Abstract

Egg freshness is a critical factor that influences the egg’s nutritional value, safety, and overall quality; consequently, it is a priority for both producers and consumers. This review examines the factors that affect egg freshness, and it evaluates both traditional and modern methods for assessing egg freshness. Traditional techniques, such as the Haugh unit test and candling, have long been utilized; however, they have limitations, which are primarily due to their destructive nature. The review also highlights advanced non-destructive methods, including Vis-NIR spectroscopy, ultrasonic testing, machine vision, thermal imaging, hyperspectral imaging, Raman spectroscopy, and NMR/MRI technologies. These techniques offer rapid and accurate assessments while preserving the integrity of the eggs. Despite the current challenges related to calibration and implementation, integrating artificial intelligence (AI) and machine learning with these innovative technologies presents a promising avenue for the improvement of freshness evaluation. This development could revolutionize quality control processes in the egg industry, ensuring consistently high-quality eggs for consumers.

1. Introduction

Eggs are one of the most accessible and affordable protein sources worldwide and are an essential ingredient in various processed foods. As egg production and consumption increase yearly, with an estimated average production of over 92,000 kilotons and an average per capita consumption of 10.8 kg between 2020 and 2022, freshness is increasingly emphasized as a critical quality characteristic that producers and consumers prioritize [1,2,3]. Given the vulnerability of eggs to quality degradation, a comprehensive understanding and effective management of freshness are crucial for advancing the egg industry. According to [4], while the interpretation of freshness varies among stakeholders, such as chemists, rheologists, nutritionists, microbiologists, producers, and consumers, they all share the standard view that it is represented by a well-preserved state immediately after production. This shared understanding underscores the need for rigorous standards and innovative inspection methods throughout egg production, processing, and distribution.

To effectively manage and evaluate these aspects, it is essential to understand that the state of an egg undergoes biochemical and physical changes throughout all stages, both before and after laying. These changes may be reflected in the egg’s taste, smell, color, and texture and are perceived by consumers as a quality degradation [5,6]. Additionally, considering that the quality and freshness of eggs do not improve after laying but instead either remain stable or decline, it is essential to understand the factors that influence these attributes before evaluating them. The factors affecting egg quality and freshness are divided into internal and external qualities, which are further segmented according to the conditions before and after laying. The quality before laying is influenced by the hen’s breed, age, diet, overall health, and disease status, all of which interact to determine internal and external qualities [7,8,9]. After laying, the primary factors influencing egg quality are storage conditions (temperature and humidity), time, and the egg production and distribution systems [10,11,12,13]. Thus, the quality and freshness of eggs can change due to the interaction of various factors, and understanding this should be a priority in the egg inspection process.

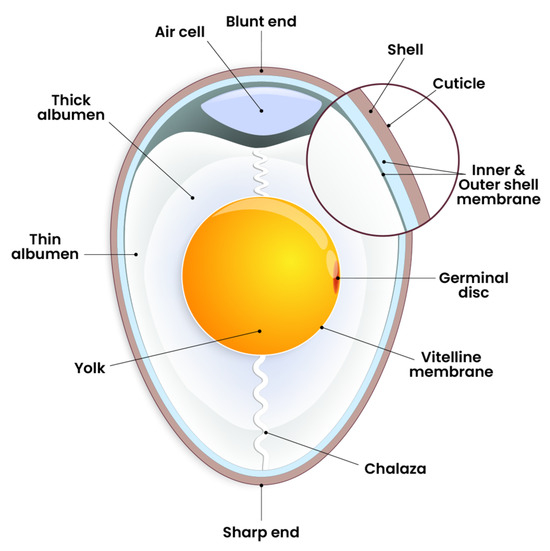

Moreover, eggs have a complex structure. As shown in Figure 1, the eggshell and multiple membranes encase the interior. This complexity necessitates considering various factors when evaluating eggs’ quality and freshness. Eggs consist of three primary components: the shell, the egg white (albumen), and the yolk; each of these imparts distinct characteristics and functionalities to the overall quality of the egg [14]. To evaluate these components, eggs undergo a comprehensive quality and freshness assessment after laying. In Korea, eggs are categorized into four grades: A, B, C, and D [15]. The United States categorizes eggs into three grade levels: AA, A, and B. Europe differentiates eggs into three classes: class A (extra fresh), class A (category I), and class B [16,17]. While grading standards vary across countries, the common evaluation criteria include the condition of the shell, the height of the air cell, and the quality of the white and yolk.

Figure 1.

Internal structure of an egg.

Following the grading process, the evaluation of egg quality encompasses two main approaches: an internal quality assessment, focusing on the condition of the albumen and yolk, and an external quality assessment, concentrating on the shell’s state [18]. Currently, the internal quality assessment primarily aims to inspect the factors that influence an egg’s condition during distribution and storage and identify defects, such as rot, blood spots, and meat spots [19]. This is achieved using non-destructive methods, such as candling and spectroscopy [20]. On the other hand, the external quality assessment, which significantly influences consumer choice and marketability, focuses on the cleanliness and shape of the eggshell through the use of candling [21,22]. The shell’s physical integrity is also evaluated using sound wave analysis, which is known for its high accuracy and efficiency [23,24].

Generally, eggs are distributed from farms to retailers within 10 days of being laid [16,17]. Subsequently, once the eggs are packaged, there are no further checks on their freshness and quality until they reach the consumer. Therefore, accurate and rapid freshness and quality measurements are essential before distributing the eggs. Currently, egg grading evaluation is mainly based on non-destructive evaluation methods and is an absolute quality indicator. However, unlike attributes such as size, color, shell thickness, integrity, and the presence of internal defects, egg freshness is not measured as an exact value; instead, it is evaluated relatively. Currently, the most commonly used method to measure egg freshness is the Haugh unit (HU), which involves the weight and albumen height of the egg, as well as the air cell height measurement.

The HU test has a significant drawback in that it requires the breaking of a random sample of eggs to measure the protein height physically, resulting in a loss of approximately 3% of the total eggs. This method is impractical for testing large quantities of eggs and unsuitable for automation, leading to significant time and labor costs. Additionally, the air cell height cannot accurately indicate freshness over the grading period after laying because it does not change significantly. Moreover, the inconsistency in the shape and position of the air cell makes automation difficult for reasons similar to those given for the HU measurement devices. Therefore, the development of methods or technologies that evaluate egg freshness as an absolute value rather than relatively has become a critical focus in the egg industry.

This review aims to explore the concept of egg freshness and its key parameters in depth, examine the limitations of traditional methods, and present the need for new methods of assessing egg freshness using advanced spectroscopic techniques. Despite advancements in understanding egg quality, the methodologies for evaluating freshness remain significantly underdeveloped and reliant on traditional and destructive techniques. These methods reduce the number of eggs available for sale and render comprehensive inspections impractical. This situation highlights the importance of accurate egg freshness assessment within the supply chain and underscores the need for reliable, non-destructive approaches. The review delves into the innovative technologies and methodologies that have recently emerged and provides an in-depth analysis of these advancements to offer new perspectives on and insights into the improvement of egg quality assessment. Developing non-destructive evaluation techniques is essential to enhance the efficiency and effectiveness of quality control within the egg industry, ensuring that consumers have access to high-quality eggs. This comprehensive examination provides an understanding of the current state of egg freshness evaluation and explores promising future research directions.

2. Physicochemical Changes in Eggs with Storage Condition and Time

2.1. Egg White (Albumen) and Yolk

The quality and freshness of eggs are subject to various physicochemical changes during storage; these changes significantly impact their nutritional value, safety, and culinary properties. Initially, the pH of a freshly laid egg is slightly acidic or nearly neutral, typically around 7.6 to 7.9 [25]. However, during storage, as the egg ages, changes in the composition of the egg white are particularly noticeable. The breakdown of carbonic acid within the egg white produces carbon dioxide and water [26]. This chemical change is catalyzed by the gradual loss of carbon dioxide through the egg’s porous shell [27,28]. Over time, the pores in the shell can become more pronounced, allowing a faster escape of carbon dioxide [29]. Consequently, the egg’s internal environment shifts toward a more alkaline condition, which, in turn, causes an increase in the pH of the egg white.

