Design and Test of Discrete Element-Based Separation Roller Potato–Soil Separation Device

Abstract

1. Introduction

2. Materials and Methods

2.1. Overall Structure and Working Principle

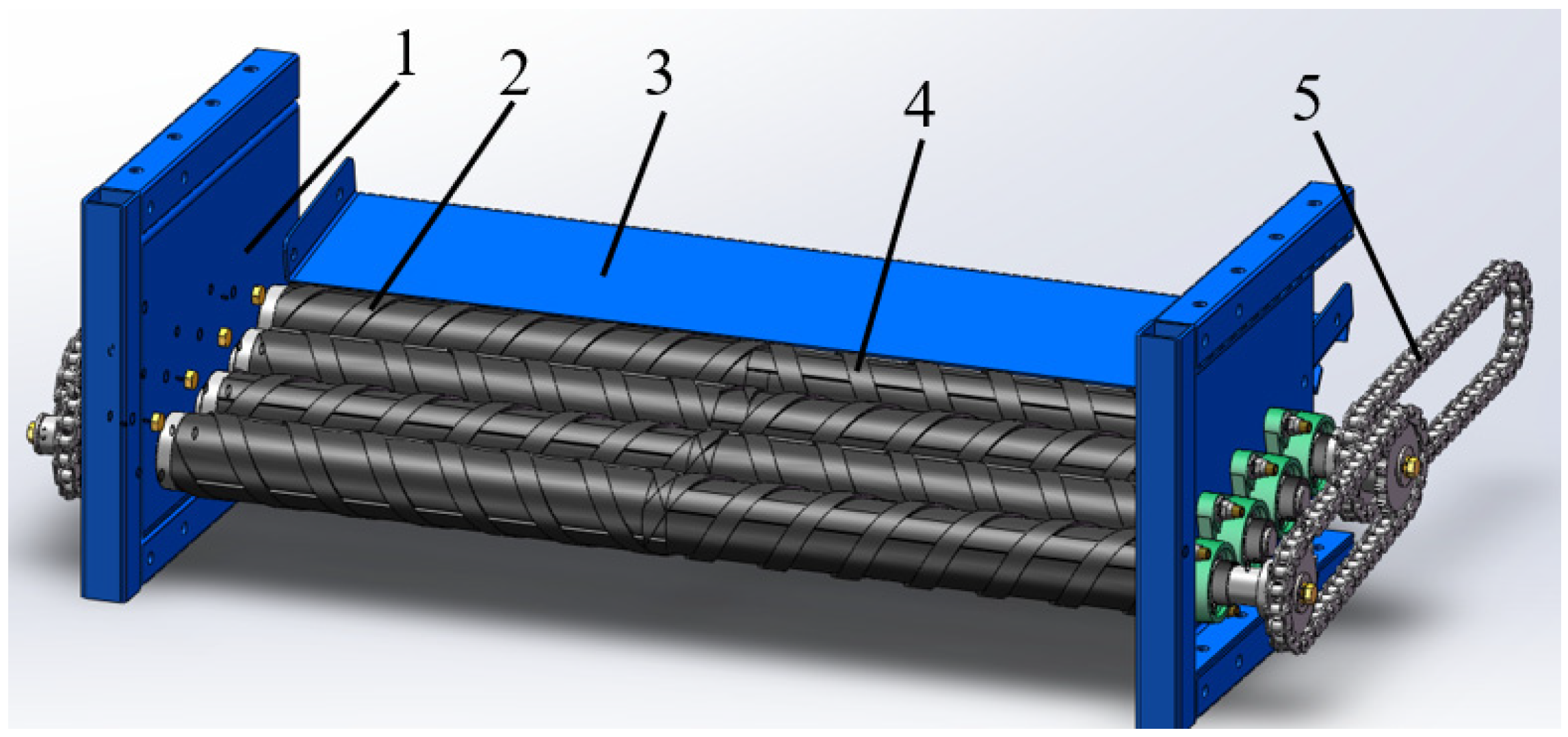

2.1.1. Overall Structure

2.1.2. Working Principle and Main Technical Parameters

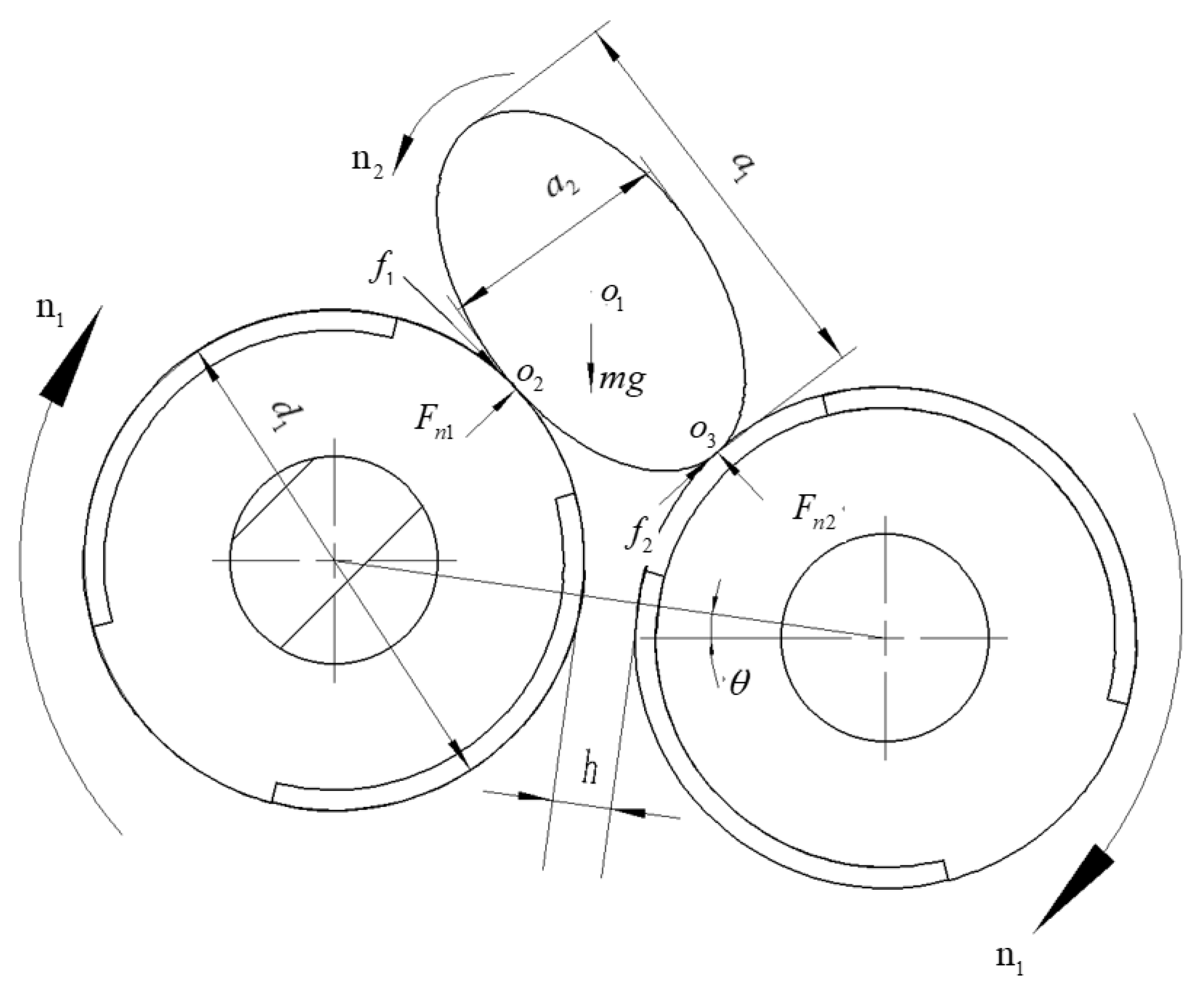

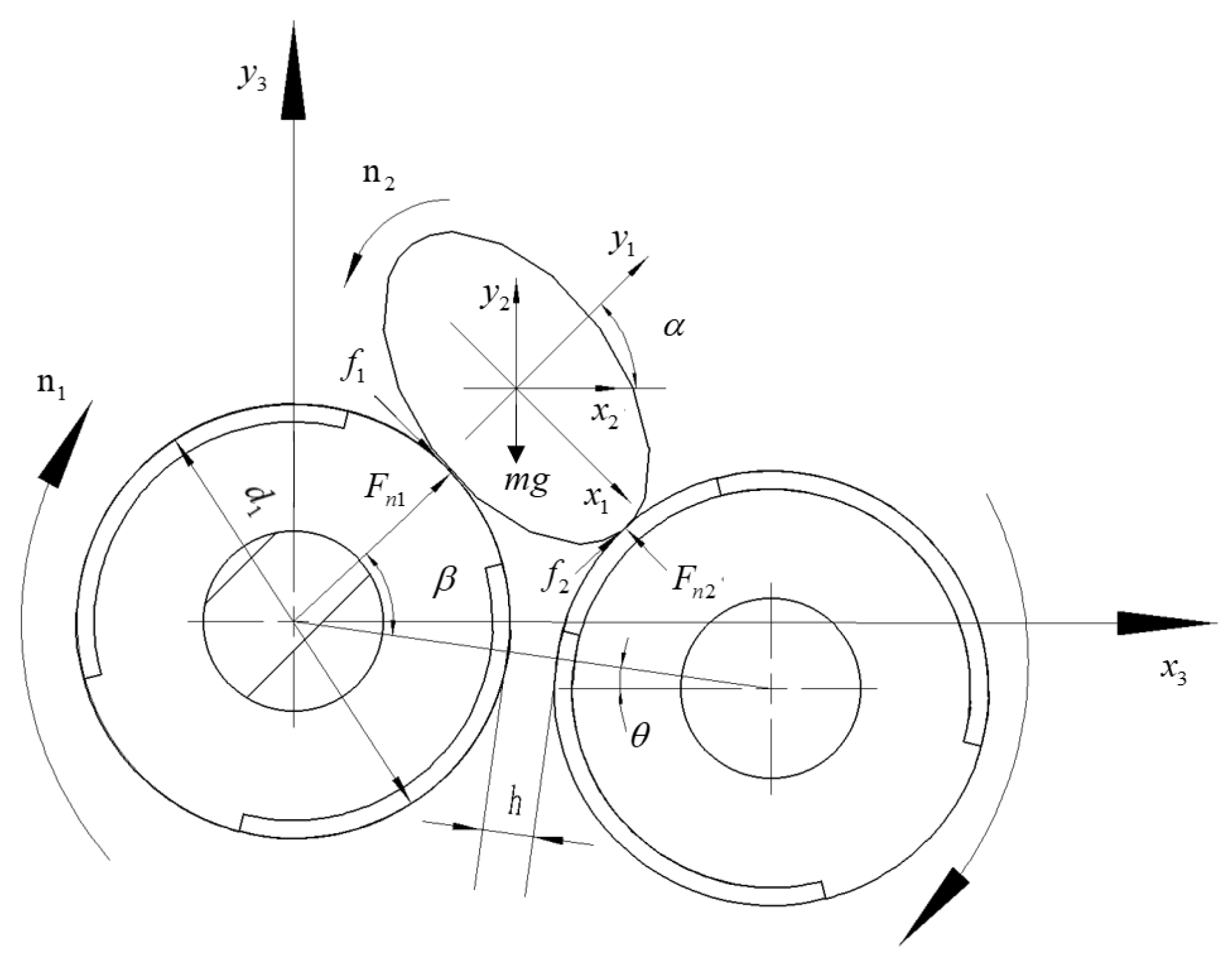

