The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes

Abstract

:1. Introduction

2. Materials and Methods

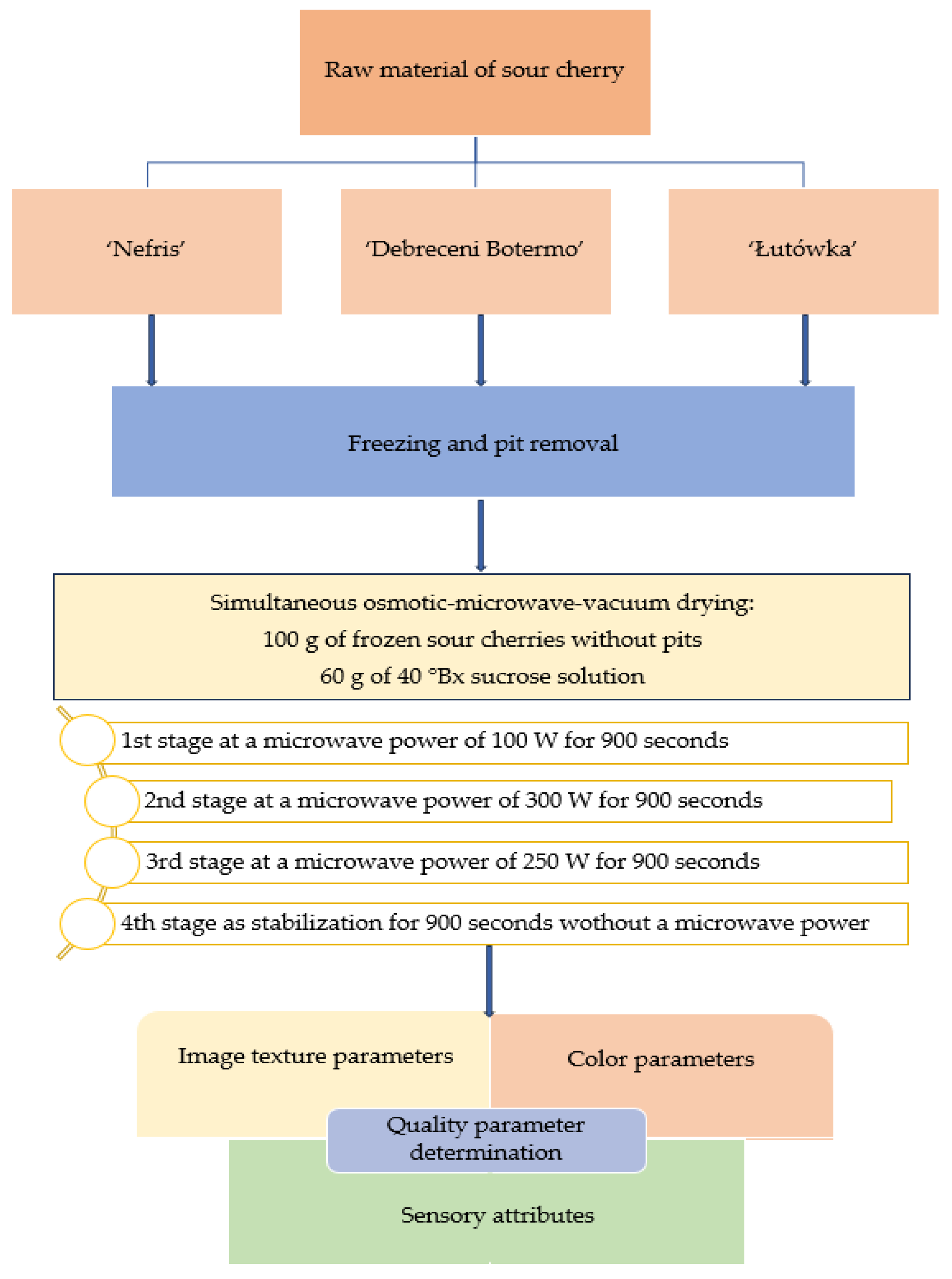

2.1. Materials

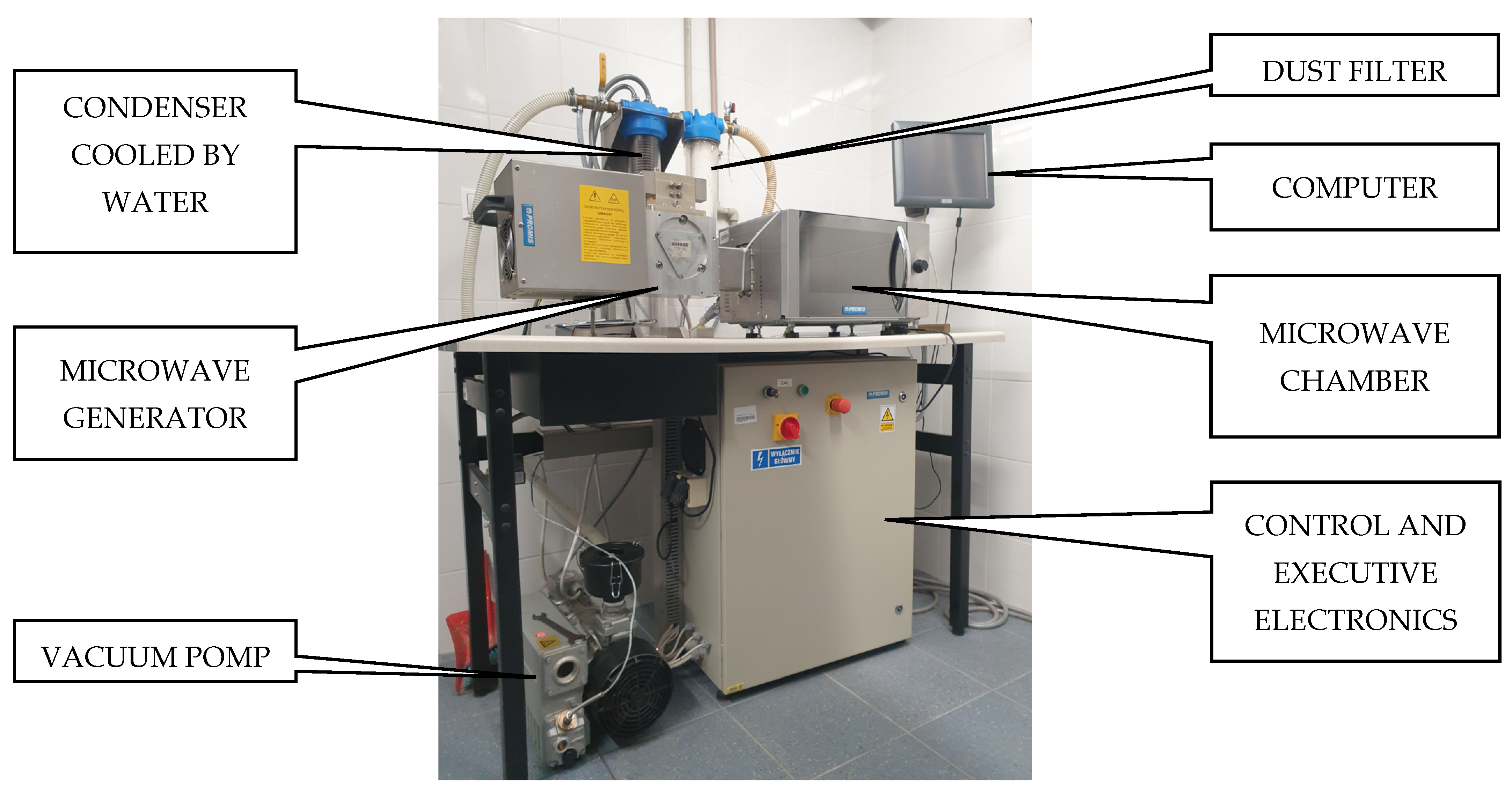

2.2. Drying Experiment

2.3. Image Analysis

2.4. Color Measurements

2.5. Sensory Analysis

2.6. Statistical Analysis

3. Results

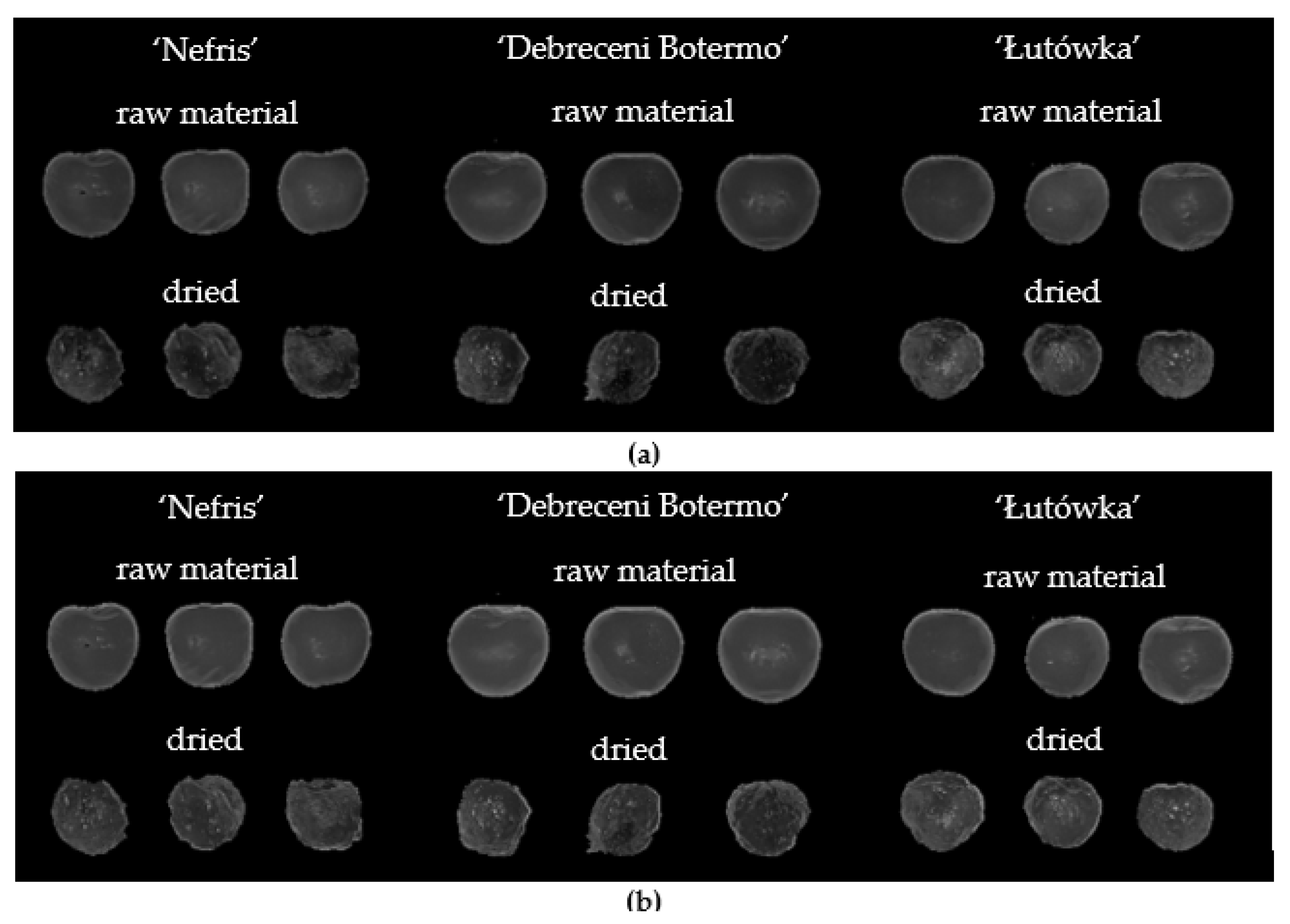

3.1. The Influence of Osmotic–Microwave–Vacuum Drying on Image Textures of Sour Cherries

3.2. The Influence of Osmotic–Microwave–Vacuum Drying on Color Parameters of Sour Cherries

