Optimizing Active Disturbance Rejection Control for a Stubble Breaking and Obstacle Avoiding Control System

Abstract

1. Introduction

2. Materials and Methods

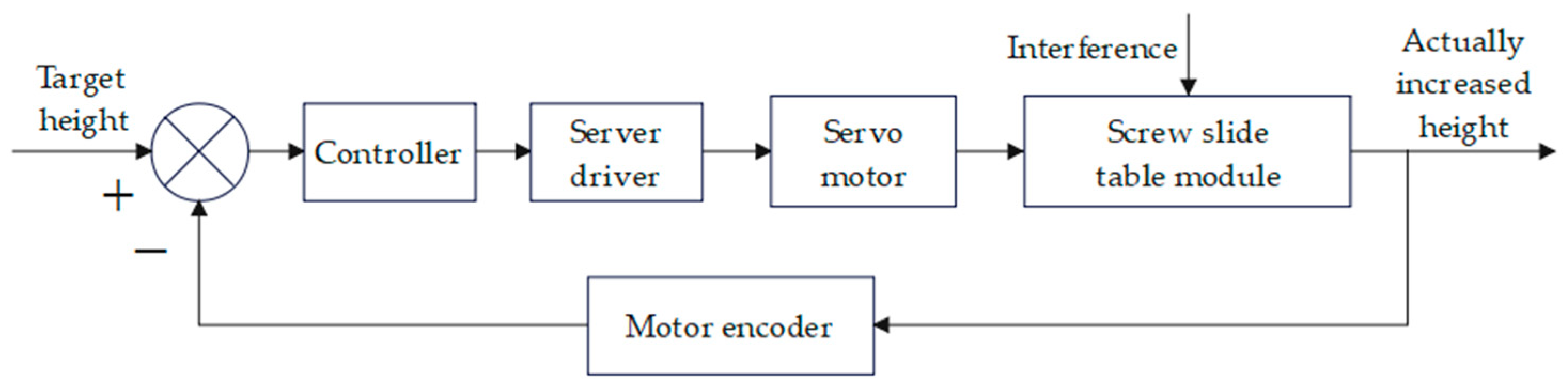

2.1. System Structure Composition and Working Principle

2.1.1. System Structure Composition

2.1.2. Working Principle of the Obstacle Avoidance Device

2.1.3. Hardware System Design

2.2. Obstacle Avoidance Control System Modeling

