The Effect of Drying Variables on the Microwave–Vacuum-Drying Characteristics of Mulberries (Morus alba L.): Experiments and Multivariate Models

Abstract

:1. Introduction

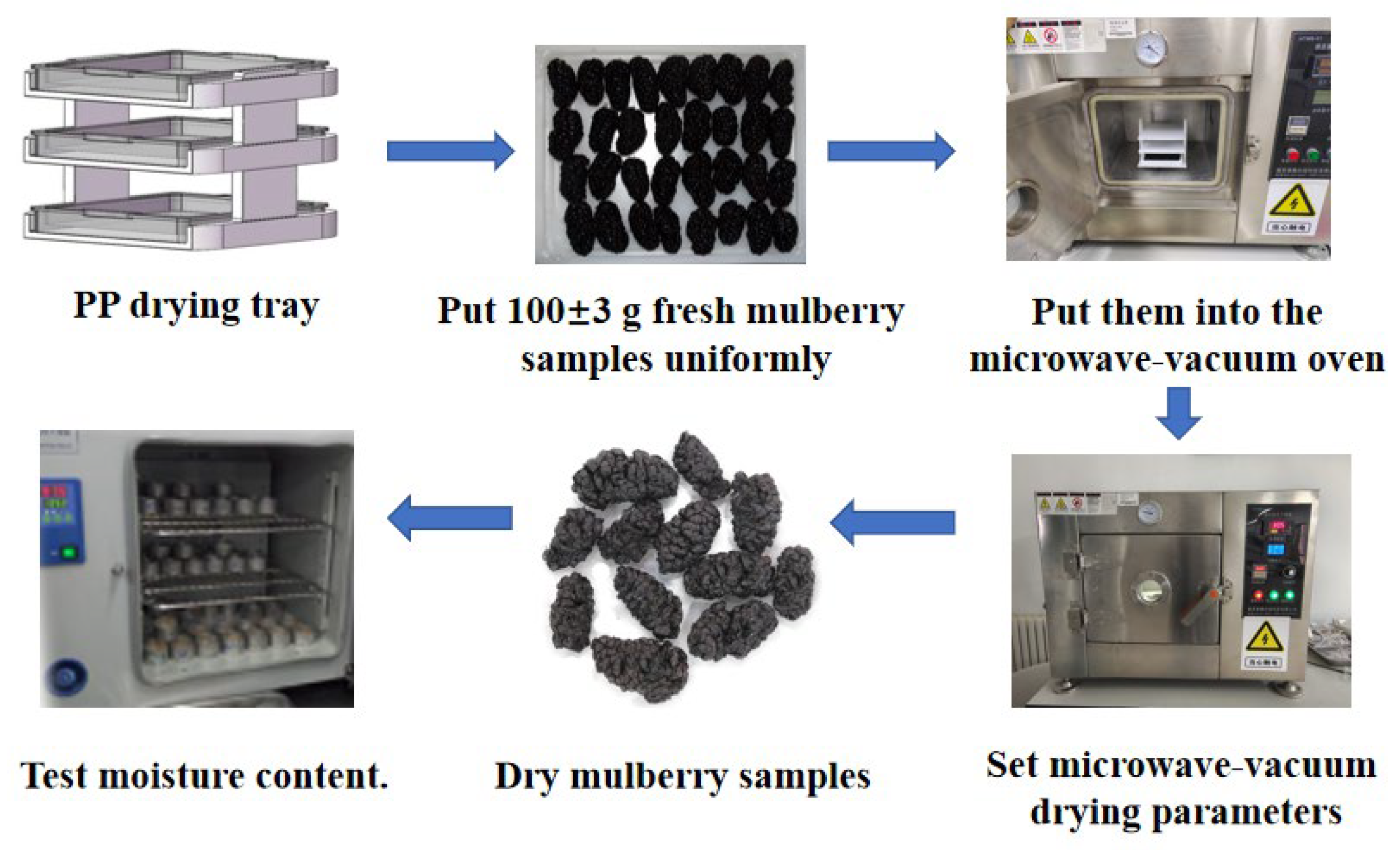

2. Methods

2.1. Materials and Methods

2.2. Test and Calculation of Parameters

2.2.1. Determination of Moisture Content

- —wet-based moisture content of the mulberries, %;

- —dry-based moisture content of the mulberries, %;

- —total mass of the mulberries, g, and —the dry material mass of the mulberries, g.

2.2.2. Calculation of Moisture Ratio

- MR—moisture ratio of the mulberries;

- —dry-based mulberry moisture content at t, %;

- —wet-based mulberry moisture content at t, %;

- —balanced dry-based moisture content of the mulberries, %.

2.2.3. Calculation of Drying Rate

- DR—drying rate of mulberries;

- —dry-based moisture content of mulberries at , g/g;

- —dry-based moisture content of mulberries at , g/g.

