Abstract

No-tillage seeding is of great significance for adjusting and improving soil structure in Northeast China. The conventional no-tillage seeder faces several issues with its row cleaner, such as a low straw cleaning rate and a high working resistance. To address these problems, this paper utilizes the bionic design method and develops a bionic elastic row cleaner inspired by the motion behavior of mole excavation. The bionic structure includes bent teeth and a torsion spring for lateral throwing. The MBD–DEM coupled simulation technology is proposed as the experimental optimization method, and it analyzes the interactions between different row cleaners, straw, and soil. The results indicate that a bionic elastic row cleaner with curved teeth and a torsion spring for lateral throwing (BA-T) had a higher straw cleaning rate and total kinetic energy of straw. It also had lower working resistance. The field test results indicate that the BA-T improved the straw cleaning rate by 13.04% and reduced the working resistance by 39.24% compared to a flat row cleaner. This outcome also validates the accuracy of the simulation experiments. This study contributes to the design of new and efficient row cleaners suitable for maize straw mulching and no-tillage conditions, thereby promoting the adoption of conservation agriculture practices.

1. Introduction

Conservation agriculture promotes the use of straw residues to cover the land surface, which can reduce soil erosion and improve soil physical and chemical properties, ensuring sustainable agricultural production [1,2,3,4]. Excessive straw coverage in agricultural production can hinder seeding efficiency and prolong the seeding cycle, thereby limiting the adoption of conservation agriculture [5,6]. No-tillage seeders, a type of agricultural machinery, are capable of seeding on land covered with straw. The no-tillage seeder removes straw residue from the seeding row using a cleaner, and then, other components complete the seeding process on the cleared surface. The straw cleaner plays a crucial role in achieving successful no-tillage seeding operations [7]. The straw cleaner typically focuses on cleaning the straw inside the seeding row. Under the practice of straw covering and returning to the field for seeding, it has been shown that cleaning the straw can improve emergence consistency [8,9], enhance crop growth, and increase yield [10,11,12]. The research on no-tillage seeders focuses on the aspect of improving the rate of straw cleaning.

The two main types of row cleaners used for no-tillage seeders are the driving and passive row cleaners [13]. The row cleaner utilizes high-speed rotating cutting tools to cut, crash, and break the straw in the seeding belt and then mixes it with the soil [14,15,16,17]. This method has the advantage of achieving a high straw cleaning rate, but it also has drawbacks such as causing high soil disturbance, consuming a lot of power, and having low operating efficiency. High-strength soil cultivation can cause significant damage to the soil structure and the soil biological communities, which is detrimental to the sustainable development of agricultural ecology [18]. Passive row straw cleaners are widely used in agricultural production due to their ability to retain soil moisture, their simple structure, and their low production cost [19]. The geometric structure of a straw cleaner is crucial for its various working parameters. Scholars have implemented design improvements for the wheel finger and wheel structure to enhance their performance. Fan et al. [20] developed a claw wheel row straw cleaner that decreased the average straw coverage on the land surface prior to seeding from 75.15% to 47.1%. Jia et al. [21] designed a concave structured row straw cleaner based on the 2BMZF-2 no-tillage seeder (Jilin Kangda Agricultural Machinery Co., Ltd., Siping, China). The straw cleaning rate achieved was 83.61%. However, the required soil depth was 70 mm, resulting in increased soil splashing and traction resistance. Hou et al. [22] developed a row straw cleaner that utilizes axial acceleration to push the straw and incorporates a booster screw to enhance the efficiency of straw conveying. This innovation resulted in a straw cleaning rate exceeding 82%. Li et al. [23] developed a row cleaner with sharp teeth that achieved a maximum cleaning rate of 90.59% in soil covered with wheat straw. The device was effective at a depth of 55 mm. The existing passive row cleaners usually use a larger operating depth to obtain sufficient driving force, thereby improving the straw cleaning rate, but this will inevitably increase the working resistance. Few reports on the research into the design of row cleaners comprehensively consider the drag reduction ability.

The bionic design has made significant contributions to the design of agricultural machinery structures, achieving goals such as reducing working component wear, detachment, and soil disturbance [24,25,26]. Moles, as soil burrowing animals, have exceptional digging capabilities. The contour and arrangement of their front paw toes are utilized to optimize the structure of various components, including rotary tillers, deep loosening shovels, and straw-cutting disks [27,28,29]. This optimization aims to minimize the working resistance. Scott and Richardson [30] designed a conceptualized mining robot by analyzing the skeletal structure and motor function morphology of mole forelimbs. The robot was designed to maximize digging output and minimize the amount of soil that needs to be excavated after optimization. These parameters could be used as the initial values in an optimization simulation or algorithm to determine the optimal size of components and location of actors. This would maximize the force output for digging while minimizing the cross-section of the robot and the amount of earth that needs to be dug through. The characteristics of mole forelimbs have significant research value and can offer a practical design solution for optimizing and improving passive straw cleaning devices.

In recent years, digital simulation technology has been widely used as an effective experimental method to optimize the parameters of key components in agricultural machinery [31]. The EDEM software 2022 utilizes the discrete element method (DEM) algorithm to simulate the dynamic behavior of soil and straw particles when subjected to stress [23]. The ADAMS software 2022 utilizes the model-based design (MBD) algorithm to solve complex multi-body contact dynamics problems in agricultural machinery [32]. Based on the MBD–DEM coupling algorithm, researchers utilized EDEM and ADAMS software to analyze and optimize the parameters of agricultural machinery, such as the biaxial stubble breaking no-tillage device and the self-excited vibration ditching machine in rice stubble fields [33,34]. The simulation results were successful, demonstrating the method’s high efficiency and accuracy.

