospect of the application of UAV remote sensing technology in smart orchard management. Crop Prot. 2025, 195, 107240. [Google Scholar] [CrossRef]

- Wang, G.; Han, Y.; Li, X.; Andaloro, J.; Chen, P.; Hoffmann, W.C.; Han, X.; Chen, S.; Lan, Y. Field evaluation of spray drift and environmental impact using an agricultural unmanned aerial vehicle (UAV) sprayer. Sci. Total Environ. 2020, 737, 139793. [Google Scholar] [CrossRef]

- Liu, Q.; Ding, M.; Zhang, H.; Wu, L.; Zhang, L.; Bao, H.; Lan, Y. Optimization of Flight Mode and Coupling Analysis of Operational Parameters on Droplet Deposition and Drift of Unmanned Aerial Spraying Systems (UASS). Agronomy 2025, 15, 367. [Google Scholar] [CrossRef]

- Taseer, A.; Han, X. Advancements in variable rate spraying for precise spray requirements in precision agriculture using Unmanned aerial spraying Systems: A review. Comput. Electron. Agric. 2024, 219, 108841. [Google Scholar] [CrossRef]

- Gu, C.; Wang, X.; Wang, X.; Yang, F.; Zhai, C. Research progress on variable-rate spraying technology in orchards. Appl. Eng. Agric. 2020, 36, 927–942. [Google Scholar] [CrossRef]

- Qiu, B.; Yan, R.; Ma, J.; Guan, X.; Ou, M. Research Progress Analysis of Variable Rate Sprayer Technology. Trans. Chin. Soc. Agric. Mach. 2015, 46, 59. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, S.; Jin, Y.; Cui, L.; Chang, C.; Ding, S.; Sun, Z.; Xue, X. Research Progress on Intelligent Variable-Rate Spray Technology for Precision Agriculture. Agronomy 2025, 15, 1431. [Google Scholar] [CrossRef]

- Dou, H.; Zhai, C.; Wang, X.; Zou, W.; Li, Q.; Chen, L. Design and experiment of the orchard target variable spraying control system based on LiDAR. Trans. Chin. Soc. Agric. Eng. 2022, 38, 11–21. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiang, S.; Chen, B.; Lü, H.; Wan, C.; Kang, F. Review on Technology and Equipment of Mechanization in Hilly Orchard. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–20. [Google Scholar] [CrossRef]

- Yan, Y.; Lan, Y.; Wang, G.; Hussain, M.; Wang, H.; Yu, X.; Shan, C.; Wang, B.; Song, C. Evaluation of the deposition and distribution of spray droplets in citrus orchards by plant protection drones. Front. Plant Sci. 2023, 14, 1303669. [Google Scholar] [CrossRef] [PubMed]

- Zhan, Y.; Chen, P.; Xu, W.; Chen, S.; Han, Y.; Lan, Y.; Wang, G. Influence of the downwash airflow distribution characteristics of a plant protection UAV on spray deposit distribution. Biosyst. Eng. 2022, 216, 32–45. [Google Scholar] [CrossRef]

- Chen, P.; Douzals, J.P.; Lan, Y.; Cotteux, E.; Delpuech, X.; Pouxviel, G.; Zhan, Y. Characteristics of unmanned aerial spraying systems and related spray drift: A review. Front. Plant Sci. 2022, 13, 870956. [Google Scholar] [CrossRef]

- Nahiyoon, S.A.; Ren, Z.; Wei, P.; Li, X.; Li, X.; Xu, J.; Yan, X.; Yuan, H. Recent Development Trends in Plant Protection UAVs: A Journey from Conventional Practices to Cutting-Edge Technologies—A Comprehensive Review. Drones 2024, 8, 457. [Google Scholar] [CrossRef]

- Qi, H.; Zhou, J.; Li, C.; Chen, P.; Liang, Y.; Huang, G.; Zou, J. Feasibility of variable rate spraying of centrifugal UAV using network RTK. Trans. Chin. Soc. Agric. Eng. 2021, 37, 81–89. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.; Deng, J.; Lan, Y.; Yin, X.; Shan, J. Design and experiment of a variable spray system for unmanned aerial vehicles based on PID and PWM control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Wang, L.; Lan, Y.; Yue, X.; Ling, K.; Cen, Z.; Cheng, Z.; Liu, Y.; Wang, J. Vision-based adaptive variable rate spraying approach for unmanned aerial vehicles. Int. J. Agric. Biol. Eng. 2019, 12, 18–26. [Google Scholar] [CrossRef]

- Chen, P.; Xu, W.; Zhan, Y.; Wang, G.; Yang, W.; Lan, Y. Determining application volume of unmanned aerial spraying systems for cotton defoliation using remote sensing images. Comput. Electron. Agric. 2022, 196, 106912. [Google Scholar] [CrossRef]

