Numerical Simulation and Analysis of the Impurity Removal Process of a Sugarcane Chopper Harvester Based on a CFD–DEM Model

Abstract

1. Introduction

2. Materials and Methods

2.1. Structure and Working Principle of the Extractor Test Bench

2.2. Simulation of the Airflow Field of the Extractor

2.2.1. Model and Meshing

2.2.2. Verification of Mesh Independence

2.2.3. Boundary Conditions and Data Calculation

2.2.4. Validation of Airflow Simulation Model

2.3. Material Discrete Element Simulation Model Construction and Parameter Setting

2.3.1. Determination of Basic Physical Parameters of Billets and Leaves

2.3.2. Discrete Meta-Simulation Model Construction for Billets and Leaves

2.3.3. Discrete Element Simulation Parameter Setting

2.4. Modelling of Gas–Solid Coupling for Extractor

2.4.1. Coupling Parameter Setting

2.4.2. Validation of the Gas–Solid Coupling Model

2.4.3. Model Validation Results

3. Results and Analysis

3.1. Simulation Analysis of the Airflow Field of the Extractor

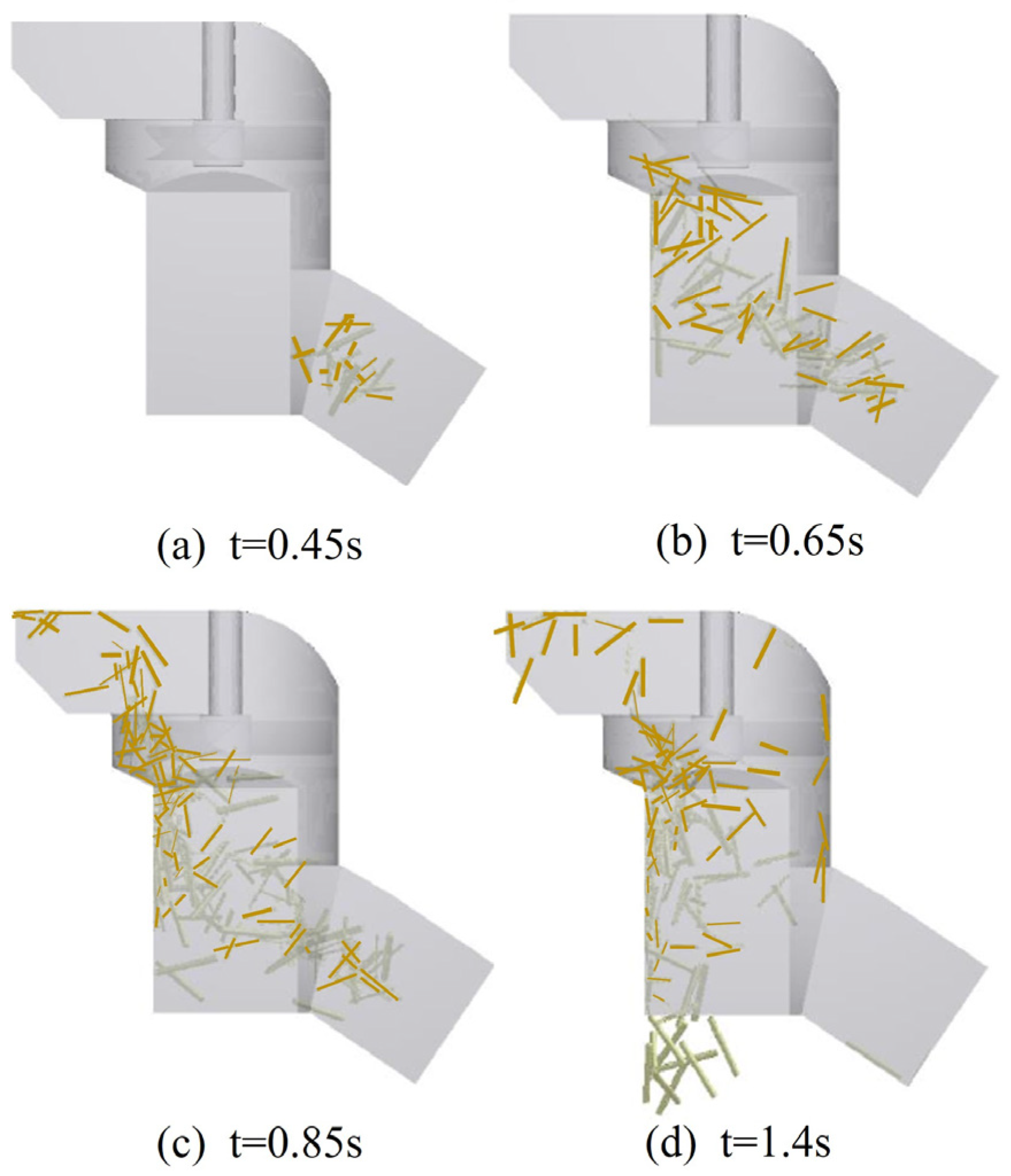

3.2. Analysis of Gas–Solid Coupling Simulation Results

3.3. Analysis of the Relationship among Parameters

3.3.1. Simulation Test Design

3.3.2. Simulation Test Results

4. Discussion

5. Conclusions

- (1)

- An airflow field model of the extractor is established. Simulation shows fan speed variation only affects values not distribution. A fan speed increase raises velocity and pressure. Near the fan blades, velocity and pressure values are higher. The area beneath the fan is the main separation zone.

- (2)

- The gas–solid coupling simulation model of the extractor was constructed, and the impurity removal process was simulated. The movement state of sugarcane material in the extractor at different times was analyzed, which lays a foundation for further exploring the impurity removal mechanism.

- (3)

- A simulation test was conducted to address the issues of the high-power consumption and high impurity rate of the extractor. The relationship between the impurity rate and the fan speed, leaf–stalk ratio, and feed rate was determined.

- (4)

