Quantitative Evaluation of Post-Tillage Soil Structure Based on Close-Range Photogrammetry

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Design

2.2. Three-Dimensional Reconstruction of the Soil Samples

2.2.1. Image Acquisition

2.2.2. Soil 3D Reconstruction

2.2.3. Model Post-Processing

2.3. Model Accuracy Verification

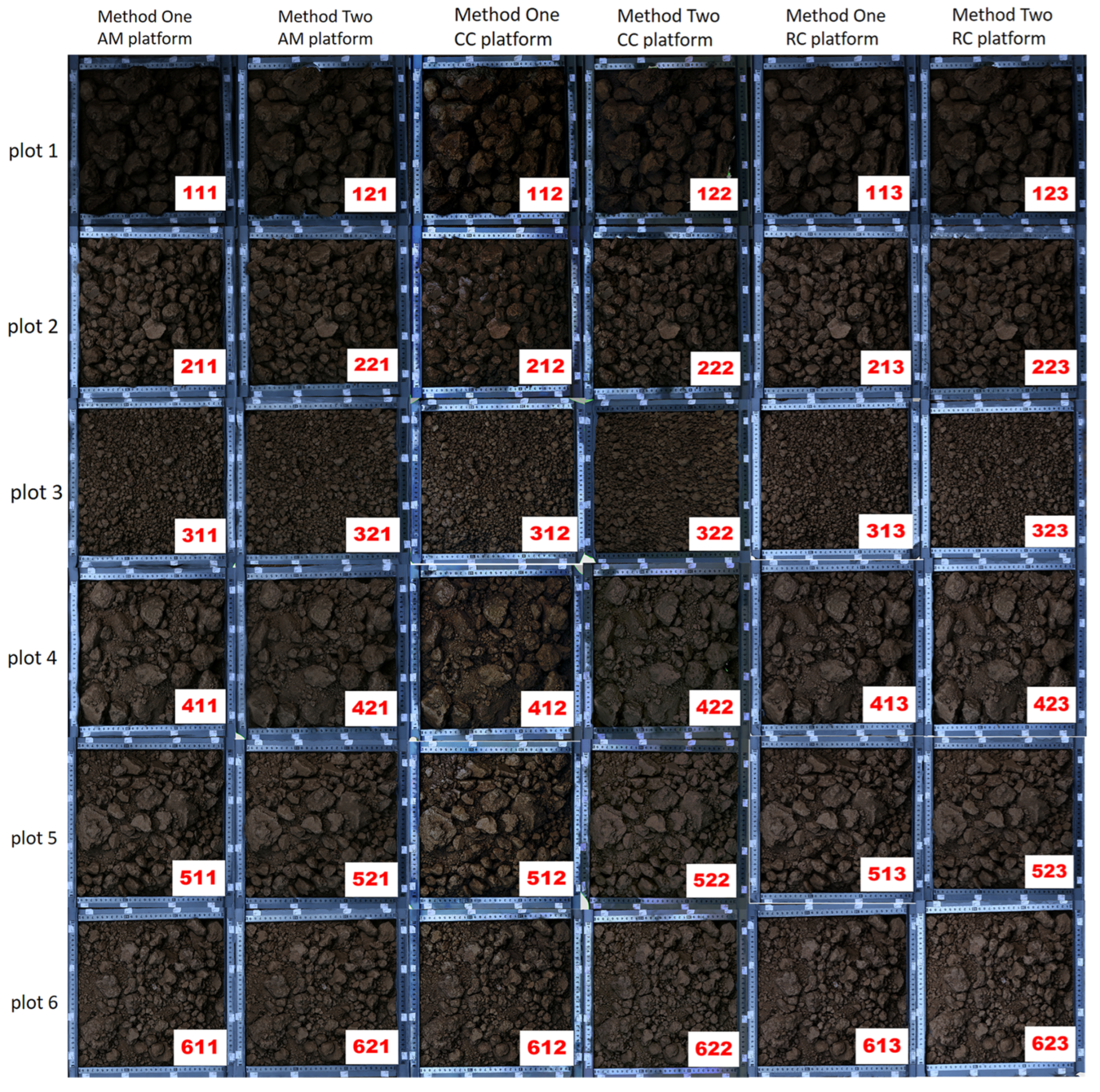

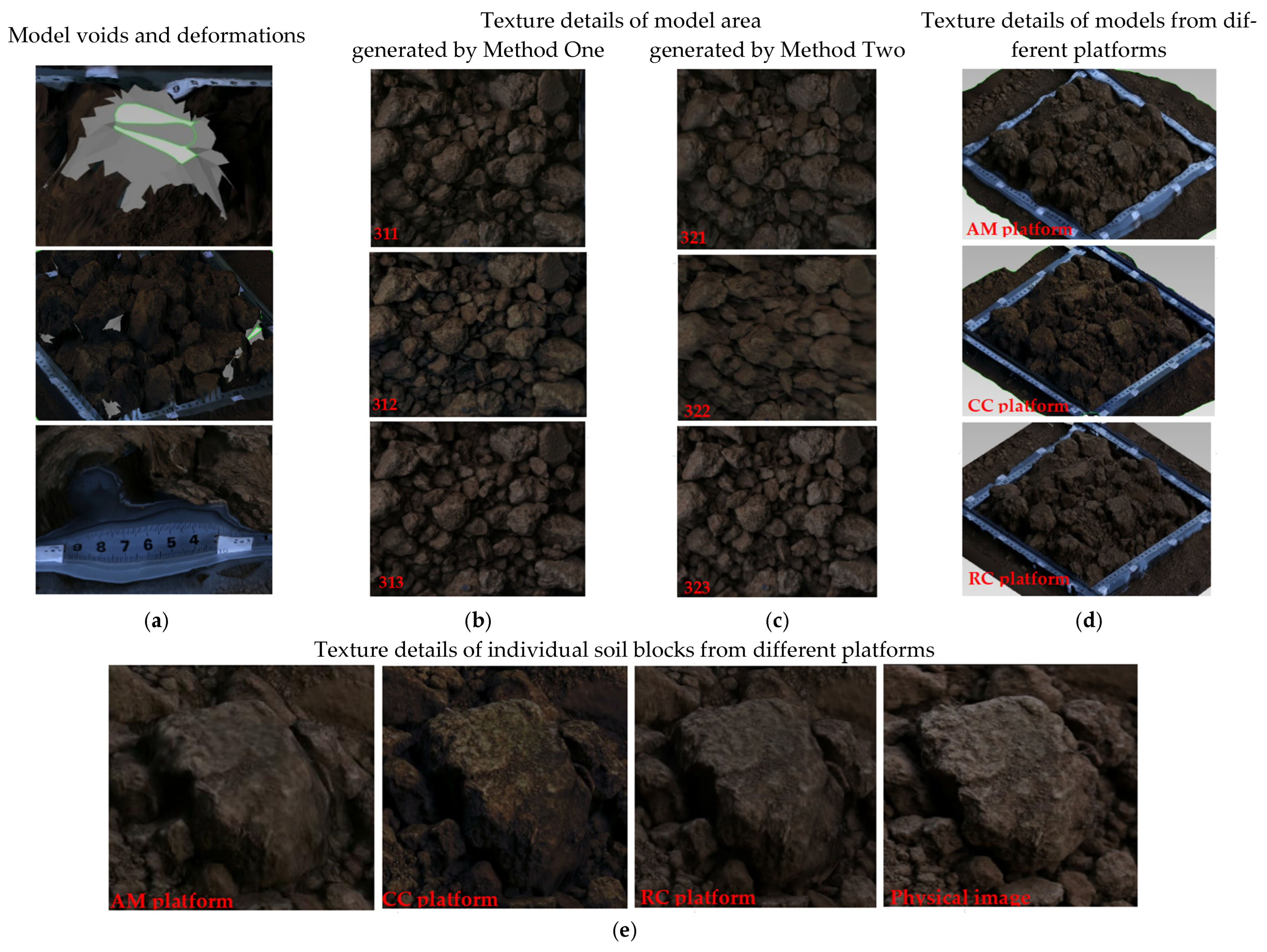

2.3.1. Qualitative Verification of Soil Model

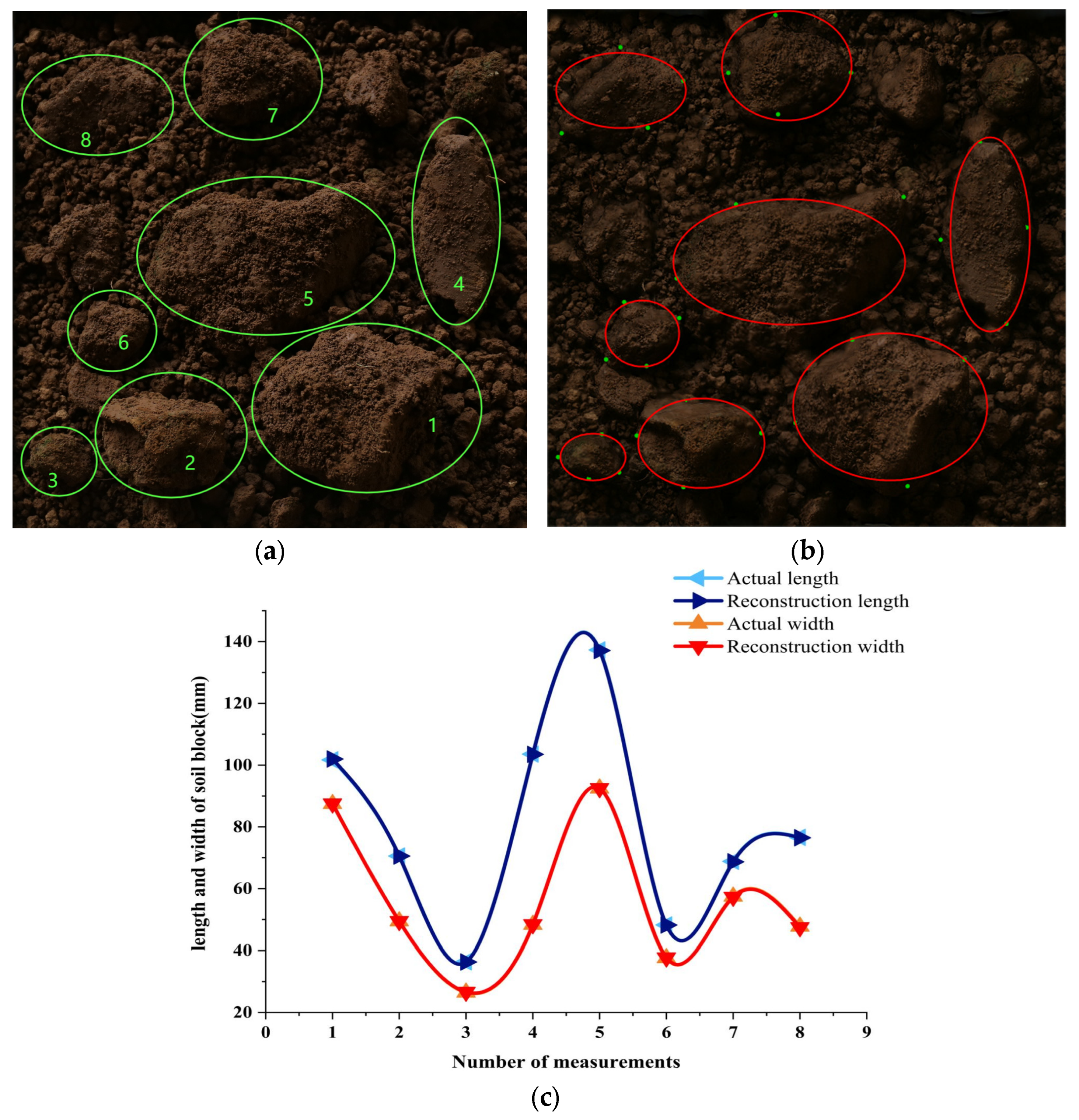

2.3.2. Quantitative Verification of Soil Model

2.4. Statistical Analysis

3. Results

3.1. Platform Selection for 3D Reconstruction of Post-Tillage Soil

3.2. Three-Dimensional Reconstruction of Post-Tillage Soil

3.2.1. Modeling Efficiency

3.2.2. Modeling Quality

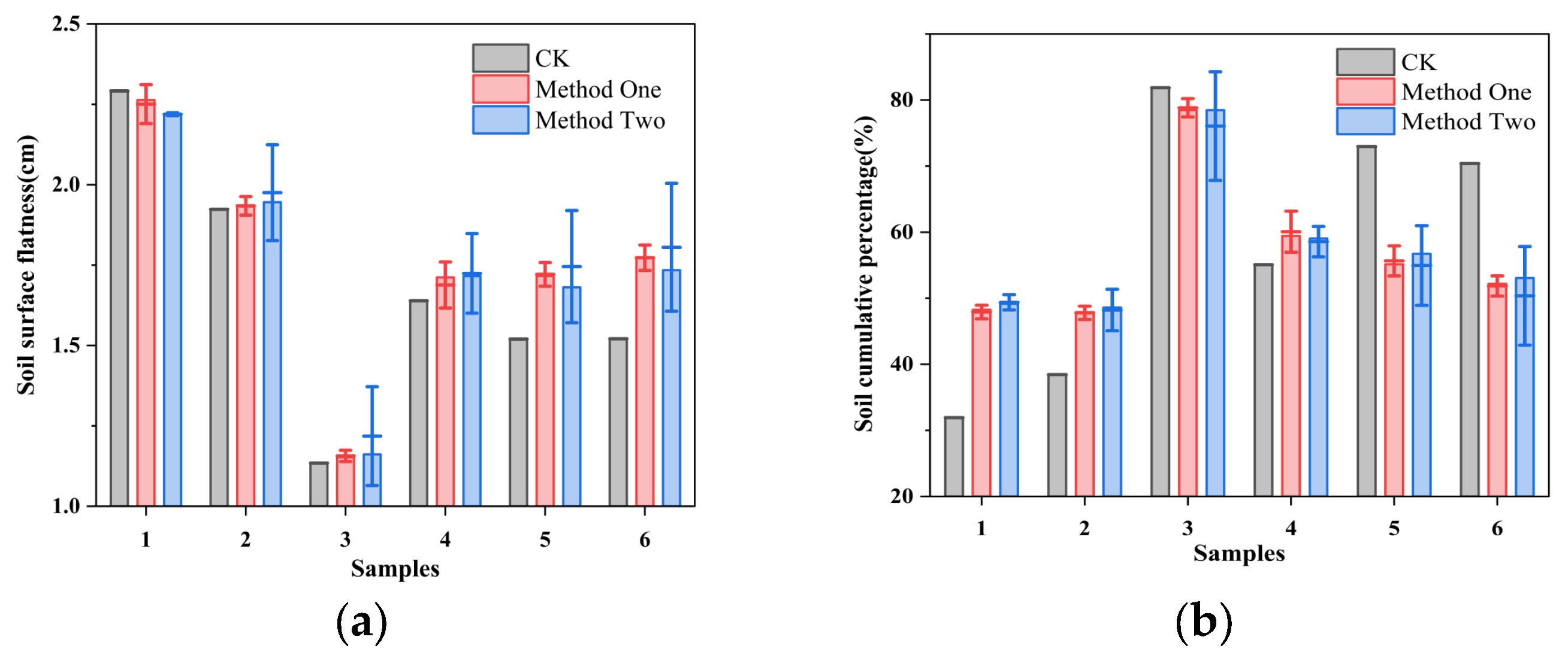

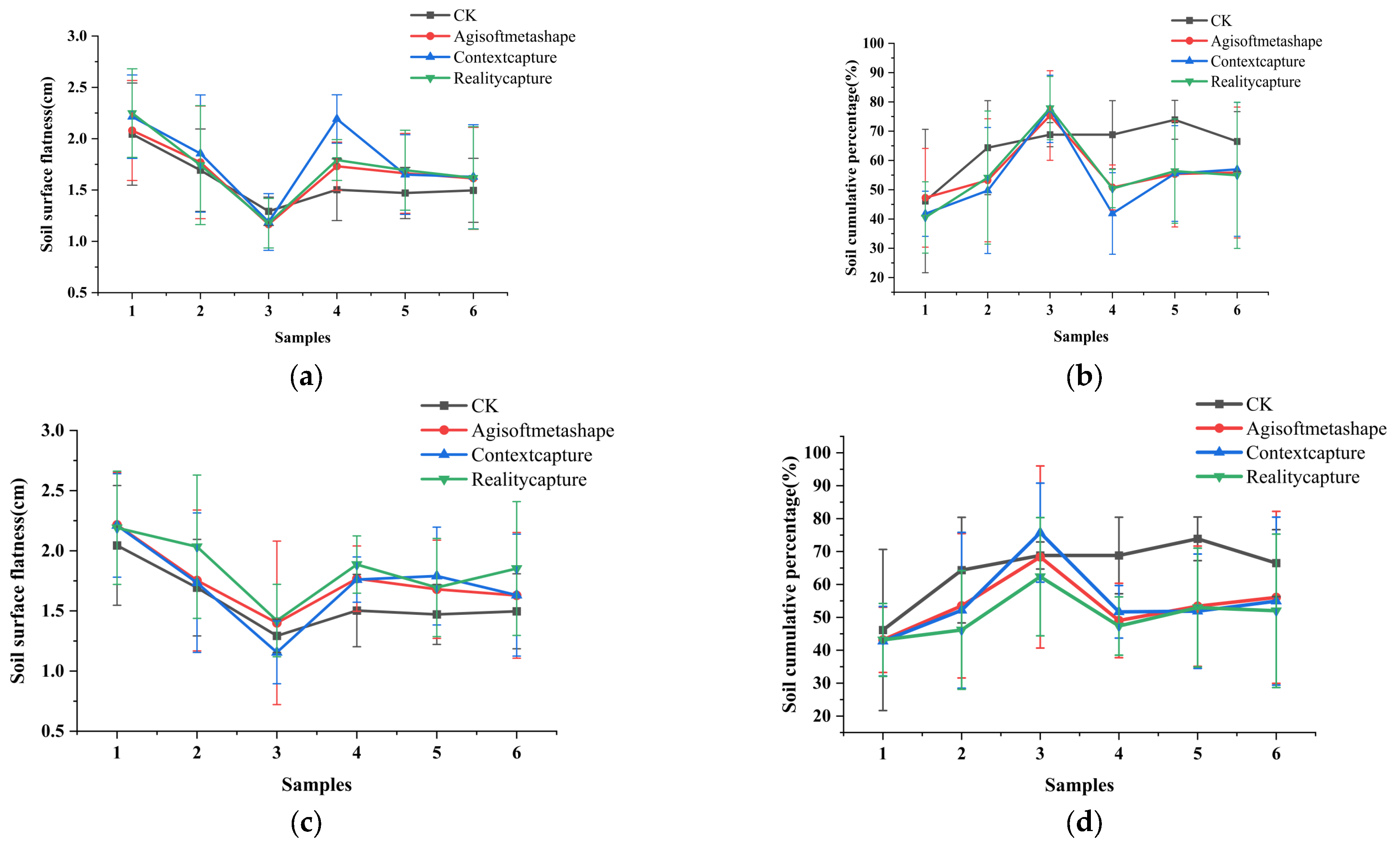

