Effects of Straw Incorporation and Decomposition on Soil Preferential Flow Patterns Using the Dye-Tracer Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Dye-Tracer Experiment

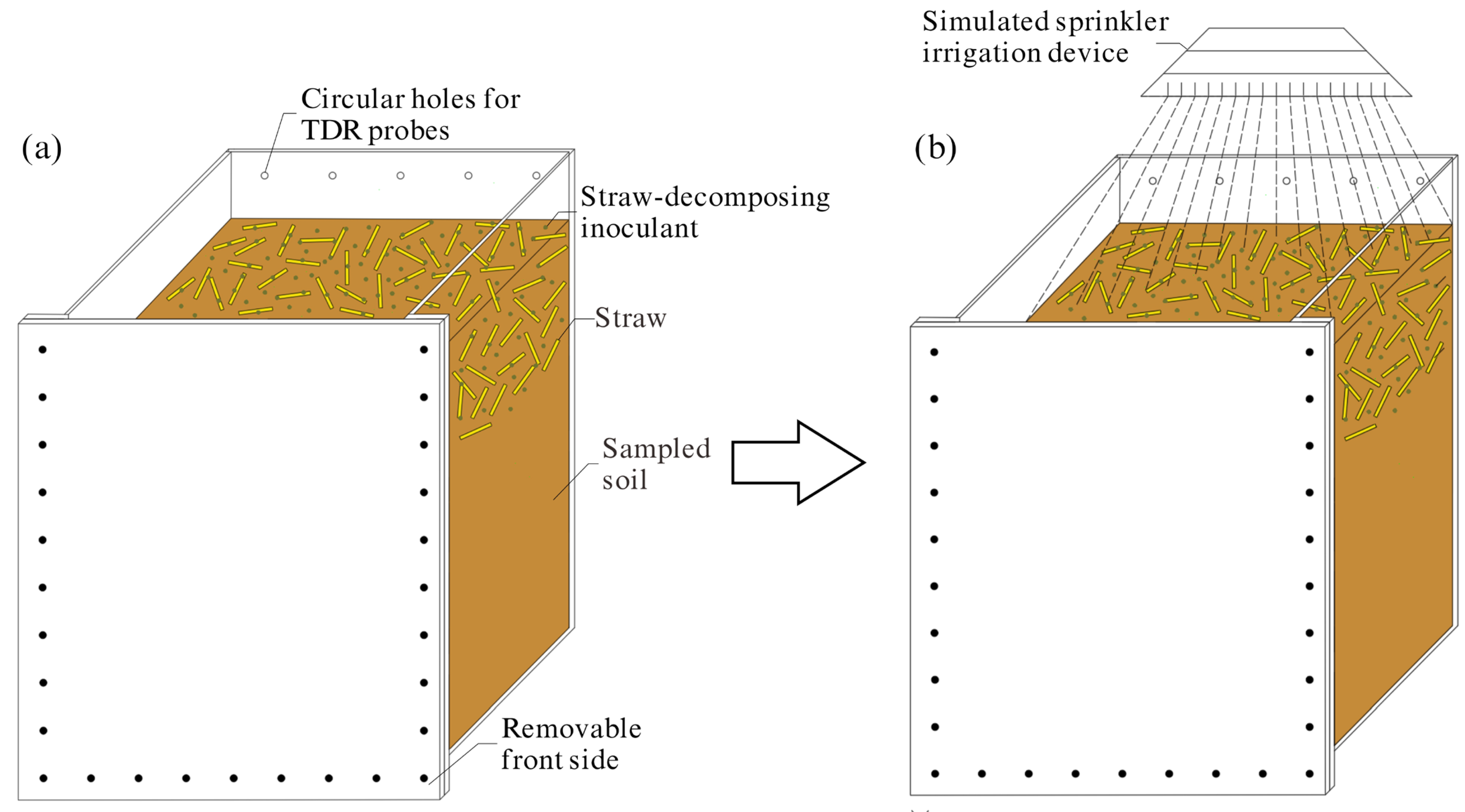

2.1.1. Experimental Setup and Treatments

