Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup

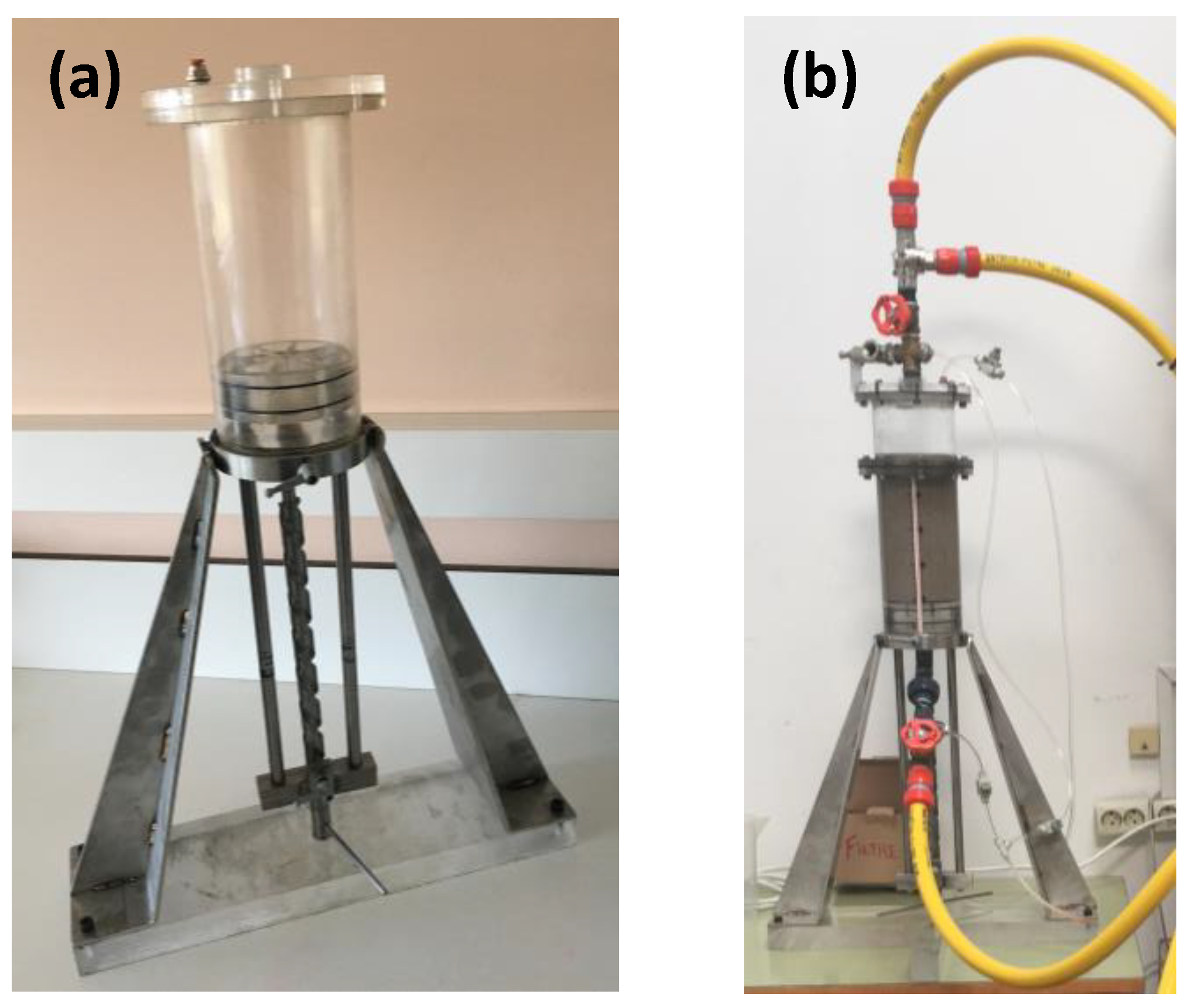

2.1.1. Experimental Filter

2.1.2. Laboratory Setup

2.1.3. Wastewater Treatment Plant Setup

2.2. Experimental Procedure

2.2.1. Filtration Experiments

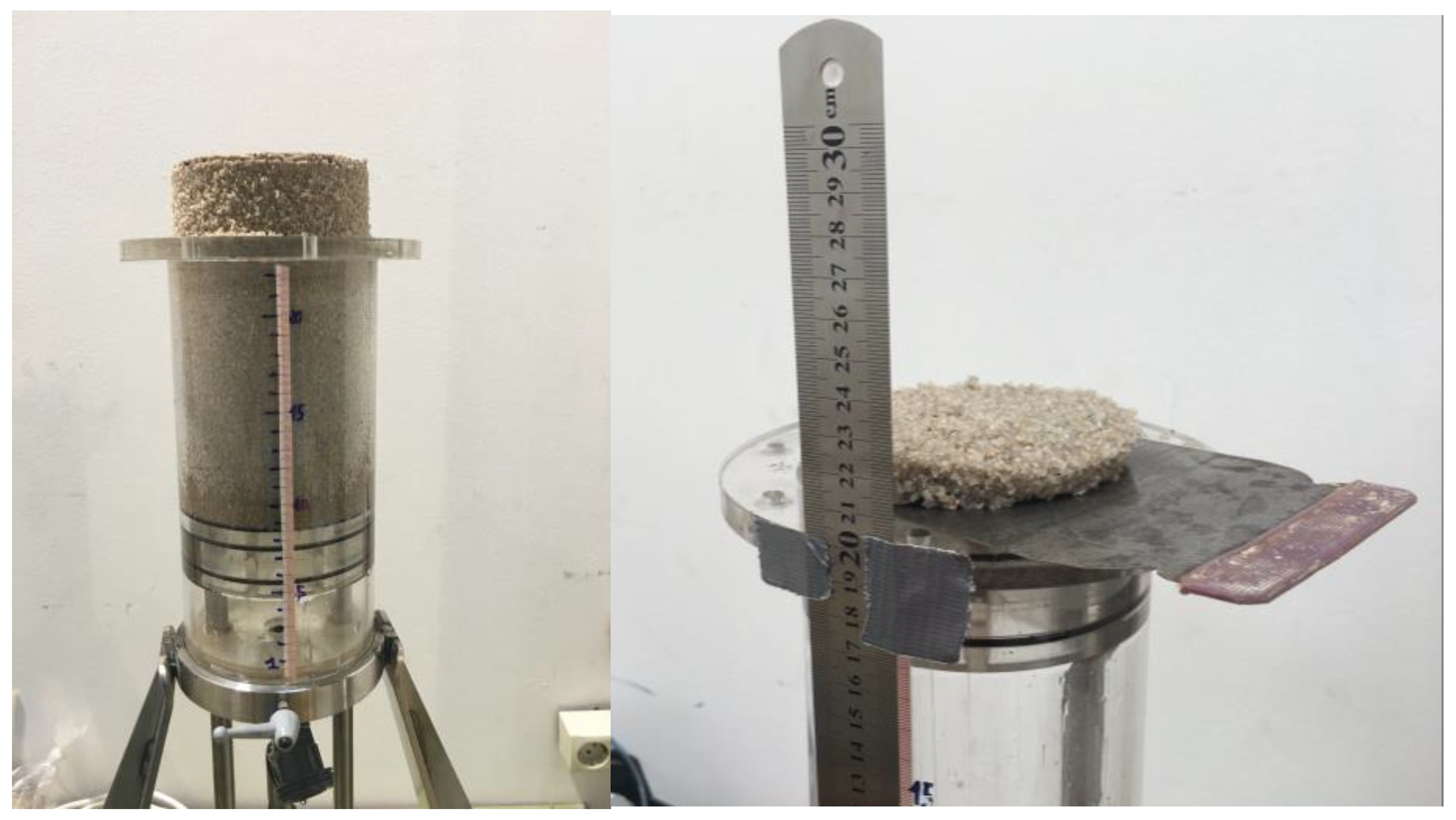

2.2.2. Measurement of the Solids Retained in the Media Bed

2.3. Statistical Treatment

3. Results

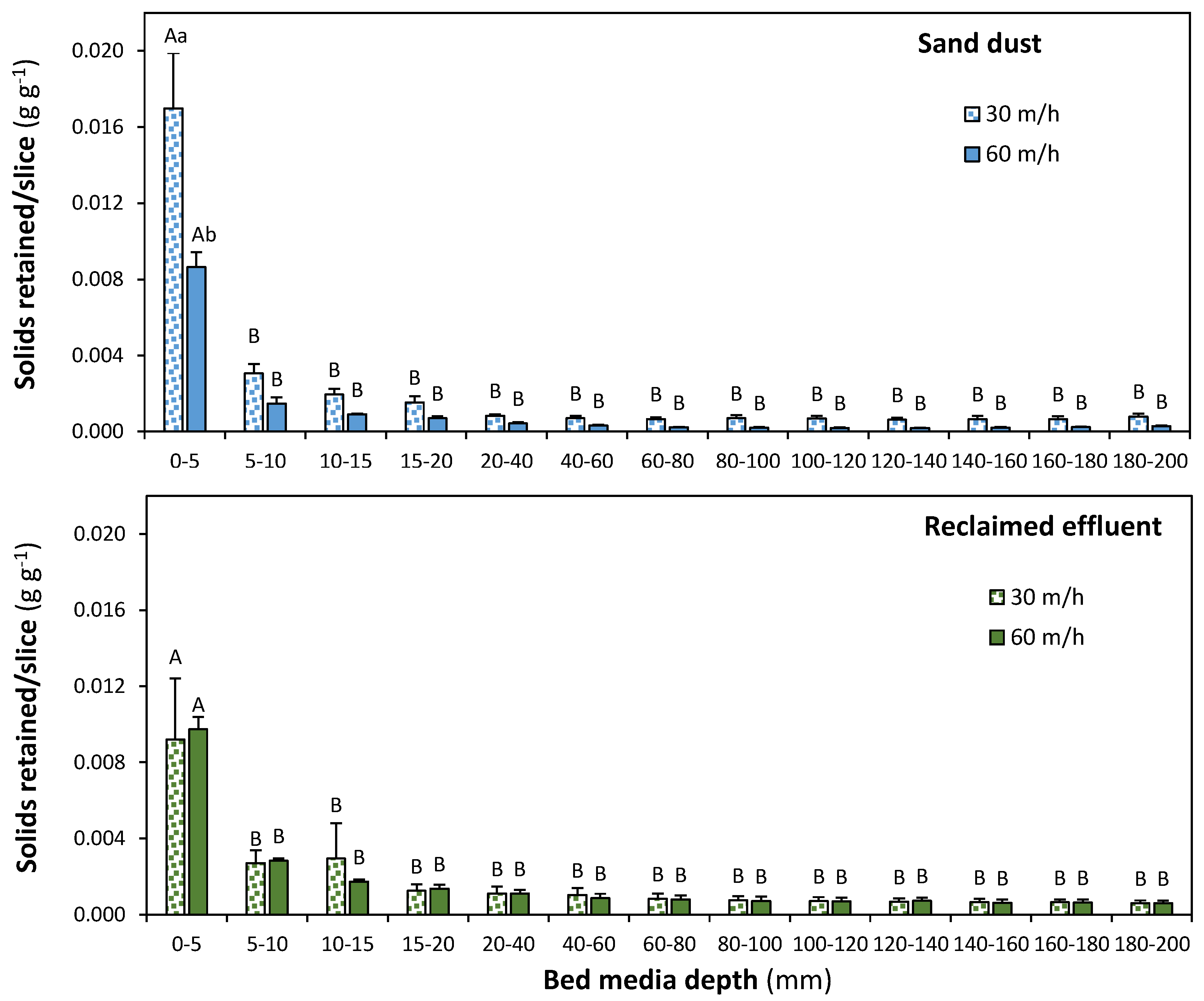