This study draws inspiration from the structure and digging behavior of mole forelimbs to design a bionic elastic row cleaner. This innovation aims to enhance straw cleaning efficiency and reduce resistance. This paper also examines the impact of various bionic structure units and combinations of bionic elastic row cleaners on indicators such as straw cleaning rate, average straw kinetic energy, and working resistance. Field experiments are conducted to demonstrate their effectiveness. A more effective research routine is identified, leading to design ideas for passive agricultural machinery components and supporting the promotion of conservation agriculture.

2. Materials and Methods

2.1. Bionic Prototype Analysis

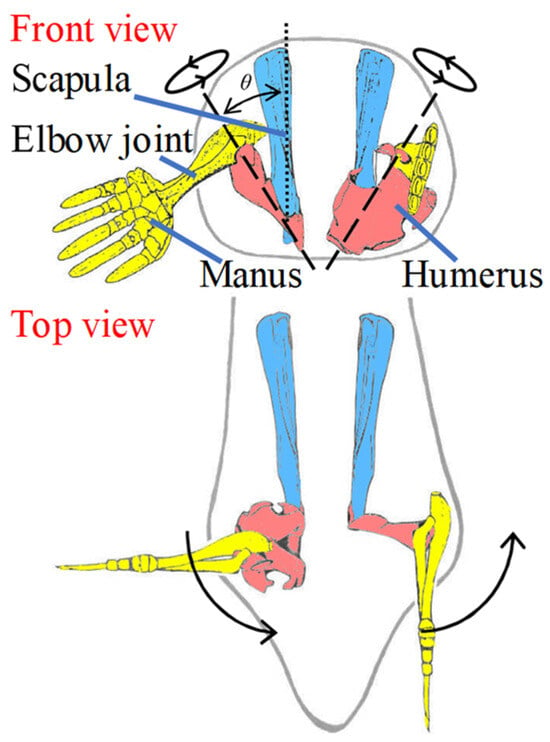

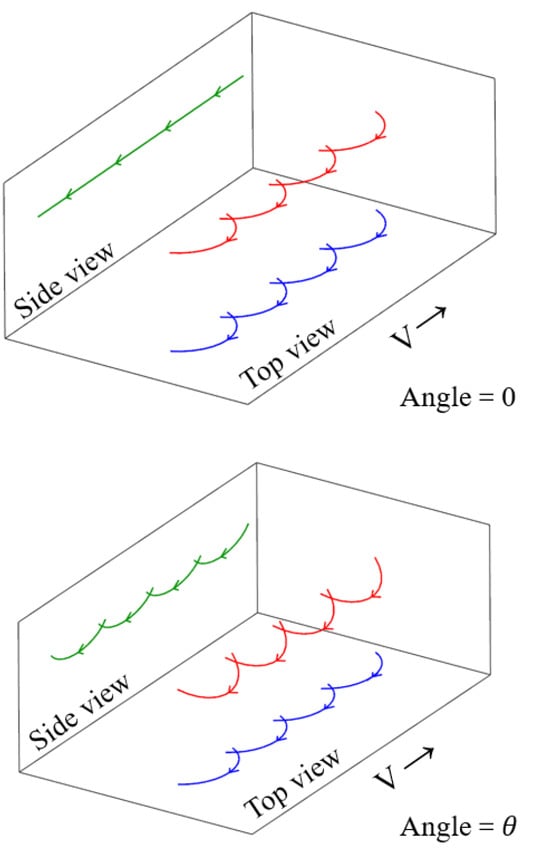

The mole uses a digging mechanism called humeral rotation digging [30,35], as illustrated in Figure 1. During the digging process, the mole’s two palms take turns, with one palm digging and the other palm and the hind limbs providing support. The mole’s palms move horizontally in a vertical plane, scraping the soil from the surface of the dug cave. After completing the digging, the palms and fingers use muscle power to push and throw the soil they come into contact with backward. Moles use their humerus to rotate around its long axis for digging, with the long axis forming an angle with the scapula. The elbow joint allows for rotation and adjustment of the height of the dug cave [36,37]. The motion trajectories of the humerus during digging, at rotation angles of 0 and θ, are depicted in Figure 2, where V is the mole’s forward direction. When the humerus is rotated by an angle of θ, the mole exhibits a slight horizontal deviation in its soil cutting trajectory (indicated by the blue line in Figure 2) during continuous digging. This deviation increases the vertical digging area of the cave (shown by the green line in Figure 2), significantly reducing the mole’s difficulty in passing through the cave. Humeral rotation digging is an efficient mechanism used by cave animals for soil transportation (source). These two advantages work together to ensure moles have efficient digging skills.

Figure 1.

Schematic diagram of functional morphology and digging motion trajectory of mole’s forelimbs (dashed line represents the rotation axis of the humerus).

Figure 2.

Schematic diagram of digging motion trajectory with humerus rotation angles of 0 and θ.

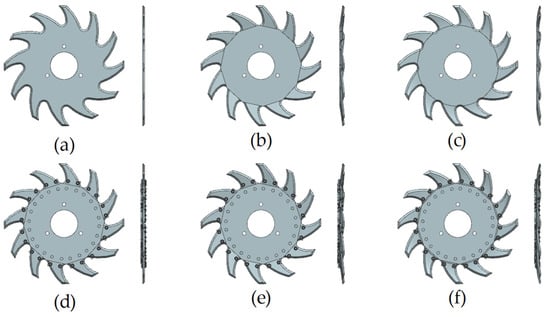

2.2. Design of Bionic Row Cleaner

Drawing inspiration from the morphology and motion function of a mole’s forelimb, this paper presents a design for the row cleaner of a finger clip no-tillage seeder. The objective of this design is to enhance the working performance of the seeder. Based on the primary structural parameters of the commonly used row cleaner in Northeast China (diameter 305 mm, thickness 4.5 mm, and teeth height 50 mm), this study proposes the design of a flat row cleaner (P). Additionally, bionic bent straight teeth with a 9° bend at the root position of the teeth (BS), bionic bent curved teeth with the side of the tooth shaped as an arc with a radius of 165 mm (BA), and a bionic torsion spring for lateral throwing (T) are incorporated into the aforementioned P, as illustrated in Figure 3. The configuration models of one type of P and five types of bionic Ps are depicted in Figure 3. These include a row cleaner with BS, a row cleaner with BA, a flat row cleaner with a torsion spring for lateral throwing (P-T), a row cleaner with a torsion spring for lateral throwing and bent straight teeth (BS-T), and a bionic elastic row cleaner with curved teeth and a torsion spring for lateral throwing (BA-T).

