Investigating the Profitability of Government-Funded Small-Scale Broiler Projects in Northern KwaZulu-Natal, South Africa

Abstract

:1. Introduction

2. Materials and Methods

2.1. Selection of the Study Areas

2.2. Sampling Method and Data Collection

2.3. Data Analysis

2.3.1. Gross Margin and Gross Profit Margin Analyses

2.3.2. The Empirical Model

3. Results

3.1. Demographic Characteristics of the Respondents

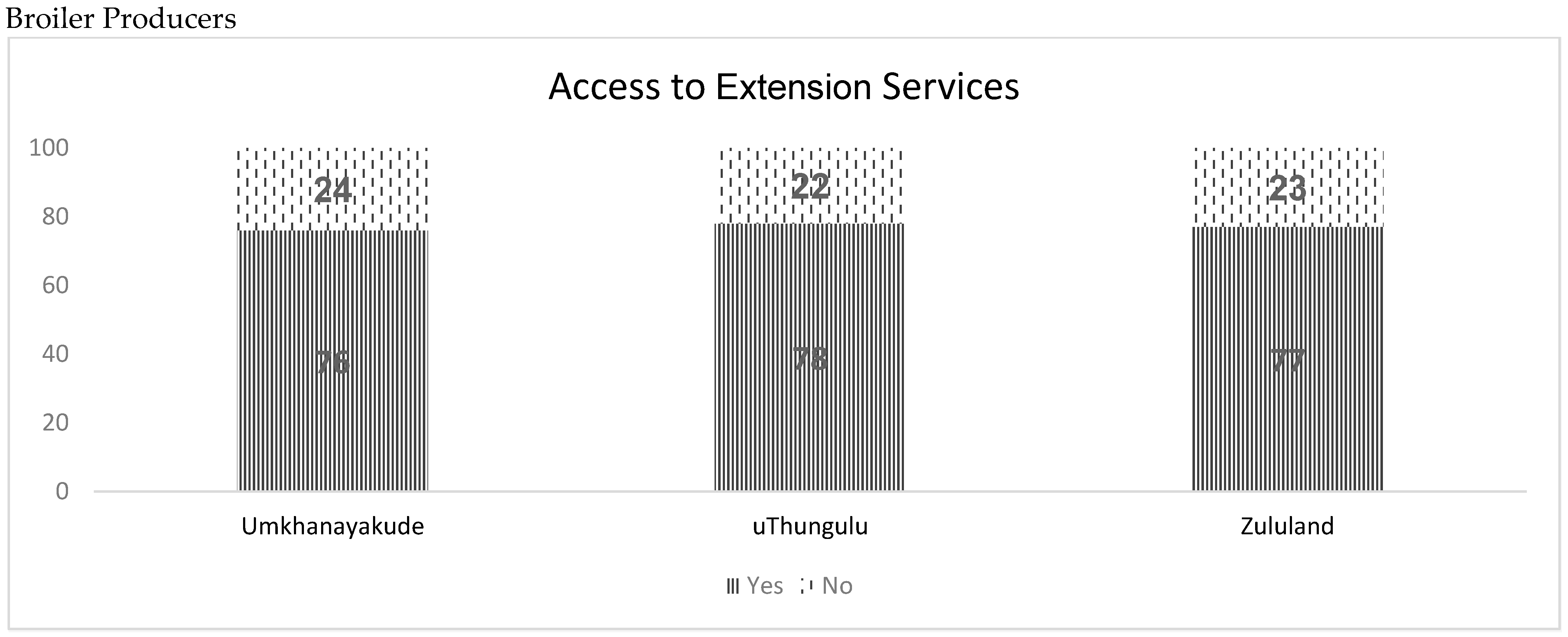

3.2. Knowledge on Broiler Production and Access to Extension Services in Northern KwaZulu-Natal

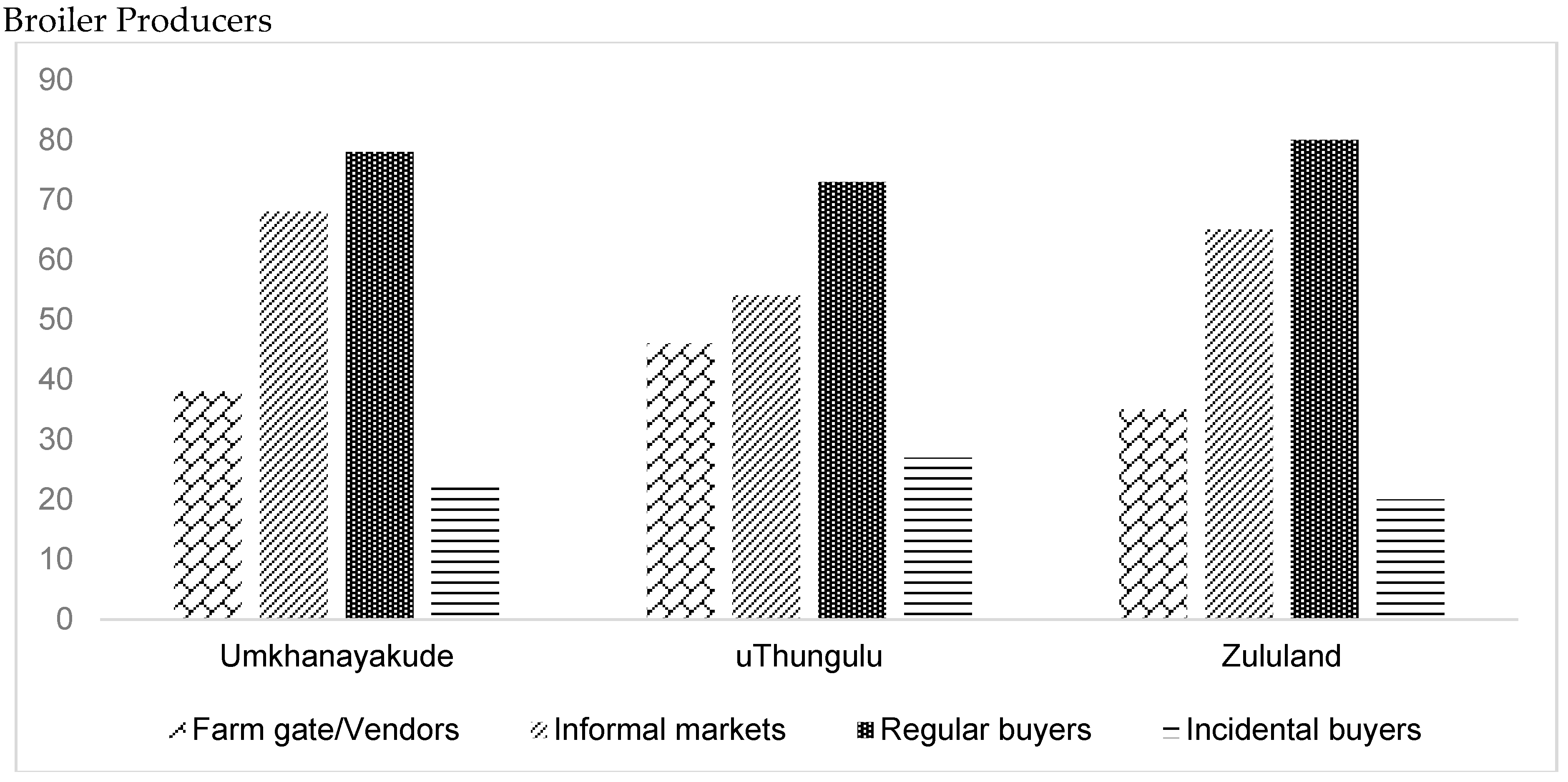

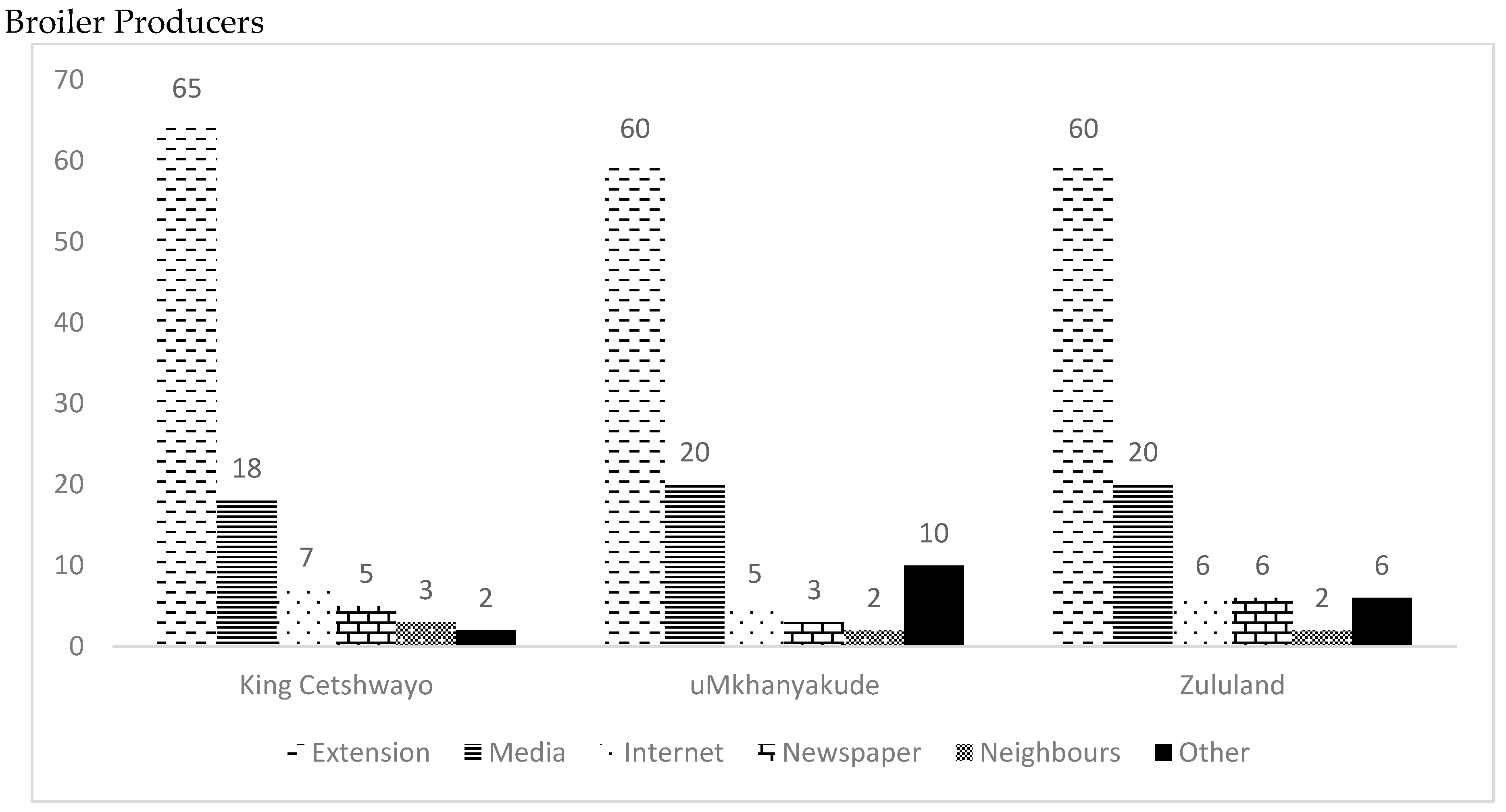