2.2.4. Crispness

2.2.5. Sensory Evaluation

2.2.6. Analysis of Data

3. Results and Discussion

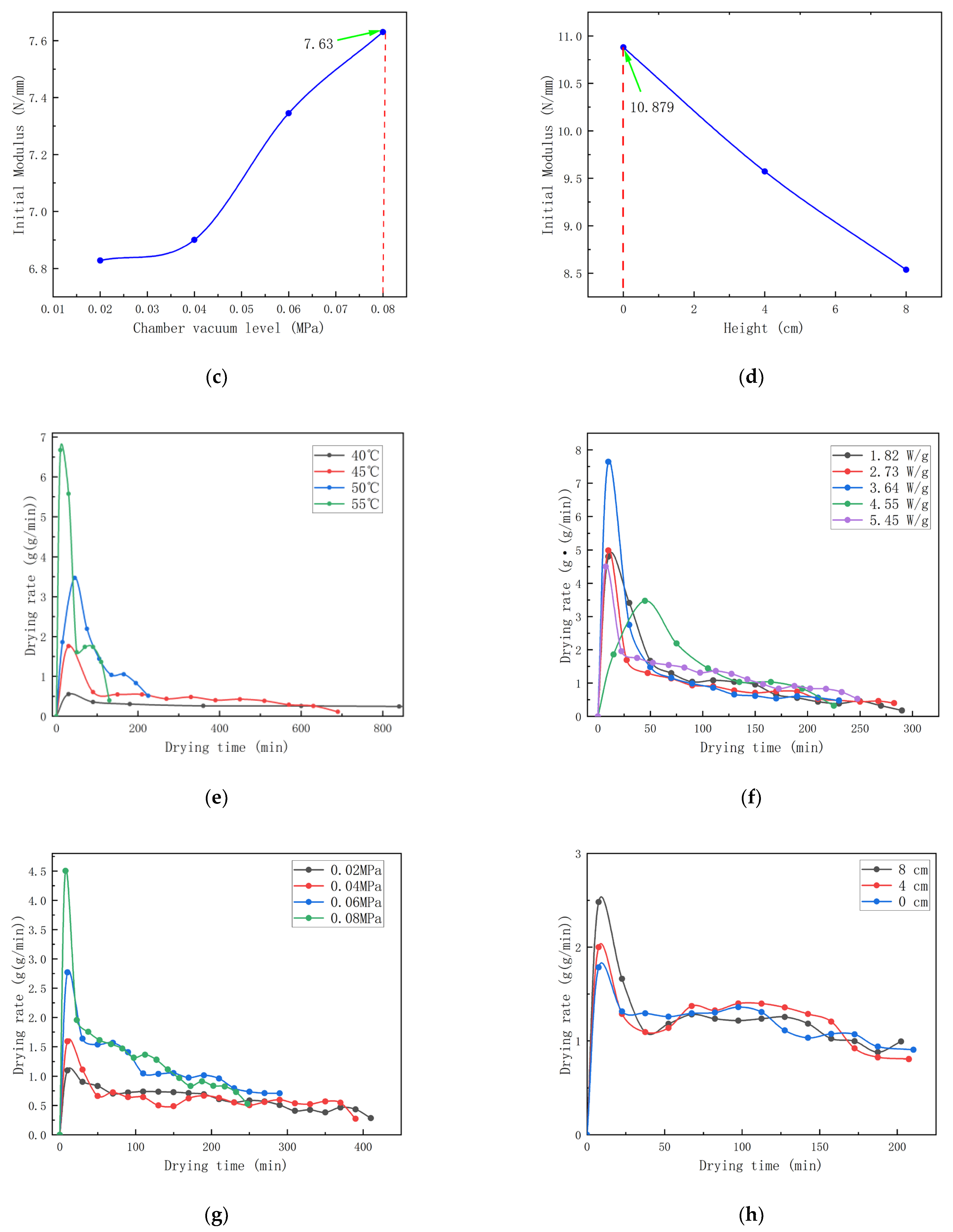

3.1. Effects of Product Surface Temperature on Crispness

3.2. Effects of Microwave Power on the Crispness of Mulberries

3.3. Effects of Chamber Vacuum Level on the Crispness of Mulberries

3.4. Effects of Drying Height on the Crispness of Mulberries

3.5. Influence of Different Control Parameters on the Sensory Evaluation of Dried Mulberries

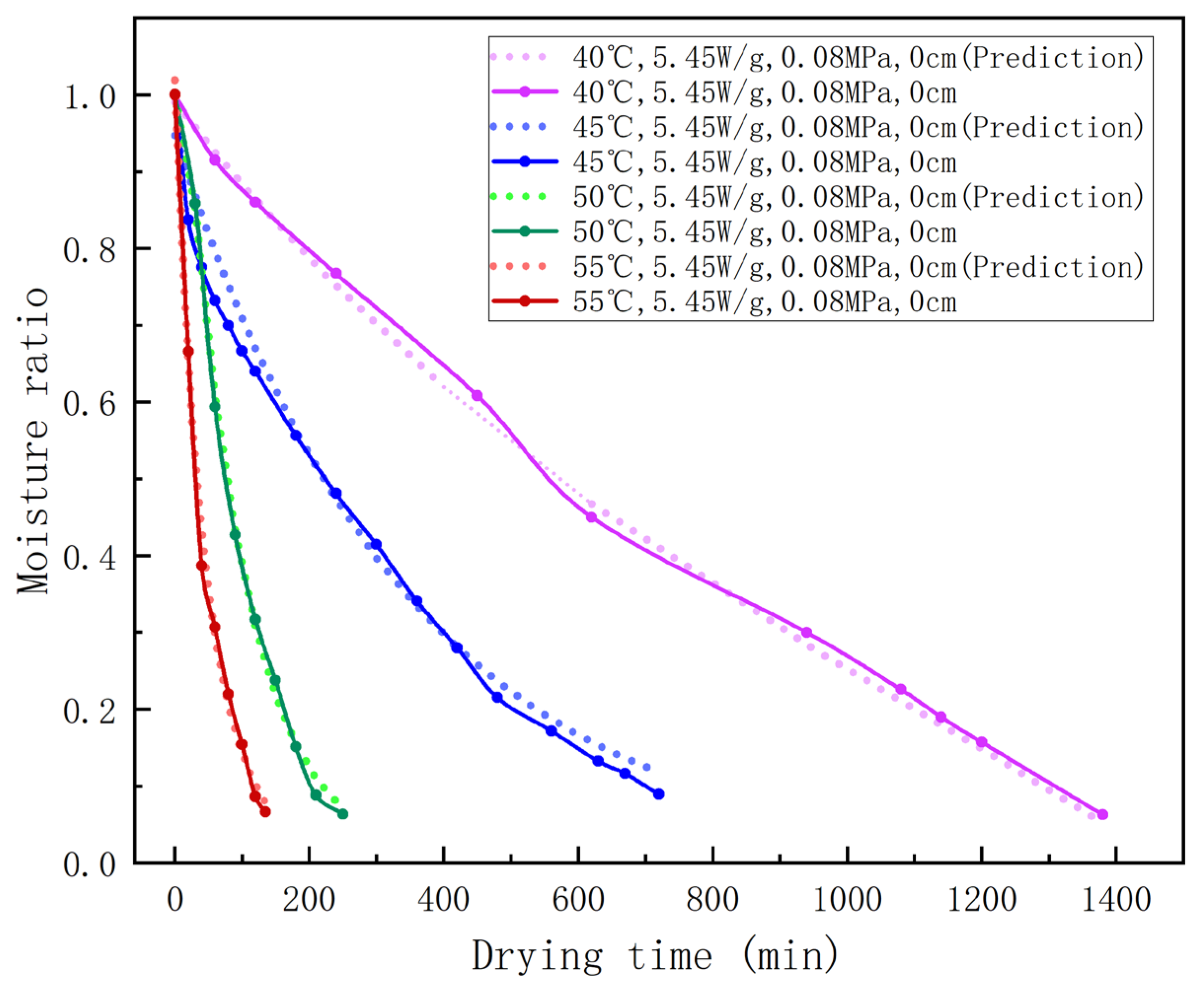

3.6. Drying Kinetic Model of Mulberries

3.7. Verification of the Drying Kinetic Model

3.8. Verification of the Humidity–Heat Transfer Model

4. Calculation of the Effective Water Diffusion Coefficient and Activation Energy

4.1. Effective Water Diffusion Coefficient

4.2. Calculation of Activation Energy

4.3. Calculation of the Diffusion Coefficient of Available Water in Mulberries

4.4. Calculation of Activation Energy of Dried Mulberries

5. Conclusions

- (1)

- The Two-term model is the most accurate at predicting the dehydration process of mulberries in the microwave–vacuum-drying apparatus, according to a comparative analysis of drying models. Moreover, the optimal equation coefficients that are applicable to temperature, power, vacuum degree and drying height are determined.

- (2)

- In the microwave–vacuum-drying process of mulberries, the temperature, power and chamber vacuum level are the major influencing factors of the drying rate of the mulberries. Microwave power is the primary cause of the increasing crispness of dried mulberries.

- (3)

- The technological parameters to achieve the highest crispness under microwave–vacuum-drying conditions include temperature = 50 °C, power = 5.45 W/g, chamber vacuum level = 0.08 MPa and local tray height = 0 cm.