2.3. Obstacle Avoidance Controller Design

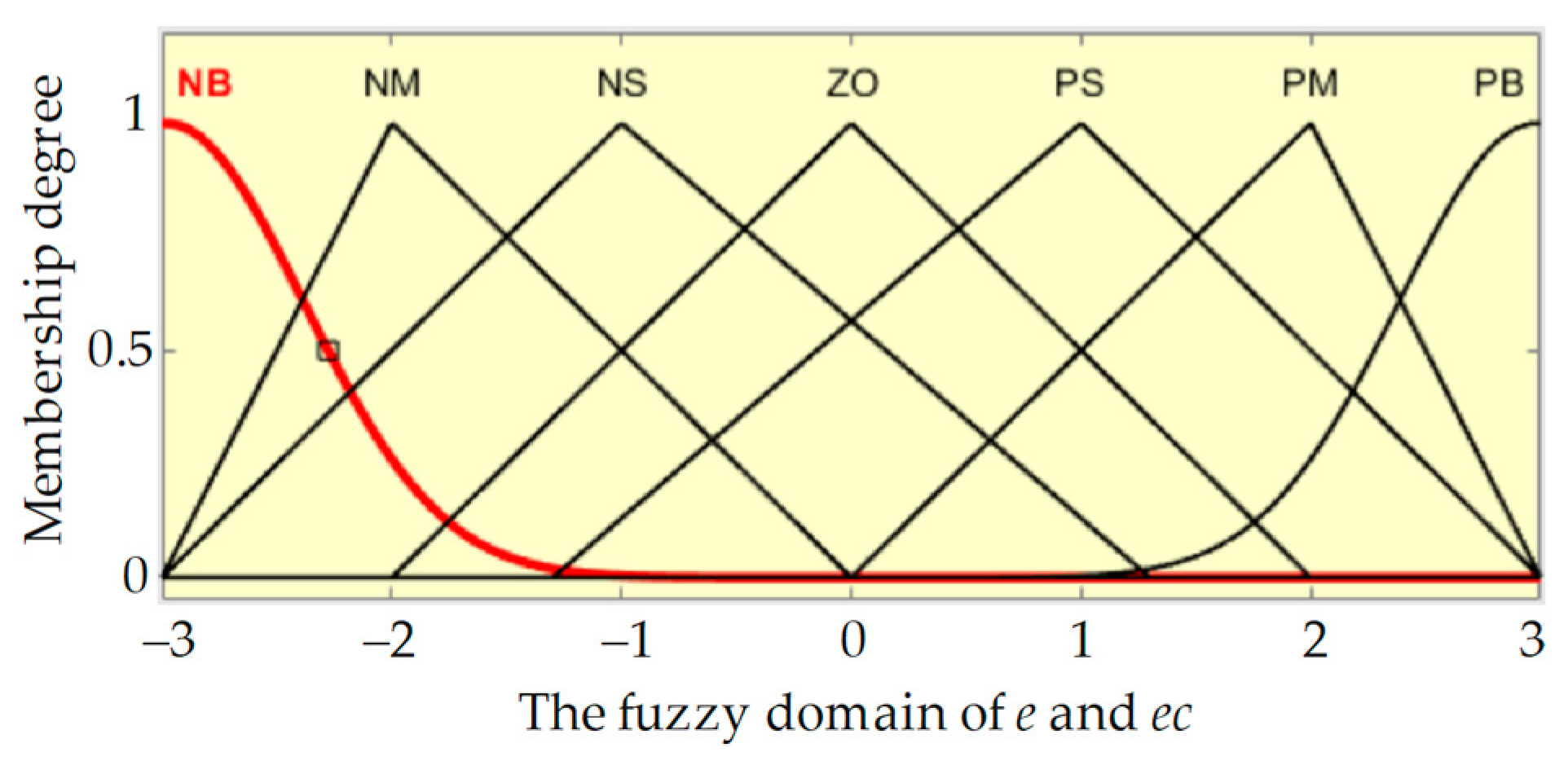

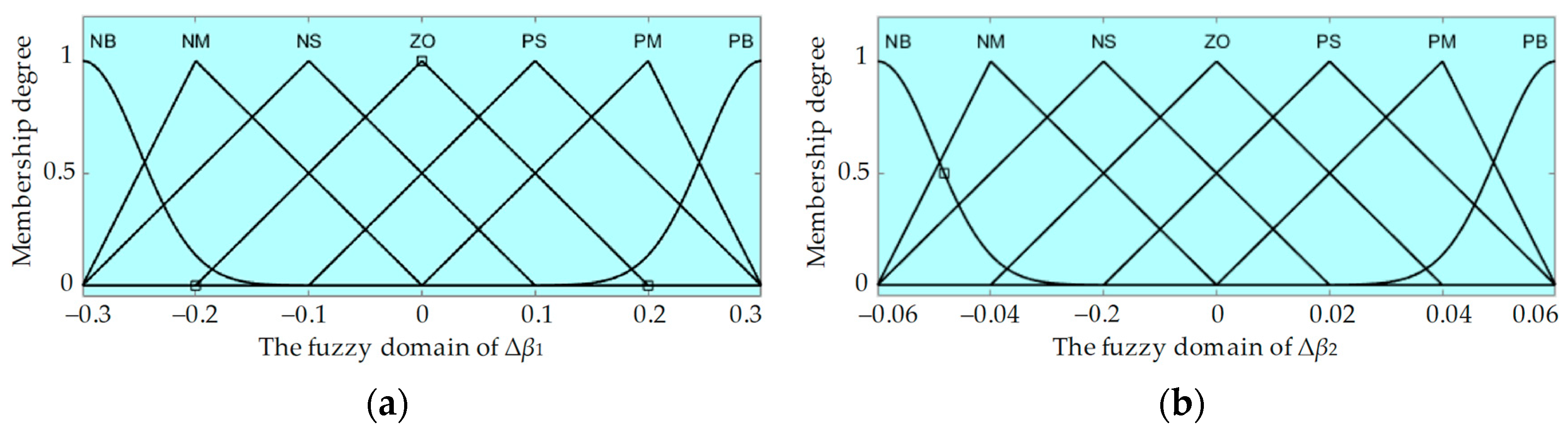

2.3.1. Fuzzy ADRC Controller Design

- When the deviations of e and ec are large, set Δβ1 as large and Δβ2 as zero or small to increase the system’s response speed and reduce overshoot;

- When the deviation of e and ec is moderate, set Δβ1 as small and Δβ2 as moderate to ensure a reasonable response time and overshoot range;