This shift in pH is critical as it affects the gel structure of the albumen. The mucin fibers, which are key components in providing the gel-like consistency of fresh egg whites, begin to lose their strength under more alkaline conditions [29,30]. This process is influenced by storage conditions, with temperature playing a pivotal role. Higher temperatures can accelerate the loss of carbon dioxide and the breakdown of proteins, leading to a more rapid increase in pH [11]. In [11], experiments were conducted to assess the impact on egg quality of temperatures of 5, 21, and 29 °C over 10 days (Table 1). They found that the quality of almost all the egg parameters changed over time; the pH of the albumen in the fresh eggs was 7.47, but by the last day at 29 °C, the pH had risen sharply to 9.11. Consequently, these environmental factors can lead to the pH of the albumen rising to 9.0 or above more quickly, impacting the egg’s freshness and edibility [31,32,33].

Table 1.

Effects of storage time and temperature on various egg quality indices [11].

The yolk undergoes similar, though subtler, changes compared to the albumen during storage. Initially, the yolk’s pH is also slightly acidic to nearly neutral, mirroring the albumen. However, as storage time progresses, the pH of the yolk slowly increases but at a less pronounced rate than that of the albumen, as shown in Table 1 [11,13,34]. This more gradual pH shift is primarily due to the yolk’s density, which acts as a buffer against rapid chemical changes [35]. Understanding these physicochemical characteristics of the egg white and yolk is crucial as they can significantly impact the shelf life and quality assessment of eggs. This indicates that innovative techniques for evaluating the physicochemical state of the egg white or yolk can play a crucial role in measuring egg freshness.

The albumen, initially clear and viscous, gradually becomes more watery due to the breakdown of proteins, which alters its structural integrity [36,37]. In [38], the author observed that the viscosity of both thin and thick albumen decreased with increasing temperature and time from 5 to 30 °C at a shear rate of 34–600 s−1. Additionally, at 20 °C and a shear rate of 34.2 s−1, the viscosity of the thick portion was 160 cp, which was 40 times higher than that of the thin portion due to high-molecular-weight complexes [38]. Similarly, the viscosity of the yolk was also influenced by storage temperature and duration. In [39], yolk viscosity was measured over 8 weeks at temperatures ranging from 4 to 16 °C, and it was found that at a shear rate of 3.4 s−1, the viscosity of the fresh yolk was 2023 mPa·s. By week 8, at 16 °C, the yolk viscosity had decreased to 425 mPa·s. Based on this research, it is evident that viscosity, like the other physicochemical changes, serves as a critical physical indicator for evaluating egg quality.

When eggs are stored, notable changes occur in the yolk index, height, and weight of both the albumen and yolk, further indicating the progression of aging [34,40,41]. The yolk index is a unit used to measure the physical quality of the yolk; this index is calculated by dividing the height of the yolk by its diameter [42,43]. In [11,44], the researchers found that the HU, albumen height, weight, and yolk index all decreased over time, with the parameters of the eggs stored at higher temperatures showing more significant declines than those kept at lower temperatures, as shown in Table 1. These physical changes in eggs are closely related to chemical transformations such as pH changes and protein degradation. Therefore, understanding why and how these factors change is essential for accurately assessing egg quality and freshness.

2.2. Air Cell

In addition to pH changes, the air cell size within an egg emerges as a critical freshness indicator. While the egg is still in the oviduct, the high body temperature of the hen, approximately 41 °C, ensures that an air cell is not present [17,43]. However, after the egg is laid and exposed to external air, the shell membrane separates from the shell, allowing the air cell to form as the egg cools [45]. Fresh eggs have a higher specific gravity, which typically results in a smaller air cell. According to [11], the specific gravity of fresh eggs was 1.086, which significantly decreased to 1.063 as the storage temperature and duration increased, as detailed in Table 1. As eggs are stored, the air cell expands due to moisture loss through evaporation—a process facilitated by the eggshell’s permeability to air and water vapor [46]. This expansion of the air cell, coupled with the concurrent loss of moisture, leads to a noticeable decrease in the egg’s overall weight and specific gravity. Consequently, with their enlarged air cells, older eggs exhibit reduced specific gravity and tend to float in water [47]. Several researchers, including those of [48], found that air cell enlargement was greatly influenced by temperature and humidity, with temperature playing a significant role in the rate of moisture evaporation and the rate at which the air cell enlarges [49]. Once formed, the air cell does not maintain its volume but continues to grow; thus, it serves as an excellent indicator for measuring the freshness of eggs.

It is clear that the size of the air cell is closely related to egg freshness. The rate at which the air cell enlarges can vary depending on the hen’s age, nutritional status, and storage conditions, such as temperature and humidity. According to various studies, the HU value, which represents egg freshness, tends to decrease as the hen ages. However, as mentioned earlier, regardless of the hen’s age, the air cell does not exist before laying. Considering that all quality and freshness measurements are conducted immediately, within five days after egg laying, it is not reasonable to evaluate freshness through the size of the air chamber, as the change in values is not accurate, and the shape and position of the air cell are random. Nevertheless, the air cell size can be used to predict the hen’s age or storage duration, making it valuable for research purposes.

Considering the information presented above, various storage conditions significantly influence the rate of physicochemical changes in eggs. Temperature, humidity, and exposure to light can either accelerate or delay the deterioration of egg quality [50,51,52]. Despite these factors, the quality and freshness of eggs inevitably decline over time. While it is possible to maintain quality for a period, preserving it indefinitely is not feasible. Therefore, a precise understanding of these physicochemical changes can enable an accurate assessment of egg quality and freshness. Among the various indicators, the albumen’s pH and viscosity have proven to be particularly effective markers of freshness. As the egg ages, the albumen pH gradually increases due to CO2 loss, while the viscosity decreases due to protein breakdown. These measurable changes provide a reliable basis for assessing freshness, making them suitable markers for consistent and practical freshness evaluation.

3. Current Methods for Assessing Egg Freshness

The assessment of egg freshness and quality has been refined over the years, with candling and the HU measurement standing out as two of the most enduring techniques [19,53]. Candling, which is a straightforward and effective method, entails shining a light through an egg to visually inspect its internal structure, offering instant insights into its condition [17]. In contrast, the HU measurement quantifies egg freshness scientifically by evaluating the height of the egg’s albumen and its correlation with the egg’s weight [54]. These methods, which have been utilized for decades, have become indispensable in the egg industry, and a balance between traditional practices and scientific precision is struck to ensure the highest standards of egg quality and safety.

3.1. Candling

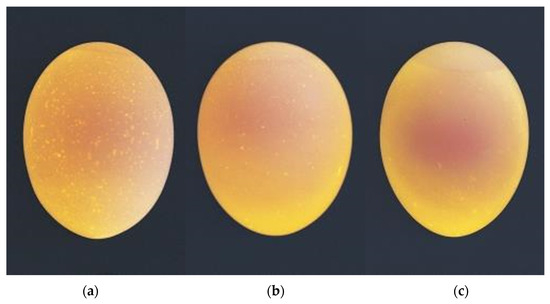

Candling is a representative non-destructive technique in the egg industry for evaluating egg quality, and it provides insights into an egg’s internal condition without causing damage [7]. By illuminating the egg with a light source, inspectors can assess factors such as the size and shape of the air cell; larger air cells typically indicate older eggs. This method also aids in identifying imperfections, such as blood and meat spots, as well as shell cracks, that can lead to freshness degradation [55,56]. Additionally, the candling method in the U.S. uses the yolk location to conduct freshness testing, as shown in Figure 2 [17]. However, the time-consuming nature of inspecting each egg and the required manual effort make it impractical to conduct candling manually with large batches. As a result, quality controllers often resort to lot judgment, assessing a sample of eggs to estimate a batch’s overall quality and freshness [17].

Figure 2.

The terms used to define the three degrees of distinctness of yolk shadow outline (in the U.S. Standards of Quality for Shell Eggs) [17]. (a) The yolk outline is slightly defined; (b) the yolk outline is fairly well defined; (c) the yolk outline is plainly visible.