3.3. Marketing Channels and Sources of Market Information for Small-Scale Broiler Producers in Northern KwaZulu-Natal

3.4. Small-Scale Broiler Production and Marketing Challenges in Northern KwaZulu-Natal

3.5. Gross Margin and Gross Profit Margin Analyses

3.6. Factors That Influence the Profitability of the Broiler Enterprises

3.7. Technical Efficiency of Broiler Production

3.8. Technical Inefficiency

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alene, A.D.; Manyong, V.M.; Omanya, G.; Mignouna, H.D.; Bokanga, M.; Odhiambo, G. Smallholder market participation under transactions costs: Maize supply and fertilizer demand in Kenya. Food Policy 2008, 33, 318–328. [Google Scholar] [CrossRef]

- Bagamba, F.; Ssenyonga, J.W.; Tushemereirwe, W.K.; Gold, C.S. Performance and profitability of the banana sub-sector in Uganda farming systems, Kampala, Uganda. In Bananas and Food Security; Picq, C., Fouré, E., Frison, E.A., Eds.; INIBAP: Montpellier, France, 1998; pp. 729–739. [Google Scholar]

- United Nations. World Population Prospects 2022; United Nations: New York, NY, USA, 2022. [Google Scholar]

- Roser, M.; Ritchie, H.; Ortiz-Ospina, E. World Population Growth. Available online: https://ourworldindata.org/world-population-growth (accessed on 12 January 2020).