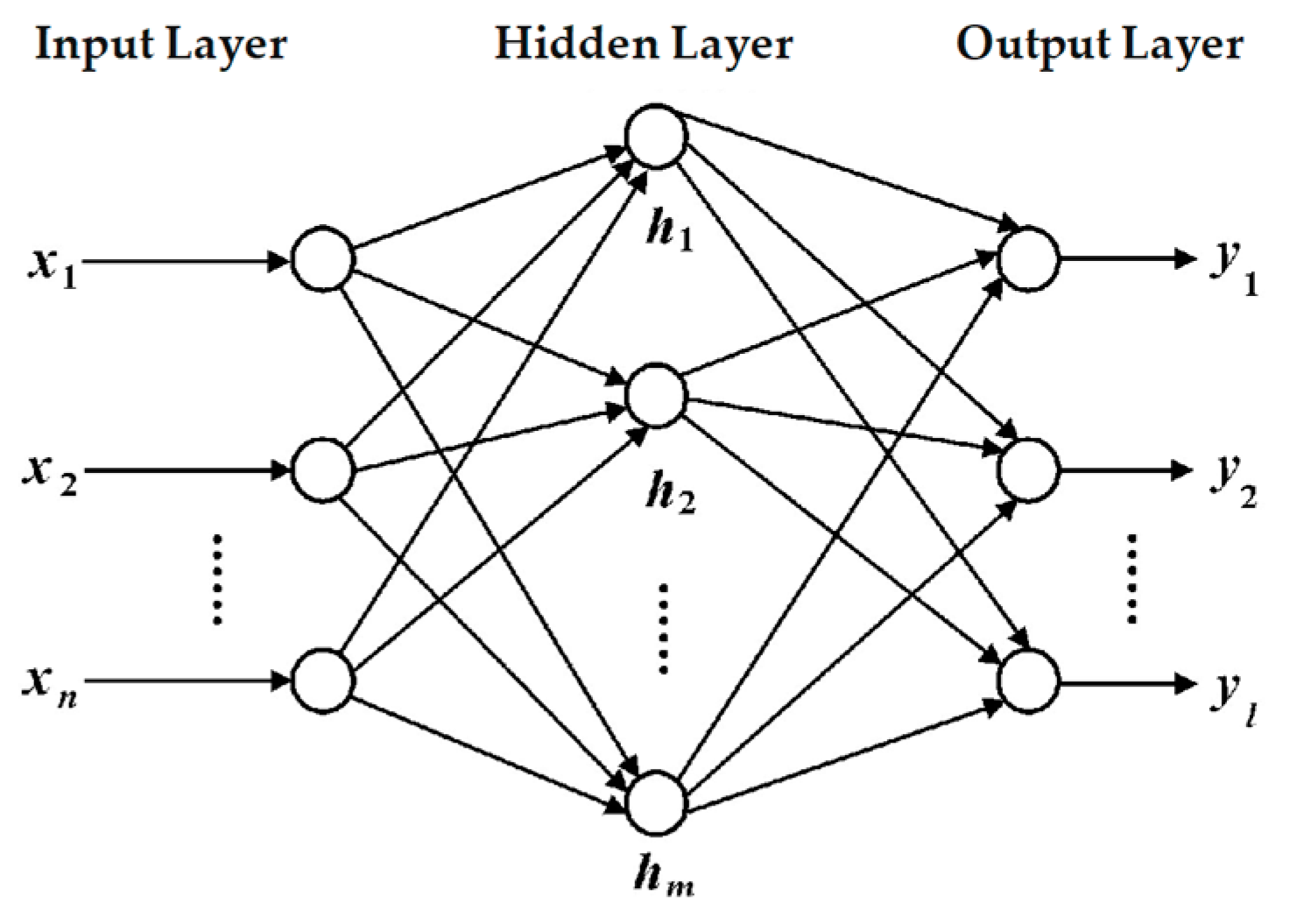

2.3.2. BPNN-Optimized Fuzzy ADRC Controller Design

- Fuzzified layer: This layer represents the membership function layer, where neurons connected with e and ec are the corresponding seven fuzzy language variables. This layer mainly fuzzifies the two input variables and calculates the membership functions of the fuzzy sets of e and ec belonging to each language variable value, respectively.

- Fuzzy rule layer: Each neuron in the fuzzy rule layer represents a fuzzy rule and is responsible for calculating the fitness of each rule.

- Output membership layer: The output membership layer calculates the language variable values of each rule’s output variable.

- Output layer: The output layer is responsible for defuzzification and obtaining the adjustable parameters of the active disturbance rejection controller. The calculation process of the BPNN optimal fuzzy control is as follows:where mij is the central value of the membership function of the jth language variable of the ith input variable xi; θij is the width of the membership function of the jth language variable of the ith input variable xi; I is the input of each layer neuron; O is the output of each layer neuron; ukm is the central value of the language-valued membership function of the mth output variable of the first rule; and σ is the width value of the language-valued membership function of the mth output variable of the first rule.