- (4)

- The diffusion coefficient of the available water during the microwave–vacuum-drying of mulberries ranges from 4.98 × 10−8 to 3.81 × 10−7, and it is positively related to temperature. The drying activation energy of mulberries is 183.923 KJ/mol.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rahimi, N.; Ahraritabas, A.; Ansarifar, E. Optimization of ultrasound-assisted osmotic dehydration of white mulberry. J. Food Process. Preserv. 2022, 46, e16966. [Google Scholar] [CrossRef]

- Kıpçak, A.S. Drying characteristics investigation of black mulberry dyied via infrared method. J. Therm. Eng. 2019, 5, 13–21. [Google Scholar] [CrossRef]

- Jiménez-González, O.; López-Malo, A.; González-Pérez, J.E.; Ramírez-Corona, N.; Guerrero-Beltrán, J.Á. Thermal and pH stability of justicia spicigera (mexican honeysuckle) pigments: Application of mathematical probabilistic models to predict pigments stability. Food Chem. Mol. Sci. 2023, 6, 100158. [Google Scholar] [CrossRef] [PubMed]

- Dai, J.; Yang, S.L.; Wang, J.; Wen, M.D.; Fu, Q.Q.; Huang, H. Effect of Microwave Vacuum Drying Conditions on Drying Characteristics and Texture Structure of Banana Chips. Trans. Chin. Soc. Agric. Mach. 2020, 51, 493–500. [Google Scholar]

- Monteiro, R.L.; Carciofi, B.A.M.; Laurindo, J.B. A microwave multi-flash drying process for producing crispy bananas. J. Food Eng. 2016, 178, 1–11. [Google Scholar] [CrossRef]

- Sun, J.R. Study on Microwave-Vacuum Freeze-Drying Technology of Oyster Mushroom and Preparation of Its Crispy Skin. Ph.D. Thesis, Shaanxi Normal University, Xi’an, China, 2019. [Google Scholar]

- Qi, L.L. Study on the Processing of Lentinus Edodes Crisps Using Dried Lentinus Edodes as Raw Materials. Ph.D. Thesis, Jiangnan University, Wuxi, China, 2013. [Google Scholar]

- Ekow, A.E.; Haile, M.A.; John, O.; Narku, E.F. Microwave-vacuum drying effect on drying kinetics, lycopene and ascorbic acid content of tomato slices. J. Stored Prod. Postharvest Res. 2013, 4, 11–22. [Google Scholar] [CrossRef]

- Dak, M.; Jain, M.K.; Jat, S.L. Optimization of microwave-vacuum drying of pomegranate arils. J. Food Meas. Charact. 2014, 8, 398–411. [Google Scholar] [CrossRef]

- Lukić, K.; Brnčić, M.; Ćurko, N.; Tomašević, M.; Valinger, D.; Denoya, G.I.; Barba, F.J.; Ganić, K.K. Effects of high power ultrasound treatments on the phenolic, chromatic and aroma composition of young and aged red wine. Ultrason. Sonochem. 2019, 59, 104725. [Google Scholar] [CrossRef]

- Puttalingappa, Y.J.; Natarajan, V.; Varghese, T.; Naik, M. Effect of microwave-assisted vacuum drying on the drying kinetics and quality parameters of Moringa oleifera leaves. J. Food Process Eng. 2022, 45, e14054. [Google Scholar] [CrossRef]

- Kiranoudis, C.T.; Tsami, E.; Maroulis, Z.B. Microwave vacuum drying kinetics of somefruits. Dry. Technol. 1997, 15, 2421–2440. [Google Scholar] [CrossRef]

- McMinn, W.A.M. Thin-layer modeling of the convective, microwave, microwave-convectiveand microwave-vacuum drying of lactose powder. J. Food Eng. 2006, 72, 113–123. [Google Scholar] [CrossRef]

- Giri, S.K.; Prasad, S. Drying kinetics and rehydration characteristics ofmicrowave-vacuum and convective hot-air mushrooms. J. Food Eng. 2005, 78, 512–521. [Google Scholar] [CrossRef]

- Wang, J.; Law, C.L.; Nema, P.K.; Zhao, J.H.; Liu, Z.L.; Deng, L.Z.; Gao, Z.J.; Xiao, H.W. Pulsed vacuum drying enhances drying kinetics andquality of lemon slices. J. Food Eng. 2018, 224, 129–138. [Google Scholar] [CrossRef]

- Xiao, H.W.; Pang, C.L.; Wang, L.H.; Bai, J.W.; Yang, W.X.; Gao, Z.J. Drying kinetics and quality of Monukkaseedless grapes dried in an air-impingement jet dryer. Biosyst. Eng. 2010, 105, 233–240. [Google Scholar] [CrossRef]

- Ju, H.Y.; El-Mashad, H.M.; Fang, X.M.; Pan, Z.L.; Xiao, H.W.; Liu, Y.H.; Gao, Z.J. Drying characteristics and modeling of yamslices under different relative humidity conditions. Dry. Technol. 2016, 34, 296–306. [Google Scholar] [CrossRef]

