Abstract

The Farm to Fork (F2F) Strategy, a key initiative of the European Commission under the European Green Deal, strives to make the European Union’s (EU) economy sustainable. Focused on the food system, the F2F Strategy prioritizes sustainability in agriculture, eco-friendly practices, biodiversity preservation, and climate change mitigation. It targets high food safety (FS) and environmental management (EM) standards across the Agri-food Supply Chain (ASC). Addressing sustainability challenges in the wine industry, this study delves into the Wine Value Chain (WVC). Emphasizing the intricate sustainability interplay within the WVC, this study concentrates on FS and EM to ensure the long-term viability of wine production. The primary goal is to create a comprehensive sustainability evaluation method for wineries, incorporating performance indicators from FS and EM components. The methodology involves assessing Food Safety Management Systems (FSMSs), evaluating Environmental Management Systems (EMSs), investigating contamination risks, and synthesizing results into a sustainability matrix. Findings highlight commendable FS practices, such as widespread Hazard Analysis and Critical Control Point (HACCP) adoption and underscore the need for increased EM focus. Notable figures include a 76.2% adoption of the HACCP system and 68.8% of wineries implementing an EMS. Performance indicators become critical for sustainability assessment, forming the cornerstone to gauge the industry’s effective sustainability management aligned with the F2F Strategy. This study stresses the holistic integration of FS and EM practices, providing insights into workforce engagement, regulatory compliance, and sustainable objectives. This research offers a tool for evaluating and advancing sustainability in the wine industry culminating in a sustainability matrix.

1. Introduction

The F2F Strategy is an initiative introduced by the European Commission [1,2]. It is part of the European Green Deal, which is a set of policy initiatives by the EU aimed at making the EU’s economy sustainable [3]. The F2F Strategy specifically focuses on the food system, aiming to make it more sustainable, resilient, and environmentally friendly. The F2F Strategy prioritizes sustainability in agriculture, emphasizing environmentally conscious practices, biodiversity preservation, and climate change mitigation. It also aims to ensure high FS standards across the food supply chain, reduce the use of chemical pesticides and fertilizers, promote the transition to organic farming, and encourage a circular economy in the food sector, thereby minimizing waste and optimizing resource utilization [4,5]. Challenges faced by the food industry in terms of sustainability are vast, covering environmental, social, and economic dimensions that impact every stage of food production, distribution, and consumption [6,7]. Addressing these complexities requires the implementation of sustainable practices that align with economic feasibility, social justice, and environmental preservation [8,9,10]. Despite some initial efforts, the food industry is still in the initial stages of adopting sustainability practices. Numerous studies have highlighted the challenges and opportunities faced by agri-food firms in relation to sustainability [11,12,13]. However, given the increasing complexity of this sector, there is an urgent need to develop more structured methodologies that systematically incorporate sustainability considerations [14].

Sustainability, broadly defined, focuses on enhancing people’s quality of life by considering social, economic, and environmental perspectives and ensuring this improvement for future generations [15,16]. The concept of sustainability arises from the four dimensions within the ASC performance [17]. The ASC covers all activities related to agricultural food handling, from producers and farmers to end consumers [18]. Aramyan et al. (2007) identify four primary performance dimensions: efficiency, flexibility, responsiveness, and food quality [17]. Moreover, an additional category is introduced to address critical aspects reflecting the social and environmental dimensions of sustainability [19]. Refining the sustainability dimension, Gold (2017) outlines indicators such as local living conditions, labor rights, land rights, end-of-life valorization through biomass recycling, environmental issues, and FS [12]. Consequently, agri-food industries allocate a substantial portion of their resources toward advertising and marketing initiatives focused on sustainability [20,21]. The ASC consumes natural resources and often causes environmental deterioration of the natural ecosystems where it develops. From this point of view, FS and EM play an important role in the sustainability of the environment where agro-industrial activity takes place [22]. According to Kumar (2022), FS and EM topics such as waste management or environmental impact assessments are two of nine key thematic research themes in sustainable food supply chains [23]. Figure 1 displays an interpretative diagram that, from a scientific perspective, grounds the reason why the evaluations of FS along with EM stand as quantitative pillars in achieving sustainability within the ASC.

Figure 1.

Diagram showing FS and EM as quantitative pillars contributing to sustainability in the ASC.

The WVC constitutes an integral component of ASC insofar as it encompasses the production, processing, distribution, and sale of agricultural products, in this instance, wine. WVC encompasses the full range of activities and processes required to bring wine from vineyard to consumer, including grape cultivation, wine production, bottling, distribution, marketing, and sales. It involves a complex network of stakeholders including grape growers, winemakers, bottlers, distributors, retailers, and consumers [24]. WVC is characterized by its emphasis on quality, tradition, and sustainability, reflecting the unique terroir of wine-producing regions, as well as the cultural and historical significance of wine [25].

Prior research underscores this multifaceted nature of sustainability in the wine sector, advocating for a comprehensive approach that balances environmental integrity with economic viability, social equity, and cultural heritage. Szolnoki (2013) underscores the diversity in sustainability practices across WVC in various wine-producing nations, highlighting the need for a holistic approach that integrates local and global sustainability standards [26]. Forbes et al. (2009) explore consumer attitudes towards environmentally sustainable wine in New Zealand, revealing a growing consumer demand for sustainability in the wine industry, which influences market dynamics and winery practices, and Pickering G. (2023) found that most consumers are in a change stage with respect to sustainable wine behaviors [27]. This consumer-driven shift towards sustainability is further corroborated by Gabzdylova et al. (2009), who examine the drivers, stakeholders, and sustainability practices within the New Zealand WVC, suggesting that stakeholder engagement and transparent sustainability reporting are key to advancing sustainable practices [28]. Marshall et al. (2005) investigate the institutional and individual drivers of environmentalism in the US wine industry, emphasizing the role of proactive environmental strategies in gaining competitive advantage and meeting regulatory and societal expectations [29]. De Steur et al. (2020) identified the role of drivers in the adoption of sustainability in Italian wineries, with internal drivers such as the protection of regional products and environmental benefits (e.g., biodiversity or landscape protection) being deemed highly important, as well as some external drivers related to environmental and product safety [30]. Santini et al. (2013) address the critical questions and research trends in wine industry sustainability, calling for a comprehensive understanding and integration of sustainable practices that encompass the entire WVC [25].

In this context, sustainability in WVC has grown in recent years, reflecting an increasing interest in environmentally friendly agricultural and viticultural practices. Sustainability, in this context, pertains to the ability to maintain wine production in the long term without compromising natural resources or harming the environmental context. Meissenheimer et al. (2001) identified specific categories within the WVC, covering a range of activities. These activities involve managing soil and plant materials, implementing vineyard practices, conducting cellar practices and wine production, handling packaging and distribution, and engaging in market development and marketing [31]. WVCs encounter challenges across three primary areas: global and environmental challenges, methodological and financial challenges, and challenges associated with the economy and the market [32]. According to Luzzani (2021), sustainability in the wine industry incorporates various aspects, including field operations, grape transformation, and the cultural and traditional heritage of wine [33]. Sustainable vitiviniculture involves a global strategy that considers economic sustainability, precision in sustainable viticulture, risks to the environment, product safety, and consumer health, along with the valuation of heritage, historical, cultural, ecological, and landscape aspects as emphasized by the Organisation Internationale de la Vigne et du Vin (OIV) (2008) [34]. This underscores the need for a comprehensive approach that includes both FS and EM in all stages of the production process.

FS refers to the assurance and set of conditions and measures needed during the production, storage, distribution, and preparation of food to ensure that, when consumed, they do not pose a risk to the health of consumers [35]. FS plays a critical role in the sustainability of wine production. FSMSs are essential for ensuring the production of safe and healthy food, incorporating prerequisite programs (PRPs) and HACCP methodologies as per the regulatory standards in the EU [36,37]. PRPs establish the necessary environmental and operational conditions, covering aspects such as the supply of sanitary water, cleanliness of equipment and facilities, pest control, good manufacturing practices, staff knowledge of FS, allergens, and food traceability [38]. HACCP is a globally recognized approach focused on identifying and controlling FS hazards through seven principles, which include hazard identification, determining Critical Control Points (CCPs), and setting critical limits for these CCPs [39]. CCPs are specific points in the food production process where controls are essential to prevent, eliminate, or reduce FS hazards to acceptable levels. The identification and management of CCPs involve a systematic analysis, employing decision tree frameworks aligned with Codex Alimentarius and ISO 22000:2018 criteria, to decide on the appropriate controls and preventive measures [40,41]. Effective management of CCPs in wine production, through regular monitoring, verification, and documentation, is critical to maintaining FS and preventing contamination [42].