2.2. Analysis of the Dynamics between the Potato and the Separation Roller

2.2.1. Force Analysis between Potato and Separation Roller

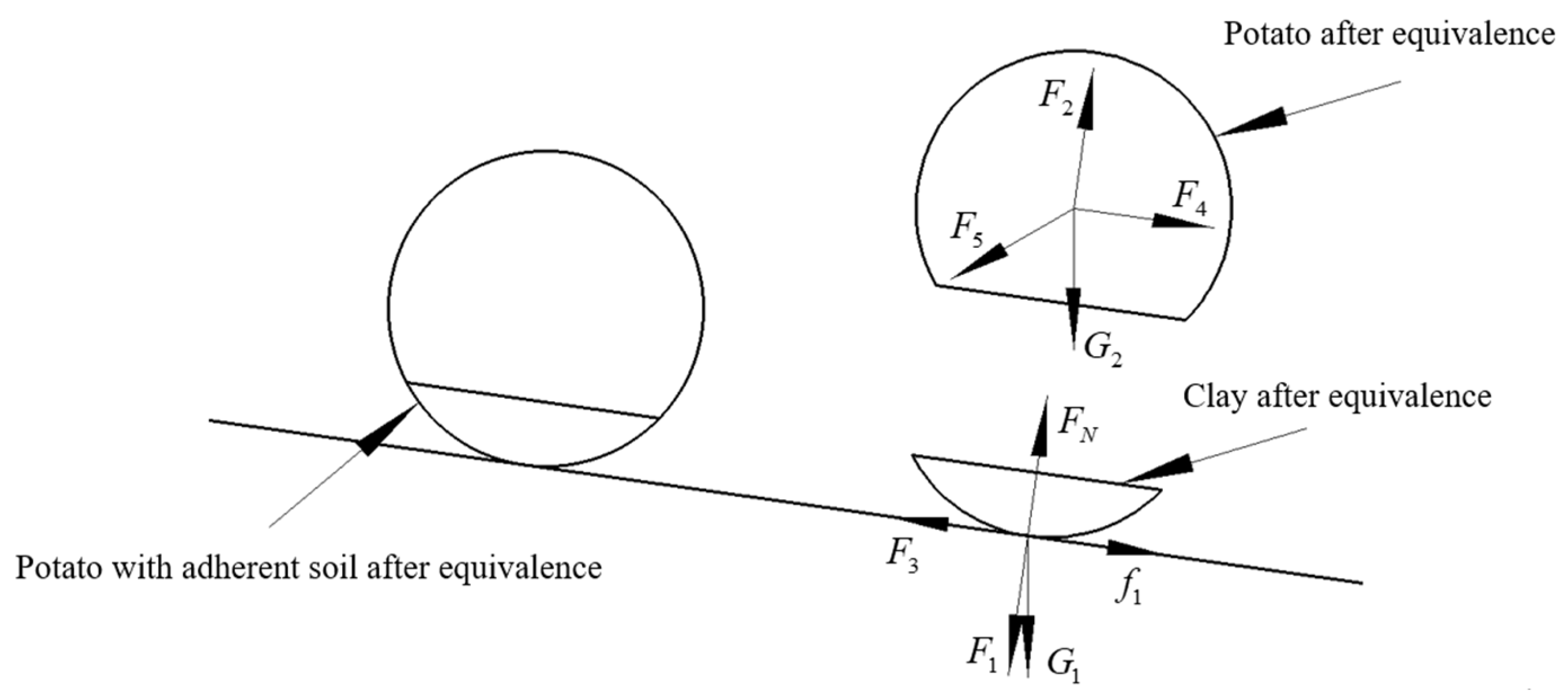

2.2.2. Technical Analysis of the Process of Separation of Clay-Heavy Soils

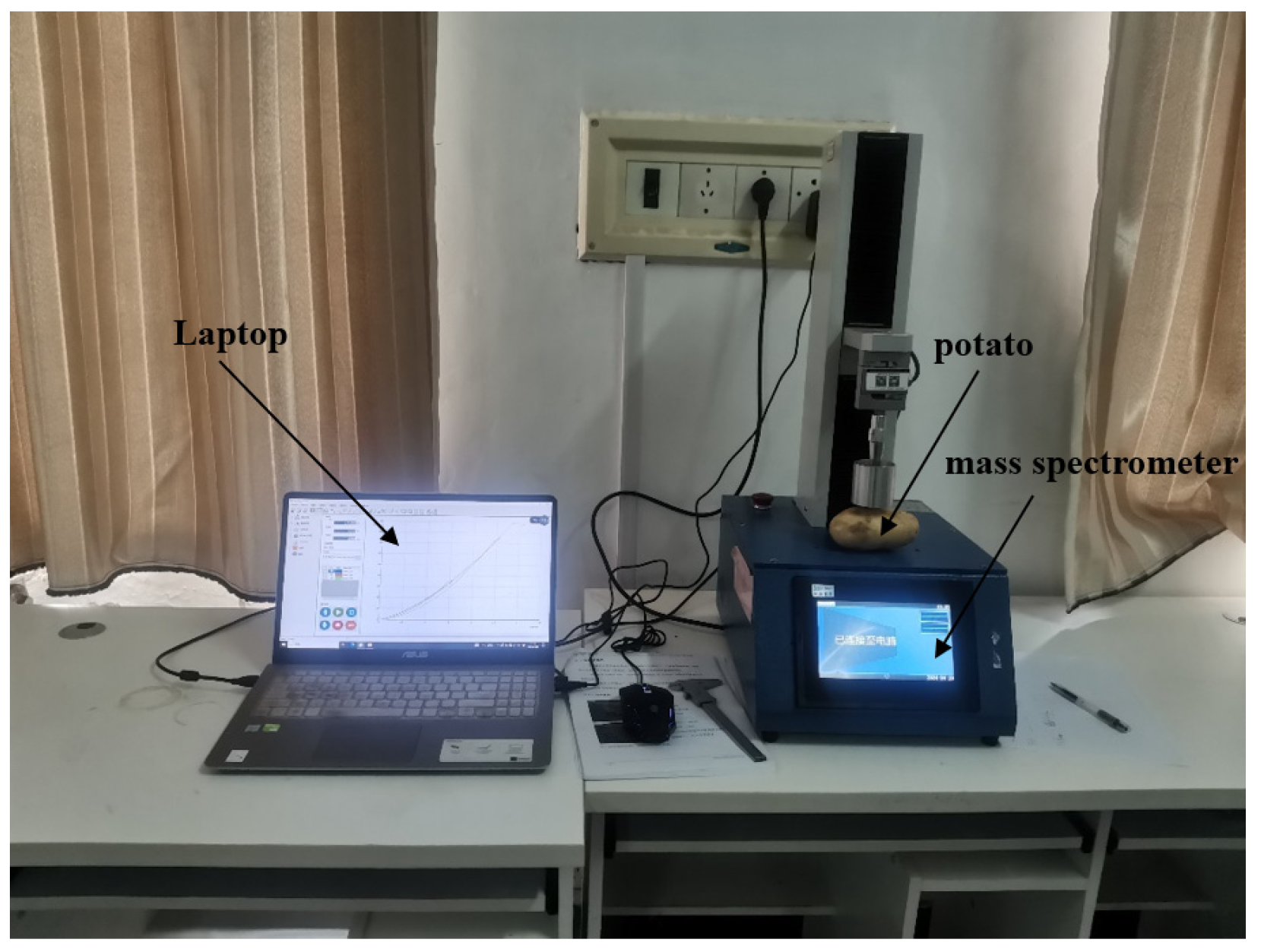

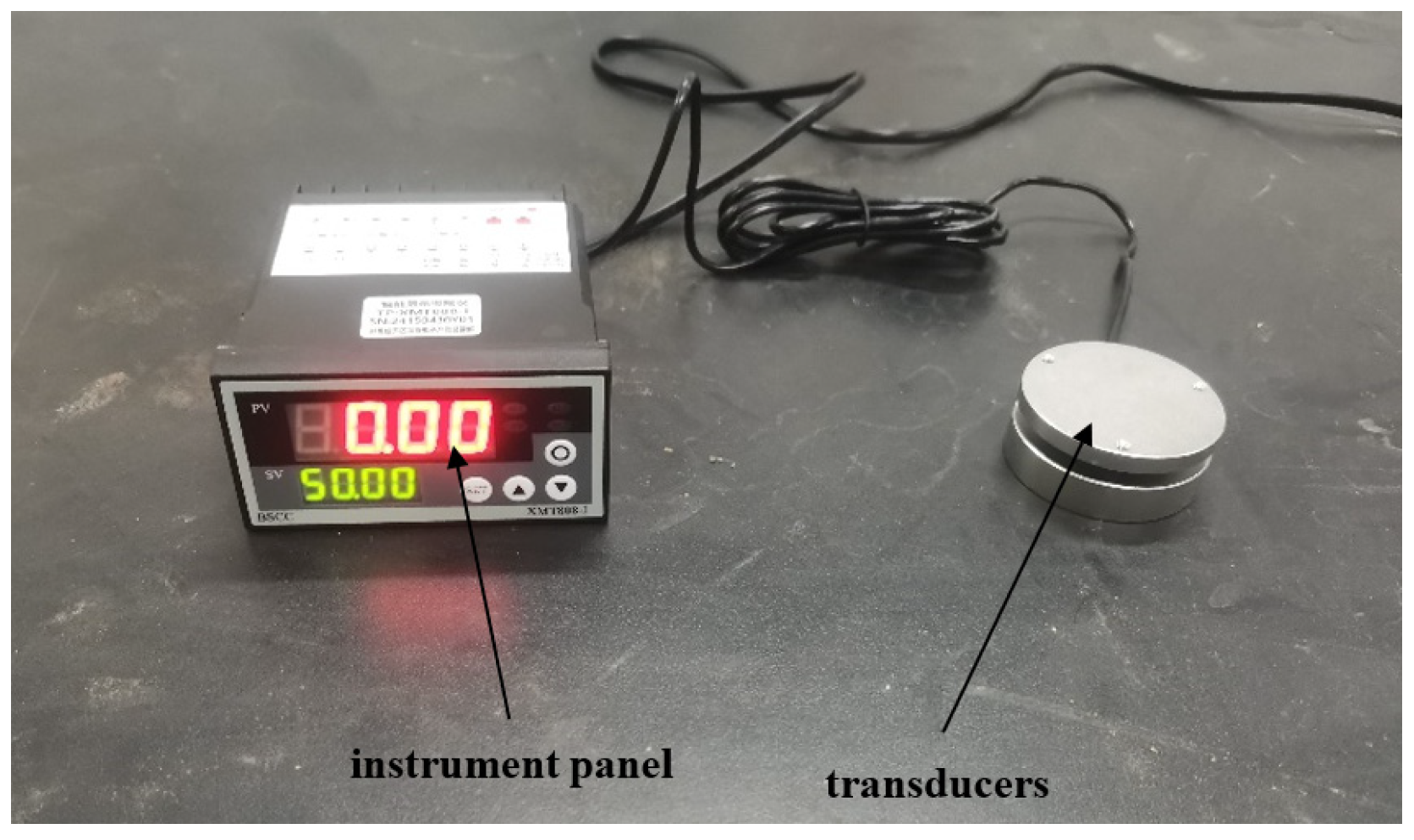