Figure 3.

Three-dimensional models of P and 5 bionic row cleaners. (a) P; (b) BS; (c) BA; (d) P-T; (e) BS-T; (f) BA-T.

2.3. Simulation Experiment for Parameter Optimization Based on MBD–DEM Coupling Algorithm

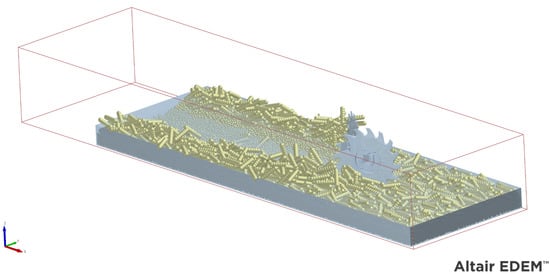

This study utilizes the coupled MBD–DEM algorithm and the coupled simulation of ADAMS and EDEM 2022 software to perform simulation experiments for parameter optimization. Firstly, EDEM software was utilized to construct the soil–straw model. ADAMS and EDEM software were then utilized to develop a coupled simulation model of the straw cleaning working process. The objective was to conduct a high-precision simulation of the row cleaner’s operational procedure.

2.3.1. Establishment of EDEM Discrete Element Model

To ensure the rational and efficient simulation and calculation, this study simplified the model of the row cleaner by eliminating irrelevant components in its operational process. The model now only includes the row cleaner installation bracket and two opposing row cleaners. Meanwhile, this study utilized the three-dimensional mapping software Creo to conduct solid modeling of the row cleaner at a 1:1 scale. The resulting model was then imported into the Geometry section of EDEM software in the appropriate format igs. Zhao et al. [38] and Wang et al. [39] provide an introduction to the establishment of discrete element simulation parameters. In these studies, the material properties of the simulation model were defined as 45 steel, with a Poisson’s ratio of 0.31, shear modulus of 7.0 × 1010 Pa, and a density of 7800 kg/m3. This study utilized a sphere with a diameter of 8 mm as a model for soil particles. The mechanical relationship model for soil particles was established as per Hertz–Mindlin with a bonding model. The model assumed a Poisson’s ratio of 0.38, shear modulus of 1.0 × 106 Pa, and a density of 1850 kg/m3. The selection of these parameters was in accordance with National standard GB/T24675.6-2009 [40] “Conservation Tillage Equipment—Smashed Straw Machine”. According to this standard, the length of corn straw smashing should not exceed 100 mm. Therefore, a linear model consisting of 8 spheres with a diameter of 20 mm and a center spacing of 10 mm, totaling 90 mm in length, was used as the straw particle model based on the actual size of field crushed straw. The mechanical relationship model for straw particles was established as a Hertz–Mindlin non-sliding contact model, incorporating a Poisson’s ratio of 0.4, a shear modulus of 1.0 × 106 Pa, and a density of 241 kg/m3. The contact parameters of the simulation material are presented in Table 1.

Table 1.

Contact parameters of simulated materials.

To replicate the real-life conditions of field straw cleaning operations, this study utilized the EDEM software to create a virtual soil tank. In order to simulate the field straw coverage prior to spring seeding in the region, the experiment established specific parameters. The soil layer thickness was set to 50 mm, while the straw layer thickness was set to 40 mm. Additionally, the dimensions of the soil tank were determined to be 2000 mm in length, 650 mm in width, and 90 mm in height. To ensure an adequate number of particles for simulation, a virtual particle factory was employed.

During the process of soil particle generation, the settling of soil particles occurs freely due to the influence of gravity. Following the generation of soil particles, the experiment applied a vertical load to calibrate the soil density above the particle group. This process compacted the soil model, ensuring consistency between the simulation and the actual soil.

2.3.2. ADAMS Motion Parameter Settings

The ADAMS 2020 software was utilized to determine the motion characteristics and connection approach of the geometric model of the row cleaner. It also established the installation bracket for the row cleaner and the row cleaner, as well as the main disk and bent teeth of the bionic elastic row cleaner, using revolute constraints as hinges. The installation bracket of the row cleaner exhibited sliding motion and was connected to the ground, with a translational constraint type. The installation bracket of the row cleaner and the row cleaner were hinged separately. The equations governing the motion of the installation bracket of the row cleaner and the ground constraint are given by −2.22 × time and 15.3 × time, respectively.

To replicate the movement of the bionic elastic row cleaner, the torsion spring was generated within the Forces module. Additionally, the I-Marker and the J-Marker were positioned on the curved teeth and the primary disk of the bionic elastic row cleaner, correspondingly. According to the initial simulation pre-experiment, the spring stiffness coefficient was established as 0.15 (N m/deg), while the damping coefficient was determined to be 0.1 (N m s/deg). The primary components of the bionic elastic row cleaner, namely the main disk and bent teeth, were designated as contact constraints. These constraints were of a solid-to-solid nature and served the purpose of restricting the movement of the bent teeth. The pertinent parameters of the setting are presented in Table 2.

Table 2.

ADAMS motion parameter settings.

The simulation process is shown in Figure 4.

Figure 4.

Coupling simulation process.

2.3.3. Simulation Experiment Indicator Testing Methods

The simulation experiment adopted a forward speed of 8 km/h (the actual working speed for the finger clamp no-tillage seeder widely applied in the region) and conducted comparative experimental research on the 5 designed bionic row cleaners (BS, BA, P-T, BS-T, BA-T) and P. The experiment aimed at evaluating the different bionic structure units on the working performance of the row cleaner, with each treatment repeated 3 times.

