2.3.1. Picking Device

Harvest efficiency

was introduced to measure the weight of the ripe fruits picked and placed into the collection box every minute on average. The harvesting rate of the ripe fruits and unripe fruits (

,

), the damage rate of the ripe fruits (

), the cleaning rate of the ripe fruits (

) and the loss rate of ripe fruits (

) were calculated according to the following Equation (1) [

8,

15,

16].

where

n1 is the number of ripe fruits harvested;

n2 is the number of ripe fruits that have not been picked;

n3 is the number of unripe fruits harvested;

n4 is the number of damaged fruits in the harvested ripe fruits;

m1 is the mass of fruits falling into the collection box, g;

m2 is the total mass of the harvested products falling into the collection box, g;

m3 is the mass of lost fruits, g.

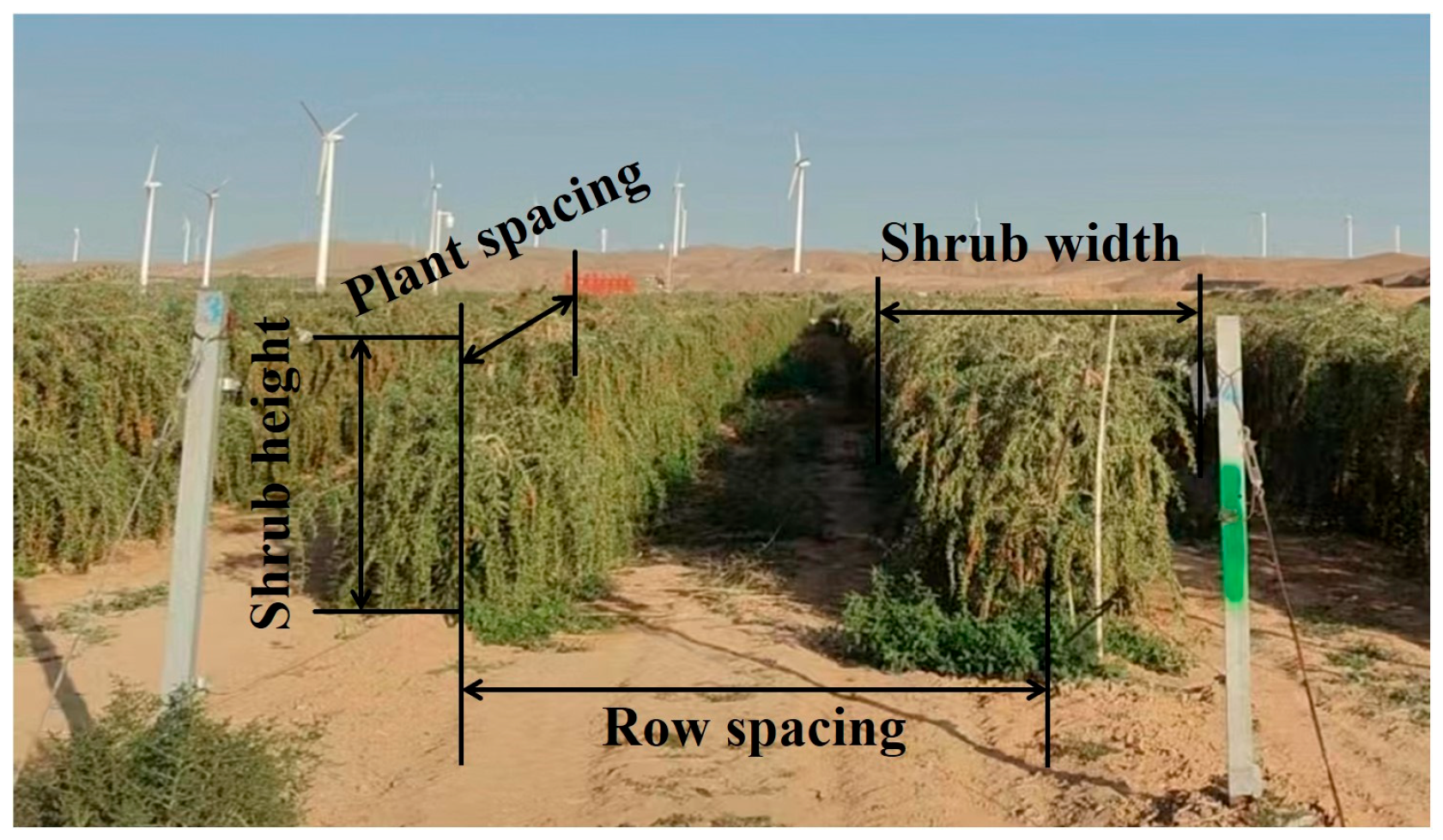

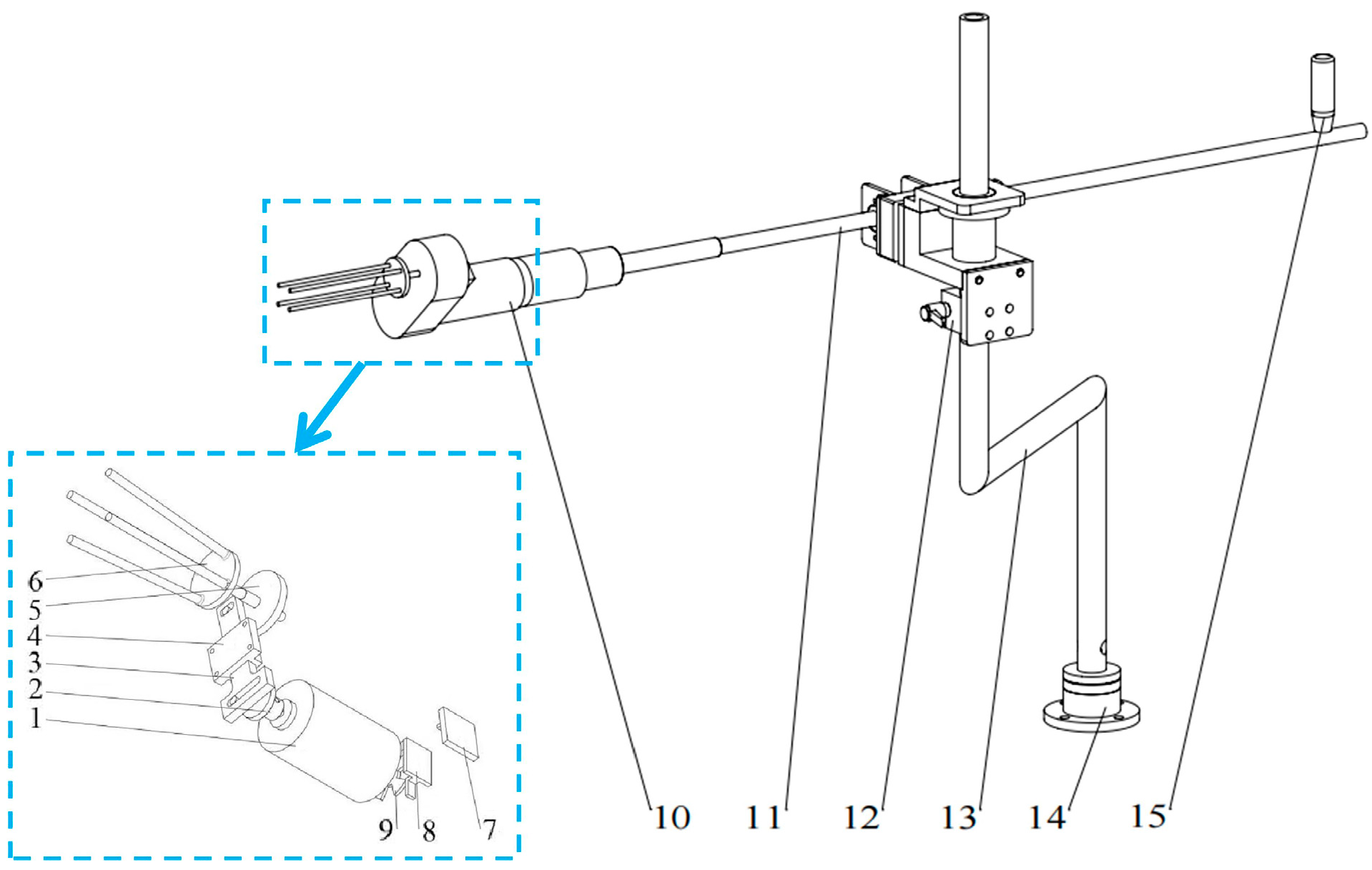