EM is essential for ensuring the long-term sustainability of wine production. Environmental considerations, such as waste reduction and recycling, efficient use of raw materials, and resource conservation, enable wineries to build trust with stakeholders and gain competitive advantages [43]. According to Gilinski et al., the focus for practitioners in the wine industry is to leave the land in better conditions than the current ones for future generations, addressing EM and incorporating strategies that minimize the negative impact of viticulture on the natural environment [44]. An EMS encompasses a set of practices, guidelines, and records established by an organization to reduce the environmental footprint of its operations [45]. EMSs are adopted by numerous organizations globally [46,47] and often align with ISO 14001:2015 standards [48], serving as a framework for active environmental stewardship [49,50]. The ISO 14001:2015 standard outlines essential criteria that all EMSs should adhere to, emphasizing ongoing, methodical enhancement. Organizations utilize this standard to boost their environmental outcomes, aligning with their environmental commitments, goals, and duties, thereby contributing to the environmental dimension of sustainability [51]. Typically, the adoption of an EMS is driven by the ethical and competitive aspirations of the organization’s leadership [52].

By incorporating both FS systems and EM in wine production, producers contribute to the sustainability of the wine industry. Baiano, A. (2021) suggests that implementing sustainable practices helps reduce the environmental footprint of wine production and promotes the conservation of natural resources [53]. Furthermore, these practices can enhance consumer credibility and perception. From the consumer perspective, sustainability is primarily associated with credibility attributes inherent to the food they consume [54].

Within this framework, the primary objective of this research is to develop a method for evaluating the advancement in the concept of sustainability in wineries. This is based on their performance in FSMSs and EMSs, measured through the creation of performance indicators derived from components of FS and EM.

2. Materials and Methods

This research initiated an extensive data collection effort, focusing on three samples of wineries situated in diverse geographic locations, covering a range of operational scales. Each group comprised over thirty wineries, enabling the application of the Central Limit Theorem (CLT) [55,56]. The CLT is a cornerstone principle in statistics that supports the use of samples of thirty or more to make inferences about a broader population. This includes the context of categorical variables, particularly when evaluating proportions or percentages. The data, meticulously collected via surveys, provide a comprehensive overview of current practices in FS and EM within the wine industry. This contextual foundation is pivotal for interpreting the results, offering a perspective through which the sustainability initiatives of wineries can be evaluated against global sustainability standards.

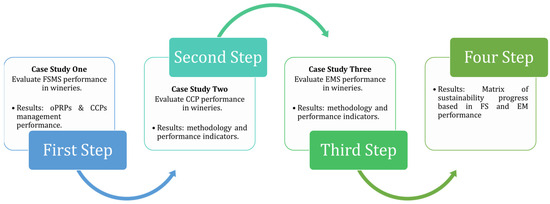

The methodological approach was structured in four well-defined steps. The first three steps were dedicated to analyzing different case studies. The first step laid the groundwork for defining the objectives of the second case, which focused on FS, while the results of the second supported the methodology to develop the indicators in the third study, which focused on EM. In each of these stages, the efficacy with which the wineries implemented the FSMS or the EMS was meticulously evaluated. The four steps involved synthesizing the three investigations to develop an FS and EM sustainability matrix based on performance indicators calculated from the results of case studies two and three. Through detailed statistical analysis and the examination of these cases, the research offers a deep dive into the sustainability practices within the wine sector based on FS and EM. Figure 2 shows the evolution of this methodological approach, inclusive of the interconnections among the steps and their congruence with the theoretical framework. The outcomes of the first case study facilitated the identification of CCPs that were inadequately managed by the wineries and the principal components that support the wineries’ performance in FS management. Leveraging these findings, the second case study delineated performance indicators for the components identified in the first phase. The third case study delved into the EM practices by examining the EMS components based on the ISO 14001:2015 standard and employed the proposed methodology to compute the indicators from the second phase to formulate performance indicators in EM. The fourth step focused on combining the findings from the three previous investigations to create a sustainability matrix based on FS and EM.

Figure 2.

Flow diagram of the methodological process.

2.1. First Step

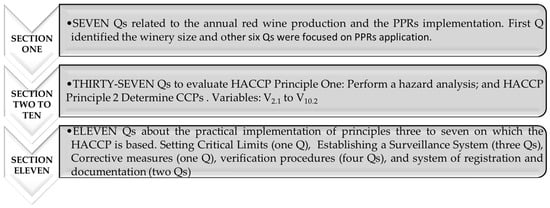

In the initial phase, a first case study was conducted to evaluate the effectiveness of the FSMS based on PRPs and the HACCP in twenty-one wineries with the Protected Designation of Origin “Vinos de Madrid”. The performance of these wineries was thoroughly assessed at various stages of the wine production process, focusing on Critical Control Points (CCPs) or operational prerequisite programs (oPRPs), including the implementation of PRPs and adherence to HACCP principles [39]. This research utilized a structured survey with fifty-five questions grouped into eleven sections. The questions employed both yes/no and multiple-choice options, with quantitative variables assigned using Likert scales. Figure 3 illustrates the questionnaire structure, detailing questions and assigned variables for the statistical process. The questionnaire is included in Appendix A.

Figure 3.

Questionnaire structure, including questions and variables for case study one.

2.2. Second Step

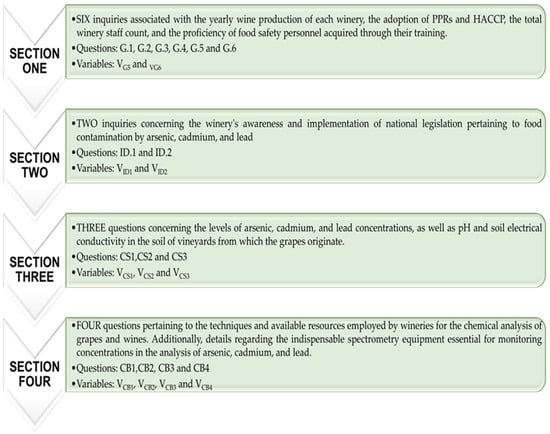

According to the findings of Lopez Santiago et al. (2022), the second case study focused on a CCP identified as inadequately controlled, specifically addressing the risk of contamination from arsenic, cadmium, and lead during the wine production process [57]. A sixteen-question survey assessed wineries’ performance in various aspects, including training workers, monitoring CCPs, understanding relevant legislation on contamination risks, and evaluating wineries’ practices regarding the chemical analysis of vineyard soils.

The questionnaire, distributed to thirty-two wineries across different Protected Designations of Origin in Spain, incorporated both yes/no and multiple-choice questions, with quantitative variables assigned using Likert scales. Figure 4 outlines the questionnaire structure. The questionnaire is included in Appendix A.

Figure 4.

Questionnaire structure, including questions and variables for case study two.