3. Results and Discussion

3.1. Simulation Comparison and Analysis

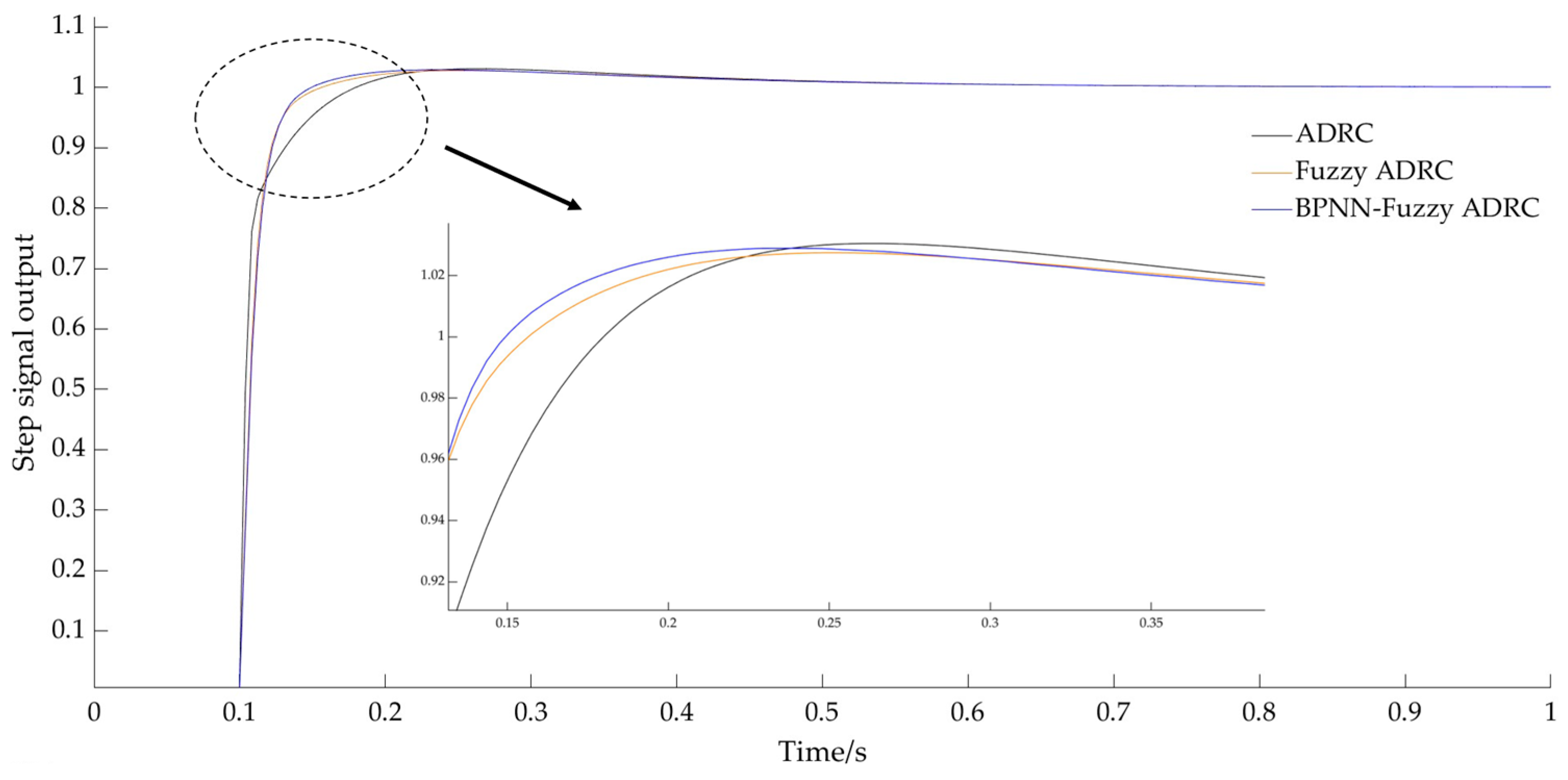

3.1.1. Step Signal Simulation

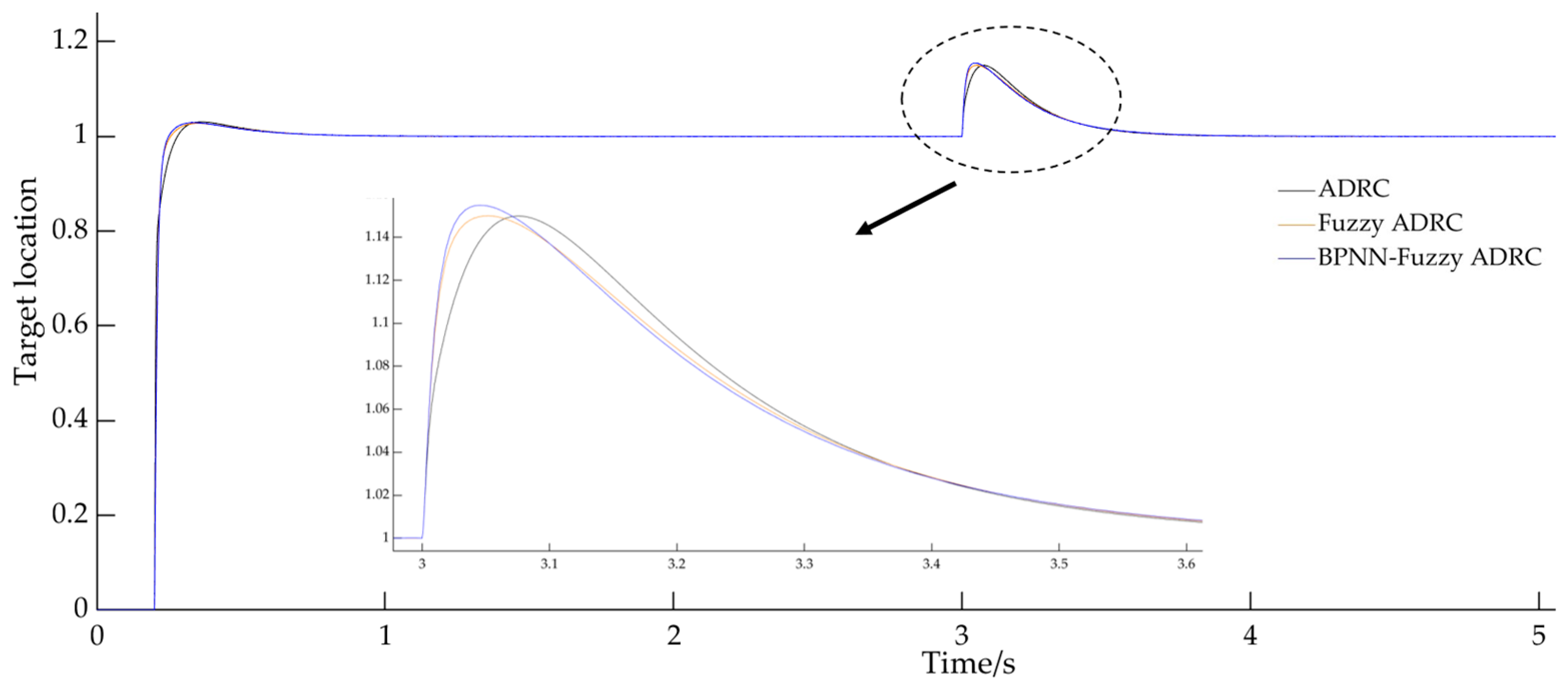

3.1.2. Anti-Disturbance Simulation

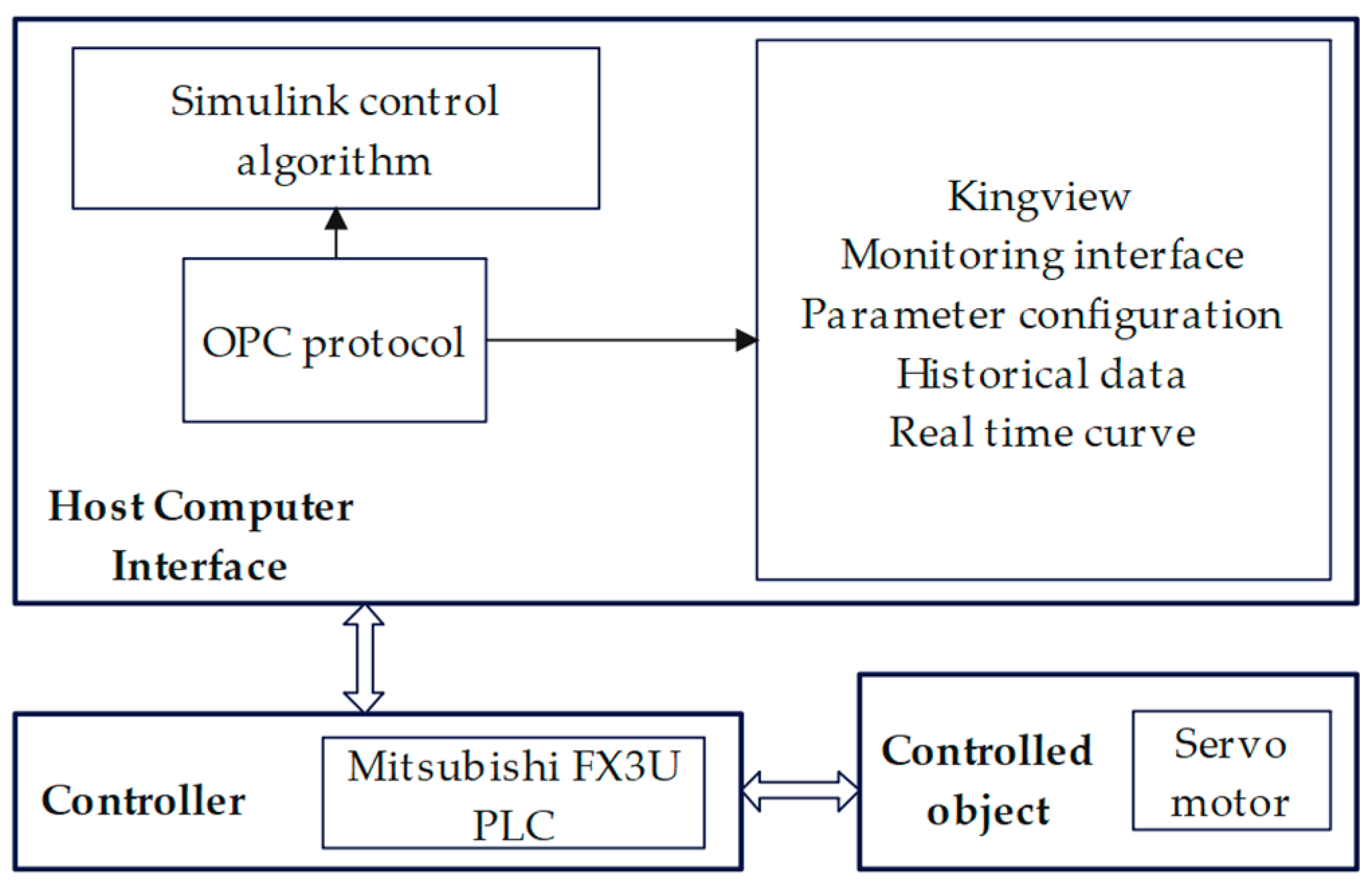

3.2. Hardware-in-the-Loop Simulation Platform Experiment

3.2.1. Hardware-in-the-Loop Simulation Platform Building

3.2.2. Control System Dynamic Performance Experiment

3.2.3. Control System Error Analysis

4. Conclusions

- Through the analysis of the implementation of conservation tillage technology in the rocky desertification areas of southwest China, an autonomous obstacle avoidance control system for stubble breaking devices was designed, and a model of the stubble breaking and obstacle avoidance control system was built. The method of obstacle avoidance control using the BPNN-algorithm-optimized fuzzy ADRC was proposed. Moreover, the experiments show that optimizing the NLSEF parameters of the