Unlocking Sows’ Welfare: The Farm-Level Economic Impact of Phasing out Farrowing Crates for Sows in the European Union’s Pig Breeding Industry

Abstract

1. Introduction

2. Economic Performance of Free-Farrowing Systems—A Literature Review

3. Materials and Methods

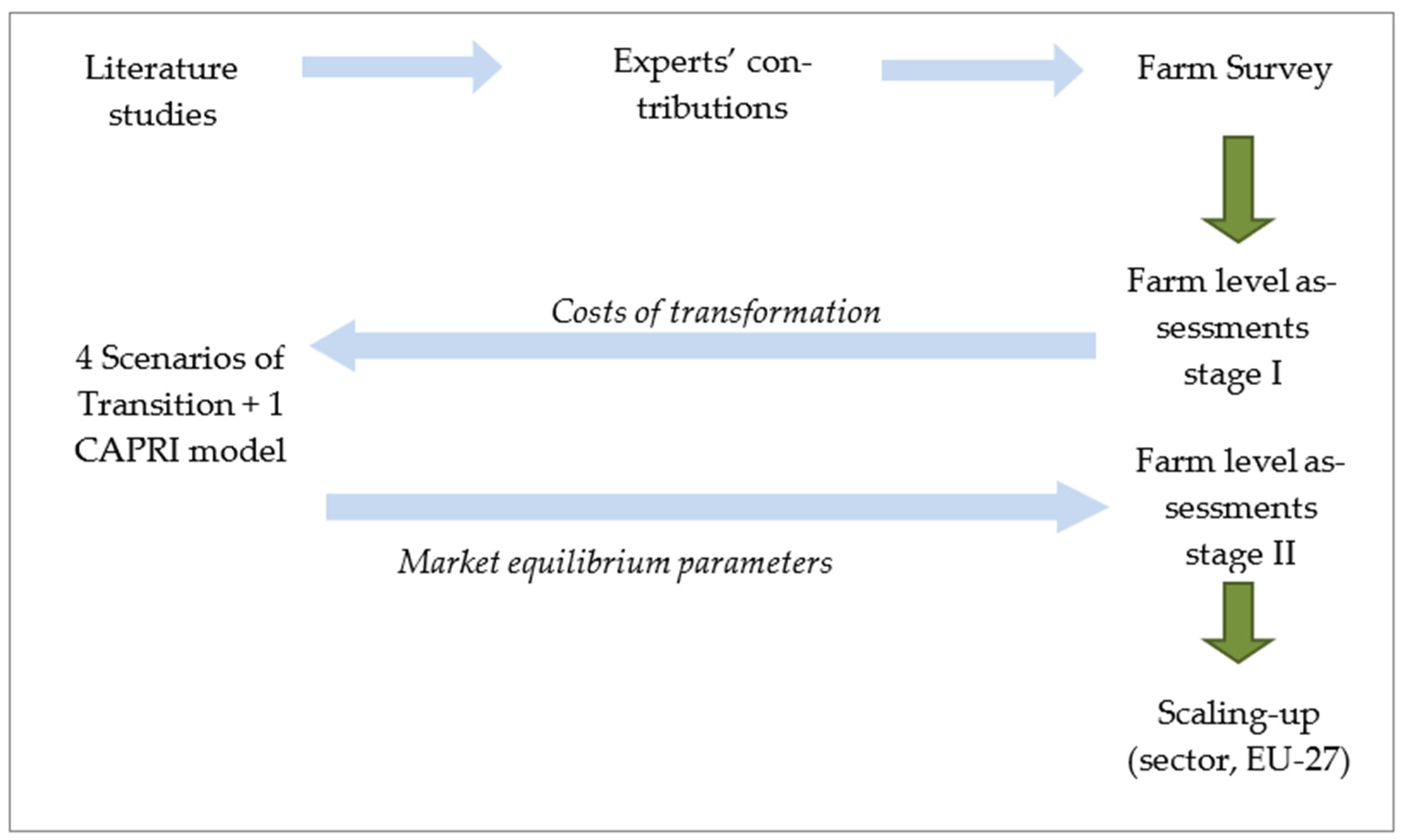

3.1. Conceptual Framework and Sources of Data

- farm characteristics, such as the size of the sow herd, the number of stands for sows and fattening pigs, and the size of farrowing pens and farrowing areas;

- technical production parameters, including sales of piglets, sows, and fatteners; the number of litters per sow; the number of piglets born alive/dead; piglet mortality; culling rates; and piglets weaned per litter;

- prices of inputs, such as labour and feed for the sows and gilt;

- inputs, including the feed intake for sows during the lactation period, labour during farrowing, and veterinary costs, including medicines;

- statements from farmers regarding their future decisions if the use of crates is banned.

- Eastern European countries (Poland, Romania, Bulgaria, Hungary, Latvia, and Croatia);

- Central and Western Europe (Austria, Belgium, France, Germany, Greece, Ireland, Italy, Portugal, Spain, and The Netherlands).

3.2. Housing Systems and Parameters Considered in the Farm-Level Assessments

- free-farrowing pens with temporary confinement (up to 5 days) and a 5.5 m2 space allowance;

- free-farrowing pens with no confinement and a 7 m2 space allowance.

- piglet mortality: +15% (in free-farrowing systems with confinement) and +20% (in free-farrowing systems with no confinement;

- number of litters per sow/year: −1.9%;

- mortality of sows: +5%;

- culling-out percentage: +15%;

- feed consumption during the lactation period (28 days): +7.3%;

- labour input: +1 min/sow/day during lactation in systems with confinement; +2 min/sow/day in systems with no confinement;

- veterinary-medicine costs: +7.5%;

- average basic cost of new farrowing pens: EUR 1700, with a depreciation period of 15 years, plus the costs for reconstructing existing buildings, averaging to EUR 1800 per pen but depending on the scenario and the region (EU-East/EU-West), ranging from EUR 1623 to EUR 2146, depreciated over 25 years;

- depreciation of the existing buildings in 25 years.

- Additional costs considered in alternative farrowing systems compared to crates included the following:

- variable costs: additional labour costs, increased feed costs during the lactation period, increased vet-med costs, and increased cost of sow replacement;

- cost for investing in new farrowing pens;

- cost for rebuilding existing places to install new pens (e.g., floor modifications);

- depreciation of the existing building.

3.3. Scenarios of Transition at Farm Level and EU Sector Level

- number of sows at the farm: if fewer than 50—the probability of exit is 100%, if more than 500—it is 0%;

- age of the farmer: if the farmer is younger than 45 years old—0%, if older than 60 years old—it is 100%;

- likelihood of a successor in the family, expressed as a percentage of the likelihood—if no successor at all—the probability of exit is 100%, if succession is certain—it is 0%.