- The parameter combinations under different impurity rates were obtained. The fan speed was adjusted according to the feed rate and leaf–stalk ratio, and these models can guide the intelligent harvesting of sugarcane in the future.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Huo, P.; Ma, S.; Su, C.; Ding, Z.; Li, W.; Qian, J.; Li, L.; Li, Y.; Zhou, B.; Peng, C.; et al. Sugarcane leaf-stalk separating technology: A critical review. Biosyst. Eng. 2023, 228, 120–148. [Google Scholar] [CrossRef]

- Ren, J.; Wu, T.; Liu, Q.; Mo, W.; Li, K. Discrete element simulation modeling method and parameter calibration of billet. J. South China Agric. Univ. 2022, 43, 124–132. [Google Scholar]

- Xing, H.; Ma, S.; Mo, J.; Zeng, B.; Liang, W.; Li, W.; Wang, F.; Bai, J.; Ding, Z. Optimization and experiment on structural parameters of impeller of extractor of sugarcane harvester. Trans. Chin. Soc. Agric. Eng. 2021, 37, 12–19. [Google Scholar]

- Wang, H.; Li, S.; Ma, F.; Li, Z. Pneumatic design of small sugarcane harvester fan. J. Agric. Mech. Res. 2015, 37, 103–107. [Google Scholar]

- Wang, F.; Yang, G.; Ke, W.; Ma, S. Effect of sugarcane chopper harvester extractor parameters on impurity removal and cane losses. IFAC-Pap. Online 2018, 51, 292–297. [Google Scholar] [CrossRef]

- Kosum, K.; Bun-art, S. Factors affecting the amount of impurities when harvesting produced sugarcane with sugarcane harvester. IOP Conf. Ser. Earth Environ. Sci. 2019, 301, 012017. [Google Scholar] [CrossRef]

- Wu, T.; Liang, X.; Liu, Q.; Zhang, Z.; Xu, H.; Huang, J.; Li, J.; Zou, X. Chopper Sugarcane Combine Harvester with Middle-Mounted Primary Extractor. Sugar Technol. 2020, 22, 589–595. [Google Scholar] [CrossRef]

- Wu, T.; Ren, J.; Liu, Q.; Zou, X.; Zhang, Z.; Zhou, S.; Feng, J.; He, L. Development of 4GDZ-132 sugarcane chopper combine harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 30–38. [Google Scholar]

- Viator, R.; Richard, E.; Viator, B.; Jackson, W.; Waguespack, H.; Birket, H. Sugarcane chopper harvester extractor fan and ground speed effects on yield and quality. Appl. Eng. Agric. 2007, 23, 31–34. [Google Scholar] [CrossRef]

