Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice

Abstract

1. Introduction

2. Materials and Methods

2.1. Basic Physical Properties of Rapeseed, Wheat, and Rice

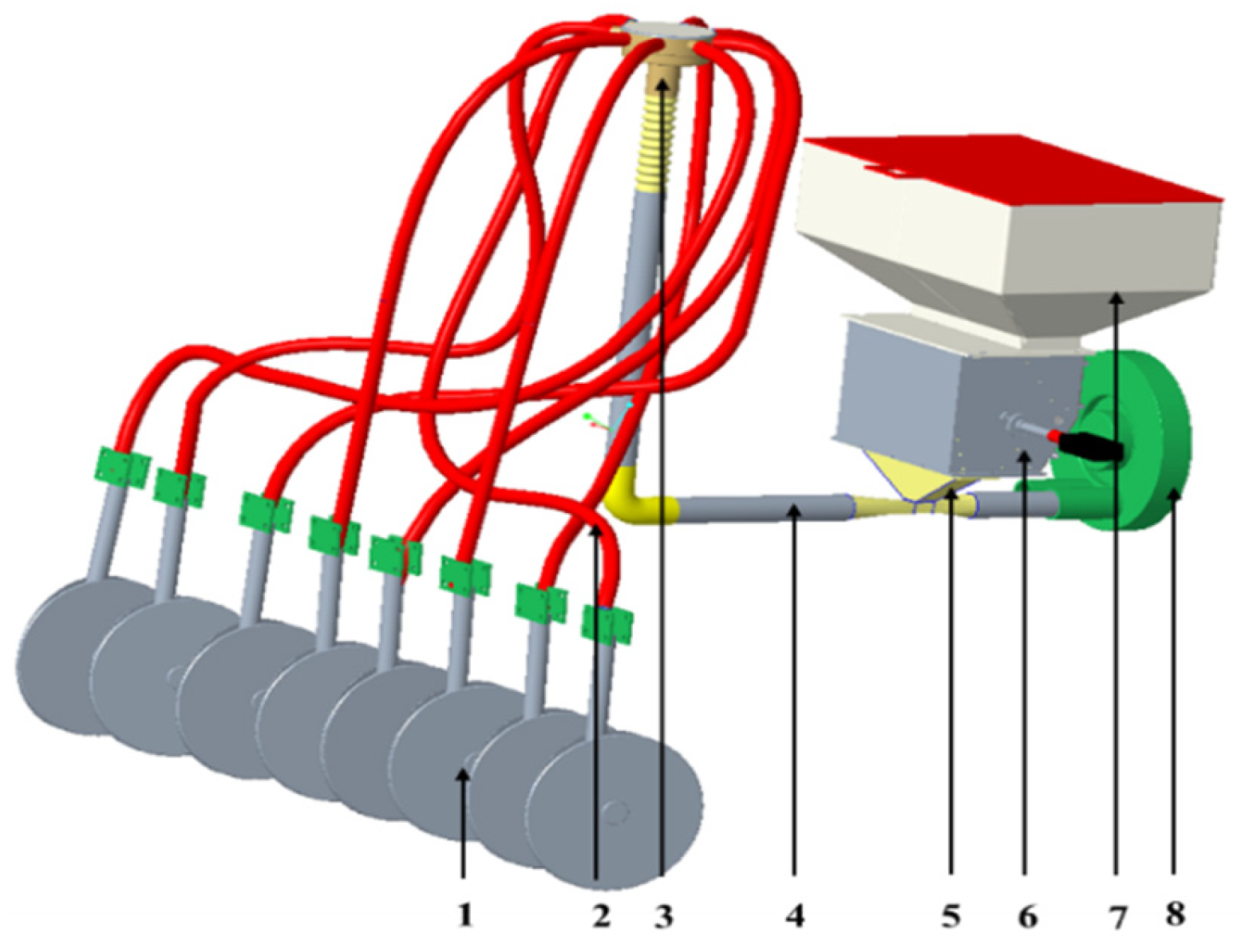

2.2. The Overall Structure and Working Principle

2.3. Mechanical Analysis of the Working Process of the Seed Plant

2.3.1. Mechanical Analysis of Seed Population in Filling Zone

2.3.2. Mechanical Analysis of Seed Population in Feeding Zone

2.4. Type Hole Shape

2.5. Type Hole Size

2.6. DEM Establishment

3. Experiments

3.1. Simulation Model Verification

3.2. Bench Test Verification

3.3. Field Experiment Verification

4. Results and Discussion

4.1. Analysis of DEM Simulation

4.2. Static Workbench Experiments

4.2.1. Effect of Working Speed of Type Hole Wheel on Feeding Rate

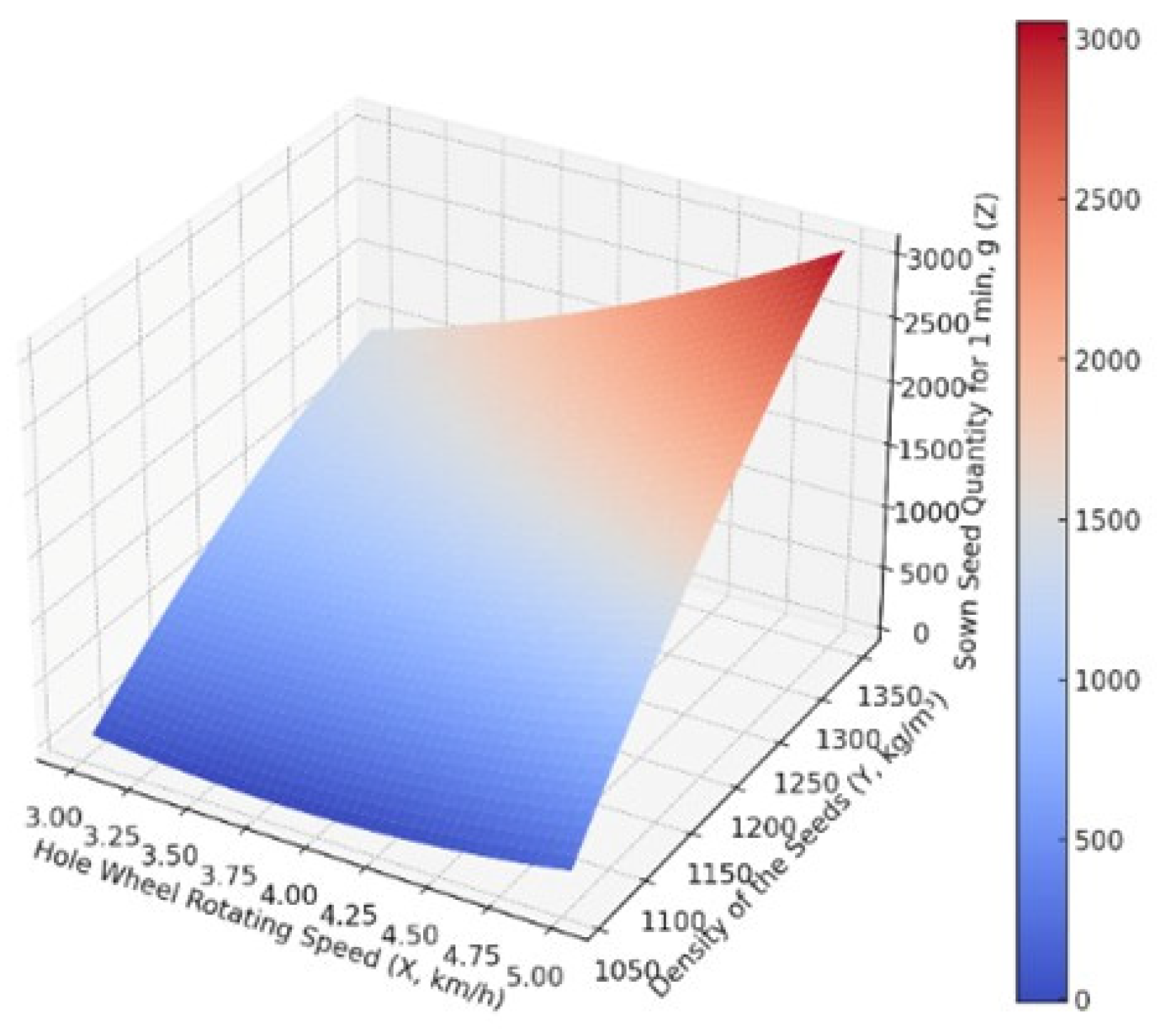

4.2.2. Analysis of Interaction Effects Between Rotating Speed and Seed Density

4.2.3. Regression Model Validation Test Results

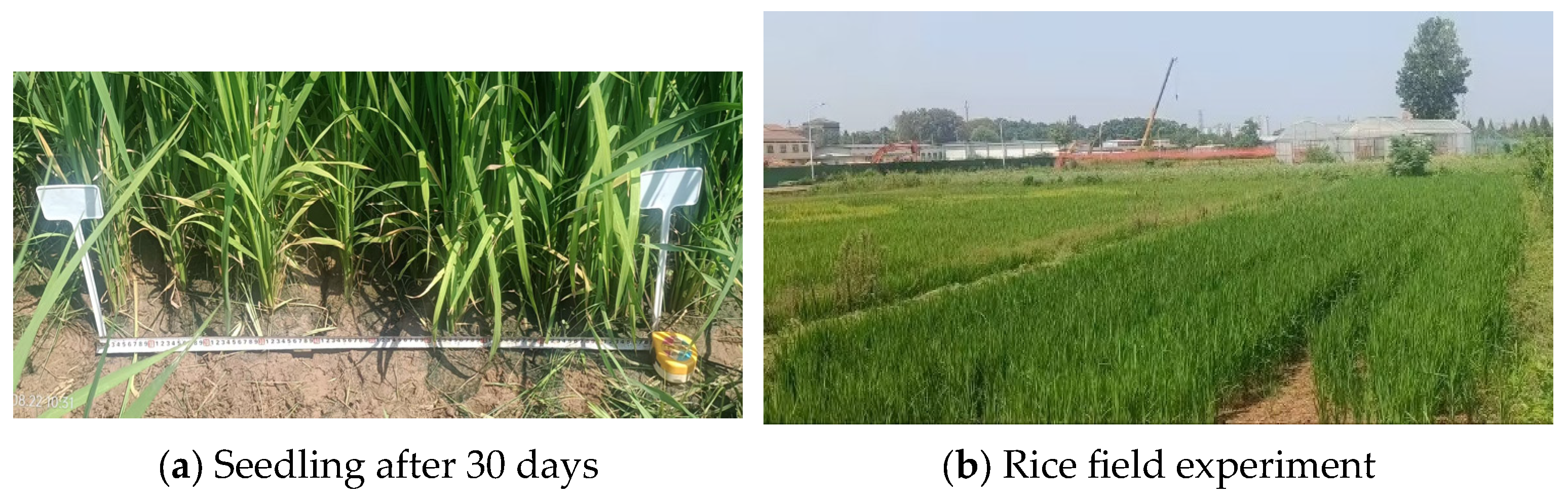

4.3. Field Experiment Results and Discussion

5. Conclusions