3.2.3. Quantitative of Soil Modeling

3.2.4. Accurate Scale of Soil Blocks

4. Discussion

4.1. Three-Dimensional Reconstruction of Post-Tillage Soil

4.2. Quantification of Post-Tillage Soil Features

5. Conclusions

- (1)

- Three-dimensional reconstruction experiments based on two image acquisition methods demonstrate that both methods exhibit comparable modeling efficiency with an equal number of images. However, Method One outperforms the other method in terms of model completeness and texture detail, thus making it the recommended approach.

- (2)

- Among the three 3D reconstruction platforms compared, AgisoftMetashape showed superior model integrity and texture detail performance. Considering both modeling efficiency and quality, AgisoftMetashape is recommended.

- (3)

- The analysis of surface flatness and cumulative percentage indicates that models reconstructed using Method One and the AgisoftMetashape platform are more closely aligned with the reference, achieving higher accuracy.

- (4)

- The measurement of soil clod size reveals that combining Method One and AgisoftMetashape and post-processing in Geomagic Wrap enables millimeter-level high-precision reconstruction and measurement.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Csikós, N.; Szabó, B.; Hermann, T. Cropland Productivity Evaluation: A 100 M Resolution Country Assessment Combining Earth Observation and Direct Measurements. Remote Sens. 2023, 15, 1236. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, X.; Sun, L. Influence of Tillage on the Mollisols Physicochemical Properties, Seed Emergence and Yield of Maize in Northeast China. Agriculture 2021, 11, 939. [Google Scholar] [CrossRef]

- Huang, C.; Huang, H.; Huang, S. Effects of Straw Returning on Soil Aggregates and Its Organic Carbon and Nitrogen Retention under Different Mechanized Tillage Modes in Typical Hilly Regions of Southwest China. Agronomy 2024, 14, 928. [Google Scholar] [CrossRef]

- Karayel, D.; Šarauskis, E. Influence of Tillage Methods and Soil Crust Breakers on Cotton Seedling Emergence in Silty-Loam Soil. Soil Tillage Res. 2024, 239, 106054. [Google Scholar] [CrossRef]

- Chen, X.; Tang, Y.; Duan, Q. Phenotypic Quantification of Root Spatial Distribution Along Circumferential Direction for Field Paddy-Wheat. PLoS ONE 2023, 18, e0279353. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, H.; Liu, J. Control Method of Seedbed Compactness Based on Fragment Soil Compaction Dynamic Characteristics. Soil Tillage Res. 2020, 198, 104551. [Google Scholar] [CrossRef]

