Abstract

In modern agriculture, packaging materials are becoming an important means of production in the technologies for harvesting bulk materials. The agricultural net currently used for this purpose is usually made of HDPE—high-density polyethylene. The aim of the study was to evaluate the agricultural net produced in light technology under the commercial name of Covernet. Based on the tests conducted for nine variants of different models of round balers and different bulk materials collected by them, it can be concluded that, in each case, the net (Tama LT) wrapped the cylindrical bales well or very well. The mean elongation of COVERNET during bale wrapping was over 8% for the tested machines and harvested materials. The tests confirmed the usefulness of the new generation of agricultural nets (Tama LT) for wrapping various agricultural bulk materials of various humidities. There is an urgent need to develop and implement in practice a technology for recovering used agricultural nets and converting them into granules that can be used again in their production.

1. Introduction

The intensive development of agriculture is connected with the biological progress and the breeding of modern variations of crop species that are more efficient and better adapted to local environmental and climatic conditions [1,2,3,4,5,6,7]. Another aspect of this progress is the implementation of new production technologies and the adaptation of new generations of materials for agricultural production which make farming more sustainable [8,9,10,11,12]. In many cases, measures taken in this area also enable the reduction in the negative impact of agriculture on directly related ecosystems. The consumption of materials that are harmful to the environment is reduced when harvesting straw and fodder [13]. In modern agriculture, packaging materials are becoming an important means of production in the technologies for harvesting bulk materials. The main problem with this method of packaging bulk materials is the generation of thousands of metric tons of waste. Another adverse effect during the HDPE production is the emission of greenhouse gases into the atmosphere. The carbon footprint of HDPE production is 1.60 kg CO2·kg−1 of polyethylene granules [14]. The agricultural net currently used for this purpose is usually made of HDPE—high-density polyethylene [15,16,17,18,19,20]. Manufacturers use various types of HDPE in the net production process [21]. High-grade raw materials of better quality make it possible to produce polymers of greater strength. In contrast, lower-quality raw materials are not as durable when using material of the same weight [22,23,24]. Therefore, manufacturers utilize thicker base material to improve the strength of agricultural nets. This means more of a consumption of raw material and more HDPE required per 1 running meter of net. This leads to an increase in the weight of the net roll and its diameter while maintaining the same length of the net. As a result, it is impossible to produce a net from a standard raw material of higher strength without increasing the diameter and weight of the roll. Considering this situation and new requirements for environmental protection, the Tama Plastic Industry in Poland has introduced an innovative solution for net production, called Tama Light Technology (Tama LT). An advanced HDPE formula was used for this purpose in combination with a completely new production technology. The technology called (Tama LT) has allowed us to manufacture a net that is lighter and, at the same time, much more durable compared to the standard net. The introduction of a new generation of lightweight agricultural netting on the market required the verification of its suitability for packing agricultural bulky materials using baling presses.

2. Materials and Methods

2.1. Research Subject

Rolls of the Tama LT net under the trade name COVERNET were used in the field tests. COVERNET is a new-generation product for packing agricultural bulk materials with a minimum breaking strength of 2.5 kN. The aquamarine color net was 123 cm wide, with a guaranteed length of 2000 m and a gross roll weight of 20.50 kg.

2.2. Test Conditions

Before starting the operation of each round baler and the harvesting of bulk materials, it was checked whether the machine settings were in accordance with the manufacturer’s recommendations. It was also checked if the owner did not make any structural changes to the machine. Then, the agrotechnical conditions during field tests were determined: the place of the test, the characteristics of the machine unit, the weather and agrotechnical conditions and the type of harvested plant material. The air temperature was measured with the LB-531 thermohygrometer (LAB-EL Laboratory Electronics, Herbaciana, Reguły, Poland) with an accuracy of 0.01 °C.