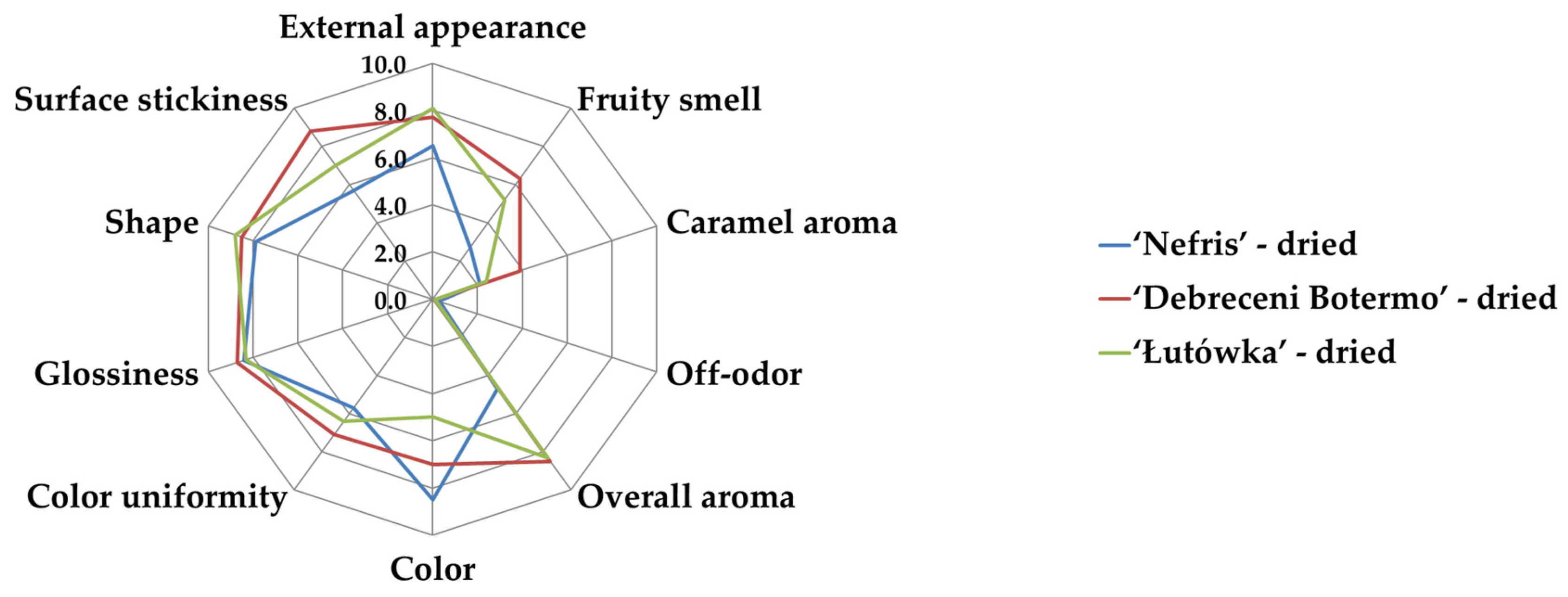

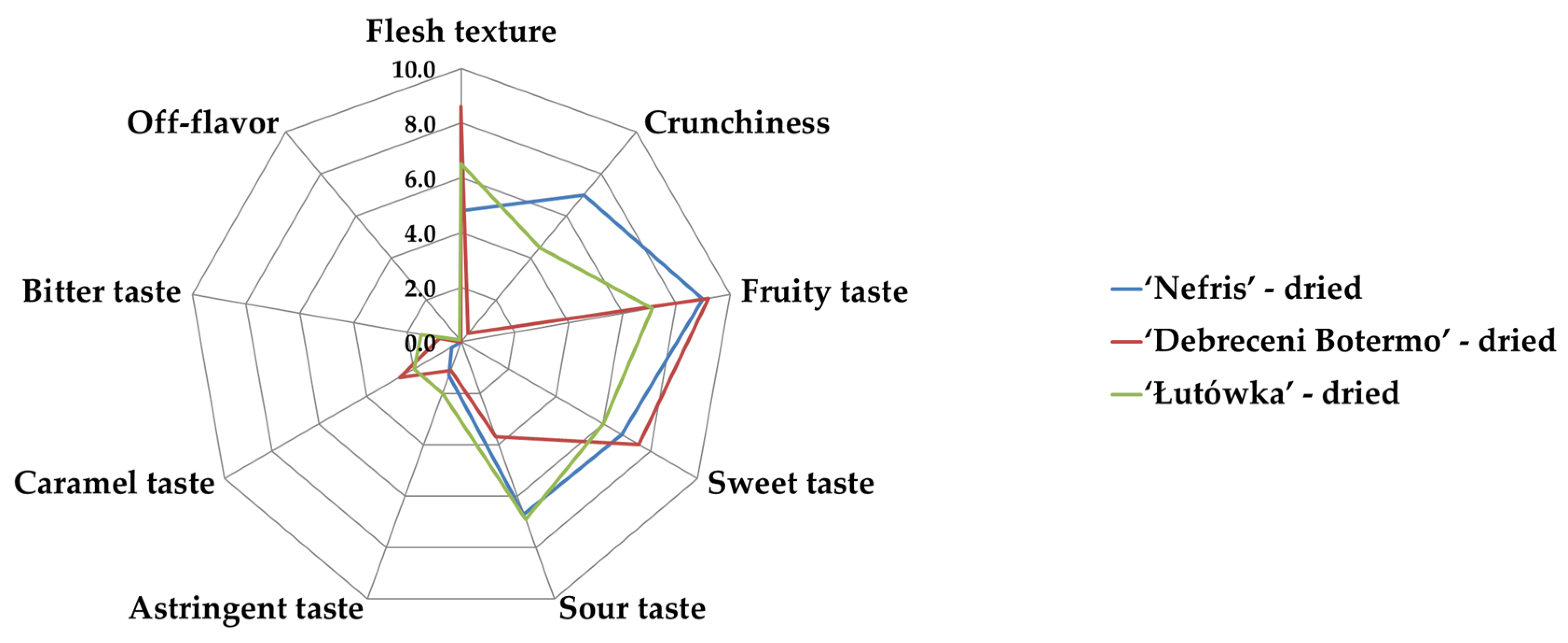

3.3. The Influence of Osmotic–Microwave–Vacuum Drying on Sensory Attributes of Sour Cherries

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Salehi, F.; Inanloodoghouz, M. Effects of gum-based coatings combined with ultrasonic pretreatment before drying on quality of sour cherries. Ultrason. Sonochem. 2023, 100, 106633. [Google Scholar] [CrossRef] [PubMed]

- Celejewska, K.; Mieszczakowska-Frąc, M.; Konopacka, D. The effect of hybrid drying (convective-microwave-ultrasound) on