Design and Discrete-Element-Method Simulation of Helix Hole-Forming Machine for Deep Planting with Large Holes

Abstract

1. Introduction

2. Materials and Methods

2.1. DPLH Technique

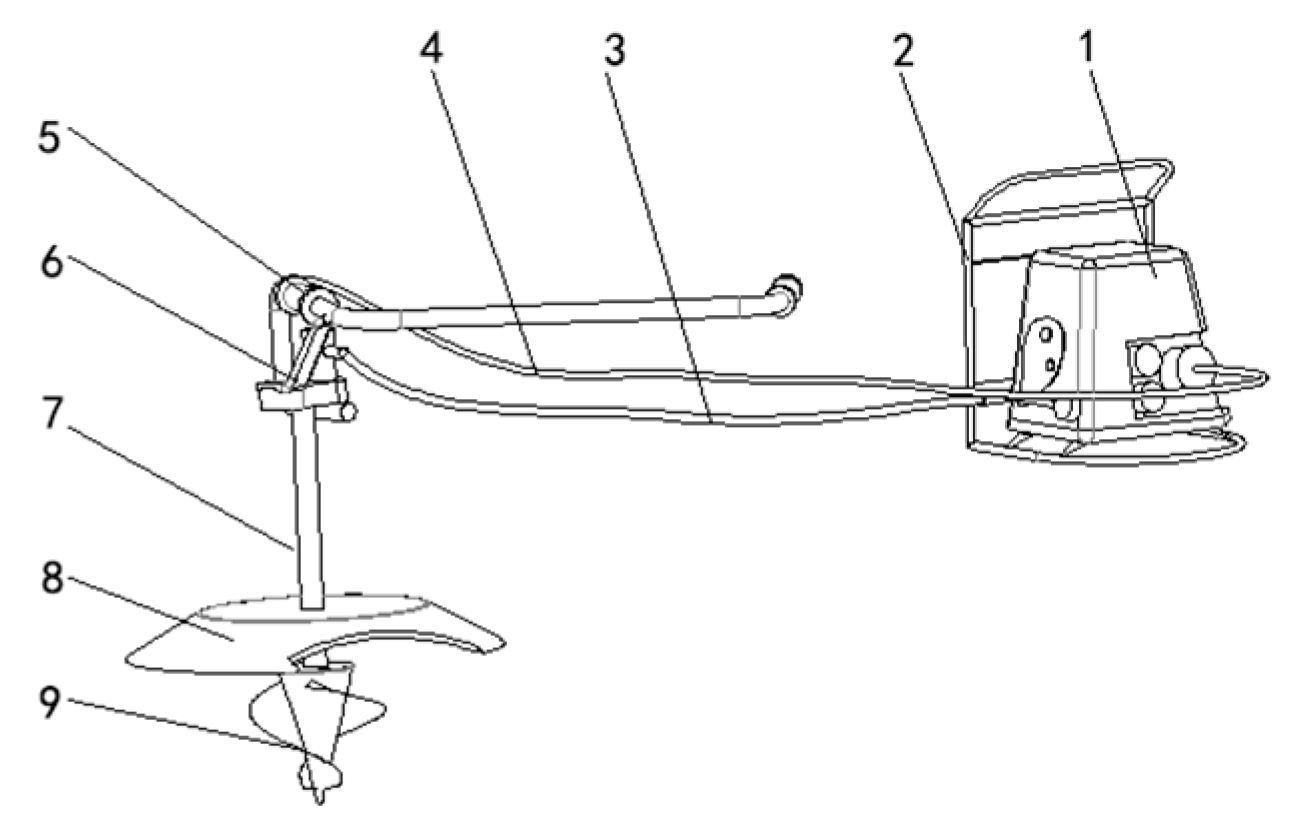