- The CADSD, with the new modifications, reduces operational complexity and costs and increases agricultural seeding efficiency;

- The bench single-factor test findings prove that the seed feed rate increases as the rotational speed rises from 3 to 7 km/h. low CV between rows indicates that the seeder maintains precision and stability across different crops;

- A regression model verification test revealed that the relative error between the theoretical and actual test values for RWR was less than 2%;

- A study examining the impact of seed density and rotating speed on feeding rate, factorial analysis, and regression modeling revealed that rotating speed has a significantly greater influence on the feeding rate than other factors;

- Field experiments were conducted during the rice sowing season to validate the CADSD sowing system. The seeding uniformity was measured at a coefficient of variation CV of 3.44%, and the crop emergence rate was 88%;

- It is strongly recommended that further modifications are required to manage increased resistance and vibrations during simultaneous fieldwork.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, M.; Wang, Z.; Luo, X.; Zang, Y.; Yang, W.; Xing, H.; Wang, B.; Dai, Y. Review of precision rice hill-drop drilling technology and machine for paddy. Int. J. Agric. Biol. Eng. 2018, 11, 1–11. [Google Scholar] [CrossRef]

- Wang, C.; Li, H.; Wang, J.; He, J.; Wang, Q.; Lu, C. CFD Simulation and Optimization of a Pneumatic Wheat Seeding Device. IEEE Access 2020, 8, 214007–214018. [Google Scholar] [CrossRef]

- Alizadeh, M.; Allameh, A. Soil properties and crop yield under different tillage methods for rapeseed cultivation in paddy fields. J. Agric. Sci. 2015, 60, 11–22. [Google Scholar] [CrossRef]

- Jin, Z.; Mu, Y.; Li, Y.; Nie, L. Effect of different rice planting methods on the water, energy, and carbon footprints of subsequent wheat. Front. Sustain. Food Syst. 2023, 7, 1173916. [Google Scholar] [CrossRef]

- Kehayov, D.; Atanasov, A.; Bozhkov, I.; Zahariev, I. Influence of seed density and gear ratio on quantity of sowed seeds. In Proceedings of the 21st International Scientific Conference Engineering for Rural Development, Latvia University of Life Sciences and Technologies, Jelgava, Latvia, 25–27 May 2022; pp. 194–198. [Google Scholar]