- Hawlader, M.N.A.; Perera, C.O.; Tian, M. Properties of modified atmosphere heat pump dried foods. J. Food Eng. 2006, 74, 392–401. [Google Scholar] [CrossRef]

- Zhang, F.; Huang, Y.L.; Kang, S.J.; Li, M.Z.; Zeng, Z.Z. Optimization of the Freezing-explosion Puffing Drying for Lanzhou Lily. Sci. Technol. Food Ind. 2019, 40, 167–173. [Google Scholar]

- GBT 16860-1997; Sensory Analysis Method Inspection of Texture Profile. State Technical Supervision Bureau: Beijing, China, 1997.

- Zhou, W.D.; Wang, H.; Wang, D.; Du, Y.H.; Zhang, K.; Qiao, Y. An experimental investigation on the influence of coal brittleness on dust generation. Powder Technol. 2020, 364, 457–466. [Google Scholar] [CrossRef]

- Tang, X.H.; Li, C.Y.; Huang, D.; Xu, Y.H.; Zhang, H.; Gong, Y.J. Microwave vacuum drying characteristics of oil camellia seed. J. Cent. South Univ. Technol. 2021, 41, 139–146+166. [Google Scholar]

- Lao, Y.Y.; Zhang, M.; Sakamon, D.; Ye, Y.F. Effect of combined infrared freeze drying andmicrowave vacuum drying on quality of kale yoghurt melts. Dry. Technol. 2020, 38, 621–633. [Google Scholar] [CrossRef]

- Paula, A.M.; Conti-Silva, A.C. Texture profile and correlation between sensory and instrumental analyses on extruded snacks. J. Food Eng. 2014, 121, 9–14. [Google Scholar] [CrossRef]

- Lewicki, P.P.; Pawlak, G. Effect of drying on microstructure of plant tissue. Dry. Technol. 2003, 21, 657–683. [Google Scholar] [CrossRef]

- Suwanchote, C.; Weerakul, J.; Sirisathitkul, C.; Nisoa, M. Color and hardness of durian chips irradiated bycontrolled low power microwave. Food Sci. Biotechnol. 2012, 21, 1767–1770. [Google Scholar] [CrossRef]

- Lv, H.; Lv, W.Q.; Cui, Z.W.; Lv, H.Z.; Ma, J.W.; Zhao, D. Analysis on drying characteristics of apple slices under different microwave conditions. Trans. Chin. Soc. Agric. 2018, 49, 433–439. [Google Scholar]

- Duan, L.L. Characteristics and regulation of porous morphological of chineseyam during microwave freeze-drying (MFD). Master’s Thesis, Henan University of Science and Technology, Luoyang, China, 2019. [Google Scholar]

- Li, W.Q.; Wan, F.X.; Luo, Y.; Wei, B.; Huang, X.P. Study on far infrared drying characteristics and dynamics of angelica sinensis slices. Chin. Tradit. Herb. Drugs 2019, 50, 4320–4328. [Google Scholar]

- Ikechukwu, G.A.; Nna, O.S. Statistical determination of the drying characteristics of thin layer ginger rhizomes. In Transactions on Engineering Technologies: World Congress on Engineering and Computer Science; Springer: Singapore, 2021; pp. 189–208. [Google Scholar]

- Guo, M.H.; Zhao, X.P.; Yan, L.; Ai, M.Y. The relationship between location in a kiln and drying defects on small-diameter daimyo oak lumber. Wood Ind. 2004, 5, 27–30. [Google Scholar]

- Sun, H.; Mao, Z.X.; Chen, Z.D. Study on the kinetic model of microwave drying of crispy chinese chestnut balls. Chin. J. Trop. Crops 2021, 42, 2067–2075. [Google Scholar]

- Viboon, C.; Vijaya, R.G.S.; Yvan, G.; Valérie, O. Microwave vacuum dryer setup and preliminary drying studies on strawberries and carrots. J. Microw. Power Electromagn. Energy A Publ. Int. Microw. Power Inst. 2007, 41, 39–47. [Google Scholar]

- Zhou, W.D.; Wang, H.T.; Wang, D.M.; Du, Y.H.; Zhang, K.; Zhang, J. The influence of pore structure of coal on characteristics of dust generation during the process of conical pick cutting. Powder Technol. 2020, 363, 559–568. [Google Scholar] [CrossRef]

- Evin, D. Microwave drying and moisture diffusivity of white mulberry: Experimental and mathematical modeling. J. Mech. Sci. Technol. 2011, 25, 2711–2718. [Google Scholar] [CrossRef]

- Al-Harahsheh, M.; Al-Muhtaseb, A.H.; Magee, T.R.A. Microwave drying kinetics of tomato pomace: Effect of osmotic dehydration. Chem. Eng. Process. 2009, 48, 524–531. [Google Scholar] [CrossRef]