2.2. Design of the Hole-Forming Machine for DPLH

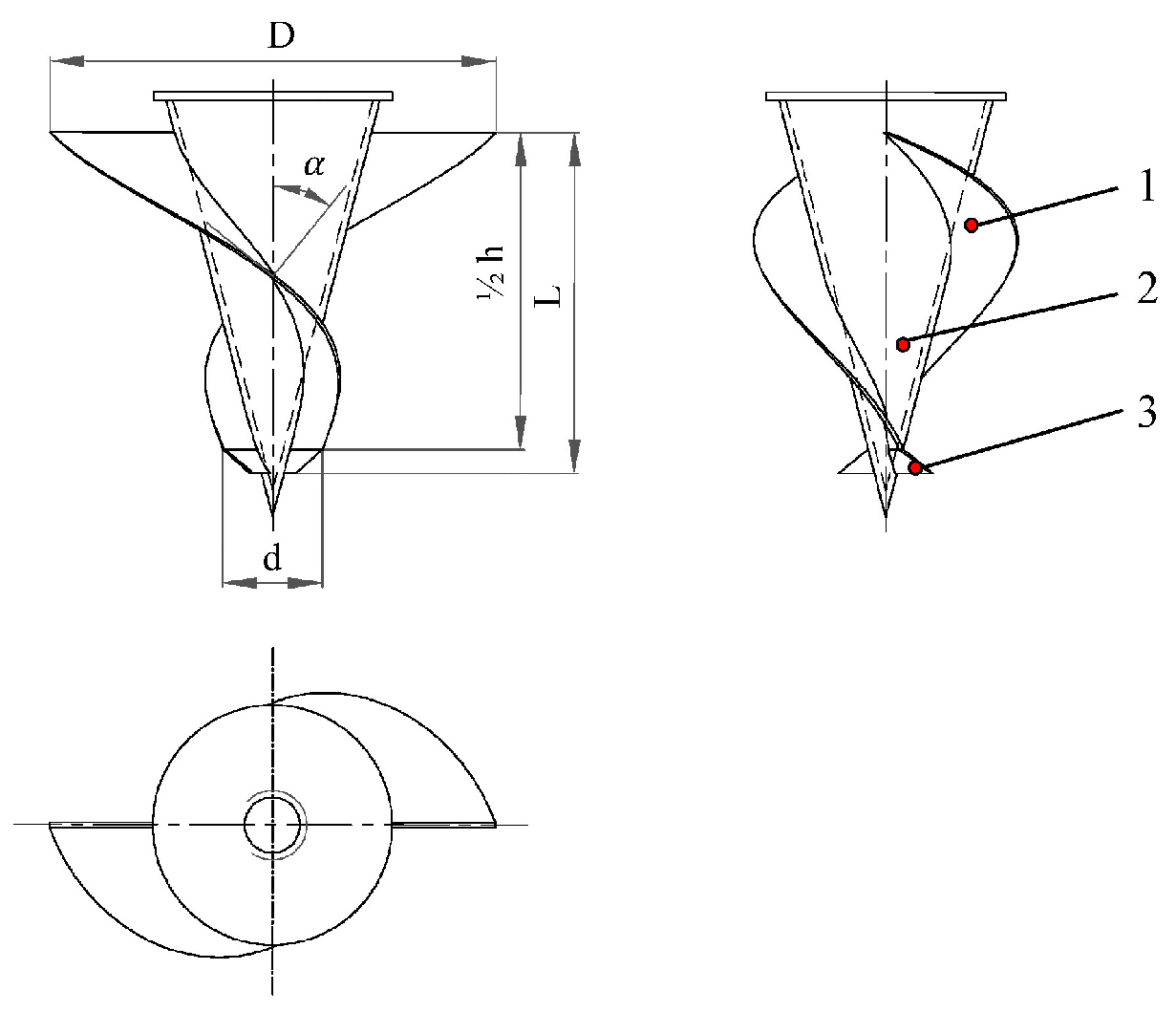

2.2.1. Design of the Spiral Hole Former

- (1)

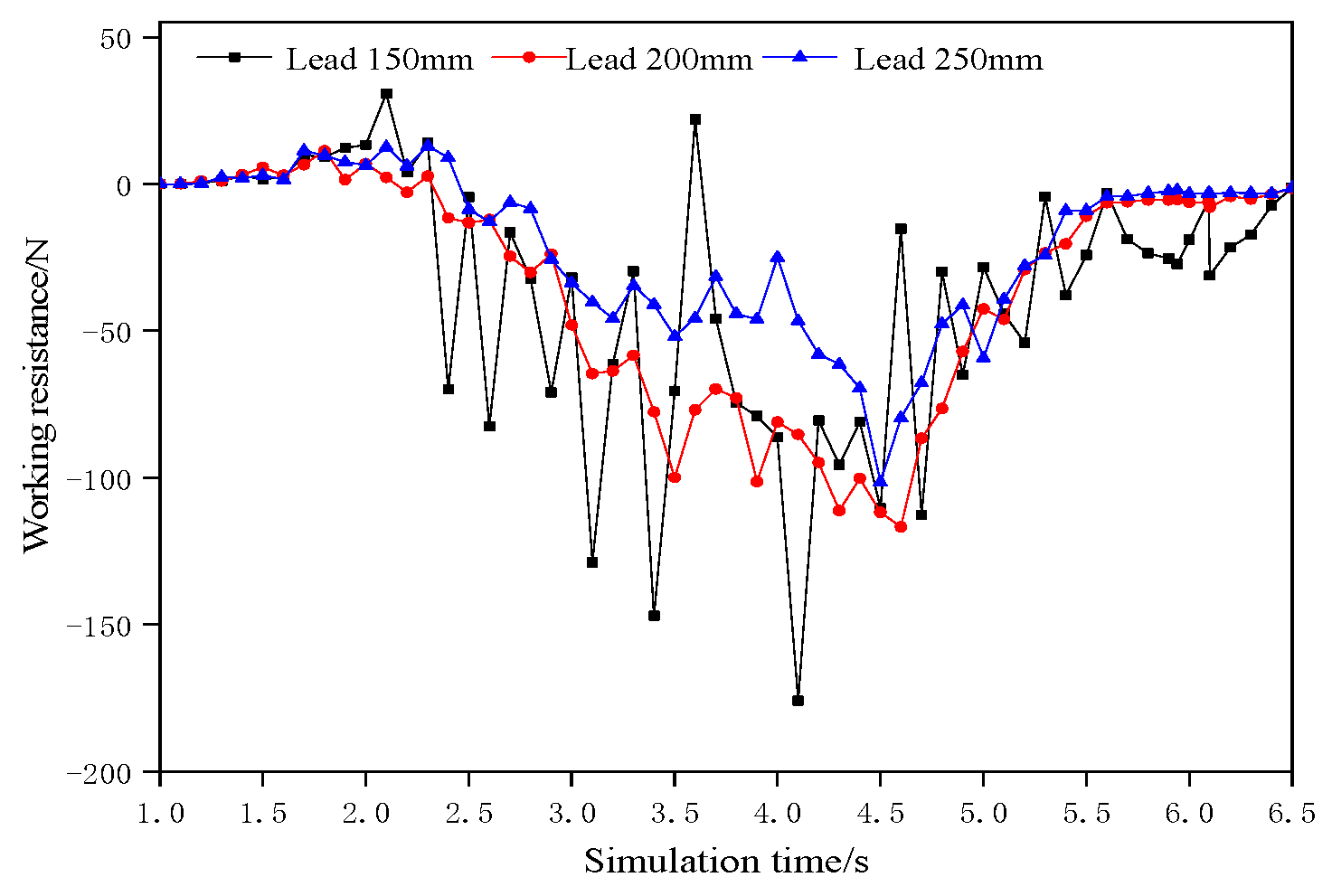

- Determination of helix angle and lead

- (2)