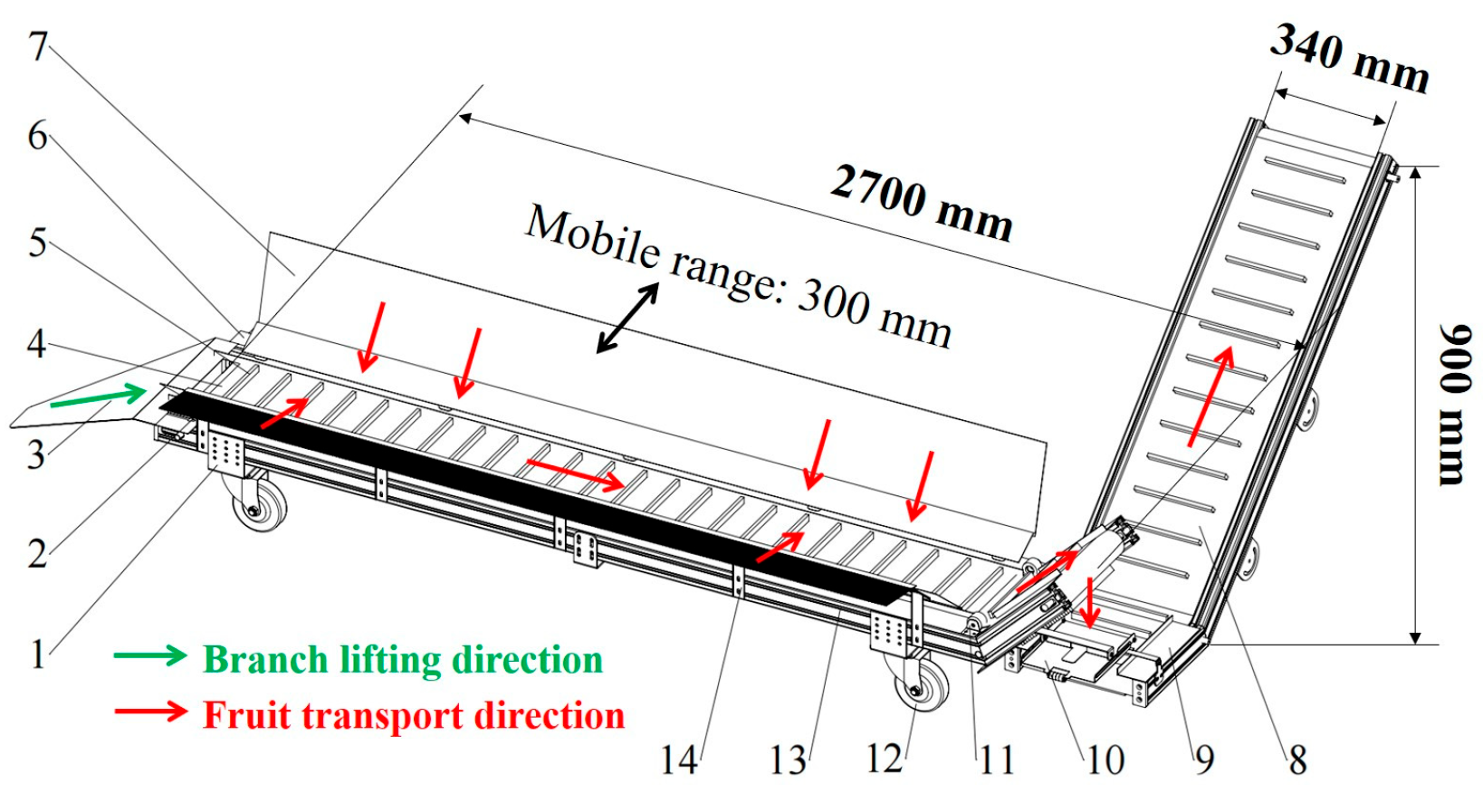

To achieve the unilateral harvesting of two shrubs at once, the harvester was equipped with two sets of same-side picking devices spaced 1000 mm apart. The structure of the picking device is shown in

Figure 3 [

23]. The actual measurement showed that the transverse picking range of the picking arm can reach 1500 mm, the longitudinal picking range can reach 1800 mm from the ground, and the front and rear adjustable range is 800 mm.