3.1. Solids Retained Regarding the Slice Mass

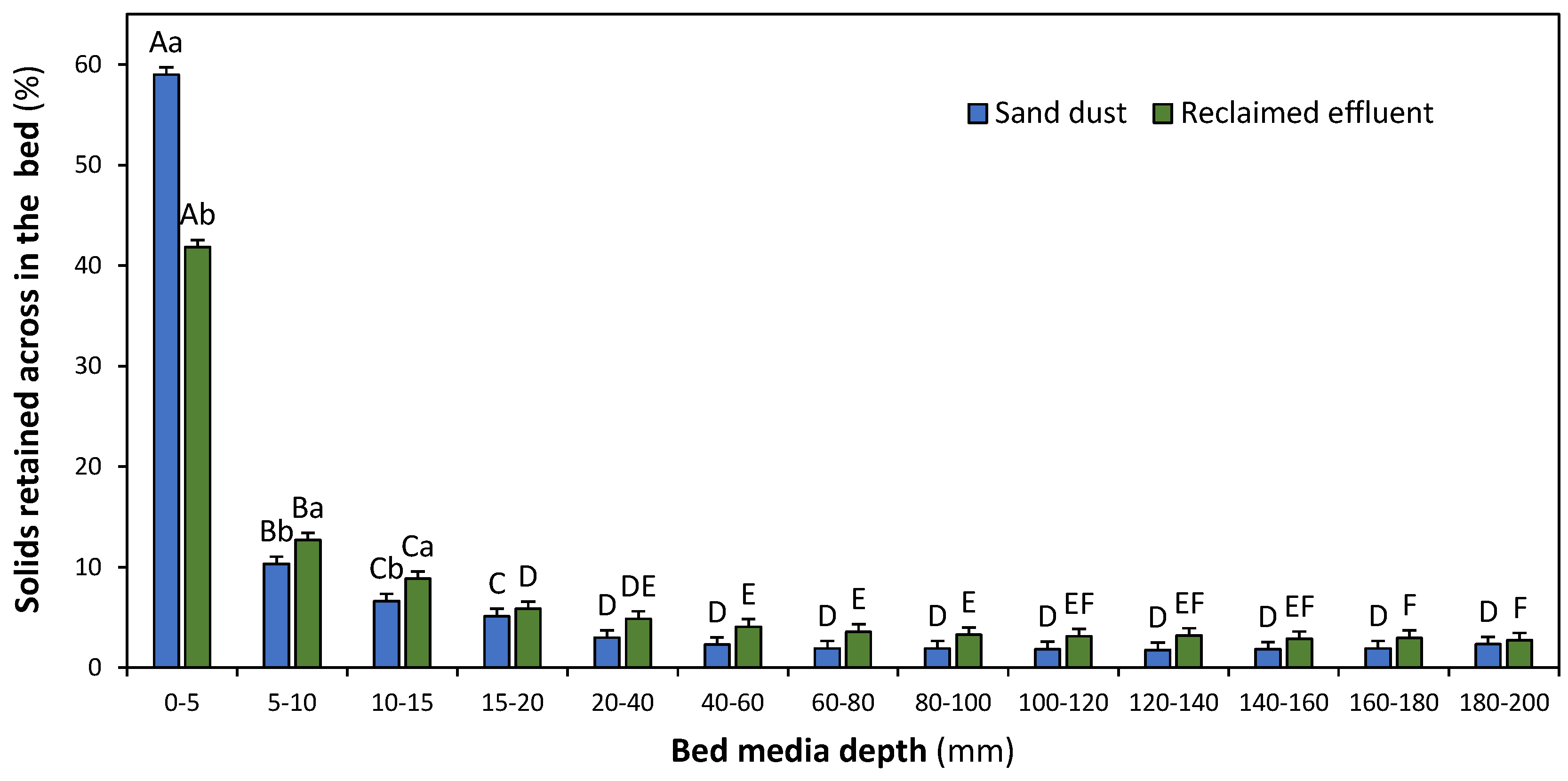

3.2. Percentage of Solids Retained across the Media

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Food and Agriculture Organization of the United Nations. The State of the World’s Land and Water Resources for Food and Agriculture—Systems at Breaking Point. Synthesis Report 2021; FAO: Rome, Italy, 2021. [Google Scholar] [CrossRef]

- Tarjuelo, J.M.; Rodriguez-Diaz, J.A.; Abadía, R.; Camacho, E.; Rocamora, C.; Moreno, M.A. Efficient Water and Energy Use in Irrigation Modernization: Lessons from Spanish Case Studies. Agric. Water Manag. 2015, 162, 67–77. [Google Scholar] [CrossRef]

- Ayars, J.E.; Bucks, D.A.; Lamm, F.R.; Nakayama, F.S. Introduction. In Microirrigation for Crop Production. Design, Operation and Management; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 1–26. [Google Scholar]

- Trooien, T.P.; Hills, D.J. Application of biological effluent. In Microirrigation for Crop Production. Design, Operation and Management; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 329–356. [Google Scholar]

- International Commission on Irrigation & Drainage. Annual Report 2021–2022. 2022. Available online: https://icid-ciid.org/icid_data_web/ar_2021.pdf (accessed on 21 December 2022).

