The Simulation and Parameter Optimization of the Hole-Forming Process of a Duckbilled Hole-Forming Device

Abstract

1. Preface

2. Analysis of the Hole-Forming Device Structure and Hole-Forming Process

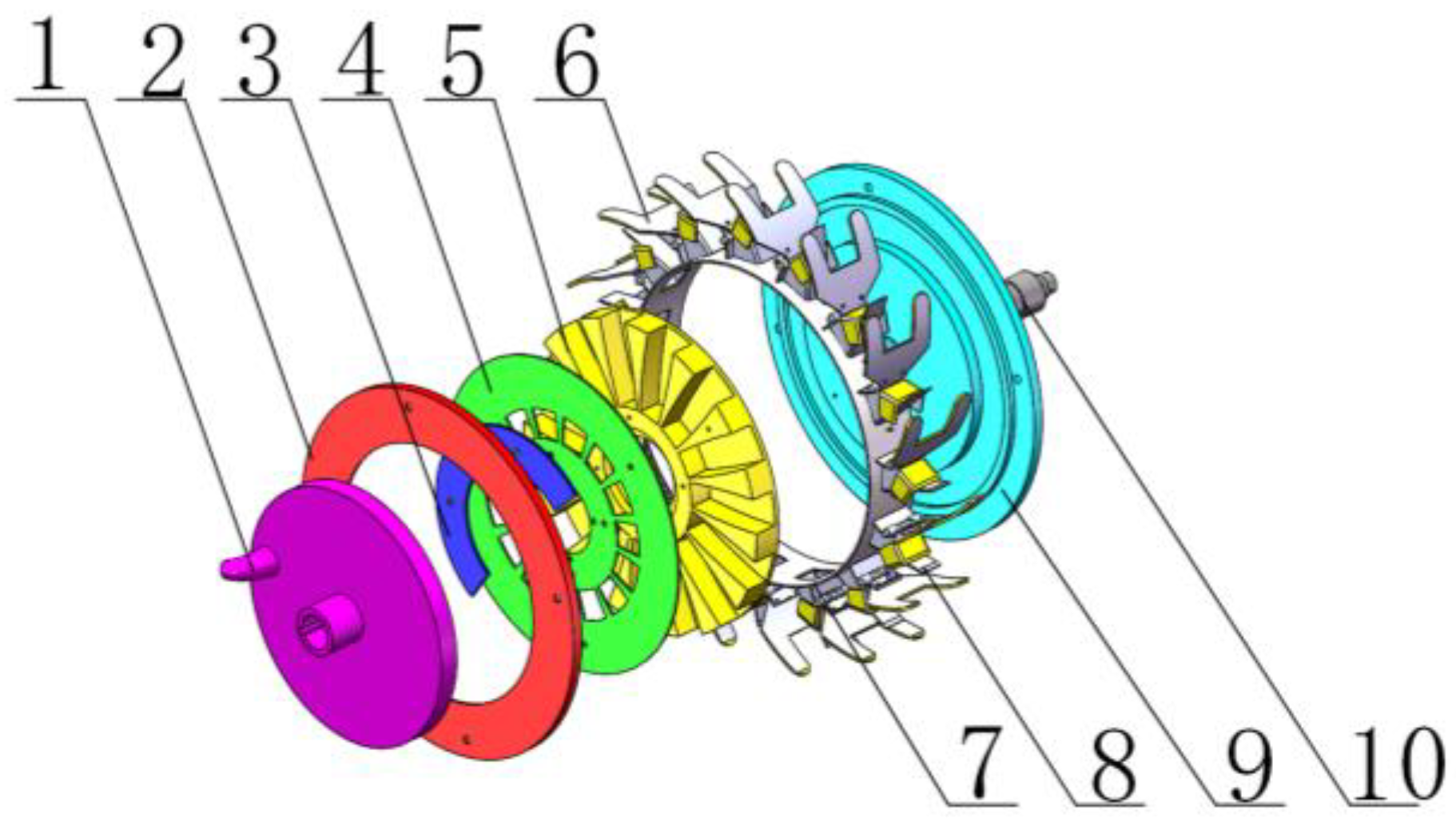

2.1. The Hole-Forming Device Structure

2.2. Analysis of the Motion Process of the Hole-Forming Device

2.2.1. Analysis of Duckbill Motion Trajectory

2.2.2. Soil Hole Contour Analysis

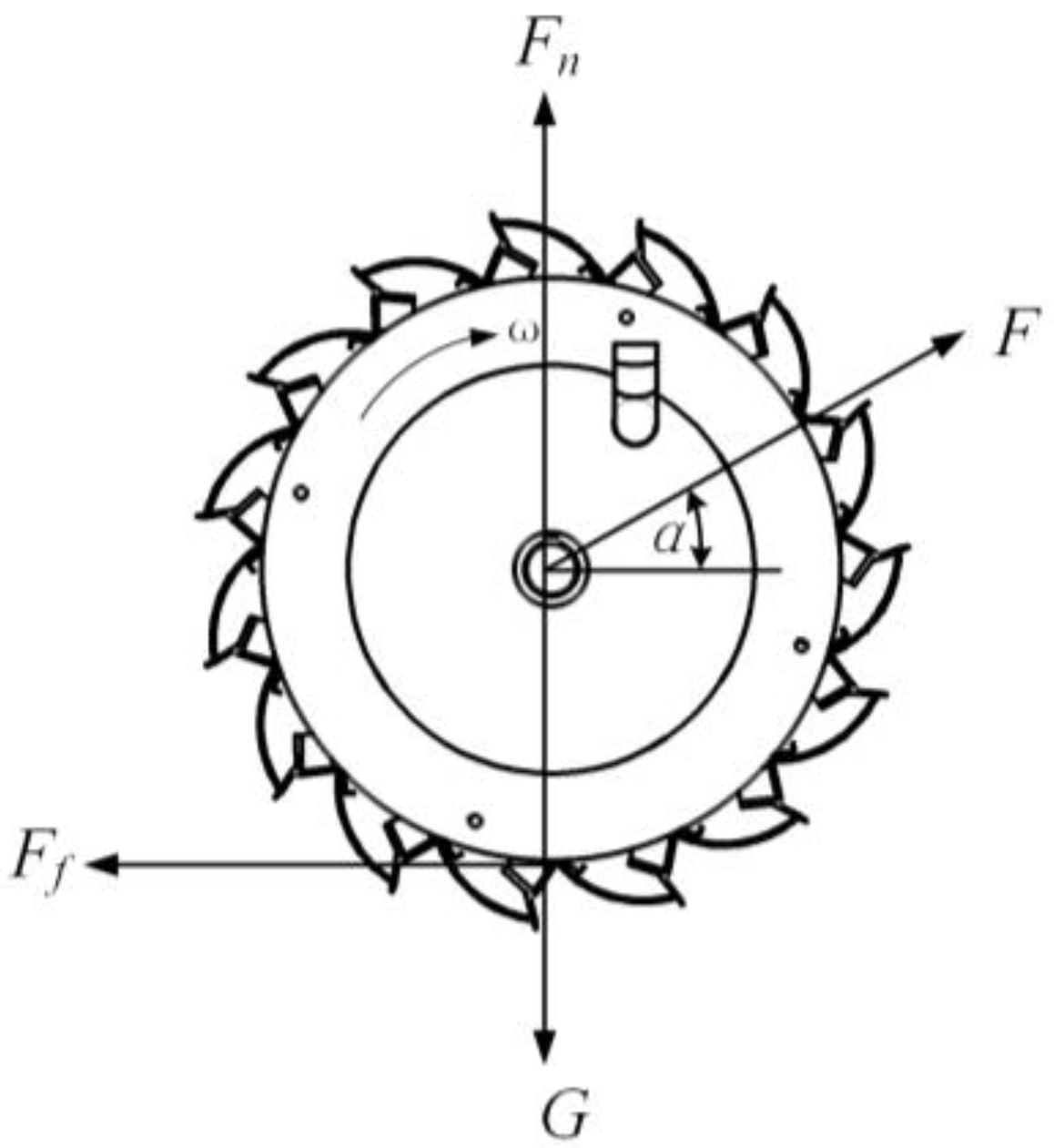

2.2.3. Dynamic Analysis of the Hole-Forming Device

3. Simulation Analysis of Hole-Forming of the Hole-Forming Device

3.1. Multi-Body Dynamics Modeling

3.2. Soil Discrete Element Modelling

3.3. Coupling Simulation

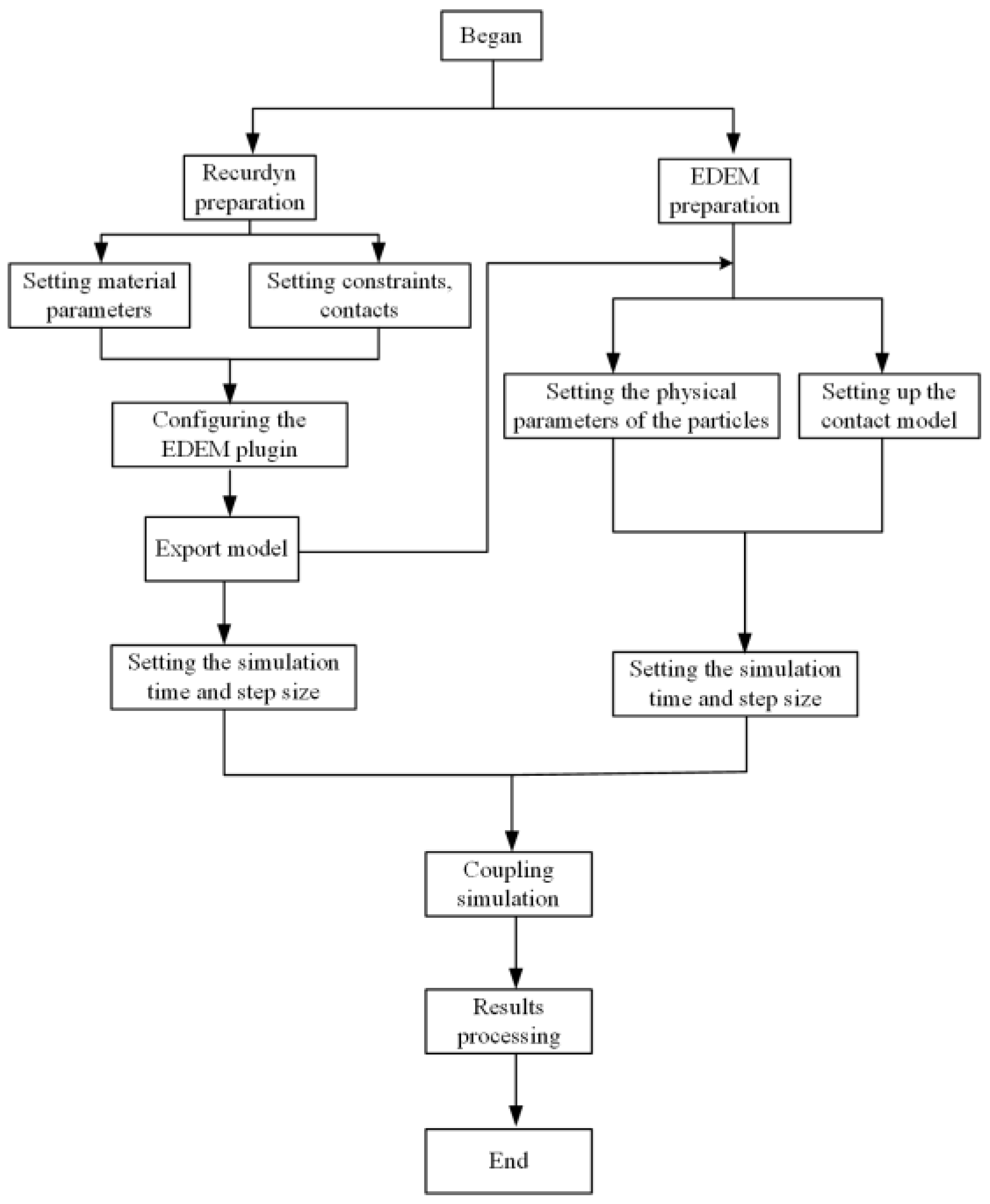

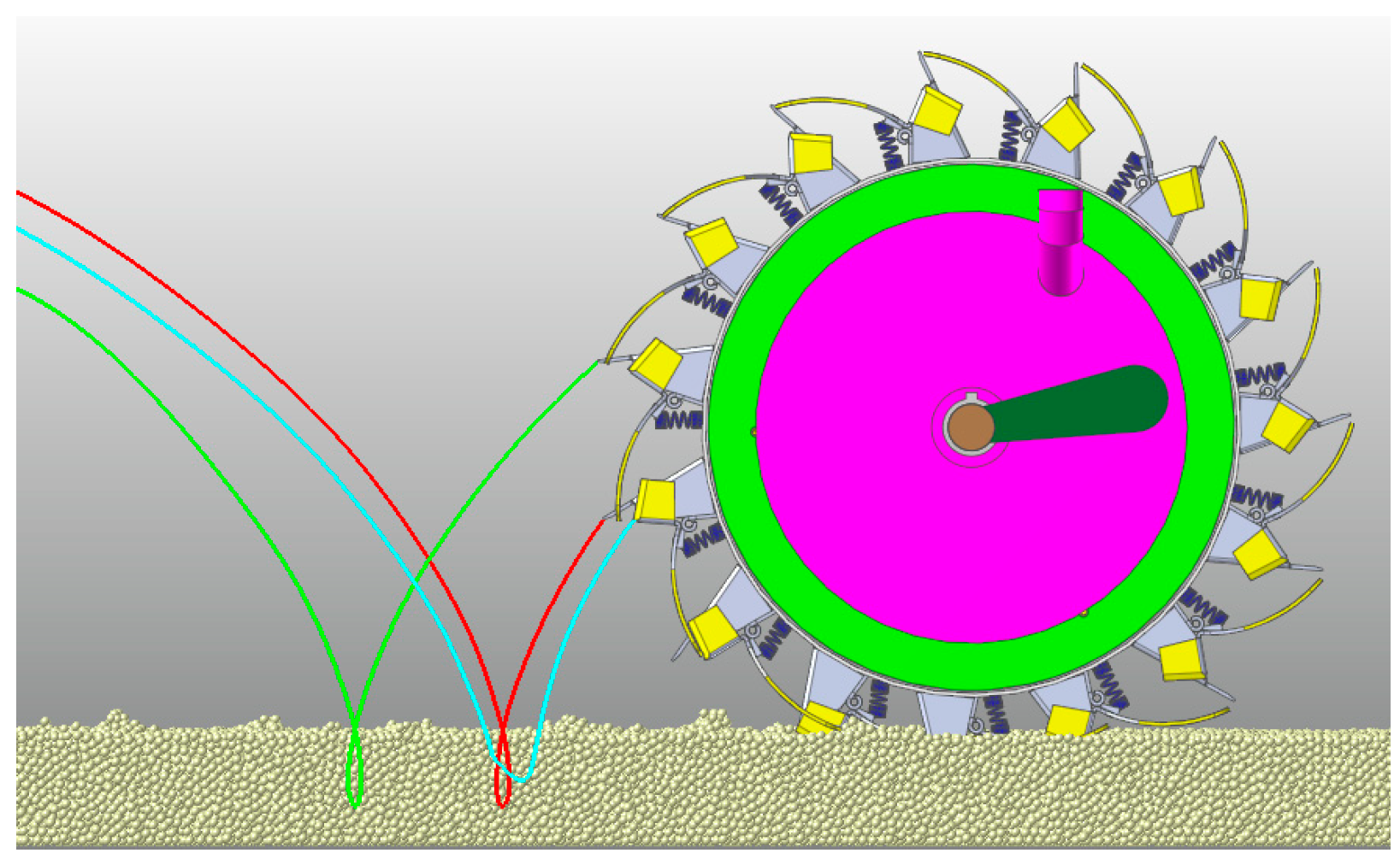

3.3.1. Coupling Simulation of a Single Duckbill

3.3.2. Integral Simulation of the Hole-Forming Device