- El-Emam, M.; Zhou, L.; Shi, W.; Han, C.; Bai, L.; Agarwal, R. Theories and Applications of CFD–DEM Coupling Approach for Granular Flow: A Review. Arch. Comput. Methods Eng. 2021, 28, 4979–5020. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Gao, F.; Zhao, Z.; Xu, L. CFD–DEM simulation of material motion in air-and-screen cleaning device. Comput. Electron. Agric. 2012, 88, 111–119. [Google Scholar] [CrossRef]

- Xu, L.; Li, Y.; Chai, X.; Wang, G.M.; Liang, Z.; Li, Y.; Li, B. Numerical simulation of gas–solid two-phase flow to predict the cleaning performance of rice combine harvesters. Biosyst. Eng. 2020, 190, 11–24. [Google Scholar] [CrossRef]

- Ding, B.; Liang, Z.; Qi, Y.; Ye, Z.; Zhou, J. Improving cleaning performance of rice combine harvesters by DEM–CFD coupling technology. Agriculture 2022, 12, 1457. [Google Scholar] [CrossRef]

- Yuan, J.; Li, H.; Qi, X.; Hu, T.; Bai, M.; Wang, Y. Optimization of airflow cylinder sieve for threshed rice separation using CFD-DEM. Eng. Appl. Comput. Fluid Mech. 2020, 14, 871–881. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, L.; Yuan, F.; Wang, L. Simulation study of rice cleaning based on DEM-CFD coupling method. Processes 2022, 10, 281. [Google Scholar] [CrossRef]

- Tang, H.; Xu, C.; Zhao, J.; Wang, J. Stripping mechanism and loss characteristics of a stripping-prior-to-cutting header for rice harvesting based on CFD-DEM simulations and bench experiments. Biosyst. Eng. 2023, 116–136. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Y.; Cui, T.; Zhang, D.; Fan, H.; Gao, X.; Su, Y.; Qiao, M.; Song, Z. Improving particle dispersion characteristics with a novel cleaning screen: Parameter design and numerical simulation. Powder Technol. 2022, 397, 116987. [Google Scholar] [CrossRef]

- Dai, F.; Xu, P.; Yuan, Z.; Shi, R.; Zhao, Y.; Song, X.; Zhao, W. Simulation and optimization experiment: Working process of a cleaning device for flax combine harvester. Agriculture 2023, 13, 2123. [Google Scholar] [CrossRef]

- Guo, W.; Yang, W.; Wen, X.; Yang, J.; Mo, J.; Zeng, B.; Nong, H. Research on simulation modeling method for debris removal of sectional sugarcane harvester. Agric. Mech. Res. 2020, 42, 6–12. [Google Scholar]

- Xing, H.; Ma, S.; Wang, F.; Bai, J.; Hu, J. Structure optimization and experiment of sugarcane chopper harvester extractor. Trans. Chin. Soc. Agric. Eng. 2020, 36, 67–75. [Google Scholar]

- Xing, H.; Ma, S.; Li, W.; Wang, F.; Bai, J.; Hu, J. Improving the performance of a sugarcane harvester extractor using design changes validated by computational fluid dynamic modelling and experiment. Biosyst. Eng. 2022, 124–138, 1537–5110. [Google Scholar] [CrossRef]

- Zhou, B.; Ma, S.; Li, W.; Li, W.; Peng, C. Study on the influence mechanism of energy consumption of sugarcane harvester extractor by fluid simulation and experiment. Agriculture 2023, 13, 1726. [Google Scholar] [CrossRef]

- Xing, H.; Ma, S.; Wang, F.; Bai, J.; Ma, J. Aerodynamic performance evaluation of sugarcane harvester extractor based on CFD. Sugar Technol. 2021, 23, 627–633. [Google Scholar] [CrossRef]

- Ren, J.; Wu, T.; Liu, Q.; Zou, X.; Li, K. Design and test of the structure of extractor negative pressure zone of sugarcane chopper harvester. Agronomy 2022, 12, 2336. [Google Scholar] [CrossRef]

- Xie, F.; Ou, Y.; Liu, Q.; Zou, X.; Feng, J. Design and experiment of trash discharging fan of sugarcane harvester. Trans. Chin. Soc. Agric. Eng. 2012, 28, 8–14. [Google Scholar]

- Yan, J.; Biao, X.; Bai, J.; Zheng, Y.; Zhao, S.; Liu, N.; Zhang, Q. Discrete element simulation of the grain mixing law in brown rice germination device. Int. J. Agric. Biol. Eng. 2024, 17, 41–48. [Google Scholar] [CrossRef]