2.3. Measurement of Stress Thresholds in Potato

2.4. Discrete Element Modelling

2.4.1. Discrete Element Modelling of Potato and Separation Rolls

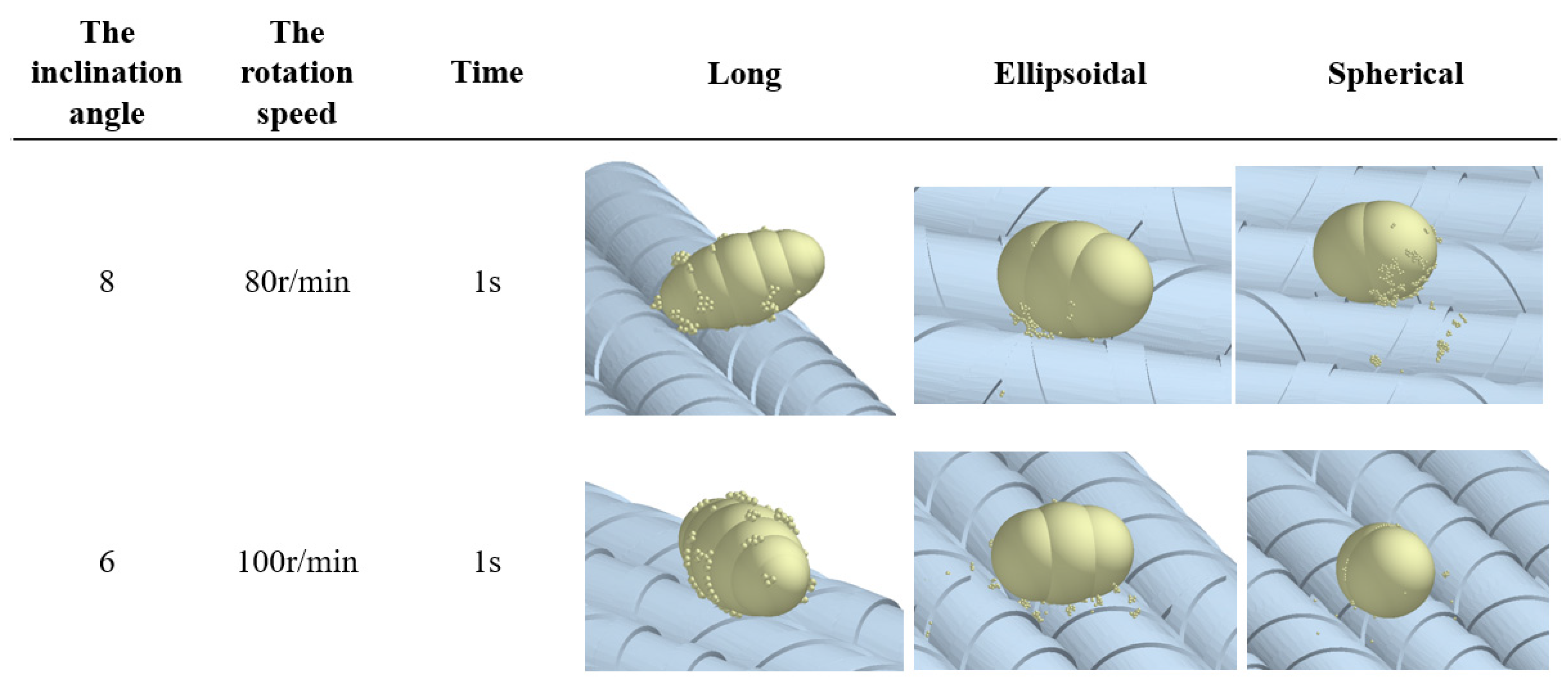

2.4.2. Analysis of the Removal Effect of Clay-Heavy Soils

2.5. Field Trial

3. Results and Discussion

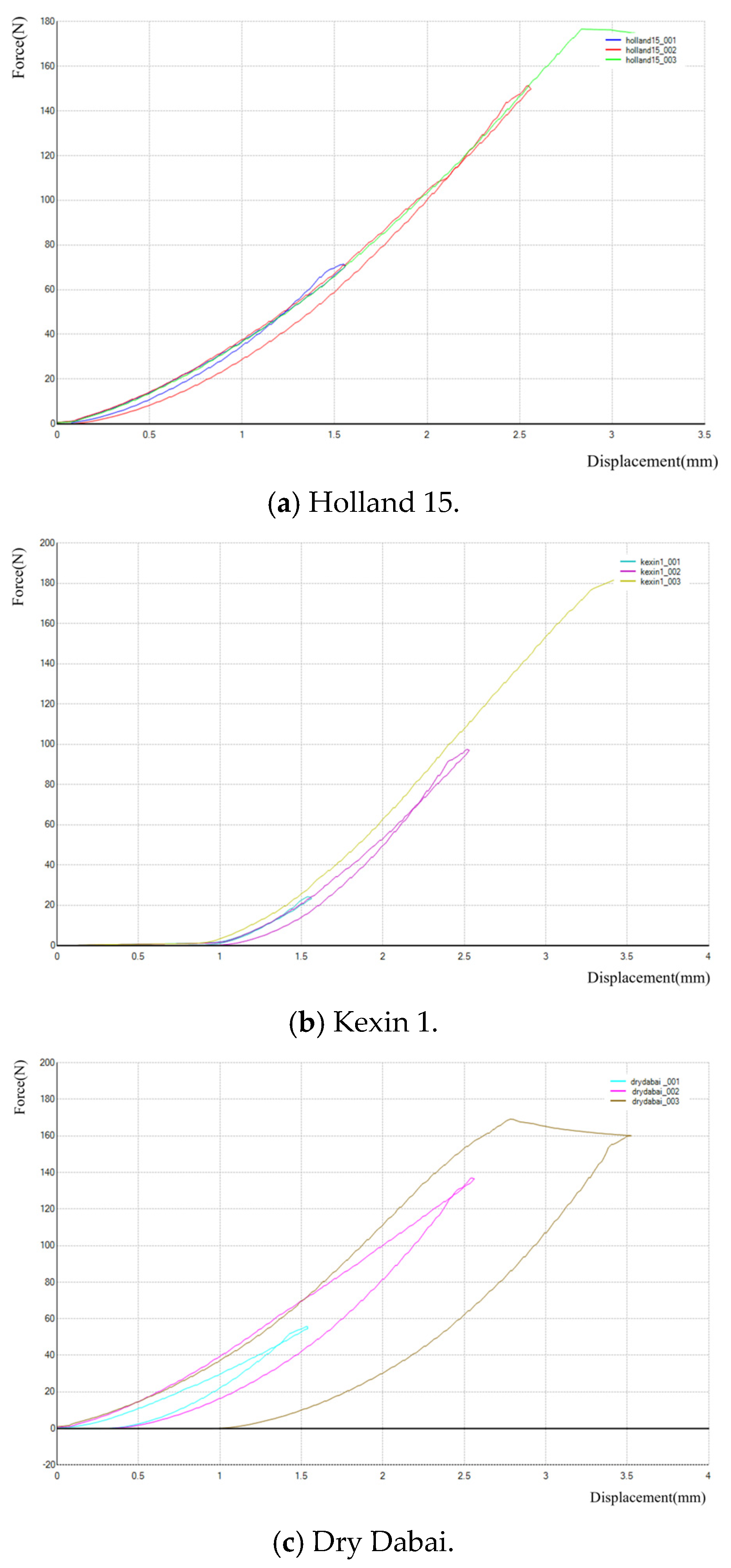

3.1. Potato Stress Threshold Test Results

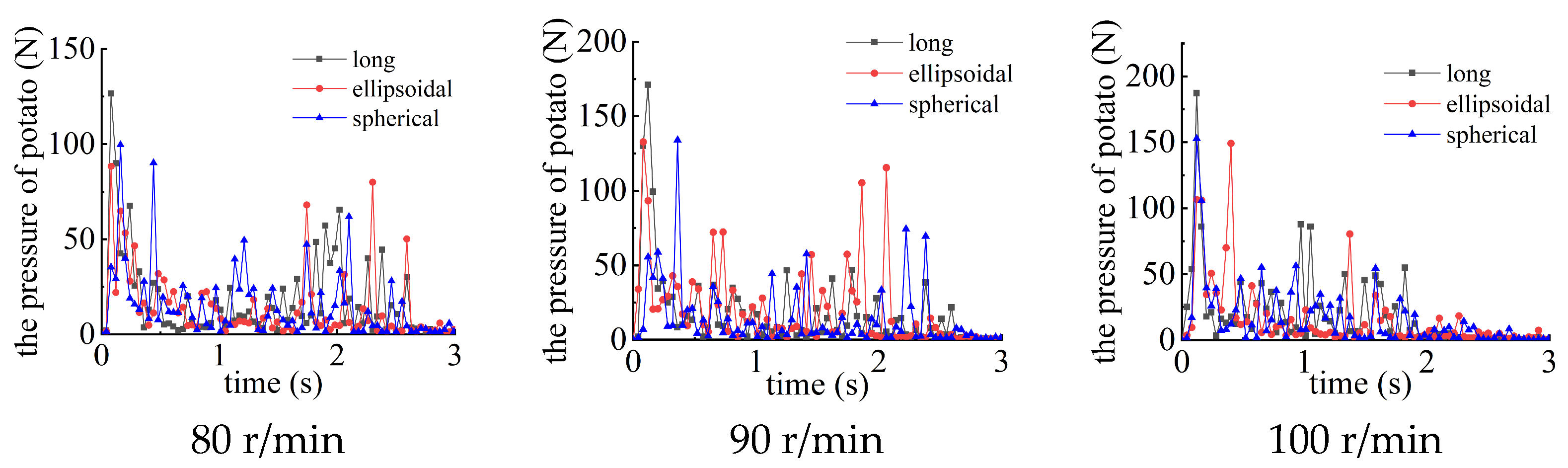

3.2. Influence of Device Inclination Angle and Separation Roller Speed on Potato Collision Characteristics

3.3. Effect of Separation Roller Center Distance on Potato Collision Characteristics

3.4. Effectiveness of Clay-Heavy Soil Removal

3.5. Results of Field Trials

4. Conclusions

- (1)

- Aiming to address the issues of the high potato injury rates and low bright potato rates in traditional potato–soil separation devices, a separation roller potato–soil separation device was designed to remove the sticky soil and increase the effective separation length. A kinetic analysis of the potato–soil separation process of the separating roller was carried out, and the key factors affecting the potato–soil separation were identified.