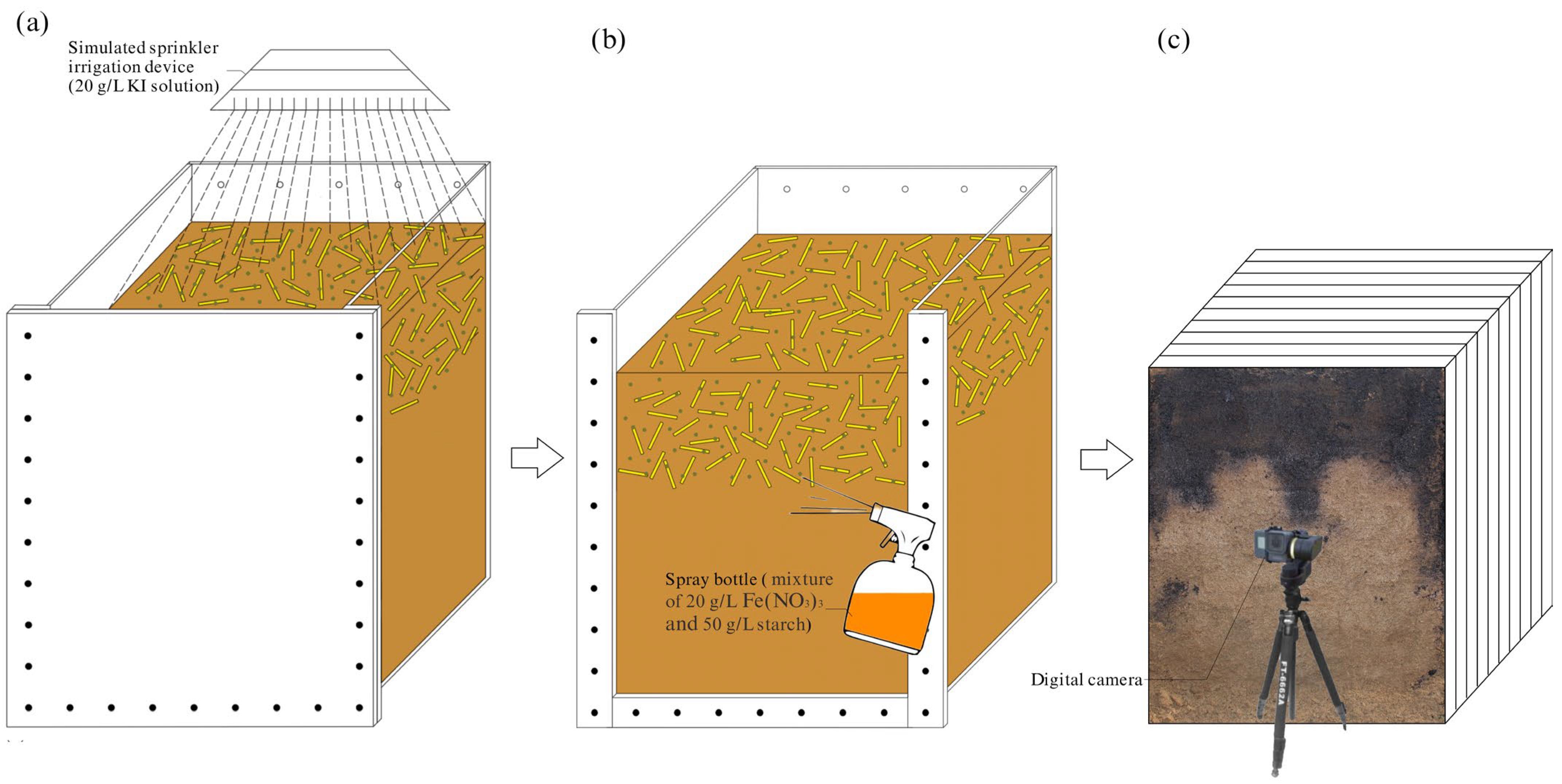

2.1.2. Experimental Processes

2.2. Measurement Indices and Methods

2.3. Image Processing and Preferential Flow Parameterization

2.4. Irrigation Quality Evaluation Indices

2.5. Statistical Analysis and Methods