2.3. Third Step

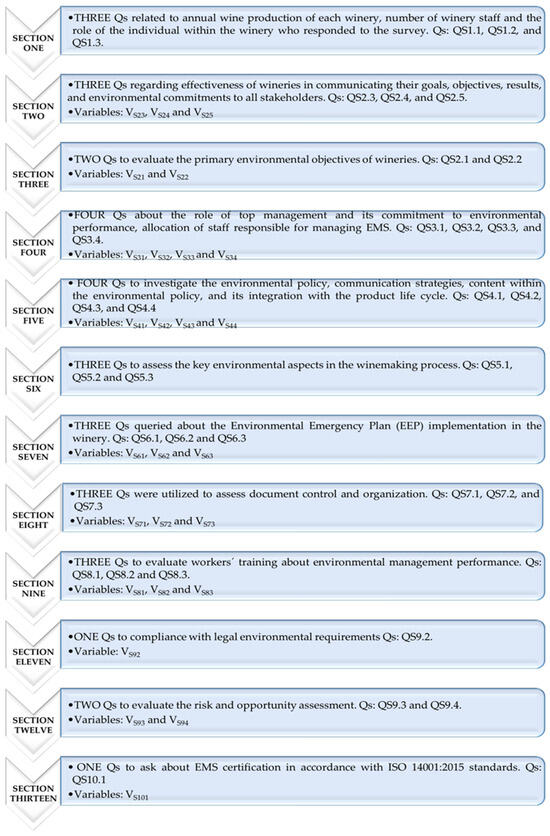

A third case study extended its scope to Italian wineries, focusing on their EMS. Conducted between June and November 2022, the survey involved a sample of 120 wineries from various regions in Italy, with the subsequent data analysis using statistical tools such as SPSS and Excel. The comprehensive questionnaire, featuring thirty-two questions in closed and open-ended formats, Likert scales, and multiple-choice options, explored aspects like winery characteristics, environmental objectives, top management involvement, communication strategies, and emergency plans. The questionnaire was distributed to a non-probabilistic sample of Italian wineries, resulting in responses from thirty-four wineries. Figure 5 provides an overview of the questionnaire structure, including questions and variables. The questionnaire is included in Appendix A.

Figure 5.

Questionnaire structure, including questions and variables for case study three.

2.4. Four Step

The fourth phase involved the three case studies that were utilized to create an FS and EM sustainability matrix using the performance indicators derived from the findings of the second and third case studies analyzed.

The three research case studies employed rigorous statistical methods, including frequencies, central position values, cross-tables, and specific nonparametric tests such as the Spearman correlation coefficient, Kendall’s Tau coefficient, and the Mann–Whitney U Test, all conducted at a predetermined significance level.

3. Results

3.1. FS Management Performance

The first case study provides a detailed look at FS in wineries, highlighting the complex nature of FSM practices, with a particular focus on the implementation of PRPs and the HACCP system. This scrutiny unravels the pivotal role of annual wine production levels, with wineries classified into distinct groups based on their production volumes, allowing for a nuanced exploration of correlations with workforce training, economic considerations, and the overall efficacy of HACCP control performance.

Within the confines of PRP implementation, the study discloses a commendable 91.5% success rate, delineating the percentage of wineries that have seamlessly integrated specific programs within the standard PRPs. An intricate analysis of FS worker training unfolds, indicating that 81% of wineries possess a workforce where at least 50% are trained in Good Manufacturing Practices in winemaking, with a discernible concentration in wineries surpassing an annual wine production of 100,000 L/year. Notably, the economic dimension is explored, revealing that 62% of wineries formulate their PRP plans without a specific annual budget, accentuating a substantive correlation between winery size and the presence of a dedicated budget for PRP development.

An exploration of HACCP implementation in wineries ensues, encompassing the overall implementation rate, performance in principles one and two, and a meticulous examination of specific control points. The study discloses a commendable 76.2% embrace of HACCP, showcasing variations contingent on annual production levels. The identified CCPs and oPRPs are thoughtfully categorized based on median values and variability, offering insights into the extent of control over each CCP. This in-depth analysis underscores the essential role of well-controlled CCPs in ensuring the safety of the final wine product.

Table 1 illustrates the control performance of CCPs and oPRPs in the red wine process through the application of a color-coded reading method, where cells were color-coded ranging from dark orange (lowest control) to dark blue (highest control).

Table 1.

Control performance of CCPs and oPRPs in the red wine process by wineries.

This contingency table was constructed utilizing the medians of categorical variables associated with each analyzed CCP. The categorization into five groups was based on the median values of each variable and the presence of significant variability, as measured by the interquartile range. Group I and Group II denote the CCPs and oPRPs with the least effective control in wineries, thereby presenting a heightened risk to the safety of the final product. Conversely, Group III and Group IV signify the CCPs and oPRPs that exhibit effective control in at least fifty percent of wineries. Group V comprises variables with a median value of three, indicating that the associated CCPs and oPRPs were consistently controlled under the category of “Always”.

Moreover, the performance analysis of CCPs highlights varying degrees of control over specific winemaking steps. Correlations between different CCPs are meticulously explored, revealing associations between safety and purity control of additives, residue control from wine clarifiers, and other key variables.

The comprehensive nature of the study delivers a detailed and nuanced analysis of HACCP implementation and control performance, shedding light on specific critical points that necessitate heightened attention to guarantee the safety and quality of the final wine product.

3.2. CCP Control Performance

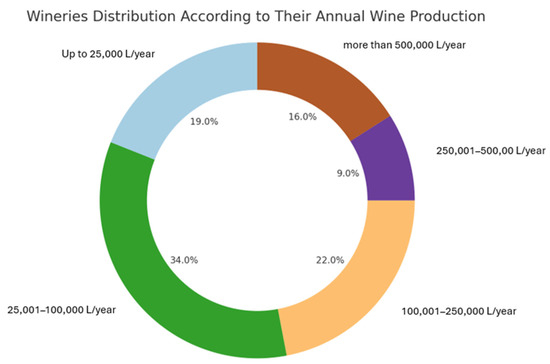

Wineries’ distribution by production capacity in the second case study is displayed in Figure 6.

Figure 6.

Wineries’ distribution by wine annual production capacity.

Study results show how wineries navigate the realms of worker training, legal compliance, and the monitoring of harmful substances like arsenic, cadmium, and lead in grapes and wines. An essential revelation from this exploration is the earnest commitment of most surveyed wineries to FS, with an impressive 96.9% adhering to regulations and 93.8% following industry standards.

The results of Table 2 show that as the winery gets bigger according to its yearly wine production, it has more workers trained in GMPs and CCPs. However, the percentage of trained workers is also high in smaller wineries. This is due to the number of workers ranging between two and three in this winery group, and, therefore, having trained a worker already reaches values of fifty percent.

Table 2.

GMP workers training and CCPs workers training by type of winery.

The correlation between winery size and the number of workers trained in both GMPs and CCPs underscores the industry’s recognition of the resource-intensive nature of such training efforts. Notably, there is a positive connection between GMPs and CCP training surfaces, revealing a systematic approach to ensuring FS. Smaller wineries, while exhibiting a high percentage of trained workers, may face limitations in absolute numbers due to their smaller workforce.

This investigation delves into legislative compliance and Heavy Metal Food Contamination Risk (HMFCR) laws, revealing suboptimal awareness among smaller wineries regarding critical regulations. The study underlines the industry-wide gap in utilizing available resources, such as information from the National Agency (AESAN), for regulatory compliance. Information from the AESAN is utilized by merely one-third of small to medium-sized wineries, those producing up to 250,000 L per year. In contrast, larger wineries, with production exceeding 250,001 L annually, show a higher usage rate at 66.7%, though this still falls short of being adequate. Additionally, there is a notable lack of clear recognition of HMFCR regulations within wineries, particularly among those with an annual production of less than 250,001 L of wine. Table 3 shows HMFCR legislation identification and HMFCR legislation updating through the AESAN by winery production capacity.

Table 3.

HMFCR legislation identification and HMFCR legislation updating through the AESAN by production capacity.

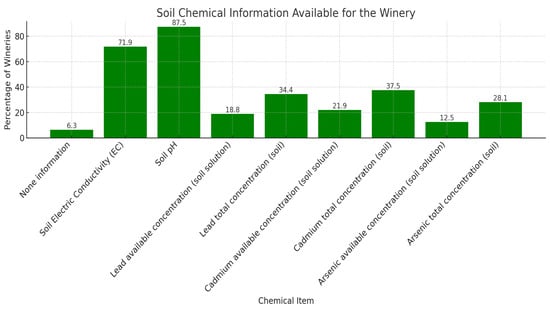

A significant number of wineries maintain records on both the physical and chemical properties of their vineyard soils, alongside data on the fertilizers applied to these soils. There exists a positive tendency among wineries to keep concurrent records of soil composition and the fertilizers applied, indicating that those with comprehensive soil analyses are likely to also possess detailed information on fertilization practices. Figure 7 reflects the proportion of wineries with data about the chemical composition of their vineyard soils.

Figure 7.