- (2)

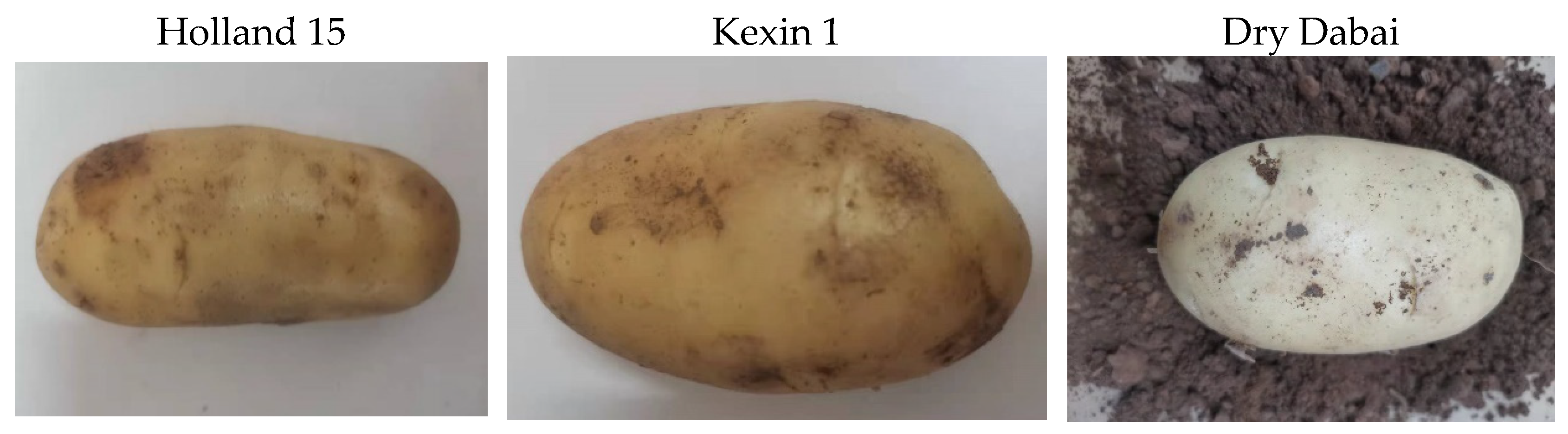

- Three kinds of potatoes, Holland 15, Kexin 1, and Dry Dabai, were collected. The relationship between pressure and deformation of the three kinds of potatoes was measured using a Texture Analyzer to derive the peak force. In addition, the friction force damage of the potatoes at different heights was measured using a pressure load cell. The force threshold of the potatoes was finally determined to be 190–195 N.

- (3)

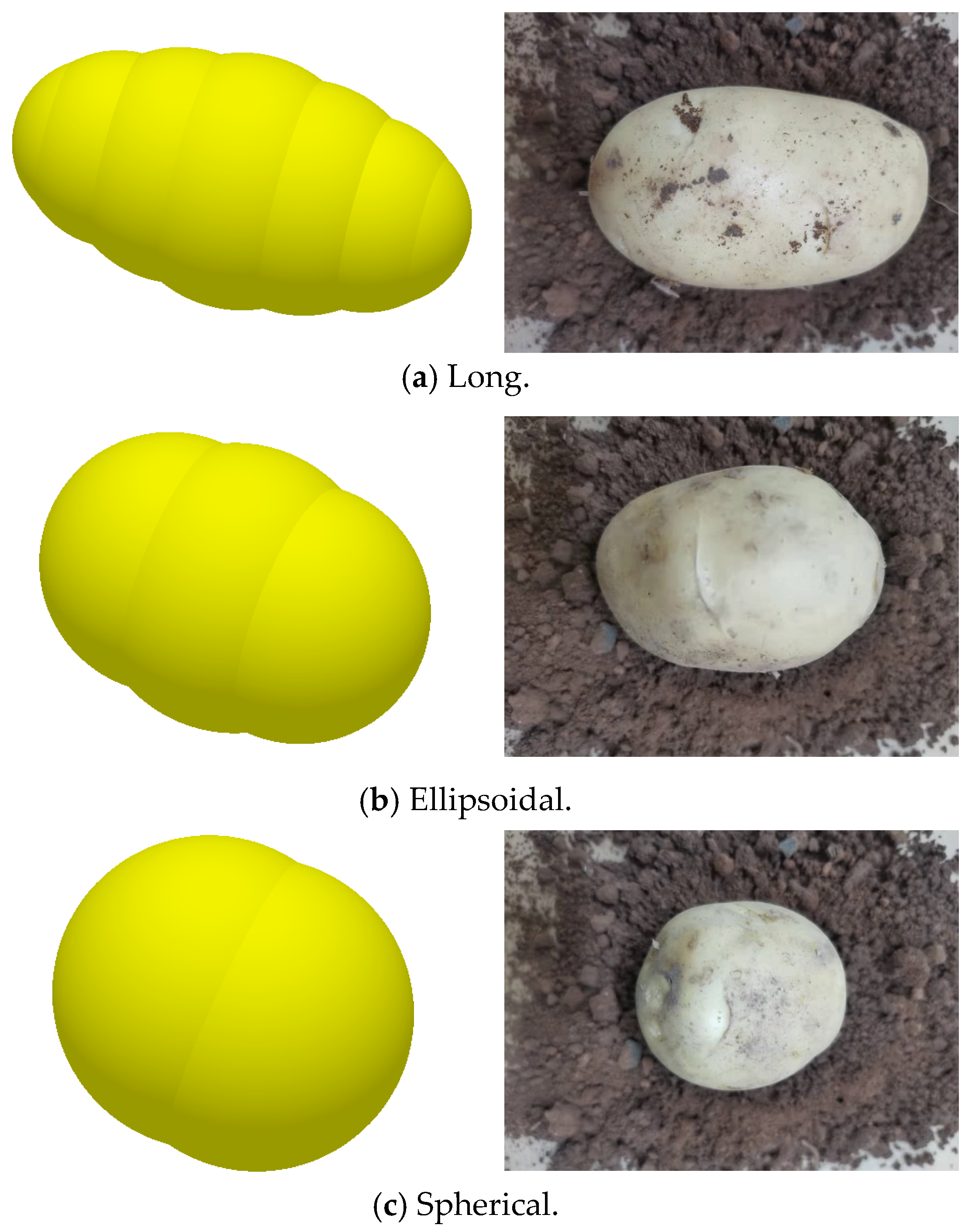

- Three kinds of discrete element models of potato, long, ellipsoidal, and spherical, were established to study the force situation of the three kinds of potato under different separation roller speeds, center distance, and device tilt angle. The simulation analysis results showed that under the conditions of separation roller speed 100 r/min, device tilt angle 6°, separation roller center distance 79 mm and separation roller speed 80 r/min, device tilt angle 8°, and separation roller center distance 79 mm, the force on the potato did not exceed the threshold. Potato could be sufficiently tumbled and frictionless to remove the viscous soil on the separation rollers.