3. Results

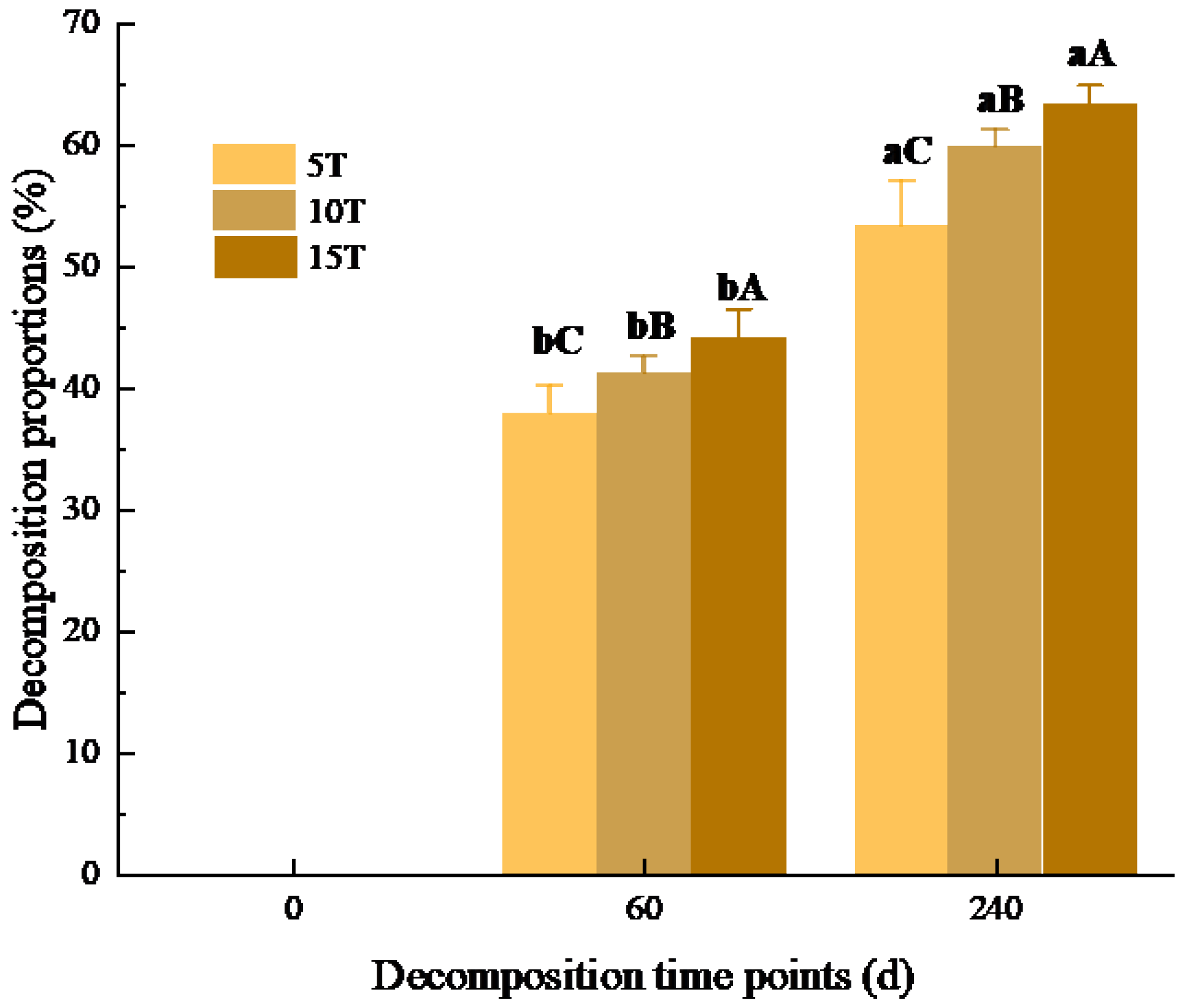

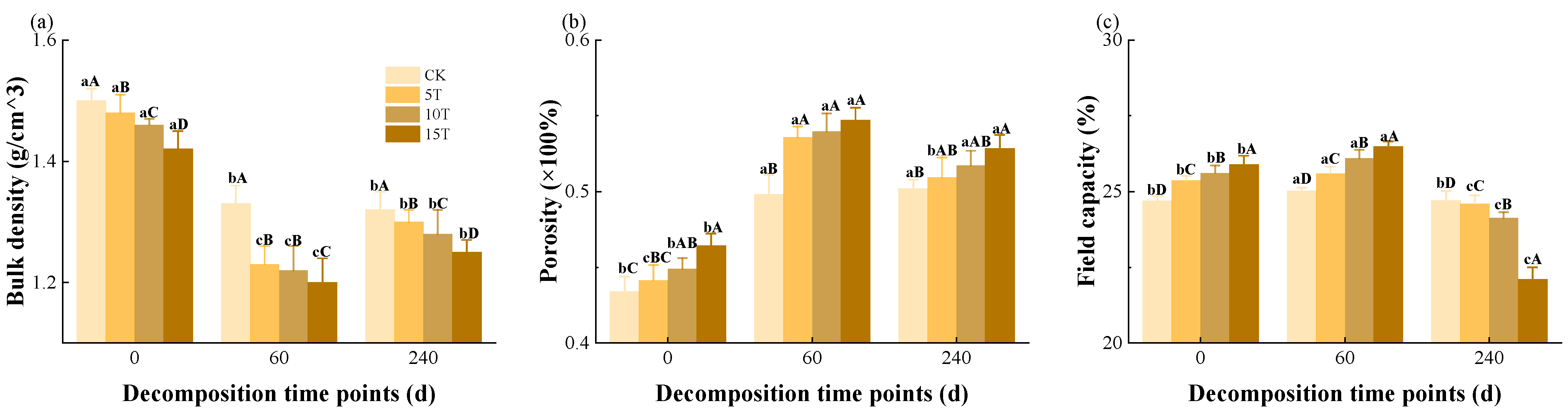

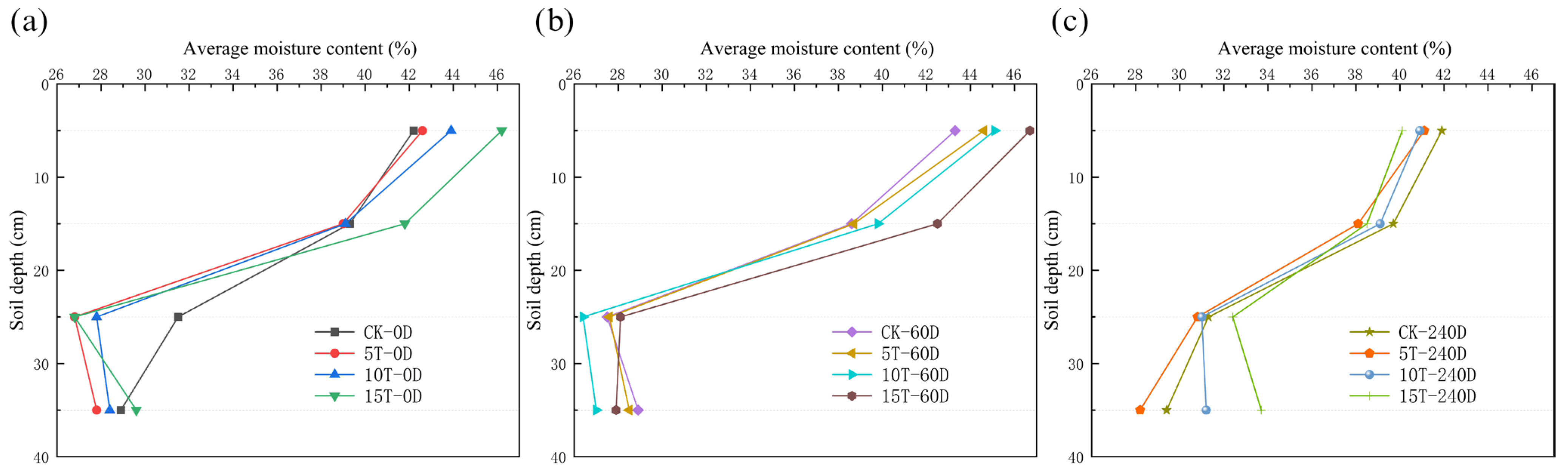

3.1. Decomposition Process and Evolution of Soil Properties

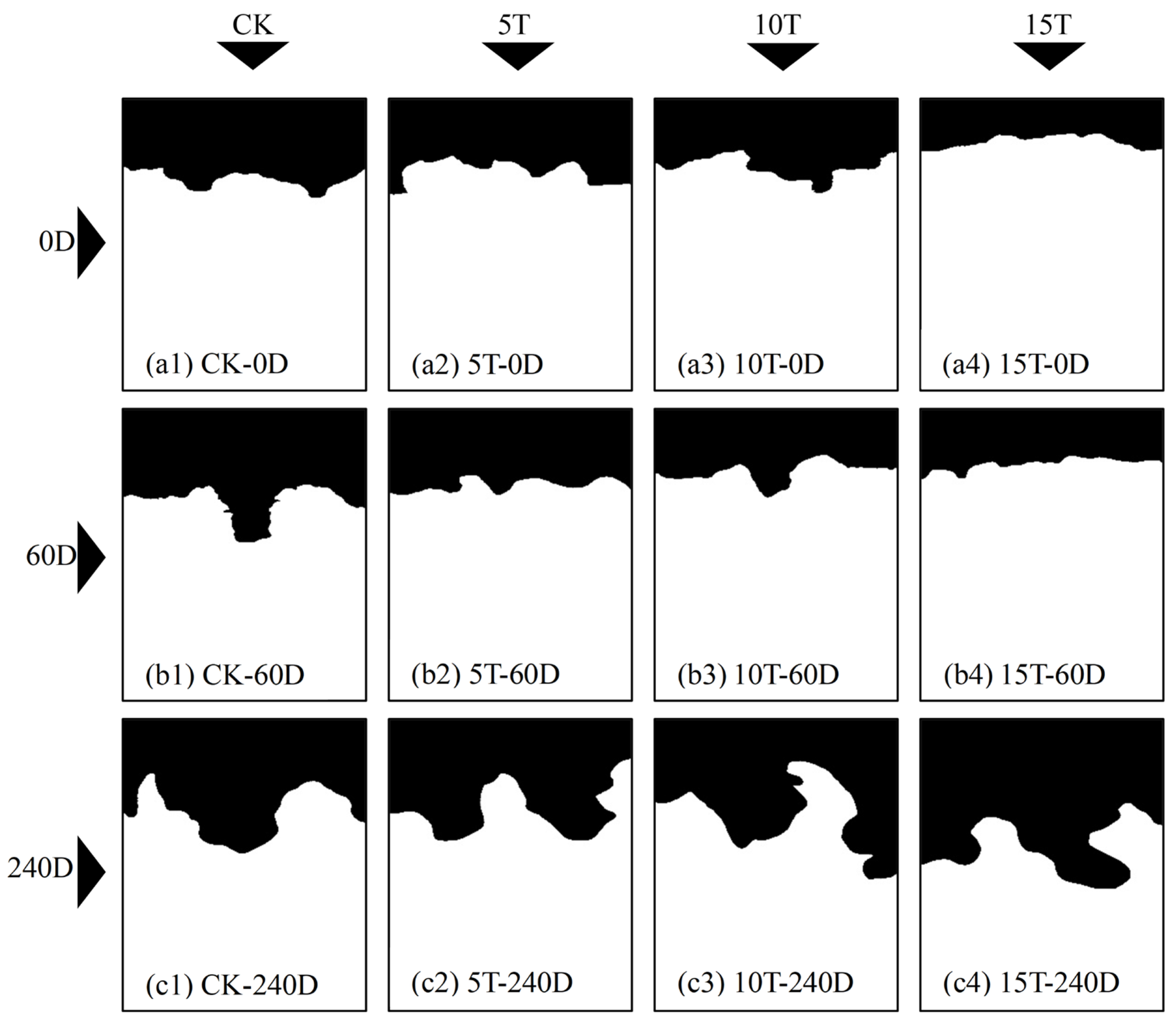