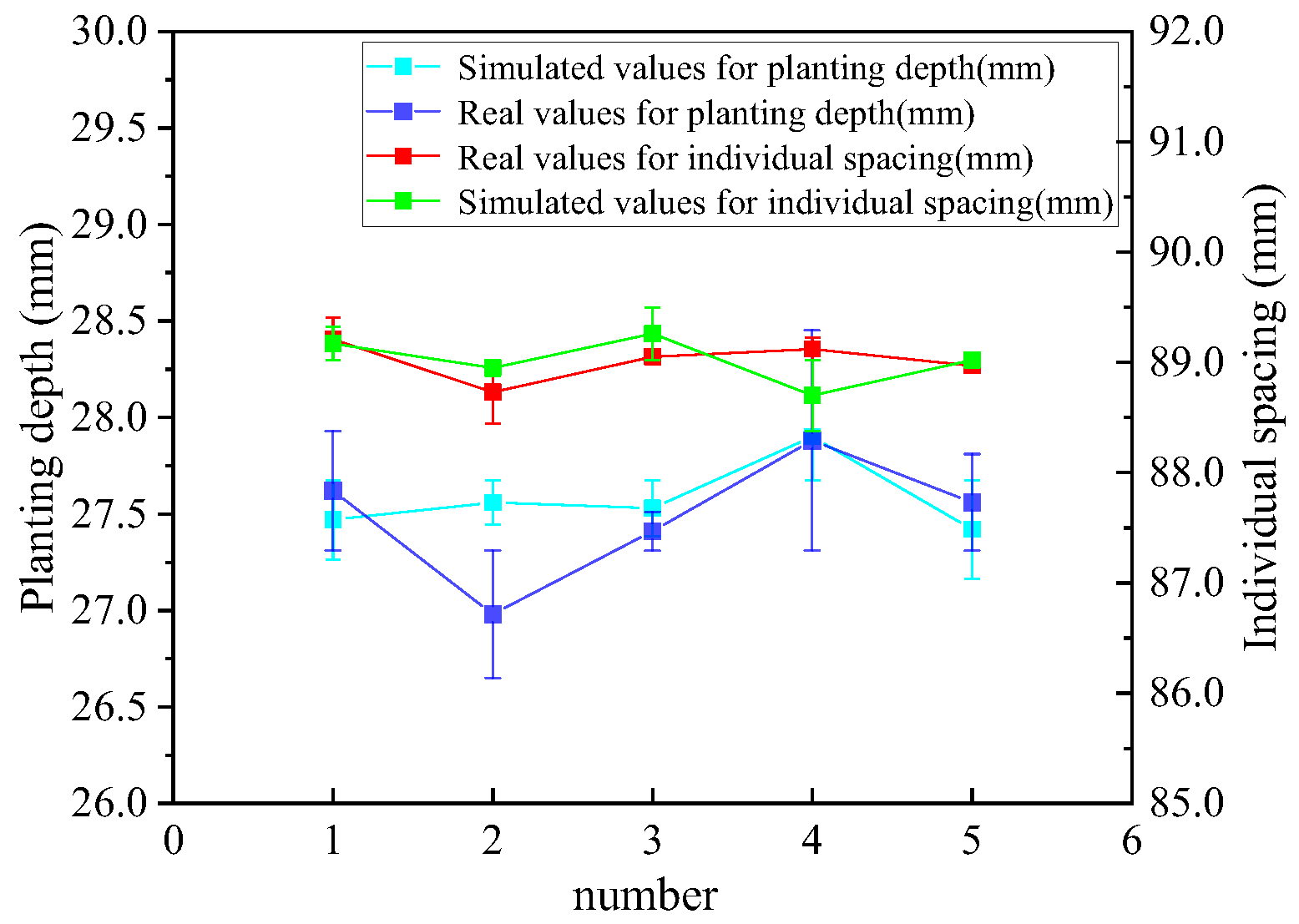

3.4. Model Validation

4. Analysis of Simulation Results

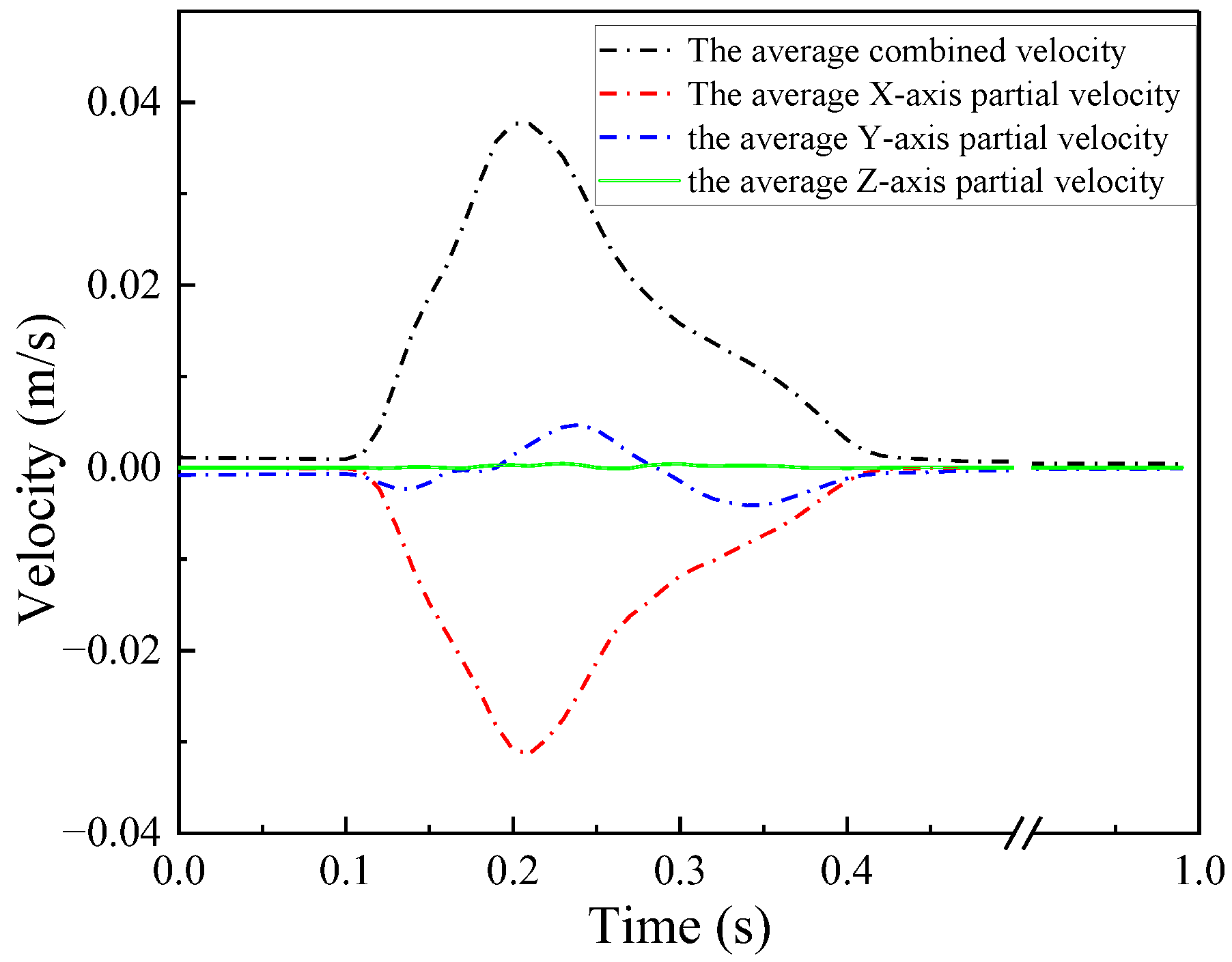

4.1. Soil Disturbance by a Single Duckbill

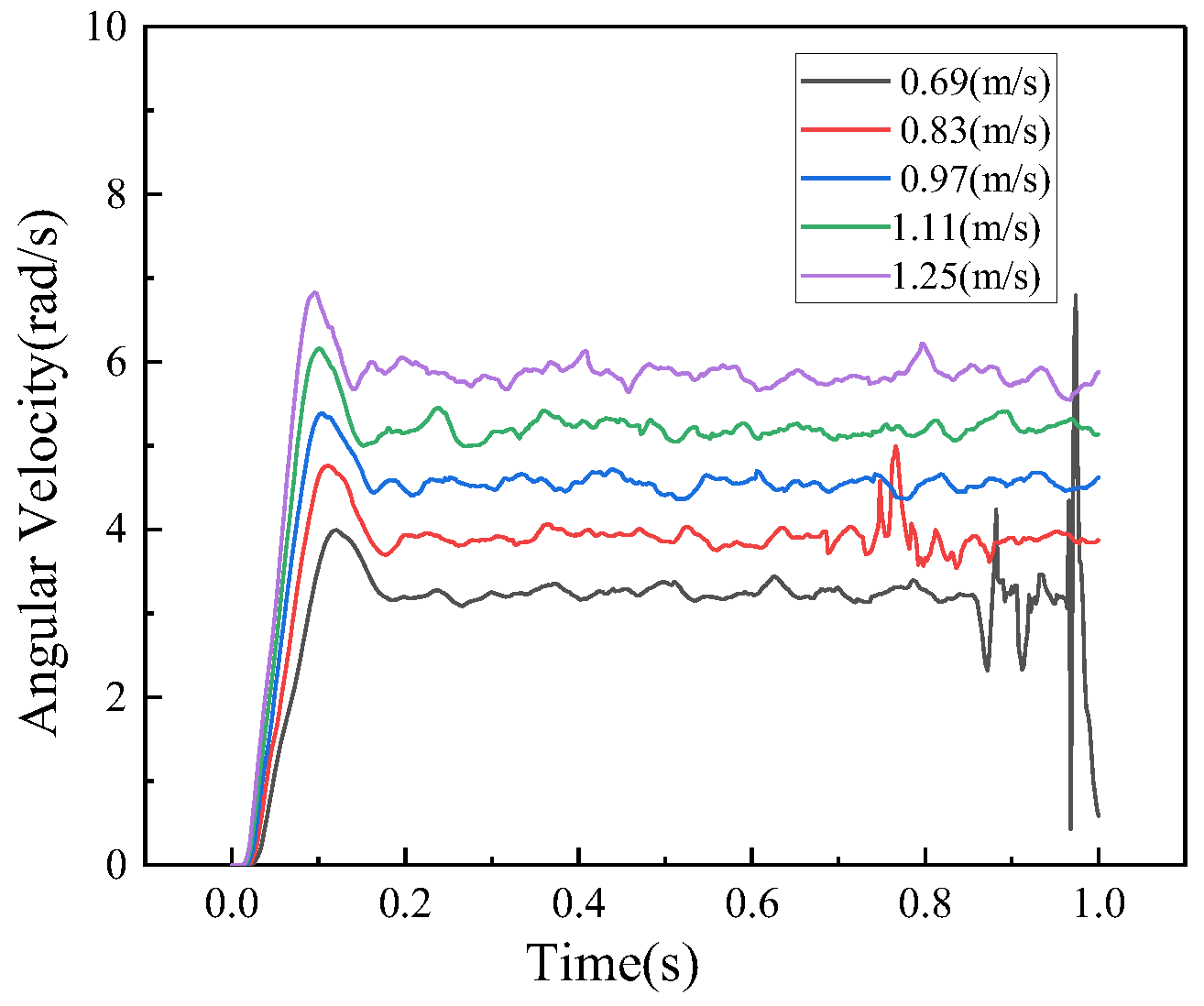

4.2. Effect of Parameters on Hole-Forming Trajectory

4.2.1. Effect of Forward Speed on Hole-Forming Trajectory

4.2.2. Effect of Traction Angle on Hole-Forming Trajectory

4.2.3. The Effect Mass of the Hole-Forming Device on Hole-Forming Trajectory

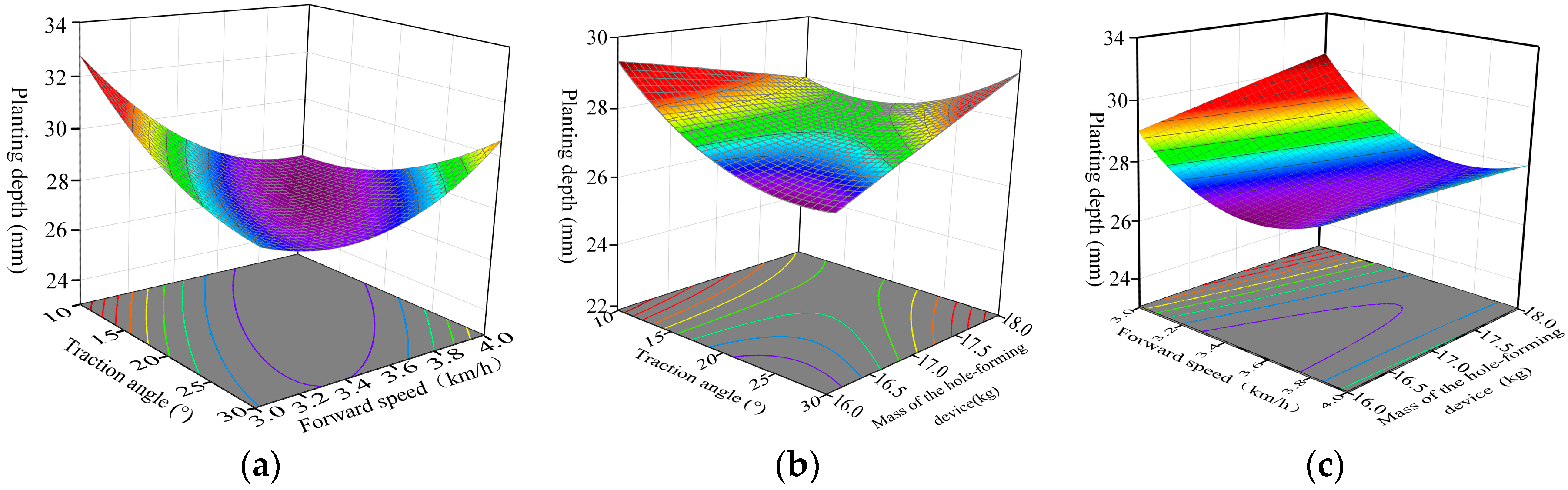

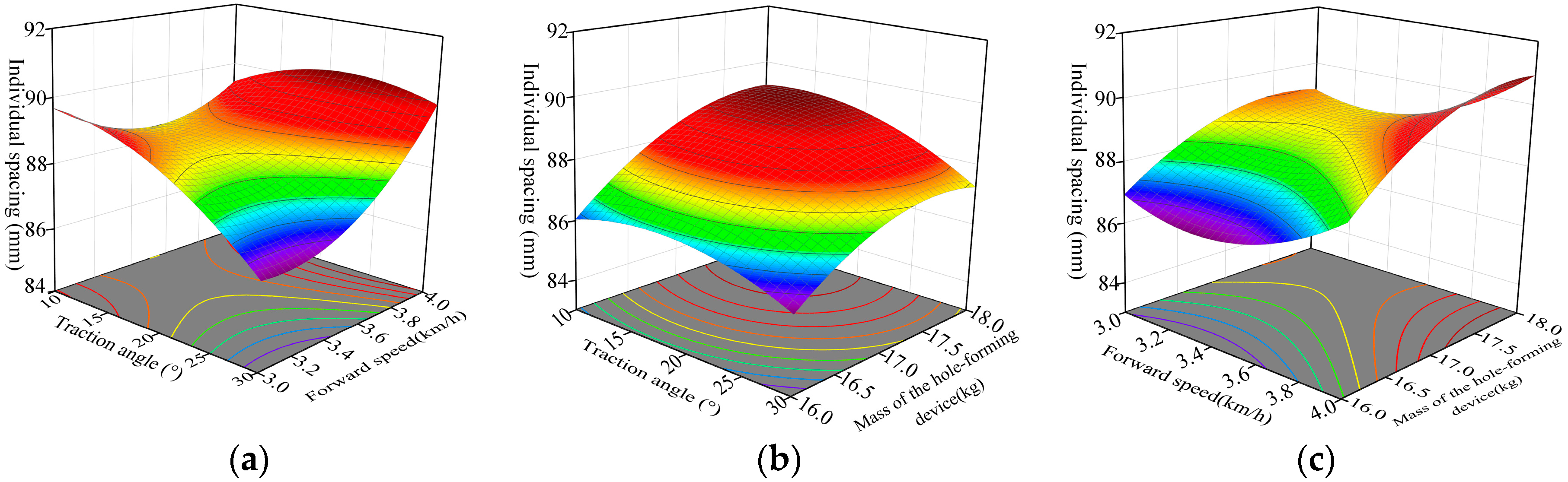

5. Simulation Optimization

5.1. Optimization Methods

5.2. Analysis of Test Results

5.3. Parameter Optimization

6. Conclusions

- Through the method of DEM-MBD coupled simulation, it is found that the disturbance of the soil in the process of hole formation by a duckbilled hole-forming device is mainly concentrated in the forward direction and vertical direction of the hole-former, and the hole is formed by squeezing and shearing the soil;