- (4)

- The field test results show that the potato–soil separation device had an injury rate of 1.25%, a rate of bright potatoes of 99.01%, and a rate of broken skin of 1.58%, which meets the requirements of the potato harvester operation quality evaluation technical specifications, structural reasonableness, and adaptability. For more information on potato harvesting in sticky soil conditions, please refer to the relevant literature.

- (5)

- The potato–soil separation unit designed in the paper is quite effective in removing clay soil, improving harvest quality, and reducing losses. The rate of bright potatoes was improved by 6.8% compared to traditional installations. The rate of potato injury and skin breakage in the installation was only about 1%. The potato–soil separation device designed in this paper can also be applied to harvesting other root crops after optimization. This study also provides new ideas for harvesting root crops in clay-heavy soil conditions.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Khamaletdinov, R.; Martynov, V.; Mudarisov, S.; Gabitov, I.; Khasanov, E.; Pervushin, A. Substantiation of rational parameters of the root crops separator with a rotating inner separation surface. J. Agric. Eng. 2019, 51, 15–20. [Google Scholar] [CrossRef]

- Lin, Y.; Li, S.; Duan, S.; Ye, Y.; Li, B.; Li, G.; Lyv, D.; Jin, L.; Bian, C.; Liu, J. Methodological evolution of potato yield prediction: A comprehensive review. Front. Plant Sci. 2023, 14, 1214006. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.; Li, Y.; Wang, B.; Gu, F.; Wu, F.; Yang, H.; Yu, Z.; Hu, Z. An Experimental Study of Axial Poisson’s Ratio and Axial Young’s Modulus Determination of Potato Stems Using Image Processing. Agriculture 2022, 12, 1026. [Google Scholar] [CrossRef]

- Johnson, C.M.; Auat Cheein, F. Machinery for potato harvesting: A state-of-the-art review. Front. Plant Sci. 2023, 14, 1156734. [Google Scholar] [CrossRef]

- Dorokhov, A.; Ponomarev, A.; Zernov, V.; Petukhov, S.; Aksenov, A.; Sibirev, A.; Sazonov, N.; Godyaeva, M. The Results of Laboratory Studies of the Device for Evaluation of Suitability of Potato Tubers for Mechanized Harvesting. Appl. Sci. 2022, 12, 2171. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, W.; Zhao, Z.; Wang, H.; Liu, X.; Zhang, H.; Li, H.; Simionescu, P.A. Development and Testing of a Self-Propelled Machine for Combined Potato Harvesting and Residual Plastic Film Retrieval. Machines 2023, 11, 432. [Google Scholar] [CrossRef]

- Xin, L.; Liang, J. Design of conveyor separation device for potato harvester and analysis of its vibration characteristics. J. Comput. Methods Sci. Eng. 2022, 22, 1385–1392. [Google Scholar] [CrossRef]

- Wang, X.; Lyu, D.; Ren, J.; Zhang, M.; Meng, P.; Li, X. Design and parameter optimization of the cleaning device for a bagged potato combine harvester. J. Agric. Mach. 2022, 38, 8–17. [Google Scholar]

- Wei, Z.; Wang, Y.; Li, X.; Wang, J.; Su, G.; Meng, P.X.; Li, Z.H. The design and experiments of the potato combine harvester with elastic rubbing technology. J. Agric. Mach. 2023, 39, 60–69. [Google Scholar]

- Murodov, R.K.; Nishonov, K.K.; Bayboboev, N.G.; Mamadaliev, A.M. Influence of elevator parameters with centrifugal separation on soil separation from potato tubers. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1112. [Google Scholar]

- Xie, H.; Gao, G.; Tian, B.; Li, B.; Zhang, S.; Huang, J. Optimization of Potato-soil Transportation Separation Mechanism Based on Discrete Element Method and TRIZ Theory. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1267. [Google Scholar]

- Li, H.; Gao, F. Improvement design of separation and conveying machinery and equipment of potato excavator in heavy soil. Phys. Chem. Earth Parts A/B/C 2023, 130, 103363. [Google Scholar] [CrossRef]

- Matmurodov, F.; Dustkulov, A.; Abdiyev, N. Mathematical simulation of transfer mechanisms of crocheting potato harvesting machine. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 883. [Google Scholar]

- Ruzhylo, Z.; Bulgakov, V.; Adamchuk, V.; Bondarchuk, A.; Ihnatiev, Y.; Krutyakova, V.; Olt, J. Experimental research into the impact of kinematic and design parameters of a spiral potato separator on the quality of plant residues and soil separation. J. Agric. Sci. 2020. [Google Scholar]

- Wu, B.; Huang, T.; Qiu, X.; Zuo, T.; Wang, X.; Xie, F. Design and Experimental Study of Potato-Soil Separation Device for Sticky Soils Condition. Appl. Sci. 2021, 11, 10959. [Google Scholar] [CrossRef]

- Hu, Y.; Su, M.; Wang, Y.; Cui, S.; Meng, F.; Yue, W.; Liu, Y.; Xu, C.; Yang, Z. Food production in China requires intensified measures to be consistent with national and provincial environmental boundaries. Nat. Food 2020, 1, 572–582. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Hu, Z.; Gu, F.; Wang, B.; Fan, J.; Yang, H.; Wu, F. DEM-MBD Coupling Simulation and Analysis of the Working Process of Soil and Tuber Separation of a Potato Combine Harvester. Agronomy 2022, 12, 1734. [Google Scholar] [CrossRef]

- Wei, Z.; Li, H.; Sun, C.; Li, X.; Liu, W.; Su, G.; Wang, F. Improvement of potato harvester with two segments of vibration and wave separation. J. Agric. Mach. 2018, 34, 42–52. [Google Scholar]

- Zhang, Z.; Wang, H.; Li, Y.; Yang, X.; Ibrahim, I.; Zhang, Z. Design and Experiment of Multi-stage Separation Buffer Potato Harvester. J. Agric. Mach. 2021, 52, 96–109. [Google Scholar]

- Mosa, A.M.; Bao, G.; Wang, G.; Hu, L.; Xu, X.; Shen, H.; Ji, L. Study on the drop impact characteristics and impact damage mechanism of sweet potato tubers during harvest. PLoS ONE 2021, 16, e0255856. [Google Scholar]

- Wei, Z.; Li, H.; Sun, C.; Su, G.; Liu, W.; Li, X. Experiments and Analysis of a Conveying Device for Soil Separation and Clod-Crushing for a Potato Harvester. Appl. Eng. Agric. 2019, 35, 987–996. [Google Scholar] [CrossRef]

- Belay, D. Design, Construction and Performance Evaluation of Potato Harvesters: A Review. Int. Res. J. Eng. Technol. (IRJET) 2021, 8, 2747–2771. [Google Scholar]

- Wang, L.; Liu, F.; Wang, Q.; Zhou, J.; Fan, X.; Li, J.; Zhao, X.; Xie, S. Design of a Spring-Finger Potato Picker and an Experimental Study of Its Picking Performance. Agriculture 2023, 13, 945. [Google Scholar] [CrossRef]