The circular motion of the eccentric in the vibratory picker was converted to the reciprocating swing of the main shaft, which made the picking rod and the branch collide at high frequency, so that the inertia could be used to achieve picking. The vibration frequency of the selected picker can be adjusted from 0 to 30 Hz. Under the optimal parameter combination of a torsion angle of 73.66°, a rod pitch of 35.51 mm, and a vibration frequency of 19.12 Hz, the picking rates of ripe and unripe fruit were 95.67% and 4.68%, respectively, and the damage rate of ripe fruit was 3.70% [

23,

24]. It can be concluded that the picker has superior harvesting performance and is suitable for application in a

L. barbarum harvester.

2.3.2. Undertaking and Transportation Device

The undertaking material has a significant impact on the effectiveness and damage rate of ripe fruit. Under the premise of adapting to the outdoor working environment, three types of materials were selected: stainless steel plate, silicone plate, and tarpaulin [

23,

25]. In order to select the suitable material, a physical test and EDEM simulation test were conducted to study the parameters of

L. barbarum fruit.

The slope sliding method was used to obtain the static friction coefficient between fruit and the material, as shown in

Figure 4. Each group was repeated 10 times, and the calculated range of static friction coefficient between the fruit and steel plate was 0.9 ± 0.05, the range between the fruit and silicone plate was 0.7 ± 0.05, and the range between the fruit and tarpaulin was 0.5 ± 0.02.

The collision recovery coefficient is defined as the ratio of the normal instantaneous separation velocity and instantaneous contact velocity at the collision contact point between L. barbarum fruit and materials before and after collision. Fruits were released at the distance of 100, 400, and 700 mm from the collision material, and the collision recovery coefficients were determined using the collision method of free fall. Experimenters used high-speed photography technology to capture the collision process and determined the first rebound height of fruit. Each fruit was used only once, with each group repeated 10 times, and the average of 10 tests was taken as the final result. Results showed that the collision recovery coefficients of the fruit–stainless steel plate, fruit–silicone plate and fruit–tarpaulin were about 0.225, 0.194 and 0.169, respectively.

The stacking angle can reflect the flow performance of

L. barbarum fruit particles. The bottomless cylinder lifting method was used for measurement, as shown in

Figure 5. The cylinder made of the undertaking material was placed on the bottom plate made of the same material, and 500 fresh fruits filled the cylinder. A universal testing machine was used to lift the cylinder at a speed of 20 mm/s to form a particle pile of fruit. The stacking angle was measured by a digital display inclinometer. The stacking angles of the fruit–stainless steel plate, fruit–silicone plate, and fruit–tarpaulin were 29.01°, 27.93°, and 30.59°, respectively.

In order to verify the accuracy and reliability of the measured parameters, the stacking effect was simulated by EDEM 2021 software and compared with the actual stacking angle. In SOLIDWORKS 2020 software, the fruit model was defined as an ellipsoid with a long axis of 17 mm, a short axis of 10 mm and a rotating radius of 10 mm and imported into EDEM software to generate a discrete element three-dimensional model. The particle factory produced 500 fruits, the lifting speed of the bottomless cylinder was set to 20 mm/s, the total simulation time was set to 2 s, the time step was set to 20% of the Rayleigh step, and the grid size was set to five times the minimum particle diameter. The intrinsic parameters of

L. barbarum fruit, stainless steel plate, silicone plate and tarpaulin obtained through physical test and data retrieval are shown in

Table 3 [

9,

26]. The simulation process and results are shown in

Figure 6.