- Chetroiu, R.; Lurchevici, L. Standard gross margin for poultry. In Proceedings of the 3rd International Symposium “Agrarian Economy and Rural Development—Realities and perspectives for Romania”, Bucharest, Romania, 11–13 October 2012; Available online: http://hdl.handle.net/10419/76865 (accessed on 15 July 2023).

- Makweya, F.L.; Oluwatayo, I.B. Consumers’ preference and willingness to pay for graded beef in Polokwane municipality, South Africa. Ital. J. Food Saf. 2019, 8, 7654. [Google Scholar] [CrossRef] [PubMed]

- Dlamini, B.R.; Rampedi, I.T.; Ifegbesan, A.P. Community Resident’s Opinions and Perceptions on the Effectiveness of Waste Management and Recycling Potential in the Umkhanyakude and Zululand District Municipalities in the KwaZulu-Natal Province of South Africa. Sustainability 2017, 9, 1835. [Google Scholar] [CrossRef]

- South African Poulty Association, 2023 Industry-Profile. Available online: https://www.sapoultry.co.za/wp-content/uploads/2023/01/2021-Industry-Profile.pdf (accessed on 12 August 2023).

- Natalie, C. Production Volume of Chicken Meat in South Africa from 2010 to 2020. 2023. Available online: https://www.statista.com/aboutus/our-research-commitment/3664/natalie-cowling (accessed on 22 October 2023).

- Statista. Per Capita Consumption of Meat in South Africa from 2010 to 2017. 2021. Available online: https://Www.Statista.Com/Statistics/963216/per-Capita-Consumption-of-Meat-by-Type-SouthAfrica/ (accessed on 20 October 2023).

- Larkin, P. Importing Chicken Will Not Save the Day”, Independent Online 2023. Available online: https://www.iol.co.za/business-report/economy/importing-chicken-will-not-save-the-day-say-experts-df552a66-a27f-4ee5-9342-a10c7dbecd11 (accessed on 30 October 2023).

- Botha, L. Chicken Import Tariffs: It’s Only Fair. Farmers Weekly. Available online: https://www.farmersweekly.co.za/agri-news/south-africa/chicken-import-tariffs-its-only-fair/ (accessed on 30 October 2023).

- Schepina, I.; Gogoleva, T.; Charykova, O. Import substitution trends in agriculture of the Russian regions. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 274, p. 012015. [Google Scholar] [CrossRef]

- Department of Agriculture, Fisheries and Forestry (DAFF). A Profile of the South African Broiler Market Value Chain. Available online: https://www.daff.gov.za/docs/AMCP/BroilerMVCP11-12.pdf (accessed on 12 January 2020).

- Birhanu, M.Y.; Osei-Amponsah, R.; Obese, F.Y.; Dessie, T. Smallholder poultry production in the context of increasing global food prices: Roles in poverty reduction and food security. Anim. Front. 2023, 13, 17–25. [Google Scholar] [CrossRef] [PubMed]

- National Agricultural Marketing Council (NAMC). Baseline Report—The Case for Smallholder Broiler Production in South Africa; NAMC: Pretoria, South Africa, 2020. [Google Scholar]

- Kwazulu-Natal Municipalities. Municipal Directories and Reports; Government of South Africa. 2023. Available online: https://www.gov.za/about-government/contact-directory (accessed on 30 October 2023).

- Mulaudzi, V. Gross Margin Analysis and Determinants of Savings among Small-Scale Broiler Producers in Vhembe District of Limpopo Province, South Africa. Master’s Thesis, University of Limpopo, Polokwane, South Africa.