- Dadali, G.; Ozbek, B. Microwave heat treatment of leek: Drying kinetic and effective moisture diffusivity. Int. J. Food Sci. Technol. 2008, 43, 1443–1451. [Google Scholar] [CrossRef]

- Sharma, G.P.; Prasad, S. Effective moisture content of garlic cloves undergoing microwave-convective drying. J. Food Eng. 2004, 65, 609–617. [Google Scholar] [CrossRef]

| Indicator | Score | Quality Description and Scoring Criteria |

|---|---|---|

| Appearance (5 points) | >2.5~5 | Uniform colour, purplish black, the overall appearance is compact and complete |

| 0~2.5 | Uneven colour, yellow brown, the overall appearance is not compact | |

| Sweetness (5 points) | >2.5~5 | The characteristic sweetness of mulberries is intense |

| 0~2.5 | It basically has the special sweet taste of mulberries | |

| Crispness (5 points) | >2.5~5 | It has a good crispness |

| 0~2.5 | Less crispy | |

| Smoky (5 points) | >2.5~5 | No smoke sensation, respiratory tract irritation during chewing |

| 0~2.5 | Smoke sensation, respiratory irritation when chewing |

| Sample | Appearance | Sweetness | Crispness | Smoky | Overall Sensory Evaluation Score | |

|---|---|---|---|---|---|---|

| Product surface temperature (°C) | 40 | 4.78 ± 0.16 c | 3.57 ± 0.43 bc | 2.16 ± 0.37 a | 3.28 ± 0.44 ab | 13.79 ± 1.4 bc |

| 45 | 3.58 ± 0.35 bc | 3.42 ± 0.31 b | 2.38 ± 0.28 a | 3.52 ± 0.12 b | 12.9 ± 1.06 b | |

| 50 | 2.52 ± 0.26 a | 3.51 ± 0.25 b | 2.84 ± 0.18 a | 3.62 ± 0.16 b | 12.49 ± 0.85 b | |

| 55 | 1.77 ± 0.91 a | 3.75 ± 0.95 bc | 2.86 ± 0.14 a | 4.40 ± 0.47 bc | 12.78 ± 2.47 bc | |

| Microwave power (W/g) | 1.82 | 4.35 ± 0.26 c | 3.29 ± 0.13 b | 2.64 ± 0.32 a | 4.26 ± 0.09 c | 14.69 ± 0.8 bc |

| 2.73 | 3.85 ± 0.21 bc | 3.19 ± 0.96 b | 2.59 ± 0.15 a | 4.35 ± 0.24 c | 13.98 ± 1.56 bc | |

| 3.64 | 3.42 ± 0.58 b | 3.35 ± 0.31 b | 2.61 ± 0.41 a | 4.62 ± 0.36 c | 13.56 ± 1.66 bc | |

| 4.55 | 2.89 ± 0.25 a | 3.58 ± 0.14 b | 3.28 ± 0.44 ab | 4.58 ± 0.25 c | 14.33 ± 1.08 bc | |

| 5.45 | 2.37 ± 0.54 a | 3.58 ± 0.24 b | 3.94 ± 0.73 b | 4.63 ± 0.36 c | 14.52 ± 1.87 bc | |

| Chamber vacuum level (MPa) | 0.02 | 2.54 ± 0.36 a | 3.64 ± 0.16 b | 3.58 ± 0.38 b | 3.94 ± 0.52 bc | 13.7 ± 1.42 b |

| 0.04 | 3.34 ± 0.34 b | 3.76 ± 0.24 bc | 3.62 ± 0.54 b | 4.12 ± 0.24 bc | 14.84 ± 1.36 bc | |

| 0.06 | 3.54 ± 0.16 bc | 4.02 ± 0.12 c | 4.07 ± 0.54 bc | 4.58 ± 0.34 c | 16.21 ± 1.16 c | |

| 0.08 | 4.26 ± 0.28 c | 4.21 ± 0.26 c | 4.21 ± 0.40 bc | 4.69 ± 0.15 c | 17.37 ± 1.09 c | |

| Drying position (cm) | 8 | 4.48 ± 0.36 c | 3.75 ± 0.85 bc | 4.81 ± 0.22 c | 3.68 ± 0.74 bc | 16.27 ± 2.17 c |

| 4 | 4.65 ± 0.58 c | 3.54 ± 0.25 b | 4.67 ± 0.13 c | 3.84 ± 0.35 c | 16.7 ± 1.31 c | |

| 0 | 4.24 ± 0.16 c | 4.31 ± 0.52 bc | 4.88 ± 0.11 c | 3.63 ± 0.19 c | 17.06 ± 0.98 c | |