Percentage of wineries with information about each chemical soil item.

A third of wineries have data on soil levels of arsenic, cadmium, and lead, but fewer have information on these elements in soil solutions. Only 10% of wineries have arsenic data, and 20% have cadmium and lead data for vineyard soils. Larger wineries are more likely to have data on total cadmium and lead concentrations, but data on arsenic are rare across all winery sizes. The most reported data is on cadmium in soil solutions, especially among mid-sized wineries. The lack of comprehensive soil contamination data hampers effective risk assessment for grape contamination. Despite this, 78.1% of wineries have their own labs for grape and wine chemical analyses, while 20% rely on external services for such analyses. However, a notable gap emerges concerning information on harmful substances like arsenic, cadmium, and lead, particularly in smaller wineries. This informational void poses a significant challenge in assessing and mitigating contamination risks during winemaking, potentially impacting the final product’s quality and safety. While larger wineries generally perform better, differences persist across winery sizes, emphasizing the necessity for targeted interventions that recognize the unique challenges faced by wineries of varying scales.

3.3. EM Performance

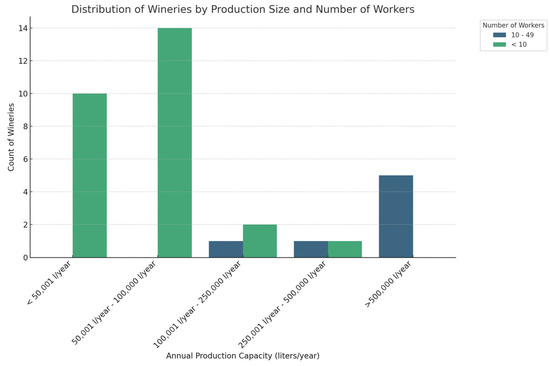

The third case study investigates key areas of EM that wineries claim to consider, including communication, commitment, leadership, environmental planning, and training. Initially, it explores the operational dimensions of the wineries, with a focus on both the annual production capacity and the workforce size.

Figure 8 illustrates the wineries’ distribution by production capacity, segmented by the number of workers, providing a layered perspective on the operational characteristics of the wineries involved in our survey. This visualization highlights the variance in production capacities, from less than 50,001 L per year to more than 500,000 L per year, and elucidates the corresponding workforce sizes, revealing the diverse approaches to production and manpower management across the sector.

Figure 8.

Relationship between production capacity and workforce size.

These insights are instrumental in understanding the scalability and adaptability of EM strategies within the wineries, underlining the critical role of operational scale in sustainable practices. Results highlight a conspicuous lack of clearly defined EM areas in Italian wineries, with only large wineries (80%) having implemented a structured focus on EM.

While the overarching results of our study highlight a pervasive ambiguity in the explicitly defined areas of EM across the surveyed wineries, a pronounced disparity becomes apparent when dissecting the data by winery size. Notably, in larger wineries, those with annual production capacities exceeding 500,000 L and staffing levels above 50 employees, a significant 80% demonstrate a clear, structured emphasis on EM practices. This is in stark contrast to their smaller counterparts, where such structured approaches are markedly less prevalent. Table 4 displays the environmental commitments and the environmental emergency scenarios that wineries have considered in their EMS categorized by their annual wine production capacity.

Table 4.

Environmental commitments and environmental emergency scenarios per annual wine production categories.

This distinction is particularly evident in the adoption of comprehensive EMSs, where larger wineries are more likely to have implemented sophisticated EMS frameworks, aligning closely with international standards such as ISO 14001:2015. Our analysis reveals that among the larger wineries, approximately 76% have either fully adopted or are in the process of implementing ISO 14001-certified systems, compared to a mere 24% among wineries with production capacities under 50,001 L per year.

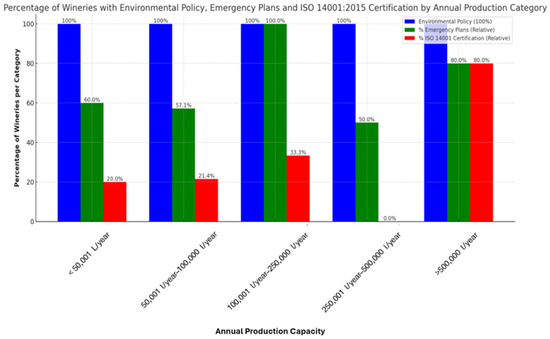

Moreover, the commitment to EM in larger wineries extends beyond mere certification. These establishments often exhibit a more holistic approach to sustainability, incorporating advanced environmental planning, rigorous training programs, and robust leadership commitment. Our results indicate that nearly 80% of the larger wineries engage in regular environmental training sessions for their employees, which are aimed at fostering a culture of sustainability and ensuring compliance with environmental policies and practices. Figure 9 shows the percentage of wineries that have established an environmental policy, emergency plans, and ISO 14001:2015 by annual wine production categories.

Figure 9.

Percentage of wineries with an environmental policy, emergency plans, and ISO 14001 certification.

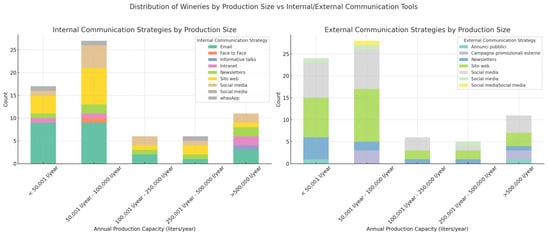

Additionally, the strategic use of environmental communication stands out as a hallmark of larger wineries’ EM efforts. A significant 90% of these wineries employ a diverse array of communication channels, both internal and external, to promote environmental awareness and report on sustainability initiatives. This includes the extensive use of digital platforms such as company websites, social media, and specialized environmental reports, ensuring a broad reach and engagement with various stakeholders, from employees and customers to regulatory bodies and the wider community. Figure 10 provides a clear depiction of how wineries communicate their environmental performance internally and externally, emphasizing the prevalence of digital and electronic communication methods in their communication practices.

Figure 10.

Internal/external environmental communication tools used by annual production categories.

Environmental communication practices, both internal and external, come under meticulous examination, revealing email as the most widely used internal communication medium (74.2%), followed by websites (45.2%) and social media (35.5%). External communication predominantly occurs through social media (84.4%) and websites (81.3%). Clients and shops emerge as the primary stakeholders receiving environmental information from wineries, emphasizing the pervasive use of Information and Communication Technologies (ICTs) for communication.

A substantial portion of wineries (71.9%) demonstrates the establishment of environmental policies and senior management leadership, with owners playing a pivotal role (50%). Key environmental objectives, such as waste and electricity consumption reduction, are identified, evaluating their alignment with long-term environmental policy commitments. A 68.8% of wineries have an EMS; however, certain deficiencies are highlighted, as evidenced by 38.7% of wineries lacking an Environmental Emergency Plan (EEP), and only 31.3% of wineries have their EMS certified according to the ISO 14001:2005 standard. The research underscores the paramount importance of these requirements for establishing a robust foundation for EM in winemaking.

The examination of environmental training for workers reveals that 71% of wineries provide training in connection with their EMS. Finally, five performance indicators assess the performance of wineries in communication, commitment, planning, other requirements, and workers’ training. The results provide a comprehensive understanding of the state of EM practices in Italian wineries, shedding light on areas of strength and aspects that may require improvement.

Effectiveness in EM is achieved through the combination of five components: communication, commitment, planning, other requirements, and workers training.

3.4. FSMS Performance Indicators

Three performance indicators were derived in the context of case study two based on the three FS components encompassing worker training, adherence to legal rules, and surveillance of hazardous substances.

A quantitative analysis of FS worker training (FSWT) was performed based on an indicator defined by Equation (1) [58,59,60]:

where

- is the aggregated FSWT variable for the winery;

- is a variable that stands for the level of workers trained in GMPs and takes values 0.33, 0.66, or 1;

- is the variable that represents the level of workers trained in CCPs and takes values 0.33, 0.66, or 1;

- is the number of variables that have been aggregated, and its value is 2.