- Determination of feed

- (3)

- Primary selection of critical speed of hole former

- (4)

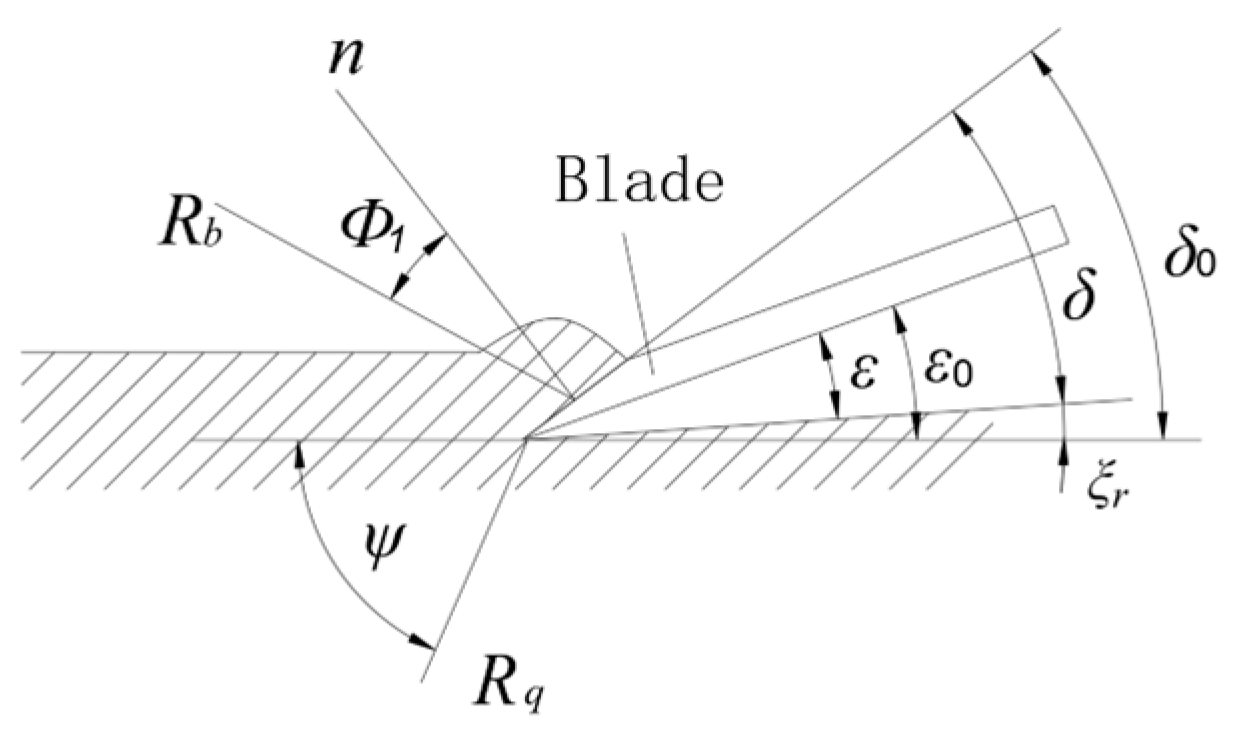

- Determination of soil cutting front angle and back angle of the blade

2.2.2. Three-Dimensional Model of the Spiral Hole Formers