- (1)

- Straw cleaning rate

Using the Grid Bin Group function in the Analyst module of the EDEM software, the number of straw particles in the test plot was counted before and after the operation (in the stable operation interval, the plot size is 1 m × 0.2 m), and the ratio of the difference between the two and the number of straw particles in the test plot before the operation was calculated.

- (2)

- Total kinetic energy of straw

The Graph function of the analyst module within the EDEM software was chosen, and the particles’ attributes were configured as Kinetic Energy in the particles option of Analyst Tree. This allows for the monitoring of the total kinetic energy of all the straw particles. The resulting data were then exported and analyzed using Excel 2019 software (Microsoft, Washington, DC, USA) to determine the average total kinetic energy of the straw particles within the operational range of the row cleaner.

- (3)

- Working resistance

The Graph function of the Analyst module in the EDEM software was utilized to acquire real-time working resistance data while the row cleaner was in operation. Excel was utilized for the computation of the average resistance value within the stable operational range, which was then documented as the working resistance.

2.4. Field Experiment

2.4.1. Field Experiment Methods

The objective of the field experiment was to assess and compare the efficacy of the bionic elastic row cleaner BA-T and P in removing straw debris during agricultural operations. Therefore, the on-site experiment was designed to specifically compare single factors, and BA-T and P were generated using simulation models.

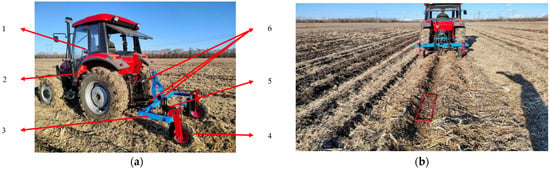

Figure 5 shows the row cleaners tested in the field experiments. The bionic bent curved teeth in the BA-T were connected to the row cleaner body using a hinge-type torsion spring. Figure 6 shows how the row cleaners were mounted. Two opposite row cleaners were mounted on the lower side of the profiling four-bar mechanism, with a connecting plate at the front for attachment to the frame.

Figure 5.

Tested row cleaners. (a) P; (b) BA-T: 1—bent curved teeth, 2—bent curved teeth after spring deformation, 3—row cleaner body, 4—torsion spring for lateral throwing.

Figure 6.

Row cleaner installation.

The field experiment site was situated at the scientific research base of Xiangyang Farm in Harbin, Heilongjiang Province, Northeast Agricultural University. The power unit utilized for the experiments was a Dongfanghong 704 tractor. Corn, a widely cultivated agricultural crop, is grown annually at this location. The row cleaner should be set based on the parameters of the conventional finger clamp no-tillage seeder commonly used in the region. These parameters included a depth of 20 mm and a working speed of 8 km/h. The experimental site was partitioned into 6 equally sized areas, each measuring 5 m in width and 70 m in length. The data collection areas for the two types of row cleaners in the field experiment were divided into three separate areas each. All the experimental indicators represented the mean values measured from 3 regions. The field experiment site and its corresponding working effect are depicted in Figure 7, respectively.

Figure 7.

Field experiment. (a) Field experiment site: 1—tractor, 2—agricultural machinery mechanical information dynamic telemetry system, 3—rackmount, 4—depth wheel, 5—row cleaner, 6—three-point hitch sensor; (b) field working results.

2.4.2. Field Experiment Indicator Testing Methods

During the operational procedure, the row cleaner primarily encompassed the interaction between the straw and the soil present within the strip. Therefore, the primary performance indicators of the device primarily encompassed the straw cleaning rate and the soil loss of the seedbed during the field experiment.

- (1)

- Field straw cleaning rate

The straw residues in three test plots were collected separately before and after the experiment. The dimensions of the test plot prior to and following the experiment were 1.0 m × 0.65 m (0.65 m planting spacing is commonly used in Northeast China) and 1.0 m × 0.2 m, respectively. The straw residue that was collected was subjected to a drying process in an oven at a controlled temperature of 55 °C for a duration of 72 h. The ratio of the difference between the residual straw weight per unit area before and after the test to the residual straw weight per unit area before the test was calculated.

- (2)

- Field working resistance

The NJTY3 agricultural machinery mechanical information dynamic telemetry system (Heilongjiang Agricultural Machinery Engineering Research Institute) was used to measure the field working resistance. Three-point suspension sensors were mounted on the frame and connected to the tractor. Real-time data were acquired by a data collector and a data processing terminal. The acquired data were exported to Excel 2019 software to calculate the average value of the combined force in the stabilization zone for each group of treatments.

2.5. Statistical Methods

This study utilized Excel 2019 and SPSS 26 software to conduct statistical analysis and perform least significant difference (LSD) analysis on the collected data. LSD analysis was employed to assess the presence of significant variations among various levels of the same experimental factors. Additionally, LSD analysis was utilized to investigate whether there were noteworthy disparities in performance indicators between the two devices in field experimental conditions.

3. Results and Discussion

3.1. Simulation Experiment Results

3.1.1. Straw Cleaning Rate

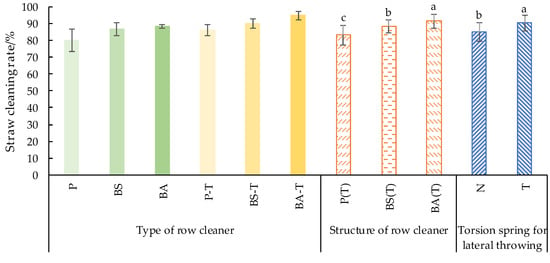

The impact of the bionic structure of bent teeth on the rate of straw cleaning was highly significant (p < 0.01), as depicted in Figure 8. Among the six types of row cleaners, there was variation in the cleaning rates, which ranged from 80.14% to 94.64%. Notably, the BA-T device exhibited the highest cleaning rate, while the P device demonstrated the lowest cleaning rate. It was observed that the row cleaners BS(T) and BA(T) with a bionic included angle of θ exhibited a higher straw cleaning rate compared to those with P(T). Among these row cleaners, the straw cleaning rate of BA(T) was found to be the highest. When comparing with P(T), the straw cleaning rates of BS(T) and BA(T) exhibited an increase of 6.29% and 10.03%, respectively. This finding aligns with the research conducted by Jia [21], which suggests that claw stubble shifting wheels with concave surfaces are more efficient in cleaning straw in the working row compared to conventional flat stubble pulleys.