- The size of the forward speed of a duckbilled hole-forming device directly affects the hole-forming performance of the hole-forming device, and a forward speed that is too small or too large will result in too large a planting depth and individual spacing, which will not be able to meet the agronomic requirements;

- Through the optimization of the hole-formation performance parameters of the hole-forming device, it is obtained that the hole-formation performance of the hole-forming device is optimal when the traction angle is 17.3°, the forward speed is 1.11 m/s, and the mass of the hole-forming device is 17.9 kg.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, Y.W.; Bai, S.H.; Niu, K. Research progress in the key technologies and equipment for cotton planting mechanization. Trans. Chin. Soc. Agric. Eng. 2023, 39, 1–11. [Google Scholar]

- Zhao, L.W.; Jin, R.C.; Sun, R.; Cui, R.M.; Ba, Y.H. Application of Agricultural Information Technology in Cotton Cultivation. Agric. Eng. Technol. 2023, 43, 88–89. [Google Scholar]

- Tian, G.R. Cotton mechanical precision sowing technology application points and promotion countermeasures. China South. Agric. Mach. 2024, 55, 62–64. [Google Scholar]

- Wang, H.T.; Sun, W.; Zhang, H.; Liu, X.L.; Li, H.; Liu, K.Y. Development of Mechanized Planting Technology on Film. Agric. Equip. Veh. Eng. 2022, 60, 7–11. [Google Scholar]

- Yan, J.W.; Wei, S.; Zhang, F.G. Present Research Status and Development Trend of Over-Film Precision Seeding Equipment. Xinjiang Agric. Mech. 2021, 2, 15–19. [Google Scholar] [CrossRef]