2.2.3. Calculation of Engine Total Power

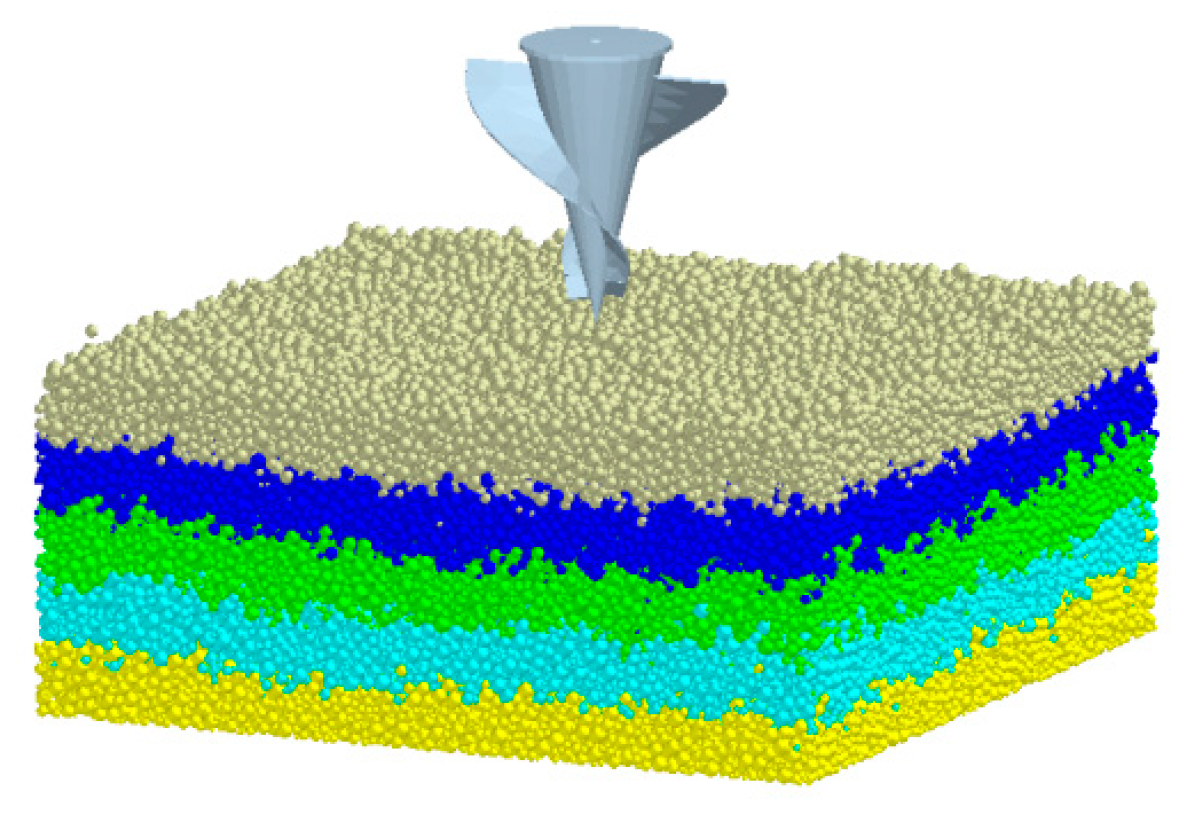

2.3. DEM Simulation

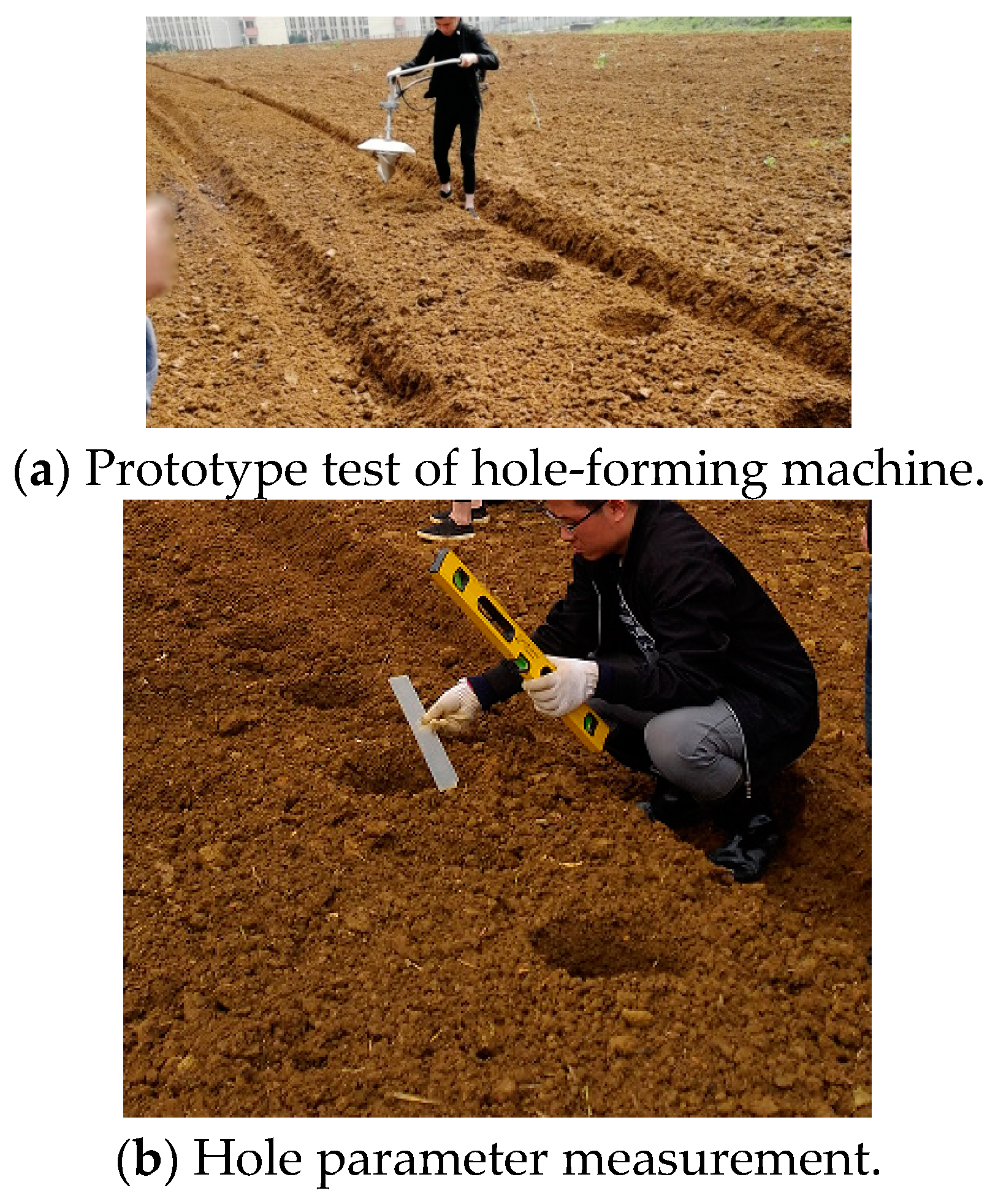

2.4. Field Test

3. Results and Discussion

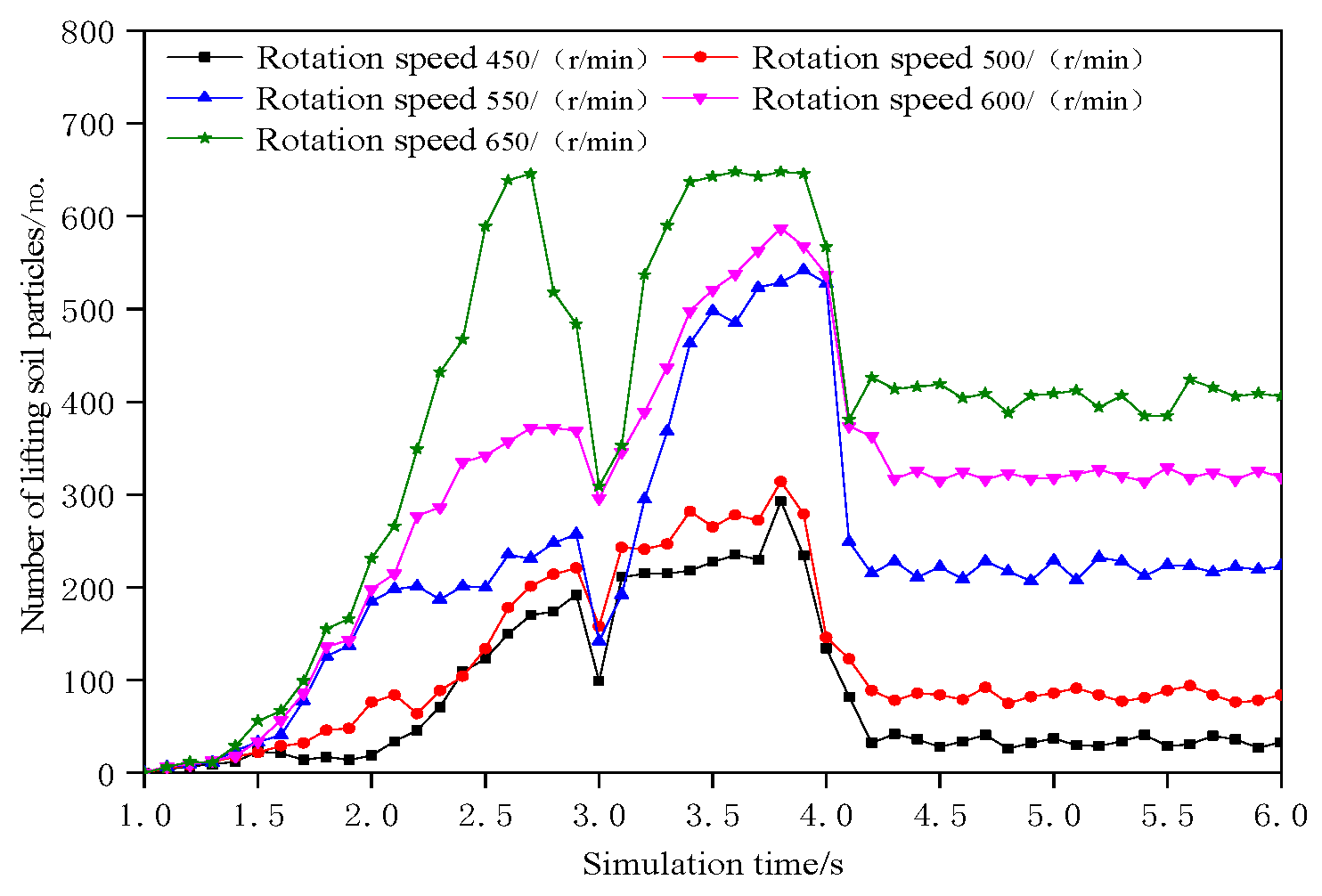

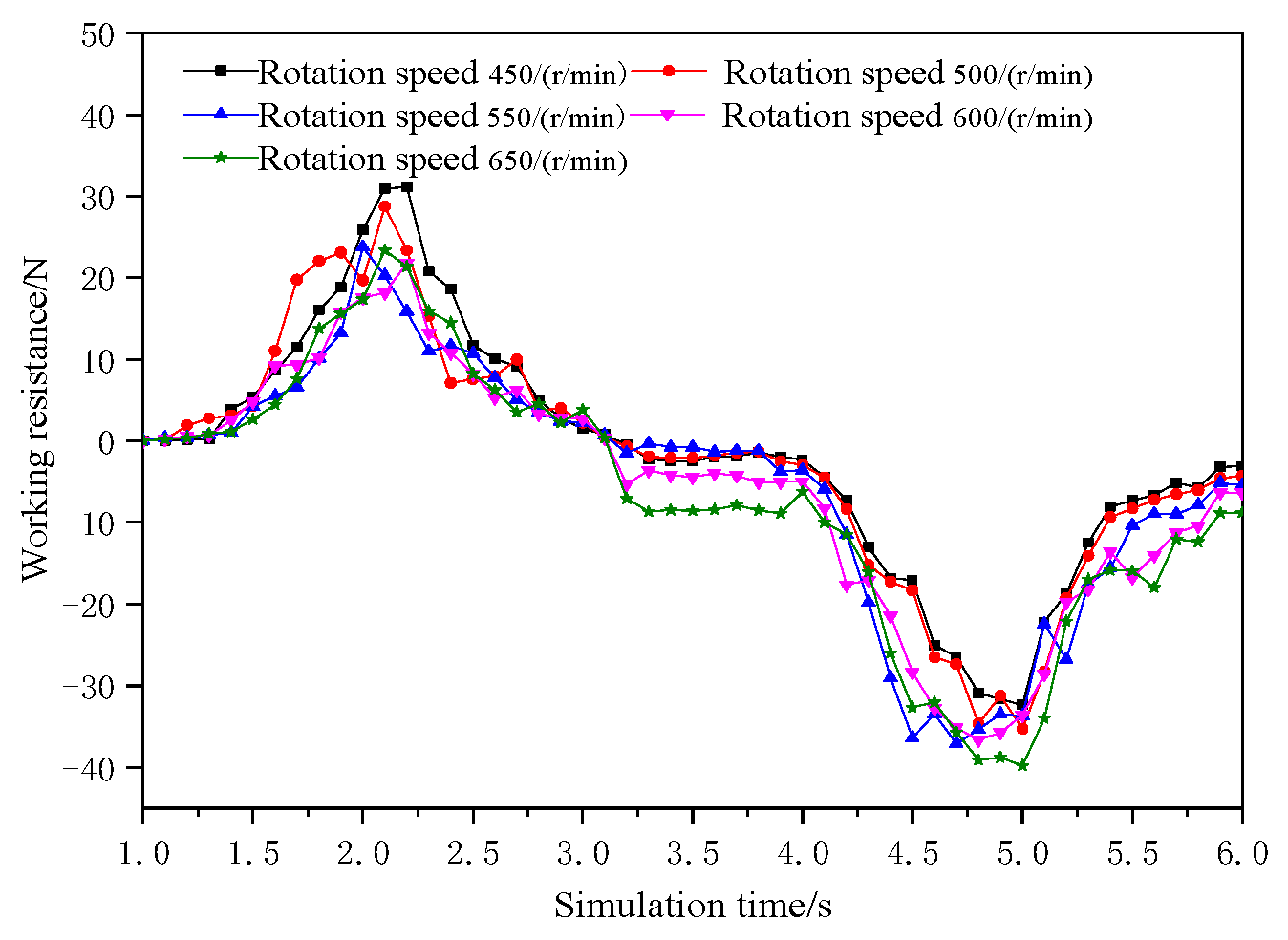