A quantitative analysis of legislation identification and updating (LIU) was performed based on an indicator defined by Equation (2):

where

- is the aggregated LIU variable for the winery;

- is a variable that stands for winery performance on legislation identification about arsenic, cadmium, and lead and takes values 0.33, 0.66, or 1;

- is a variable that represents winery performance on updated legislation information through AESAN and takes values 0 or 1;

- is the number of variables that have been aggregated, and its value is 2.

A quantitative analysis of critical control point chemical analysis performance (CCP-MCHEM) was evaluated based on an indicator defined by Equation (3):

where

- is the aggregated CCP-MCHEM variable for the winery;

- is a variable that stands for chemical information about arsenic, cadmium, and lead concentrations in the soil that a winery had; is each item of this multiple-choice question (yes = 0.125, no = 0);

- is a variable that represents the wineries’ capacity to hold a chemical analysis by their own or external means. if , otherwise, ;

- is a variable that stands for the wineries’ capacity to hold arsenic, cadmium, and lead chemical analysis by their own or external means. if , otherwise, ;

- is the number of variables that have been aggregated, and its value is 3.

3.5. EMS Performance Indicators

Five performance indicators were derived in the context of case study three based on the five EM components encompassing communication, commitment, planning, other requirements, and workers training.

A quantitative analysis of environmental communication was performed based on an indicator defined by Equation (4) [58,59]:

where

- is the aggregated communication variable for the winery;

- is the internal communication strategy variable of the winery; is each item of this multiple-choice question (yes = 0.167, no = 0);

- is the external communication strategy variable of the winery; is each item of this multiple-choice question (yes = 0.167, no = 0);

- is the stakeholder’s variable to whom the winery communicates its environmental information of the winery; is each item of this multiple-choice question (yes = 0.167, no = 0);

- is the environmental policy communication variable of the winery; is each item of this multiple-choice question (yes = 0.125, no = 0);

- is the number of variables that have been aggregated, and its value is 4.

A quantitative measure of environmental commitment was performed based on an indicator defined by Equation (5):

where

- is the aggregated commitment variable for each winery;

- is the winery environmental policy variable of the winery (yes = 1, no = 0);

- is the environmental director variable of the winery (yes = 1, no = 0);

- measures the senior management environmental system evaluation frequency (it could take one of next four values, 1 if (at least every six months), 0.75 (more than once a year), 0.50 (annually), and 0 (never reviewed));

- is the environmental evaluation procedure variable of the winery (yes = 1, no = 0);

- is the number of variables that have been aggregated, and its value is 4.

A quantitative measure of environmental planning was performed based on an indicator defined by Equation (6):

where

- is the aggregated EM planning variable for each winery;

- measures the wineries’ primary environmental objectives of the winery; is each item of this multiple-choice question (yes = 0.112, no = 0);

- is the EM specific areas variable of the winery; is each item of this multiple-choice question (yes = 0.112, no = 0);

- is the environmental commitments variable of the winery; is each item of this multiple-choice question (yes = 0.125, no = 0);

- is the life cycle aspects variable; is each item of this multiple-choice question (yes = 0.334, no = 0);

- is the winery energy consumption environmental aspect variable of the winery (yes = 1, no = 0);

- is the waste management performance environmental aspect variable of the winery (yes = 1, no = 0);

- is the fermentation emissions performance environmental aspect variable of the winery (yes = 1, no = 0);

- is the legal environmental requirements variable of the winery (yes = 1, no = 0);

- is the risk assessment variable (it could take one of the following three values: 1 if (quantitative method), 0.50 (qualitative method), and 0 (none));

- is the opportunity assessment variable (it could take one of the following three values: 1 if (quantitative method), 0.50 (qualitative method), and 0 (none));

- is the number of variables that have been aggregated, and its value is 10.

A quantitative measure of other environmental requirements was performed based on an indicator defined by Equation (7):

where

- is the aggregated other environmental requirements variable for each winery;

- is the EEP availability variable of the winery (yes = 1, no = 0);

- measures the kind of emergencies in the EEP of the winery; is each item of this multiple-choice question (yes = 0.167, no = 0);

- measures the EEP evaluation frequency (it could take one of the following four values: 1 if (at least every six months), 0.75 (more than once a year), 0.50 (annually), and 0 (never reviewed));

- is the EMS document availability variable of the winery (yes = 1, no = 0);

- measures how the EMS information is recorded in the winery; is each item of this multiple-choice question (yes = 0.2, no = 0);

- measures the document control frequency (it could take one of the following four values: 1 if (at least every six months), 0.75 (annually), 0.50 (more than once a year), and 0 (never reviewed));

- is the legal environmental requirements variable of the winery (yes = 1, no = 0);

- is the number of variables that have been aggregated, and its value is 7.

A quantitative measure of environmental training for workers was performed based on an indicator defined by Equation (8):

where

- is the aggregated environmental worker training variable for each winery;

- is the EMS workers training availability variable of the winery (yes = 1, no = 0);

- measures the workers training frequency (it could take one of the following four values: 1 if (at least every six months), 0.75 (annually), 0.50 (more than once a year), and 0 (never));

- measures the number of employees who participate in environmental training courses annually (it could take one of the following four values: 1 (more than 75%), 0.75 (between 50% and 75%), 0.50 (between 25% and 50%), and 0.25 (less than 25%));

- is the number of variables that have been aggregated, and its value is 3.

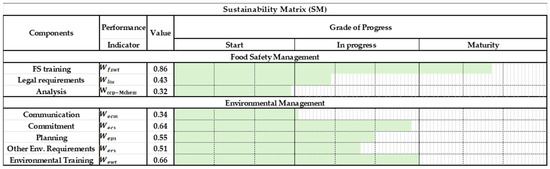

3.6. Matrix of Sustainability Based on FS and EM

The sustainability matrix (SM), which illustrates the progress towards sustainability in wineries through FS and EM metrics, is formulated by integrating the findings from case studies two and three, respectively. The FS performance indicators, derived from the second case study, and the EM performance indicators, sourced from the third case study, collectively inform the matrix. Presented in Figure 11, the SM encapsulates the FSMS performance by averaging the scores from the winery sample in the second case study, alongside the EMS performance, which similarly utilizes the average scores from the third case study’s winery sample. The matrix employs a color-coded scheme for ease of interpretation, where each indicator’s value is depicted by a green line. The classification of sustainability progress is delineated as “Start” for indicator values ranging from 0 to 0.33, indicating initial stages; “In progress” for values from 0.34 to 0.67, denoting ongoing development; and “Maturity” for values from 0.68 to 1, signifying advanced integration of sustainability practices.

Figure 11.

Sustainability matrix (SM) based on the performance of the FSMS and EMS.

FSMS indicators, which cover aspects like worker training, legal compliance, and monitoring of hazardous substances, offer a comprehensive view of winery FS practices. The Wfswt indicator, which measures the extent of training in GMPs and CCPs, emphasizes the importance of thorough training in reducing contamination risks and ensuring wine safety. This indicator’s high scores reflect wineries’ substantial investment in training, indicating a deep-rooted culture of food safety. However, it also points to the ongoing need to update and expand training programs to meet new FS challenges and regulations.

The Wliu indicator assesses how well wineries keep up with laws concerning substances like arsenic, cadmium, and lead. The intermediate scores here show a moderate level of legal awareness and compliance, suggesting a gap in knowledge sharing and the need for stronger systems to keep wineries informed about food safety laws.

The Wccp-Mchem indicator evaluates the ability to analyze chemical hazards, a key part of FS. Its lower scores indicate room for improvement in analytical capabilities and the adoption of more thorough testing methods to proactively manage contamination risks.

These FS indicators collectively offer a detailed look at the strengths and areas for improvement in winery FS practices, aligning with wider sustainability goals and ensuring consumer health and safety. This analysis highlights the intricate relationship between training, compliance, and hazard management in creating a strong FS framework that is crucial for sustainable and responsible wine production.