- Singhal, V.; Ghosh, J.; Jinger, D. Cover Crop Technology—A Way Towards Conservation Agriculture: A Review. Indian J. Agric. Sci. 2020, 90, 2275–2284. [Google Scholar] [CrossRef]

- Guo, Y.; Cui, M.; Xu, Z. Spatial Characteristics of Transfer Plots and Conservation Tillage Technology Adoption: Evidence from a Survey of Four Provinces in China. Agriculture 2023, 13, 1601. [Google Scholar] [CrossRef]

- Guan, C.; Fu, J.; Xu, L. Study on the Reduction of Soil Adhesion and Tillage Force of Bionic Cutter Teeth in Secondary Soil Crushing. Biosyst. Eng. 2022, 213, 133–147. [Google Scholar] [CrossRef]

- Tunio, M.H.; Gao, J.; Shaikh, S.A. Potato Production in Aeroponics: An Emerging Food Growing System in Sustainable Agriculture Forfood Security. Chil. J. Agric. Res. 2020, 80, 118–132. [Google Scholar] [CrossRef]

- Sirjani, E.; Sameni, A.; Mahmoodabadi, M. In-Situ Wind Tunnel Experiments to Investigate Soil Erodibility, Soil Fractionation and Wind-Blown Sediment of Semi-Arid and Arid Calcareous Soils. Catena 2024, 241, 108011. [Google Scholar] [CrossRef]

- Moursy, F.I.; Gaber, E.; Samak, M. Sand Drift Potential in El-Khanka Area, Egypt. Water Air Soil Pollut. 2002, 136, 225–242. [Google Scholar] [CrossRef]

- Zhang, C.; Zhou, J.; Yan, H. Effects of Different Irrigation Amounts and Biochar Application on Soil Physical and Mechanical Properties in the Short Term. Irrig. Drain. 2024, 73, 866–881. [Google Scholar] [CrossRef]

- Mohammadi, F.; Maleki, M.R.; Khodaei, J. Control of Variable Rate System of a Rotary Tiller Based on Real-Time Measurement of Soil Surface Roughness. Soil Tillage Res. 2022, 215, 105216. [Google Scholar] [CrossRef]

- Mattia, F.; Davidson, M.W.; Le Toan, T. A Comparison between Soil Roughness Statistics Used in Surface Scattering Models Derived from Mechanical and Laser Profilers. IEEE Trans. Geosci. Remote Sens. 2003, 41, 1659–1671. [Google Scholar] [CrossRef]

- Valani, G.P.; Vezzani, F.M.; Cavalieri-Polizeli, K.M.V. Soil Quality: Evaluation of on-Farm Assessments in Relation to Analytical Index. Soil Tillage Res. 2020, 198, 104565. [Google Scholar] [CrossRef]

- Gallardo-Carrera, A.; Léonard, J.; Duval, Y. Effects of Seedbed Structure and Water Content at Sowing on the Development of Soil Surface Crusting under Rainfall. Soil Tillage Res. 2007, 95, 207–217. [Google Scholar] [CrossRef]

- Iwasaki, K.; Shimoda, S.; Nakata, Y. Remote Sensing of Soil Ridge Height to Visualize Windbreak Effectiveness in Wind Erosion Control: A Strategy for Sustainable Agriculture. Comput. Electron. Agric. 2024, 219, 108778. [Google Scholar] [CrossRef]

- Zang, Y.; Meng, S.; Hu, L. Optimization Design and Experimental Testing of a Laser Receiver for Use in a Laser Levelling Control System. Electronics 2020, 9, 536. [Google Scholar] [CrossRef]

- Luhmann, T.; Chizhova, M.; Gorkovchuk, D. Fusion of Uav and Terrestrial Photogrammetry with Laser Scanning for 3D Reconstruction of Historic Churches in Georgia. Drones 2020, 4, 53. [Google Scholar] [CrossRef]

- Vingiani, S.; Buttafuoco, G.; Fagnano, M. A Multisensor Approach Coupled with Multivariate Statistics and Geostatistics for Assessing the Status of Land Degradation: The Case of Soils Contaminated in a Former Outdoor Shooting Range. Sci. Total Environ. 2024, 933, 172398. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Li, J. Training Strategy and Intelligent Model for in-Situ Rapid Measurement of Subgrade Compactness. Autom. Constr. 2024, 165, 105581. [Google Scholar] [CrossRef]

- Sharma, A.; Jain, A.; Gupta, P. Machine Learning Applications for Precision Agriculture: A Comprehensive Review. IEEE Access 2020, 9, 4843–4873. [Google Scholar] [CrossRef]

- Martinez-Agirre, A.; Álvarez-Mozos, J.; Milenković, M. Evaluation of Terrestrial Laser Scanner and Structure from Motion Photogrammetry Techniques for Quantifying Soil Surface Roughness Parameters over Agricultural Soils. Earth Surf. Process. Landf. 2020, 45, 605–621. [Google Scholar] [CrossRef]

- Solem, D.-Ø.E.; Nau, E. Two New Ways of Documenting Miniature Incisions Using a Combination of Image-Based Modelling and Reflectance Transformation Imaging. Remote Sens. 2020, 12, 1626. [Google Scholar] [CrossRef]

- Thevara, D.J.; Kumar, C.V. Application of Photogrammetry to Automated Finishing Operations. In Proceedings of the 2nd International conference on Advances in Mechanical Engineering (ICAME 2018), Burhaniye, Turkey, 27–29 June 2018. [Google Scholar]

- Wang, C.; Zhang, G.; Chen, S. Soil Surface Roughness of Sloping Croplands Affected by Land Degradation Degree and Residual of Incorporated Straw. Geoderma 2024, 444, 116872. [Google Scholar] [CrossRef]