2.3. Measurement Methods

Before putting a roll of COVERNET in the machine’s hopper, the distances between the net threads were measured to compare them after the bale had been wrapped. Comparing the distance between the threads in the net roll and in the wrapped bale allowed for determining the percentage net elongation during wrapping. For this purpose, the base of “10 triangles in the net” extended from a roll was calculated on a level surface before being placed in the machine’s hopper, and then their length was measured. The measurement was conducted in four repetitions, and the measured distances of “10 bases of triangles” were recorded. Once the bale was wrapped, the base of the “10 triangles in the net” was calculated again on the inner layer of the net surface, and their length was measured. The outer net layer was not included in the measurements. The number of net wrap layers was determined (NL). Once the bale was unloaded from the round baler, the width of the net coverage was measured from the front and back of the bale. The measurement was conducted with a tape measure in four repetitions, and the measured distances were recorded with an accuracy of 1 mm.

2.4. Statistical Analysis

Parametric and non-parametric methods were applied in the statistical analysis of the measurement results, depending on the results of tests verifying the analysis assumptions. The distribution normality was checked using the Shapiro–Wilk test. Then, Pearson’s correlation or non-parametric Spearman’s rank correlation was used to determine whether the results of the measurements of net features depend on the order in which the bales were formed. The correlation between length 10Δ [cm] (LEN 10Δ) and the percentage net elongation (ELO) were also checked. The t-distribution method or the Wilcoxon non-parametric method (when the distribution normality assumption was not met) was used to compare the averages of two dependent populations. These methods were used to compare the mean net coverage at the bale front (CF) and at the bale back (CB). A correlation analysis between features of different types and a comparison of averages between features of the same type were carried out to determine whether all features should be analyzed separately. If no significant differences between the averages or a strong correlation was shown, only selected features were analyzed. The conclusions on these features were transferred to the other corresponding features: length 10Δ and elongation (ELO). In order to visually assess the results of the tests of round balers and the bulk materials collected by them, descriptive statistics were calculated and presented in a graphic form as violin plots. These charts showed the range of feature variability and the number of observations corresponding to a given feature value. A variance analysis was carried out for each of the features, with round balers and collected bulk materials as factors. Before starting the analysis, the homogeneity of variance of the compared factor levels was checked using Levene’s test. If the assumptions of the normal variance analysis were not met, the non-parametric Kruskal–Wallis test was used. All analyses were carried out in the STATISTICA statistical package, and the violin plots were made using the ggplot2 procedure on the R statistical platform.

3. Results

The COVERNET from Tama, produced in light technology (Tama LT), was evaluated during field tests in the agrotechnical period between 3 June 2017 and 25 August 2017 during the harvesting of various agricultural bulk materials with round balers. The tests were conducted in several regions of Poland in farms equipped with a round baler, which voluntarily agreed to test the new generation of agricultural nets. The following bulk materials were collected: dried mixed-grass fodder intended for silage and straw from various cereal species: winter rye, winter triticale, winter wheat and spring barley. The air temperature during the harvesting of dried greens fodders ranged from 19 to 27 °C. During the harvesting of straw from various species of cereals, the air temperature ranged from 21 to 26 °C. COVERNET was tested in round balers from domestic manufacturers of agricultural machinery: Sipma S.A., UNIA Sp. z.o.o., POL-MOT Warfama S.A. and METAL-FACH Sp. z o.o. (Table 1).

Table 1.

Variants harvest of bulk materials during tests of the COVERNET mesh produced in the Tama LT technology.

The collected test results were evaluated with the Shapiro–Wilk test to verify the null hypothesis confirming their normal distribution. The test showed that most of the analyzed round balers and the bulk materials they collected did not meet this assumption (Table 2).

Table 2.

p-values of the Shapiro–Wilk test of normality.

The assumption about the distribution normality of all the results for the round balers and the bulk materials collected by them was not met. Therefore, correlations between the bale number and the results of the measurements of respective features were determined using the non-parametric Spearman’s rank correlation (Table 3). All determined coefficients have values close to zero, so it can be concluded that there is no relationship. Therefore, the number of bales made by round balers did not affect the quality of net wrapping.

Table 3.

Dependence of features on bale number—Spearman’s rank correlations.