Recent technological advancements have led to the exploration of the automation of the candling process through the combination of machine vision and artificial intelligence (AI), specifically deep learning [57,58]. This innovative approach aims to develop systems capable of conducting comprehensive inspections across entire batches, thereby overcoming the limitations of manual candling. By leveraging high-resolution imaging and sophisticated algorithms, these automated systems can efficiently detect a wide range of quality indicators, from the condition of the eggshell surface to the typical features assessable through traditional candling, facilitating a more consistent and efficient quality assessment process. Nevertheless, these advanced technologies have not reached commercialization, primarily due to accuracy and processing speed issues. For commercialization, a target accuracy of approximately 95–99%, typically closer to 99%, is generally required to ensure reliable quality assessment. The processing speed must also cover large-scale operations, which can handle around 260,000 eggs per hour, to be feasible for industry-level adoption. Overcoming these obstacles could significantly transform egg quality management, propelling the egg industry forward by ensuring high assessment standards.

3.2. Haugh Unit (HU) Measurement

The HU measurement serves as a quantitative complement to candling in the assessment of egg freshness and quality. This method involves measuring the height of the albumen at a point 1 cm from the edge of the yolk and calculating the HU value using the following equation [43]:

where

- HU = Haugh Unit

- H = Height of thick albumen (mm)

- W = Egg weight (g)

Higher HU values indicate fresher eggs with firmer albumen, making this method invaluable for detailed quality assessments and research due to its provision of objective and quantifiable data.

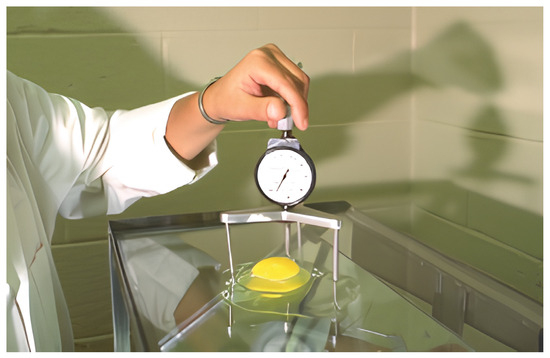

However, as shown in Figure 3, unlike candling, the requirement of the HU measurement to break the egg precludes its use for non-destructive inspection of entire batches. Additionally, according to the reports in [17], the United States discontinued the use of HU tests in 1981 due to the high rate of broken eggs. Moreover, the necessity for specific equipment and precise calibration poses challenges, potentially limiting its application in environments that demand rapid, large-scale quality assessments. Therefore, overcoming these issues necessitates the development of alternative quality measurement equipment that can replace the HU.

Figure 3.

Egg grader demonstrating the use of a Haugh meter by measuring the height of the thick albumen [17].

4. Non-Destructive Techniques for Assessing Egg Freshness

The assessment of egg freshness is crucial in the poultry industry to ensure product quality and safety [52]. Traditional methods, while effective, typically involve destructive measurements, leading to a waste of time and resources. These conventional approaches reduce the number of eggs available for sale and increase the operational costs for producers, making the search for alternative methods imperative. In response to this, non-destructive techniques have been developed over the years to assess egg freshness without compromising the integrity of the eggs. The advent of these technologies marks a significant shift toward more sustainable and efficient quality control processes in the poultry industry. These methods significantly reduce the assessment time and increase throughput by enabling rapid testing and minimal sample preparation. Moreover, their non-destructive nature ensures that the eggs remain intact and salable post-evaluation, reducing waste and enhancing profitability.

Furthermore, these non-destructive techniques have the capability to be integrated into online processing lines; thus, they represent a leap forward in automation and scalability. This integration allows real-time quality assessment, facilitating immediate decision making and action, which are crucial in maintaining high product quality and safety standards. The development and implementation of these advanced technologies not only streamline the quality control process but also significantly drive the industry’s advancement toward more environmentally friendly and cost-effective practices.

Recent advancements in portable instruments, particularly those based on spectroscopy, have shown significant promise in enhancing egg freshness assessment. Portable spectrometers have been developed to provide rapid and non-destructive analysis suitable for field or online evaluations, as demonstrated in studies such as [59,60]. These tools offer prediction accuracies comparable to conventional benchtop devices, enabling more flexible and real-time monitoring capabilities. The emergence of these portable instruments plays a crucial role in guiding the future direction of egg freshness technology development by making advanced quality control more accessible and adaptable to various production environments.

4.1. Vis-NIR Spectroscopy

Visible and near-infrared (Vis-NIR) spectroscopy has emerged as a pivotal non-destructive technique in evaluating egg quality and freshness [18]. This method leverages the spectral absorption characteristics of materials in the visible to near-infrared range (350–2500 nm), providing a rapid and efficient means of analyzing the internal quality of eggs without compromising their integrity [18]. In [61], Vis-NIR spectroscopy was utilized to build a model predicting albumen pH and HU values using wavelengths acquired in the 411–1729 nm range. This was accomplished using a partial least squares regression (PLSR) model. The study found that the correlation coefficients for HU and albumen pH were 0.89 and 0.95, as shown in Table 2, respectively, and 10 specific wavelengths in the Vis-NIR spectrum were utilized. When used on a validation set, the developed model showed R2 values of 0.90 for albumen pH, 0.79 for HU, and 0.89 for the number of storage days, demonstrating the model’s effectiveness in predicting these quality parameters.

Table 2.

Calibration and validation results of the prediction models for all three parameters using Vis-NIR spectroscopy [61].

The principle of Vis-NIR spectroscopy lies in the interaction between light and the egg components. Some wavelengths are absorbed when light in the Vis-NIR range is directed onto an egg. In contrast, others are reflected or transmitted, depending on the molecular composition and structure of the egg contents. This interaction produces a unique spectral signature that can correlate with various freshness parameters, such as albumen height, air cell diameter, yolk index, and contaminants or defects [20,62,63,64].

One of the key advantages of Vis-NIR spectroscopy is its ability to provide quick and non-destructive assessments, making it highly suitable for online quality control in the egg industry. In [63], the visible spectrum range of 200–1100 nm was used to monitor blood spots in real time. The experiment involved eggs with actual blood spots and those with artificially created blood spots. The author developed a partial least squares discriminant analysis (PLS-DA) model and selected wavelengths of 576–579 nm and 607–609 nm. As a result, in all 220 eggs, the normal eggs and those with blood spots were successfully differentiated. This capability, combined with the rapid collection of spectral data, enables the high-throughput screening of eggs. However, despite its numerous benefits, applying Vis-NIR spectroscopy in egg freshness assessment is not without challenges. The technique requires careful calibration and validation to ensure accurate and reliable results. Currently, the accuracy of Vis-NIR spectroscopy can vary depending on factors such as eggshell color, thickness, and surface cleanliness.

Table 3 summarizes fundamental studies employing various systems, such as benchtop and portable NIR instruments, to monitor egg freshness. It illustrates how different chemometric techniques have been integrated to improve the accuracy and practicality of these assessments. These examples highlight the versatility and potential of Vis-NIR spectroscopy in various settings, from controlled laboratory environments to real-time industrial applications.

Table 3.

Applications of NIR spectroscopy in egg freshness assessment.

However, while Vis-NIR spectroscopy holds substantial promise, further research is necessary to address its current limitations. Future efforts should focus on developing more robust calibration models that account for the diverse shell characteristics found in eggs, thereby enhancing the technique’s consistency and reliability across different egg types. Additionally, integrating AI and machine learning algorithms to improve the speed and efficiency of spectral data processing would further advance this technology, enabling more accurate, real-time assessments suitable for large-scale industrial use.

4.2. Ultrasonic

Ultrasonic testing has become an innovative, non-destructive approach to the assessment of the freshness of eggs. Utilizing high-frequency sound waves that penetrate the eggshell, this technique interacts with the internal components of the egg. The sound waves are reflected back with varying intensities, influenced by the density and composition of the egg contents, which evolve as the egg ages. This method offers critical insights into the internal quality of eggs, such as the condition of the albumen and yolk, without compromising the eggshell’s integrity [67].

The principle underlying ultrasonic testing in egg freshness evaluation is that sound waves traverse materials of differing densities at distinct speeds. In eggs, freshness is indicated by firmer albumen and a more intact yolk, which alter the transmission and reflection of sound waves. Ultrasonic technology was used to measure egg quality in [68]. The experiments measured the internal quality and phase velocity of eggs at intervals of one week over a period of five weeks at the temperature of 5 °C and room temperature (22–25 °C). The author employed an ultrasonic beam with a frequency of 150 kHz and a sampling rate of 2.5 Gs/s, observing that the phase velocity tended to decrease in both temperature ranges as the internal quality of the eggs changed. However, predicting exact HU values based on phase velocity alone was challenging, indicating the need for further research to measure albumen quality.