- Chen, M.; Liu, X.; Hu, P.; Zhai, X.; Han, Z.; Shi, Y.; Zhu, W.; Wang, D.; He, X.; Shang, S. Study on rotor vibration potato-soil separation device for potato harvester using DEM-MBD coupling simulation. Comput. Electron. Agric. 2024, 218, 0168–1699. [Google Scholar] [CrossRef]

- Li, J. Study and Optimum Design on Separation and Screening Performance of Potato and Soil of Potato Harvester; Inner Mongolia Agricultural University: Huhhot, China, 2019. [Google Scholar]

- Jia, B.; Sun, W.; Zhao, Z.; Wang, H.; Zhang, H.; Liu, X.; Li, H. Design and Field Test of a Remotely Controlled Self-Propelled Potato Harvester with Manual Sorting Platform. Am. J. Potato Res. 2023, 100, 193–209. [Google Scholar] [CrossRef]

- Li, Y.; Fan, J.; Hu, Z.; Luo, W.; Yang, H.; Shi, L.; Wu, F. Calibration of Discrete Element Model Parameters of Soil around Tubers during Potato Harvesting Period. Agriculture 2022, 12, 1475. [Google Scholar] [CrossRef]

- Mu, G.; Wang, W.; Zhang, T.; Hu, L.; Zheng, W.; Zhang, W. Design and Experiment with a Double-Roller Sweet Potato Vine Harvester. Agriculture 2022, 12, 1559. [Google Scholar] [CrossRef]

- Gangopadhyay, M.; Zhao, P.; Tian, Y.; Li, Y.; Xu, G.; Tian, S.; Huang, Z. Potato (Solanum tuberosum L.) tuber-root modeling method based on physical properties. PLoS ONE 2020, 15, e0239093. [Google Scholar]

- Wei, Z.; Su, G.; Li, X.; Wang, F.; Sun, C.; Meng, P. Parameter optimization and Test of Potato Harvester Wavy Sieve Based on EDEM. Agric. Mach 2020, 51, 109–122. [Google Scholar]

- NY/T 648-2015; Technical Specification for Quality Evaluation of Potato Harvesters. China Standard Press: Beijing, China, 2015.

| Technical Parameters | Numerical Values |

|---|---|

| Separation Roller Rotation Speed | 80–100 r/min |

| Pitch of spiral | 130 mm |

| Thread height | 5 mm |

| Device tilt angle | 6–10° |

| Number of left-hand separation rollers | 4 |

| Number of right-hand separation rollers | 4 |

| Separation roller diameter | 72 mm |

| Number of separation roller stages | 4 |

| Parameters | Numerical Value |

|---|---|

| Poisson’s ratio of potato pieces | 0.5 [30] |

| Potato density | 1048 kg/m3 |

| Shear modulus of potato pieces | 1.366 Mpa |

| Coefficient of recovery between plots | 0.66 |

| Static friction factor between potatoes | 0.452 |

| The factor of kinetic friction between potatoes | 0.024 |

| Rubber Poisson’s ratio | 0.49 |

| Rubber shear modulus | 1 Mpa |

| Rubber density | 960 kg/m3 |

| Coefficient of recovery of collision between rubber and potato | 0.7 |

| Coefficient of static friction between rubber and potato | 0.5 |

| Dynamic friction factor between rubber and potato | 0.4 |

| 0.5 m | 0.7 m | 1 m | 1.5 m | |

|---|---|---|---|---|

| Holland 15 | 71.2 | 115.3 | 141.7 | 205.3 |

| 64.9 | 120.1 | 136.2 | 197.2 | |

| 66.5 | 113.2 | 142.6 | 198.6 | |

| Kexin 1 | 53.7 | 132.7 | 137.6 | 190.8 |

| 55.0 | 126.1 | 134.2 | 197.5 | |

| 56.6 | 123.4 | 128.4 | 195.1 | |

| Dry Dabai | 66.1 | 118.3 | 146.1 | 193.2 |

| 67.5 | 122.6 | 134.1 | 201.1 | |

| 71.3 | 126.7 | 141.6 | 197.9 |

| The Inclination Angle | The Rotation Speed | Long | Ellipsoidal | Spherical |

|---|---|---|---|---|

| 8 | 80 r/min | 164.14 | 113.48 | 95.55 |

| 90 r/min | 183.62 | 172.33 | 164.88 | |

| 100 r/min | 204.62 | 207.92 | 191.75 | |

| 10 | 80 r/min | 113.67 | 103.77 | 114.11 |

| 90 r/min | 131.87 | 78.41 | 76.60 | |

| 100 r/min | 162.49 | 119.58 | 99.28 |

| The Inclination Angle | The Rotation Speed | Spacing | Long | Ellipsoidal | Spherical |

|---|---|---|---|---|---|

| 6 | 100 r/min | 5 mm | 147.15 | 140.80 | 128.67 |

| 7 mm | 189.81 | 169.41 | 141.13 | ||

| 9 mm | 201.53 | 194.10 | 181.59 | ||

| 8 | 80 r/min | 5 mm | 125.44 | 145.31 | 138.60 |

| 7 mm | 170.49 | 188.62 | 144.53 | ||

| 9 mm | 195.43 | 207.02 | 172.63 |

| Model | Obvious Rate/% | Injury Rate/% | Abrasion Rate/% |

|---|---|---|---|

| Traditional model | 92.21 | 4.92 | 8.45 |

| Design model | 99.01 | 1.25 | 1.58 |

| 98.64 | 1.43 | 1.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, X.; Liu, J.; Zhao, Y.; Zhang, C.; Zhang, X.; Wang, Y. Design and Test of Discrete Element-Based Separation Roller Potato–Soil Separation Device. Agriculture 2024, 14, 1053. https://doi.org/10.3390/agriculture14071053

Du X, Liu J, Zhao Y, Zhang C, Zhang X, Wang Y. Design and Test of Discrete Element-Based Separation Roller Potato–Soil Separation Device. Agriculture. 2024; 14(7):1053. https://doi.org/10.3390/agriculture14071053

Chicago/Turabian StyleDu, Xinwu, Jin Liu, Yueyun Zhao, Chenglin Zhang, Xiaoxuan Zhang, and Yanshuai Wang. 2024. "Design and Test of Discrete Element-Based Separation Roller Potato–Soil Separation Device" Agriculture 14, no. 7: 1053. https://doi.org/10.3390/agriculture14071053

APA StyleDu, X., Liu, J., Zhao, Y., Zhang, C., Zhang, X., & Wang, Y. (2024). Design and Test of Discrete Element-Based Separation Roller Potato–Soil Separation Device. Agriculture, 14(7), 1053. https://doi.org/10.3390/agriculture14071053