This was followed by the calculation of the descriptive statistics (Table 3) of all analyzed features: mean, minimum and maximum value, standard deviation and standard error. The calculation results led to the conclusion that the baling presses picked the net correctly, and the set number of layers in most of the tested baling presses and collected bulk materials did not change. This proves that the factory settings of the machines made by the operator before the start of harvesting do not change during operation. The net is correctly picked by the wrapping devices installed in the round balers, regardless of their design. During the wrapping operation, there is no slipping effect of the thinner net (Tama LT) on the feeding rollers of the net bale wrapping device. The number of net wraps of bales for the Sipma Z-569/1 Farna II baler during the harvest of spring barley straw was 2.2. For the UNIA DF 1.7 Zd machine during the harvest of dried green fodder, the number of net wraps of bales was 2.6. For the Warfama Z-543 baler during the harvest of spring barley and winter wheat straw, the number of net layers was 2.5. Very small differences in the number of net layers placed on successive cylindrical bales were found only in three cases: Sipma PS 1211 FARMA PLUS round balers when harvesting winter triticale straw, UNIA Df 1.8 Dd when harvesting dried green fodder and Sipma Z-569/1 Farna II when harvesting dried green fodder. These differences had no effect on the shape of the bales after unloading them from the round baler chamber. The shape of the bales also did not change during the loading into the means of transport, during the transport to the farm, when wrapping the fodder bales with foil or during the storage of winter triticale bales in a heap. Very small differences in the number of net wraps may result from collecting dried fodder, characterized by a higher humidity and generating less tension on the net. Then, when unloading the net-wrapped bales from the round baler chamber, there may be slight movements of the net on the bale. The net loses its ability to move when the threads catch on the stalks of the collected bulk material sticking out on the outer surface of the bale. The number of bale wraps with the net during the harvesting of dried green fodder for the Sipma Z-569/1 Farna II machine ranged from 2.3 to 2.5 (mean 2.4), and for UNIA Df 1.8 Dd, it ranged from 2.7 to 2.8 (mean 2.73). Cylindrical bales formed from dry cereal straw generate more tension on the net than bales of dried green fodder, hay or straw of a higher moisture content. Very small differences in the number of net layers placed on cylindrical bales harvested with the Sipma PS 1211 FARMA PLUS round baler during the harvesting of winter triticale straw resulted from the manual control of the net feeding function in the panel controlling the round baler’s parameters. The number of wraps with the net Tama LT on a bale of winter triticale straw ranged from 2.2 to 3.5 (mean 3.64). Furthermore, no changes in the net length or elongation were found in the Metal-Fach Z-562 round baler when harvesting winter rye and winter wheat straw. In this case, the machine was set to the maximum number of net wraps, which was 2.8. The maximum number of bale wraps with the net aimed at the best possible protection of the harvested straw from weather conditions, as it was stored in an outdoor heap.

The smallest and highest mean net coverage of the bale was 112.75 cm and 125 cm, respectively; the differences in coverage between the front and back of the bale were small. The Wilcoxon test was used to compare two dependent populations of the back and front of the bales and demonstrated that these means differ significantly (Table 4 and Table 5).

Table 4.

Descriptive statistics of round balers collecting dried green fodder.

Table 5.

Descriptive statistics of round balers collecting straw after harvesting cereals.

The analysis of the results of the length 10Δ on the net before attaching it to the machine hopper and then after wrapping the bale with the net allowed us to determine its percentage elongation. The results of the length 10Δ were the same for the net before it was attached to the machine hopper, which proves the high quality of the net. After wrapping the bale with the net, the length 10Δ leads to the conclusion that the mean values of this parameter are similar for all tested round balers and collected bulk materials. This demonstrates a high correlation between these features. The calculated Spearman’s rank correlation coefficient for all observations was r = 0.9947. The general correlation coefficient for the tested round balers and collected bulk materials was 0.7807 for variant 5.2. and 1.0000 for the other variants. All correlation coefficients are significant at the significance level of 0.05, so one of the analyzed features, i.e., net elongation, can be selected for further analysis.