- Solé-Torres, C.; Lamm, F.R.; Duran-Ros, M.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Assessment of microirrigation field distribution uniformity procedures for pressure-compensating emitters under potential clogging conditions. Trans. ASABE 2021, 64, 1063–1071. [Google Scholar] [CrossRef]

- Nakayama, F.S.; Boman, B.J.; Pitts, D.J. Maintenance. In Microirrigation for Crop Production. Design, Operation and Management; Lamm, F.R., Ayars, J.E., Nakayama, F.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 389–430. [Google Scholar]

- Tajrishy, M.A.; Hills, D.J.; Tchobanoglous, G. Pretreatment of secondary effluent for drip irrigation. J. Irrig. Drain. Eng. 1994, 120, 716–731. [Google Scholar] [CrossRef]

- Ravina, I.; Paz, E.; Sofer, Z.; Marm, A.; Schischa, A.; Sagi, G.; Yechialy, Z.; Lev, Y. Control of clogging in drip irrigation with stored treated municipal sewage effluent. Agric. Water Manag. 1997, 33, 127–137. [Google Scholar] [CrossRef]

- Capra, A.; Scicolone, B. Recycling of Poor Quality Urban Wastewater by Drip Irrigation Systems. J. Clean. Prod. 2007, 15, 1529–1534. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Puig-Bargués, J.; Arbat, G.; Barragán, J.; Ramírez de Cartagena, F. Effect of filter, emitter and location on clogging when using effluents. Agric. Water. Manag. 2009, 96, 67–79. [Google Scholar] [CrossRef]

- Tripathi, V.K.; Rajput, T.B.S.; Patel, N. Performance of different filter combinations with surface and subsurface drip irrigation systems for utilizing municipal wastewater. Irr. Sci. 2014, 32, 379–391. [Google Scholar] [CrossRef]

- Wu, W.-Y.; Huang, Y.; Liu, H.-L.; Yin, S.-Y.; Niu, Y. Reclaimed water filtration efficiency and drip irrigation emitter performance with different combinations of sand and disc filters. Irrig. Drain. 2015, 64, 362–369. [Google Scholar] [CrossRef]

- Hasani, A.M.; Aminpour, Y.; Nikmehr, S.; Puig-Bargués, J.; Maroufpoor, E. Performance of sand filter with disc and screen filters in irrigation with rainbow trout fish effluent. Irrig. Drain. 2022; in press. [Google Scholar] [CrossRef]

- Ives, K.J. Rapid filtration. Water Res. 1970, 4, 201–223. [Google Scholar] [CrossRef]

- Cescon, A.; Jiang, J.-Q. Filtration Process and Alternative Filter Media Material in Water Treatment. Water 2020, 12, 3377. [Google Scholar] [CrossRef]

- Mesquita, M.; Testezlaf, R.; Ramirez, J.C.S. The effect of media bed characteristics and internal auxiliary elements on sand filter head loss. Agric. Water Manag. 2012, 115, 178–185. [Google Scholar] [CrossRef]

- Arbat, G.; Pujol, T.; Puig-Bargués, J.; Duran-Ros, M.; Montoro, L.; Barragán, J.; Ramírez de Cartagena, F. An Experimental and Analytical Study to Analyze Hydraulic Behavior of Nozzle-Type Underdrains in Porous Media Filters. Agric. Water Manag. 2013, 126, 64–74. [Google Scholar] [CrossRef]

- De Deus, F.P.; Testezlaf, R.; Mesquita, M. Eficiência de filtros de areia pressurizados na remoção de diferentes tamanhos de partículas da água de irrigação. Pesq. Agropec. Bras. 2015, 50, 939–948. [Google Scholar] [CrossRef]

- García Nieto, P.J.; García-Gonzalo, E.; Arbat, G.; Duran-Ros, M.; Ramírez de Cartagena, F.; Puig-Bargués, J. Pressure drop modelling in sand filters in micro-irrigation using gradient boosted regression trees. Biosyst. Eng. 2018, 171, 41–51. [Google Scholar] [CrossRef]

- Jiao, Y.; Feng, J.; Liu, Y.; Yang, L.; Han, M. Sustainable operation mode of a sand filter in a drip irrigation system using Yellow River water in an arid area. Water Supply 2020, 20, 3636–3645. [Google Scholar] [CrossRef]

- Graciano-Uribe, J.; Pujol, T.; Puig-Bargués, J.; Duran-Ros, M.; Arbat, G.; Ramírez de Cartagena, F. Assessment of Different Pressure Drop-Flow Rate Equations in a Pressurized Porous Media Filter for Irrigation Systems. Water 2021, 13, 2179. [Google Scholar] [CrossRef]