- Türk, Y.; Özçelik, V.; Akduman, E. Capabilities of Using Uavs and Close Range Photogrammetry to Determine Short-Term Soil Losses in Forest Road Cut Slopes in Semi-Arid Mountainous Areas. Environ. Monit. Assess. 2024, 196, 149. [Google Scholar] [CrossRef]

- Epple, L.; Kaiser, A.; Schindewolf, M. A Review on the Possibilities and Challenges of Today’s Soil and Soil Surface Assessment Techniques in the Context of Process-Based Soil Erosion Models. Remote Sens. 2022, 14, 2468. [Google Scholar] [CrossRef]

- Yong, L.; Chengmin, H.; Baoliang, W. A Unified Expression for Grain Size Distribution of Soils. Geoderma 2017, 288, 105–119. [Google Scholar] [CrossRef]

- García-Luna, R.; Senent, S.; Jimenez, R. Using Telephoto Lens to Characterize Rock Surface Roughness in Sfm Models. Rock Mech. Rock Eng. 2021, 54, 2369–2382. [Google Scholar] [CrossRef]

- Zheng, F.; Wackrow, R.; Meng, F.-R. Assessing the Accuracy and Feasibility of Using Close-Range Photogrammetry to Measure Channelized Erosion with a Consumer-Grade Camera. Remote Sens. 2020, 12, 1706. [Google Scholar] [CrossRef]

- Sunvittayakul, P.; Kittipadakul, P.; Wonnapinij, P. Cassava Root Crown Phenotyping Using 3D Multi-View Stereo Reconstruction. Sci. Rep. 2022, 12, 10030. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, I.; Ha, E. Uav Photogrammetry for Soil Surface Deformation Detection in a Timber Harvesting Area, South Korea. Forests 2023, 14, 980. [Google Scholar] [CrossRef]

- Song, J.; Du, S.; Yong, R. Drone Photogrammetry for Accurate and Efficient Rock Joint Roughness Assessment on Steep and Inaccessible Slopes. Remote Sens. 2023, 15, 4880. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, C.; Haala, N. Guided by Model Quality: Uav Path Planning for Complete and Precise 3D Reconstruction of Complex Buildings. Int. J. Appl. Earth Obs. Geoinf. 2024, 127, 103667. [Google Scholar] [CrossRef]

- Croce, V.; Billi, D.; Caroti, G. Comparative Assessment of Neural Radiance Fields and Photogrammetry in Digital Heritage: Impact of Varying Image Conditions on 3D Reconstruction. Remote Sens. 2024, 16, 301. [Google Scholar] [CrossRef]

- Liu, K.; Sozzi, M.; Gasparini, F. Combining Simulations and Field Experiments: Effects of Subsoiling Angle and Tillage Depth on Soil Structure and Energy Requirements. Comput. Electron. Agric. 2023, 214, 108323. [Google Scholar] [CrossRef]

- Gabara, G.; Sawicki, P. Crbedaset: A Benchmark Dataset for High Accuracy Close Range 3D Object Reconstruction. Remote Sens. 2023, 15, 1116. [Google Scholar] [CrossRef]

- Đokić, M.; Manić, M.; Đorđević, M. Remote Sensing and Nuclear Techniques for High-Resolution Mapping and Quantification of Gully Erosion in the Highly Erodible Area of the Malčanska River Basin, Eastern Serbia. Environ. Res. 2023, 235, 116679. [Google Scholar] [CrossRef]

- Sorrentino, G.; Menna, F.; Remondino, F. Close-Range Photogrammetry Reveals Morphometric Changes on Replicative Ground Stones. PLoS ONE 2023, 18, e0289807. [Google Scholar] [CrossRef]

- Ferenčík, M.; Dudáková, Z.; Kardoš, M. Measuring Soil Surface Changes after Traffic of Various Wheeled Skidders with Close-Range Photogrammetry. Forests 2022, 13, 976. [Google Scholar] [CrossRef]

- Gao, J.; Shi, Y.; Cai, Y. Research on the Application of Uav Oblique Photogrammetry to Lilong Housing: Taking Meilan Lane as an Example. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2023, 48, 629–635. [Google Scholar] [CrossRef]

- Nielsen, M.S.; Nikolov, I.; Kruse, E.K. Quantifying the Influence of Surface Texture and Shape on Structure from Motion 3D Reconstructions. Sensors 2022, 23, 178. [Google Scholar] [CrossRef]

- Lewińska, P.; Głowacki, O.; Moskalik, M. Evaluation of Structure-from-Motion for Analysis of Small-Scale Glacier Dynamics. Measurement 2021, 168, 108327. [Google Scholar] [CrossRef]

- Ding, H.; Wilson, D.I.; Yu, W. Assessing and Quantifying the Surface Texture of Milk Powder Using Image Processing. Foods 2022, 11, 1519. [Google Scholar] [CrossRef]

- Gabara, G.; Sawicki, P. A New Approach for Inspection of Selected Geometric Parameters of a Railway Track Using Image-Based Point Clouds. Sensors 2018, 18, 791. [Google Scholar] [CrossRef]

- Shan, J.; Zhu, H.; Yu, R. Feasibility of Accurate Point Cloud Model Reconstruction for Earthquake-Damaged Structures Using Uav-Based Photogrammetry. Struct. Control Health Monit. 2023, 2023, 7743762. [Google Scholar] [CrossRef]