fuzzy ADRC controller using the BPNN algorithm with strong learning ability can improve the system’s control performance and anti-inference capability while avoiding overly relying on expert experience in fuzzy control.

- According to the performance indexes of the simulation results, it can be seen that the fuzzy ADRC obstacle avoidance control system based on BPNN optimization reduces the regulation time by 70.6% and 1.1%, and the overshoot is reduced by 95% and 90%, respectively. Moreover, the system can return to a steady state as soon as possible after introducing noise signal interference, proving that the model has high dynamic stability and anti-interference capability.

- A hardware-in-the-loop simulation experiment platform of the obstacle avoidance control system was built, and the results demonstrated that the BPNN fuzzy ADRC controller has a regulation time of less than 1 s for each servo motor response speed change when the input signal is a continuous step signal. When the target position h changes rapidly and continuously in the 2–10 s, at this time, although the speed ω can quickly approach the target value, there will be an overshoot, and the overshoot is 8–10%, which is different from the simulation results. After theoretical analysis, it is concluded that the source of error is an unavoidable system error. Therefore, the control system proposed still has an excellent control effect within the error range. The hardware-in-the-loop platform experiment could verify the reasonableness and feasibility of the BPNN fuzzy ADRC controller designed in this paper.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, D.H.; Jia, H.C.; Chen, F.; He, Y.H.Z. Impacts of rocky desertification on maize drought risk in Southwest China. Trans. Chin. Soc. Agric. Eng. 2017, 33, 172–178. [Google Scholar]

- National Bureau of Statistics of China. China Statistical Yearbook; China Statistics Press: Beijing, China, 2023.