- Zulu, E. Profitability of Smallholder Cowpea Production in Zambia. Bachelor’s Thesis, University of Zambia, Lusaka, Zambia, 2011. [Google Scholar]

- Ramukhithi, T.F.; Nephawe, K.A.; Mpofu, T.J.; Raphuku, T.; Munhuweyi, K.; Ramukhithi, F.V.; Mtileni, B. An Assessment of Economic Sustainability and Efficiency in Small-Scale Broiler Farms in Limpopo: A Review. Sustainability 2023, 15, 2030. [Google Scholar] [CrossRef]

- Phiri, P.T.; Ruzhani, F.; Madzokere, F.; Madududu, P. Factors affecting the profitability of smallholder broiler production in Mutare district, Manicaland Province, Zimbabwe: A Quantile Regression Approach. Cogent Econ. 2023, 11, 221660. [Google Scholar] [CrossRef]

- South Australian Farm Gross Margin and Enterprise Planning Guide. 2022. Available online: https://www.google.com/search?q=19.22.+South+Australian+Farm+Gross+Margin+and+Enterprise+Planning+Guide+2022&rlz=1C1GCEA_enZA1080ZA1080&oq=19.22.%09South+Australian+Farm+Gross+Margin+and+Enterprise+Planning+Guide+2022&gs_lcrp=EgZjaHJvbWUyBggAEEUYOdIBCTU1OTBqMGoxNagCALACAA&sourceid=chrome&ie=UTF-8 (accessed on 19 November 2023).

- Greene, W.H. Econometric Analysis; Pearson: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Ullah, S.; Zaefarian, G.; Ulla, F. How to use instrumental variables in addressing endogeneity: A step-by-step procedure for non-specialists. Ind. Mark. Manag. 2020, 96, A1–A6. [Google Scholar] [CrossRef]

- Stock, J.H.; Yogo, M. Testing for weak instruments in linear IV regression, National Bureau of Economic Research & Harvard University (Prepared for the Festschrift in honour of Thomas Rothenberg), February 2003. Available online: https://scholar.harvard.edu/files/stock/files/testing_for_weak_instruments_in_linear_iv_regression.pdf (accessed on 19 November 2023).

- Parente, P.M.D.C.; Santos Silva, J.M.C. A cautionary note on tests of overidentifying restrictions. Econ. Lett. 2012, 115, 314–317. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Product. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Bruce, A.K.K.; Donkoh, S.A.; Ayamga, M. Improved Rice Variety Adoption and its Effects on Farmers’ Output in Ghana. J. Dev. Agric. Econ. 2014, 6, 242–248. [Google Scholar] [CrossRef]

- Nata, J.T.; Mjelde, J.W.; Boadu, F.O. Household adoption of soil-improving practices and food insecurity in Ghana. Agric. Food Secur. 2014, 3, 17. [Google Scholar] [CrossRef]

- Dessale, M. Analysis of technical efficiency of smallholder wheat growing farmers of Jamma district, Ethiopia. J. Agric. Food Secur. 2019, 8, 1–8. [Google Scholar] [CrossRef]

- Alabi, R.A.; Aruna, M.B. Technical efficiency of family poultry production in the Niger Delta, Nigeria. J. Cent. Eur. Agric. 2005, 531–538. [Google Scholar]

- Mbanasor, J.; Kalu, K. Economic efficiency of commercial vegetable production system in Akwa Ibom State, Nigeria: A translog Stochastic Frontier Cost Function Approach. Trop. Sub-Trop. Agroecosystems 2008, 8, 313–318. [Google Scholar]

- Ahiale, E.D.; Abunyuwah, I.; Yenibehit, N.Y. Technical efficiency analysis of broiler production in the Mampong Municipality of Ghana. J. Econ. Sustain. Dev. 2019, 10, 152–158. [Google Scholar]

- Nkukwana, T.T. Global poultry production: Current impact and future outlook on the South African poultry industry. S. Afr. J. Anim. Sci. 2018, 48, 869–884. [Google Scholar] [CrossRef]

- Selaledi, L.A. The Impact of Supply Chain on Sustainability of Small-Scale Poultry Farmers in Ratlou Local Municipality, North West Province. Master’s Thesis, University of South Africa, Pretoria, South Africa, 2017. [Google Scholar]

- Gabre-Madhin, E. Market Institutions, Transaction Costs, and Social Capital in the Ethiopian Grain Market; International Food Policy Research Institute (IFPRI) Research Report; International Food Policy Research Institute (IFPRI): Washington, DC, USA, 2001. [Google Scholar]