3.4. Aggregation (Scaling-Up) Procedure

4. Results and Discussion

4.1. Farm Characteristics

4.2. Indicators Estimated for Alternative Farrowing Systems

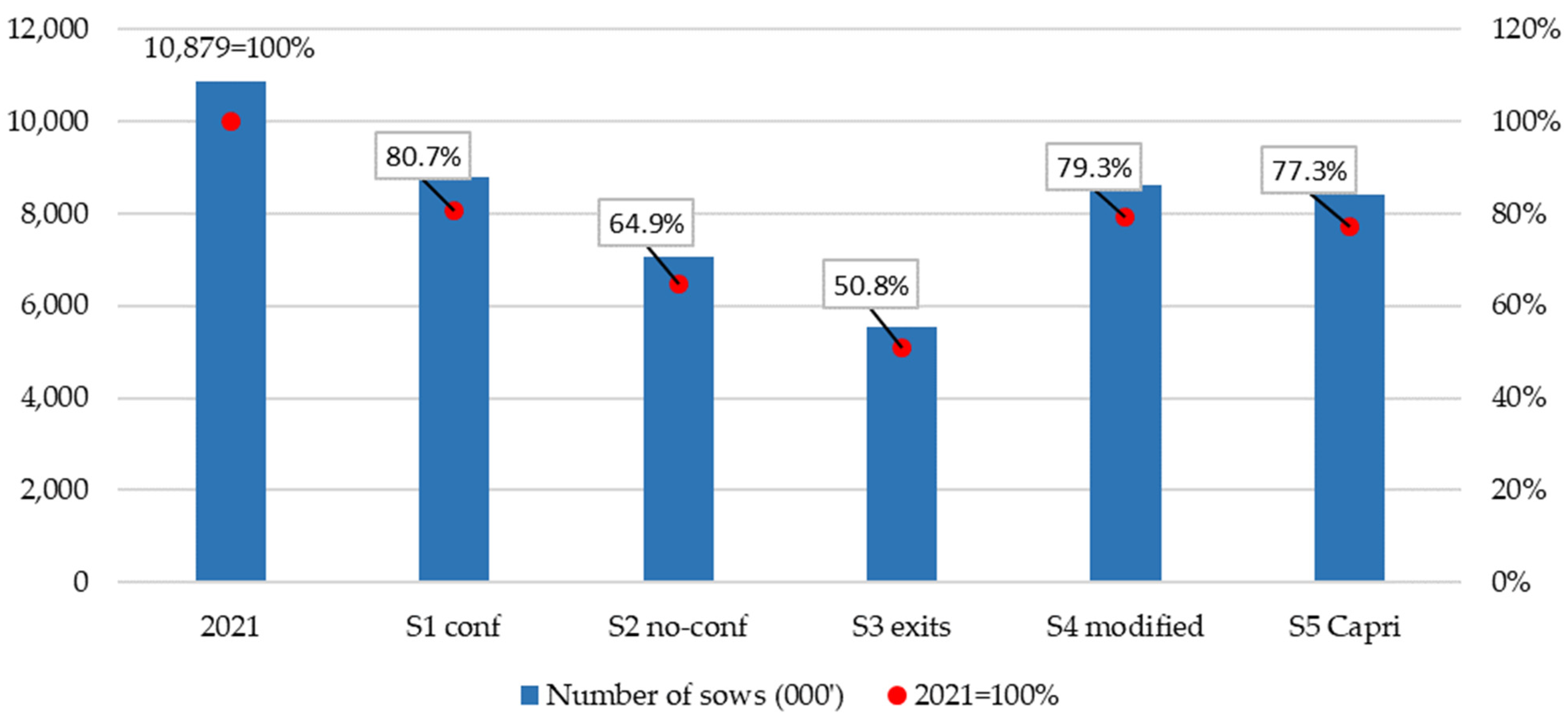

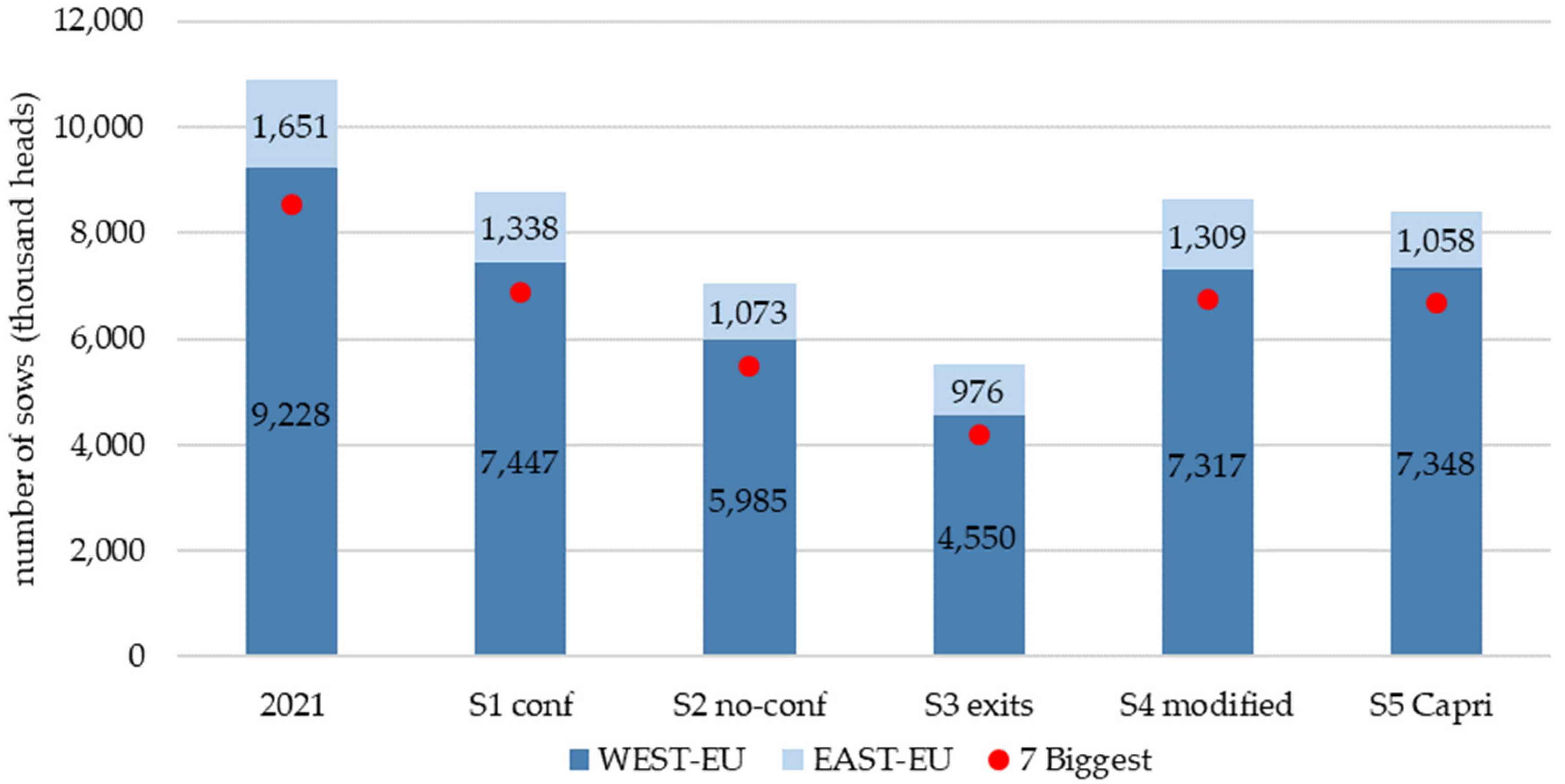

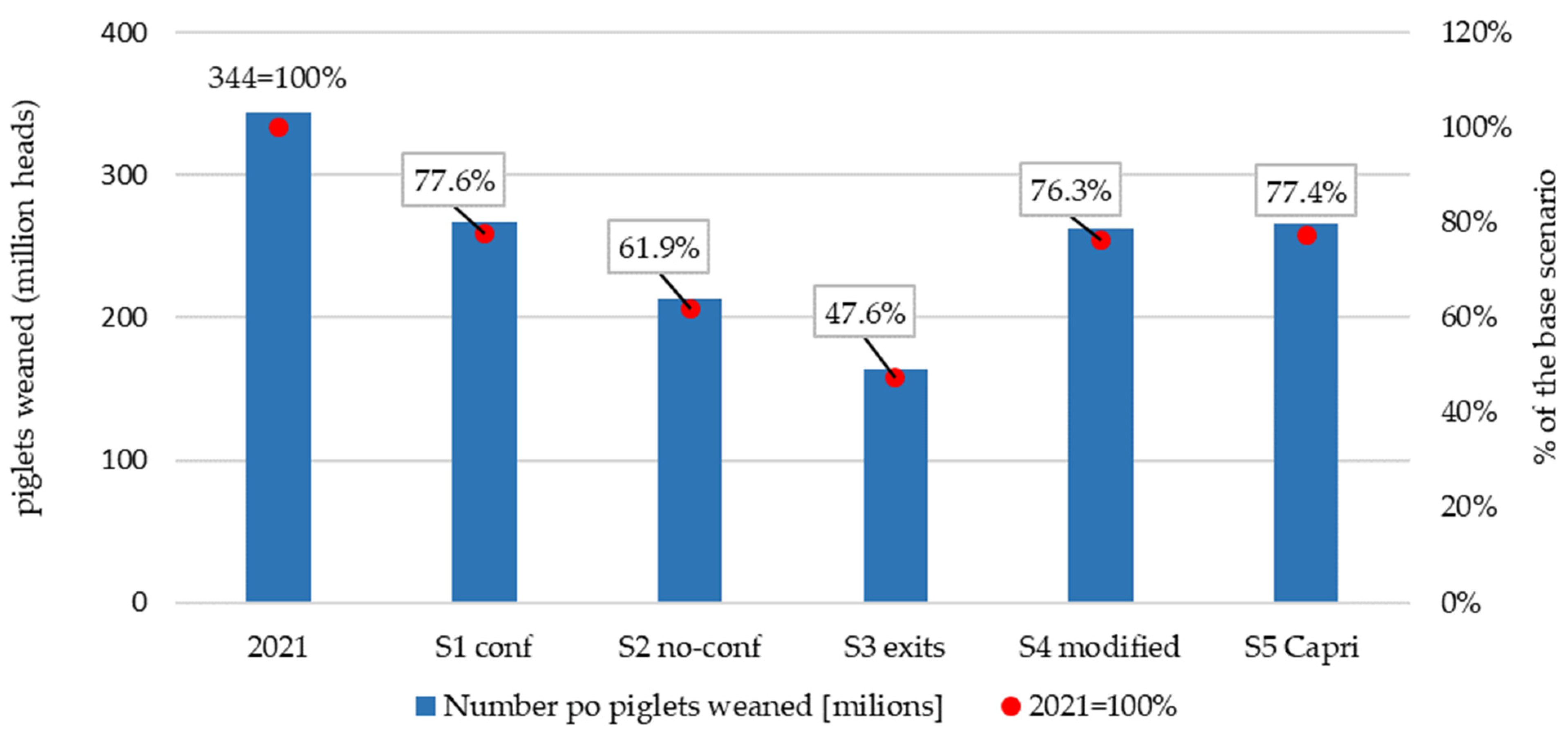

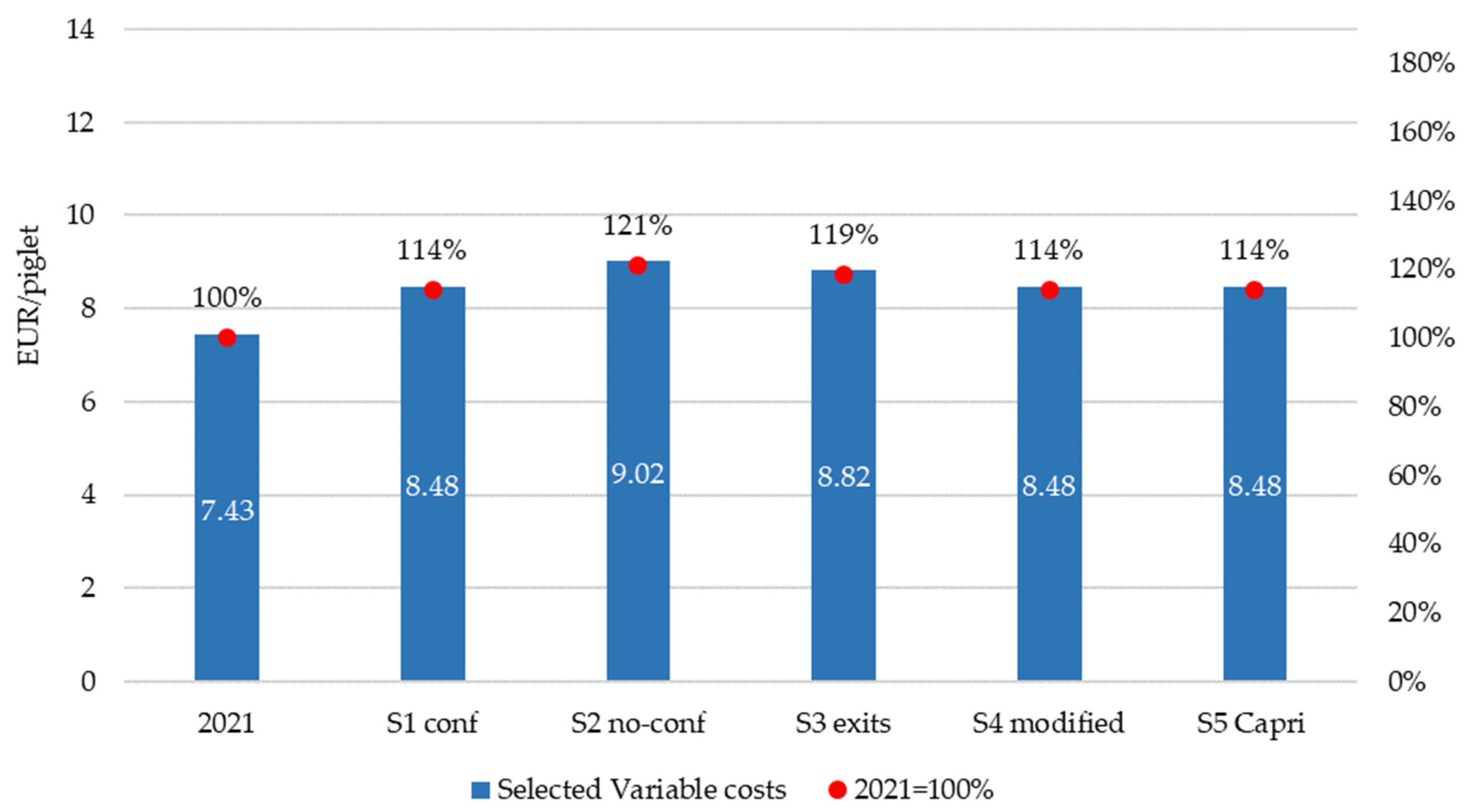

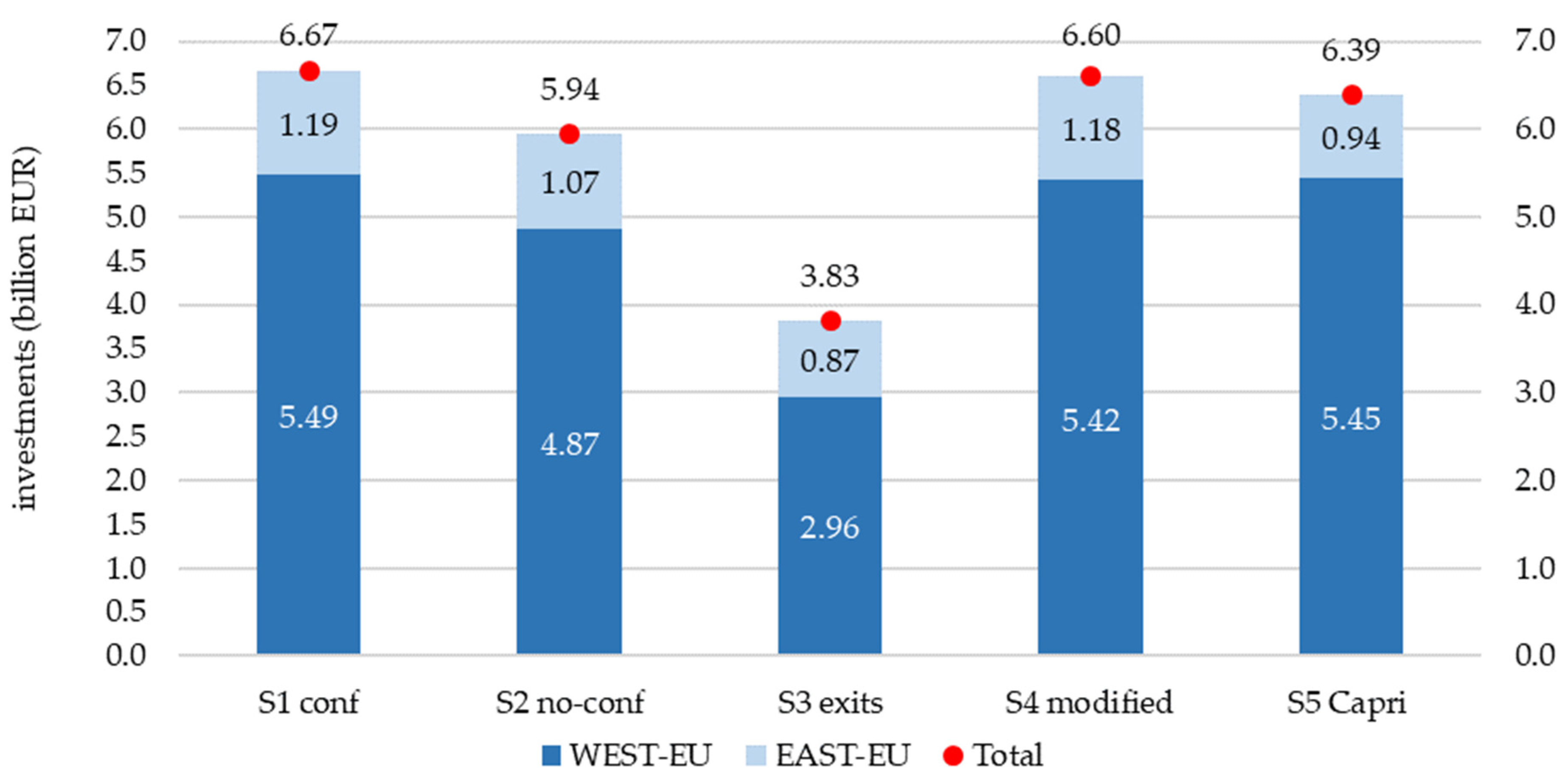

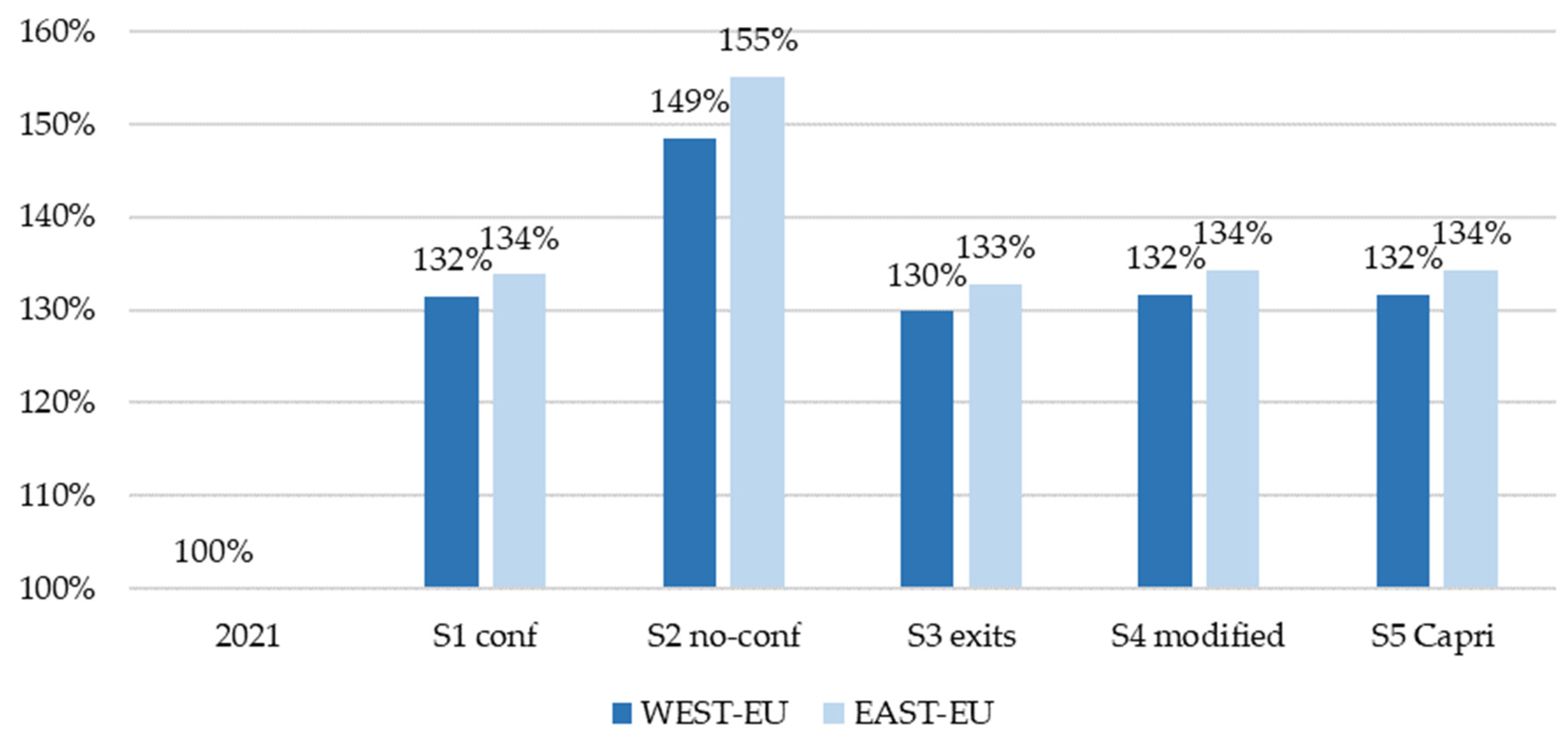

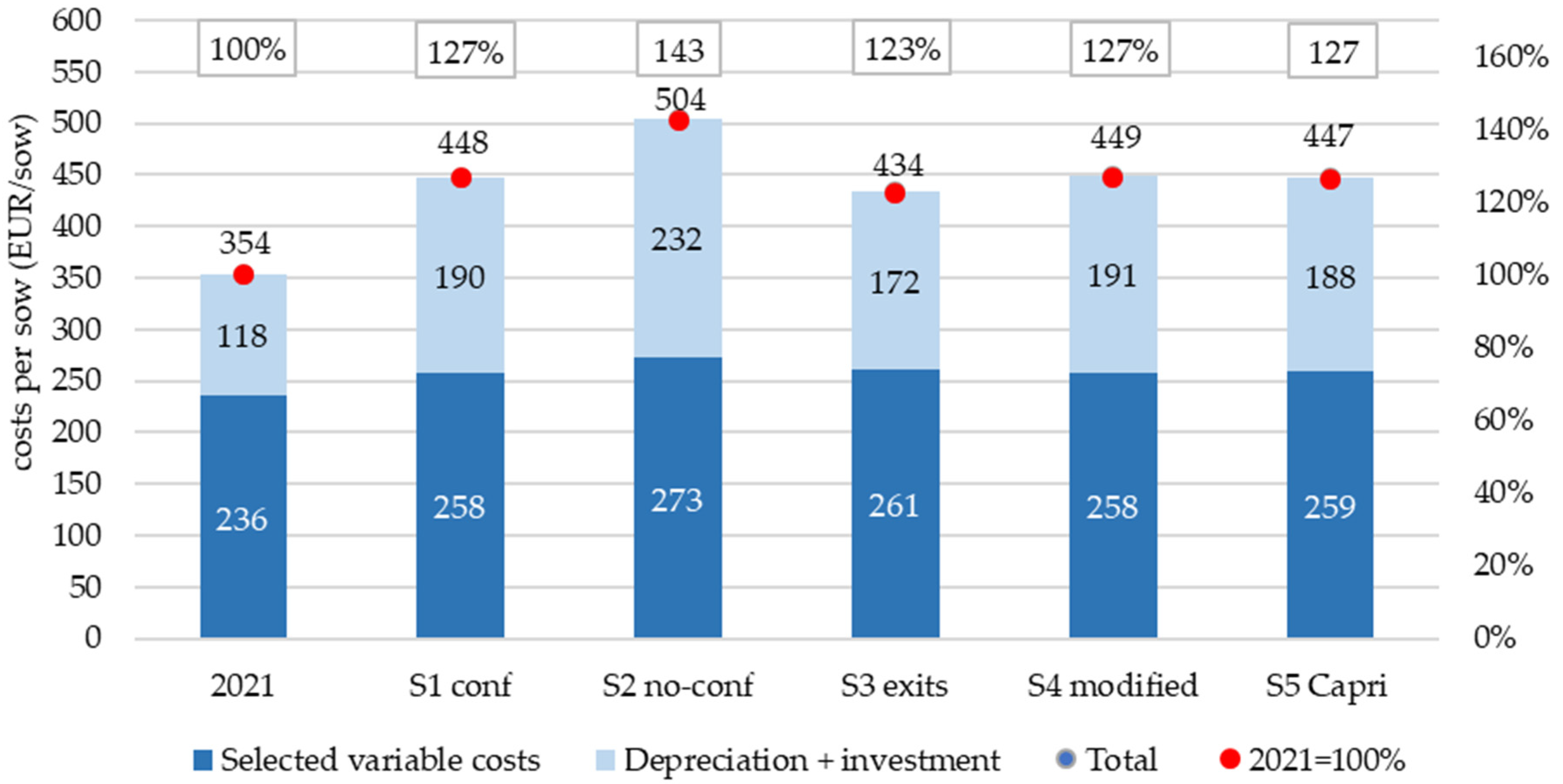

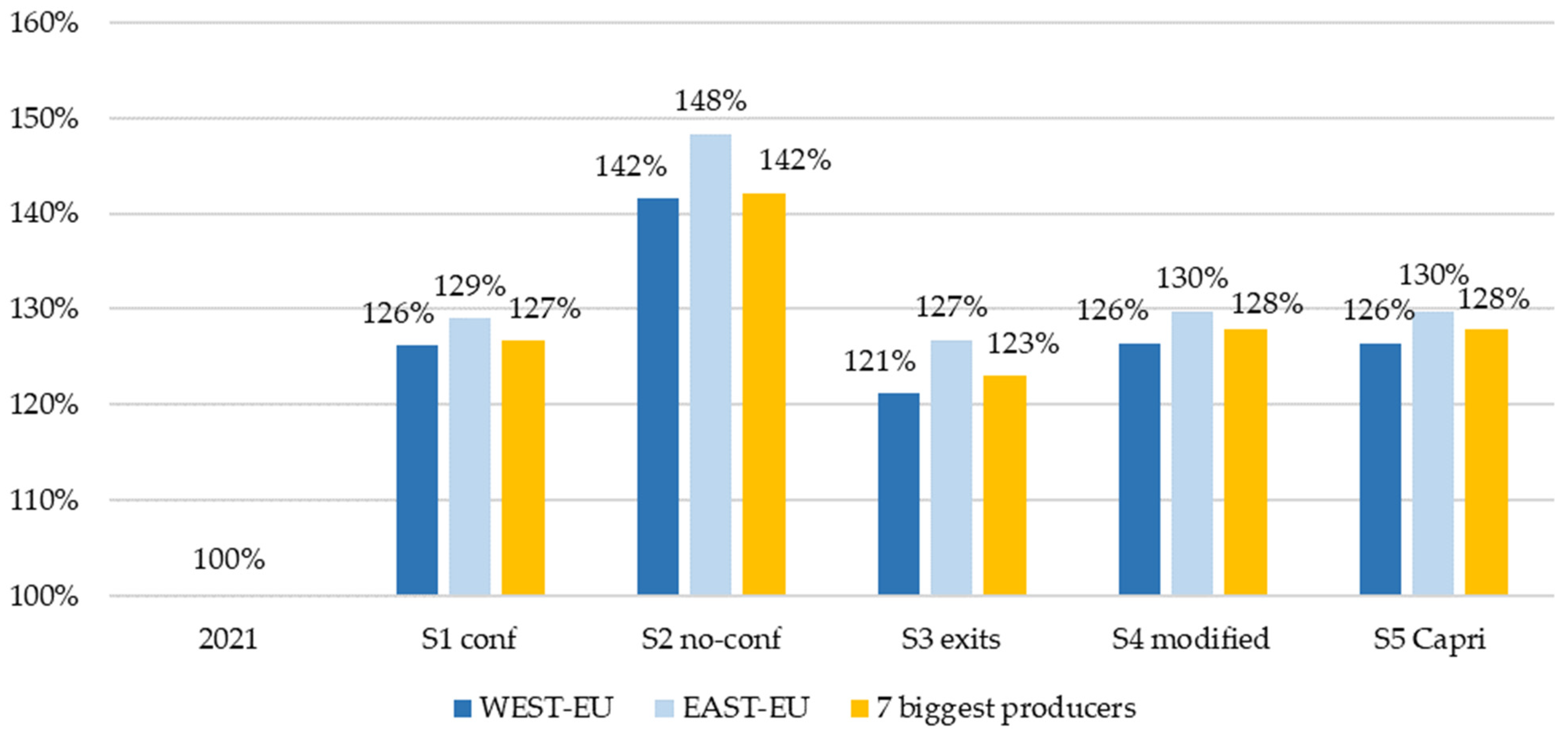

4.3. Results Aggregated for the EU-27 Pig Sector according to 5 Scenarios

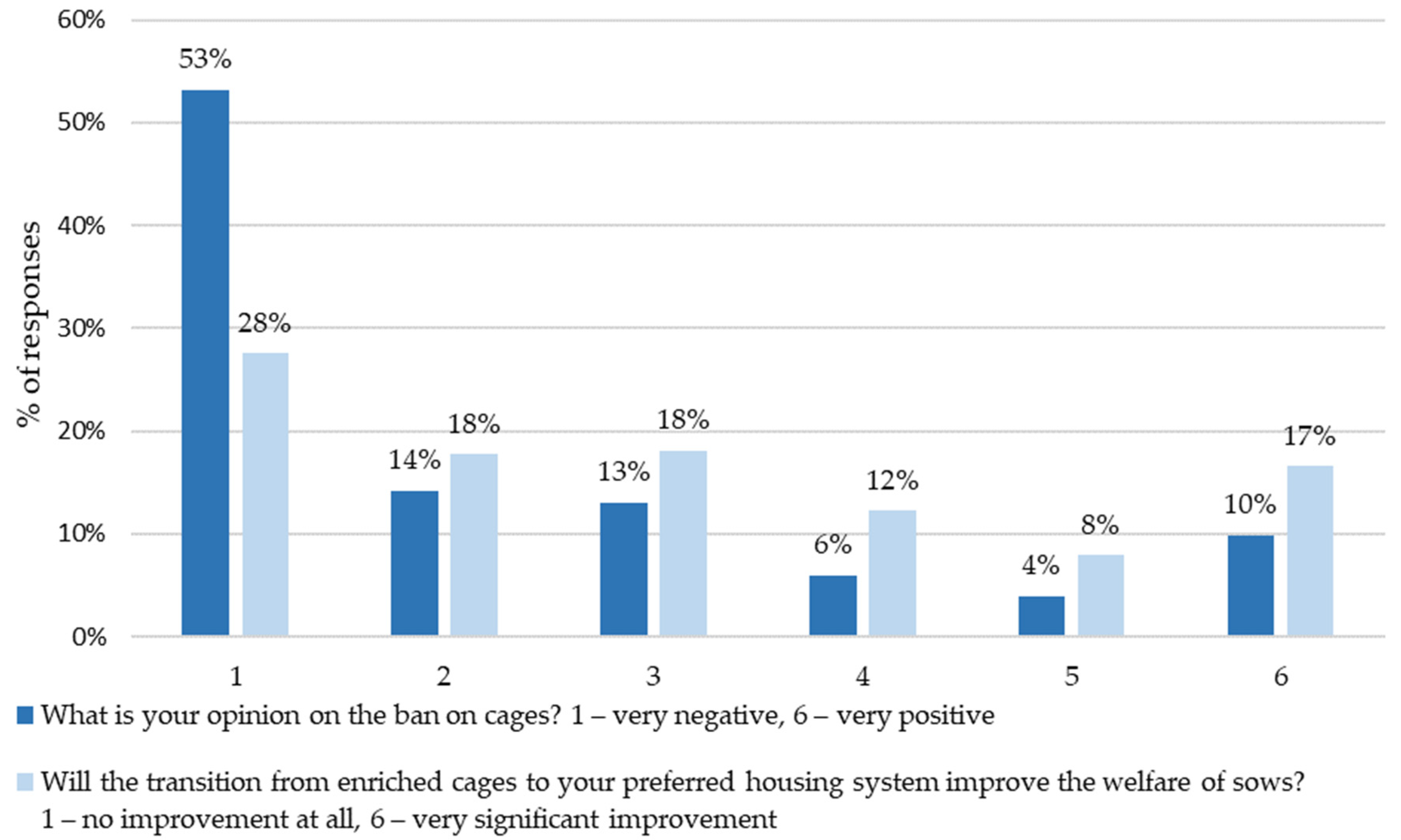

4.4. Farmers’ Opinions on the Planned Banning of Farrowing Crates

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rojek, B. Animal Welfare Protection in the EU Strategy and Law; European Parliamentary Research Service: Brussels, Belgium, 2023. [Google Scholar]