A significant drawback of ultrasonic technology applied to eggs is that it requires contact measurement, which can be inefficient and economically costly due to contamination and breakage risks, particularly in egg farms that process upward of 250,000 eggs per hour. Developing and applying non-contact or laser-based ultrasonic technology is essential to overcome these limitations. Additionally, given the round shape of eggs, future research should focus on identifying optimal frequencies that ensure uniform sound wave transmission and improve the accuracy of reflected signals, which is crucial for developing predictive models tailored to egg quality assessment.

4.3. Machine Vision

Machine vision technology is increasingly utilized as a non-destructive tool for assessing egg freshness, leveraging digital imaging and automated analysis. This technology operates on the principle of capturing high-resolution images and interpreting visual data through algorithms. The process begins with high-resolution cameras that take detailed images of the eggs, followed by image-processing software that analyzes these images for specific characteristics. This allows for extracting meaningful information, such as dimensions, color variations, and structural anomalies, which can be correlated with freshness indicators. By employing sophisticated algorithms, these images are analyzed using various freshness indicators, such as shell integrity, color changes, and potential internal defects that might be discernible through the shell.

At the heart of machine vision lies its capacity to process and interpret complex visual data with a speed and precision unattainable by human inspectors. In [69], image processing algorithms with transillumination methods were used to obtain the characteristics of the yolk and air cells. By calculating the area ratios of the yolk to the entire egg and the air cell to the entire egg, a real-time model for determining actual HU values was developed through experimentation. The R2 value and the mean error of the egg freshness prediction model were 0.96 and 8.39%, respectively. Similarly, in [70], a model was developed to predict HU values using the air cell and yolk area measurements, achieving an accuracy of over 90%. These advanced imaging technologies quantify the subtle internal characteristics of eggs, providing a comprehensive assessment of each egg’s condition. This method is especially effective in identifying early signs of quality degradation, which might not be visible to the naked eye.

Despite machine vision’s numerous advantages, such as its ability to enhance product safety and consistency while reducing reliance on manual inspection, its implementation in egg freshness assessment comes with challenges. The accuracy of this technology depends heavily on the imaging system’s quality and the robustness of the analysis algorithms. Factors such as lighting conditions, field of view, camera angles, and the orientation of the eggs can significantly affect the precision of the assessments. Therefore, developing and continually refining sophisticated algorithms to adapt to these variables is crucial to maintaining accurate and reliable evaluations.

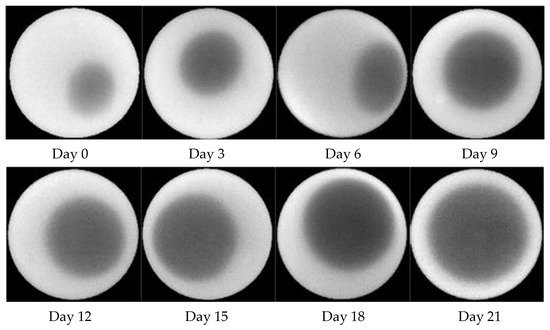

4.4. Thermal Imaging

Thermal imaging technology is utilized as an innovative, non-destructive tool in studying egg freshness, primarily by focusing on detecting changes in the size of the air cell. This method uses infrared technology to capture the subtle differences in infrared radiation (1000 nm–14,000 nm) emitted from the egg’s surface; these variations are translated into thermal images. Figure 4 provides a visual representation of the temperature distribution across the egg; the air cell, whose size increases as the egg ages, is particularly emphasized. The effectiveness of thermal imaging in egg freshness assessment lies in its ability to detect the enlargement of the air cell, a natural process that occurs as eggs lose moisture and carbon dioxide over time. This enlargement leads to discernible changes in the thermal patterns captured in the images. By precisely analyzing these patterns, thermal imaging offers a non-destructive and rapid means of gauging the egg’s age and, by extension, its freshness. The ability to scan multiple eggs simultaneously makes this technique especially valuable and greatly enhances the efficiency of quality control processes in egg production and processing facilities.

Figure 4.

Changes in the size of air cells taken with a thermal imaging camera (from day 0 to day 21).

Eight parameters, including the major axis, minor axis, eccentricity, center coordinates of the egg’s edges, and radius, were used to measure egg freshness through examination of the air cell [71]. The accuracy of air cell detection using thermal imaging was very high at 92.32%. Additionally, the egg thermal images were segmented using SegNet neural network image segmentation technology, achieving an image segmentation accuracy of 98.87% and an egg freshness prediction accuracy of 94.52%. In [72,73], a model was also developed to predict freshness by detecting the air cell and using the area values of the entire egg and the air cell. With the recent advancements in AI, research integrating AI technology with thermal imaging continues to progress. However, environmental factors can significantly influence the accuracy of thermal imaging readings. Furthermore, because the changes in air cell size vary depending on the health status, age, and storage conditions of the hens, extensive data collection is necessary to ensure reliability and efficiency.

Thermal imaging technology is subject to accuracy fluctuations due to environmental factors, such as temperature and humidity. Therefore, future research should focus on developing models that provide consistent results across varying environmental conditions. Additionally, while thermal imaging has primarily been used to assess freshness by examining the egg’s air cell, much of the current research compares thermal imaging results to HU measurements, which are widely used as freshness indicators. However, commercialization has been challenging due to the lower predictive reliability of HU during the grading process, from laying to distribution. To address this, future studies should explore alternative freshness indicators that could be compared with thermal imaging data, enabling the development of models and methods that more accurately predict freshness.

4.5. Hyperspectral Imaging

Hyperspectral imaging (HSI) is a new non-destructive detection technology that has been optimized to analyze morphological and chemical information in the agricultural and food industries [74,75,76]. It captures the spatial image information and spectral information of pixels across many spectral bands in a sample [77,78]. Some researchers have also utilized hyperspectral imaging mounted on drones to monitor crops [79]. The strength of HSI lies in its capacity to detect subtle changes in the eggshell that may reflect underlying freshness levels. For example, subtle changes in the eggshell’s color or glossiness can occur as eggs age, which HSI can capture and quantify. While imperceptible to the naked eye, these changes can be significant freshness indicators when analyzed using sophisticated spectral analysis techniques.

By employing machine learning and pattern recognition algorithms, it is possible to relate these surface characteristics to freshness levels, enabling the creation of predictive models that can accurately estimate the egg’s freshness from its external appearance alone. Pattern recognition algorithms used in HSI can be categorized into supervised, unsupervised, and semi-supervised types. Supervised algorithms, such as support vector machines (SVMs) and Random Forests, require labeled training data to classify and predict freshness accurately. Unsupervised algorithms, such as k-means clustering and principal component analysis (PCA), are used to identify patterns in data without prior labeling, helping to detect unexpected relationships in spectral data. Semi-supervised algorithms combine both approaches, leveraging a smaller set of labeled data alongside a larger set of unlabeled data to improve model training and predictive accuracy. Each type contributes uniquely to analyzing HSI data, allowing for flexible model development suited to specific research needs.

In [80], the hyperspectral data of egg samples in the wavelength range of 400.68–1001.612 nm were acquired, and a classification model was developed to predict freshness by comparing it to HU values. The training model achieved an accuracy of 99.29%, and the testing model achieved an accuracy of 97.89%. Similarly, the authors of [81] compared measurements obtained in the 900–1700 nm wavelength range with HU values. Using the PLSR method, a calibration model for HU values was developed, showing an R2 value of 0.91 and a root mean square error of calibration (RMSEC) value of 4.58.

The application of HSI in this context offers a non-destructive, rapid, and objective means of assessing egg quality on a large scale, which is particularly beneficial for egg processing facilities looking to ensure product consistency and safety. However, developing accurate predictive models requires a comprehensive dataset that includes hyperspectral images of eggs at various freshness stages, accompanied by the corresponding freshness data obtained through traditional methods. This necessitates a collaborative effort between imaging specialists, data scientists, and food technologists to fine-tune the algorithms for optimal performance. Moreover, the high cost and challenges associated with processing and managing large volumes of data pose significant barriers to the commercialization of hyperspectral imaging technology. Future research should focus on selecting specific wavelength ranges related to freshness and leveraging AI-based models to optimize data analysis and management. This approach could reduce hardware costs and enhance data processing efficiency, facilitating the broader adoption of HSI in the industry.