3.2. Preferential Flow Patterns in Different Decomposition Processes

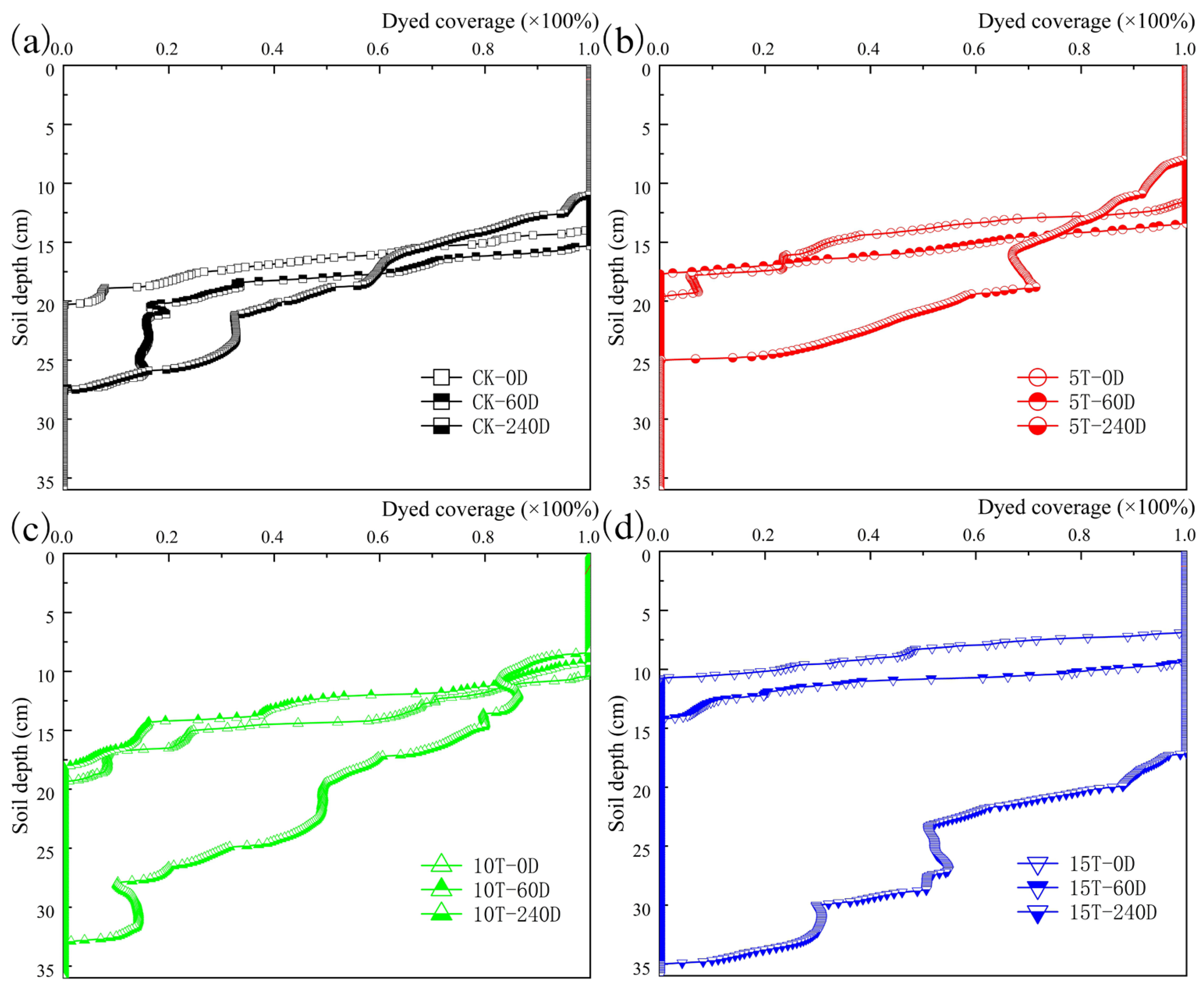

3.3. Dyed Coverage

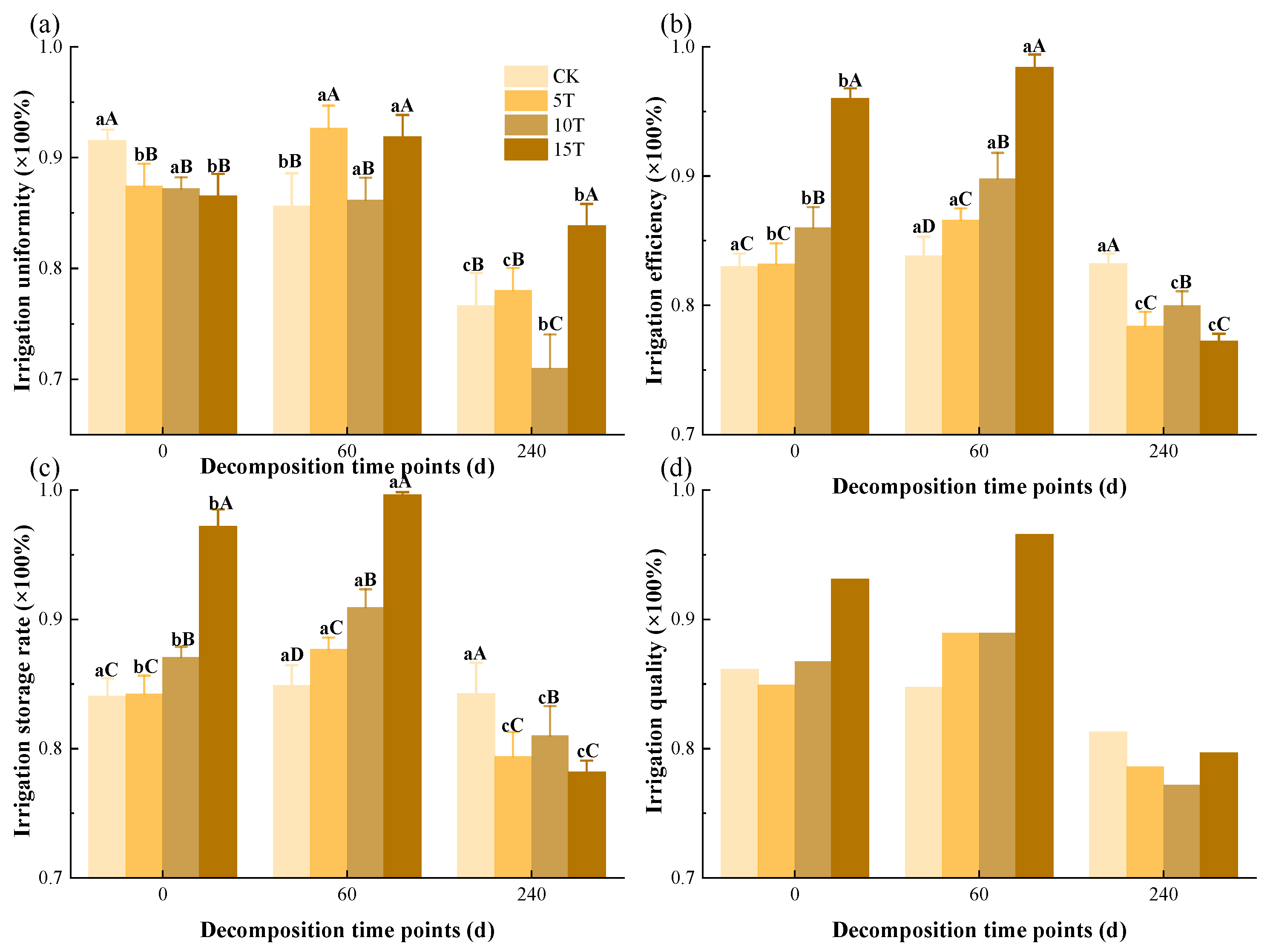

3.4. Irrigation Quality

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- An, W.; Gao, D.; Pan, T.; Zeng, C.; Wang, W. Effect of rice straw returning on paddy soil water-stable aggregate distribution and stability in the paddy field of Fuzhou plain. Acta Sci. Circumstantiae 2016, 36, 1833–1840. [Google Scholar] [CrossRef]