- Song, L.H.; Wang, K.H.; Yan, X.M. Characteristics of soil fauna communities in the Karst region, Southwest China, based on meta-analysis. Acta Ecol. Sin. 2018, 38, 984–990. [Google Scholar]

- Liu, X.; Wang, R.T.; Zhang, F. Research on evaluation of food security in southwest China. J. Southwest Univ. (Nat. Sci. Ed.) 2024, 46, 115–124. [Google Scholar]

- He, J.; Li, H.W.; Chen, H.T.; Lu, C.Y.; Wang, Q.J. Research progress of conservation tillage technology and machine. Trans. Chin. Soc. Agric. Mach. 2018, 49, 1–19. [Google Scholar]

- Wang, Q.J.; Cao, X.P.; Wang, C.; Li, H.W.; He, J.; Lu, C.Y. Research progress of no/minimum tillage corn seeding technology and machine in northeast black land of China. Trans. Chin. Soc. Agric. Mach. 2021, 52, 1–15. [Google Scholar]

- Han, J.Q. Auto- disturbances- rejection controller and it’s applications. Control Decis. 1998, 13, 19–23. [Google Scholar]

- Tian, H.T.; Xie, Y.; Shi, L.L.; Liu, H. Application of fuzzy cuckoo search algorithm in active disturbance rejection control of variable pitch of wind turbines. Acta Energiae Solaris Sin. 2021, 42, 222–229. [Google Scholar]

- Wang, S.M.; Fan, W.C. Simulation application of improved second order ADRC in PMSM. Fire Control Command Control 2020, 45, 162–166. [Google Scholar]

- Li, J.Z.; Xu, P.F.; Zhou, H.P.; Zheng, C.L. Research on traction motor control strategy of mine electric locomotive based on improved ADRC. Coal Technol. 2022, 41, 177–181. [Google Scholar]

- Qu, L.Z.; Qiao, W.; Qu, L.Y. Active-disturbance-rejection-based sliding-mode current control for permanent-magnet syn-chronous motors. IEEE Trans. Power Electron. 2021, 36, 754. [Google Scholar] [CrossRef]

- Tian, B.; Cui, J.; Lu, H. Adaptive finite-time attitude tracking of quadrotors with experiments and comparsons. IEEE Trans. Ind. Electron. 2019, 66, 9428–9438. [Google Scholar] [CrossRef]

- Li, F.P. Study on ADRC parameter optimization using CPSO for clamping force control system. Math. Probl. Eng. 2018, 2018, 2159274. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, Q.; Zhu, Q.X.; Chen, S. Dynamic performance optimization of machine tool ballscrew feed system based on comprehensive indicators. Trans. Chin. Soc. Agric. Mach. 2019, 50, 404–412. [Google Scholar]

- Jeong, H.S. Novel torque motor model for performance design and analysis of a servo valve with permanent magnets. J. Mech. Sci. Technol. 2018, 32, 2253–2259. [Google Scholar] [CrossRef]

- Han, J.Q. From PID technique to active disturbances rejection control technique. Control Eng. China 2002, 9, 13–18. [Google Scholar]

- Han, J.Q.; Wang, W. Nonlinear tracking-differentiator. J. Syst. Sci. Math. Sci. 1994, 14, 177–183. [Google Scholar]

- Han, J.Q. Nonlinear state error feedback control law-NLSEF. Control Decis. 1995, 10, 221–225. [Google Scholar]

- Han, J.Q. The “extended state observer” of a class of uncertain systems. Control Decis. 1995, 10, 85–88. [Google Scholar]

- Boukhalfa, G.; Belkacem, S.; Chikhi, A. Genetic algorithm and particle swarm optimization tuned fuzzy PID controller on direct torque control of dual star induction motor. J. Cent. South Univ. 2019, 26, 1886–1896. [Google Scholar] [CrossRef]

- Tian, M.; Bai, J.B.; Li, J.Q. Variable rate fertilization control system for liquid fertilizer based on genetic algorithm. Trans. Chin. Soc. Agric. Eng. 2021, 37, 21–30. [Google Scholar]

- Zhang, K.F.; Jiang, T.; Shao, L.; Su, L.C.; Ye, T. Research on precision temperature control of laser diode based on the novel fuzzy-PID conrol unit. Opt. Precis. Eng. 2017, 25, 648–655. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Dong, W.J.; Xiong, Z.Q.; Hu, Z.Q.; Wang, D.H.; Ding, Y.C. Design and experiment of fuzzy adaptive pure pursuit control of crawler-type rape seeder. Trans. Chin. Soc. Agric. Mach. 2021, 52, 105–114. [Google Scholar]

- Zhang, D.S.; Yang, G.; Zhao, X.T.; Yang, X.Q.; Gao, X.F. Optimization design of vane diffuser and volute in vertical centrifugal pump based on back propagation neural network. Trans. Chin. Soc. Agric. Mach. 2022, 53, 130–139. [Google Scholar]