The experimental results showed that the simulated stacking angle of the fruit–stainless steel plate was 28.82°, the simulated stacking angle of the fruit–silicone plate was 28.42°, and the simulated stacking angle of the fruit–tarpaulin was 30.72°. The relative errors with the actual stacking angle were 0.66, 1.72, and 0.42%, respectively, indicating that the calibrated parameters were accurate and reliable.

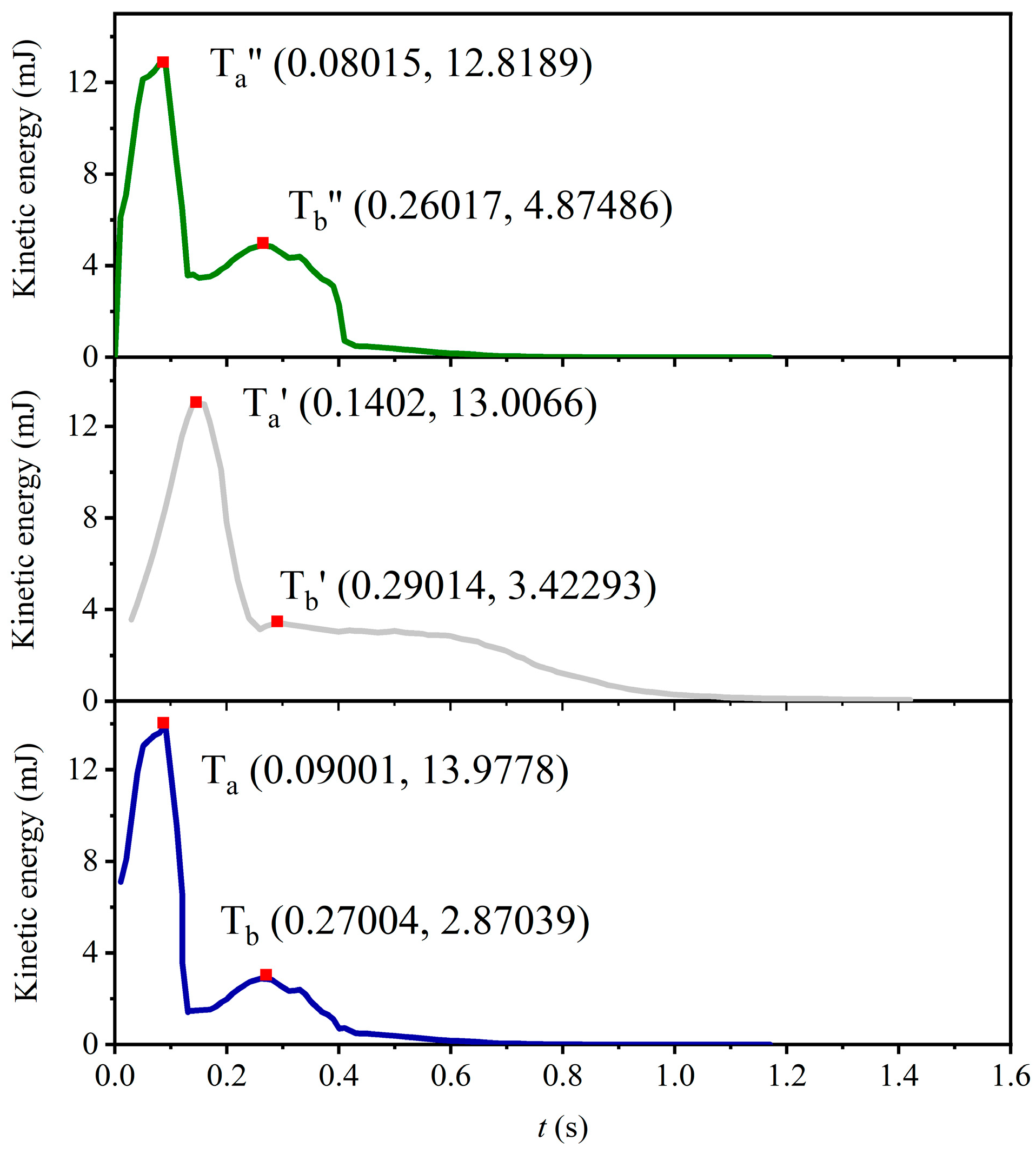

Drop models with different undertaking materials were established in EDEM software, and the quality of fruit was analyzed based on deformation energy. The drop height was set to 1000 mm, initial velocity was set to 0, and drop acceleration was set to the gravitational acceleration. In the post-processor,