3.1. Parameter Optimization Based on DEM

3.2. Analysis of Hole-Forming Mechanism

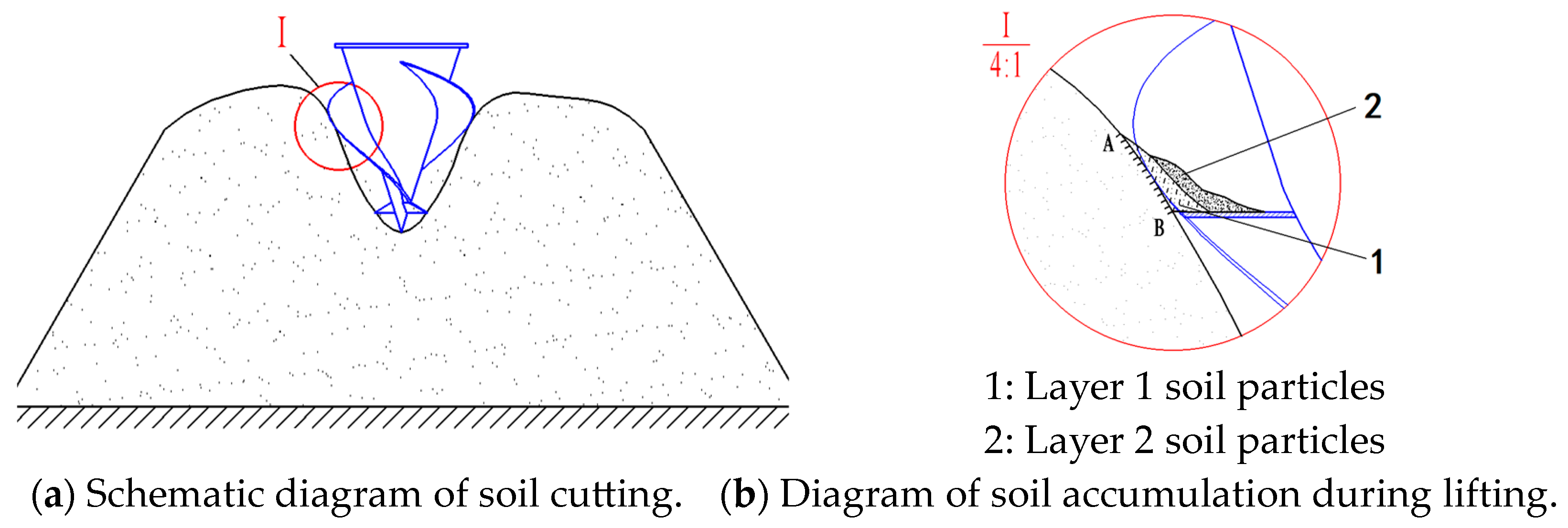

3.2.1. Theoretical Analysis of Hole-Forming Mechanism

3.2.2. DEM Analysis of Hole-Forming Mechanism

3.3. Analysis of Field Test Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, D.; Gong, Y.; Zhu, Y.; Yao, K.; Chen, X.; Wang, G.; Zhang, X. Design and experiment of key part of 2ZXS-2 cantaloupe transplanter. INMATEH Agric. Eng. 2022, 68, 367–372. [Google Scholar] [CrossRef]