- Teshome, F.T.; Bayabil, H.K.; Hoogenboom, G. Unmanned Aerial Vehicle (Uav) Imaging and Machine Learning Applications for Plant Phenotyping. Comput. Electron. Agric. 2023, 212, 108064. [Google Scholar] [CrossRef]

- Yavuz, M.; Tufekcioglu, M. Assessment of Flood-Induced Geomorphic Changes in Sidere Creek of the Mountainous Basin Using Small Uav-Based Imagery. Sustainability 2023, 15, 11793. [Google Scholar] [CrossRef]

- Harris, R.C.; Kennedy, L.M.; Pingel, T.J. Assessment of Canopy Health with Drone-Based Orthoimagery in a Southern Appalachian Red Spruce Forest. Remote Sens. 2022, 14, 1341. [Google Scholar] [CrossRef]

- Meivel, S.; Maheswari, S. Monitoring of Potato Crops Based on Multispectral Image Feature Extraction with Vegetation Indices. Multidimens. Syst. Signal Process. 2022, 33, 683–709. [Google Scholar] [CrossRef]

- Collins, T.; Woolley, S.I.; Gehlken, E. Automated Low-Cost Photogrammetric Acquisition of 3d Models from Small Form-Factor Artefacts. Electronics 2019, 8, 1441. [Google Scholar] [CrossRef]

- Moyano, J.; Nieto-Julián, J.E.; Bienvenido-Huertas, D. Validation of Close-Range Photogrammetry for Architectural and Archaeological Heritage: Analysis of Point Density and 3D Mesh Geometry. Remote Sens. 2020, 12, 3571. [Google Scholar] [CrossRef]

- Chen, S.; Yan, Q.; Qu, Y. Ortho-Nerf: Generating a True Digital Orthophoto Map Using the Neural Radiance Field from Unmanned Aerial Vehicle Images. Geo-Spat. Inf. Sci. 2024, 18, 1–20. [Google Scholar] [CrossRef]

- Jarahizadeh, S.; Salehi, B. A Comparative Analysis of Uav Photogrammetric Software Performance for Forest 3D Modeling: A Case Study Using Agisoft Photoscan, Pix4dmapper, and Dji Terra. Sensors 2024, 24, 286. [Google Scholar] [CrossRef]

- Pell, T.; Li, J.Y.; Joyce, K.E. Demystifying the Differences between Structure-from-Motionsoftware Packages for Pre-Processing Drone Data. Drones 2022, 6, 24. [Google Scholar] [CrossRef]

- Derenne, B.; Nantet, E.; Verly, G. Complementarity between in Situ Studies and Photogrammetry: Methodological Feedback from a Roman Shipwreck in Caesarea, Israel. In Proceedings of the 2019 Underwater 3D Recording and Modelling “A Tool for Modern Applications and CH Recording”, Limassol, Cyprus, 2–3 May 2019. [Google Scholar]

| Soil Block Scale | Specific Gravity | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | |

| >50 mm | 80% | 40% | 20% | 20% | ||

| 50~20 mm | 80% | 20% | 40% | 20% | ||

| 20~5 mm | 80% | 20% | 20% | 40% | ||

| <5 mm | 20% | 20% | 20% | 20% | 20% | 20% |

| Platforms | Image Acquisition Equipment | Application | Advantages | Disadvantages | Resource |

|---|---|---|---|---|---|

| Agisoft Metashape | camera | Cassava root cap | high quality; millimeter-level accuracy | not suitable for complex objects | [33] |

| UAV, camera | Forest road | high local resolution; low error rate; centimeter-level accuracy | poor data acquisition and processing performance | [28] | |

| UAV | Potato fields | centimeter-level accuracy | brightness and soil moisture affect modeling accuracy | [18] | |

| UAV | Soil in wood harvest area | centimeter-level accuracy | difficult data acquisition | [34] | |

| UAV | Gully | fast speed; high economic efficiency; millimeter-level accuracy | lighting affects image quality | [40] | |

| UAV | Rocks on steep slopes | sub-millimeter accuracy | weather and environment impacted | [35] | |

| camera | River slabs and pebbles | millimeter-level accuracy | equipment used affects accuracy | [41] | |

| camera | Forest soil | millimeter-level accuracy | long data processing time, software knowledge-impacted, lighting-impacted | [42] | |

| Context Capture | UAV | Local architecture | minimal field measurement time; low labor cost | environment-impacted | [43] |

| camera | 3D-printed artificial products | sub-millimeter accuracy | photo capture method impacts reconstruction | [44] | |

| camera | Small-scale glacier | decimeter-level accuracy | low accuracy with ground control point requirement | [45] | |

| camera | Irregular 3D model | centimeter-level accuracy | strict image capture requirements | [26] | |

| Reality Capture | camera | Powdered milk | fast; cost-effective; high measurement efficiency; millimeter-level accuracy | lighting and background impact reconstruction | [46] |

| camera | Archeological sites and landscape stone materials | high usability, efficiency, and accuracy; sub-millimeter accuracy | extra lighting is required for image capture | [25] | |

| UAV, camera | Historic church | centimeter-level accuracy | mutual occlusion; lengthy computation time for numerous images | [20] | |

| camera | Railway tracks | low cost; sub-millimeter accuracy | / | [47] | |

| Pix4DMapper | UAV | Buildings damaged by earthquakes | millimeter-level accuracy | long duration; low model completeness | [48] |

| UAV | Aboveground of crops | centimeter-accurate phenotypic data acquisition | accuracy and potential require validation | [49] | |

| UAV | Ahavi River basin | low cost; short duration; precise measurements; meter-level accuracy | / | [50] | |