- Goudarzi, N. Computational fluid dynamics methods for wind turbines performance analysis. In Advanced Wind Turbine Technology; Hu, W., Ed.; Springer International Publishing: Cham, Switzerland, 2018; Volume 2, pp. 47–57. [Google Scholar]

- Ma, H.; Zhou, L.; Liu, Z.; Chen, M.; Xia, X.; Zhao, Y. A review of recent development for the CFD-DEM investigations of non-spherical particles. Powder Technol. 2022, 412, 117972. [Google Scholar] [CrossRef]

- GB/T 10178-2006; Industrial Fans—Performance Testing In Situ. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standardization Administration of China: Beijing, China, 2006.

- Huang, W.; Zeng, B.; Mo, J.; Yang, Z.; Zhang, X.; Mo, F. Comparative Experiment Research of Mechanized Harvesting Newly Planted Cane and Ratoon Cane. Mod. Agric. Equip. 2020, 41, 27–32. [Google Scholar]

- Ren, J.; Wu, T.; Mo, W.; Li, K.; Hu, P.; Xu, F.; Liu, Q. Discrete Element Simulation Modeling Method and Parameters Calibration of Sugarcane Leaves. Agronomy 2022, 12, 1796. [Google Scholar] [CrossRef]

- JB/T 6275-2019; Sugarcane Combine Harvester. The Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2019.

- Fan, C.; Zhang, D.; Yang, L.; Cui, T.; He, X.; Dong, J.; Zhao, H. Power consumption and performance of a maize thresher with automatic gap control based on feed rate monitoring. Biosyst. Eng. 2022, 216, 147–164. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, R.; Zhang, M.; Li, M.; Zhang, Z.; Li, H. Design of feed rate monitoring system and estimation method for yield distribution information on combine harvester. Comput. Electron. Agric. 2022, 201, 107322. [Google Scholar] [CrossRef]

- Jie, Z.; Zhou, X. Study on Mathematical Model of Feed Quantity Sensor Measuring. J. Agric. Mach. 2001, 32, 53–55. [Google Scholar]

| Parameters | Value |

|---|---|

| Impeller diameter/mm | 954 |

| Impeller width/mm | 124 |

| Number of leaves | 3 |

| Blade installation angle/° | 38.04 |

| Incoming trending area/m2 | 0.386 |

| The trending area/m2 | 0.344 |

| Speed range/(rev/min) | 0–1200 |

| Material | Property | Mean | Standard Deviation |

|---|---|---|---|

| Billet | Geometric dimensions/ (L × Φ)/mm × mm | 250.3 × 32.04 | 3.20 × 2.41 |

| Density/g·cm−3 | 1.03 | 0.03 | |

| Moisture content/% | 72.50 | 5.01 | |

| Suspension speed/(m/s) | 9.92 | 0.473 | |

| Leaf | Geometric dimensions/ (L × W × H) /mm × mm × mm | 250.30 × 36.89 × 0.40 | 10.23 × 12.66 × 1.20 |

| Density/g·cm−3 | 0.38 | 0.07 | |

| Moisture content/% | 10.33 | 0.97 | |

| Suspension speed/(m/s) | 3.655 | 0.34 | |

| Whole cane | Leaf–stalk ratio/% | 25 | 3.00 |

| (a) | |||

| Material | Poisson’s Ratio | Shear Modulus /MPa | Density /g·cm−3 |

| Billet | 0.35 | 10.8×104 | 1.03 |

| Leaf | 0.30 | 300 | 0.38 |

| Steel | 0.30 | 7.9×104 | 7.85 |

| (b) | |||

| Material | Recovery Coefficient | Static Friction Coefficient | Dynamic Friction Coefficient |