| Serial Number | Model Name | Model Equation |

|---|---|---|

| 1 | Henderson and Pabis | MR = a exp(−kt) |

| 2 | Lewis | MR = exp(−kt) |

| 3 | Page | MR = exp(−ktn) |

| 4 | Two-term | MR = a1 exp(−k1t) + a2 exp(−k2t) |

| 5 | Logarithmic | MR = a exp(−kt) + c |

| 6 | Two-term exponential | MR = ae − kt + (1 − a)e − kat |

| 7 | Weibull distribution | MR = e − (t/a)β |

| Drying Conditions | Model Number | R2 | X2 | RMSE |

|---|---|---|---|---|

| Product surface temperature | 1 | 0.983~0.994 | 0.007~0.051 | 0.023~0.423 |

| 2 | 0.981~0.994 | 0.007~0.034 | 0.024~0.037 | |

| 3 | 0.982~0.996 | 0.004~0.040 | 0.019~0.036 | |

| 4 | 0.997~0.999 | 0.0036~0.0039 | 0.012~0.018 | |

| 5 | 0.996~0.989 | 0.006~0.010 | 0.020~0.029 | |

| 6 | 0.995~0.996 | 0.006~0.008 | 0.020~0.022 | |

| 7 | 0.982~0.994 | 0.007~0.034 | 0.024~0.037 | |

| Microwave power | 1 | 0.952~0.987 | 0.018~0.050 | 0.036~0.054 |

| 2 | 0.927~0.985 | 0.057~0.109 | 0.032~0.067 | |

| 3 | 0.983~0.996 | 0.004~0.042 | 0.019~0.033 | |

| 4 | 0.996~0.999 | 0.003~0.009 | 0.007~0.016 | |

| 5 | 0.973~0.993 | 0.020~0.041 | 0.022~0.040 | |

| 6 | 0.988~0.993 | 0.019~0.020 | 0.021~0.028 | |

| 7 | 0.927~0.985 | 0.057~0.109 | 0.032~0.067 | |

| Chamber vacuum level | 1 | 0.867~0.990 | 0.040~0.498 | 0.027~0.107 |

| 2 | 0.852~0.990 | 0.043~0.557 | 0.028~0.113 | |

| 3 | 0.944~0.993 | 0.024~0.178 | 0.023~0.070 | |

| 4 | 0.987~0.999 | 0.001~0.167 | 0.007~0.034 | |

| 5 | 0.987~0.998 | 0.002~0.185 | 0.011~0.034 | |

| 6 | 0.987~0.998 | 0.002~0.185 | 0.011~0.034 | |

| 7 | 0.852~0.990 | 0.043~0.557 | 0.028~0.113 | |

| Position height | 1 | 0.948~0.972 | 0.069~0.151 | 0.050~0.071 |

| 2 | 0.930~0.958 | 0.103~0.199 | 0.062~0.082 | |

| 3 | 0.991~0.996 | 0.009~0.023 | 0.020~0.029 | |

| 4 | 0.995~0.997 | 0.013~0.028 | 0.017~0.023 | |

| 5 | 0.993~0.997 | 0.008~0.014 | 0.018~0.025 | |

| 6 | 0.993~0.997 | 0.008~0.014 | 0.018~0.025 | |

| 7 | 0.930~0.958 | 0.103~0.199 | 0.062~0.082 |

| Temperature/°C | Power/W | Chamber Vacuum Level/MPa | Height/cm | a1 | a2 | k1 | k2 | R2 | X2 | RMSE |

|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 500 | 0.08 | 0 | 1.0028 | −0.0122 | 0.0011 | −0.0019 | 0.9968 | 0.0036 | 0.0183 |

| 45 | 500 | 0.08 | 0 | −0.0019 | 0.9492 | −0.0051 | 0.0029 | 0.9902 | 0.0106 | 0.0272 |

| 50 | 500 | 0.08 | 0 | 1.2030 | −0.2030 | 0.0114 | 2.3519 | 0.9986 | 0.0039 | 0.0118 |

| 55 | 500 | 0.08 | 0 | 0.2481 | 0.7710 | 0.0428 | 0.0170 | 0.9957 | 0.0059 | 0.0202 |

| 50 | 200 | 0.08 | 0 | 0.8131 | 0.1887 | 0.008 | 0.0657 | 0.9963 | 0.0087 | 0.0157 |

| 50 | 300 | 0.08 | 0 | 0.8760 | 0.1240 | 0.0062 | 2.6926 | 0.9913 | 0.0301 | 0.0233 |

| 50 | 400 | 0.08 | 0 | 0.3413 | 0.6589 | 0.0937 | 0.0084 | 0.9991 | 0.0034 | 0.0075 |

| 50 | 500 | 0.08 | 0 | 1.2030 | −0.2030 | 0.0114 | 56.416 | 0.9986 | 0.0039 | 0.0118 |