- Manona, S.S. Smallholder Agriculture as Local Economic Development (LED) Strategy in Rural South Africa: Exploring Prospects in Pondoland, Eastern Cape. Master’s Thesis, University of Western Cape, Cape Town, South Africa, 2005. [Google Scholar]

- Nassar, M.K.; Lyu, S.; Zentek, J.; Brockmann, G.A. Dietary fiber content affects growth, body composition, and feed intake and their associations with a major growth locus in growing male chickens of an advanced intercross population. Livest. Sci. 2019, 227, 135–142. [Google Scholar] [CrossRef]

- Guèye, E.F. Gender issues in family poultry production systems in low-income food-deficit countries. Am. J. Altern. Agric. 2003, 18, 185–195. [Google Scholar] [CrossRef]

- Hoverstadt, P. The Fractal Organization: Creating Sustainable Organizations with the Viable System Model; Wiley: Chichester, UK, 2008. [Google Scholar]

- Food and Agriculture Organization (FAO). Globalization of Food Systems in Developing Countries: Impact on Food Security and Nutrition; FAO food and nutrition paper 83; Food and Agriculture Organization: Rome, Italy, 2004. [Google Scholar]

- Kaliba, A.R.M.; Verkuijl, H.; Mwangi, W. Factors affecting adoption of improved maize seeds and use of inorganic fertilizer for maize production in the intermediate and lowland zones of Tanzania. J. Agric. Appl. Econ. 2000, 32, 35–47. [Google Scholar] [CrossRef]

- Poultry New. Poultry Crisis Deepens as South Africa Culls 7.5 Million Birds Amidst Worsening Bird Flu Outbreaks. 2023. Available online: https://www.poultryproducer.com/poultry-crisis-deepens-as-south-africa-culls-7-5-million-birds-amidst-worsening-bird-flu-outbreaks/# (accessed on 30 October 2023).

- Al Jazeera and News Agencies. Power Crisis, Bird Flu Trigger Imminent Chicken Shortage in South Africa. 2023. Available online: https://www.aljazeera.com/economy/2023/9/21/power-crisis-bird-flu-trigger-imminent-chicken-shortage-in-south-africa (accessed on 30 October 2023).

- BnetHub. Coccidiosis Disease of the Lazy Farmer. 2023. Available online: https://bnethub.com/coccidiosis-disease-of-the-lazy-farmer/ (accessed on 30 October 2023).

| Variable | Description | Measurement Type | Priori Expectation (+/−) |

|---|---|---|---|

| Age | Actual years of the small-scale broiler producer | Continuous | − |

| Gender | The sex of the small-scale broiler producer (male/female) | Dummy | +/− |

| Education Years of schooling | Level of education attained Number of years in school by the small-scale broiler producer | Dummy Continuous | + + |

| Farm production costs | Operational costs | Continuous | − |

| Farmgate price | Price of the broiler at the farm level | Continuous | + |

| Access to markets | Availability of ready output markets for the broilers (yes/no) | Dummy | + |

| Distance | The physical distance in km to the market | Continuous | − |

| Market Information | Whether the small-scale broiler producer has access to information on broiler marketing (yes/no) | Dummy | + |

| Storage | Whether the small-scale broiler producer has access to storage facilities and refrigeration (yes/no) | Dummy | + |

| Transport | Whether the small-scale broiler producer has access to their own transport (yes/no) | Dummy | + |

| Electricity | Whether the small-scale broiler producer has access to electricity (yes/no) | Dummy | + |

| Extension | Whether the small-scale broiler producer has access to extension services (yes/no) | Dummy | +/− |

| Demographic Parameter | King Cetshwayo | uMkhanyakude | Zululand | |

|---|---|---|---|---|

| Age (years) | 51 (12.29) | 49 (10.8) | 61 (13.97) | |

| Age categories | <30 | 0 | 0 | 8 |

| 30–39 | 5 | 12 | 16 | |

| 40–49 | 20 | 24 | 24 | |

| 50–59 | 25 | 36 | 32 | |

| >60 | 50 | 16 | 20 | |

| Gender | Male | 33 | 80 | 80 |

| Female | 67 | 20 | 20 | |

| Level of education | No Education | 9 | 10 | 12 |

| Primary | 52 | 60 | 62 | |

| Secondary | 30 | 28 | 20 | |

| Tertiary | 9 | 2 | 6 | |

| Government-Funded Small-Scale Producers | Small-Scale Producers that Supply the Commercial Chicken Farm | |||