Turning to EM indicators, the Wecx and Wewt quantitatively reflect wineries’ sustainability efforts. For example, the Wecx score of 0.64 signals a strong commitment to environmental sustainability through established policies and active management, though there is room to increase the frequency of EMS reviews. The Wewt score, close to the “Maturity” level at 0.66, points to the significant role of environmental training in wineries, suggesting solid groundwork with potential for further growth. The Wepx indicates ongoing environmental planning efforts, though the need for better alignment, especially regarding fossil fuel consumption, suggests areas for strategic improvement. The Werx indicator shows a moderate implementation level (0.51) of additional environmental management practices, with variations in emergency preparedness and documentation control indicating the need for more consistent management approaches. Wecm, with a low score in the “In progress” category (0.34), highlights a lack of effective communication strategies in environmental management, suggesting that wineries could benefit from better internal and external communication of their environmental policies and practices to enhance EM effectiveness.

Analyzing the distribution of these eight indicators within these categories reveals the nuanced progress wineries have made toward sustainability. For example, the “In progress” status for many indicators suggests a significant potential for improvement, especially in legal requirements and physicochemical analysis for FS and in commitment and environmental training for EM. This nuanced interpretation can inform targeted strategies for wineries to enhance their sustainability practices.

The alignment of the SM with the F2F Strategy’s objectives is crucial. The matrix’s indicators can be directly linked to F2F goals such as reducing the environmental footprint, ensuring FS, and promoting sustainable practices. The SM not only serves as a diagnostic tool but also guides strategic decision-making for wineries. By identifying areas of strength and potential improvement, the SM can inform targeted interventions. For example, wineries scoring lower in the workers training component (Wewt) might invest more in training programs, while those with lower environmental commitment scores might focus on enhancing their EMS policies and management engagement.

4. Discussion

The wine production industry, like other agricultural sectors, must undergo transformative evolution to align with sustainability objectives. Effectively integrating sustainability into wine production demands methodical approaches, considering the intricate challenges and opportunities inherent in the process. Strategies such as FS assurance, responsible agricultural practices, and the reduction of environmental impacts are identified as pivotal for wineries [61,62].

An in-depth investigation into FS reveals substantial variations in the control performance of thirty-seven CCPs and oPRPs assessed during the wine production process. Out of these thirty-seven elements, twenty-two received favorable evaluations, while fifteen exhibited notable performance disparities based on specific practices within each winery.

It is imperative to underscore that significant control deficiencies observed in wineries were associated with various aspects, including the management of trace metals, fungicides, and pesticides in grapes or wine from a chemical perspective. Similarly, deficiencies in biological controls, such as microorganisms on equipment, and operational stage controls, like the duration of must in crushers, demonstrated suboptimal performance. In instances where both CCPs and oPRPs are inadequately controlled, there is an increased risk of potential hazards, such as the presence of microorganisms, trace metals, fungicides, pesticides, or other hazardous substances in grapes or wine [42,63,64].

Performance indicators play a fundamental role in assessing the sustainability of wineries in terms of FS, enabling the measurement of the effectiveness of risk management practices.

Illustrating the importance of indicators in FS is the training component . The “Maturity” grade of progress indicates that wineries have achieved an advanced stage in the training component. This suggests a shared commitment among wineries to invest in training to address contamination risks effectively. These findings align with research emphasizing the significance of aspects related to FS culture, particularly concerning human factors and specialized training [65,66].

Progress in the legislation component is measured by and shows a performance level of “In progress” (0.43). This emphasizes the need for greater knowledge and compliance with European legislation related to FS concerning the risks of contamination by heavy metals. The progression in legislation-related activities is a crucial aspect in ensuring compliance and addressing contamination risks.

Progress in the analysis component is reflected by achieving a “Start” level in . The analysis component, crucial for identifying and controlling the presence of arsenic, cadmium, and lead in grapes and wines, is considered the least mature in terms of performance. Wineries need to focus more on progressing in the legislation and analysis components to enhance their ability to manage contamination risks effectively and thus achieve greater progress in their sustainability.

Hence, the sustainability of wineries in terms of FS is currently classified as “In progress”, with considerable scope for improvement, particularly in the components of legal requirements and analysis. Our results are aligned with the pros and cons of sustainable wine production found by Szolnoki, G. [26].

EM research reveals that main environmental objectives, focusing on waste, electricity, and water reduction, emerge as central to sustainability efforts. However, there is a need for more consistent alignment between long-term commitments and annual objectives. Wineries prioritize objectives such as waste reduction, electricity, and water consumption reduction, aligning with their sustainability goals. However, there is room for improvement in synchronizing with fossil fuel consumption objectives. These findings align with other studies about environmental aspects and impacts in the winemaking process and measures to reduce them [67,68,69].

Emergency preparedness varies, with 38.7% lacking plans, emphasizing the need for improvement. The results reveal that the significance of ISO 14001:2015 certification is low, which is in line with other studies conducted in the Italian wine sector [70,71].

Environmental performance indicators provide insights into the progress of sustainability concepts, reflecting their global commitment to enhancing environmental sustainability. The communication component indicator () reveals a lack of progress as evidenced by a value corresponding to the “Start” grade of progress (0.34). It is imperative for wineries to concentrate on refining their communication strategies to improve overall EM effectiveness.

The environmental commitment indicator () achieves a 0.64 that corresponds to an “In progress” grade of performance. It exhibits a robust commitment to environmental sustainability through well-established policies and dedicated senior management teams, although the frequency of EMS reviews varies. Carrillo Higueras et al. [72] found that winery managers consider their own attitudes towards the environment and their perceptions of control as the most important factors when adopting environmental commitment in their organization.

The planning component indicator () reveals a landscape where “In progress” grades of progress are prevalent, indicating continual efforts in environmental planning across wineries. However, there is room for improved alignment, especially in fossil fuel consumption objectives. Findings are aligned with the research study recommendations obtained by Gierling F. et al. [73], and it is also in agreement with a previous study conducted by Carronquino J. et al. [74], since environmental planning has not been sufficient to promote adaptation and mitigation to climate change.

Other requirements () generally show that wineries are “In progress” in implementing other EM requirements. Emergency preparedness varies, with 38.7% lacking plans, emphasizing the need for improvement. Organizing and controlling documentation is crucial for nearly a hundred percent of wineries, with half of them updating it annually to align with ISO 14001, emphasizing their commitment to EM traceability through the document system. Nevertheless, one-third of wineries fall short in completing this yearly updating process, presenting an opportunity for improvement in maintaining their EMS documentation.

The workers training component () currently indicates an “In progress” status with a progress level of 0.66. This level closely approaches “Maturity”, underscoring the significance of environmental training for wineries. These findings highlight the critical role of environmental training in the winemaking industry.

The sustainability of wineries in terms of EM is at a stage of medium progress, with components such as commitment and environmental training approaching maturity. These findings align with the research on environmental sustainability in wineries conducted by Baiano A. (2021) [53].

Our research reveals critical insights essential for advancing the wine sector. The sustainability of wineries in terms of FS is presently described as “In progress”, signifying a significant potential for improvement, particularly in the facets of legal requirements and analysis. This implies that wineries must enhance their compliance with FS regulations and refine their physicochemical analysis processes to boost FS outcomes. In terms of the sustainability of wineries, EM is observed to be at a moderate level of advancement. Notably, elements like the commitment to sustainability and environmental training are on the verge of reaching full maturity, indicating a growing recognition and incorporation of environmental considerations into the operational principles of wineries. These findings highlight the differentiated progress in the winery industry towards sustainability, pointing out specific areas where focused initiatives can lead to more substantial improvements.

5. Conclusions

Against the backdrop of global concerns about the sustainability of agricultural and food production, the EU policy emerges with a central focus through the F2F Strategy, emphasizing the need for a paradigm shift towards principles that seamlessly integrate environmental preservation, FS, and nutritious sustenance.

In this context, the concept of sustainability necessitates interpretation through methods capable of quantifying its evolution and progress within wineries. This comprehensive exploration of sustainability in wineries, which is in alignment with the F2F Strategy and considers both FS and EM perspectives, sheds light on crucial aspects requiring attention and improvement within the wine production industry.

This study underscores the imperative for the wine production industry to undergo transformative evolution, aligning with sustainability objectives in line with the goals of the F2F Strategy. Actions such as FS assurance and environmental impact reduction are identified as pivotal for wineries in achieving sustainability.