the bioactive properties of osmo-treated sour cherries. J. Hortic. Res. 2018, 26, 23–36. [Google Scholar] [CrossRef]

- Popovic, B.M.; Micic, N.; Potkonjak, A.; Blagojevic, B.; Pavlovic, K.; Milanov, D.; Juric, T. Novel extraction of polyphenols from sour cherry pomace using natural deep eutectic solvents—Ultrafast microwave-assisted NADES preparation and extraction. Food Chem. 2022, 366, 130562. [Google Scholar] [CrossRef] [PubMed]

- Wojdyło, A.; Figiel, A.; Lech, K.; Nowicka, P.; Oszmiański, J. Effect of convective and vacuum–microwave drying on the bioactive compounds, color, and antioxidant capacity of sour cherries. Food Bioprocess Technol. 2014, 7, 829–841. [Google Scholar] [CrossRef]

- Veres, Z.; Holb, I.; Nyéki, J.; Szabó, Z.; Szabó, T.; Remenyik, J.; Fári, M.G. Antioxidant and anthocyanin contents of tart cherry cultivars. Acta Hortic. 2008, 795, 787–792. [Google Scholar] [CrossRef]

- Abrankó, L.; Nagy, Á.; Szilvássy, B.; Stefanovits-Bányai, É.; Hegedűs, A. Genistein isoflavone glycoconjugates in sour cherry (Prunus cerasus L.) cultivars. Food Chem. 2015, 166, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Homoki, J.R.; Nemes, A.; Fazekas, E.; Gyémánt, G.; Balogh, P.; Gál, F.; Al-Asri, J.; Mortier, J.; Wolber, G.; Babinszky, L.; et al. Anthocyanin composition, antioxidant efficiency, and α-amylase inhibitor activity of different Hungarian sour cherry varieties (Prunus cerasus L.). Food Chem. 2016, 194, 222–229. [Google Scholar] [CrossRef] [PubMed]

- Głowacka, A.; Rozpara, E.; Hallmann, E. The Dynamic of Polyphenols Concentrations in Organic and Conventional Sour Cherry Fruits: Results of a 4-Year Field Study. Molecules 2020, 25, 3729. [Google Scholar] [CrossRef]