|---|---|---|---|---|

| Allocable Costs | Average Production Cost Per Unit/100 (ZAR) | Average Share of the Variable Production Cost (%) | Average Production Cost Per Unit/100 (ZAR) | Average Share of the Variable Production Cost (%) |

| Day-old chickens | 485.00 | 18.9 | 439.59 | 20.0 |

| Feed costs | 1479.85 | 67.3 | 1567.13 | 71.3 |

| Vitamins and vaccinations | 25.11 | 0.98 | 13.19 | 0.6 |

| House sanitation/Maintenance | 8.44 | 0.32 | 15.39 | 0.7 |

| Shavings | 13.15 | 0.51 | 37.36 | 1.7 |

| Gas for brooder/Heating and electricity | 130.00 | 5.06 | 72.53 | 3.3 |

| Other costs | 427.93 | 16.65 | 52.75 | 2.4 a |

| Mean Total Allocable Costs | 2569.48 | 2197.94 | ||

| Mean Total Gross Income | 4320.00 | 5248.00 | ||

| Mean Gross Margin | 1750.52 | 3050.06 | ||

| % Gross Profit Margin | 31 | 57.7 | ||

| Unstandardized Coefficients | Standardized Coefficients | |||||

|---|---|---|---|---|---|---|

| Variable | β | Std. Error | β | t | Sig. | VIF |

| Constant | −320.484 | 143.637 | - | −2.231 | 0.029 | - |

| Age | 1.430131 | 19.257 | 0.058 | 1.119 | 0.267 | 1.213 |

| Gender | −33.30587 | 0.642 | 0.101 | 1.832 | 0.071 * | 1.360 |

| Educational | 10.67333 | 11.044 | 0.075 | 1.401 | 0.166 | 1.263 |

| Price | 27.28735 | 1.699 | 0.951 | 16.016 | 0.001 *** | 1.572 |

| Market Distance | −5.523696 | 6.291 | −0.046 | −0.817 | 0.417 | 1.420 |

| Information | 39.67955 | 23.426 | −0.095 | −1.739 | 0.087 * | 1.321 |

| Electricity | 3.648271 | 27.490 | −0.003 | −0.058 | 0.954 | 1.297 |

| Extension | −67.09641 | 25.296 | 0.140 | 2.722 | 0.008 ** | 1.179 |

| R-squared (Adjusted R-Squared) | 0.850 (0.832) | |||||

| Durbin–Watson | 1.504 | |||||

| F-test | 41.310 (Prob > 0.000) | |||||

| Akaike crit. (AIC) | 868.268 Bayesian crit (BIC) = 891.443 | |||||

| Gross Margin | Coef. | St.Err. | t-Value | p-Value | [95% Conf.Interval] | |

|---|---|---|---|---|---|---|

| Education | 25.394 | 18.39 | 1.38 | 0.167 | −10.649 | 61.436 |

| Gender | −34.051 | 20.212 | −1.68 | 0.092 * | −73.665 | 5.564 |

| Age | 1.57 | 0.654 | 2.40 | 0.016 ** | 0.288 | 2.852 |

| Marital Status | −9.605 | 11.81 | −0.81 | 0.416 | −32.752 | 13.541 |

| Extension | −73.704 | 24.844 | −2.97 | 0.003 *** | −122.397 | −25.011 |

| Price | 27.12 | 1.637 | 16.57 | 0.000 *** | 23.913 | 30.328 |

| Market Distance | −4.89 | 6.033 | −0.81 | 0.418 | −16.714 | 6.935 |

| Information | 30.947 | 23.823 | 1.30 | 0.194 | −15.746 | 77.64 |

| Electricity | 9.771 | 26.753 | 0.37 | 0.715 | −42.665 | 62.206 |

| Constant | −231.15 | 123.535 | −1.87 | 0.061 | −473.273 | 10.973 |

| Mean dependent variable | 1747.020 | SD dependent variable | 180.445 | |||

| R-squared | 0.848 | Number of obs. | 75 | |||

| Chi-squared | 419.784 | Prob > chi2 | 0.000 | |||

| Variables | OLS | IV | 2SLS |

|---|---|---|---|

| Gender | −33.30587 | −34.05081 | −34.05081 |

| Age | 1.430131 | 1.57019 | 1.57019 |

| Education | 10.67333 | 25.39357 | 25.39357 |

| Ext. Access | −67.09641 | −73.70401 | −73.70401 |