The SM is composed of the performance indicators of wineries in different components of sustainability in terms of FS and EM, and it plays a fundamental role in assessing wineries’ approach to F2F Strategy goals. SM provides a comprehensive framework for wineries to evaluate their efforts for being more sustainable, addressing specific areas requiring focused attention and improvement in both FS and EM dimensions.

Protected Designations of Origin, cooperatives, and regulatory bodies can play a key role in supporting sustainability development by proposing incentives such as rewards or public subsidies for wineries that demonstrate better performance in FM and EM. By using the proposed SM as an evaluation tool, these entities can establish clear and objective criteria to measure the commitment and effectiveness of sustainable practices in the wine sector, thus promoting continuous improvement and recognizing significant efforts towards a more sustainable future.

Leadership plays a crucial role in establishing a strong culture towards sustainability within wineries, where owners and managers must lead by example, showing unwavering commitment to the effectiveness of FSMSs and EMSs. This dedication not only fosters an environment where all workers feel motivated to align with the objectives of senior management but also facilitates the identification of strengths and areas susceptible to improvement. By doing so, it enriches the perspective on the various approaches adopted by the industry and the level of commitment to sustainability, which is vital for promoting safer and more sustainable practices in the wine sector.

Finally, there is ample opportunity to further study and delve into the methodology of indicators calculation and its application to other sectors within the agro-industry. The application of artificial intelligence based on machine learning and neural networks emerges as a promising approach. These techniques have the capability to enhance existing indicators by incorporating new attributes, aiming to facilitate the prediction of sustainability. This process involves expanding the predictive capacity through the identification and evaluation of additional factors that impact sustainability in this specific context. The deployment of these advanced methodologies opens the door to a deeper and more precise understanding of sustainable aspects in the operations of wineries and other agro-industrial entities, thereby providing a more comprehensive and anticipatory approach to sustainability management in these sectors.

Author Contributions

Conceptualization, J.L.-S., A.M.S. and M.T.G.-V.; methodology, J.L.-S., F.A.B.M.Y., F.R.M. and M.T.G.-V.; validation, J.L.-S., F.R.M. and M.T.G.-V.; formal analysis, J.L.-S.; investigation, J.L.-S. and M.T.G.-V.; data curation, J.L.-S.; writing—original draft preparation, J.L.-S.; writing—review and editing, J.L.-S., A.M.S., F.A.B.M.Y., F.R.M. and M.T.G.-V.; supervision, A.M.S., F.A.B.M.Y., F.R.M. and M.T.G.-V. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data used in this study are available on fair request to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Appendix A.1. Survey for the Analysis of Implementation and Deployment of HACCP System in Wineries Producing Red Wine

- * Indicates That the Question is Mandatory

- Email Address *

- G.0

- What is your annual production level of young red wine? Mark only one oval.

- ○

- up to 25,000 L/year

- ○

- between 25,001 and 100,000 L/year

- ○

- between 100,001 and 250,000 L/year

- ○

- between 250,001 and 500,000 L/year

- ○

- more than 500,001 L/year

- G.1

- Have you implemented a prerequisite program according to the food hygiene legislation?* Mark only one oval.

- ○

- Yes

- ○

- No

- G.2

- Indicate which type of prerequisite plans you have implemented. * Select all that apply.

- □

- G.2.1 Maintenance of premises, facilities, and equipment

- □

- G.2.2 Good Manufacturing Practices Plan

- □

- G.2.3 Cleaning and disinfection plan

- □

- G.2.4 Waste control plan

- □

- G.2.5 Pest control plan

- □

- G.2.6 Control plan for water supply

- □

- G.2.7 Traceability control plan

- □

- G.2.8 Supplier control plan

- □

- G.2.9 Allergen control plan

- □

- G.2.10 Worker training plan

- G.3

- Do winery operators have training related to good viticulture practices (BPV)?* Mark only one oval.

- ○

- No operator has BPV training.

- ○

- More than half of the operators have BPV training.

- ○

- All operators have BPV training.

- G.4

- Do winery operators know the prerequisite plans implemented in the winery? Mark only one oval.

- ○

- No operator is aware of the implemented prerequisite plans.

- ○

- More than half of the operators are aware of the implemented prerequisite plans.

- ○

- All operators are aware of the implemented prerequisite plans.

- G.5

- Does the winery have a specific annual budget for the execution of the prerequisite plans?* Mark only one oval.

- ○

- The winery does not have an annual budget for this matter.

- ○

- The winery carries out plans as needed but does not have a detailed annual budget.

- ○

- The winery has a detailed annual budget, which it executes in a planned manner.

- G.6

- Has the winery implemented a Hazard Analysis and Critical Control Point (HACCP) System?* Mark only one oval.

- ○

- Yes

- ○

- No

- Harvest and Transportation

- 2.1

- Are periodic inspections carried out in the vineyards prior to the harvest?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 2.2

- Are inspections conducted in the vineyards during the harvest to control hygiene measures during this stage?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 2.3

- Is the time taken to transport grapes destined for the production of red wine measured from the vineyard to the winery?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Receipt of the harvest at the winery

- 3.1

- Is the measurement of residues of fungicides and/or pesticides in grapes destined for the production of red wine carried out when received at the winery?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 3.2

- Is the presence of mycotoxins from rotting grapes checked?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 3.3

- Is the presence of contamination by metals (cadmium, lead, arsenic) in grapes checked?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 3.4

- Is the presence of contamination by vegetable residues, dust, and/or metallic elements in grapes checked?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Pre-fermentation Treatments

- 4.1

- Is the cleanliness of tanks controlled to eliminate residues of microorganisms?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 4.2

- Is the absence of cleaning and disinfection products from performing these tasks in the tanks controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Grape Crushing and Paste Pumping

- 5.1

- Is it controlled that the maintenance time of the must in the crusher is less than two hours?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 5.2

- Is the cleanliness of the crushing equipment controlled with a frequency not exceeding two days?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 5.3

- Is the absence of cleaning and disinfection products from performing these tasks in the tanks, press, and/or pumping equipment controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Sulfiting and Fermentation

- 6.1

- Is the safety and purity of additives controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 6.2

- Is the absence of microorganisms in the equipment and tanks controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Alcoholic Fermentation, Maceration, Racking, Pressing of Grape Pomace, Malolactic Fermentation, and Finishing Fermentation

- 7.1

- Is the concentration of ethyl carbamate in the fermented must controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.2

- Is the concentration of sulfur dioxide in the fermented must controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.3

- Is the purity and safety of yeasts controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.4

- Is the temperature controlled during fermentation?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.5

- Is the pH of red wine controlled during malolactic fermentation?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.6

- Is hygiene controlled during racking and pressing operations?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 7.7

- Is the cleanliness of pressing equipment controlled with a frequency not exceeding two days?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Racking, Clarification, and Filtration

- 8.1

- Are the cleaning procedures for tanks and racking equipment controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.2

- Are the maintenance and cleaning procedures of the facilities controlled during the racking stage?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.3

- Is the purity and safety of the agents used as clarifiers in red wine controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.4

- Is the absence of residues from the agents used as clarifiers in red wine controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.5

- Is the absence of foreign elements from the filters in red wine controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.6

- Are hygiene operations controlled during clarification and filtration operations?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 8.7

- Is the absence of cleaning and disinfection products from racking, clarification, and filtration tasks in tanks and/or equipment controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Cold Stabilization

- 9.1

- Are the limit concentrations of metals (traces of As, Cu, Pb) in red wine controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 9.2

- Is it controlled that the additives used are those allowed by current food legislation?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Bottling and Labeling

- 10.1

- Are bottle cleaning procedures controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.2

- Are maintenance and cleaning procedures for the red wine bottling line controlled?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.3

- Is there microbiological control of the red wine bottling line and bottles?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.4

- Is it controlled that the cork or a similar plug used for closing the bottles has undergone microbiological control?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.5

- Is it controlled that the label used is correctly coded?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.6

- Is it controlled that the label used correctly describes mandatory information about allergens?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- 10.7

- Is it controlled that the label used correctly describes information about the Denomination of Origin Vinos de Madrid?* Mark only one oval.

Never (0)/Hardly ever (1)/Usually (2)/Always (3).

- Application of HACCP Principles

- 11.1

- Have the winery’s managers set objective and critical limit levels for each of the identified critical points?* Mark only one oval.