- Zhen, W.; Hao, F. Study on the Influence of Different Straw-returning Manners on Soil Structure and Characters of Soil Water Evaporation. J. Soil Water Conserv. 2009, 23, 224–228,251. [Google Scholar] [CrossRef]

- Pan, J.; Dai, W.; Shang, Z.; Guo, R. Review of research progress on the influence and mechanism of field straw residue incorporation on soil organic matter and nitrogen availability. Chin. J. Eco-Agric. 2013, 21, 526–535. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, J.; Yang, Y.; Chai, R.; Ye, X.; Gao, H.; Ma, D.; Zhang, J.; Zhou, Y. Effect mechanism of long-term straw returning on shrinkage characteristic in typical Shajiang black soil. Trans. Chin. Soc. Agric. Eng. 2019, 35, 119–124. [Google Scholar] [CrossRef]

- Fan, Q.; Li, J.; Li, J.; Liu, Z.; Huang, C.; Yang, Z.; Gao, Z. Effect of Different Crop Straw Mulching on Alluvial Soil Structure Improvement. J. Soil Water Conserv. 2020, 34, 230–236. [Google Scholar] [CrossRef]

- Wu, H.; Chen, X.-B.; Jiang, B.; Qin, Z.-C.; Liu, S.-J.; Liu, J.-J. Effects of straw returning to movement characteristics of soil preferential flow in sugarcane fields. J. Appl. Ecol. 2022, 33, 141–148. [Google Scholar] [CrossRef]

- Han, X.-Z.; Zou, W.-X.; Wang, F.-X.; Wang, F.-J. Construction effect of fertile cultivated layer in black soil. J. Appl. Ecol. 2009, 20, 2996–3002. [Google Scholar] [CrossRef]

- Bhattacharyya, R.; Chandra, S.; Singh, R.D.; Kundu, S.; Srivastva, A.K.; Gupta, H.S. Long-term farmyard manure application effects on properties of a silty clay loam soil under irrigated wheat-soybean rotation. Soil Tillage Res. 2007, 94, 386–396. [Google Scholar] [CrossRef]

- Fang, H.; Li, Y.; Zhou, H.; Yan, X.; Peng, X. Effects of Straw Incorporation on Paddy Soil Structure in Rice-Wheat Rotation System. Trans. Chin. Soc. Agric. Mach. 2018, 49, 297–302. [Google Scholar] [CrossRef]

- Zou, W.X.; Han, X.Z.; Lu, X.C.; Hao, X.X.; You, M.Y.; Zhang, Y.H. Effects of straw incorporated to different locations in soil profile on straw humification coefficient and maize yield. J. Appl. Ecol. 2017, 28, 563–570. [Google Scholar] [CrossRef]

- Naveed, M.; Moldrup, P.; Vogel, H.-J.; Lamande, M.; Wildenschild, D.; Tuller, M.; de Jonge, L.W. Impact of long-term fertilization practice on soil structure evolution. Geoderma 2014, 217, 181–189. [Google Scholar] [CrossRef]

- Gao, M.; Li, N.; Peng, J.; Chen, K.; Gao, T.; Han, X. Effects of straw and biochar returning on soil aggregates distribution and organic carbon content in brown soil. J. Plant Nutr. Fertitizer 2020, 26, 1978–1986. [Google Scholar] [CrossRef]

- Mangalassery, S.; Sjoegersten, S.; Sparkes, D.L.; Sturrock, C.J.; Mooney, S.J. The effect of soil aggregate size on pore structure and its consequence on emission of greenhouse gases. Soil Tillage Res. 2013, 132, 39–46. [Google Scholar] [CrossRef]

- Wu, J.; Guo, X.; Lu, J.; Wan, S.; Wang, Y.; Xu, Z.; Zhang, X. Decomposition characteristics of wheat straw and effects on soil biological properties and nutrient status under different rice cultivation. Acta Ecol. Sin. 2013, 33, 565–575. [Google Scholar] [CrossRef]

- Strong, D.T.; De Wever, H.; Merckx, R.; Recous, S. Spatial location of carbon decomposition in the soil pore system. Eur. J. Soil Sci. 2004, 55, 739–750. [Google Scholar] [CrossRef]

- De Gryze, S.; Jassogne, L.; Six, J.; Bossuyt, H.; Wevers, M.; MerckX, R. Pore structure changes during decomposition of fresh residue: X-ray tomography analyses. Geoderma 2006, 134, 82–96. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Zhou, Y.; Fu, Q.; Zhang, L.; Liu, L. Effects of Straw Mulching and Tillage on Soil Water Characteristics. Trans. Chin. Soc. Agric. Mach. 2019, 50, 333–339. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Y.; Zhang, Y.; Peng, L.; Chen, Q. Releasing characteristics of nonpoint source pollutants from straws under submerging condition. Acta Ecol. Sin. 2012, 32, 1854–1860. [Google Scholar] [CrossRef]