Figure 8.

Impact of 6 cleaners and each bionic structure on the straw cleaning rate: error bars are standard deviations, values are standard errors, means followed by different lowercase letters are significantly different according to LSD multiple range test at a significance level of 0.050.

The findings from additional research indicate that the cleaning rate of different row cleaners in the presence or absence of T varies significantly (p < 0.05). This is illustrated in Figure 8. The row cleaner equipped with a T bionic structure exhibited a significantly higher straw cleaning rate, which was observed to increase by an average of 5.31%. This finding aligns with the research conducted by Zhao [41], which suggests that the spring mechanism enables the storage and transfer of energy to the object in contact during the recovery process.

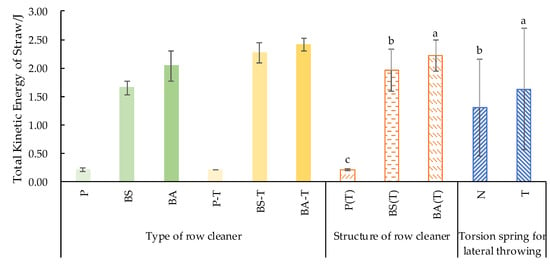

3.1.2. Total Kinetic Energy of Straw

The impact of the bionic structure with bent teeth on the overall kinetic energy of the straw was highly significant (p < 0.01), as illustrated in Figure 9. Different row cleaners exhibited varying levels of total kinetic energy on the straw, with values ranging from 0.21 J to 2.41 J. Among these devices, the BA-T demonstrated the highest average kinetic energy on the straw, while P exhibited the lowest average kinetic energy on the straw. It was observed that the total kinetic energy of the bionic row cleaners BS(T) and BA(T) with an included angle of θ was found to be greater than that of the row cleaners P(T) with planar structures. Among these, the row cleaner with the highest total kinetic energy was denoted as BA(T), with a value of 2.22 J. The application of BS(T) and BA(T) resulted in a significant increase in the total kinetic energy of straw, with BS(T) increasing it by 833.33% and BA(T) increasing it by 957.14% compared to P(T). Through careful analysis, the aforementioned results can be attributed to the utilization of row cleaners equipped with a bionic structure consisting of bent teeth. This unique design facilitated the outward projection of straw contact along the tangent direction of the tooth end, resulting in a significantly higher total average kinetic energy of the straw. This phenomenon bears resemblance to the impact of a disk harrow on soil. The disk harrow, characterized by its concave structure, is capable of generating lateral kinetic energy to facilitate the lateral movement of soil. On the other hand, the disk plow, with its flat structure, can only exert shear force [42].

Figure 9.

Impact of 6 cleaners and each bionic structure on total kinetic energy of straw: error bars are standard deviations, values are standard errors, means followed by different lowercase letters are significantly different according to LSD multiple range test at a significance level of 0.05.

Through conducting additional research, the findings indicate that the presence or absence of a T bionic structure led to notable variations in the total kinetic energy of different row cleaners (p < 0.01), as depicted in Figure 9. The incorporation of the T bionic structure resulted in a substantial enhancement in the total kinetic energy of the row cleaner. On average, this increase amounted to 25.4%. The primary cause for the aforementioned outcomes is the inward opening of the bent teeth due to the torsion spring’s lateral throwing effect. During the process of restoring the deformed teeth, the torsion spring’s elastic potential energy is transformed into kinetic energy in the straw. This allows the straw to acquire additional kinetic energy, similar to the findings of Hou [22]. This research demonstrated that active rotating teeth can increase the kinetic energy of corn straw compared to rigid teeth, thereby enhancing the lateral throwing capability of the straw.

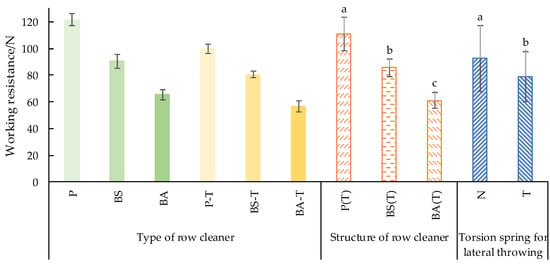

3.1.3. Working Resistance

The bionic structure with bent teeth exhibited significant impact on working resistance (p < 0.01), as illustrated in Figure 10. Several row cleaners exhibited varying levels of working resistance, with values ranging from 56.71 N to 121.62 N. Among these devices, P demonstrated the highest working resistance, while BA-T exhibited the lowest. In the context of straw row cleaners with lateral throwing bionic elements, it was observed that the working resistance of BS(T) and BA(T), which incorporated a bionic included angle of θ, was comparatively lower than that of P(T) with a plane structure. Among these, BA(T) exhibited the lowest working resistance. The working resistance of BS(T) and BA(T) decreased by 22.79% and 44.82%, respectively, compared to that of P(T). Through conducting additional research, the findings indicated a notable disparity in the working resistance (p < 0.01) between lateral throwing bionic structures equipped with torsion springs and those without. The working resistance of row cleaners equipped with torsion springs for lateral throwing bionic structures exhibited a decrease, with an average reduction of 13.49%. The experimental results presented in this study provide evidence of the digging and drag reduction capabilities associated with the angle formed between the humerus and scapula of the forelimbs of moles [28].

Figure 10.