- Liu, K.Y.; Sun, W.; Zhang, H.; Liu, X.L.; Li, H.; Wang, H.T.; Tian, B. General situation of development of mechanized soil covering technology on film. Agric. Equip. Veh. Eng. 2023, 61, 10–13. [Google Scholar]

- Quan, W.; Wu, M.L.; Luo, H.F.; Chen, C.P.; Xie, W. Soil hole opening methods and parameters optimization of pot seedling transplanting machine for rapeseed. Trans. Chin. Soc. Agric. Eng. 2020, 36, 13–21+327. [Google Scholar]

- Zhou, G.; Shi, L.R.; Zhao, W.Y.; Xin, S.L.; Yang, X.P. Design and simulation of precision seeder for flax indryland ridge with plastic-film. Agric. Res. Arid. Areas 2019, 37, 245–252. [Google Scholar]

- Hou, S.Y.; Ji, Z.C.; Xue, D.H.; Wang, X.; Feng, B.J.; Chen, H.T. Improved Design and Test of Straw Cleaning Device Suitable for No-tillage Seeding Unit. Trans. Chin. Soc. Agric. Mach. 2023, 54, 111–122. [Google Scholar]

- Hou, S.Y.; Wang, S.Z.; Zhu, X.X.; Zhang, J.C.; Ji, W.W.; Chen, H.T. Design and Experiment of Side-open Sliding Cutting Film Broken Seeding Unit Based on Straw Fiber Film. Trans. Chin. Soc. Agric. Mach. 2021, 52, 155–165. [Google Scholar]

- Liao, Q.X.; Pei, L.M.; Zhang, Q.S.; Wang, L.; Luo, Z.C.; Fu, M.L. Design and Experiment of Rolling Film Cutting and Hole Punching Device for Rapeseed Seeder with Film Mulching and Perforating. Trans. Chin. Soc. Agric. Mach. 2023, 54, 85–98. [Google Scholar]

- Bao, Q.Y. Development of a New Bionic Subsoiler Based on DEM. Master’s Thesis, Shandong Agricultural University, Taian, China, 2018. [Google Scholar]

- Kim, Y.-S.; Lee, S.-D.; Baek, S.-Y.; Jeon, H.-H.; Lee, J.-H.; Siddique, A.A.; Kim, Y.-J.; Kim, W.-S.; Sim, T.; Yi, S.; et al. Development of DEM-MBD coupling model for draft force prediction of agricultural tractor with plowing depth. Comput. Electron. Agric. 2022, 202, 107405. [Google Scholar] [CrossRef]