- Liang, B. Study on the Quality Characteristics, Influencing Factors and Upgrading Techniques of Honghe Tobacco Leaves. Ph.D. Thesis, Huazhong Agricultural University, Wuhan, China, 2018. [Google Scholar]

- Liu, G. Analysis and Experiment on the Cavitation of Dry and Wet Soil Environments. Ph.D. Thesis, Guizhou University, Guiyang, China, 2018. [Google Scholar]

- Liu, J.; Yuan, G.; Yang, Y. Development of multifunctional compound soil preparation machine for rotary tillage, ridging and pond. For. Mach. Woodwork. Equip. 2017, 45, 34–36. [Google Scholar]

- Yan, F.; Hu, X.; Li, J.; Li, W.; Lu, Y.; Tang, B.; Long, W.; Zhao, L.; Wang, J.; Wang, Y. Design of small stepping electric pond-beating transplanter. Anhui Agric. Sci. Bull. 2017, 23, 140–142+146. [Google Scholar]

- Xiang, W.; Wu, M.; Lyu, J.; Ma, L.; Quan, W.; Liu, J. Design and testing of transplanting hole-forming machine for potted rapeseed seedlings. In Proceedings of the 2019 11th International Conference on Measuring Technology and Mechatronics Automation, ICMTMA 2019, Qiqihar, China, 28–29 April 2019; pp. 49–56. [Google Scholar]

- Xiang, W.; Wu, M.; Guan, C.; He, Y. Design and test of transplanting hole-forming machine for rapeseed potted seedlings. Trans. Chin. Soc. Agric. Mach. 2017, 48, 40–48. [Google Scholar]

- Jiang, K. Study on the theory of soil-lifting by the drill bit of the digger—Discussion on the critical speed of the drill bit. J. Cent. South Univ. For. Technol. 1997, 3, 71–75. [Google Scholar]

- Quan, W.; Wu, M.; Guan, C.; Luo, H. Experimental study on the shape optimization of the hole-forming device of rape pot seedling transplanter. J. Agric. Sci. Technol. 2021, 23, 97–106. [Google Scholar]

- Xiang, W.; Wu, M.; Lu, J.; Ma, L.; Quan, W.; Liu, J.; Xiao, L. Simulation and experimental study on the working performance of rape transplanting hole-forming device based on DEM. J. Agric. Sci. Technol. 2019, 21, 70–81. [Google Scholar]

- Quan, W.; Wu, M.; Luo, H.; Chen, C.; Xie, W. Hole-forming operation mode and parameter optimization of rape pot seedling transplanter. Trans. Chin. Soc. Agric. Eng. 2020, 36, 13–21+327. [Google Scholar]

- Han, C.; Xu, Y.; You, J.; Zhang, J.; Yuan, P. Parameter optimization of the hole-forming machine of semi-automatic compressed matrix watermelon pot seedling transplanter. Trans. Chin. Soc. Agric. Eng. 2019, 35, 48–56. [Google Scholar]

- Huang, X.; Yuan, M.; Mao, H.; Chao, J. Study on transplanting techniques of flue-cured tobacco seedlings under plastic film in Xiangxi tobacco-growing areas. Mod. Agric. Sci. Technol. 2017, 15, 9+13. [Google Scholar]

- Wang, D.; Sun, Y.; Du, Y.; Liu, Y.; Wang, Y.; Ma, X.; Zhang, Y.; Zhang, R. Effects of transplanting time and methods on the growth, yield and quality of flue-cured tobacco. Crops 2021, 2, 87–95. [Google Scholar]

- Feng, C.; Wang, X.; Zhang, J.; Dong, J.; Yu, X.; Wang, Y.; Ling, A. Study on the optimum light transmittance of plastic film for transplanting seedlings under plastic film. Chin. Tob. Sci. 2020, 41, 16–21. [Google Scholar]

- Yu, L.; Hu, C.; Xu, Z.; Zhang, F.; Fu, D. Design and experiment of spiral hole-forming device for big nest transplantation. J. Agric. Mech. Res. 2020, 42, 198–202. [Google Scholar]

- Liu, G.; Yu, L.; Chen, X.; Wu, X. Design and experiment of backpack deep-planting hole-forming machine. Jiangsu Agric. Sci. 2018, 46, 263–267. [Google Scholar]

- Kumawat, L. Development of draft force estimation model for hand tractor powered digger-cum-conveyor by rake angle and digging depth. J. Biosyst. Eng. 2023, 48, 152–164. [Google Scholar] [CrossRef]

- Zhao, Z. Finite Element Analysis of Drill Bit and Motion Simulation of Suspension Mechanism of Digger. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2010. [Google Scholar]

- Qu, J. Finite Element Analysis of the Main Shaft of the Digging Machine and Dynamic Simulation of the Suspension Mechanism. Ph.D. Thesis, Northeast Forestry University, Harbin, China, 2006. [Google Scholar]

- CAAMS. Agricultural Machinery Design Manual; China Agricultural Science and Technology Press: Beijing, China, 2007. [Google Scholar]

- Geng, D. New Agricultural Mechanics; National Defense Industry Press: Beijing, China, 2011. [Google Scholar]

- Ji, Y.; Yu, M.; Li, C. Discrete element simulation of shovel pore-forming machine. J. Jiangsu Univ. (Nat. Sci. Ed.) 2014, 35, 40–43. [Google Scholar]