- Clausen, S.K.; Andersen, S.B.; Henriksen, K.; Toldam-Andersen, T.; Grout, B.W.W. Assessment of genetic diversity within sour cherry clones. Sci. Hortic. 2013, 164, 556–562. [Google Scholar] [CrossRef]

- Grafe, C.; Schuster, M. Physicochemical Characterization of Fruit Quality Traits in a German Sour Cherry Collection. Sci. Hortic. 2014, 180, 24–31. [Google Scholar] [CrossRef]

- Konopacka, D.; Markowski, J.; Plocharski, W.; Rozpara, E. New or lesser known cultivar selection as a tool for sensory and nutritional value enhancement of osmo-convectively dried sour cherries. LWT-Food Sci. Technol. 2014, 55, 506–512. [Google Scholar] [CrossRef]

- Šumić, Z.; Tepić, A.; Vidović, S.; Jokić, S.; Malbaša, R. Optimization of frozen sour cherries vacuum drying process. Food Chem. 2013, 136, 55–63. [Google Scholar] [CrossRef]

- Siucińska, K.; Mieszczakowska-Frąc, M.; Połubok, A.; Konopacka, D. Effects of Ultrasound Assistance on Dehydration Process and Bioactive Component Retention of Osmo-Dried Sour Cherries. J. Food Sci. 2016, 81, C1654–C1661. [Google Scholar] [CrossRef] [PubMed]

- Milić, A.; Daničić, T.; Tepić Horecki, A.; Šumić, Z.; Bursać Kovačević, D.; Putnik, P.; Pavlić, B. Maximizing Contents of Phytochemicals Obtained from Dried Sour Cherries by Ultrasound-Assisted Extraction. Separations 2021, 8, 155. [Google Scholar] [CrossRef]

- Salehi, F.; Inanloodoghouz, M.; Ghazvineh, S. Influence of microwave pretreatment on the total phenolics, antioxidant activity, moisture diffusivity, and rehydration rate of dried sweet cherry. Food Sci. Nutr. 2023, 11, 7870–7876. [Google Scholar] [CrossRef] [PubMed]

- Nowicka, P.; Wojdyło, A.; Lech, K.; Figiel, A. Influence of osmodehydration pretreatment and combined drying method on the bioactive potential of sour cherry fruits. Food Bioprocess Technol. 2015, 8, 824–836. [Google Scholar] [CrossRef]

- Konopacka, D.; Piecko, J.; Krawczyk, Ł.; Kowalska, W.; Celejewska, K. Method of Drying. Fruit. Patent PL 236950 B1, 8 March 2021. (In Polish). [Google Scholar]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A. Mazda—A software for texture analysis. In Proceedings of the 2007 International Symposium on Information Technology Convergence (ISITC 2007), Jeonju, Republic of Korea, 23–24 November 2007; pp. 245–249. [Google Scholar]

- Szczypiński, P.M.; Strzelecki, M.; Materka, A.; Klepaczko, A. MaZda—A software package for image texture analysis. Comput. Methods Programs Biomed. 2009, 94, 66–76. [Google Scholar] [CrossRef]

- Strzelecki, M.; Szczypiński, P.; Materka, A.; Klepaczko, A. A software tool for automatic classification and segmentation of 2D/3D medical images. Nucl. Instrum. Methods Phys. Res. Sect. Accel. Spectrom. Detect. Assoc. Equip. 2013, 702, 137–140. [Google Scholar] [CrossRef]

- PN-EN ISO 13299:2016-05; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. International Organization for Standardization (ISO): Geneva, Switzerland, 2016.

- PN-EN ISO 8589:2010/A1:2014–07; Sensory Analysis. General Guidance for the Design of Test Rooms. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- PN-EN ISO 8586:2014-03; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization (ISO): Geneva, Switzerland, 2014.