- Cui, S.; Yin, X.; Chen, F.; Tang, H.; Li, F.; Zhang, H. Effects of tillage and straw returning on nitrogen leakage in double rice cropping field. Trans. Chin. Soc. Agric. Eng. 2011, 27, 174–179. [Google Scholar] [CrossRef]

- Jarvis, N.J. A review of non-equilibrium water flow and solute transport in soil macropores: Principles, controlling factors and consequences for water quality. Eur. J. Soil Sci. 2020, 71, 279–302. [Google Scholar] [CrossRef]

- Beven, K.; Germann, P. Macropores and water flow in soils revisited. Water Resour. Res. 2013, 49, 3071–3092. [Google Scholar] [CrossRef]

- Cey, E.E.; Rudolph, D.L. Field study of macropore flow processes using tension infiltration of a dye tracer in partially saturated soils. Hydrol. Processes 2009, 23, 1768–1779. [Google Scholar] [CrossRef]

- Zhou, H.; Fang, H.; Mooney, S.J.; Peng, X. Effects of long-term inorganic and organic fertilizations on the soil micro and macro structures of rice paddies. Geoderma 2016, 266, 66–74. [Google Scholar] [CrossRef]

- Mooney, S.J.; Morris, C. Morphological approach to understanding preferential flow using image analysis with dye tracers and X-ray computed tomography. Catena 2008, 73, 204–211. [Google Scholar] [CrossRef]

- Guntiñas, M.E.; Leirós, M.C.; Trasar-Cepeda, C.; Gil-Sotres, F. Effects of moisture and temperature on net soil nitrogen mineralization: A laboratory study. Eur. J. Soil Biol. 2012, 48, 73–80. [Google Scholar] [CrossRef]

- Stanford, G.; Frere, M.H.; Schwaninger, D.H. Temperature coefficient of soil nitrogen mineralization. Soil Sci. 1973, 115, 321–323. [Google Scholar] [CrossRef]

- Zou, W.; Han, X.; Yan, J.; Chen, X.; Lu, X.; Qiu, C.; Hao, X. Effects of incorporation depth of tillage and straw returning on soil physical properties of black soil in Northeast China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–18. [Google Scholar] [CrossRef]

- Zhang, G.S.; Chan, K.Y.; Li, G.D.; Huang, G.B. Effect of straw and plastic film management under contrasting tillage practices on the physical properties of an erodible loess soil. Soil Tillage Res. 2008, 98, 113–119. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.K.; Saha, S.; Mani, P.K.; Mandal, B. Effect of organic inputs on aggregate associated organic carbon concentration under long-term rice-wheat cropping system. Geoderma 2010, 154, 379–386. [Google Scholar] [CrossRef]

- Zhang, Z.B.; Peng, X.; Wang, L.L.; Zhao, Q.G.; Lin, H. Temporal changes in shrinkage behavior of two paddy soils under alternative flooding and drying cycles and its consequence on percolation. Geoderma 2013, 192, 12–20. [Google Scholar] [CrossRef]

- Niu, J.; Yu, X.; Zhang, Z. The present and future research on preferential flow. Acta Ecol. Sin. 2006, 26, 231–243. [Google Scholar] [CrossRef]

- Sasal, M.C.; Andriulo, A.E.; Taboada, M.A. Soil porosity characteristics and water movement under zero tillage in silty soils in Argentinian Pampas. Soil Tillage Res. 2006, 87, 9–18. [Google Scholar] [CrossRef]

- Wuest, S.B. Surface versus incorporated residue effects on water-stable aggregates. Soil Tillage Res. 2007, 96, 124–130. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, W.; Yuan, W.; Ma, X.; Zhou, Z.; Liu, S. Effects of different types of rice straw and returning depth on decomposition course of straw in double cropping rice region. Soil Fert. Sci. China 2022, 2, 170–174. [Google Scholar] [CrossRef]

- Yan, C. Study on Decomposition Rule of Rice Straw Returning to Field and Soil Nutrient Characteristics. Ph.D. Thesis, Northeast Agricultural University, Harbin, China, 2015. [Google Scholar]

- Shanghong, C.; Zhonglin, Z.H.U.; Jie, W.U.; Dinghui, L.I.U.; Changquan, W. Decomposition Characteristics of Straw Return to Soil and Its Effect on Soil Fertility in Purple Hilly Region. J. Soil Water Conserv. 2006, 20, 141–144. [Google Scholar] [CrossRef]

- Ma, Y.; Teng, D.; Yi, S.; Liu, S.; Wang, H. Effects of Straw Mulching and Decomposition Rate on Soil Temperature and Humidity and Maize Yield. Trans. Chin. Soc. Agric. Mach. 2021, 52, 90–99. [Google Scholar] [CrossRef]

- Sa, R.; Yang, H.; Fan, F.; Tai, J. Effect of Amount of Straw Returning to Field and Straw-Decomposing Inoculant on Degradation Rate of Straw and Soil Physicochemical Properties. J. Henan Agric. Sci. 2018, 47, 56–61. [Google Scholar] [CrossRef]

- Zhao, S.; Li, K.; Zhou, W.; Qiu, S.; Huang, S.; He, P. Changes in soil microbial community, enzyme activities and organic matter fractions under long-term straw return in north-central China. Agric., Ecosyst. Environ. 2016, 216, 82–88. [Google Scholar] [CrossRef]

- Dai, Z.; Lu, J.; Li, X.; Lu, M.; Yang, W.; Gao, X. Nutrient release characteristic of different crop straws manure. Trans. Chin. Soc. Agric. Eng. 2010, 26, 272–276. [Google Scholar] [CrossRef]