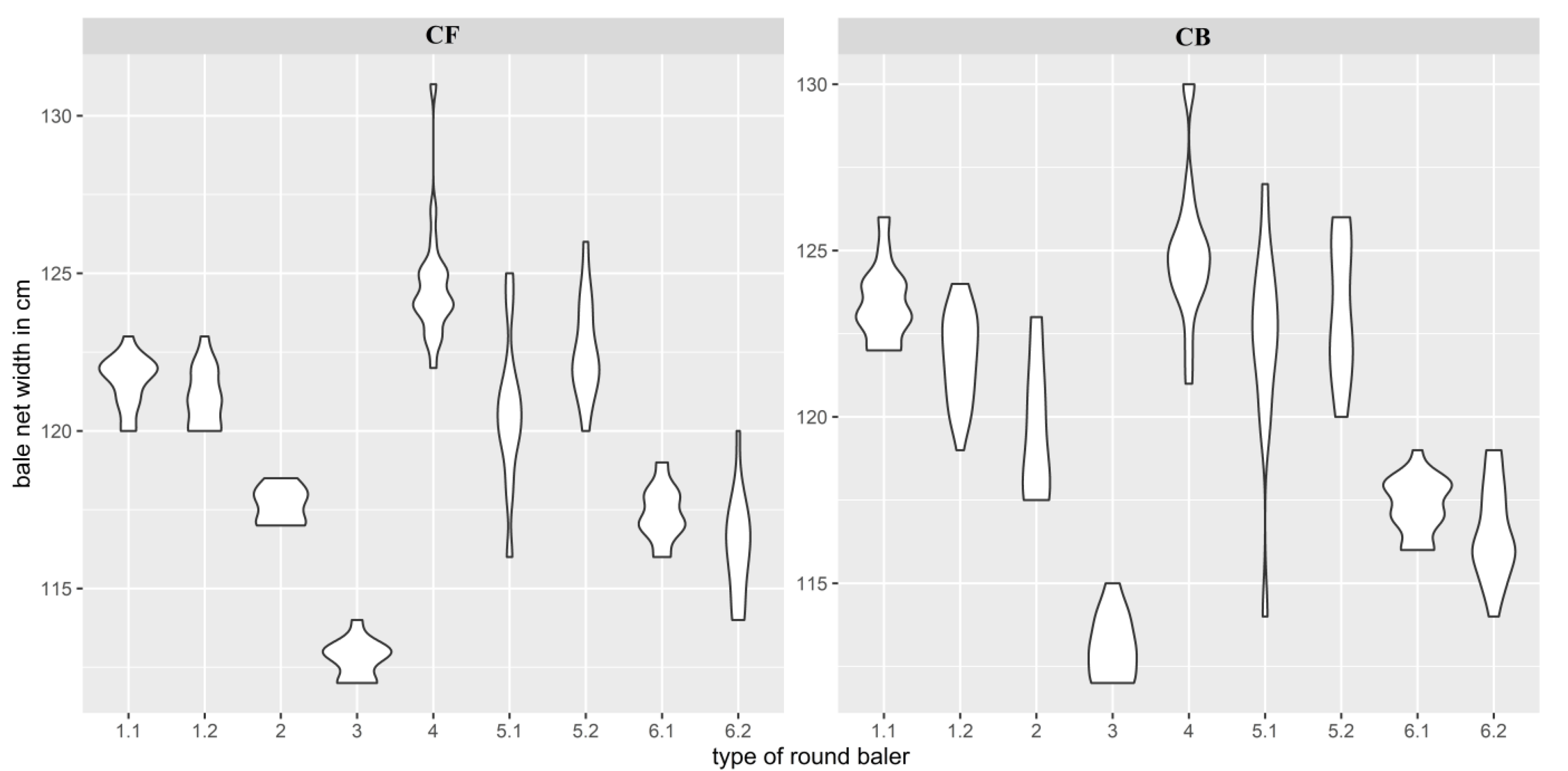

The coverage of cylindrical bales with a light type net (Tama LT) on the front and back in the tested variants for the respective machines and bulk materials is presented in the violin plots. Their shape is similar, which may indicate the lack of significant differences between the means of these features in the respective test variants. However, the results of the Wilcoxon test for all observations showed that the means of CF from CB differ significantly. In order to check this assumption, a comparison test was conducted for two means for dependent populations—the Wilcoxon test when the assumption of distribution normality was not met, and the t-distribution test when the assumption was met (Table 6). Since, in some of the analyzed presses and the bulk materials collected by them, the mean CF and CB differ significantly, all these features will be taken into consideration in the following sections.