- Horuz, E.; Bozkurt, H.; Karataş, H.; Maskan, M. Effects of Hybrid (Microwave-Convectional) and Convectional Drying on Drying Kinetics, Total Phenolics, Antioxidant Capacity, Vitamin C, Color and Rehydration Capacity of Sour Cherries. Food Chem. 2017, 230, 295–305. [Google Scholar] [CrossRef]

- Siucińska, K.; Konopacka, D.; Mieszczakowska-Frąc, M.; Połubok, A. The effects of ultrasound on quality and nutritional aspects of dried sour cherries during shelf-life. LWT Food Sci. Technol. 2016, 68, 168–173. [Google Scholar] [CrossRef]

- Simsek, M.; Süfer, Ö. Influence of different pretreatments on hot air and microwave-hot air combined drying of white sweet cherry. Turk. J. Agric.-Food Sci. Technol. 2021, 9, 1172–1179. [Google Scholar] [CrossRef]

- Piecko, J.; Konopacka, D.; Mieszczakowska-Frąc, M.; Kruczyńska, D.; Celejewska, K. Drying kinetic and selected physico—Chemical properties of fresh cranberries preserved with microwave—Vacuum process. In Proceedings of the IDS’2018—21st International Drying Symposium, Valencia, Spain, 11–14 September 2018; pp. 1927–1934. [Google Scholar]

- Przybył, K.; Duda, A.; Koszela, K.; Stangierski, J.; Polarczyk, M.; Gierz, Ł. Classification of Dried Strawberry by the Analysis of the Acoustic Sound with Artificial Neural Networks. Sensors 2020, 20, 499. [Google Scholar] [CrossRef] [PubMed]

- Przybył, K.; Gawałek, J.; Koszela, K. Application of Artificial Neural Network for the Quality-Based Classification of Spray-Dried Rhubarb Juice Powders. J. Food Sci. Technol. 2023, 60, 809–819. [Google Scholar] [CrossRef] [PubMed]

- Bisri, A.; Man, M. Machine Learning Algorithms Based on Sampling Techniques for Raisin Grains Classification. Int. J. Inform. Vis. 2023, 7, 7–14. [Google Scholar] [CrossRef]

- Baigvand, M.; Banakar, A.; Minaei, S.; Khodaei, J.; Behroozi-Khazaei, N. Machine vision system for grading of dried figs. Comput. Electron. Agric. 2015, 119, 158–165. [Google Scholar] [CrossRef]

- Raihen, M.N.; Akter, S. Prediction modeling using deep learning for the classification of grape-type dried fruits. Int. J. Math. Comput. Eng. 2024, 2, 1–12. [Google Scholar] [CrossRef]

- Fouda, T.; Shimaa, S. Using imaging analyses to predict chemical properties of orange fruits. Sci. Pap. Manag. Econ. Eng. Agric. Rural Dev. 2014, 14, 83–86. [Google Scholar]

- Baiano, A.; Terracone, C.; Peri, G.; Romaniello, R. Application of hyperspectral imaging for prediction of physico-chemical and sensory characteristics of table grapes. Comput. Electron. Agric. 2012, 87, 142–151. [Google Scholar] [CrossRef]

- Karydas, C.; Iatrou, M.; Kouretas, D.; Patouna, A.; Iatrou, G.; Lazos, N.; Gewehr, S.; Tseni, X.; Tekos, F.; Zartaloudis, Z.; et al. Prediction of Antioxidant Activity of Cherry Fruits from UAS Multispectral Imagery Using Machine Learning. Antioxidants 2020, 9, 156. [Google Scholar] [CrossRef]

| Boundary Values | ||

|---|---|---|

| Attribute | 0—Minimum | 10—Maximum |

| External appearance | Non-attractive | Very attractive |

| Fruity smell | Imperceptible | Very intense |

| Caramel aroma | Imperceptible | Very intense |

| Off-odor | Imperceptible | Very intense |

| Overall aroma | Unpleasant, irritating | Very pleasant |

| Color | Bright | Dark |

| Color uniformity | Non-uniform | Uniform |

| Glossiness | Matte | Glossy |

| Shape | Strongly deformed | Close to round |

| Surface stickiness | Dry | Very sticky |

| Flesh texture | Very hard | Soft |

| Crunchiness | No sound or short, quiet sound | Long, loud sound |

| Fruity taste | Imperceptible | Very intense |

| Sweet taste | Imperceptible | Very intense |

| Sour taste | Imperceptible | Very intense |

| Astringent taste | Imperceptible | Very intense |

| Caramel taste | Imperceptible | Very intense |

| Bitter taste | Imperceptible | Very intense |

| Off-flavor | Imperceptible | Very intense |

| Flavor | Empty, uncharacteristic | Rich, aromatic, palatable |

| Overall quality | Poor quality, unharmonized | Very good quality, harmonized |

| Sample | RHMean | GHMean | BHMean | LHMean | aHMean | bHMean | XHMean | YHMean | ZHMean |