- Li, B.; Chen, Y.; Chen, J. Modeling of soil-claw interaction using the discrete element method (DEM). Soil Tillage Res. 2016, 158, 177–185. [Google Scholar] [CrossRef]

- Huang, Y.; Hang, C.; Yuan, M.; Wang, B.; Zhu, X. Discrete element simulation and experiment of subsoiling soil disturbance behavior. Trans. Chin. Soc. Agric. Mach. 2016, 47, 80–88. [Google Scholar]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Three-dimensional discrete element modeling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosyst. Eng. 2014, 121, 105–117. [Google Scholar] [CrossRef]

- Fang, H.; Ji, C.; Farman, A.C.; Guo, J.; Zhang, Q.Y.; Chaudhry, A. Analysis of soil movement behavior in rotary tillage process based on discrete element method. Trans. Chin. Soc. Agric. Mach. 2016, 47, 22–28. [Google Scholar]

- Wang, X.; Yue, B.; Gao, X.; Zheng, Z.; Zhu, R.; Huang, Y. Simulation and test of soil disturbance behavior of subsoiling shovel with different wing shovel installation heights. Trans. Chin. Soc. Agric. Mach. 2018, 49, 124–136. [Google Scholar]

- Feng, C. Study on Viscosity Reduction and Desorption of Pepper Duckbill Planter Based on Yellow Clay. Ph.D. Thesis, Guizhou University, Guiyang, China, 2022. [Google Scholar]

- Yu, L.; Liu, G.; Zhang, F.; Wu, X.; Hu, C. Test and Analysis for Performance on the Knapsack Well-cellar Making Machine for Seedling Transplanting. J. Agric. Mech. Res. 2018, 40, 141–145. [Google Scholar]

- Hu, C.; Yu, L.; Xu, Z.; Zhang, F.; Chen, Y. Improvement and Experiment Main Component of Well-cellar Making Machine for Tobacco Seedling Transplanting. J. Agric. Mech. Res. 2019, 41, 198–202. [Google Scholar]

| Parametric | Numerical Value |

|---|---|

| The major diameter of the hole former/mm | 200 |

| The minor diameter of the hole former/mm | 100 |

| The spiral length/mm | 150 |

| 10–20 | |

| Spiral lead/mm | 110–250 |

| Feed rate/mm·r−1 | 11 |

| Critical speed range/rpm | 236–425 |

| Parameters | Numerical Value |

|---|---|

| Density of soil particles/kg·m−3 | 1000 |

| Poisson’s ratio of soil | 0.3 |

| Shear modulus of soil/MPa | 1 |

| Density of 65Mn steel/kg·m−3 | 7800 |

| Poisson’s ratio of stainless steel | 0.3 |

| Shear modulus of 65Mn steel/MPa | 79,000 |

| JKR surface energy of soil–soil/J·m−2 | 0.177 |

| Coefficient of restitution of soil–soil | 0.510 |

| Static friction coefficient of soil–soil | 0.72 |

| Rolling friction coefficient of soil–soil | 0.076 |

| Coefficient of restitution of soil–65Mn steel | 0.658 |

| Static friction coefficient of soil–65Mn steel | 0.938 |

| Rolling friction coefficient of soil–65Mn steel | 0.026 |

| Particle Diameter (mm) | Soil | Sand and Gravel | ||

|---|---|---|---|---|

| Average Mass (g) | Average Percentage (%) | Average Mass (g) | Average Percentage (%) | |

| 0–0.5 | 217.98 | 20.76 | 20.91 | 15.32 |

| 0.5–1 | 252.53 | 24.05 | 30.32 | 22.21 |

| 1–2 | 192.99 | 18.38 | 47.17 | 34.56 |

| 2–5 | 342.41 | 32.61 | 30.86 | 22.61 |

| ≥5 | 44.10 | 4.2 | 7.23 | 5.3 |

| Measuring Parameter | /mm | /mm | /UPH |

|---|---|---|---|

| Maximum | 273 | 214 | 812 |

| Minimum | 212 | 148 | 759 |

| Mean | 235 | 167 | 786 |

| Variable coefficient | 4.5% | 5.4% | |

| Qualification rate | 93.7% | 89.5% | |

| Qualification rate of hole | 88.5% | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Zheng, L.; Liang, P.; Wu, X.; Zhang, F.; Zhao, L. Design and Discrete-Element-Method Simulation of Helix Hole-Forming Machine for Deep Planting with Large Holes. Agriculture 2024, 14, 801. https://doi.org/10.3390/agriculture14060801

Yu L, Zheng L, Liang P, Wu X, Zhang F, Zhao L. Design and Discrete-Element-Method Simulation of Helix Hole-Forming Machine for Deep Planting with Large Holes. Agriculture. 2024; 14(6):801. https://doi.org/10.3390/agriculture14060801

Chicago/Turabian StyleYu, Lihua, Le Zheng, Pengfei Liang, Xuemei Wu, Fugui Zhang, and Limei Zhao. 2024. "Design and Discrete-Element-Method Simulation of Helix Hole-Forming Machine for Deep Planting with Large Holes" Agriculture 14, no. 6: 801. https://doi.org/10.3390/agriculture14060801

APA StyleYu, L., Zheng, L., Liang, P., Wu, X., Zhang, F., & Zhao, L. (2024). Design and Discrete-Element-Method Simulation of Helix Hole-Forming Machine for Deep Planting with Large Holes. Agriculture, 14(6), 801. https://doi.org/10.3390/agriculture14060801