Table 6.

Comparison test of two dependent means between CF and CB; Wilcoxon and Student’s t depending on the fulfillment of assumptions.

The dispersion of observations in all plots (Figure 1) varies, which may indicate the heterogeneity of variance. In addition, it is not always symmetrical, which proves that the hypothesis of the distribution compatibility with the normal distribution is rejected (Table 2).

Figure 1.

Cover the bales with COVERNET (Tama LT) on the front and back of the bale. 1.1—Sipma Z-569/1 Farma II—dried green fodder; 1.2—Sipma Z-569/1 Farma II—spring barley straw; 2—UNIA DF 1,7 Zd—dried green fodder; 3—UNIA DF 1,8 Dd—dried green fodder; 4—Sipma PS 1211 FARMA PLUS—winter triticale straw; 5.1—Warfama Z-543—spring barley straw; 5.2—Warfama Z-543—winter wheat straw; 6.1—Metal-Fach Z-562—winter rye straw; 6.2—Metal-Fach Z-562—winter wheat straw.

The experimental system was non-orthogonal (Table 1), and, therefore, the comparison was made for levels of one factor that was a combination of two factors: press and bulk material. Since the assumption of the homogeneity of variance for the compared groups was not met for any of the features (p-value < 0.05), the non-parametric Kruskal–Wallis test was used.

The results of the non-parametric analysis of variance are shown in Table 7. No significant differences in terms of all features were found between the balers of the same manufacturer collecting different bulk materials.

Table 7.

Kruskal–Wallis test p-value for multiple (two-sided) comparisons between round baler and bulk material levels.

There were no significant differences between the forage harvesting machines in terms of the elongation of the net while wrapping the bales. The lowest net elongation of 6.71% was found for the Metal–Fach Z-562 baler when harvesting winter wheat straw. The greatest elongation of the net, amounting to 9.33%, was found for the Sipma PS 1211 FARMA PLUS machine during the harvesting of straw from winter triticale. However, significant differences in the wrapping of the bales with the net in the front and back were found between the Sipma Z-569/1 Farma II baler and the UNIA DF 1.8 Dd baler, which collected dried forage. Wrapping the bales by the UNIA DF 1.8 Dd round baler over a smaller width (CF = 112.75 and CB = 112.08) was directly caused by the design of the wrapping device in the machine. During bale wrapping, the fed net was additionally narrowed on the guiding roller, leading to its distribution over a narrower width. Round balers that collected spring barley straw did not differ significantly in their analyzed features. On the other hand, the balers harvesting winter wheat straw differed in bale wrapping in the front and back and did not differ in the case of the net elongation. In the Metal-Fach Z-562 baling press, a metal roller placed in guides was used to brake the roll and to tension the net. In this case, the acting force was always the same and could not be changed. Overall, out of the 36 pairs of compared factor levels, 19, 20 and 25 pairs did not differ in terms of the front coverage (CF), back coverage (CB) and net elongation (ELO), respectively, which is the majority of the pairs compared.

The introduction a new generation of lightweight nets for wrapping bulk materials to the Polish market of agricultural means of production has resulted in a gradual reduction in the consumption of HDPE for the production of agricultural nets in subsequent years (2017–2022) (Table 8). This can also reduce the weight of waste, which is about twice as high because of the plant material, soil and moisture affecting the net.

Table 8.

Estimated HDPE consumption data in Poland for the production of agricultural mesh in the years 2017–2022 in Mg.