- Shah, K.; Alam, M.S.; Nasir, F.E.; Qadir, M.U.; Haq, I.U.; Khan, M.T. Design and Performance Evaluation of a Novel Variable Rate Multi-Crop Seed Metering Unit for Precision Agriculture. IEEE Access 2022, 10, 133152–133163. [Google Scholar] [CrossRef]

- Xue, P.; Xia, X.; Gao, P.; Ren, D.; Hao, Y.; Zheng, Z.; Zhang, J.; Zhu, R.; Hu, B.; Huang, Y.; et al. Double-Setting Seed-Metering Device for Precision Planting of Soybean at High Speeds. Trans. ASABE 2019, 62, 187–196. [Google Scholar] [CrossRef]

- Ahmad, F.; Adeel, M.; Qiu, B.; Ma, J.; Shoaib, M.; Shakoor, A.; Chandio, F.A. Sowing uniformity of bed-type pneumatic maize planter at various seedbed preparation levels and machine travel speeds. Int. J. Agric. Biol. Eng. 2021, 14, 165–171. [Google Scholar] [CrossRef]

- Hai, N.T.; Chosa, T.; Tojo, S.; Thi-Hien, N. Application of a similarity measure using fuzzy sets to select the optimal plan for an air-assisted rice seeder. Appl. Sci. 2021, 11, 6715. [Google Scholar] [CrossRef]

- Abdallah, A.D.; Liao, Q.; Ibrahim, E.J.; Wang, L. Design and experiment of the pneumatic cylinder type precision metering system for wheat. Int. J. Agric. Biol. Eng. 2023, 16, 88–94. [Google Scholar] [CrossRef]

- Dengyu, X.; Wu, M.; Xie, W.; Liu, R.; Luo, H. Design and experimental study of the general mechanical pneumatic combined seed metering device. Appl. Sci. 2021, 11, 7223. [Google Scholar] [CrossRef]

- Gao, X.; Xie, G.; Li, J.; Shi, G.; Lai, Q.; Huang, Y. Design and validation of a centrifugal variable-diameter pneumatic high-speed precision seed-metering device for maize. Biosyst. Eng. 2023, 227, 161–181. [Google Scholar] [CrossRef]

- Jin, M.; Ding, Y.; Yu, H.; Liu, H.; Jiang, Y.; Fu, X. Optimal structure design and performance tests of seed metering device with fluted rollers for precision wheat seeding machine. IFAC-PapersOnLine 2018, 51, 509–514. [Google Scholar]

- Li, Q.; Feng, J.; Jiang, W. Design and experiment on precision seed metering device for narrow-row and dense planting of soybean. INMATEH Agric. Eng. 2022, 67, 353–363. [Google Scholar] [CrossRef]

- Wang, J.; Tang, H.; Wang, J.; Li, X.; Huang, H. Optimization design and experiment on ripple surface type pickup finger of precision maize seed metering device. Int. J. Agric. Biol. Eng. 2017, 10, 61–71. [Google Scholar]

- Twizerimana, A.; Niyigaba, E.; Mugenzi, I.; Ngnadong, W.A.; Li, C.; Hao, T.Q.; Shio, B.J.; Hai, J.B. The Combined Effect of Different Sowing Methods and Seed Rates on the Quality Features and Yield of Winter Wheat. Agriculture 2020, 10, 153. [Google Scholar] [CrossRef]

- Grossnickle, S.C.; Ivetić, V. Direct Seeding in Reforestation—A Field Performance Review. Reforesta 2017, 4, 94–142. [Google Scholar] [CrossRef]

- Yatskul, A.; Lemiere, J.-P. ScienceDirect Influence of the divider head functioning conditions and geometry on the seed’s distribution accuracy of the air-seeder. Biosyst. Eng. 2017, 161, 120–134. [Google Scholar] [CrossRef]

- Kumar, V.J.F.; Durairaj, C.D. Influence of head geometry on the distributive performance of air-assisted seed drills. J. Agric. Eng. Res. 2000, 75, 81–95. [Google Scholar] [CrossRef]

- Mudarisov, S.; Badretdinov, I.; Rakhimov, Z.; Lukmanov, R.; Nurullin, E. Numerical simulation of two-phase “Air-Seed” flow in the distribution system of the grain seeder. Comput. Electron. Agric. 2020, 168, 105151. [Google Scholar] [CrossRef]