- Zaki, M.G.H.; Abuarab, M.E.-S.; Sultan, W.M.; Kassem, M.A.E.-W. Evaluation of friction head loss as a function of media filter performance via different underdrain types and media specifications. Agric. Eng. Int. CIGR J. 2021, 23, 1–11. [Google Scholar]

- Hu, Y.; Wu, W.; Liu, H.; Huang, Y.; Bi, X.; Liao, R.; Yin, S. Dimensional Analysis Model of Head Loss for Sand Media Filters in a Drip Irrigation System Using Reclaimed Water. Water 2022, 14, 961. [Google Scholar] [CrossRef]

- Bové, J.; Arbat, G.; Pujol, T.; Duran-Ros, M.; Ramírez de Cartagena, F.; Velayos, J.; Puig-Bargués, J. Reducing Energy Requirements for Sand Filtration in Microirrigation: Improving the Underdrain and Packing. Biosyst. Eng. 2015, 140, 67–78. [Google Scholar] [CrossRef]

- Mesquita, M.; Testezlaf, R.; de Deus, F.P.; da Rosa, L.M. Characterization of flow lines generated by pressurized sand filter underdrains. Chem. Eng. Trans. 2017, 58, 715–720. [Google Scholar] [CrossRef]

- Mesquita, M.; de Deus, F.P.; Testezlaf, R.; Da Rosa, L.M.; Diotto, A.V. Design and Hydrodynamic Performance Testing of a New Pressure Sand Filter Diffuser Plate Using Numerical Simulation. Biosyst. Eng. 2019, 183, 58–69. [Google Scholar] [CrossRef]

- Pujol, T.; Puig-Bargués, J.; Arbat, G.; Chaves, M.; Duran-Ros, M.; Pujol, J.; Ramírez de Cartagena, F. Numerical study of the hydraulic effect of modifying the outlet pipe and diffuser plate in pressurized sand filters with wand type underdrains. J. ASABE 2022, 65, 609–619. [Google Scholar] [CrossRef]

- Mesquita, M.; de Deus, F.P.; Testezlaf, R.; Diotto, A.V. Removal efficiency of pressurized sand filters during the filtration process. Desalin. Water Treat. 2019, 161, 132–143. [Google Scholar] [CrossRef]

- Solé-Torres, C.; Puig-Bargués, J.; Duran-Ros, M.; Arbat, G.; Pujol, J.; Ramírez de Cartagena, F. Effect of Underdrain Design, Media Height and Filtration Velocity on the Performance of Microirrigation Sand Filters Using Reclaimed Effluents. Biosyst. Eng. 2019, 187, 292–304. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Puig-Bargués, J.; Cufí, S.; Solé-Torres, C.; Arbat, G.; Pujol, J.; Ramírez de Cartagena, F. Effect of different filter media on emitter clogging using reclaimed effluents. Agric. Water Manag. 2022, 266, 107591. [Google Scholar] [CrossRef]

- Burt, C.M. Hydraulics of commercial sand media filter tanks used for agricultural drip irrigation. In ITRC Report No. R 10001. Irrigation Training and Research Center; California Polytechnic State University: San Luis Obispo, CA, USA, 2010. [Google Scholar]

- De Deus, F.P.; Testezlaf, R.; Mesquita, M. Assessment methodology of backwashing in pressurised sand filters. Rev. Bras. Eng. Agric. Ambient. 2016, 20, 600–605. [Google Scholar] [CrossRef]

- Duran-Ros, M.; Solé-Torres, C.; Ait-Mouheb, N.; Molle, B.; Arbat, G.; Puig-Bargués, J. Media filter fouling assessment using optical coherence tomography: New methodology. Biosyst. Eng. 2021, 204, 26–35. [Google Scholar] [CrossRef]

- EN 16713-1:2016; Domestic Swimming Pools—Water Systems—Part 1: Filtration Systems—Requirements and Test Methods. CEN: Brussels, Belgium, 2016.