- Hasimu, A.; Chen, Y. Soil disturbance and draft force of selected seed openers. Soil Tillage Res. 2014, 140, 48–54. [Google Scholar] [CrossRef]

- Zhao, H.; Li, H.; Ma, S.; He, J.; Wang, Q.; Lu, C.; Zheng, Z.; Zhang, C. The effect of various edge-curve types of plain-straight blades for strip tillage seeding on torque and soil disturbance using DEM. Soil Tillage Res. 2020, 202, 104674. [Google Scholar] [CrossRef]

- Li, J.W.; Li, X.Y.; Hu, B.; Gu, T.L.; Wang, Z.J.; Wang, H.L. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Chen, X.G.; Zhao, Y. Development of double-film mulch precision planter for cotton seeding. Trans. Chin. Soc. Agric. Eng. 2010, 26, 106–112. [Google Scholar]

- Chen, X.G.; Wang, M. Study on Key Factors of the Duckbill Punch Roller-type Pneumatic Metering Device. J. Agric. Mech. Res. 2011, 33, 130–133+137. [Google Scholar]

- Huang, Y.H.; Quan, L.Z.; Hu, G.F.; Quan, W.; Shi, F.G. Calibration of Discrete Element Contact Parameters for Various Materials and Soils with Different Moisture Content. J. Agric. Sci. Technol. 2024, 26, 98–109. [Google Scholar]

- Wang, X.; Zhang, S.; Pan, H.; Zheng, Z.; Huang, Y.; Zhu, R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosyst. Eng. 2019, 182, 138–150. [Google Scholar] [CrossRef]

- Zhou, H.B.; Chen, Y.; Mohammad, A.S. Modelling of soil–seed contact using the Discrete Element Method (DEM). Biosyst. Eng. 2014, 121, 56–66. [Google Scholar] [CrossRef]

- Jia, C.P. A DEM-Based Study on the Mechanism of Cup-Soil Interaction in a High-Speed Transplanting Machine for Cavity Tray Seedlings. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

- Wa, L.P.C.; Li, Y.L.; Su, C.; Zhao, H.; Dong, X.Q.; Song, J.N.; Wang, J.C. Simulation of soil tillage characteristics and influence analysis of particle sphere type based on EEPA contact model. J. China Agric. Univ. 2021, 26, 193–206. [Google Scholar]

- Han, W.; Wang, S.Z.; Zhang, Q.; Tian, Y.H. Discrete element parameter calibration of micron sized powder particles based on JKR contact modlel. China Powder Sci. Technol. 2021, 27, 60–69. [Google Scholar]

- Wang, W.D.; Liu, X.W. Soil-water characteristic curves based on the non-contact case of three particles of unequa size. J. Nanchang Univ. (Eng. Technol.) 2023, 45, 38–43+58. [Google Scholar]

- Hang, C.; Gao, X.; Yuan, M.; Huang, Y.; Zhu, R. Discrete element simulations and experiments of soil disturbance as affected by the tine spacing of subsoiler. Biosyst. Eng. 2018, 168, 73–82. [Google Scholar] [CrossRef]

- Wu, P.; Zhang, X.; Zeng, Z.; Chen, Y. DEM simulation of subsoiling for soil disturbance as affected by soil layering and working speed. Smart Agric. Technol. 2024, 7, 100385. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Ma, Y.; Tong, J.; Zhang, Z. DEM simulation of bionic subsoilers (tillage depth > 40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Ni, X.D.; Xu, G.J.; Wang, Q.; Peng, X.R.; Wang, J.; Hu, B. Design and Experiment of Pneumatic Cylinder Array Precision Seed-metering Device for Cotton. Trans. Chin. Soc. Agric. Mach. 2017, 48, 58–67. [Google Scholar]

- Lu, B.; Ni, X.; Li, S.; Li, K.; Qi, Q. Simulation and Experimental Study of a Split High-Speed Precision Seeding System. Agriculture 2022, 12, 1037. [Google Scholar] [CrossRef]

| Serial Number | Unit | Kinematic Pair |

|---|---|---|

| 1 | Ground, coupling shaft | Translate |

| 2 | End cap assembly, coupling shaft | Fixed |

| 3 | Dividing grid combination, coupling shaft | Revolute |

| 4 | Moving duckbill combination, dividing grid combination | Revolute |

| 5 | Moving duckbill combination, dividing grid combination | Spring |

| Parameter | Value |

|---|---|

| Soil particle density/(kg·m−3) | 1569 |

| Density of steel/(kg·m−3) | 7801 |

| Soil particle radius/mm | 3 |

| Soil Poisson’s ratio | 0.36 |

| Steel Poisson’s ratio | 0.29 |

| Shear modulus of soil/MPa | 1 × 106 |

| Shear modulus of steer/MPa | 8.02 × 1010 |

| Restitution coefficient between soil particles | 0.4 |

| Restitution coefficient of soil and steel | 0.5 |

| Static friction coefficient between soil particles | 0.49 |

| Static friction coefficient between soil and steel | 0.46 |

| Dynamic friction coefficient between soil particles | 0.29 |

| Dynamic friction coefficient between soil and steel | 0.15 |

| Normal contact stiffness coefficient between soil–soil particles/(N/m3) | 1.9 × 105 |

| Tangential contact stiffness coefficient between soil–soil particles/(N/m3) | 1.4 × 105 |

| Critical normal stress between soil and soil particles/Pa | 55,000 |

| Critical tangential stress between soil and soil particles/Pa | 55,000 |

| Bonding radius/mm | 3.5 |

| Number | Simulated Values for Planting Depth | Real Values of Planting Depth | Simulated Values for Individual Spacing | Real Values of Individual Spacing |

|---|---|---|---|---|

| 1 | 27.47 | 27.62 | 89.17 | 89.21 |

| 2 | 27.56 | 26.98 | 88.95 | 88.73 |

| 3 | 27.53 | 27.41 | 89.26 | 89.05 |

| 4 | 27.9 | 27.88 | 88.70 | 89.12 |

| 5 | 27.42 | 27.56 | 89.02 | 88.97 |

| Forward Speed (m/s) | Planting Depth (mm) | Individual Spacing (mm) |

|---|---|---|

| 0.69 | 30.67 | 92.43 |

| 0.83 | 26.78 | 89.73 |

| 0.97 | 29.08 | 89.48 |

| 1.11 | 29.19 | 89.91 |

| 1.25 | 29.32 | 91.01 |

| Traction Angle (°) | Planting Depth (mm) | Individual Spacing (mm) |

|---|---|---|

| 0 | 29.78 | 88.78 |

| 10 | 29.46 | 89.59 |

| 20 | 26.71 | 89.41 |

| 30 | 26.68 | 89.36 |

| 40 | 26.50 | 89.50 |

| Mass of the Hole-Forming Device (kg) | Planting Depth (mm) | Individual Spacing (mm) |