4.6. Raman Spectroscopy

Raman spectroscopy has emerged as a promising non-destructive method for assessing egg quality and freshness. This technique functions by scattering monochromatic light to analyze molecular vibrations, thereby creating unique spectral fingerprints that indicate the chemical composition of a sample. According to a recent study [82], micro-Raman spectroscopy was employed to measure egg yolk and shell quality under varying storage conditions. The study found correlations between specific Raman peaks and quality coefficients, demonstrating the method’s ability to monitor changes related to proteins and lipids as eggs age. Specific Raman peaks at wavenumbers such as 1002 cm−1 for proteins, 1301 cm−1 for lipids, and 3057 cm−1 for choline methyl vibrations were identified as critical markers [82]. The reduction of these peaks over time indicated protein degradation, lipid oxidation, and carotenoid depletion, aligning with the observed loss of freshness in eggs. The study further employed PLS-DA to classify eggs stored under different conditions with up to 80% validation accuracy [82], showcasing the practical applications of Raman spectroscopy in quality control.

Additionally, in [83], Raman spectroscopy was used to scan the external information of the eggshell and obtain spectra. By measuring the HU values, yolk index, albumen pH, and the diameter of the air cell, a full-band PLSR model was constructed for the range of 100–3000 cm−1. The results were notable, as the HU values, albumen pH, and air cell diameter could be predicted with correlation coefficients exceeding 0.9 [83]. This further supports the potential of Raman spectroscopy for accurately predicting key freshness indicators from the eggshell surface.

Despite its advantages, such as rapid analysis and minimal sample preparation, challenges remain in applying Raman spectroscopy on an industrial scale. These include high equipment costs and the complexity of interpreting high-dimensional spectral data. Future research should focus on optimizing data analysis algorithms and integrating Raman systems with AI technologies to enable more robust, automated quality assessments suitable for large-scale operations.

4.7. Fluorescence Spectroscopy

Fluorescence spectroscopy has emerged as a valuable non-destructive technique for monitoring egg freshness. This method operates by exciting intrinsic fluorophores within the egg at specific wavelengths and measuring their emission spectra, providing insights into molecular interactions and changes during storage. Key fluorophores in eggs include aromatic amino acids, like tryptophan and vitamin A, predominantly found in the yolk and albumen [84,85,86].

A study by [86] analyzed the fluorescence properties of tryptophan (excitation at 290 nm; emission range 305–430 nm) and vitamin A (excitation range 270–350 nm; emission at 410 nm) to monitor egg freshness over time. The results show significant shifts in the fluorescence spectra as eggs aged, indicating protein structural changes and lipid environment variations. This study reports classification accuracies of 97.5% for calibration and 96.3% for validation using factorial discriminant analysis (FDA), demonstrating the method’s effectiveness for yolk freshness assessment [86].

Further research conducted under modified atmospheric conditions using front-face fluorescence spectroscopy (FFFS) demonstrates that changes in the fluorescence spectra of tryptophan and Maillard reaction products could accurately discriminate egg storage time [87]. PCA and FDA analyses reveal that specific spectral markers provided robust differentiation between eggs stored under different CO2 levels, achieving an accuracy of over 90% for distinguishing fresh from stored eggs [87]. Similarly, another FFFS study shows that classification models incorporating PCA and FDA yielded a classification accuracy of approximately 69.4% for albumen-based data and up to 97.2% when combining data from albumen and yolk [84]. Additionally, egg yolk fluorescence analysis reveals that vitamin A emission intensity diminished as storage progressed, correlating with the shift of water from albumen to yolk, a crucial indicator of freshness.

The transition of fluorescence spectroscopy into a reliable tool for egg freshness assessment will require extensive research and validation. Challenges, such as calibrating the technique to account for the unique properties of eggshells, developing algorithms capable of interpreting complex fluorescence data, and establishing baseline fluorescence signatures for fresh versus aged eggs, need to be addressed. Despite these hurdles, the potential benefits of incorporating fluorescence spectroscopy into egg quality assessment protocols are significant, warranting continued exploration and development in this promising area.

4.8. Low-Field NMR

Low-field nuclear magnetic resonance (NMR) technology, while traditionally less common in egg freshness assessment, has shown significant potential due to its non-destructive nature and the valuable insights it provides into the internal structure of eggs. By operating at lower magnetic field strengths, low-field NMR becomes more accessible and cost-effective for industrial applications, offering an innovative method to assess egg freshness.

This technique’s utility in evaluating egg freshness lies in its ability to detect variations in water distribution and mobility within the egg, which are critical indicators of aging. Fresh eggs are characterized by tightly bound water within the albumen and yolk. Over time, as eggs age, structural changes result in increased water mobility, which low-field NMR can effectively measure. A study [88] demonstrates that transverse relaxation time (T2) distribution curves revealed three distinct water phases: bound, immobile, and free water. The relaxation times and peak areas for bound and immobile water showed strong correlations with egg freshness indicators, such as the thick albumen height and HU, with correlation coefficients reaching up to 0.929 and 0.917, respectively [88]. Additionally, the Back Propagation Neural Network (BPNN) model in the study strongly predicted the HU, achieving an R2 value of 0.874 and a mean relative error (MRE) of 3.673% [88]. The model achieved an identification rate of 93.233% for egg grade classification [88]. These findings underscore the potential of low-field NMR as a precise and non-invasive method for assessing egg freshness.

Despite these promising results, challenges remain for the widespread adoption of low-field NMR. Factors, such as egg size and shell thickness, and environmental conditions, like temperature, can impact measurement accuracy, necessitating thorough calibration and data interpretation. Furthermore, integrating low-field NMR into high-throughput egg processing operations presents logistical challenges that must be addressed. Future research should focus on enhancing real-time data processing, developing more robust prediction models, and creating scalable solutions for industrial implementation to fully leverage low-field NMR technology in maintaining egg quality and safety standards.

4.9. MRI

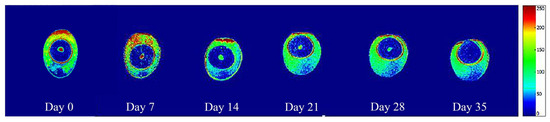

Magnetic resonance imaging (MRI) represents a promising frontier in egg quality assessment, providing an in-depth look at the internal structures of eggs with a level of detail not achievable through conventional methods. Unlike low-field NMR, which is adept at analyzing bulk properties, like water content and distribution, MRI offers high-resolution images illuminating the egg’s internal architecture, including the yolk, albumen, and air cell. This capability is crucial for detecting subtle changes indicative of egg freshness and identifying internal anomalies, making MRI a potentially powerful tool for ensuring egg quality. In a study [89], researchers measured the internal water status of eggs using a 0.55 T (23 MHz for protons) MRI system and observed that water gradually diffuses out through the blunt end pores of the egg, with the yolk shifting toward the blunt end during storage, as shown in Figure 5. This type of analysis highlights MRI’s ability to provide detailed insights into internal egg dynamics that correlate with freshness indicators.

Figure 5.

Nuclear magnetic images of eggs on days 0, 7, 14, 21, 28, and 35 of storage. The images were obtained using an MesoMR, conducted with a 0.55 T (23 MHz for protons), 60 mm vertical bore MR system. The egg samples were stored at 25 °C and 50–60% relative humidity with their blunt end up [89]. (Reprinted with permission of Elsevier, Amsterdam, Copyright © 2020).

While MRI offers clear advantages, its widespread adoption in the egg industry has significant challenges. The technology’s high cost, substantial installation space, and slower operational speeds compared to other non-destructive techniques, like low-field NMR, currently hinder its feasibility for routine use in egg quality control, especially in settings that require rapid, high-volume processing. Additionally, the complexity of MRI systems demands specialized knowledge for operation and interpretation, adding another layer of complexity to its integration into the egg production line. These challenges emphasize the importance of considering cost, size, and maintenance when applying MRI technology in egg farms.