- European Commission. Commission Staff Working Document Evaluation of the European Union Strategy for the Protection and Welfare of Animals 2012–2015, SWD (2021) 76 Final, Brussels, 31.3.2021; European Commission: Brussels, Belgium, 2021.

- European Commission. Communication from the Commission to the European Parliament, the Council and the European Economic and Social Committee on the European Union Strategy for the Protection and Welfare of Animals 2012–2015, COM(2012) 6 Final, 19.1.2012, Brussels; European Commission: Brussels, Belgium, 2012.

- Council Directive 2008/120/EC; Laying Down Minimum Standards for the Protection of Pigs. Council of the European: Brussels, Belgium, 2009; pp. 5–13.

- European Commission 2023. COMMUNICATION FROM THE COMMISSION on the European Citizens’ Initiative (ECI) “Stop Finning-Stop the Trade”, Brussels, 5.7.2023, C(2023) 4489 Final, Brussels, Belgium. 2023. Available online: https://citizens-initiative.europa.eu/sites/default/files/2023-07/C_2023_4489_1_EN.pdf (accessed on 15 September 2023).

- Federal Law Journal of Austria —Amendment of Animal Welfare Act. Verordnung des Bundesministers für Soziales, Gesundheit, Pflege und Konsumentenschutz, mit der die 1. Tierhaltungsverordnung geändert wird; Nr. 296/2022, 27.07.2022. Available online: https://www.ris.bka.gv.at/eli/bgbl/II/2022/296/20220727 (accessed on 13 December 2023).

- Federal Law Journal of Germany—Amendment of Animal Welfare Act. Siebte Verordnung zur Änderung der Tierschutz Nutztierhaltungsverordnung; Nr. 2020:302, 03.07.2020; Bundesrat: Berlin, Germany, 2020.

- Federal Law Journal of Germany—Amendment of Animal Welfare Act; Nr. 2019:587, 19.07.2019; Bundesrat: Berlin, Germany, 2019. Available online: https://www.bundesrat.de/SharedDocs/drucksachen/2019/0501-0600/587-19.pdf?__blob=publicationFile&v=1 (accessed on 20 September 2023).

- Danish Crown. Danish Crown Animal Welfare Position Statement 2023. September 2023, pp. 1–28. Available online: https://www.danishcrown.com/media/14233/animal-welfare-position-statement.pdf (accessed on 3 November 2023).

- Hansen, S.T. Tre Gange Så Mange Kan Få Tilskud Til Løse Søer. Landbrugsavisen.Dk. GRIS. Available online: https://landbrugsavisen.dk/gris/tre-gange-s%C3%A5-mange-kan-f%C3%A5-tilskud-til-l%C3%B8se-s%C3%B8er (accessed on 15 August 2022).

- Quendler, E.; Podiwinsky, C.; Baumgartner, J.; Winckler, C.; Boxberger, J. Performance, Labour and Economic Aspects of Different Farrowing Systems. April 2009. Available online: https://cigrjournal.org/index.php/Ejounral/article/view/1135/1187 (accessed on 23 April 2023).