- Zhang, X.H.; Wang, Y.Z.; Zhang, L.; Peng, C.J.; Fan, G.J. Design and experiment of wheat pneumatic centralized seeding distributing system. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2018, 49, 59–67. [Google Scholar]

- Yang, S.; Liao, Y.; Liao, Q. Experimental study on pneumatic seed-metering system of 2BFQ-6 precision planter for rapeseed. Trans. Chin. Soc. Agric. Eng. 2012, 18, 57–62. [Google Scholar]

- Akhalaya, B.K.; Gromov, V.V.; Gaiko, O.A.; Akopyan, A.S. New metering device for pneumatic seeding machine. In Proceedings of the Innovative Technologies in Science and Education (ITSE 2020 Conference), Divnomorskoe Village, Russia, 19–30 August 2020; pp. 472–474. [Google Scholar]

- Tarasenko, V.; Bondarenko, L.; Shcherbakova, N.; Horbova, N. Sowing Units for Drilling Vegetable Crops. In Modern Development Paths of Agricultural Production; Nadykto, V., Ed.; Springer: Berlin/Heidelberg, Germany, 2019; pp. 289–298. [Google Scholar]

- Baoshan, W.; Lei, W.; Yitao, L.; Chong, W.U.; Mei, C.A.; Qingxi, L. Design and test of seeding wheels of precision hole-seeding centralized metering device for small particle size seeds. Nongye Jixie Xuebao/Trans. Chin. Soc. Agric. Mach. 2022, 53, 64–76. [Google Scholar]

- Li, X.; Liao, Q.; Wang, L.; Li, M.; Du, W. Design and experiments of the type-hole wheel with high-speed air-assisted centralized metering device for rice, wheat and rapeseed. Nongye Gongcheng Xuebao/Trans. Chin. Soc. Agric. Eng. 2023, 39, 35–48. [Google Scholar]

- Vaishnavi, D.; Rathinakumari, A.C.; Kumaran, G.S. Physical and Engineering Properties of Vegetable Seeds Relevant for Development of Protray Vacuum Seeder for Vegetable Nursery. Andhra Agric. J. 2018, 65, 179–183. [Google Scholar]

- Li, Z.; Zhong, J.; Gu, X.; Zhang, H.; Chen, Y.; Wang, W.; Zhang, T.; Chen, L. DEM Study of Seed Motion Model-Hole-Wheel Variable Seed Metering Device for Wheat. Agriculture 2023, 13, 23. [Google Scholar] [CrossRef]

- Lei, X.L.; Yang, W.H.; Yang, L.J.; Liu, L.Y.; Liao, Q.X.; Ren, W.J. Design and experiment of seed hill feeding device in pneumatic centralized metering device for hybrid rice. Trans. CSAM 2018, 49, 58–67. [Google Scholar]

- GB/T 25418-2022; Method of Grain Direct Seeding Machine. China Agriculture Press: Beijing, China, 2022.

- Wu, Z.; Li, M.; Lei, X.; Wu, Z.; Jiang, C.; Zhou, L.; Ma, R.; Chen, Y. Simulation and parameter optimisation of a centrifugal rice seeding spreader for a UAV. Biosyst. Eng. 2020, 192, 275–293. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, S.; Luo, C.; Li, W.; Liao, Y. Design and Experimentation of an Aerial Seeding System for Rapeseed Based on an Air-Assisted Centralized Metering Device and a Multi-Rotor Crop Protection UAV. Appl. Sci. 2020, 10, 8854. [Google Scholar] [CrossRef]

| Crop | Length (mm) | Width (mm) | Thickness (mm) | Sphericity % | 1000 Seed Mass, (g) | Angle of Repose (°) |

|---|---|---|---|---|---|---|

| Wheat (Lei Xiaoping 9023) | 6.30 | 3.09 | 2.75 | 45.63 | 44.87 | 28.22 |

| Rice (Quanyou 737) | 10.9 | 2.9 | 2.2 | 36.24 | 24.05 | 28.81 |

| Rapeseed (Huayouze 62) | 2.26 | 2.07 | 2.01 | 95.50 | 3.83 | 22.72 |

| Parameter | Rapeseed | Wheat | Rice | Aluminum Alloy | Engineering Plastic ABS | |