Figure 6 shows the curves of the average kinetic energy of the fruit over time. In

Figure 6, point A represents the moment when the fruit comes into contact with the undertaking device. At this point, all the gravitational potential energy of the fruit is converted into kinetic energy. At point B, the maximum rebound height of the fruit is reached. Assuming that the kinetic energy at point A is T

a and the kinetic energy at point B is T

b, the energy lost by the fruit is defined: T = T

a − T

b. As shown in

Figure 7, the deformation energy of

L. barbarum fruit is minimal when using tarpaulin as the undertaking material. Therefore, based on simulation analysis, the selected undertaking material was tarpaulin.

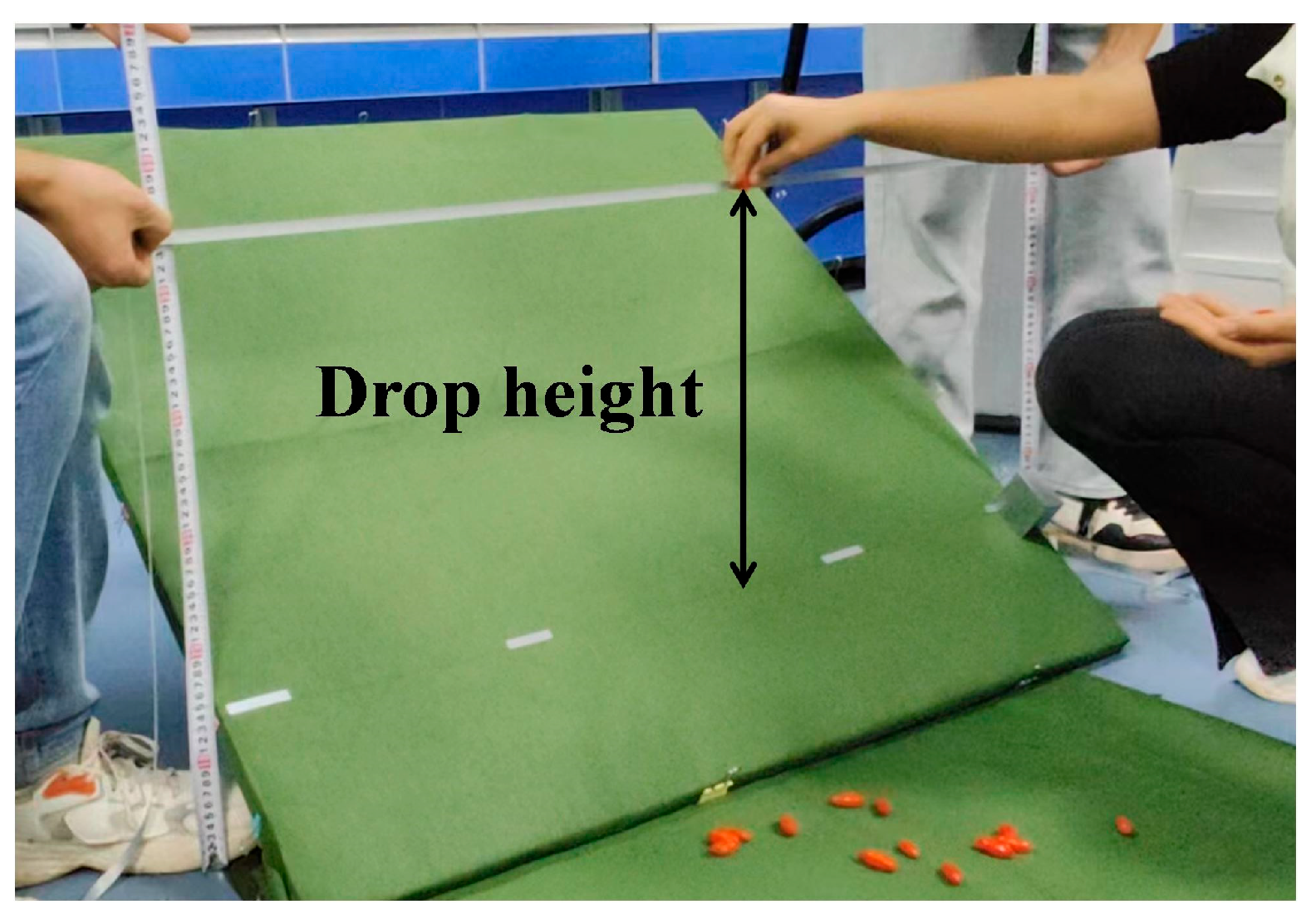

The drop test was conducted using drop height as the factor, as shown in

Figure 8. The drop height was set to 400, 700 and 1000 mm, respectively, and 50 fresh fruits of Ningqi No. 7 were used in each group of tests. After the test, the long and short axes of the softened surface were measured, and the damaged area was calculated according to the elliptic area formula. According to the damaged area, fruits were divided into four levels: Level 0, with no obvious damage; Level 1, there is a small amount of damage on the surface of the fruit, and the damage area is less than 25% of the fruit surface area; Level 2, the damage area accounts for 25–50% of the fruit surface area; Level 3, the damage area accounts for more than 50% of the fruit surface area [

27]. Using the damage index

zd calculated according to Equation (2) as the evaluation index [

27], the test results are shown in

Table 4.

where

LD is the damage level;

N is the number of fruits at this level;

LM is the maximum damage level;

NT is the total number of fruits.

In summary, tarpaulin was selected as the undertaking material, and the structure of the undertaking and transportation device structure is shown in

Figure 9. Based on the growth characteristics of

L. barbarum and the working efficiency of the picker, the height of the conveyor baffle was set to 20 mm, the spacing between the baffles was 100 mm, and the conveyor belt speed was set to 0–4 m/min. A receiving plate was designed between the two conveyor belts to prevent fruit leakage. A brush with a hair height of 150 mm was selected as the buffer device to be installed on the edge of the outer bracket.