- Qing, Y.; Liu, Z.Y.; Zhang, Y. Research and Practice of Neural Network PID Process Control Algorithm Based on Offshore Oil and Gas Platform. J. Phys. Conf. Ser. 2020, 1486, 032039. [Google Scholar]

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Load | G | 80 | kg |

| Screw diameter | d | 10 | cm |

| Lifting effective stroke | x | 200 | mm |

| Lifting speed | V | 0.1 | m/s |

| Screw lead | PAo | 10 | mm/r |

| Motor power | P | 400 | w |

| Motor rated speed | ω | 3000 | rpm |

| Motor rated torque | T | 1.28 | N·m |

| Rotor moment of inertia | J | 0.008 | kg·m2 |

| Torque coefficient | Kt | 1.27 | N·m |

| Armature inductance | L | 0.002 | H |

| Stator resistance | R | 2 | Ω |

| Back EMF coefficient | Ke | 0.008 | V/rpm |

| Number of pole pairs | Pn | 4 |

| ec | NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|---|

| e | ||||||||

| NB | PB | PB | PM | PM | PS | ZO | ZO | |

| NM | PB | PB | PM | PS | PS | ZO | NS | |

| NS | PM | PM | PM | PS | ZO | NS | NS | |

| ZO | PM | PM | PS | ZO | NS | NM | NM | |

| PS | PS | PS | ZO | NS | NS | NM | NM | |

| PM | PS | ZO | NS | NM | NM | NM | NB | |

| PB | ZO | ZO | NM | NM | NM | NB | NB | |

| ec | NB | NM | NS | ZO | PS | PM | PB | |

|---|---|---|---|---|---|---|---|---|

| e | ||||||||

| NB | PS | NS | NB | NB | NB | NM | PS | |

| NM | PS | NS | NB | NM | NM | NS | ZO | |

| NS | ZO | NS | NM | NM | NS | NS | ZO | |

| ZO | ZO | NS | NS | NS | NS | NS | ZO | |

| PS | ZO | ZO | ZO | ZO | ZO | ZO | ZO | |

| PM | PB | PS | PS | PS | PS | PS | PB | |

| PB | PB | PM | PM | PM | PM | PS | PB | |

| Type | Rise Time/s | Overshoot/% | Adjustment Time/s |

|---|---|---|---|

| ADRC | 0.056 | 2 | 0.303 |

| Fuzzy ADRC | 0.039 | 1 | 0.100 |

| BPNN Fuzzy ADRC | 0.039 | 0.1 | 0.089 |

| Test Number | Kingview Input Command (r/min) | Servo Motor Speed (r/min) |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 60 | 60 |

| 3 | 120 | 121 |

| 4 | 300 | 302 |

| 5 | 500 | 499 |

| 6 | 800 | 795 |

| 7 | 1200 | 1198 |

| 8 | 1500 | 1504 |

| 9 | 2000 | 1997 |

| 10 | 2500 | 2501 |

| Test Number | Kingview Input Command (r/min) | Servo Motor Speed (r/min) |

|---|---|---|

| 1 | 0 | 0 |

| 2 | 80 | 81 |

| 3 | 100 | 102 |

| 4 | 300 | 299 |

| 5 | 500 | 496 |

| 6 | 800 | 800 |

| 7 | 1200 | 1198 |

| 8 | 1800 | 1800 |

| 9 | 2000 | 2001 |

| 10 | 2800 | 2797 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Huang, T.; Bai, L.; Zhang, W. Optimizing Active Disturbance Rejection Control for a Stubble Breaking and Obstacle Avoiding Control System. Agriculture 2024, 14, 786. https://doi.org/10.3390/agriculture14050786

Zhu H, Huang T, Bai L, Zhang W. Optimizing Active Disturbance Rejection Control for a Stubble Breaking and Obstacle Avoiding Control System. Agriculture. 2024; 14(5):786. https://doi.org/10.3390/agriculture14050786

Chicago/Turabian StyleZhu, Huibin, Tao Huang, Lizhen Bai, and Wenkai Zhang. 2024. "Optimizing Active Disturbance Rejection Control for a Stubble Breaking and Obstacle Avoiding Control System" Agriculture 14, no. 5: 786. https://doi.org/10.3390/agriculture14050786

APA StyleZhu, H., Huang, T., Bai, L., & Zhang, W. (2024). Optimizing Active Disturbance Rejection Control for a Stubble Breaking and Obstacle Avoiding Control System. Agriculture, 14(5), 786. https://doi.org/10.3390/agriculture14050786