| Farmgate Prices | 27.28735 | 27.12044 | 27.12044 |

| Market Distance | −5.523696 | −4.889636 | −4.889636 |

| Market Information | 39.67955 | 30.94707 | 30.94707 |

| Access to Electricity | 3.648271 | 9.770902 | 9.770902 |

| Gross Income | Coef. | Std. Err. | Z | p > z | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| Frontier | ||||||

| Flock Size | 0.0253697 | 0.0129673 | 1.96 | 0.050 ** | −0.0000458 | 0.050785 |

| Feeds | 0.0877613 | 0.0305764 | 2.87 | 0.004 *** | 0.0278328 | 0.14769 |

| Labour | 13.851 | 0.0978389 | 141.57 | 0.000 *** | 13.65924 | 14.04276 |

| Medication | 0.0032996 | 0.0171971 | 0.19 | 0.848 | −0.0304061 | 0.037005 |

| Constant | −22.2411 | |||||

| Inefficiency Model | Coef. | Std. Err. | Z | p > z | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| Age | 4.135937 | 0.3426792 | 12.07 | 0.000 *** | 3.464298 | 4.807576 |

| Gender | −2.554404 | 1.082274 | −2.36 | 0.018 ** | −4.675621 | −0.43319 |

| Education | −2.955808 | 1.079291 | −2.74 | 0.006 *** | −5.071179 | −0.84044 |

| Extension | 1.341414 | 1.513759 | 0.89 | 0.376 | −1.625499 | 4.308328 |

| Constant | −19.28456 | |||||

| Coef. | Std. Err. | Z | p > z | [95% Conf. Interval] | ||

|---|---|---|---|---|---|---|

| U-Sigma | ||||||

| Age | 0.9937991 | 0.2713766 | 3.66 | 0.000 *** | 0.4619107 | 1.525688 |

| Education | 1.409272 | 0.4279824 | 3.29 | 0.001 *** | 0.5704423 | 2.248103 |

| Extension | 0.4924208 | 0.802442 | 0.61 | 0.539 | −1.080337 | 2.065178 |

| Constant | −7.311918 | |||||

| V-Sigma | Coef. | Std. Err. | Z | p > z | [95% Conf. Interval] | |

|---|---|---|---|---|---|---|

| Age | −0.7776877 | 0.1170086 | −6.65 | 0.000 *** | −1.00702 | −0.54836 |

| Education | 0.1430705 | 0.4574664 | 0.31 | 0.754 | −0.7535471 | 1.039688 |

| Extension | −0.9391633 | 0.6854974 | −1.37 | 0.171 | −2.282714 | 0.404387 |

| Market Information | −0.0429347 | 0.5843637 | −0.07 | 0.941 | −1.188266 | 1.102397 |

| Constant | −2.786895 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mdletshe, S.T.C.; Obi, A. Investigating the Profitability of Government-Funded Small-Scale Broiler Projects in Northern KwaZulu-Natal, South Africa. Agriculture 2023, 13, 2269. https://doi.org/10.3390/agriculture13122269

Mdletshe STC, Obi A. Investigating the Profitability of Government-Funded Small-Scale Broiler Projects in Northern KwaZulu-Natal, South Africa. Agriculture. 2023; 13(12):2269. https://doi.org/10.3390/agriculture13122269

Chicago/Turabian StyleMdletshe, Sifiso Themba Clement, and Ajuruchukwu Obi. 2023. "Investigating the Profitability of Government-Funded Small-Scale Broiler Projects in Northern KwaZulu-Natal, South Africa" Agriculture 13, no. 12: 2269. https://doi.org/10.3390/agriculture13122269

APA StyleMdletshe, S. T. C., & Obi, A. (2023). Investigating the Profitability of Government-Funded Small-Scale Broiler Projects in Northern KwaZulu-Natal, South Africa. Agriculture, 13(12), 2269. https://doi.org/10.3390/agriculture13122269