2.3.3. Winnowing Device

Due to the close binding force between the flowers, leaves, fruit, and stalks of

L. barbarum and the presence of dust on the surface of shrubs and in the air, the harvested products are prone to containing impurities. To ensure sufficient separation of the target harvest and impurities, the harvester was designed with a winnowing device, as shown in

Figure 10. The feeding port and guide baffle were designed as a whole and connected to the longitudinal conveyor belt and fan. A secondary buffer device was also installed below to reduce damage to the fruit.

The optimal wind speed was calculated under the critical condition that

L. barbarum fruit was not blown out of the machine. The initial speed of the harvested products entering the device from the inlet was set to 0. The harvested products were subjected to vertical gravity and horizontal wind force. According to the displacement equation, Equation (3) can be obtained:

where

t is the time required for

L. barbarum fruit to fall into the collection box from the feeding port, s;

d is the diameter of the air duct, mm;

af is the horizontal acceleration of fruit, m/s

2;

xf is the maximum horizontal distance for fruit not to be blown out of the machine, mm.

According to Newton’s second law, Equation (4) can be derived:

where

Fw is the wind force, N;

mf is the weight of

L. barbarum fruit, g, referring to the average weight of ripe Ningqi No. 7 in

Table 1.

The windward area of the fruit was calculated based on the maximum cross-sectional area of the fruit, referring to the average values of the transverse and longitudinal diameters in

Table 1. The windward area was calculated using the elliptical area formula. Combined with the wind force calculation formula, the following equation can be obtained:

where

vw is the required airflow speed, m/s;

ρ is air density, g/L, and the density of normal dry air can be taken as 1.293 g/L;

la is the transverse diameter of

L. barbarum fruit, mm, referring to

Table 1;

lb is the longitudinal diameter of

L. barbarum fruit, mm, referring to

Table 1.

The optimal airflow speed of the fan was calculated to be 6.86 m/s. Therefore, an SF3-2 pipeline-type energy-saving and low-noise axial flow fan with an airflow speed of 0–8 m/s was adopted.