4. Conclusions

No studies of a similar nature were found in the available literature, which would present the results of a new generation of LT agricultural netting for packing bulk materials. There are also no data in the context of the environmental burden caused by agricultural nets. Based on the tests conducted for nine variants of different models of round balers and the different bulk materials collected by them, it can be concluded that, in each case, the net (Tama LT) wrapped the cylindrical bales well or very well. The Tama LT net has received a positive assessment. In every variant tested, the Tama LT net held the compressed material well, maintaining its form shaped in the baler chamber. When the machine was equipped with a net wrapping device for adjusting the net tension during the wrapping, the bales were completely covered with the net. By increasing the braking force of the Tama LT net roll, it was possible to wrap the outer surface around the bale circumference, as well as the side surfaces, which is very beneficial. In this case, the edges of the bales are even, so they can be wrapped more precisely when harvesting green fodder for silage. Then, better conditions are provided for the silage of green fodder to obtain a better quality of the fodder. The mean elongation of the COVERNET during the bale wrapping was over 8% for the tested machines and harvested materials. The Tama LT net was efficiently picked and fed by the wrapping devices of various designs used in the tested round balers. The Tama LT net also ensured the trouble-free operation of the balers. The tests confirmed the usefulness of the new generation of agricultural nets (Tama LT) for wrapping various agricultural bulk materials of various humidities. There were no cases of bale deformation or net breaking when the bales were unloaded from the bale chamber onto the field surface. There was also no net breaking and no bale deformation during the bale loading, transport and storage in heaps. Therefore, the net manufactured in the LT technology with a breaking strength of 2.5 kN guarantees that it can be used for wrapping bales of various agricultural bulk materials. The new-generation agricultural netting can be used for baling presses equipped with wrapping devices. The net produced in light technology (Tama LT) is therefore a high-quality product that is usable under various harvesting conditions, despite the lower weight per 1 m of the net.

There is currently no developed technology for recycling used agricultural netting after its use in the harvesting of agricultural bulk materials. The introduced new technology for the agricultural net production allows for reducing CO2 emissions by 25% compared to the standard technology. This is directly related to the lower demand for granulate at the stage of agricultural net production in modern LT technology. At the same time, there is an urgent need to develop and implement in practice a technology for recovering used agricultural nets and converting them into granules that can be used in their production.

Author Contributions

Conceptualization, I.K.; Methodology, I.K.; Validation, B.Z. and P.R.; Formal analysis, K.K.; Data curation, I.K. and B.Z.; Writing—original draft, I.K.; Writing—review & editing, P.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study did not require ethical approval.

Data Availability Statement

Data supporting the reported results can be found in the Department of Agronomy at the University of Life Sciences.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dőring, T.F.; Kovacs, G.; Wolfe, M.S.; Murphy, K. Evolutionary plant breeding in cereals—Into new era. Sustainability 2011, 3, 1944–1971. [Google Scholar] [CrossRef]

- Gacek, E.S. Modyfikacje prac hodowlanych i doświadczalnictwa odmianowego dla potrzeb zrównoważonych, niskonakładowych i ekologicznych systemów gospodarowania w rolnictwie. Biul. Inst. Hod. I Aklim. Roślin 2017, 282, 139–150. (In Polish) [Google Scholar]

- Wicki, L. Postęp w plonowaniu odmian pszenicy ozimej i żyta w doświadczeniach odmianowych w Polsce. Rocz. Nauk. Stowarzyszenia Ekon. Rol. I Agrobiz. 2017, XIX, 224–230. (In Polish) [Google Scholar]

- Arseniuk, E.; Oleksiak, T. Postęp w hodowli głównych roślin uprawnych w Polsce i możliwości jego wykorzystania do 2020 roku. Stud. I Rap. IUNG-PIB 2009, 14, 293–306. (In Polish) [Google Scholar] [CrossRef]

- Mańkowski, D.R. Postęp biologiczny w hodowli, nasiennictwie i produkcji ziemniaka w Polsce. Część I. Przegląd ilościowych metod oceny postępu hodowlanego i odmianowego. Biul. Inst. Hod. I Aklim. Roślin 2009, 251, 153–173. (In Polish) [Google Scholar]

- Trethowan, R.M.; van Ginkel, M.; Rajaram, S. Progress in breeding wheat for yield and adaptation in global drought affected environments. Crop Sci. 2002, 42, 1441–1446. [Google Scholar] [CrossRef]

- Ustun, A.; Allen, F.L.; English, B.C. Genetic progress in soybean of the U.S. Midsouth. Crop Sci. 2001, 41, 993–998. [Google Scholar] [CrossRef]

- Święcicki, W.K.; Surma, M.; Koziara, W.; Skrzypczak, G.; Szukała, J.; Bartkowiak-Broda, I.; Zimny, J.; Banaszak, Z.; Marciniak, K. Nowoczesne technologie w produkcji roślinnej—Przyjazne dla człowieka i środowiska. Pol. J. Agron. 2011, 7, 102–112. [Google Scholar]