|---|---|---|---|---|---|---|---|---|---|

| ‘Nefris’—raw material | 45.51 (8.18) a | 26.28 (2.97) a | 27.00 (4.35) a | 60.59 (4.61) a | 134.39 (2.79) a | 130.02 (1.27) a | 5.11 (1.09) a | 4.48 (0.77) a | 3.64 (0.77) a |

| ‘Nefris’—dried | 41.56 (3.87) b | 21.78 (2.09) b | 23.64 (2.29) b | 55.83 (2.57) b | 134.93 (1.26) a | 129.66 (2.29) a | 4.24 (0.65) b | 3.52 (0.55) b | 2.88 (0.52) b |

| ‘Debreceni Botermo’—raw material | 49.81 (5.06) a | 31.19 (4.32) a | 32.24 (5.55) a | 65.37 (4.67) a | 134.12 (0.97) a | 129.53 (0.90) a | 6.40 (1.27) a | 5.81 (1.20) a | 4.98 (1.33) a |

| ‘Debreceni Botermo’—dried | 45.29 (10.18) b | 25.97 (11.50) b | 27.79 (11.02) b | 60.35 (11.05) b | 134.60 (2.65) a | 129.55 (1.25) a | 5.08 (2.85) b | 4.45 (2.84) b | 3.78 (2.76) b |

| ‘Łutówka’—raw material | 54.60 (7.89) a | 30.69 (3.83) a | 32.25 (5.01) a | 66.93 (4.96) a | 136.07 (2.32) a | 130.43 (1.49) a | 6.90 (1.35) a | 5.97 (1.06) a | 4.93 (1.10) a |

| ‘Łutówka’—dried | 47.37 (9.88) b | 22.64 (10.32) b | 24.88 (9.80) b | 59.07 (9.61) b | 136.66 (3.35) a | 130.60 (1.95) a | 4.97 (2.82) b | 4.04 (2.85) b | 3.18 (2.79) b |

| Sample | L* | a* | b* | ΔE |

|---|---|---|---|---|

| ‘Nefris’—raw material | 21.89 (3.64) a | 13.80 (6.33) a | 7.56 (3.47) a | 1.98 |

| ‘Nefris’—dried | 21.85 (2.92) a | 12.02 (3.68) a | 6.69 (1.43) a | |

| ‘Debreceni Botermo’—raw material | 20.79 (3.13) a | 11.67 (2.32) a | 5.72 (2.09) a | 10.44 |

| ‘Debreceni Botermo’—dried | 28.90 (11.28) b | 8.18 (2.23) b | 0.14 (1.62) b | |

| ‘Łutówka’—raw material | 21.99 (3.15) a | 13.60 (4.48) a | 6.89 (2.75) a | 6.30 |

| ‘Łutówka’—dried | 27.04 (3.08) b | 16.95 (4.17) b | 5.18 (2.57) b |

| Dried Sample | Overall Quality (0–10) | Flavor (0–10) |

|---|---|---|

| ‘Nefris’ | 8.9 (0.9) | 9.0 (1.0) |

| ‘Debreceni Botermo’ | 8.9 (1.2) | 7.6 (0.7) |

| ‘Łutówka’ | 8.8 (1.1) | 8.9 (0.6) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ropelewska, E.; Konopacka, D.; Piecko, J. The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes. Agriculture 2024, 14, 54. https://doi.org/10.3390/agriculture14010054

Ropelewska E, Konopacka D, Piecko J. The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes. Agriculture. 2024; 14(1):54. https://doi.org/10.3390/agriculture14010054

Chicago/Turabian StyleRopelewska, Ewa, Dorota Konopacka, and Jan Piecko. 2024. "The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes" Agriculture 14, no. 1: 54. https://doi.org/10.3390/agriculture14010054

APA StyleRopelewska, E., Konopacka, D., & Piecko, J. (2024). The Quality Assessment of Sour Cherries Dried Using an Innovative Simultaneous Osmotic–Microwave–Vacuum Approach Based on Image Textures, Color Parameters, and Sensory Attributes. Agriculture, 14(1), 54. https://doi.org/10.3390/agriculture14010054