Impact of 6 cleaners and each bionic structure on working resistance: error bars are standard deviations, values are standard errors, means followed by different lowercase letters are significantly different according to LSD multiple range test at a significance level of 0.05.

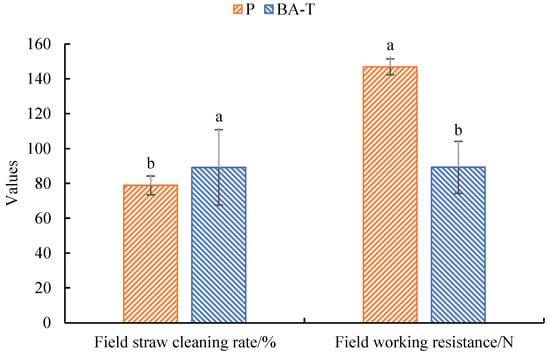

3.2. Field Experiment Results

The BA-T treatment exhibited a significantly higher straw cleaning rate (p ≤ 0.01) and a significantly lower working resistance compared to the P treatment (p ≤ 0.01), as illustrated in Figure 11. The results of the field experiment demonstrated that the utilization of the BA-T, equipped with bent teeth and a T bionic structure, led to a 13.04% increase in the straw cleaning rate and a 39.24% reduction in working resistance compared to the use of P.

Figure 11.

Analysis of field experiment results: error bars are standard deviations, values are standard errors, means followed by different lowercase letters are significantly different according to LSD multiple range test at a significance level of 0.05.

3.3. Discussion

3.3.1. Simulation Experiments

The bionic structure of bent teeth, including BS and BA, along with the incorporation of T, holds significant importance in influencing the performance indicators of the row cleaner. In the context of straw cleaning operations, it is advantageous to have a higher straw cleaning rate and a lower working resistance, as this contributes to the smooth progress of subsequent seeder operations. These factors are crucial in ensuring that there is sufficient soil in the seedbed, enhancing the uniformity and consistency of the seedbed, and reducing the fuel consumption of the tractor.

Combining the aforementioned analysis, it can be concluded that the straw row cleaners that possessed a bionic structure with bent teeth had a greater effect on the kinetic energy and working resistance. Meanwhile, the presence or absence of side-throwing torsion springs (T) had a greater effect on the straw clearing rate. For straw row cleaners that lacked torsion springs and utilized lateral throwing bionic structures, the bionic structure of bent teeth reduced the working resistance by an average of 35.9%. Straw row cleaners equipped with bent teeth and torsion springs for lateral throwing were found to effectively minimize the working resistance and enhance the straw cleaning rate. The average working resistance of the proposed straw row cleaners was only 56.4% of that observed in the flat structure straw row cleaners (P), while the average straw removal rate was elevated by 15.2%. Therefore, this study manufactured BA-T type straw row cleaners and conducted field experiments to validate its operational efficiency.

3.3.2. Field Experiments

The findings of the field experiment aligned with those of MBD–DEM coupled simulation experiment, suggesting that MBD–DEM coupled simulation experiment accurately simulated the dynamics of soil straw particles during straw cleaning operations and effectively represented the straw cleaning process.

In the context of contemporary research findings, scholars have employed the approach of optimizing the operational parameters of the straw cleaning apparatus in order to enhance the efficiency of straw cleaning. To provide specific details, Jia et al. [21] conducted an experiment in which they inserted their straw cleaning device into the soil at a depth of 70 mm. The results showed that the straw cleaning rate achieved was 83.61%. Li et al. [23] developed a novel row cleaner with sharp teeth. Their device demonstrated a high straw cleaning rate of 90.59% under wheat-straw-covered ground conditions. However, the depth of penetration required for optimal performance was 55 mm. Although the aforementioned research findings have the potential to enhance the efficiency of straw removal, the excessive penetration of the straw removal wheel into the soil can result in an increase in the working resistance. In this study, a novel straw cleaning device was developed by taking inspiration from the forelimbs of moles, which served as a bionic prototype. The straw cleaning rate can be enhanced by augmenting the kinetic energy of the straw. Therefore, bionic elastic row cleaners may exhibit greater competence.

4. Conclusions

Taking the forelimbs of a mole as the bionic prototype, this paper presents the design of five row cleaners incorporating bionic units. Based on the coupled simulation model of MBD–DEM, this paper assesses the operational efficiency of bionic row cleaners and identifies their optimal structure. The data obtained from the field experiments provide evidence of the practicality of the bionic row cleaner and the virtual simulation model.

Through the analysis of the structural and functional morphology of the forelimbs of moles, the bionic structures of bent teeth and torsion springs for lateral throwing were applied to the design of a row cleaner. As a result, five bionic structure elements were developed for the row cleaner.

The ADAMS–EDEM coupled simulation technology was utilized to perform simulation experiments. This study aimed to analyze the working performance of six row cleaners through a comparative analysis. The results of the simulation test indicated that the both bionic structures had a positive impact on the operational efficiency of the row cleaner. The average working resistance was only 56.4% of that of the P, while the average straw cleaning rate increased by 15.2% compared with that of the P. Among the five bionic row cleaners, BA-T exhibited the highest level of comprehensive performance.

Based on field verification, the experimental results indicated that the straw cleaning rate of BA-T was 89.14%, with the working resistance was 107 N, thereby satisfying the criteria set for strip tillage technology.

Future research endeavors will involve conducting multi-factor experiments in order to optimize the primary structural parameters of BA-T. The objective will be to determine the most optimal combination of these structure parameters. In addition, farm-scale experimental studies will be conducted to assess the field performance of the device and its impact on crop growth.