|---|---|---|

| 15 | 27.50 | 89.31 |

| 16 | 28.12 | 89.44 |

| 17 | 28.27 | 90.03 |

| 18 | 28.73 | 89.70 |

| 19 | 29.18 | 89.18 |

| Coding | Experimental Factors | ||

|---|---|---|---|

| Traction Angle X1/(°) | Forward Speed X2/(m/s) | Mass of the Hole-Forming Device X3/(kg) | |

| −1.682 | 3.2 | 0.75 | 15.3 |

| −1 | 10 | 0.83 | 16 |

| 0 | 20 | 0.97 | 17 |

| 1 | 30 | 1.11 | 18 |

| 1.682 | 36.8 | 1.19 | 18.7 |

| Test Serial Number | Experimental Factors | Evaluating Indicator | |||

|---|---|---|---|---|---|

| X1 | X2 | X3 | Planting Depth Y1/% | Individual Spacing Y2/% | |

| 1 | −1 | −1 | −1 | 32.96 | 87.3 |

| 2 | 1 | −1 | −1 | 26.72 | 85.1 |

| 3 | −1 | 1 | −1 | 29.14 | 87.1 |

| 4 | 1 | 1 | −1 | 29.62 | 88.1 |

| 5 | −1 | −1 | 1 | 32.85 | 90.3 |

| 6 | 1 | −1 | 1 | 29.9 | 86.3 |

| 7 | −1 | 1 | 1 | 26.68 | 90.3 |

| 8 | 1 | 1 | 1 | 31.7 | 90.5 |

| 9 | −1.682 | 0 | 0 | 29.96 | 87.5 |

| 10 | 1.682 | 0 | 0 | 29.68 | 85.3 |

| 11 | 0 | −1.682 | 0 | 33.17 | 90.4 |

| 12 | 0 | 1.682 | 0 | 29.9 | 92.5 |

| 13 | 0 | 0 | −1.682 | 26.8 | 83.9 |

| 14 | 0 | 0 | 1.682 | 27.8 | 88.1 |

| 15 | 0 | 0 | 0 | 27.7 | 88.7 |

| 16 | 0 | 0 | 0 | 27.51 | 88.65 |

| 17 | 0 | 0 | 0 | 26.94 | 88.32 |

| 18 | 0 | 0 | 0 | 28.22 | 88.31 |

| 19 | 0 | 0 | 0 | 27.65 | 88.54 |

| 20 | 0 | 0 | 0 | 26.94 | 88.34 |

| 21 | 0 | 0 | 0 | 26.97 | 88.15 |

| 22 | 0 | 0 | 0 | 27.7 | 88.47 |

| 23 | 0 | 0 | 0 | 27.89 | 89.4 |

| Source | Planting Depth | Individual Spacing | ||||||

|---|---|---|---|---|---|---|---|---|

| df | Mean Square | F-Value | p-Value | df | Mean Square | F-Value | p-Value | |

| Model | 9 | 10.46 | 46.74 | 0.0001 ** | 9 | 8.96 | 74.86 | 0.0001 ** |

| X1 | 1 | 1.27 | 5.67 | 0.0333 * | 1 | 5.54 | 46.32 | 0.0001 ** |

| X2 | 1 | 8.52 | 38.10 | 0.0001 ** | 1 | 8.12 | 67.87 | 0.0001 ** |

| X3 | 1 | 1.40 | 6.25 | 0.0265 * | 1 | 20.82 | 174.02 | 0.0001 ** |

| X1X2 | 1 | 26.97 | 120.56 | 0.0001 ** | 1 | 6.85 | 57.20 | 0.0001 ** |

| X1X3 | 1 | 7.66 | 34.25 | 0.0001 ** | 1 | 0.8450 | 7.06 | 0.0197 * |

| X2X3 | 1 | 1.49 | 6.65 | 0.0229 * | 1 | 0.2450 | 2.05 | 0.1761 |

| X12 | 1 | 12.18 | 54.43 | 0.0001 ** | 1 | 8.09 | 67.63 | 0.0001 ** |

| X22 | 1 | 34.89 | 155.94 | 0.0001 ** | 1 | 18.25 | 152.54 | 0.0001 ** |

| X32 | 1 | 0.0038 | 0.0170 | 0.8984 | 1 | 11.62 | 97.09 | 0.0001 ** |

| Residual | 13 | 0.2238 | 13 | 0.1197 | ||||

| Lack of Fit | 5 | 0.2455 | 1.17 | 0.4014 | 5 | 0.0960 | 0.7141 | 0.6303 |

| Pure Error | 8 | 0.2101 | 8 | 0.1344 | ||||

| Cor Total | 22 | 22 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Ni, X.; Cai, W.; Li, K. The Simulation and Parameter Optimization of the Hole-Forming Process of a Duckbilled Hole-Forming Device. Agriculture 2024, 14, 843. https://doi.org/10.3390/agriculture14060843

Zhao B, Ni X, Cai W, Li K. The Simulation and Parameter Optimization of the Hole-Forming Process of a Duckbilled Hole-Forming Device. Agriculture. 2024; 14(6):843. https://doi.org/10.3390/agriculture14060843

Chicago/Turabian StyleZhao, Binqiang, Xiangdong Ni, Wenqing Cai, and Kezhi Li. 2024. "The Simulation and Parameter Optimization of the Hole-Forming Process of a Duckbilled Hole-Forming Device" Agriculture 14, no. 6: 843. https://doi.org/10.3390/agriculture14060843

APA StyleZhao, B., Ni, X., Cai, W., & Li, K. (2024). The Simulation and Parameter Optimization of the Hole-Forming Process of a Duckbilled Hole-Forming Device. Agriculture, 14(6), 843. https://doi.org/10.3390/agriculture14060843