- Chidgey, K.L.; Morel, P.C.H.; Stafford, K.J.; Barugh, I.W. Sow and piglet productivity and sow reproductive performance in farrowing pens with temporary crating or farrowing crates on a commercial New Zealand pig farm. Livest. Sci. 2015, 173, 87–94. [Google Scholar] [CrossRef]

- Karlen, G.A.M.; Hemsworth, P.H.; Gonyou, H.W.; Fabrega, E.; Strom, A.D.; Smits, R.J. The welfare of gestating sows in conventional stalls and large groups on deep litter. Appl. Anim. Behav. Sci. 2007, 105, 87–101. [Google Scholar] [CrossRef]

- Anil, L.; Anil, S.S.; Deen, J.; Baidoo, S.K.; Wheaton, J.E. Evaluation of well-being, productivity, and longevity of pregnant sows housed in groups in pens with an electronic sow feeder or separately in gestation stalls. Am. J. Vet. Res. 2005, 66, 1630–1638. [Google Scholar] [CrossRef] [PubMed]

- Mcglone, J.; von Borell, E.; Deen, J.; Johnson, A.; Levis, D.; Meunier-Salaon, M.; Morrow, J.; Reeves, D.; Salak-Johnson, J.; Sundberg, P. Reviews: Compilation of the Scientific Literature Comparing Housing Systems for Gestating Sows and Gilts Using Measures of Physiology, Behavior, Performance, and Health1. Prof. Anim. Sci. 2004, 20, 105–117. [Google Scholar] [CrossRef]

- Baxter, E.M.; Lawrence, A.B.; Edwards, S.A. Alternative farrowing accommodation: Welfare and economic aspects of existing farrowing and lactation systems for pigs. Animal 2012, 6, 96–117. [Google Scholar] [CrossRef] [PubMed]

- Einarsson, S.; Sjunnesson, Y.; Hultén, F.; Eliasson-Selling, L.; Dalin, A.-M.; Lundeheim, N.; Magnusson, U. A 25 years experience of group-housed sows–reproduction in animal welfare-friendly systems. Acta Vet. Scand 2014, 56, 37. [Google Scholar] [CrossRef] [PubMed]

- Hales, J.; Moustsen, V.A.; Nielsen, M.B.F.; Hansen, C.F. Temporary confinement of loose-housed hyperprolific sows reduces piglet mortality1. J. Anim. Sci. 2015, 93, 4079–4088. [Google Scholar] [CrossRef] [PubMed]

- Zotti, E.; Resmini, F.A.; Schutz, L.G.; Volz, N.; Milani, R.P.; Bridi, A.M.; Alfieri, A.A.; Da Silva, C. A Impact of piglet birthweight and sow parity on mortality rates, growth performance, and carcass traits in pigs. Rev. Bras. Zootec. 2017, 46, 856–862. [Google Scholar] [CrossRef]

- Mazzoni, C.; Scollo, A.; Righi, F.; Bigliardi, E.; Di Ianni, F.; Bertocchi, M.; Parmigiani, E.; Bresciani, C. Effects of three different designed farrowing crates on neonatal piglets crushing: Preliminary study. Ital. J. Anim. Sci. 2018, 17, 505–510. [Google Scholar] [CrossRef]

- Morgan, L.; Klement, E.; Novak, S.; Eliahoo, E.; Younis, A.; Sutton, G.A.; Abu-Ahmad, W.; Raz, T. Effects of group housing on reproductive performance, lameness, injuries and saliva cortisol in gestating sows. Prev. Vet. Med. 2018, 160, 10–17. [Google Scholar] [CrossRef] [PubMed]

- Glencorse, D.; Plush, K.; Hazel, S.; D’Souza, D.; Hebart, M. Impact of Non-Confinement Accommodation on Farrowing Performance: A Systematic Review and Meta-Analysis of Farrowing Crates Versus Pens. Animals 2019, 9, 957. [Google Scholar] [CrossRef] [PubMed]

- Buoio, E.; Costa Annamaria. Space allowance and piglets survival rate in the farrowing crate. Large Anim. Rev. 2020, 26, 239–247. [Google Scholar]

- Zhang, X.; Li, C.; Hao, Y.; Gu, X. Effects of Different Farrowing Environments on the Behavior of Sows and Piglets. Animals 2020, 10, 320. [Google Scholar] [CrossRef] [PubMed]

- Ko, H.-L.; Temple, D.; Hales, J.; Manteca, X.; Llonch, P. Welfare and performance of sows and piglets in farrowing pens with temporary crating system on a Spanish commercial farm. Appl. Anim. Behav. Sci. 2022, 246, 105527. [Google Scholar] [CrossRef]

- Chapinal, N.; de la Torre, J.R.; Cerisuelo, A.; Gasa, J.; Baucells; Coma, J.; Vidal, A.; Manteca, X. Evaluation of welfare and productivity in pregnant sows kept in stalls or in 2 different group housing systems. J. Vet. Behav. 2010, 5, 82–93. [Google Scholar] [CrossRef]

- AHDB; Davis, C.; Wilkins, B.; Barber, C. Evidence report: Comparing the Potential Implications of Widespread Use of Different Farrowing Systems in the British Pig Sector. United Kingdom, August 2020. Available online: https://projectblue.blob.core.windows.net/media/Default/Market%20Intelligence/COP/AHDB%20Alternative%20Farrowing%20Report.pdf (accessed on 23 April 2023).

- Mitchell, L.; Romanowicz, B.; Sawyer, P.; Reyes, E.; Deblitz, C. Pig Network the Pig Industry’s Transition to Group Sow Housing: Economic and Welfare Assess-Ments. Braunschweig, Germany and Poling, UK, April 2017. Available online: https://literatur.thuenen.de/digbib_extern/dn058694.pdf (accessed on 23 April 2023).

- Seddon, Y.M.; Cain, P.J.; Guy, J.H.; Edwards, S.A. Development of a spreadsheet based financial model for pig producers considering high welfare farrowing systems. Livest. Sci. 2013, 157, 317–321. [Google Scholar] [CrossRef]

- Bates, R.O.; Edwards, D.B.; Korthals, R.L. Sow performance when housed either in groups with electronic sow feeders or stalls. Livest. Prod. Sci. 2003, 79, 29–35. [Google Scholar] [CrossRef]

- REDACTIE VARKENS. Aeres Applies Innovative Well Farrowing Free-range Farrowing Pens. Available online: https://www.varkens.nl/nieuws/2020/12/08/aeres-neemt-innovatieve-wellfarrowing-vrijloopkraamhokken-in-gebruik (accessed on 8 December 2020).

- AHDB. 2021 Pig Cost of Production in Selected Countries. 2022, pp. 1–31. Available online: https://projectblue.blob.core.windows.net/media/Default/Pork/Pork%20MI%20files/CostPigProduction2021_221117_WEB.pdf (accessed on 2 November 2023).

- Potori, N.; Majewski, E.; Malak-Rawlikowska, A.; Himics, M.; Witzke, P.; Egri, E.; Erdos, A.; Gębska, M.; Grontkowska, A.; Hamulczuk, M.; et al. An Assessment of the Impacts of the Phasing out of Cages in EU Livestock Farming: The Pig and Layer Sectors. Brussels, Belgium, January 2023. Available online: https://www.copa-cogeca.eu/Flexpage/DownloadFile/?id=13425681 (accessed on 4 October 2023).

- Potori, N.; Himics, M.; Witzke, P.; Szabo, Z.; Savoly, J.; Egri, E. Socio-economic Implications of Banning Conventional Farrowing Crates in EU Pig Farming: A CAPRI-based Scenario Analysis. Stud. Agric. Econ. Dec. 2023, 125, 136–142. [Google Scholar] [CrossRef]

| Selected Production Efficiency Indicators | References | Values for Free-Farrowing Systems (FFS) vs. Crates (Smaller “<” or Larger “>”) |

|---|---|---|

| Litters/sow/year Decreased number of litters per sow per year and duration of inter-farrowing period | [11,12] | FFS < Crates |

| Sow mortality (%) | [13] | FFS > Crates |

| Culling-out percentage (%) | [14] | FFS > Crates |

| Mortality of piglets (%) Pigs born alive or dead per litter Pre-weaning mortality (%) | [12,13,14,15,16,17,18,19,20,21,22,23,24,25] | FFS > Crates |

| Number or percentage of crushed piglets | [13,23,24] | FFS > Crates |

| Average weight of piglets at birth (kg) | [13,15,19,25] | FFS ≥ Crates |

| Weaned piglets (piglets/sow; kg/sow; piglets/m2; kg/m2) | [11,12,22] | FFS < Crates |