Author Contributions

Conceptualization, Q.W.; methodology, Q.W.; software, Q.W. and Z.W.; validation, Z.W. and Z.Z.; formal analysis, S.Y. and K.Z.; investigation, Q.W. and W.Z.; resources, Q.W.; data curation, Q.W. and X.S.; writing—original draft preparation, Q.W.; writing—review and editing, S.Y. and K.Z.; visualization, J.W. and W.Z.; supervision, J.W.; project administration, J.W.; funding acquisition, Q.W. and J.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the National Natural Science Foundation of China (No. 52005094), Heilongjiang Provincial Key Research and Development Program (No. 2022ZX05B04), Heilongjiang Provincial Natural Science Foundation of China (No. LH2022E006), Heilongjiang Postdoctoral Foundation (No. LBH-Z19041), and the Scholars Program of Northeast Agricultural University (No. 20QC10).

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors would like to thank their schools and colleges, the funding providers of the project and those who provided English editing services during the preparation of this manuscript. All support and assistance is sincerely appreciated.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Blanco-Canqui, H.; Lal, R. Crop Residue Removal Impacts on Soil Productivity and Environmental Quality. Crit. Rev. Plant Sci. 2009, 28, 139–163. [Google Scholar] [CrossRef]

- Awada, L.; Lindwall, C.W.; Sonntag, B. The development and adoption of conservation tillage systems on the Canadian Prairies. Int. Soil Water Conserv. Res. 2014, 2, 47–65. [Google Scholar] [CrossRef]

- Ren, Z.; Han, X.; Feng, H.; Wang, L.; Ma, G.; Li, J.; Lv, J.; Tian, W.; He, X.; Zhao, Y. Long-term conservation tillage improves soil stoichiometry balance and crop productivity based on a 17-year experiment in a semi-arid area of northern China. Sci. Total Environ. 2023, 908, 168283. [Google Scholar] [CrossRef]

- Nunes, M.R.; Karlen, D.L.; Veum, K.S.; Moorman, T.B.; Cambardella, C.A. Biological soil health indicators respond to tillage intensity: A US meta-analysis. Geoderma 2020, 369, 114335. [Google Scholar] [CrossRef]

- Ren, S.; Guo, B.; Wu, X.; Zhang, L.; Ji, M.; Wang, J. Winter wheat planted area monitoring and yield modeling using MODIS data in the Huang-Huai-Hai Plain, China. Comput. Electron. Agric. 2021, 182, 106049. [Google Scholar] [CrossRef]

- Allmaras, R.; Langdale, G.; Unger, P.; Dowdy, R.; Van Doren, D. Adoption of conservation tillage and associated planting systems. In Soil Management for Sustainability; Soil and Water Conservation Society: Ankeny, IA, USA, 1991; pp. 53–83. [Google Scholar]

- Fallahi, S.; Raoufat, M.H. Row-crop planter attachments in a conservation tillage system: A comparative study. Soil Tillage Res. 2008, 98, 27–34. [Google Scholar] [CrossRef]

- Wu, F.; Zhai, L.C.; Xu, P.; Zhang, Z.B.; Baillo, E.H.; Tolosa, L.N.; Kimotho, R.N.; Jia, X.L.; Guo, H.Q. Effects of deep vertical rotary tillage on the grain yield and resource use efficiency of winter wheat in the Huang-Huai-Hai Plain of China. J. Integr. Agric. 2021, 20, 593–605. [Google Scholar] [CrossRef]

- Hou, S.Y.; Zhu, Y.F.; Zhu, X.X.; Wang, Y.J.; Ji, W.Y.; Chen, H.T. Design and experiment of a straw clearing mulching no-tillage planter. Biosyst. Eng. 2022, 221, 69–80. [Google Scholar] [CrossRef]

- Raoufat, M.H.; Matbooei, A. Row cleaners enhance reduced tillage planting of corn in Iran. Soil Tillage Res. 2007, 93, 152–161. [Google Scholar] [CrossRef]

- Kaspar, T.; Erbach, D. Improving stand establishment in no-till with residue-clearing planter attachments. Trans. ASAE-Am. Soc. Agric. Eng. 1998, 41, 301–306. [Google Scholar]

- Brandelero, E.M.; De Araújo, A.G.; Ralisch, R. Coverage Mobilization by Different No-Tillage in-Line Handling Mechanisms. Eng. Agrícola 2015, 35, 89–97. [Google Scholar] [CrossRef]

- Liao, Q.; Gao, H.; Shu, C. Present situations and prospects of anti-blocking technology of no-tillage planter. Trans. CSAE 2004, 20, 108–120. [Google Scholar]

- Shi, Y.Y.; Sun, X.; Wang, X.C.; Hu, Z.C.; Newman, D.; Ding, W.M. Numerical simulation and field tests of minimum-tillage planter with straw smashing and strip laying based on EDEM software. Comput. Electron. Agric. 2019, 166, 105021. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, C.; Chen, L.; Li, Z.; Huang, X.; Li, J. Design and experiment of active straw-removing anti-blocking device for maize no-tillage planter. Trans. Chin. Soc. Agric. Eng. 2017, 33, 10–17. [Google Scholar]

- Yang, L.; Zhang, R.; Gao, N.N.; Cui, T.; Liu, Q.W.; Zhang, D.X. Performance of no-till corn precision planter equipped with row cleaners. Int. J. Agric. Biol. Eng. 2015, 8, 15–25. [Google Scholar] [CrossRef]

- Wenyan, Y.; Dianbao, Z.; Hequan, M.; Peide, C.; Maojian, W.; Peisong, D. Design and experiment of oblique anti-blocking device for no-tillage planter with shallow plowing stubble clearing. Trans. Chin. Soc. Agric. Mach. 2022, 53, 42–52. [Google Scholar]

- Wang, Y.M.; Li, N.; Ma, Y.H.; Tong, J.; Pfleging, W.; Sun, J.Y. Field experiments evaluating a biomimetic shark-inspired (BioS) subsoiler for tillage resistance reduction. Soil Tillage Res. 2020, 196, 104432. [Google Scholar] [CrossRef]

- Gao, H.; Li, W. Conservation Tillage Techniques and Implements; Chemical Industry Press: Beijing, China, 2004. [Google Scholar]