- Van Staden, S.J.; Haarhoff, J. The use of filter media to determine filter cleanliness. Phy. Chem. Earth 2011, 36, 1135–1140. [Google Scholar] [CrossRef]

- Baird, R.B.; Eaton, A.D.; Rice, E.W. (Eds.) Standard Methods for the Examination of Water and Wastewater, 23rd ed.; American Public Health Association, American Water Works Association, Water Environment Federation: Washington, DC, USA, 2017. [Google Scholar]

- Haarhoff, J.; van Staden, S.J. Measurement and expression of granular filter cleanliness. WaterSA 2013, 39, 701–706. [Google Scholar]

- Adin, A.; Elimelech, M. Particle filtration for wastewater irrigation. J. Irrig. Drain. Eng. 1989, 115, 474–487. [Google Scholar] [CrossRef]

- Pujol, J.; Espinach, F.X.; Duran-Ros, M.; Arbat, G.; Pujol, T.; Ramírez de Cartagena, F.; Puig-Bargués, J. Environmental Assessment of Underdrain Designs for Granular Media Filters in Drip Irrigation Systems. Agriculture 2022, 12, 810. [Google Scholar] [CrossRef]

| Type of Particle Added | Target (and Actual Average ± Standard Deviation) Filtration Velocity (m h−1) | Media Bed Slices (mm) 1 |

|---|---|---|

| Inorganic (A4 sand dust) | 30 (30.5 ± 0.8) | 0–5 5–10 10–15 15–20 20–40 40–60 60–80 80–100 100–120 120–140 140–160 160–180 180–200 |

| 60 (59.5 ± 1.6) | ||

| Organic (reclaimed effluent) | 30 (31.4 ± 2.1) | |

| 60 (62.0 ± 2.7) |

| Type of Particle | Target Filtration Velocity (m h−1) | Flow (m3 h−1) | Added Solids 1 (g) | Filtered Volume (m3) | Water Temperature (°C) |

|---|---|---|---|---|---|

| Inorganic (A4 dust sand) | 30 | 2.95 ± 0.16 | 8.38 ± 2.13 | 0.72 ± 0.18 | 24.2 ± 1.3 |

| 60 | 5.69 ± 0.15 | 3.95 ± 0.88 | 0.32 ± 0.07 | 22.8 ± 1.1 | |

| Organic (reclaimed effluent) | 30 | 2.99 ± 0.17 | 7.84 ± 3.99 | 0.46 ± 0.14 | 19.9 ± 1.4 |

| 60 | 5.89 ± 0.26 | 20.28 ± 8.75 | 1.68 ± 1.06 | 17.6 ± 1.2 |

| Parameter | p-Value |

|---|---|

| Model | <0.001 |

| Filtration velocity | 0.001 |

| Type of particle | n.s. 1 |

| Bed depth slice | <0.001 |

| Filtration velocity × type of particle | 0.003 |

| Filtration velocity × bed depth slice | 0.020 |

| Type of particle × bed depth slice | 0.013 |

| Filtration velocity × type of particle × bed depth slice | 0.002 |

| Parameter | p-Value |

|---|---|

| Model | <0.001 |

| Filtration velocity | n.s. 1 |

| Type of particle | n.s. |

| Bed depth slice | <0.001 |

| Filtration velocity × type of particle | n.s. |

| Filtration velocity × bed depth slice | n.s. |

| Type of particle × bed depth slice | <0.001 |

| Filtration velocity × type of particle × bed depth slice | n.s. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duran-Ros, M.; Pujol, J.; Pujol, T.; Cufí, S.; Arbat, G.; Ramírez de Cartagena, F.; Puig-Bargués, J. Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems. Agriculture 2023, 13, 458. https://doi.org/10.3390/agriculture13020458

Duran-Ros M, Pujol J, Pujol T, Cufí S, Arbat G, Ramírez de Cartagena F, Puig-Bargués J. Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems. Agriculture. 2023; 13(2):458. https://doi.org/10.3390/agriculture13020458

Chicago/Turabian StyleDuran-Ros, Miquel, Joan Pujol, Toni Pujol, Sílvia Cufí, Gerard Arbat, Francisco Ramírez de Cartagena, and Jaume Puig-Bargués. 2023. "Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems" Agriculture 13, no. 2: 458. https://doi.org/10.3390/agriculture13020458

APA StyleDuran-Ros, M., Pujol, J., Pujol, T., Cufí, S., Arbat, G., Ramírez de Cartagena, F., & Puig-Bargués, J. (2023). Solid Removal across the Bed Depth in Media Filters for Drip Irrigation Systems. Agriculture, 13(2), 458. https://doi.org/10.3390/agriculture13020458