| UAV | Red cloud cedar forest | low labor cost; centimeter-level accuracy | time-consuming | [51] | |

| UAV | Potato | centimeter-level accuracy | weather-impacted | [52] |

| Plots | Platform | Method One | Method Two | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Soil Surface Flatness | Soil Cumulative Percentage | Soil Surface Flatness | Soil Cumulative Percentage | ||||||||||||||

| RC | CC | AM | CK | RC | CC | AM | CK | RC | CC | AM | CK | RC | CC | AM | CK | ||

| 1 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | 0.997 ** | 1 | 0.832 ** | 1 | 0.941 ** | 1 | 0.831 ** | 1 | |||||||||

| AM | 0.987 ** | 0.981 ** | 1 | 0.879 ** | 0.898 ** | 1 | 0.955 ** | 0.976 ** | 1 | 0.866 ** | 0.839 ** | 1 | |||||

| CK | 0.028 | 0.006 | 0.040 | 1 | 0.071 | −0.025 | −0.143 | 1 | −0.077 | 0.093 | 0.025 | 1 | 0.043 | 0.003 | 0.216 | 1 | |

| 2 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | 0.989 ** | 1 | 0.973 ** | 1 | 0.961 ** | 1 | 0.593* | 1 | |||||||||

| AM | 0.884 ** | 0.851 ** | 1 | 0.758 * | 0.665 * | 1 | 0.926 ** | 0.992 ** | 1 | 0.411 | 0.956 ** | 1 | |||||

| CK | 0.633 * | 0.605 * | 0.522 | 1 | 0.482 | 0.575 * | 0.247 | 1 | 0.691 * | 0.618 * | 0.606 * | 1 | 0.648 * | 0.469 | 0.309 | 1 | |

| 3 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | 0.993 ** | 1 | 0.936 ** | 1 | 0.960 ** | 1 | 0.744 * | 1 | |||||||||

| AM | 0. 980 ** | 0.988 ** | 1 | 0.934 ** | 0.992 ** | 1 | −0.023 | −0.016 | 1 | 0.363 | 0.122 | 1 | |||||

| CK | 0.928 ** | 0.956 ** | 0.972 ** | 1 | 0.272 | 0.168 | 0.181 | 1 | 0.890 ** | 0.967 ** | −0.116 | 1 | 0.133 | 0.585 * | −0.069 | 1 | |

| 4 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | −0.179 | 1 | −0.249 | 1 | 0.633 * | 1 | 0.229 | 1 | |||||||||

| AM | 0.970 ** | −0.172 | 1 | 0.781 * | −0.250 | 1 | 0.893 ** | 0.856 ** | 1 | 0.898 ** | 0.062 | 1 | |||||

| CK | 0.624 * | −0.145 | 0.695 * | 1 | −0.188 | −0.250 | 0.058 | 1 | 0.556 | 0.519 | 0.697 * | 1 | −0.074 | 0.060 | −0.040 | 1 | |

| 5 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | 0.985 ** | 1 | 0.954 ** | 1 | 0.826 ** | 1 | 0.883 ** | 1 | |||||||||

| AM | 0.992 ** | 0.994 ** | 1 | 0.965 ** | 0.968 ** | 1 | 0.995 ** | 0.824 ** | 1 | 0.932 ** | 0.932 ** | 1 | |||||

| CK | 0.821 ** | 0.879 ** | 0.873 ** | 1 | 0.799 * | 0.898 ** | 0.921 ** | 1 | 0.881 ** | 0.772 * | 0.917 ** | 1 | 0.837 ** | 0.679 * | 0.864 ** | 1 | |

| 6 | RC | 1 | 1 | 1 | 1 | ||||||||||||

| CC | 0.998 ** | 1 | 0.981 ** | 1 | 0.996 ** | 1 | 0.996 ** | 1 | |||||||||

| AM | 0.998 ** | 0.994 ** | 1 | 0.993 ** | 0.967 ** | 1 | 0.980 ** | 0.991 ** | 1 | 0.999 ** | 0.995 ** | 1 | |||||

| CK | 0.582 * | 0.559 | 0.595 * | 1 | 0.424 | 0.412 | 0.503 | 1 | 0.539 | 0.554 | 0.592 * | 1 | 0.531 | 0.492 | 0.506 | 1 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Guo, Y.; Hu, J.; Xu, G.; Liu, W.; Ma, G.; Ding, Q.; He, R. Quantitative Evaluation of Post-Tillage Soil Structure Based on Close-Range Photogrammetry. Agriculture 2024, 14, 2124. https://doi.org/10.3390/agriculture14122124

Chen X, Guo Y, Hu J, Xu G, Liu W, Ma G, Ding Q, He R. Quantitative Evaluation of Post-Tillage Soil Structure Based on Close-Range Photogrammetry. Agriculture. 2024; 14(12):2124. https://doi.org/10.3390/agriculture14122124

Chicago/Turabian StyleChen, Xinxin, Yongxiu Guo, Jianping Hu, Gaoming Xu, Wei Liu, Guoxin Ma, Qishuo Ding, and Ruiyin He. 2024. "Quantitative Evaluation of Post-Tillage Soil Structure Based on Close-Range Photogrammetry" Agriculture 14, no. 12: 2124. https://doi.org/10.3390/agriculture14122124

APA StyleChen, X., Guo, Y., Hu, J., Xu, G., Liu, W., Ma, G., Ding, Q., & He, R. (2024). Quantitative Evaluation of Post-Tillage Soil Structure Based on Close-Range Photogrammetry. Agriculture, 14(12), 2124. https://doi.org/10.3390/agriculture14122124