- Maghsoudi, H.; Minaei, S.; Ghobadian, B.; Masoudi, H. Ultrasonic sensing of pistachio canopy for low-volume precision spraying. Comput. Electron. Agric. 2015, 112, 149–160. [Google Scholar] [CrossRef]

- Gil, E.; Llorens, J.; Llop, J.; Fàbregas, X.; Escolà, A.; Rosell-Polo, J. Variable rate sprayer. Part 2–Vineyard prototype: Design, implementation, and validation. Comput. Electron. Agric. 2013, 95, 136–150. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Y.; He, X.; Liu, W. Precision variable-rate spraying robot by using single 3D LIDAR in orchards. Agronomy 2022, 12, 2509. [Google Scholar] [CrossRef]

- Luo, S.; Wen, S.; Zhang, L.; Lan, Y.; Chen, X. Extraction of crop canopy features and decision-making for variable spraying based on unmanned aerial vehicle LiDAR data. Comput. Electron. Agric. 2024, 224, 109197. [Google Scholar] [CrossRef]

- Guo, N.; Xu, N.; Kang, J.; Zhang, G.; Meng, Q.; Niu, M.; Wu, W.; Zhang, X. A Study on Canopy Volume Measurement Model for Fruit Tree Application Based on LiDAR Point Cloud. Agriculture 2025, 15, 130. [Google Scholar] [CrossRef]

- Zhao, X.; Guo, Q.; Su, Y.; Xue, B. Improved progressive TIN densification filtering algorithm for airborne LiDAR data in forested areas. ISPRS J. Photogramm. Remote Sens. 2016, 117, 79–91. [Google Scholar] [CrossRef]

- Wang, S.; Ji, J.; Zhao, L.; Li, J.; Zhang, M.; Li, S. Canopy Segmentation of Overlapping Fruit Trees Based on Unmanned Aerial Vehicle LiDAR. Agriculture 2025, 15, 295. [Google Scholar] [CrossRef]

- Nurunnabi, A.; West, G.; Belton, D. Robust Locally Weighted Regression Techniques for Ground Surface Points Filtering in Mobile Laser Scanning Three Dimensional Point Cloud Data. IEEE Trans. Geosci. Remote Sens. 2016, 54, 2181–2193. [Google Scholar] [CrossRef]

- Axelsson, P. DEM generation from laser scanner data using adaptive TIN models. Int. Arch. Photogramm. Remote Sens. 2000, 33, 110–117. [Google Scholar]

- Li, W.; Guo, Q.; Jakubowski, M.K.; Kelly, M. A new method for segmenting individual trees from the lidar point cloud. Photogramm. Eng. Remote Sens. 2012, 78, 75–84. [Google Scholar] [CrossRef]

- Zhu, H.; Salyani, M.; Fox, R.D. A portable scanning system for evaluation of spray deposit distribution. Comput. Electron. Agric. 2011, 76, 38–43. [Google Scholar] [CrossRef]

- ISO 24253-1:2015; Crop Protection Equipment—Spray Deposition Test for Field Crop. International Organization for Standardization: Geneva, Switzerland, 2015.

| Equipment | Item | Parameter |

|---|---|---|

| DJI T30 | Total weight | 36.5 kg |

| Maximum spraying takeoff weight | 66.5 kg | |

| Maximum motor power | 3600 W/rotor | |

| Nozzle model | SX11001VS | |

| Atomized particle size | 130–250 μm | |

| Maximum spray volume | 7.2 L/min | |

| DJI M300 RTK | Total weight | 6.3 kg |

| Maximum takeoff weight | 9 kg | |

| RTK position accuracy | Vertical 1 cm + 1 ppm Horizontal 1.5 cm + 1 ppm | |

| Zenmuse L1 | Image sensor | 1 inch |

| Effective pixels | 20 MP | |

| Lens parameters | 8.8 mm / 24 mm | |

| FOV | 95° | |

| Aperture | f/2.8–f/11 | |

| Digitization footprint | 520 MB/ha | |

| DJI Matrice 3M | Total weight | 951 g |

| Image sensor | 4/3 CMOS | |

| Effective pixels | 20 MP | |

| Lens parameters | 24 mm | |

| Aperture | f/2.8–f/11 | |

| FOV | 84° |

| Canopy Volume (m3) | Tree Species | Spray Level | |

|---|---|---|---|

| Citrus | Litchi | ||

| x | I | ||

| II | |||

| III | |||

| — | IV | ||

| Treatment | Tree Species | Spray Type | Flight Parameters | Spray Rate |

|---|---|---|---|---|

| T1 | Litchi | Variable spray | 1 m/s | 0.2 L/level |

| T2 | Variable spray | 1 m/s | 0.4 L/level | |

| T3 | Continuous spray | 0.5 m/s | 5.4 L/min | |

| T4 | Continuous spray | 1 m/s | 5.4 L/min | |

| T5 | Citrus | Variable spray | 1 m/s | 0.2 L/level |

| T6 | Continuous spray | 2 m/s | 5.4 L/min |

| Tree Species | Minimum (m3) | Maximum (m3) | Mean ± SD (m3) | Coefficient of Variation |