|---|---|---|---|---|---|---|

| Three axes diminution mm3 | 2 × 2 × 2 | 6 × 3 × 3 | 10.2 × 3 × 2 | |||

| Density kg/m3 | 1060 | 1350 | 1125 | 2700 | 1060 | |

| Poisson’s ratio | 0.25 | 0.42 | 0.30 | 0.30 | 0.394 | |

| Shear modules/pa | 1.1 × 107 | 5.1 × 107 | 1.01 × 108 | 2.7 × 1010 | 8.96 × 108 | |

| Collision recovery coefficient | Seed-seed SAA Seed-ABS | 0.60 | 0.42 | 0.50 | ||

| 0.60 | 0.50 | 0.45 | ||||

| 0.75 | 0.60 | 0.001 | ||||

| Static friction coefficient | Seed-seed SAA Seed-ABS | 0.50 | 0.35 | 0.50 | ||

| 0.30 | 0.40 | 0.57 | ||||

| 0.30 | 0.40 | 1.0 | ||||

| Dynamic friction coefficient | Seed-seed SAA Seed-ABS | 0.01 | 0.05 | 0.01 | ||

| 0.01 | 0.05 | 0.01 | ||||

| 0.01 | 0.05 | 1.03 | ||||

| X, (km/h) | Y, (kg/m3) |

|---|---|

| 3 | 1060 |

| 3 | 1125 |

| 3 | 1350 |

| 4 | 1060 |

| 4 | 1125 |

| 4 | 1350 |

| 5 | 1060 |

| 5 | 1125 |

| 5 | 1350 |

| Independent Variables | Dependent Variables | |

|---|---|---|

| X (km/h) | Y (kg/m3) | Z (g) |

| 3 | 1060 | 46.34 |

| 3 | 1125 | 411.9 |

| 3 | 1350 | 1523.47 |

| 4 | 1060 | 61.18 |

| 4 | 1125 | 604.06 |

| 4 | 1350 | 2014.66 |

| 5 | 1060 | 0097.92 |

| 5 | 1125 | 1012.08 |

| 5 | 1350 | 3116.62 |

| Variable | Eigenvalue | Total, % | Cumulative, Eigenvalue | Cumulative, % |

|---|---|---|---|---|

| X | 2.428 × 108 | 94.21 | 2.428 × 108 | 94.21 |

| Y | 2.566 × 104 | 5.66 | 2.566 × 104 | 99.87 |

| Variable | Beta | Std. Err. | t (4) | p-Level |

|---|---|---|---|---|

| X | −1.711 | 0.554 | −3.086 | 0.037 |

| Y | 1.670 | 0.152 | 11.009 | 0.0004 |

| X2 | 1.797 | 0.521 | 3.445 | 0.026 |

| X × Y | −1.288 | 0.247 | −5.214 | 0.006 |

| Crop | RS (r/min) | TR (g/min) | AR (g/min) | CV% | RE% |

|---|---|---|---|---|---|

| Wheat | 30 | 2000 | 2014.66 | 0.31 | 0.73 |

| 38 | 3100 | 3116.62 | 0.53 | 0.53 | |

| Rice | 30 | 600 | 604.060 | 0.06 | 0.67 |

| 38 | 1000 | 1012.08 | 0.09 | 1.2 | |

| Rapeseed | 30 | 60 | 61.18 | 0.15 | 1.96 |

| 38 | 100 | 97.92 | 0.10 | 2.08 |

| Parameter | Qualification Index | Test Value |

|---|---|---|

| Seeding uniformity coefficient of variation CV% | 3.89 | 3.44 |

| Emergence rate % | 89 | 88 |

| The number of seedlings | 27 | 26.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albasheer, A.H.; Liao, Q.; Wang, L.; Abdallah, A.D.; Lin, J. Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice. Agriculture 2024, 14, 2355. https://doi.org/10.3390/agriculture14122355

Albasheer AH, Liao Q, Wang L, Abdallah AD, Lin J. Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice. Agriculture. 2024; 14(12):2355. https://doi.org/10.3390/agriculture14122355

Chicago/Turabian StyleAlbasheer, Alfarog H., Qingxi Liao, Lei Wang, Anas Dafaallah Abdallah, and Jianxin Lin. 2024. "Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice" Agriculture 14, no. 12: 2355. https://doi.org/10.3390/agriculture14122355

APA StyleAlbasheer, A. H., Liao, Q., Wang, L., Abdallah, A. D., & Lin, J. (2024). Design and Preliminary Evaluation of a Precision Cylindrical Air-Assisted Drill Sowing Device for Rapeseed, Wheat, and Rice. Agriculture, 14(12), 2355. https://doi.org/10.3390/agriculture14122355