- Mikołajczyk, K.; Dabert, M.; Nowakowska, J.; Podkowinski, J.; Poplawska, W.; Bartkowiak-Broda, I. Conversion of the RAPD OPC021150 marker of the Rfo restorer gene into a SCAR marker for rapid selection of oilseed rape. Plant Breed. 2008, 127, 647–649. [Google Scholar] [CrossRef]

- Dawson, J.C.; Rivière, P.; Berthellot, J.F.; Mercier, F.; de Kochko, P.; Galic, N.; Pin, S.; Serpolay, E.; Thomas, M.; Giuliano, S.; et al. Collaborative plant breeding for organic agricultural systems in developed countries. Sustainability 2011, 3, 1206–1223. [Google Scholar] [CrossRef]

- Murphy, K.M.; Lammer, D.; Lyon, S.R.; Carter, B.; Jones, S.S. Breeding for organic and low-input farming systems: An evolutionary-participatory breeding method for inbred cereal grains. Renew. Agric. Food Syst. 2005, 20, 48–55. [Google Scholar] [CrossRef]

- Finckh, M.R. Integration of breeding and technology into diversification strategies for disease control in modern agriculture. Eur. J. Plant Pathol. 2008, 121, 399–409. [Google Scholar] [CrossRef]

- Kotecki, A. Climate change for the European Green Deal. In Proceedings of the Scientific Conference: The Role of Agricultural Sciences in the Implementation of the Concept of a Sustainable Food System “from Farm to Fork”, Chełm, Poland, 7–8 June 2022. (In Polish). [Google Scholar]

- Hammond, G.; Jones, C.; Lowrie, F.; Tse, P. The Inventory of Carbon and Energy (ICE); University of Bath: Bath, UK, 2011; p. 128, © BSRIA BG 10/2011; ISBN 978 0 86022 703 8. [Google Scholar]

- Briassoulis, D.; Mistriotis, A.; Eleftherakis, D. Mechanical behaviour and properties of agricultural nets Part I: Testing methods for agricultural nets. Polym. Test. 2007, 26, 822–832. [Google Scholar] [CrossRef]

- Briassoulis, D.; Mistriotis, A.; Eleftherakis, D. Mechanical behaviour and properties of agricultural nets. Part II: Analysis of the performance of the main categories of agricultural nets. Polym. Test. 2007, 26, 970–984. [Google Scholar] [CrossRef]

- Castellano, S.; Scarascia Mugnozza, G.; Russo, G.; Briassoulis, D.; Mistriotis, A.; Hemming, S.; Waaijenberg, D. Plastic nets in agriculture: A general review of types and applications. Appl. Eng. Agric. 2008, 24, 799–808. [Google Scholar] [CrossRef]

- Chodak, I. High modulus polyethylene fibres: Preparation, properties and modification by crosslinking. Prog. Polym. Sci. 1998, 23, 1409–1442. [Google Scholar] [CrossRef]

- Ward, I.M. Recent developments in the science and technology of high modulus flexible polymers. Macromol. Symp. 1995, 100, 1–14. [Google Scholar] [CrossRef]

- Barham, P.J.; Keller, A. Review: High-strength polyethylene fibres from solution and gel spinning. J. Mater. Sci. 1985, 20, 2281-2032. [Google Scholar] [CrossRef]

- Tayyab, H.; Ibnelwaleed, A.H. Effect of short chain branching of LDPE on its miscibility with linear HDPE. Macromol. Mater. Eng. 2004, 289, 198–203. [Google Scholar] [CrossRef]

- Tama Polska Sp. z o.o. CPA Technical; Crop Packaging Association: Alton, UK, 2011; Volume 1, p. 4. (In Polish) [Google Scholar]

- Tama Polska Sp. z o.o. CPA Technical; Crop Packaging Association: Alton, UK, 2011; Volume 2, p. 4. (In Polish) [Google Scholar]

- Tama Polska Sp. z o.o. CPA Technical; Crop Packaging Association: Alton, UK, 2012; Volume 3, p. 4. (In Polish) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).