|---|---|---|---|---|

| Citrus | 6.26 | 43.44 | 22.15 ± 9.12 | 41.20% |

| Litchi | 10.79 | 96.35 | 35.72 ± 25.13 | 70.37% |

| Tree Species | Class | Volume Range (m3) | Sample Count | Proportion (%) | Mean ± SD (m3) |

|---|---|---|---|---|---|

| Litchi | I | 34 | 47.2 | ||

| II | 28 | 38.9 | |||

| III | 12 | 16.7 | |||

| IV | 6 | 8.3 | |||

| Citrus | I | 30 | 41.1 | ||

| II | 27 | 37.0 | |||

| III | 16 | 21.9 |

| Tree Species | Tree ID | Canopy Volume (m3) | Class |

|---|---|---|---|

| Litchi | 1 | 44.3 | II |

| 2 | 91.6 | IV | |

| 3 | 56.9 | III | |

| 4 | 13.9 | I | |

| Citrus | 1 | 36.5 | III |

| 2 | 25.3 | II | |

| 3 | 18.1 | I | |

| 4 | 24.0 | II | |

| 5 | 33.7 | III | |

| 6 | 18.2 | I |

| Tree ID | Application Rate (L) | CV (%) | |

|---|---|---|---|

| Center Application | Multi-Point Application | ||

| 1 | 1.2 | 162.91 | 95.32 |

| 2 | 181.48 | 98.15 | |

| 3 | 160.67 | 102.74 | |

| 4 | 78.90 | 88.93 | |

| 1 | 1.0 | 181.81 | 103.67 |

| 2 | 193.71 | 97.84 | |

| 3 | 156.73 | 105.21 | |

| 4 | 94.68 | 92.45 | |

| 1 | 0.8 | 152.68 | 107.39 |

| 2 | 198.63 | 112.56 | |

| 3 | 143.23 | 98.77 | |

| 4 | 107.13 | 104.82 | |

| Treatment | Tree ID | Application Parameter | Coverage (%) | Ground Deposition (μg/cm2) |

|---|---|---|---|---|

| T1 | 1 | 0.4 L | a | c |

| 2 | 0.8 L | a | ||

| 3 | 0.6 L | b | ||

| 4 | 0.2 L | d | ||

| T2 | 1 | 0.8 L | c | c |

| 2 | 1.6 L | a | ||

| 3 | 1.2 L | b | ||

| 4 | 0.4 L | d | ||

| T3 | 1 | Flight speed 0.5 m/s | b | a |

| 2 | a | |||

| 3 | b | |||

| 4 | b | |||

| T4 | 1 | Flight speed 1.0 m/s | b | b |

| 2 | a | |||

| 3 | c | |||

| 4 | b | |||

| T5 | 1 | 0.6 L | a | c |

| 2 | 0.4 L | b | ||

| 3 | 0.2 L | c | ||

| 4 | 0.4 L | b | ||

| 5 | 0.6 L | a | ||

| 6 | 0.2 L | d | ||

| T6 | 1 | Flight speed 2.0 m/s | c | b |

| 2 | b | |||

| 3 | b | |||

| 4 | c | |||

| 5 | b | |||

| 6 | b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Ma, H.; Cui, Z.; Li, Z.; Wu, J.; Liao, J.; Liu, H.; Wang, Y.; Lan, Y. Field Study of UAV Variable-Rate Spraying Method for Orchards Based on Canopy Volume. Agriculture 2025, 15, 1374. https://doi.org/10.3390/agriculture15131374

Chen P, Ma H, Cui Z, Li Z, Wu J, Liao J, Liu H, Wang Y, Lan Y. Field Study of UAV Variable-Rate Spraying Method for Orchards Based on Canopy Volume. Agriculture. 2025; 15(13):1374. https://doi.org/10.3390/agriculture15131374

Chicago/Turabian StyleChen, Pengchao, Haoran Ma, Zongyin Cui, Zhihong Li, Jiapei Wu, Jianhong Liao, Hanbing Liu, Ying Wang, and Yubin Lan. 2025. "Field Study of UAV Variable-Rate Spraying Method for Orchards Based on Canopy Volume" Agriculture 15, no. 13: 1374. https://doi.org/10.3390/agriculture15131374

APA StyleChen, P., Ma, H., Cui, Z., Li, Z., Wu, J., Liao, J., Liu, H., Wang, Y., & Lan, Y. (2025). Field Study of UAV Variable-Rate Spraying Method for Orchards Based on Canopy Volume. Agriculture, 15(13), 1374. https://doi.org/10.3390/agriculture15131374