On the other hand, the evolution of MRI technology contributes to a more nuanced landscape in egg quality assessment. Efforts to develop more compact and cost-efficient MRI machines, coupled with the potential integration of AI to expedite image analysis, could make MRI a more feasible option for egg quality assessment in the future. If challenges related to cost, size, and speed can be effectively addressed, the integration of MRI might enrich the toolbox available for egg quality assessment, offering an additional, non-invasive method to complement existing techniques.

With the growing demand for reliable and non-invasive methods to assess egg freshness, each technique discussed offers unique benefits and presents specific challenges that must be considered. Table 4 provides a comparative overview of these non-destructive methods, summarizing their advantages and limitations in the context of egg quality assessment.

Table 4.

Comparative overview of non-destructive techniques for egg freshness assessment.

This comparison underscores the importance of selecting the appropriate technique based on specific operational and research needs. While some methods, such as Vis-NIR spectroscopy and machine vision, offer rapid and scalable solutions ideal for industrial use, others, like MRI, provide detailed internal insights that are valuable for more targeted studies but come with higher operational costs and complexity.

To advance the field of egg freshness assessment, future research should prioritize the refinement of these technologies through the integration of AI and machine learning for enhanced data processing and predictive accuracy. Additionally, efforts should be made to develop more portable and cost-effective versions of these instruments, ensuring their adaptability across different production scales and environments. This multifaceted approach will help bridge the gap between current technological capabilities and industry demands, promoting a more sustainable and effective quality control process.

5. Conclusions

The non-destructive evaluation of egg quality and freshness is becoming increasingly crucial in the egg industry, where there is an ever-growing consumer demand for fresh, high-quality eggs. Understanding how various factors, including storage conditions, hen health, and production systems, influence freshness is vital for improving the overall quality control process. Traditional methods, though effective, often fall short in terms of efficiency and precision, particularly when it comes to maintaining the integrity of the eggs. As such, the development of non-destructive technologies is not only necessary but inevitable for modernizing the egg industry.

Among various non-destructive methods, the technologies that focus on assessing the air cell, albumen, and yolk have shown significant potential. For instance, measuring changes in air cell size provides valuable insights into freshness, though its accuracy can vary depending on storage conditions and the time after laying. Freshness assessments focusing on the albumen and yolk have proven to be more precise, offering higher accuracy. Further research on the rapid changes in eggs within the first 10 days of storage is needed, particularly with regard to temperature fluctuations. This will enable better calibration of non-destructive tools and improve the overall reliability of these methods.

Moving forward, integrating AI and machine learning into non-destructive inspection systems presents a transformative opportunity for the egg industry. By leveraging these advanced technologies, the industry can streamline quality control processes, making them faster, more accurate, and scalable. Additionally, future research should prioritize developing more affordable and high-speed technologies with acceptable accuracy to ensure widespread adoption across various scales of egg production. These innovations can make advanced egg freshness detection tools more accessible to smaller producers, promoting consistency and efficiency throughout the industry. Ultimately, such advancements will enhance the management of egg freshness, providing consumers with high-quality products while reducing food waste and supporting sustainability in egg production. Continued development and refinement of these technologies are essential for long-term improvements in quality control processes, benefiting producers and consumers.

Author Contributions

Conceptualization, T.-G.R. and B.-K.C.; methodology, T.-G.R.; validation, B.-K.C.; investigation, T.-G.R.; writing—original draft preparation, T.-G.R.; writing—review and editing, B.-K.C.; supervision, B.-K.C.; funding acquisition, B.-K.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Chungnam National University, Republic of Korea.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- FAO. FAO Statistical Yearbook—World Food and Agriculture; FAO: Rome, Italy, 2023; pp. 1–384. [Google Scholar] [CrossRef]

- OECD. Egg Projections: Production and Food Consumption; OECD: Paris, France, 2022. [CrossRef]

- OECD. OECD-FAO Agricultural Outlook 2023–2032; OECD: Paris, France, 2023. [CrossRef]

- Cardello, A.V.; Schutz, H.G. The Concept of Food Freshness: Uncovering its Meaning and Importance to Consumers; ACS Publications: Washington, DC, USA, 2003. [Google Scholar]

- Yimenu, S.M.; Kim, J.; Kim, B. Prediction of egg freshness during storage using electronic nose. Poult. Sci. 2017, 96, 3733–3746. [Google Scholar] [CrossRef] [PubMed]

- Çiftçi, H.G.; Bilge, G.; Aytaç, E. Monitoring the quality changes and freshness assessment of eggs based on chemometrics method. J. Food Process Eng. 2024, 47, e14591. [Google Scholar] [CrossRef]

- Jacob, J.P.; Miles, R.D.; Mather, F.B. Egg Quality; Cooperative Extension Service, Institute of Food and Agricultural Sciences (IFAS); University of Florida: Gainesville, FL, USA, 2000; Volume 24. [Google Scholar]

- Roberts, J.R. Factors affecting egg internal quality and egg shell quality in laying hens. J. Poult. Sci. 2004, 41, 161–177. [Google Scholar] [CrossRef]

- Travel, A.; Nys, Y.; Bain, M. Effect of hen age, moult, laying environment and egg storage on egg quality. In Improving the Safety and Quality of Eggs and Egg Products; Elsevier: Amsterdam, The Netherlands, 2011; pp. 300–329. [Google Scholar]

- Dedousi, A.; Stojčić, M.Đ.; Sossidou, E. Effects of housing systems on keel bone damage and egg quality of laying hens. In Proceedings of the Veterinary Research Forum, Urmia, Iran, 15 December 2020; p. 299. [Google Scholar]

- Samli, H.; Agma, A.; Senkoylu, N. Effects of storage time and temperature on egg quality in old laying hens. J. Appl. Poult. Res. 2005, 14, 548–553. [Google Scholar] [CrossRef]

- Kumari, A.; Tripathi, U.K.; Maurya, V.; Kumar, M. Internal quality changes in eggs during storage. Int. J. Sci. Environ. Technol. 2020, 9, 615–624. [Google Scholar]

- Yamak, U.S.; Sarica, M.; Erensoy, K.; Ayhan, V. The effects of storage conditions on quality changes of table eggs. J. Consum. Prot. Food Saf. 2021, 16, 71–81. [Google Scholar] [CrossRef]

- Okubo, T.; Akachi, S.; Hatta, H. Structure of hen eggs and physiology of egg laying. In Hen Eggs; CRC Press: Boca Raton, FL, USA, 2018; pp. 1–12. [Google Scholar]

- Ministry of Agriculture, Food and Rural Affairs (MAFRA). Detailed Standards for Livestock Product Grading; Ministry of Agriculture, Food and Rural Affairs: Sejong, Republic of Korea, 2018; p. 40.

- United Nations Economic Commission for Europe (UNECE). Egg-1 UNECE Standard Eggs-In-Shell; United Nations: New York, NY, USA, 2017.

- United States Department of Agriculture (USDA). USDA Egg-Grading Manual; United States Department of Agriculture: Washington, DC, USA, 2020.

- Mertens, K.; Kemps, B.; Perianu, C.; De Baerdemaeker, J.; Decuypere, E.; De Ketelaere, B.; Bain, M. Advances in egg defect detection, quality assessment and automated sorting and grading. Improv. Saf. Qual. Eggs Egg Prod. 2011, Volume 1, 209–241. [Google Scholar]

- Stadelman, W.J. Quality identification of shell eggs. In Egg Science and Technology; CRC Press: Boca Raton, FL, USA, 2017; pp. 39–66. [Google Scholar]

- Kim, J.; Semyalo, D.; Rho, T.-G.; Bae, H.; Cho, B.-K. Non-Destructive Detection of Abnormal Chicken Eggs by Using an Optimized Spectral Analysis System. Sensors 2022, 22, 9826. [Google Scholar] [CrossRef]

- Bell, D. Egg Shell Quality: Its Impact on Production, Processing and Marketing Economics; University of California: Riverside, CA, USA, 1998. [Google Scholar]

- Chukwuka, O.; Okoli, I.; Okeudo, N.; Udedibie, A.; Ogbuewu, I.; Aladi, N.; Iheshiulor, O.; Omede, A. Egg quality defects in poultry management and food safety. Asian J. Agric. Res. 2011, 5, 1–16. [Google Scholar] [CrossRef]