| Billet–billet | 0.45 | 0.53 | 0.04 |

| Billet–steel | 0.45 | 0.35 | 0.03 |

| Leaf–leaf | 0.002 | 0.21 | 0.05 |

| Leaf–steel | 0.003 | 0.3 | 0.03 |

| Levels | Test Factors | ||

|---|---|---|---|

| A/(rev/min) | B/(kg/s) | C/% | |

| −1 | 700 | 10 | 20 |

| 0 | 900 | 15 | 25 |

| 1 | 1100 | 20 | 30 |

| NO. | Test Factors | Test Indicators | ||

|---|---|---|---|---|

| A/(rev/min) | B/(kg/s) | C/% | Y/% | |

| 1 | −1 | −1 | −1 | 9.2 |

| 2 | −1 | −1 | 0 | 9.6 |

| 3 | −1 | −1 | 1 | 10 |

| 4 | −1 | 0 | −1 | 11.1 |

| 5 | −1 | 0 | 0 | 13.3 |

| 6 | −1 | 0 | 1 | 12.5 |

| 7 | −1 | 1 | −1 | 13.2 |

| 8 | −1 | 1 | 0 | 13.4 |

| 9 | −1 | 1 | 1 | 12.7 |

| 10 | 0 | −1 | −1 | 7.6 |

| 11 | 0 | −1 | 0 | 8.4 |

| 12 | 0 | −1 | 1 | 7.5 |

| 13 | 0 | 0 | −1 | 9.3 |

| 14 | 0 | 0 | 0 | 10.4 |

| 15 | 0 | 0 | 1 | 8.9 |

| 16 | 0 | 1 | −1 | 10.3 |

| 17 | 0 | 1 | 0 | 12.4 |

| 18 | 0 | 1 | 1 | 11.5 |

| 19 | 1 | −1 | −1 | 5.3 |

| 20 | 1 | −1 | 0 | 4.1 |

| 21 | 1 | −1 | 1 | 3.7 |

| 22 | 1 | 0 | −1 | 6.3 |

| 23 | 1 | 0 | 0 | 6.5 |

| 24 | 1 | 0 | 1 | 5.5 |

| 25 | 1 | 1 | −1 | 6.7 |

| 26 | 1 | 1 | 0 | 7.1 |

| 27 | 1 | 1 | 1 | 6.7 |

| Source of Variance | Sum of Squares | Degrees of Freedom | Mean Square | F | p |

|---|---|---|---|---|---|

| Model | 213.16 | 9 | 23.68 | 67.34 | <0.0001 ** |

| A | 156.64 | 1 | 156.64 | 445.38 | <0.0001 ** |

| B | 45.44 | 1 | 45.44 | 129.2 | <0.0001 ** |

| C | 0 | 1 | 0 | 0 | 1 |

| AB | 0.8008 | 1 | 0.8008 | 2.28 | 0.1497 |

| AC | 1.4 | 1 | 1.4 | 3.98 | 0.0622 |

| BC | 0.2133 | 1 | 0.2133 | 0.6066 | 0.4468 |

| A2 | 4.56 | 1 | 4.56 | 12.98 | 0.0022 ** |

| B2 | 1.25 | 1 | 1.25 | 3.54 | 0.0771 |

| C2 | 2.85 | 1 | 2.85 | 8.1 | 0.0112 * |

| Residual | 5.98 | 17 | 0.3517 | − | − |

| Sum | 219.14 | 26 | − | − | − |

| R2 = 0.9727 | R2adj = 0.9583 | CV = 6.58% | Adequate Precision = 28.3766 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, T.; Li, F.; Liu, Q.; Ren, J.; Huang, J.; Qin, Z. Numerical Simulation and Analysis of the Impurity Removal Process of a Sugarcane Chopper Harvester Based on a CFD–DEM Model. Agriculture 2024, 14, 1392. https://doi.org/10.3390/agriculture14081392

Wu T, Li F, Liu Q, Ren J, Huang J, Qin Z. Numerical Simulation and Analysis of the Impurity Removal Process of a Sugarcane Chopper Harvester Based on a CFD–DEM Model. Agriculture. 2024; 14(8):1392. https://doi.org/10.3390/agriculture14081392

Chicago/Turabian StyleWu, Tao, Fatang Li, Qingting Liu, Jiahui Ren, Jibai Huang, and Zhanji Qin. 2024. "Numerical Simulation and Analysis of the Impurity Removal Process of a Sugarcane Chopper Harvester Based on a CFD–DEM Model" Agriculture 14, no. 8: 1392. https://doi.org/10.3390/agriculture14081392

APA StyleWu, T., Li, F., Liu, Q., Ren, J., Huang, J., & Qin, Z. (2024). Numerical Simulation and Analysis of the Impurity Removal Process of a Sugarcane Chopper Harvester Based on a CFD–DEM Model. Agriculture, 14(8), 1392. https://doi.org/10.3390/agriculture14081392