| Feed intake (kg/day/sow) | [13,26] | FFS > Crates |

| Labour (hours per sow per year) | [11,16] | FFS > Crates |

| Space for farrowing (m2) | [22,25,27] | FFS > Crates |

| Investment needs and housing (euros/m2) | [27] | FFS > Crates |

| Costs of investments (euros/sow place) | [16,27,28] | FFS > Crates |

| Cost of vet and medicines (euros/piglet) | [27] | FFS > Crates |

| Costs of production and gross margins | [11,16,27,29] | FFS > Crates |

|

S3exit: “All the Farm Declarations for Alternative Systems Included” |

Switch to Free Farrowing with Confinement (5.5 m2) |

Switch to Free-Farrowing System with No Confinement (7 m2) |

Switch to Pig Fattening | Exit from Production |

|---|---|---|---|---|

| TOTAL | 60.2% | 4.3% | 5.1% | 30.4% |

| EU-West | 54.2% | 3.2% | 7.0% | 35.7% |

| EU-East | 67.3% | 5.7% | 2.8% | 24.1% |

| S4modified: “Farm Declarations for Alternative Systems Were Modified “ | Switch to Free Farrowing with Confinement (5.5 m2) | Switch to Free-Farrowing System with No Confinement 7 m2 | Switch to Pig Fattening | Exit from Production |

| TOTAL | 94.5% | 4.3% | 0.3% | 0.8% |

| EU-West | 95.7% | 3.2% | 0.4% | 0.8% |

| EU-East | 93.2% | 5.7% | 0.3% | 0.8% |

| Country |

Number of Sows (2021, Thousands of Heads) | Share in the Total EU | Percentage of Sows in Crates |

|---|---|---|---|

| Spain | 2684.9 | 24.7% | 99% |

| Germany | 1583.0 | 14.6% | 99% |

| Denmark | 1235.0 | 11.4% | 95% |

| France | 928.0 | 8.5% | 96% |

| The Netherlands | 910.0 | 8.4% | 98% |

| Poland | 654.1 | 6.0% | 95% |

| Italy | 551.0 | 5.1% | 99% |

| Belgium | 386.3 | 3.6% | 95% |

| Romania | 298.9 | 2.7% | 99% |

| Hungary | 240.7 | 2.2% | 99% |

| Portugal | 229.6 | 2.1% | 99% |

| Austria | 224.1 | 2.1% | 95% |

| Ireland | 144.8 | 1.3% | 99% |

| Czechia | 126.4 | 1.2% | 95% |

| Sweden | 120.7 | 1.1% | 0% |

| Croatia | 104.0 | 1.0% | 95% |

| Greece | 100.0 | 0.9% | 99% |

| Finland | 93.0 | 0.9% | 60% |

| Bulgaria | 65.8 | 0.6% | 99% |

| Lithuania | 44.3 | 0.4% | 95% |

| Latvia | 39.7 | 0.4% | 95% |

| Slovakia | 37.2 | 0.3% | 99% |

| Cyprus | 31.0 | 0.3% | 95% |

| Malta | 3.7 | 0.0% | 99% |

| Luxembourg | 3.1 | 0.0% | 99% |

| Estonia | 25.7 | 0.2% | 95% |

| Slovenia | 14.2 | 0.1% | 95% |

| TOTAL EU | 10,879.1 | 100.0% | 96.2% |

| EU-West | 9228.2 | 84.8% | 96.1% |

| EU-East | 1650.9 | 15.2% | 96.6% |

| 7 Largest Pig-Producing Countries (SP, DE, DK, FR, NL, IT, and PL) | 8546.0 | 78.6% | 97.7% |

| Clusters (EU-West/EU-East; Farm Size in No. of Sows per Farm) | Number of Farms in the Sample | Average Number of Sows per Farm | Number of Sows in the Sample | Average Size of Farrowing Pen (m2) | Mortality of Piglets | Number of Litters/Sow/Year | Piglets Weaned per Sow per Year | Mortality of Sows | Replacement Ratio (%) | Amount of Feed for Sows in the Lactation Period (28 Days) kg/sow/day | Requested Transition Period (Years) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SAMPLE | 225 | 897.9 | 202,038 | 4.7 | 10.7% | 2.3 | 28.4 | 6.0% | 42% | 6.4 | 15.4 |

| EU-West | 121 | 906.6 | 109,700 | 4.7 | 11.4% | 2.3 | 29.9 | 5.9% | 44% | 6.4 | 18.2 |

| EU-East | 104 | 887.9 | 92,338 | 4.8 | 9.9% | 2.2 | 26.7 | 6.2% | 39% | 6.3 | 12.3 |

| Number of sows at the farm | |||||||||||

| ≤70 | 43 | 43.1 | 1853 | 4.9 | 9.7% | 2.2 | 25.3 | 5.2% | 39% | 6.2 | 14.4 |

| 71–200 | 47 | 143.1 | 6725 | 5.2 | 11.5% | 2.2 | 26.4 | 6.0% | 39% | 6.6 | 17.4 |

| 201–500 | 39 | 360.7 | 14,066 | 4.6 | 10.2% | 2.3 | 29.7 | 5.4% | 41% | 6.5 | 16.2 |

| 501–1000 | 40 | 747.3 | 29,890 | 4.3 | 11.4% | 2.3 | 29.5 | 6.4% | 44% | 6.3 | 16.7 |

| >1000 | 56 | 2669.7 | 149,504 | 4.5 | 10.7% | 2.3 | 30.9 | 6.8% | 46% | 6.2 | 13.2 |

| Crates | Free Farrowing with Confinement—5.5 m2 | Free Farrowing No Confinement—7 m2 | Free Farrowing with Confinement (% Change) | Free Farrowing No Confinement (% Change) | |

|---|---|---|---|---|---|

| Number of sows per farm (mean) | (difference vs. crates (%)) | ||||

| SAMPLE | 897.9 | 719.4 | 570.8 | −19.9% | −36.4% |

| EU-West | 906.6 | 724.5 | 575.1 | −20.1% | −36.6% |

| EU-East | 887.9 | 713.5 | 565.9 | −19.6% | −36.3% |

| Grouped by herd size | |||||

| ≤70 | 43.1 | 36.3 | 29.3 | −15.8% | −32.0% |

| 71–200 | 143.1 | 124.8 | 105.9 | −12.8% | −26.0% |

| 201–500 | 360.7 | 295.6 | 234.4 | −18.0% | −35.0% |

| 501–1000 | 747.3 | 578.2 | 458.1 | −22.6% | −38.7% |

| >1000 | 2669.7 | 2138.9 | 1691.7 | −19.9% | −36.6% |

| Piglets’ mortality (%) | (difference vs. crates (%)) | ||||

| SAMPLE | 10.7 | 12.3 | 12.9 | +15% | +20% |

| EU-West | 11.4 | 13.1 | 13.7 | +15% | +20% |

| EU-East | 9.9 | 11.4 | 11.9 | +15% | +20% |

| Grouped by herd size | |||||

| ≤70 | 9.7 | 11.2 | 11.6 | +15% | +20% |

| 71–200 | 11.5 | 13.2 | 13.8 | +15% | +20% |

| 201–500 | 10.2 | 11.7 | 12.2 | +15% | +20% |

| 501–1000 | 11.4 | 13.1 | 13.7 | +15% | +20% |

| >1000 | 10.7 | 12.4 | 12.9 | +15% | +20% |

| Number of piglets weaned per sow (number of litters × piglets weaned/L) | (difference vs. crates (%)) | ||||

| SAMPLE | 28.4 | 27.4 | 27.2 | −3.7% | −4.3% |

| EU-West | 29.9 | 28.7 | 28.6 | −3.8% | −4.4% |

| EU-East | 26.7 | 25.8 | 25.6 | −3.6% | −4.1% |

| Grouped by herd size | |||||

| ≤70 | 25.3 | 24.4 | 24.3 | −3.5% | −4.1% |

| 71–200 | 26.4 | 25.3 | 25.2 | −3.9% | −4.5% |

| 201–500 | 29.7 | 28.7 | 28.5 | −3.6% | −4.1% |

| 501–1000 | 29.5 | 28.4 | 28.2 | −3.8% | −4.5% |

| >1000 | 30.9 | 29.7 | 29.6 | −3.7% | −4.3% |

| Feed cost per piglet weaned during lactation (EUR) | (difference vs. crates (%)) | ||||

| SAMPLE | 4.6 | 5.1 | 5.1 | +11.4% | +12.1% |

| EU-West | 4.5 | 5.0 | 5.0 | +11.6% | +12.3% |

| EU-East | 4.7 | 5.2 | 5.2 | +11.2% | +11.9% |

| Grouped by herd size | |||||

| ≤70 | 4.9 | 5.4 | 5.4 | +11.2% | +11.8% |

| 71–200 | 4.9 | 5.5 | 5.6 | +11.6% | +12.4% |

| 201–500 | 4.5 | 5.0 | 5.0 | +11.3% | +11.9% |

| 501–1000 | 4.4 | 4.9 | 4.9 | +11.6% | +12.3% |

| >1000 | 4.1 | 4.6 | 4.7 | +11.4% | +12.1% |

| Sow replacement costs per piglet weaned (EUR) | (difference vs. crates (%)) | ||||