| 50 | 600 | 0.08 | 0 | 0.9672 | 0 | 0.0073 | −0.0499 | 0.9965 | 0.0042 | 0.0154 |

| 50 | 600 | 0.02 | 0 | −0.0035 | 0.9905 | −0.0113 | 0.0061 | 0.9961 | 0.0206 | 0.0186 |

| 50 | 600 | 0.04 | 0 | 31.8664 | −30.8849 | −0.0005 | −0.0006 | 0.9993 | 0.0011 | 0.0075 |

| 50 | 600 | 0.06 | 0 | 29.4302 | −28.4779 | −0.0012 | −0.0012 | 0.9867 | 0.1669 | 0.0340 |

| 50 | 600 | 0.08 | 0 | 0.9672 | 0 | 0.0073 | −0.0499 | 0.9965 | 0.0042 | 0.0154 |

| 50 | 600 | 0.08 | 8 | −42.8892 | 43.8979 | 0.0015 | 0.0016 | 0.9967 | 0.0135 | 0.0175 |

| 50 | 600 | 0.08 | 4 | 59.9441 | −58.9205 | 0.0009 | 0.0009 | 0.9946 | 0.0285 | 0.0227 |

| 50 | 600 | 0.08 | 0 | 91.0552 | −90.0602 | 0.0181 | 0.0183 | 0.9956 | 0.0123 | 0.0201 |

| Product Surface Temperature/°C | Microwave Power/W/g | Chamber Vacuum Level/MPa | Height/cm | Linear Equation Expression | R2 | ) | |

|---|---|---|---|---|---|---|---|

| Product surface temperature | 40 | 4.55 | 0.08 | 0 | 0.9312 | 4.98 × 10−8 | |

| 45 | 4.55 | 0.08 | 0 | 0.9678 | 1.11 × 10−7 | ||

| 50 | 4.55 | 0.08 | 0 | 0.9893 | 3.37 × 10−7 | ||

| 55 | 4.55 | 0.08 | 0 | 0.9924 | 5.74 × 10−7 | ||

| Microwave power | 50 | 1.82 | 0.08 | 0 | 0.9924 | 2.61 × 10−7 | |

| 50 | 2.73 | 0.08 | 0 | 0.9707 | 2.17 × 10−7 | ||

| 50 | 3.64 | 0.08 | 0 | 0.9818 | 2.84 × 10−7 | ||

| 50 | 4.55 | 0.08 | 0 | 0.9893 | 3.37 × 10−7 | ||

| 50 | 5.45 | 0.08 | 0 | 0.9236 | 2.75 × 10−7 | ||

| Chamber vacuum level | 50 | 5.45 | 0.02 | 0 | 0.8603 | 1.82 × 10−7 | |

| 50 | 5.45 | 0.04 | 0 | 0.9608 | 2.43 × 10−7 | ||

| 50 | 5.45 | 0.06 | 0 | 0.7868 | 1.96 × 10−7 | ||

| 50 | 5.45 | 0.08 | 0 | 0.9236 | 2.75 × 10−7 | ||

| Height | 50 | 5.45 | 0.08 | 8 | 0.9328 | 3.81 × 10−7 | |

| 50 | 5.45 | 0.08 | 4 | 0.9296 | 3.75 × 10−7 | ||

| 50 | 5.45 | 0.08 | 0 | 0.9590 | 3.54 × 10−7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cong, Y.; Liu, Y.; Tang, Y.; Ma, J.; Wang, X.; Shen, S.; Zhang, H. The Effect of Drying Variables on the Microwave–Vacuum-Drying Characteristics of Mulberries (Morus alba L.): Experiments and Multivariate Models. Agriculture 2023, 13, 1843. https://doi.org/10.3390/agriculture13091843

Cong Y, Liu Y, Tang Y, Ma J, Wang X, Shen S, Zhang H. The Effect of Drying Variables on the Microwave–Vacuum-Drying Characteristics of Mulberries (Morus alba L.): Experiments and Multivariate Models. Agriculture. 2023; 13(9):1843. https://doi.org/10.3390/agriculture13091843

Chicago/Turabian StyleCong, Yuyang, Yang Liu, Yurong Tang, Jiale Ma, Xingyu Wang, Shuai Shen, and Hong Zhang. 2023. "The Effect of Drying Variables on the Microwave–Vacuum-Drying Characteristics of Mulberries (Morus alba L.): Experiments and Multivariate Models" Agriculture 13, no. 9: 1843. https://doi.org/10.3390/agriculture13091843

APA StyleCong, Y., Liu, Y., Tang, Y., Ma, J., Wang, X., Shen, S., & Zhang, H. (2023). The Effect of Drying Variables on the Microwave–Vacuum-Drying Characteristics of Mulberries (Morus alba L.): Experiments and Multivariate Models. Agriculture, 13(9), 1843. https://doi.org/10.3390/agriculture13091843