- ○

- No, for none of them.

- ○

- Yes, but only for those where applicable mandatory regulations exist.

- ○

- Yes, for each and every one of them following applicable mandatory regulations and/or professional technical recommendations.

- 11.2

- Has the winery established a monitoring system for critical control points?* Mark only one oval.

- ○

- Yes

- ○

- No

- 11.3

- If a CCP monitoring system is established, what checking methods are used?* (Check all that apply from the following list). Select all that apply.

- ○

- Visual observation

- ○

- Sensory evaluation (smell, taste, aroma, texture)

- ○

- Physical determinations (temperature, relative humidity, pH)

- ○

- Chemical analysis

- ○

- Microbiological analysis

- 11.4.

- Does the winery have a written monitoring program detailing the surveillance activities of hazards and their CCPs at each stage of red wine production? ?* Mark only one oval.

- ○

- Yes

- ○

- No

- 11.5

- Does the winery have a written procedure for establishing corrective measures to be applied in case of deviations in each critical control point (CCP)?* Mark only one oval.

- ○

- Yes

- ○

- No

- 11.6

- Does the winery have a procedure for verifying the effectiveness of the CCP control system? ?* Mark only one oval.

- ○

- Yes

- ○

- No

- 11.7

- If yes, does this verification procedure detail the frequency of control for each critical control point (CCP) and the person in charge of performing it? ?* Mark only one oval.

- ○

- Yes

- ○

- No

- 11.8

- If yes, please indicate which people are involved in verifying the effectiveness of the CCP system. Check all options that apply.

- ○

- Winery owner

- ○

- Winery manager

- ○

- Quality manager or similar

- ○

- Winemaker

- ○

- Operators

- ○

- Others

- 11.9

- Does the winery conduct an annual internal audit of the Critical Control Points (CCPs) and control analysis?* Mark only one oval.

- ○

- No

- ○

- Yes, but with a frequency greater than one year.

- ○

- Yes, annually.

- 11.10

- Does the winery have a record and documentation system for the HACCP system? ?* Mark only one oval.

- ○

- There are no records or written documents.

- ○

- Yes, there are records and written documents, but they are not complete or not updated periodically.

- ○

- Yes, there is a complete and periodically updated record and documentation system.

- 11.11

- If yes, what documents does the winery’s HACCP system contain? (Check all options that apply)

- ○

- List of HACCP system team members

- ○

- Description of stages and production process of red wine

- ○

- Analysis of hazards and determination of preventive measures

- ○

- Identification of Critical Control Points (CCP)

- ○

- Surveillance program containing surveillance activities

- ○

- Corrective measures procedure

- ○

- Results of verifications and internal audits

- ○

- Document and record management procedure

- ○

- Records generated by the HACCP system.

Appendix A.2. Analysis of Wineries Performance about Critical Control Points Related to Risk Control Contamination by Arsenic, Cadmium, and Lead in Grapes/Wines during Winemaking

- * Obligatory

- General data of the winery

- G.1

- What is your annual level of red wine production?* (Mark only one)

up to 25,000 L/year

between 25,001 and 100,000 L/year

between 100,001 and 250,000 L/year

between 250,001 and 500,000 L/year more than 500,001 L/year

- G.2

- Do you have a prerequisite program in place, according to the legislation on food hygiene?* (Mark only one)

Yes/No

- G.3

- Does the winery have a Hazard Analysis and Critical Control Point (HACCP) system in place?* (Mark only one)

Yes/No

- G.4

- How many people work in wine production operations in the winery?*

- G.5

- Do winery workers have training about good manufacturing practices (GMPs)?* (Mark only one)

No worker has GMP training.

More than half of workers have GMP training.

All workers have GMP training.

- G.6

- Do winery workers have control training and monitoring of critical points (CCPs)?* (Mark only one)

No worker has training in the controlling and monitoring of CCPs.

More than half of workers have training in control and monitoring of the CCPs.

All workers have training in control and monitoring of the CCPs.

- Information available on arsenic, cadmium, and leads in the raw material (Critical Control Point)

- ID 1.

- The winery has identified the legislation relating to food contamination by the following: (check all those you consider).

Arsenic/Cadmium/Lead

- ID 2.

- The winery uses the updated information available from the Spanish Agency for Food Safety and Nutrition (AESAN) on heavy metals food risk. * (Mark only one)

Yes/No

- CS 1.

- Does the winery have information related to the physical-chemical analysis of where do the grapes used in winemaking come from?* (Mark only one)

Yes (Skip to question 11)/No

- CS 2.

- Does the winery have information on the fertilizers used in the fertilization of the soil from which the grapes used in winemaking come from?* (Mark only one)

Yes/No

- Information available on the concentration of arsenic, cadmium, and lead in the soil

- CS 3.

- The available information on the analysis of vineyard arable soil holds data on the following:

- Select all that apply.

Total Arsenic Concentration in Soil

Concentration of Arsenic Available in Soil

Total Cadmium Concentration in Soil

Cadmium Concentration Available in Soil

Total Lead Concentration in Soil

Lead Concentration Available in Soil

Soil pH

Electrical conductivity of the soil

- Control of the raw material (analysis procedures in the winery)

- CB 1.

- Does the winery have its own laboratory to perform a chemical analysis of grapes and wines?* (Mark only one)

Yes/No

- CB 2.

- If you do NOT have your own laboratory, do you use an external laboratory to perform a chemical analysis of grapes and wines?* (Mark only one)

Yes/No

- CB 3.

- Does the warehouse have the technology and personnel to perform a metal analysis using atomic absorption spectrometry?* (Mark only one)

Yes/No

- CB 4.

- If you do NOT have your own laboratory, do you use an external laboratory to perform a metal analysis using atomic absorption spectrometry on grapes and wines?*

Yes/No

- Professional profile that performs the survey

- You can tell us about your job inside the winery. (Mark only one)

Owner

Director/Manager

Winemaker

Winery Operator

Administrative/management/commercial staff

Other

Appendix A.3. Environmental Management System Questionnaire (Italy)

- * Obligatory

- Company name *

- E-mail address *

- S1.1 Annual production capacity. Mark only one oval.

- ○

- Less than 50,001 L/year.

- ○

- 50,001 L/year—100,000 L/year.

- ○

- 100,001 L/year—250,000 L/year.

- ○

- 250,001 L/year—1,000,000 L/year.

- ○

- More than 1,000,000 L/year.

- S1.2 Number of employees. Mark only one oval.

- ○

- <10.

- ○

- 10 to 49.

- ○

- 50 to 249.

- ○

- 250.

- S1.3 Job position in the company. Mark only one oval.

- ○

- General Manager.

- ○

- Owner Manager.

- ○

- Ecological Manager.

- ○

- Administration Officer.

- ○

- Vineyard Manager Executive Director.

- ○

- Other

- S2.1 What are the company’s main environmental objectives? Select all that apply.

- ○

- Electricity consumption reduction.

- ○

- Water consumption reduction.

- ○

- Land use reduction.

- ○

- Greenhouse gas emissions reduction.

- ○

- Other gas emissions reduction.

- ○

- Waste production reduction.

- ○

- Use of raw materials reduction.

- ○

- Substances released into the soil reduction.

- ○

- Other

- S2.2 Does the company have any of the following areas/departments? Select all that apply.

- ○

- Environmental Management.

- ○

- Leadership.

- ○

- Planning of environmental objectives.

- ○

- Environmental risk and opportunities.

- ○

- Resources and environmental support.

- ○

- Communication.

- ○

- Operation and environmental control.

- ○

- Emergency response.

- ○

- Monitoring, analysis, and evaluation of EMS performance.

- S2.3 What is the company’s internal communication strategy? Select all that apply.

- ○

- Website.

- ○

- Email.

- ○

- Social media (Facebook, Instagram, etc.).

- ○

- Newsletters.

- ○

- Internal staff site.

- ○

- Other

- S2.4 What is the company’s external communication strategy? Select all that apply.

- ○

- Website.

- ○

- Social media (Facebook, Instagram, etc.).

- ○

- Newsletters.

- ○

- Advertisement.

- ○

- Marketing campaigns.

- ○

- Other