| SAMPLE | 4.4 | 5.2 | 5.2 | +17.9% | +18.7% |

| EU-West | 4.3 | 5.1 | 5.1 | +18.3% | +19.1% |

| EU-East | 4.6 | 5.4 | 5.4 | +17.6% | +18.3% |

| Grouped by herd size | |||||

| ≤70 | 4.3 | 5.1 | 5.1 | +17.8% | +18.4% |

| 71–200 | 4.6 | 5.4 | 5.4 | +18.0% | +18.8% |

| 201–500 | 4.1 | 4.9 | 4.9 | +17.9% | +18.6% |

| 501–1000 | 4.6 | 5.4 | 5.4 | +18.1% | +19.0% |

| >1000 | 4.4 | 5.2 | 5.3 | +17.9% | +18.6% |

| Additional labour cost per piglet (EUR) | |||||

| SAMPLE | − | 0.6 | 1.1 | ||

| EU-West | − | 0.5 | 1.1 | ||

| EU-East | − | 0.6 | 1.2 | ||

| Grouped by herd size | |||||

| ≤70 | − | 0.7 | 1.3 | ||

| 71–200 | − | 0.6 | 1.3 | ||

| 201–500 | − | 0.5 | 1.0 | ||

| 501–1000 | − | 0.5 | 1.0 | ||

| >1000 | − | 0.5 | 1.0 | ||

| VET-MED costs (average) per piglet weaned (EUR) | (difference vs. crates (%)) | ||||

| SAMPLE | 1.3 | 1.5 | 1.5 | +11.6% | +12.4% |

| EU-West | 1.4 | 1.6 | 1.6 | +11.8% | +12.5% |

| EU-East | 1.2 | 1.3 | 1.3 | +11.5% | +12.1% |

| Grouped by herd size | |||||

| ≤70 | 1.5 | 1.7 | 1.7 | +11.4% | +12.1% |

| 71–200 | 1.4 | 1.6 | 1.6 | +11.9% | +12.6% |

| 201–500 | 1.3 | 1.4 | 1.4 | +11.5% | +12.2% |

| 501–1000 | 1.2 | 1.4 | 1.4 | +11.8% | +12.6% |

| >1000 | 1.2 | 1.3 | 1.3 | +11.6% | +12.3% |

| Total variable costs per piglet weaned (EUR) | (difference vs. crates (%)) | ||||

| SAMPLE | 8.0 | 9.2 | 9.8 | +14.5% | +22.2% |

| EU-West | 7.9 | 9.1 | 9.7 | +14.7% | +22.1% |

| EU-East | 8.2 | 9.3 | 10.0 | +14.2% | +22.4% |

| Grouped by herd size | |||||

| ≤70 | 8.3 | 9.6 | 10.2 | +15.3% | +23.5% |

| 71–200 | 8.6 | 9.9 | 10.6 | +14.6% | +22.8% |

| 201–500 | 7.8 | 9.0 | 9.5 | +14.8% | +22.1% |

| 501–1000 | 7.9 | 9.0 | 9.7 | +14.0% | +21.6% |

| >1000 | 7.6 | 8.6 | 9.2 | +13.8% | +21.2% |

| Investment in new pen, value per piglet weaned (EUR/piglet weaned) | |||||

| SAMPLE | 1.3 | 1.3 | |||

| EU-West | 1.1 | 1.1 | |||

| EU-East | 1.5 | 1.5 | |||

| Grouped by herd size | |||||

| ≤70 | 1.9 | 1.9 | |||

| 71–200 | 1.4 | 1.4 | |||

| 201–500 | 1.1 | 1.1 | |||

| 501–1000 | 1.1 | 1.1 | |||

| >1000 | 1.0 | 1.0 | |||

| Depreciation of existing building and equipment, EUR per piglet weaned (difference vs. crates (%)) | |||||

| SAMPLE | 5.2 | 7.3 | 9.2 | +40.9% | +77.2% |

| EU-West | 4.0 | 5.6 | 7.1 | +40.2% | +77.0% |

| EU-East | 6.6 | 9.3 | 11.7 | +41.4% | +77.4% |

| Grouped by herd size | |||||

| ≤70 | 6.4 | 8.7 | 11.0 | +35.4% | +70.2% |

| 71–200 | 6.0 | 8.1 | 9.9 | +35.0% | +64.6% |

| 201–500 | 4.4 | 6.3 | 8.1 | +43.2% | +82.5% |

| 501–1000 | 4.7 | 6.9 | 8.8 | +48.0% | +88.1% |

| >1000 | 4.5 | 6.7 | 8.5 | +46.7% | +87.3% |

| Depreciation of new investments in pens, existing buildings, and equipment per piglet weaned | |||||

| SAMPLE | 5.2 | 8.6 | 10.5 | +65.4% | +101.8% |

| EU-West | 4.0 | 6.7 | 8.2 | +67.4% | +104.3% |

| EU-East | 6.6 | 10.8 | 13.2 | +63.9% | +100.0% |

| Grouped by herd size | |||||

| ≤70 | 6.4 | 10.6 | 12.8 | +64.4% | +99.1% |

| 71–200 | 6.0 | 9.5 | 11.3 | +58.5% | +88.2% |

| 201–500 | 4.4 | 7.4 | 9.1 | +67.0% | +106.4% |

| 501–1000 | 4.7 | 8.0 | 9.8 | +70.9% | +111.2% |

| >1000 | 4.5 | 7.7 | 9.5 | +68.9% | +109.7% |

| Total costs of transition (variable costs + depreciation of new investments and existing buildings) per piglet weaned (EUR) | (difference vs. crates (%)) | ||||

| SAMPLE | 13.2 | 17.8 | 20.3 | +34.5% | +53.5% |

| EU-West | 11.9 | 15.8 | 17.9 | +32.4% | +49.7% |

| EU-East | 14.8 | 20.1 | 23.2 | +36.4% | +57.1% |

| Grouped by herd size | |||||

| ≤70 | 14.7 | 20.2 | 23.1 | +36.8% | +56.5% |

| 71–200 | 14.6 | 19.4 | 21.9 | +32.6% | +49.6% |

| 201–500 | 12.2 | 16.3 | 18.7 | +33.7% | +52.6% |

| 501–1000 | 12.6 | 17.0 | 19.5 | +35.0% | +54.7% |

| >1000 | 12.1 | 16.3 | 18.7 | +34.4% | +54.3% |

| Broad Opinion (n = 68) wrong direction/resignation from pig production/decreasing competitiveness/disaster to producers—(negative: 82% of answers) useful idea/positive change/no difference—(positive: 18% of answers) |

| Animal Welfare (n = 43) severe increase in piglet mortality/higher mortality of sows (negative: 74% of answers) better welfare of sows (positive: 26% of answers) |

| Human Welfare (n = 13) sows will be more aggressive when protecting their piglets/difficult to find workers/dangerous to workers (negative: 100% of answers) |

| Farm Economics (n = 36) increased production costs/decreased productivity/worse efficiency/high investment costs/need for EU support/deterioration of working conditions for staff/problems with staff |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malak-Rawlikowska, A.; Majewski, E.; Potori, N.; Hamulczuk, M.; Szili, V.; Egri, E. Unlocking Sows’ Welfare: The Farm-Level Economic Impact of Phasing out Farrowing Crates for Sows in the European Union’s Pig Breeding Industry. Agriculture 2024, 14, 187. https://doi.org/10.3390/agriculture14020187

Malak-Rawlikowska A, Majewski E, Potori N, Hamulczuk M, Szili V, Egri E. Unlocking Sows’ Welfare: The Farm-Level Economic Impact of Phasing out Farrowing Crates for Sows in the European Union’s Pig Breeding Industry. Agriculture. 2024; 14(2):187. https://doi.org/10.3390/agriculture14020187

Chicago/Turabian StyleMalak-Rawlikowska, Agata, Edward Majewski, Norbert Potori, Mariusz Hamulczuk, Viktor Szili, and Edit Egri. 2024. "Unlocking Sows’ Welfare: The Farm-Level Economic Impact of Phasing out Farrowing Crates for Sows in the European Union’s Pig Breeding Industry" Agriculture 14, no. 2: 187. https://doi.org/10.3390/agriculture14020187

APA StyleMalak-Rawlikowska, A., Majewski, E., Potori, N., Hamulczuk, M., Szili, V., & Egri, E. (2024). Unlocking Sows’ Welfare: The Farm-Level Economic Impact of Phasing out Farrowing Crates for Sows in the European Union’s Pig Breeding Industry. Agriculture, 14(2), 187. https://doi.org/10.3390/agriculture14020187