- So, J.-H.; Joe, S.Y.; Hwang, S.H.; Hong, S.J.; Lee, S.H. Current advances in detection of abnormal egg: A review. J. Anim. Sci. Technol. 2022, 64, 813. [Google Scholar] [CrossRef]

- Sun, L.; Bi, X.-K.; Lin, H.; Zhao, J.-W.; Cai, J.-R. On-line detection of eggshell crack based on acoustic resonance analysis. J. Food Eng. 2013, 116, 240–245. [Google Scholar] [CrossRef]

- Feddern, V.; Prá, M.C.D.; Mores, R.; Nicoloso, R.d.S.; Coldebella, A.; Abreu, P.G.d. Egg quality assessment at different storage conditions, seasons and laying hen strains. Ciência Agrotecnologia 2017, 41, 322–333. [Google Scholar] [CrossRef]

- Stadelman, W.J.; Newkirk, D.; Newby, L. Egg Science and Technology; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Li-Chan, E.C.; Powrie, W.D.; Nakai, S. The chemistry of eggs and egg products. In Egg Science and Technology; CRC Press: Boca Raton, FL, USA, 2017; pp. 105–175. [Google Scholar]

- Solomon, S. The eggshell: Strength, structure and function. Br. Poult. Sci. 2010, 51, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Eke, M.; Olaitan, N.; Ochefu, J. Effect of storage conditions on the quality attributes of shell (table) eggs. Niger. Food J. 2013, 31, 18–24. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Tu, Y.; Zhao, Y.; Luo, X.; Wang, J.; Wang, M. Changes in gel characteristics of egg white under strong alkali treatment. Food Hydrocoll. 2015, 45, 1–8. [Google Scholar] [CrossRef]

- Qi, L.; Zhao, M.-C.; Li, Z.; Shen, D.-H.; Lu, J. Non-destructive testing technology for raw eggs freshness: A review. SN Appl. Sci. 2020, 2, 1113. [Google Scholar] [CrossRef]

- Min, B.; Nam, K.C.; Jo, C.; Ahn, D.U. Irradiation of shell egg on the physicochemical and functional properties of liquid egg white. Poult. Sci. 2012, 91, 2649–2657. [Google Scholar] [CrossRef]

- Scott, T.; Silversides, F.G. The effect of storage and strain of hen on egg quality. Poult. Sci. 2000, 79, 1725–1729. [Google Scholar] [CrossRef]

- Jin, Y.; Lee, K.; Lee, W.; Han, Y. Effects of storage temperature and time on the quality of eggs from laying hens at peak production. Asian-Australas. J. Anim. Sci. 2011, 24, 279–284. [Google Scholar] [CrossRef]

- Sharp, P.F.; Powell, C.K. Increase in the pH of the white and yolk of hens’ eggs. Ind. Eng. Chem. 1931, 23, 196–199. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, L.; Wu, Y.; Huang, X.; Wang, G.; Song, H.; Geng, F.; Luo, P. Mechanism of differences in characteristics of thick/thin egg whites during storage: Physicochemical, functional and molecular structure characteristics analysis. Food Chem. 2022, 369, 130828. [Google Scholar] [CrossRef] [PubMed]

- Raji, A.; Aliyu, J.; Igwebuike, J.; Chiroma, S. Effect of storage methods and time on egg quality traits of laying hens in a hot dry climate. ARPN J. Agric. Biol. Sci. 2009, 4, 1–7. [Google Scholar]

- LANG, E.R.; RHA, C. Apparent shear viscosity of native egg white. Int. J. Food Sci. Technol. 1982, 17, 595–606. [Google Scholar] [CrossRef]

- Severa, L.; Nedomová, Š.; Křivánek, I.; Buchar, J. Rheological properties of ageing egg yolk. Acta Univ. Agric. Silv. Mendel. Brun 2005, 53, 127–138. [Google Scholar] [CrossRef]

- Heiman, V.; Carver, J. The albumen index as a physical measurement of observed egg quality. Poult. Sci. 1936, 15, 141–148. [Google Scholar] [CrossRef]

- Silversides, F.; Scott, T.A. Effect of storage and layer age on quality of eggs from two lines of hens. Poult. Sci. 2001, 80, 1240–1245. [Google Scholar] [CrossRef]

- Nys, Y.; Bain, M.; Van Immerseel, F. Egg chemistry, production and consumption. In Improving the Safety and Quality of Eggs and Egg Products; Elsevier: Amsterdam, The Netherlands, 2011; Volume 1. [Google Scholar]

- Kashimori, A. The Illustrated Egg Handbook; Context Publications: New York, NY, USA, 2017. [Google Scholar]

- Tabidi, M.H. Impact of storage period and quality on composition of table egg. Adv. Environ. Biol. 2011, 5, 856–861. [Google Scholar]

- Hester, P.Y. Effects of temperature and storage conditions on eggs. In Egg Innovations and Strategies for Improvements; Elsevier: Amsterdam, The Netherlands, 2017; pp. 125–134. [Google Scholar]

- Parkhurst, C.; Mountney, G.J. Poultry Meat and Egg Production; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Akter, Y.; Kasim, A.; Omar, H.; Sazili, A.Q. Effect of storage time and temperature on the quality characteristics of chicken eggs. J. Food Agric. Environ. 2014, 12, 87–92. [Google Scholar]

- Grashorn, M.; Juergens, A.; Bessei, W. Effects of storage conditions on egg quality. Lohmann Inf. 2016, 50, 22–27. [Google Scholar]

- Rho, T.-G.; Park, D.-S.; Kim, J.; Cho, B.-K. Non-Destructive Measurement of Egg Air Cell using Longwave Infrared Thermal Imaging. J. Korean Soc. Nondestruct. Test. 2023, 43, 145–153. [Google Scholar] [CrossRef]

- Brake, J.; Walsh, T.; Benton, C., Jr.; Petitte, J.; Meijerhof, R.; Penalva, G. Egg handling and storage. Poult. Sci. 1997, 76, 144–151. [Google Scholar] [CrossRef] [PubMed]

- Hagan, J.K.; Eichie, F.O. Egg quality of two layer strains as influenced by extended storage periods and storage temperatures. Livest. Res. Rural Dev. 2019, 31, 145. [Google Scholar]

- Vaclavik, V.A.; Christian, E.W.; Vaclavik, V.A.; Christian, E.W. Eggs and egg products. Essent. Food Sci. 2008, 205–235. [Google Scholar]

- Ernst, R.; Bradley, F.; Delany, M.; Abbott, U.; Craig, R. Egg Candling and Breakout Analysis; UCANR Publications: Oakland, CA, USA, 2004. [Google Scholar]

- Haugh, R.R. The Haugh unit for measuring egg quality. U. S. Egg Poult. Mag. 1937, 43, 552–573. [Google Scholar]

- Jensen, L.S.; Sauter, E.; Stadelman, W. The detection and disintegration of blood spots as related to age of eggs. Poult. Sci. 1952, 31, 381–387. [Google Scholar] [CrossRef]

- Pennington, M.E.; Betts, H.M.P.; Jenkins, M.K. How to Candle Eggs; USA Department of Agriculture: Washington, DC, USA, 1918.