- Fan, X.; Jia, H.; Zhang, W.; Yang, H.; Gu, Y.; Li, H. Parametric analysis of finger-type anti-blocking residue-cleaner for no-till planting. Trans. Chin. Soc. Agric. Mach. 2011, 42, 56–60. [Google Scholar]

- Honglei, J.; Hang, L.; Haibo, Y. Simulation and experiment on stubble clearance mechanism with concave claw-type for no-tillage planter. Trans. Chin. Soc. Agric. Mach. 2018, 49, 68–77. [Google Scholar]

- Shouyin, H.; Zhangchi, J.; Donghui, X.; Xing, W.; Binjie, F.; Haitao, C. Improved Design and Test of Straw Cleaning Device Suitable for No-tillage Seeding Unit. Trans. Chin. Soc. Agric. Mach. 2023, 54, 111–122. [Google Scholar]

- Li, X.; Zhang, Y.; He, H.; Wang, B.; Zhou, H.; Geng, D.; Zhang, Y. Design and Experiment of Row Cleaner with Staggered Disc Teeth for No-Till Planter. Agriculture 2023, 13, 1373. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Hu, B.; Gu, T.; Wang, Z.; Wang, H. Analysis of the resistance reduction mechanism of potato bionic digging shovels in clay and heavy soil conditions. Comput. Electron. Agric. 2023, 214, 108315. [Google Scholar] [CrossRef]

- Jia, H.L.; Wang, W.J.; Wang, W.P.; Zheng, J.; Wang, Q.; Zhuang, J. Application of anti-adhesion structure based on earthworm motion characteristics. Soil Tillage Res. 2018, 178, 159–166. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Ma, Y.; Tong, J.; Zhang, Z. DEM simulation of bionic subsoilers (tillage depth > 40 cm) with drag reduction and lower soil disturbance characteristics. Adv. Eng. Softw. 2018, 119, 30–37. [Google Scholar] [CrossRef]

- Song, W.; Jiang, X.H.; Li, L.K.; Ren, L.L.; Tong, J. Increasing the width of disturbance of plough pan with bionic inspired subsoilers. Soil Tillage Res. 2022, 220, 105356. [Google Scholar] [CrossRef]

- Yang, Y.; Tong, J.; Ma, Y.; Jiang, X.; Li, J. Design and experiment of biomimetic rotary tillage blade based on multiple claws characteristics of mole rats. Trans. Chin. Soc. Agric. Eng. 2019, 35, 37–45. [Google Scholar]

- Li, M.; Chen, D.H.; Zhang, S.J.; Tong, J. Biomimeitc Design of a Stubble-Cutting Disc Using Finite Element Analysis. J. Bionic Eng. 2013, 10, 118–127. [Google Scholar] [CrossRef]

- Scott, R.G.; Richardson, R.C. Realities of biologically inspired design with a subterranean digging robot example. In Proceedings of the 6th IASTED International Conference on Robotics and Applications, Cambridge, MA, USA, 31 October–2 November 2005; pp. 226–231. [Google Scholar]

- Goodwin, G.C.; Medioli, A.M.; Sher, W.; Vlacic, L.B.; Welsh, J.S. Emulation-based virtual laboratories: A low-cost alternative to physical experiments in control engineering education. IEEE Trans. Educ. 2010, 54, 48–55. [Google Scholar] [CrossRef]

- Caixia, S.; Shichuan, C.; Yitao, L.; Qingxi, L.; Xingyu, W.; Yuntong, L. Parameter Optimization and Experiment of Forward Laying Device for Rape Windrower Based on ADAMS. Trans. Chin. Soc. Agric. Mach. 2022, 53. [Google Scholar]

- Li, J.; Li, H.C.; Chen, Y.Y.; Lin, P.Y.; Zhang, Q.Q.; Cheng, Y.; Yang, Z.; Huang, G.W. Research on Ditching Mechanism of Self-Excited Vibration Ditching Machine. Agronomy 2023, 13, 905. [Google Scholar] [CrossRef]

- Zhu, H.B.; Wu, X.; Bai, L.Z.; Qian, C.; Zhao, H.R.; Li, H. Development of the biaxial stubble breaking no-tillage device for rice stubble field based on EDEM-ADAMS simulation. Trans. Chin. Soc. Agric. Eng. 2022, 38, 10–22. [Google Scholar]

- Gorman, M.L.; Stone, R.D. The Natural History of Moles; Cornell University Press: Ithaca, NY, USA, 1990. [Google Scholar]

- Yalden, D.W. The Anatomy of mole locomotion. J. Zool. 1966, 149, 55–64. [Google Scholar] [CrossRef]

- Barnosky, A.D. Locomotion in moles (Insectivora, Proscalopidae) from the middle Tertiary of North America. Science 1982, 216, 183–185. [Google Scholar] [CrossRef]

- Zhao, J.L.; Wang, X.G.; Zhuang, J.; Liu, H.L.; Wang, Y.J.; Yu, Y.J. Coupled Bionic Design Based on Primnoa Mouthpart to Improve the Performance of a Straw Returning Machine. Agriculture 2021, 11, 775. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, H.; Zhou, W.; Wang, J. Design and Experiment of Automatic Width Control Row Cleaners. Trans. Chin. Soc. Agric. Mach. 2021, 52, 25–35. [Google Scholar]

- GB/T24675.6-2009; Agricultural Industry Standards of the People’s Republic of China.Conservation Tillage Equipment–Smashed Straw Machine. China National Standardization Administration, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2009.

- Zhao, J.L.; Lu, Y.; Wang, X.G.; Zhuang, J.; Han, Z.W. A bionic profiling-energy storage device based on MBD-DEM coupled simulation optimization reducing the energy consumption of deep loosening. Soil Tillage Res. 2023, 234, 105824. [Google Scholar] [CrossRef]

- Godbolé, R.D. Comparing Rolling Coulters Based on Soil Disturbance. Ph.D. Dissertation, Iowa State University, Ames, IA, USA, 1997. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).