- Wu, F.; Zhang, K.; Zai, S.; Wang, H.; Zhao, C. Impact of mixed straw on soil hydraulic properties. Trans. Chin. Soc. Agric. Eng. 2015, 31, 101–105. [Google Scholar] [CrossRef]

- Zhao, L.; Li, L.; Cai, H.; Shi, X.; Xue, S. Comprehensive Effects of Organic Materials Incorporation on Soil Hydraulic Conductivity and Air Permeability. Sci. Agric. Sin. 2019, 52, 1045–1057. [Google Scholar] [CrossRef]

- Yue, H.J.; Fan, G.S. Nonlinear prediction model of soil field water capacity. Water Sav. Irrig. 2015, 243, 76–79+84. [Google Scholar] [CrossRef]

- Chen, J.; Wu, P.; Zhang, Z.; Gideon, O.; Wang, Z. The Relationship between WDPTand Soil Organic Matter. J. Irrig. Drain. 2012, 31, 96–98+118. [Google Scholar] [CrossRef]

- Wang, X.J.; Jia, Z.K.; Liang, L.Y.; Yang, B.P.; Ding, R.X.; Nie, J.F.; Wang, J.P. Maize straw effects on soil aggregation and other properties in arid land. Soil Tillage Res. 2015, 153, 131–136. [Google Scholar] [CrossRef]

- Liu, X.Z. Effect of straw returning mode on soil stability of farmland aggregate particle size composition. Northeast Agric. Sci. 2021, 46, 34–37+104. [Google Scholar] [CrossRef]

- Qian, S.G. Correlation between field water capacity and mechanical composition of soil bulk density. Soil Bull. 1981, 5, 12–14. [Google Scholar] [CrossRef]

- Wang, Y.; Kuang, F.; Ma, S.; Wang, Y.; Li, L.; Tang, J.; Zhu, B. Effects of shredded straw and burned straw returning to the field on soil porosity and organic carbon in cultivated layer of calcareous purple soil. J. Agro-Environ. Sci. 2022, 41, 526–536. [Google Scholar] [CrossRef]

- Kasteel, R.; Garnier, P.; Vachier, P.; Coquet, Y. Dye tracer infiltration in the plough layer after straw incorporation. Geoderma 2007, 137, 360–369. [Google Scholar] [CrossRef]

- Iqbal, A.; Beaugrand, J.; Garnier, P.; Recous, S. Tissue density determines the water storage characteristics of crop residues. Plant Soil 2013, 367, 285–299. [Google Scholar] [CrossRef]

- Li, J.; Hu, M.; Lu, J. Water Absorption Capacity of Straw Returns and Its Decomposing Matters. Bull. Soil Water Conserv. 2016, 36, 85–90. [Google Scholar] [CrossRef]

- Zhang, H.; Pang, H.; Lu, C.; Liu, N.; Zhang, X.; Li, Y. Pore characteristics of straw interlayer based on computed tomography images and its influence on soil water infiltration. Trans. Chin. Soc. Agric. Eng. 2019, 35, 114–122. [Google Scholar] [CrossRef]

| Soil Properties | Values |

|---|---|

| Soil type | Clay loam |

| Classification | Hapludalf, alfisols |

| Specific gravity | 2.65 |

| Dry bulk density | 1.17 g/cm3 |

| Initial moisture content | 3.27% volumetric water content |

| Initial porosity | 43% |

| Field capacity | 24.69% volumetric water content |

| Saturated moisture content | 55.80% volumetric water content |

| Saturated hydraulic conductivity | 6.23 × 10−2 cm/min |

| EC | 1.2 mS/cm |

| pH | 7.23 |

| CK | 5 t/ha | 10 t/ha | 15 t/ha | |

|---|---|---|---|---|

| 0 d | 1.683 | 1.652 | 1.643 | 1.559 |

| 60 d | 1.691 | 1.671 | 1.621 | 1.625 |

| 240 d | 1.691 | 1.689 | 1.706 | 1.762 |

| Irrigation Quality | Irrigation Quality | |

|---|---|---|

| Preferential flow coefficient | −0.743 ** | |

| The fractal dimension values of the wetting front | −0.874 ** |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Z.; Wang, C.; Zhu, C.; Chen, X.; Zhai, Y.; Ma, L.; Sun, N.; Cai, J.; Fu, Y. Effects of Straw Incorporation and Decomposition on Soil Preferential Flow Patterns Using the Dye-Tracer Method. Agriculture 2024, 14, 201. https://doi.org/10.3390/agriculture14020201

Duan Z, Wang C, Zhu C, Chen X, Zhai Y, Ma L, Sun N, Cai J, Fu Y. Effects of Straw Incorporation and Decomposition on Soil Preferential Flow Patterns Using the Dye-Tracer Method. Agriculture. 2024; 14(2):201. https://doi.org/10.3390/agriculture14020201

Chicago/Turabian StyleDuan, Zhengyu, Ce Wang, Chengli Zhu, Xiaoan Chen, Yaming Zhai, Liang Ma, Nan Sun, Jiahao Cai, and Yu Fu. 2024. "Effects of Straw Incorporation and Decomposition on Soil Preferential Flow Patterns Using the Dye-Tracer Method" Agriculture 14, no. 2: 201. https://doi.org/10.3390/agriculture14020201

APA StyleDuan, Z., Wang, C., Zhu, C., Chen, X., Zhai, Y., Ma, L., Sun, N., Cai, J., & Fu, Y. (2024). Effects of Straw Incorporation and Decomposition on Soil Preferential Flow Patterns Using the Dye-Tracer Method. Agriculture, 14(2), 201. https://doi.org/10.3390/agriculture14020201