- Vasileva, A.; Gorbunova, E.; Vasilev, A.; Peretyagin, V.; Chertov, A.; Korotaev, V. Assessing exterior egg quality indicators using machine vision. Br. Poult. Sci. 2018, 59, 636–645. [Google Scholar] [CrossRef]

- Omid, M.; Soltani, M.; Dehrouyeh, M.H.; Mohtasebi, S.S.; Ahmadi, H. An expert egg grading system based on machine vision and artificial intelligence techniques. J. Food Eng. 2013, 118, 70–77. [Google Scholar] [CrossRef]

- Cozzolino, D.; Sanal, P.; Schreuder, J.; Williams, P.J.; Assadi Soumeh, E.; Dekkers, M.H.; Anderson, M.; Boisen, S.; Hoffman, L.C. Predicting Egg Storage Time with a Portable Near-Infrared Instrument: Effects of Temperature and Production System. Foods 2024, 13, 212. [Google Scholar] [CrossRef]

- Cruz-Tirado, J.; da Silva Medeiros, M.L.; Barbin, D.F. On-line monitoring of egg freshness using a portable NIR spectrometer in tandem with machine learning. J. Food Eng. 2021, 306, 110643. [Google Scholar] [CrossRef]

- Abdel-Nour, N.; Ngadi, M.; Prasher, S.; Karimi, Y. Prediction of egg freshness and albumen quality using visible/near infrared spectroscopy. Food Bioprocess Technol. 2011, 4, 731–736. [Google Scholar] [CrossRef]

- Kemps, B.J.; Bamelis, F.R.; De Ketelaere, B.; Mertens, K.; Tona, K.; Decuypere, E.M.; De Baerdemaeker, J.G. Visible transmission spectroscopy for the assessment of egg freshness. J. Sci. Food Agric. 2006, 86, 1399–1406. [Google Scholar] [CrossRef]

- Chen, M.; Zhang, L.; Xu, H. On-line detection of blood spot introduced into brown-shell eggs using visible absorbance spectroscopy. Biosyst. Eng. 2015, 131, 95–101. [Google Scholar] [CrossRef]

- Dong, X.; Tang, X.; Dong, J.; Shen, Z.; Li, Y.; Peng, Y.; Li, Y. Nondestructive egg freshness assessment of air chamber diameter by VIS-NIR spectroscopy. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; p. 1. [Google Scholar]

- Wang, F.; Lin, H.; Xu, P.; Bi, X.; Sun, L. Egg freshness evaluation using transmission and reflection of NIR spectroscopy coupled multivariate analysis. Foods 2021, 10, 2176. [Google Scholar] [CrossRef]

- Yao, K.; Sun, J.; Zhang, B.; Du, X.; Chen, C. On-line monitoring of egg freshness using a portable NIR spectrometer combined with deep learning algorithm. Infrared Phys. Technol. 2024, 138, 105207. [Google Scholar] [CrossRef]

- Aboonajmi, M.; Setarehdan, S.; Akram, A.; Nishizu, T.; Kondo, N. Prediction of poultry egg freshness using ultrasound. Int. J. Food Prop. 2014, 17, 1889–1899. [Google Scholar] [CrossRef]

- Aboonajmi, M.; Akram, A.; Nishizu, T.; Kondo, N.; Setarehdan, S.; Rajabipour, A. An ultrasound based technique for the determination of poultry egg quality. Res. Agric. Eng. 2010, 56, 26–32. [Google Scholar] [CrossRef]

- Qin, H.; Wang, W.; Chu, X.; Jiang, H.; Zhao, X.; Jia, B.; Yang, Y.; Kimuli, D.; Dong, A.; Wang, B. Research on the nondestructive detection of egg freshness based on image processing. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018; p. 1. [Google Scholar]

- Wang, Q.; Deng, X.; Ren, Y.; Ding, Y.; Xiong, L.; Ping, Z.; Wang, k. Egg freshness detection based on digital image technology. Sci. Res. Essay 2009, 4, 1073–1079. [Google Scholar]

- Zhang, J.; Lu, W.; Jian, X.; Hu, Q.; Dai, D. Nondestructive Detection of Egg Freshness Based on Infrared Thermal Imaging. Sensors 2023, 23, 5530. [Google Scholar] [CrossRef]

- Freni, F.; Quattrocchi, A.; Piccolo, S.; Montanini, R. Quantitative evaluation of eggs freshness using flash thermography. Quant. InfraRed Thermogr. J. 2020, 17, 13–25. [Google Scholar] [CrossRef]

- Nakaguchi, V.M.; Ahamed, T. Fast and Non-Destructive Quail Egg Freshness Assessment Using a Thermal Camera and Deep Learning-Based Air Cell Detection Algorithms for the Revalidation of the Expiration Date of Eggs. Sensors 2022, 22, 7703. [Google Scholar] [CrossRef]

- Park, B.; Lu, R. Hyperspectral Imaging Technology in Food and Agriculture; Springer: Berlin/Heidelberg, Germany, 2015; Volume 1. [Google Scholar]

- Lu, B.; Dao, P.D.; Liu, J.; He, Y.; Shang, J. Recent advances of hyperspectral imaging technology and applications in agriculture. Remote Sens. 2020, 12, 2659. [Google Scholar] [CrossRef]

- Wu, D.; Sun, D.-W. Advanced applications of hyperspectral imaging technology for food quality and safety analysis and assessment: A review—Part II: Applications. Innov. Food Sci. Emerg. Technol. 2013, 19, 15–28. [Google Scholar] [CrossRef]

- ElMasry, G.; Sun, D.-W. Principles of hyperspectral imaging technology. In Hyperspectral Imaging for Food Quality Analysis and Control; Elsevier: Amsterdam, The Netherlands, 2010; pp. 3–43. [Google Scholar]

- Kamruzzaman, M.; Sun, D.-W. Introduction to hyperspectral imaging technology. In Computer Vision Technology for Food Quality Evaluation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 111–139. [Google Scholar]

- Tao, H.; Feng, H.; Xu, L.; Miao, M.; Yang, G.; Yang, X.; Fan, L. Estimation of the yield and plant height of winter wheat using UAV-based hyperspectral images. Sensors 2020, 20, 1231. [Google Scholar] [CrossRef] [PubMed]

- Yao, K.; Sun, J.; Zhou, X.; Nirere, A.; Tian, Y.; Wu, X. Nondestructive detection for egg freshness grade based on hyperspectral imaging technology. J. Food Process Eng. 2020, 43, e13422. [Google Scholar] [CrossRef]

- Suktanarak, S.; Teerachaichayut, S. Non-destructive quality assessment of hens’ eggs using hyperspectral images. J. Food Eng. 2017, 215, 97–103. [Google Scholar] [CrossRef]

- Davari, M.; Bahreini, M.; Sabzevari, Z. Developing a non-destructive method for the detection of egg quality and freshness using micro-Raman spectroscopy. Appl. Food Res. 2024, 4, 100453. [Google Scholar] [CrossRef]

- Liu, Y.; Ren, X.; Yu, H.; Cheng, Y.; Guo, Y.; Yao, W.; Xie, Y. Non-destructive and online egg freshness assessment from the egg shell based on Raman spectroscopy. Food Control 2020, 118, 107426. [Google Scholar] [CrossRef]

- Karoui, R.; Schoonheydt, R.; Decuypere, E.; Nicolaï, B.; De Baerdemaeker, J. Front face fluorescence spectroscopy as a tool for the assessment of egg freshness during storage at a temperature of 12.2 C and 87% relative humidity. Anal. Chim. Acta 2007, 582, 83–91. [Google Scholar] [CrossRef]

- Karoui, R.; Kemps, B.; Bamelis, F.; De Ketelaere, B.; Merten, K.; Schoonheydt, R.; Decuypere, E.; De Baerdemaeker, J. Development of a rapid method based on front face fluorescence spectroscopy for the monitoring of egg freshness: 1—Evolution of thick and thin egg albumens. Eur. Food Res. Technol. 2006, 223, 303–312. [Google Scholar] [CrossRef]

- Karoui, R.; Kemps, B.; Bamelis, F.; De Ketelaere, B.; Merten, K.; Schoonheydt, R.; Decuypere, E.; De Baerdemaeker, J. Development of a rapid method based on front-face fluorescence spectroscopy for the monitoring of egg freshness: 2—Evolution of egg yolk. Eur. Food Res. Technol. 2006, 223, 180–188. [Google Scholar] [CrossRef]

- Karoui, R.; Nicolaï, B.; De Baerdemaeker, J. Monitoring the egg freshness during storage under modified atmosphere by fluorescence spectroscopy. Food Bioprocess Technol. 2008, 1, 346–356. [Google Scholar] [CrossRef]

- Hu, M.; Zhao, M.; Qi, L.; Li, D.; Wang, X.; Li, Z.; Zhao, S.; Fan, K. Non-destructive inspection method for egg freshness evaluation via low-field nuclear magnetic resonance technology. J. Food Meas. Charact. 2024, 18, 7295–7307. [Google Scholar] [CrossRef]

- Tan, W.; Zhang, Q.; Yang, L.; Tian, L.; Jia, J.; Lu, M.; Liu, X.; Duan, X. Actual time determination of egg freshness: A centroid rate based approach. Food Packag. Shelf Life 2020, 26, 100574. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).